CarTwin—Development of a Digital Twin for a Real-World In-Vehicle CAN Network

Abstract

1. Introduction and Motivation

- 1.

- We use fine-grained details of a real vehicle CAN network, such as wire lengths, stub lengths, the number of nodes communicating on the bus and the real-world information that is sent on the network;

- 2.

- We use MATLAB models to implement ECU functionalities related to braking (Anti-lock Brake System), seat-belt status and seat position checks for airbag deployment (Restraints Control Module), remote keyless actions (Remote Function Actuator), entertainment and multimedia (Accessory Protocol Interface Module), wheel steering (Power Steering Control Module), engine and transmission controls (Powertrain Control Module) and the information presented to the driver (Instrument Panel Cluster);

- 3.

- We implement a tool in a high-level language that provides signal inputs to the models and records the CAN traffic from the bus, making the digital twin easy to use for experimental purposes.

2. Background and Related Work

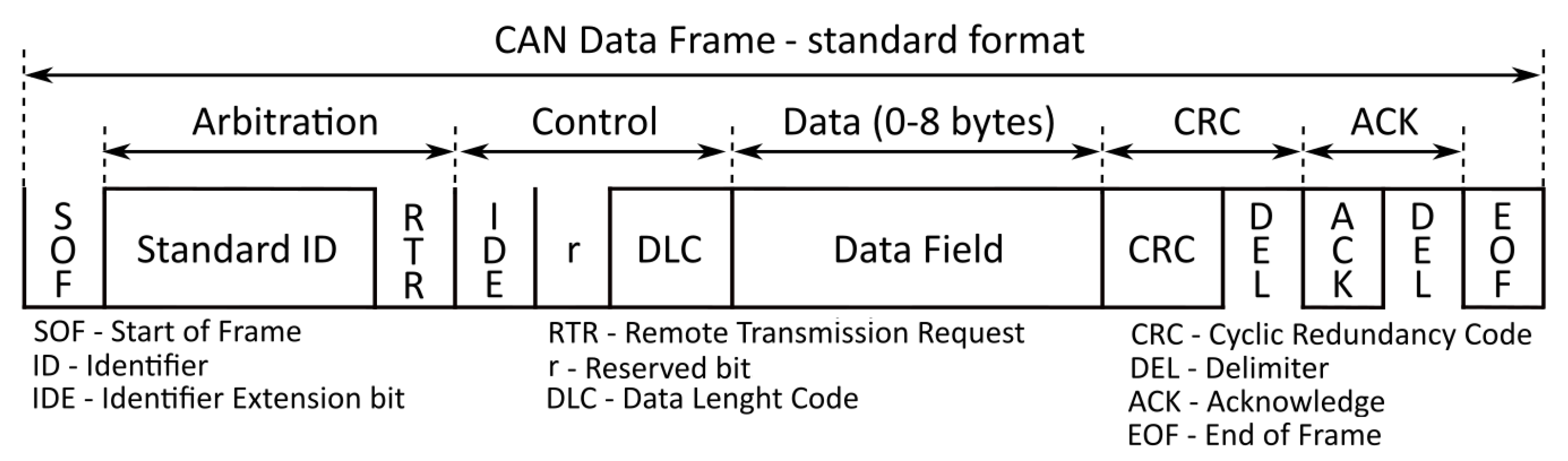

2.1. Background of the CAN Bus

2.2. Related Work

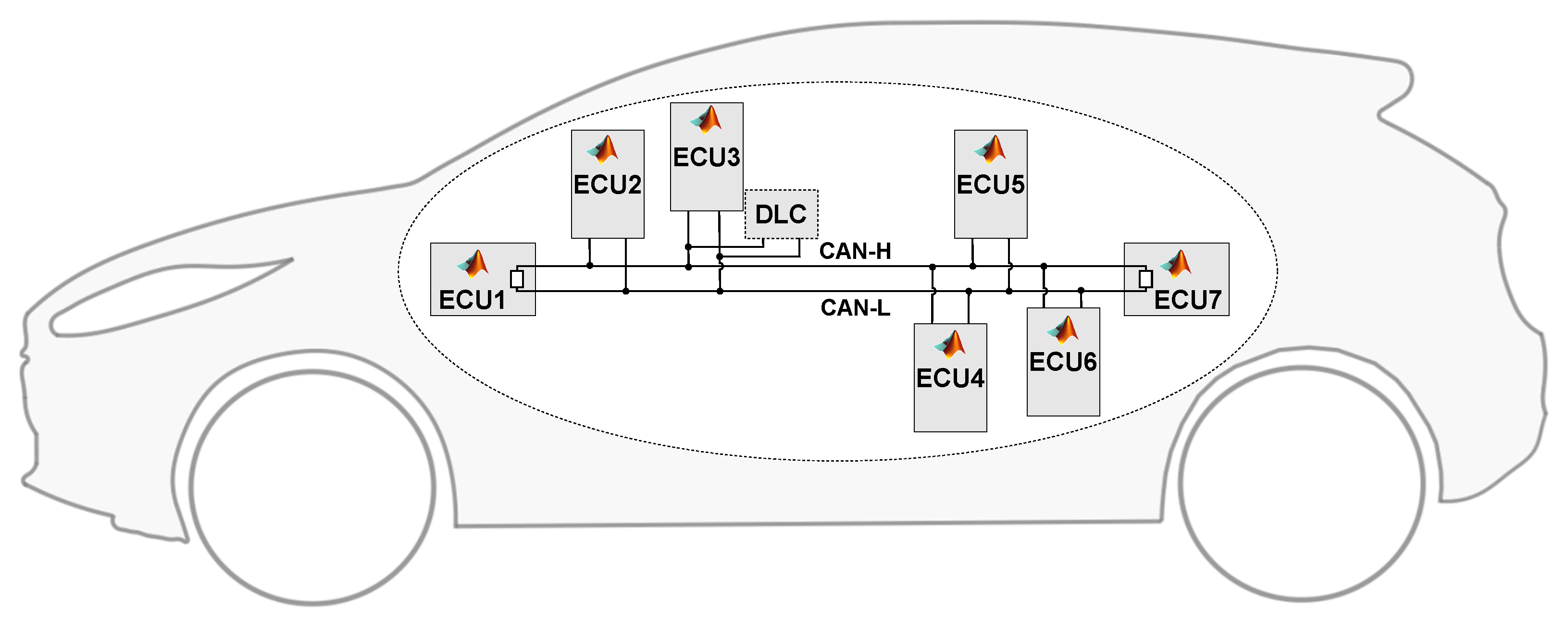

3. Topology of the Real-World In-Vehicle CAN

3.1. The In-Vehicle Subsystems

3.2. Wiring Schematic and Details

4. System Level Implementation Based on Simulink Models

Design and Validation of Models

- 1.

