Research on Rigid–Elastic Coupling Flight Dynamics of Hybrid Wing Body Based on a Multidiscipline Co-Simulation

Abstract

1. Introduction

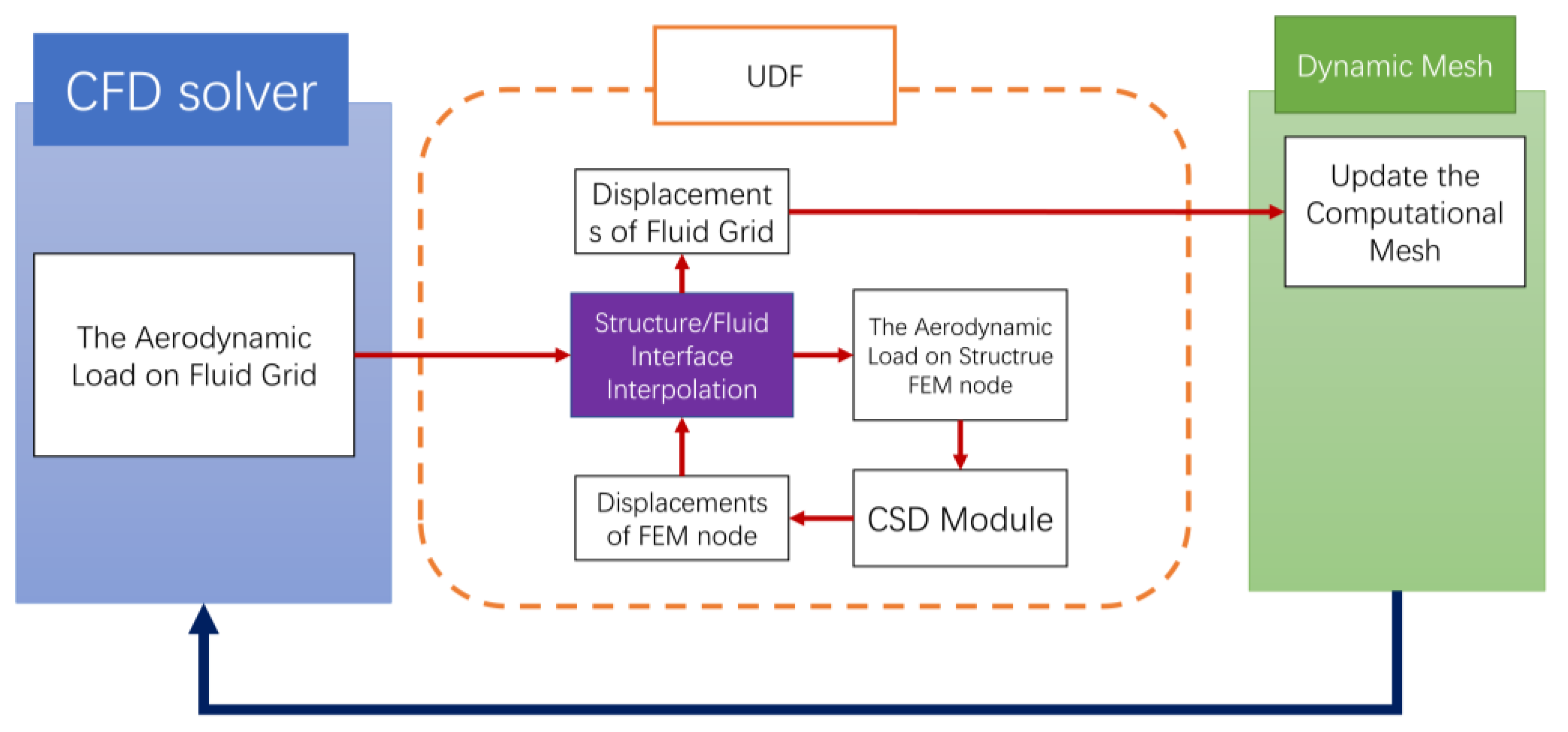

2. Framework of Co-Simulation

3. Development and Validation of CFD/CSD Coupled Solvers