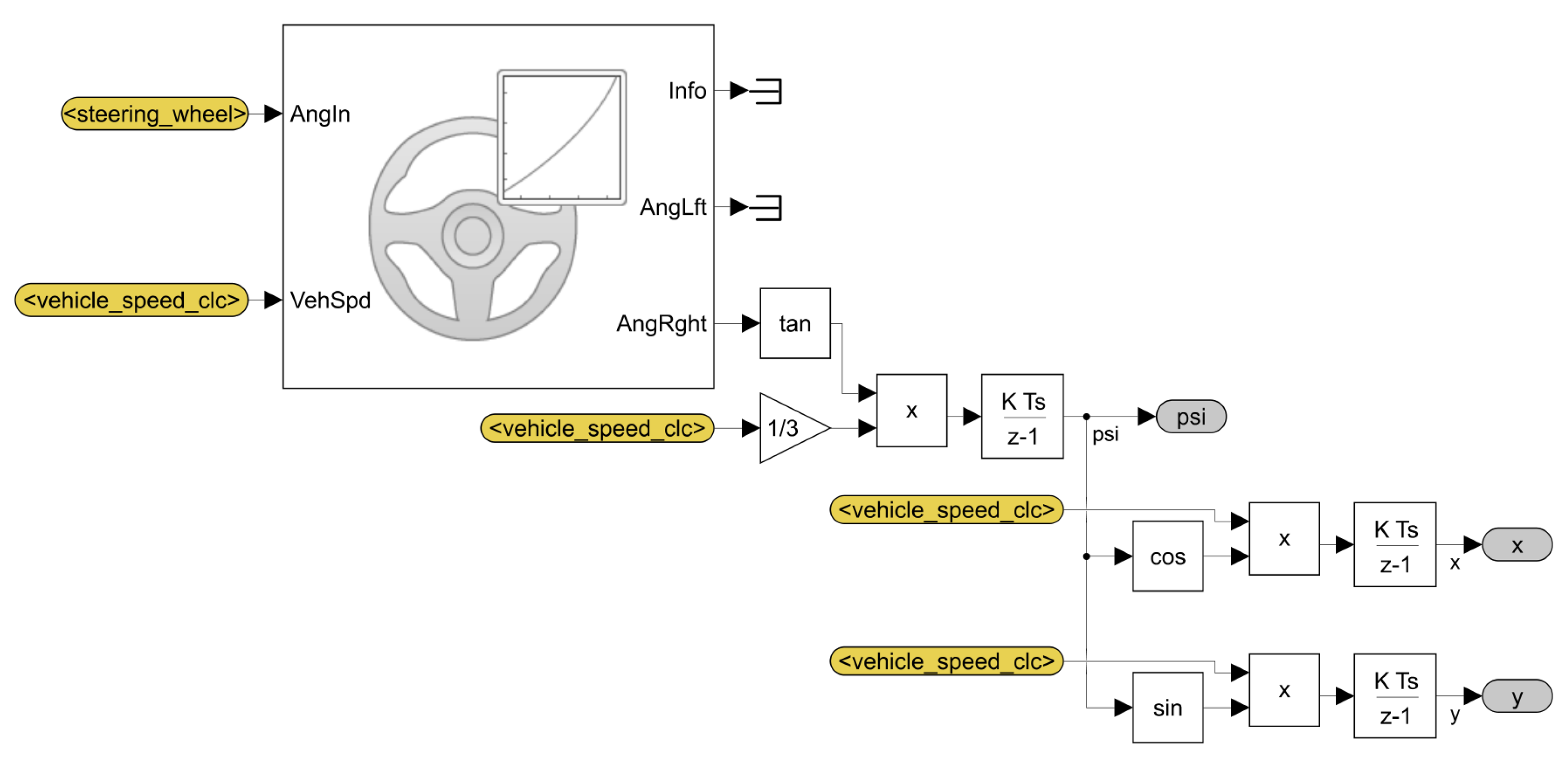

- Power Steering Control Module (PSCM): In Figure 6, we illustrate the implementation of the steering controller, which computes the steering command based on the steering wheel angle from the driver and the vehicle speed. To implement the steering controller, we use the Mapped Steering block from the Simulink library. This block computes the left and right wheel angles based on the steering wheel angle and vehicle speed using interpolation tables. Using the right wheel angle, we then compute the vehicle trajectory, i.e., , , as shown in Equations (1) and (2) and rotation angle, i.e., , as depicted in Equation (3):

- 2.

- Anti-lock Brake System (ABS): In Figure 7i, we model the estimation of the speed for each wheel based on vehicle speed and brake information (when the brake is pressed, the speed of each wheel is decreased using an integral controller). In Figure 7ii, we depict the calculation of the brake command for the front-left wheel. In Figure 7iii, we depict the calculation of the vehicle speed after braking using a proportional controller, which uses as a limit the preset vehicle speed target when the ABS is not braking on any wheel or zero when the ABS is braking on at least one wheel. The ABS ECU computes the slip for each wheel as shown in Equation (4):In this equation, s is the slip of a wheel, is the speed of the wheel and v is the vehicle speed. The state of the brake command is computed based on the slip of the wheel and vehicle speed, i.e., (input valve is open and output valve is closed, the pressure goes to the wheel), (wheel is locked, input valve is closed to prevent more pressure to the wheel) and (the output valve is open, the pressure is released and the wheel can rotate). The state of the brake commands is used to control the valves, i.e., to open or close the valves. The same functionally is implemented on all vehicle wheels.

- 3.

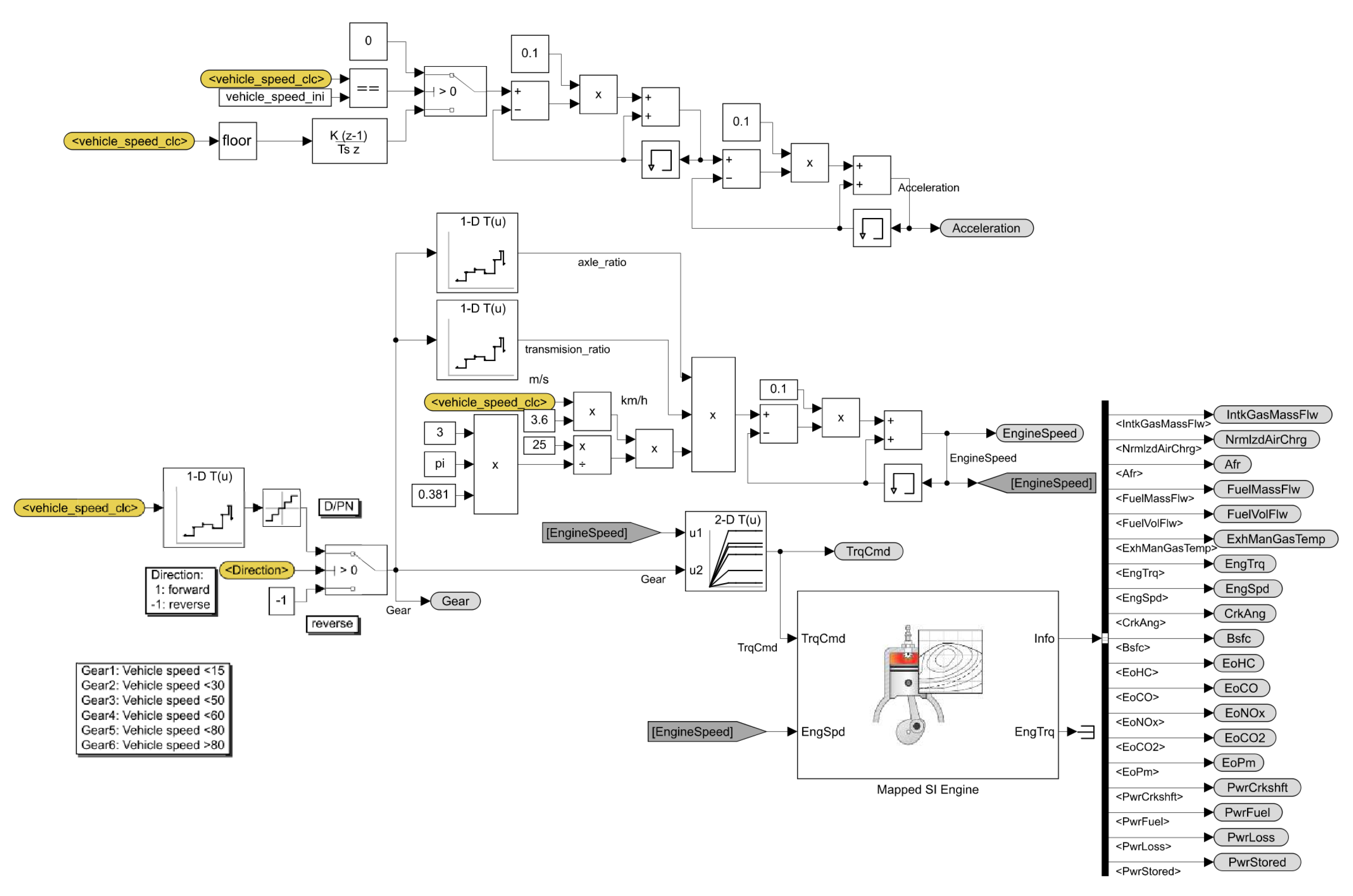

- Powertrain Control Module (PCM): The PCM implements very complex functionalities in order to ensure the efficiency and stability of the engine. In our model, we compute the main functionalities of the PCM, i.e., acceleration, torque, gear, engine speed, engine power, air mass flow, fuel flow, exhaust temperature, efficiency and emission performance. In Figure 8, we depict our implementation of the PCM module. Based on vehicle speed, as outlined in Equation (5), we compute the vehicle acceleration as the derivative of the vehicle speed with respect to time:As part of the equation terms, is the acceleration, v is the vehicle speed and t represents the time. In order to eliminate the spike of the acceleration value, we apply two low pass filters with a filtering coefficient of 0.1. The gear is computed using a interpolation table, which has as an input the vehicle speed and uses the flat interpolation method to select the corresponding value of the gear. Based on the engine speed and gear, we estimate the engine torque using a 2-D lookup table. Using the gear of the vehicle, we compute the engine speed as presented in Equation (6):In the equation above, is the engine speed, is the shaft vehicle speed, is the axle ratio and is the transmission ratio for each gear. The shaft vehicle speed is computed based on vehicle speed as shown in Equation (7):In this case, v is the vehicle speed and 0.381(m) is the considered wheel radius.To compute other powertrain signals, we used the Mapped SI Engine block from the Simulink library, which implements a spark-ignition engine model based on the torque and engine speed. This model uses several look-up tables to compute the engine air mass flow, normalized engine cylinder air mass, air-fuel ratio (AFR), engine fuel flow, volumetric fuel flow, engine exhaust gas temperature, engine crankshaft absolute angle, engine brake-specific fuel consumption, engine out hydrocarbon emission mass flow, engine out carbon monoxide emission mass flow rate, engine out nitric oxide and nitrogen dioxide emissions mass flow, engine out carbon dioxide emission mass flow, engine out particulate matter emission mass flow, crankshaft power, fuel input power and power loss.

- 4.