3.1. Initialization of Simulation

3.2. Structure/Fluid Interface Interpolation

3.3. Structural Dynamics Equation

3.4. Procedure of CFD/CSD Simulation

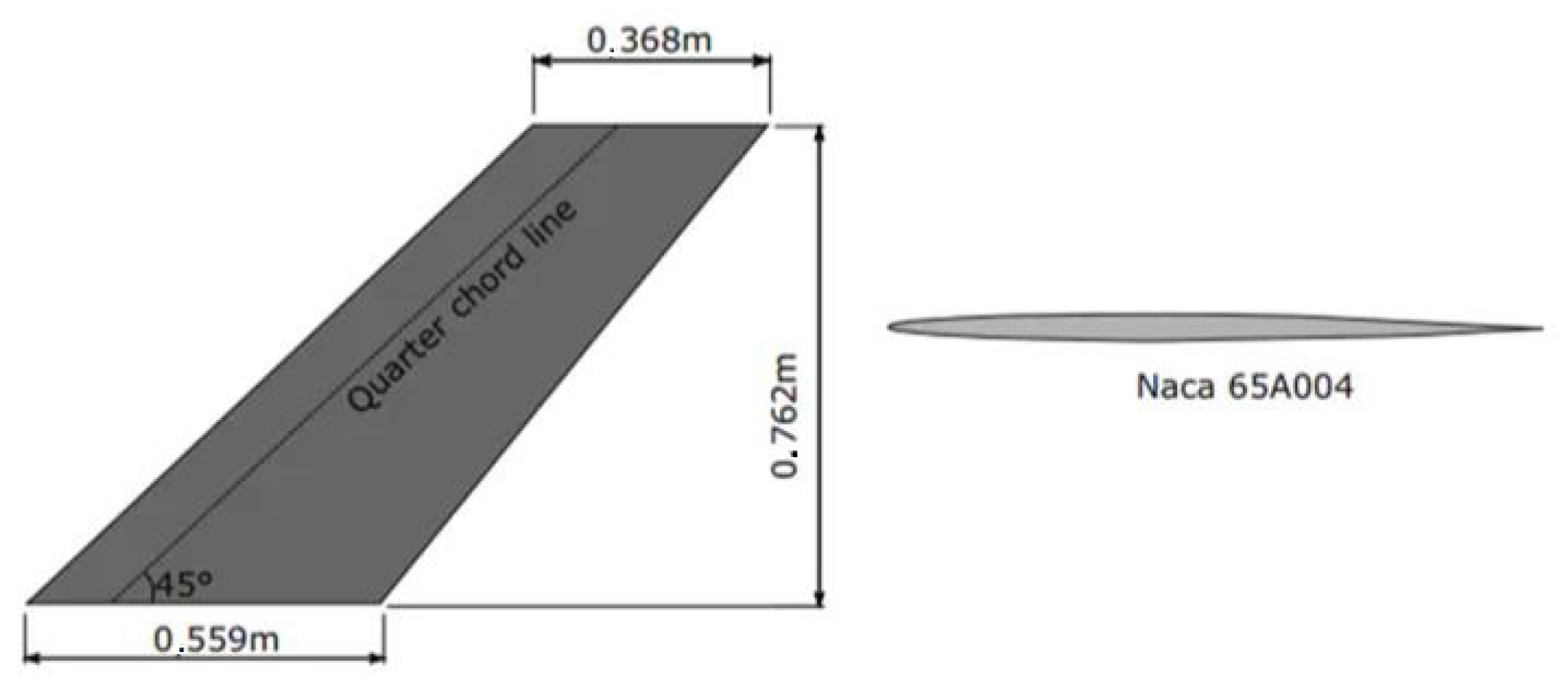

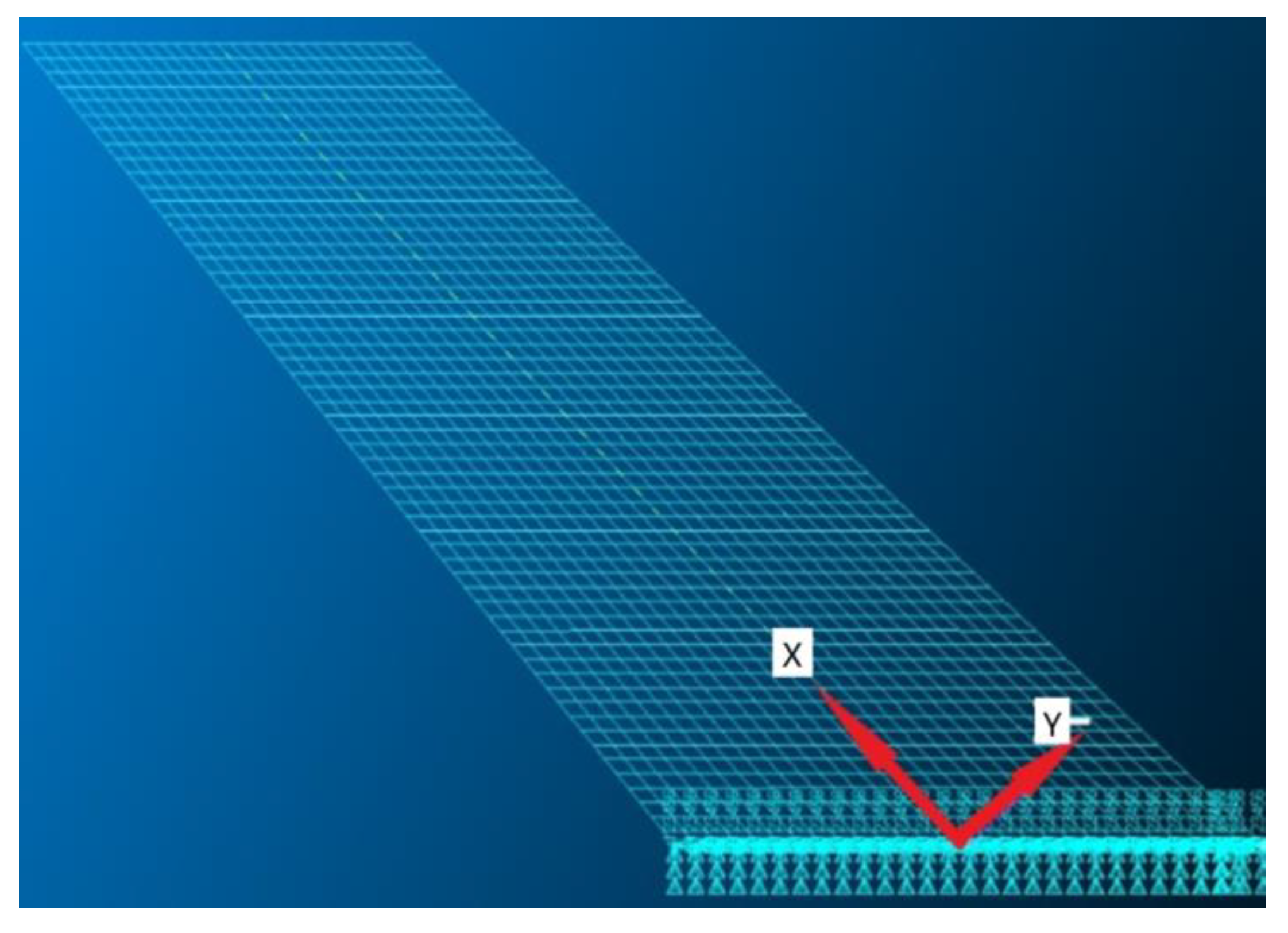