- Instrument Panel Cluster (IPC): The IPC module displays considerable information for the driver that is received from other ECUs or are internally computed. In our work, the IPC module computes the trip distance, average vehicle speed and the buckle alert. In Figure 9i, we show the model for the calculation of the the buckle status (if the car is moving with more than 10 m/s and the seatbelt is not buckled, the buckle alert is shown to the driver). In Figure 9ii, we show the implementation of the trip distance, which is computed as the integral of vehicle speed as outlined in Equation (8):Due to the fact that the vehicle speed is computed in m/s in our models, in order to have the trip distance in km, we convert it from meter to kilometer and round it to two decimals. In Figure 9iii, we depict the calculation on the average vehicle speed.

- 5.

- Restraints Control Module (RCM): In Figure 10i, we show the Simulink model for the calculation of the airbag status based on vehicle speed and buckle status (if the car is moving with more than 10 m/s and the seatbelt is buckled, the airbag is active).

- 6.

- Accessory Protocol Interface Module (APIM): In Figure 10ii, we show the Simulink model for the calculation of the rear camera status based on direction. If the car is moving in reverse, the rear camera is turned on. Otherwise, the rear camera is turned off.

- 7.

- Remote Function Actuator (RFA): In Figure 11, we show the Simulink model for the calculation of door status based on a signal acquired from a button. If the door lock button is continuously pressed and the door is unlocked, after 1 s, the door status is updated to locked. If the door is locked, the status is updated to unlocked after another second.

5. Hardware and Software Level Deployment of the Digital Twin

6. Experimental Evaluation of the Digital Twin

6.1. Results

6.2. Possible Applications

6.3. Comparison to Related Works

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuhnert, F.; Stürmer, C.; Koster, A. Five Trends Transforming the Automotive Industry; PricewaterhouseCoopers GmbH Wirtschaftsprüfungsgesellschaft: Berlin, Germany, 2018; Volume 1, pp. 1–48. [Google Scholar]

- Fathy, H.K.; Filipi, Z.S.; Hagena, J.; Stein, J.L. Review of hardware-in-the-loop simulation and its prospects in the automotive area. In Proceedings of the Modeling and Simulation for Military Applications, Orlando, FL, USA, 22 May 2006; Volume 6228, pp. 117–136. [Google Scholar] [CrossRef]

- Belhocine, A.; Bouchetara, M. Thermomechanical modelling of dry contacts in automotive disc brake. Int. J. Therm. Sci. 2012, 60, 161–170. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Vaimann, T.; Kallaste, A.; Kuts, V. Digital twin for propulsion drive of autonomous electric vehicle. In Proceedings of the 2019 IEEE 60th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 7–9 October 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Paper 2014, 1, 1–7. [Google Scholar]

- INCOSE. Definition for Digital Twin; INCOSE: San Diego, CA, USA, 2022. [Google Scholar]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Shetty, S.S. Development of a Digital Twin of a Toyota Prius Mk4. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2022. [Google Scholar]

- Koscher, K.; Czeskis, A.; Roesner, F.; Patel, S.; Kohno, T.; Checkoway, S.; McCoy, D.; Kantor, B.; Anderson, D.; Shacham, H.; et al. Experimental Security Analysis of a Modern Automobile. In Proceedings of the 2010 IEEE Symposium on Security and Privacy, Oakland, CA, USA, 16–19 May 2010; pp. 447–462. [Google Scholar] [CrossRef]

- Checkoway, S.; McCoy, D.; Kantor, B.; Anderson, D.; Shacham, H.; Savage, S.; Koscher, K.; Czeskis, A.; Roesner, F.; Kohno, T. Comprehensive Experimental Analyses of Automotive Attack Surfaces. In Proceedings of the 20th USENIX Conference on Security, San Diego, CA, USA, 10–12 August 2011; p. 6. [Google Scholar]

- Nie, S.; Liu, L.; Du, Y. Free-Fall: Hacking Tesla from Wireless to CAN Bus. Briefing Black Hat USA 2017, 25, 1–16. [Google Scholar]

- ISO11898-1; Road Vehicles—Controller Area Network (CAN)—Part 1: Data Link Layer and Physical Signalling. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO11898-2; Road Vehicles—Controller Area Network (CAN)—Part 2: High-Speed Medium Access Unit. International Organization for Standardization: Geneva, Switzerland, 2016.

- Zuberi, K.M.; Shin, K.G. Non-Preemptive Scheduling of Messages on Controller Area Network for Real-Time Control Applications. In Proceedings of the Real-Time Technology and Applications Symposium, Chicago, IL, USA, 15–17 May 1995; pp. 240–249. [Google Scholar] [CrossRef]

- Livani, M.A.; Kaiser, J.; Jia, W. Scheduling Hard and Soft Real-Time Communication in a Controller Area Network. Control Eng. Prac. 1999, 7, 1515–1523. [Google Scholar] [CrossRef]

- Tindell, K.; Burns, A.; Wellings, A. Calculating Controller Area Network (CAN) Message Response Times. IFAC Proc. Vol. 1994, 27, 35–40. [Google Scholar] [CrossRef]

- Leen, G.; Heffernan, D. TTCAN: A new time-triggered controller area network. Microprocess. Microsyst. 2002, 26, 77–94. [Google Scholar] [CrossRef]

- Farsi, M.; Ratcliff, K.; Barbosa, M. An introduction to CANopen. Comput. Control Eng. J. 1999, 10, 161–168. [Google Scholar] [CrossRef]

- Proenza, J.; Miro-Julia, J. MajorCAN: A Modification to the Controller Area Network Protocol to Achieve Atomic Broadcast. In Proceedings of the ICDCS Workshop on Group Communications and Computations, Taipei, Taiwan, 10 April 2000; pp. C72–C79. [Google Scholar]

- Ziermann, T.; Wildermann, S.; Teich, J. CAN+: A new backward-compatible Controller Area Network (CAN) protocol with up to 16× higher data rates. In Proceedings of the 2009 Design, Automation & Test in Europe Conference & Exhibition, Nice, France, 20–24 April 2009; pp. 1088–1093. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The digital twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Hänel, A.; Schnellhardt, T.; Wenkler, E.; Nestler, A.; Brosius, A.; Corinth, C.; Fay, A.; Ihlenfeldt, S. The development of a digital twin for machining processes for the application in aerospace industry. Procedia CIRP 2020, 93, 1399–1404. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.K.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.; Warrian, P.J. Digital twin for the Oil and Gas Industry: Overview, Research Trends, Opportunities, and Challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Rodrigues, T.K.; Liu, J.; Kato, N. Application of Cybertwin for Offloading in Mobile Multiaccess Edge Computing for 6G Networks. IEEE Internet Things J. 2021, 8, 16231–16242. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Yang, Y.; Zhou, L.; Ren, L.; Wang, F.; Liu, R.; Pang, Z.; Deen, M.J. A Novel Cloud-Based Framework for the Elderly Healthcare Services Using Digital Twin. IEEE Access 2019, 7, 49088–49101. [Google Scholar] [CrossRef]

- Magargle, R.; Johnson, L.; Mandloi, P.; Davoudabadi, P.; Kesarkar, O.; Krishnaswamy, S.; Batteh, J.; Pitchaikani, A. A Simulation-Based Digital Twin for Model-Driven Health Monitoring and Predictive Maintenance of an Automotive Braking System. In Proceedings of the 12th International Modelica Conference, Prague, Czech Republic, 15–17 May 2017; pp. 35–46. [Google Scholar] [CrossRef]

- Merkle, L.; Segura, A.S.; Grummel, J.T.; Lienkamp, M. Architecture of a Digital Twin for Enabling Digital Services for Battery Systems. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; pp. 155–160. [Google Scholar] [CrossRef]