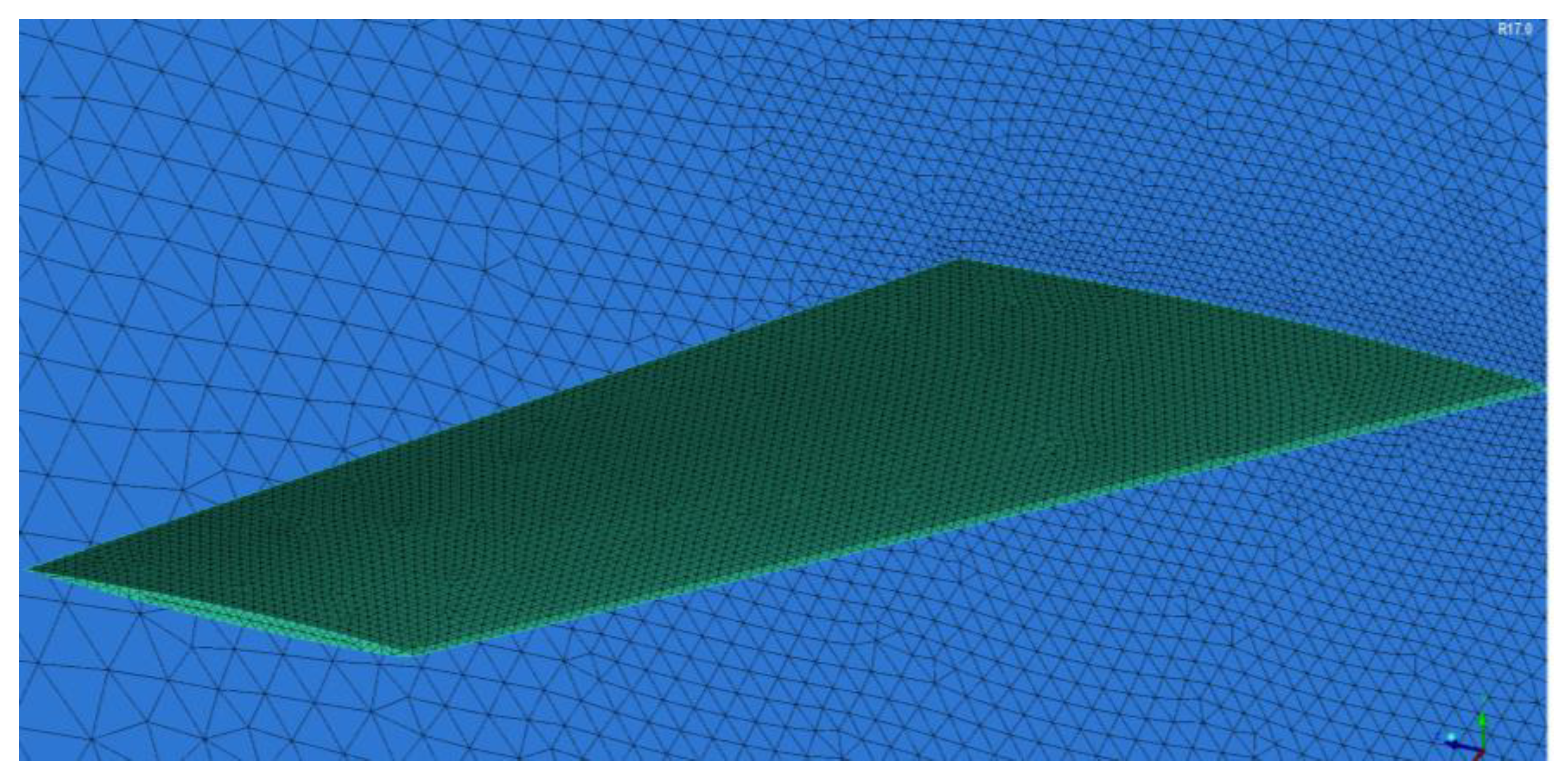

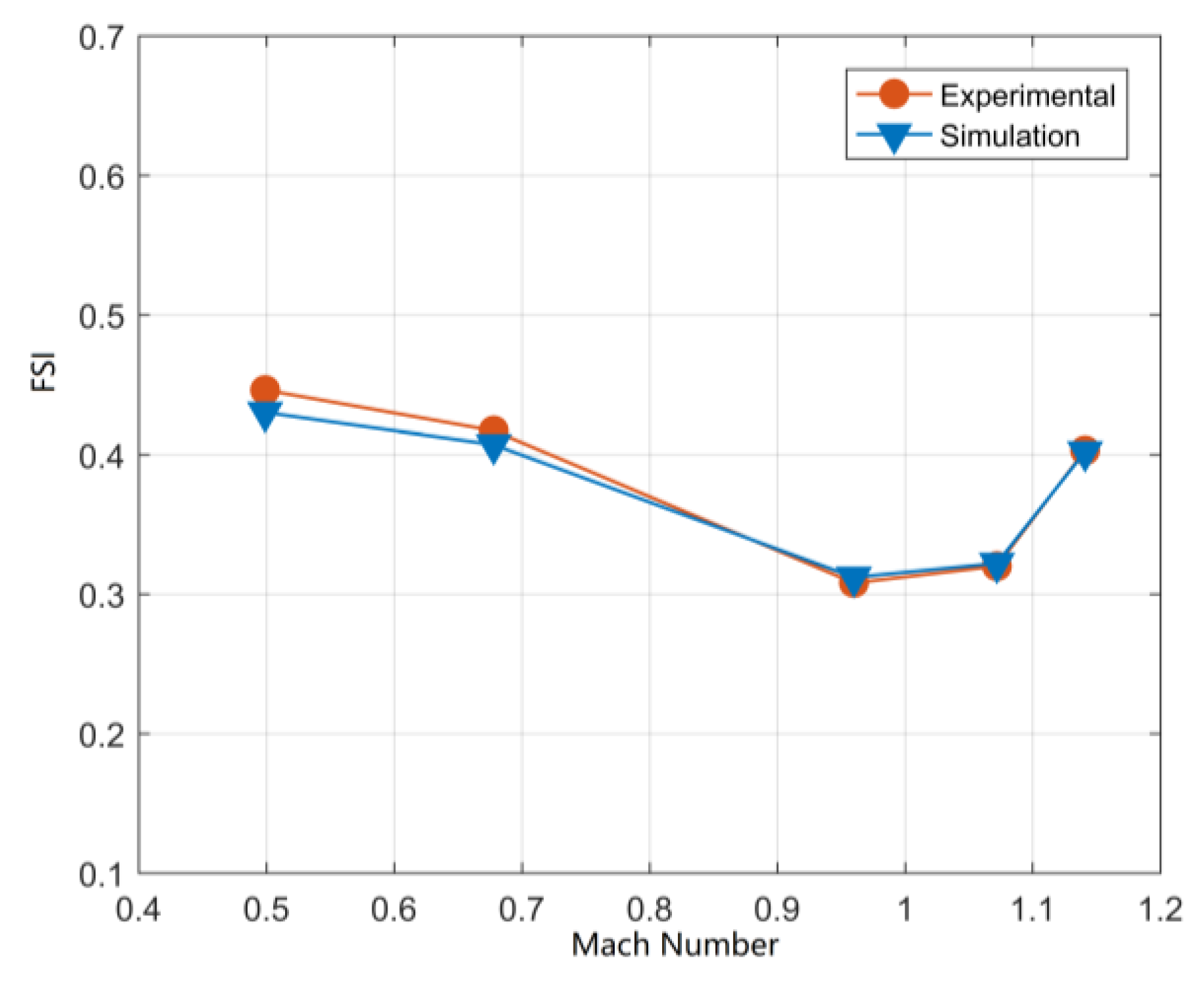

3.5. Verification of the CFD/CSD Co-Simulation