- Tharma, R.; Winter, R.; Eigner, M. An Approach for the Implementation of the Digital Twin in the Automotive Wiring Harness Field. In Proceedings of the DS 92, DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 3023–3032. [Google Scholar] [CrossRef]

- Yu, B.; Chen, C.; Tang, J.; Liu, S.; Gaudiot, J.L. Autonomous Vehicles Digital Twin: A Practical Paradigm for Autonomous Driving System Development. Computer 2022, 55, 26–34. [Google Scholar] [CrossRef]

- Conti, M.; Donadel, D.; Turrin, F. A Survey on Industrial Control System Testbeds and Datasets for Security Research. IEEE Commun. Surv. Tutor. 2021, 23, 2248–2294. [Google Scholar] [CrossRef]

- Damjanovic-Behrendt, V. A Digital Twin-based Privacy Enhancement Mechanism for the Automotive Industry. In Proceedings of the 2018 International Conference on Intelligent Systems (IS), Funchal, Portugal, 25–27 September 2018; pp. 272–279. [Google Scholar] [CrossRef]

- Pokhrel, A.; Katta, V.; Colomo-Palacios, R. Digital Twin for Cybersecurity Incident Prediction: A Multivocal Literature Review. In Proceedings of the IEEE/ACM 42nd International Conference on Software Engineering Workshops, Seoul, Republic of Korea, 27 June–19 July 2020; pp. 671–678. [Google Scholar] [CrossRef]

- Sellitto, G.P.; Masi, M.; Pavleska, T.; Aranha, H. A Cyber Security Digital Twin for Critical Infrastructure Protection: The Intelligent Transport System Use Case. In Proceedings of the IFIP Working Conference on The Practice of Enterprise Modeling, Riga, Latvia, 24–26 November 2021; pp. 230–244. [Google Scholar] [CrossRef]

- R20-11; Specification of Secure Onboard Communication. AUTOSAR: San Diego, CA, USA, 2020.

- Kurt, B.; Gören, S. Development of a Mobile News Reader Application Compatible with In-Vehicle Infotainment. In Proceedings of the International Conference on Mobile Web and Intelligent Information Systems, Barcelona, Spain, 6–8 August 2018; pp. 18–29. [Google Scholar] [CrossRef]

- Lee, D.; Kim, K.S.; Kim, S. Controller Design of an Electric Power Steering System. IEEE Trans. Control Syst. Technol. 2017, 26, 748–755. [Google Scholar] [CrossRef]

- Gurban, E.H.; Groza, B.; Murvay, P.S. Risk Assessment and Security Countermeasures for Vehicular Instrument Clusters. In Proceedings of the 2018 48th Annual IEEE/IFIP International Conference on Dependable Systems and Networks Workshops (DSN-W), Luxembourg, 25–28 June 2018; pp. 223–230. [Google Scholar] [CrossRef]

- Groza, B.; Gurban, H.E.; Murvay, P.S. Designing Security for In-vehicle Networks: A Body Control Module (BCM) Centered Viewpoint. In Proceedings of the Dependable Systems and Networks Workshop, Toulouse, France, 28 June–1 July 2016; pp. 176–183. [Google Scholar] [CrossRef]

- Garcia, F.; Oswald, D.; Kasper, T.; Pavlides, P. Lock It and Still Lose It—On the (In)Security of Automotive Remote Keyless Entry Systems. In Proceedings of the 25th USENIX Security Symposium, USENIX Association, Austin, TX, USA, 10–12 August 2016; pp. 929–944. [Google Scholar]

- Oswald, D.F. Wireless Attacks on Automotive Remote Keyless Entry Systems. In Proceedings of the 6th International Workshop on Trustworthy Embedded Devices, Vienna, Austria, 28 October 2016; pp. 43–44. [Google Scholar] [CrossRef]

- Ibrahim, O.A.; Hussain, A.M.; Oligeri, G.; Di Pietro, R. Key is in the Air: Hacking Remote Keyless Entry Systems. In Security and Safety Interplay of Intelligent Software Systems; Springer: Berlin, Germany, 2018; pp. 125–132. [Google Scholar] [CrossRef]

- Wouters, L.; Marin, E.; Ashur, T.; Gierlichs, B.; Preneel, B. Fast, Furious and Insecure: Passive Keyless Entry and Start Systems in Modern Supercars. IACR Trans. Cryptogr. Hardw. Embed. Syst. 2019, 2019, 66–85. [Google Scholar] [CrossRef]

- Dürrwang, J.; Braun, J.; Rumez, M.; Kriesten, R. Security Evaluation of an Airbag-ECU by Reusing Threat Modeling Artefacts. In Proceedings of the 2017 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 14–16 December 2017; pp. 37–43. [Google Scholar] [CrossRef]

- Mun, H.; Han, K.; Lee, D.H. Ensuring Safety and Security in CAN-Based Automotive Embedded Systems: A Combination of Design Optimization and Secure Communication. IEEE Trans. Veh. Technol. 2020, 69, 7078–7091. [Google Scholar] [CrossRef]

- Ishak, M.K.; Khan, F.K. Unique Message Authentication Security Approach based Controller Area Network (CAN) for Anti-lock Braking System (ABS) in Vehicle Network. Procedia Comput. Sci. 2019, 160, 93–100. [Google Scholar] [CrossRef]

- Guo, L.; Ye, J.; Du, L. Cyber–Physical Security of Energy-Efficient Powertrain System in Hybrid Electric Vehicles Against Sophisticated Cyberattacks. IEEE Trans. Transp. Electrif. 2020, 7, 636–648. [Google Scholar] [CrossRef]

- Ye, J.; Guo, L.; Yang, B.; Li, F.; Du, L.; Guan, L.; Song, W. Cyber–Physical Security of Powertrain Systems in Modern Electric Vehicles: Vulnerabilities, Challenges, and Future Visions. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 9, 4639–4657. [Google Scholar] [CrossRef]

- Hoff, U.; Scott, D. Challenges for wiring harness development. CAN Newsletter Magazine, March 2020; 14–19. [Google Scholar]

- Zhou, A.; Li, Z.; Shen, Y. Anomaly Detection of CAN Bus Messages Using a Deep Neural Network for Autonomous Vehicles. Appl. Sci. 2019, 9, 3174. [Google Scholar] [CrossRef]

- Hossain, M.D.; Inoue, H.; Ochiai, H.; Fall, D.; Kadobayashi, Y. LSTM-Based Intrusion Detection System for In-Vehicle Can Bus Communications. IEEE Access 2020, 8, 185489–185502. [Google Scholar] [CrossRef]

- Andreica, T.; Curiac, C.D.; Jichici, C.; Groza, B. Android Head Units vs. In-Vehicle ECUs: Performance Assessment for Deploying In-Vehicle Intrusion Detection Systems for the CAN Bus. IEEE Access 2022, 10, 95161–95178. [Google Scholar] [CrossRef]

- Kim, H.; Jeong, Y.; Choi, W.; Lee, D.H.; Jo, H.J. Efficient ECU Analysis Technology Through Structure-Aware CAN Fuzzing. IEEE Access 2022, 10, 23259–23271. [Google Scholar] [CrossRef]

- Aldhyani, T.H.; Alkahtani, H. Attacks to Automatous Vehicles: A Deep Learning Algorithm for Cybersecurity. Sensors 2022, 22, 360. [Google Scholar] [CrossRef]

- Islam, R.; Devnath, M.K.; Samad, M.D.; Al Kadry, S.M.J. GGNB: Graph-based Gaussian naive Bayes intrusion detection system for CAN bus. Veh. Commun. 2022, 33, 100442. [Google Scholar] [CrossRef]

- Toyama, T.; Yoshida, T.; Oguma, H.; Matsumoto, T. PASTA: Portable Automotive Security Testbed with Adaptability; Blackhat Europe: London, UK, 2018. [Google Scholar]

- Gay, C.; Toyama, T.; Oguma, H. Resistant Automotive Miniature Network. In Proceedings of the Chaos Computer Congress, Leipzig, Germany, 27–30 December 2020. [Google Scholar]

| CAN Signal | CAN ID | Transmitter | Data Size (bits) |

|---|---|---|---|

| Vehicle speed target | 0 × 7FA | CAN tool | 16 |

| Vehicle direction | 0 × 7FB | CAN tool | 2 |

| Brake status | 0 × 7FB | CAN tool | 1 |

| Steering wheel angle | 0 × 7FD | CAN tool | 16 |

| Buckle status | 0 × 7FE | CAN tool | 1 |

| Engine speed | 0 × 11 | PCM | 32 |

| Gear | 0 × 13 | PCM | 4 |

| Vehicle speed | 0 × 24 | ABS | 32 |

| Vehicle steering offset | 0 × 30 | PSCM | 32 |

| Vehicle position X | 0 × 31 | PSCM | 32 |

| Vehicle position Y | 0 × 31 | PSCM | 32 |

| Airbag status | 0 × 40 | RCM | 1 |

| Vehicle average speed | 0 × 21 | IPC | 32 |

| Trip distance | 0 × 21 | IPC | 32 |

| Buckle alert | 0 × 22 | IPC | 1 |

| Door lock status | 0 × 40 | RFA | 1 |

| Rear camera video status | 0 × 12 | APIM | 1 |

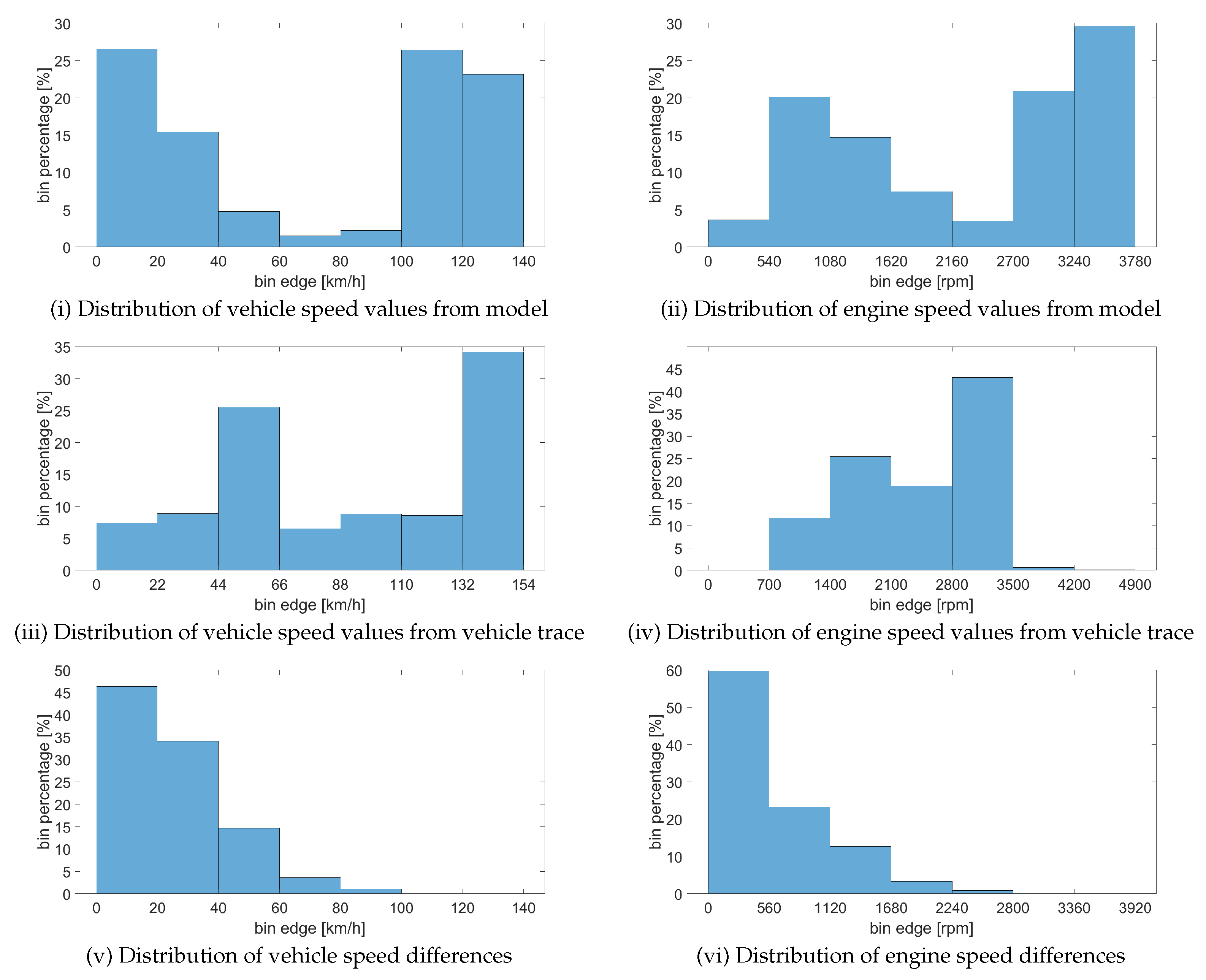

| Signal | Bin Width | Bin Percentages [Bins 1 to 7] |

|---|---|---|

| Vehicle speed (model) | 20 [km/h] | 27, 15, 5, 2, 2, 26, 23 [%] |

| Engine speed (model) | 540 [rpm] | 4, 20, 15, 7, 3, 21, 30 [%] |

| Vehicle speed (trace) | 22 [km/h] | 7, 9, 25, 7, 9, 9, 34 [%] |

| Engine speed (trace) | 700 [rpm] | 0, 12, 25, 19, 43, 1, 0 [%] |

| Vehicle speed (difference) | 20 [km/h] | 46, 34, 15, 4, 1, 0, 0 [%] |

| Engine speed (difference) | 560 [rpm] | 60, 23, 13, 3, 1, 0, 0 [%] |

| Signal | Range | Mean Difference | Correlation Coefficient |

|---|---|---|---|

| Vehicle speed | 0–148 [km/h] | 25.08 | 0.85 |

| Engine speed | 0–4597 [rpm] | 610.01 | 0.71 |

| Correlation Coefficients | ||||||

|---|---|---|---|---|---|---|

| Experiment | No Attack Frames | Attack at | Attack at | Attack at | Attack at | Attack Only |

| Generic trace | 0.88 | 0.70 | 0.57 | 0.43 | 0.35 | 0.00 |

| CarTwin | 0.93 | 0.83 | 0.72 | 0.61 | 0.56 | 0.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popa, L.; Berdich, A.; Groza, B. CarTwin—Development of a Digital Twin for a Real-World In-Vehicle CAN Network. Appl. Sci. 2023, 13, 445. https://doi.org/10.3390/app13010445

Popa L, Berdich A, Groza B. CarTwin—Development of a Digital Twin for a Real-World In-Vehicle CAN Network. Applied Sciences. 2023; 13(1):445. https://doi.org/10.3390/app13010445

Chicago/Turabian StylePopa, Lucian, Adriana Berdich, and Bogdan Groza. 2023. "CarTwin—Development of a Digital Twin for a Real-World In-Vehicle CAN Network" Applied Sciences 13, no. 1: 445. https://doi.org/10.3390/app13010445

APA StylePopa, L., Berdich, A., & Groza, B. (2023). CarTwin—Development of a Digital Twin for a Real-World In-Vehicle CAN Network. Applied Sciences, 13(1), 445. https://doi.org/10.3390/app13010445