4. Development and Validation of CFD/RBD Coupled Solvers

4.1. Reference Frame

4.2. Flight Dynamic Equations

4.3. CFD/RBD Co-Simulation Procedure

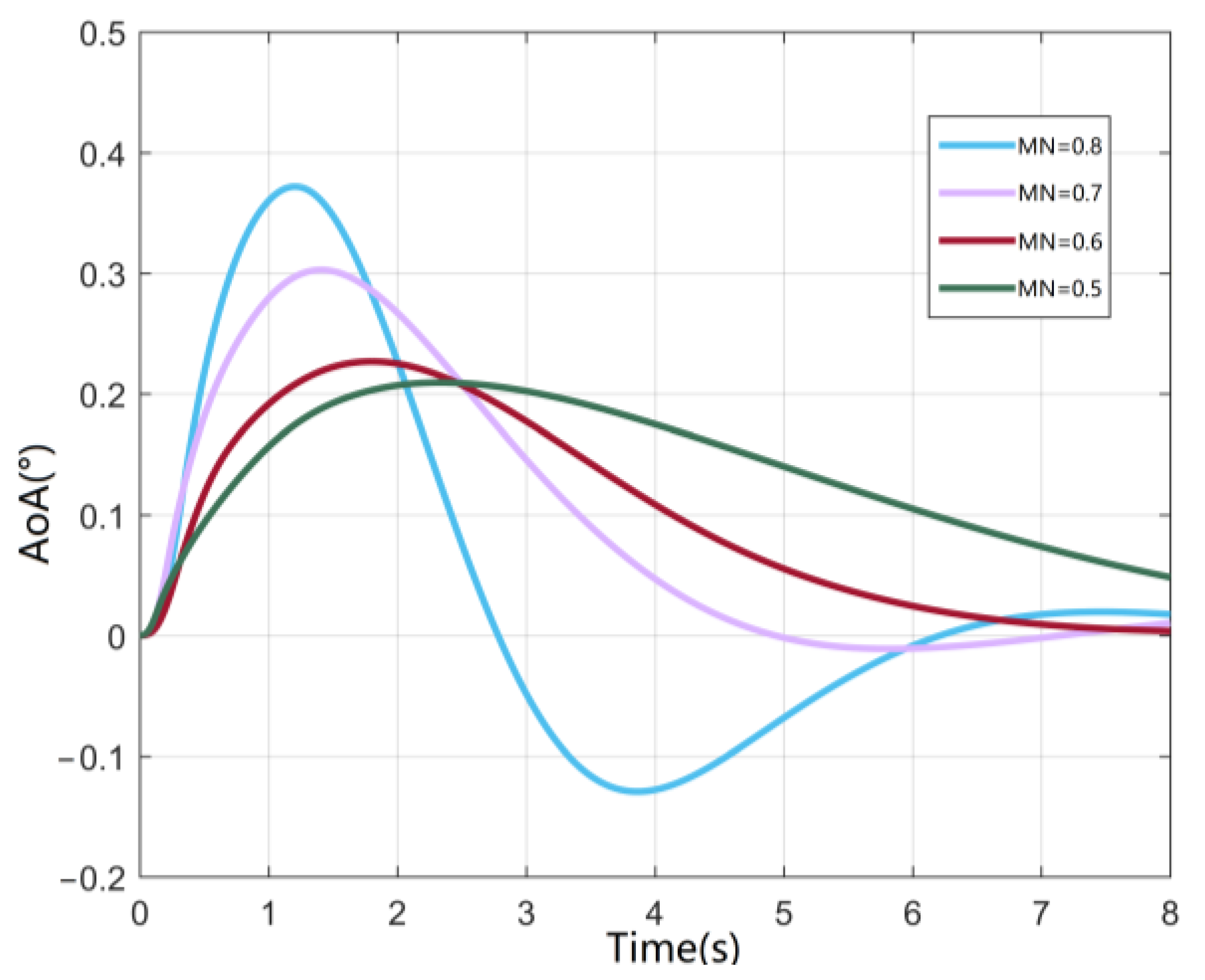

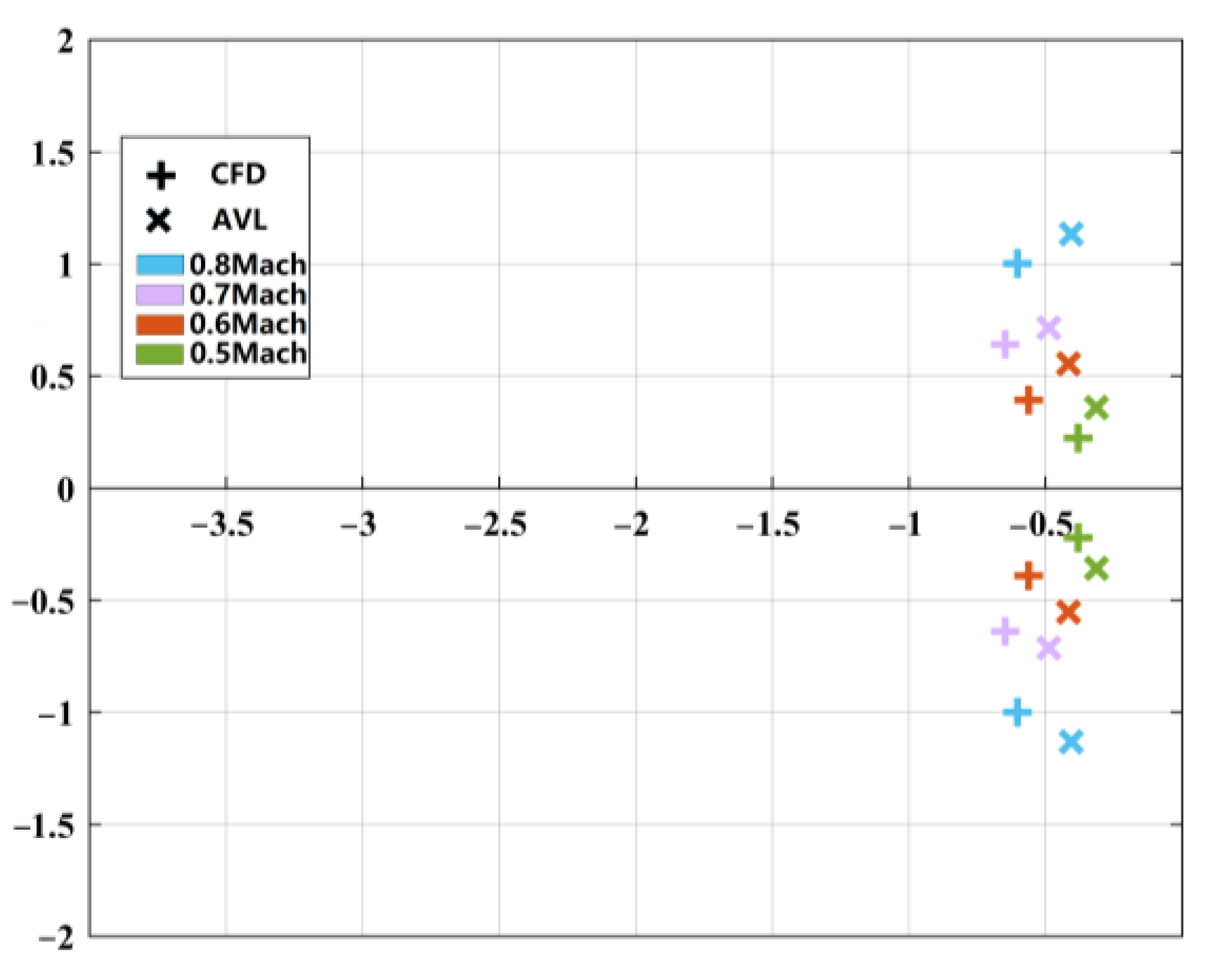

4.4. Verification of RBD/CFD Co-Simulation

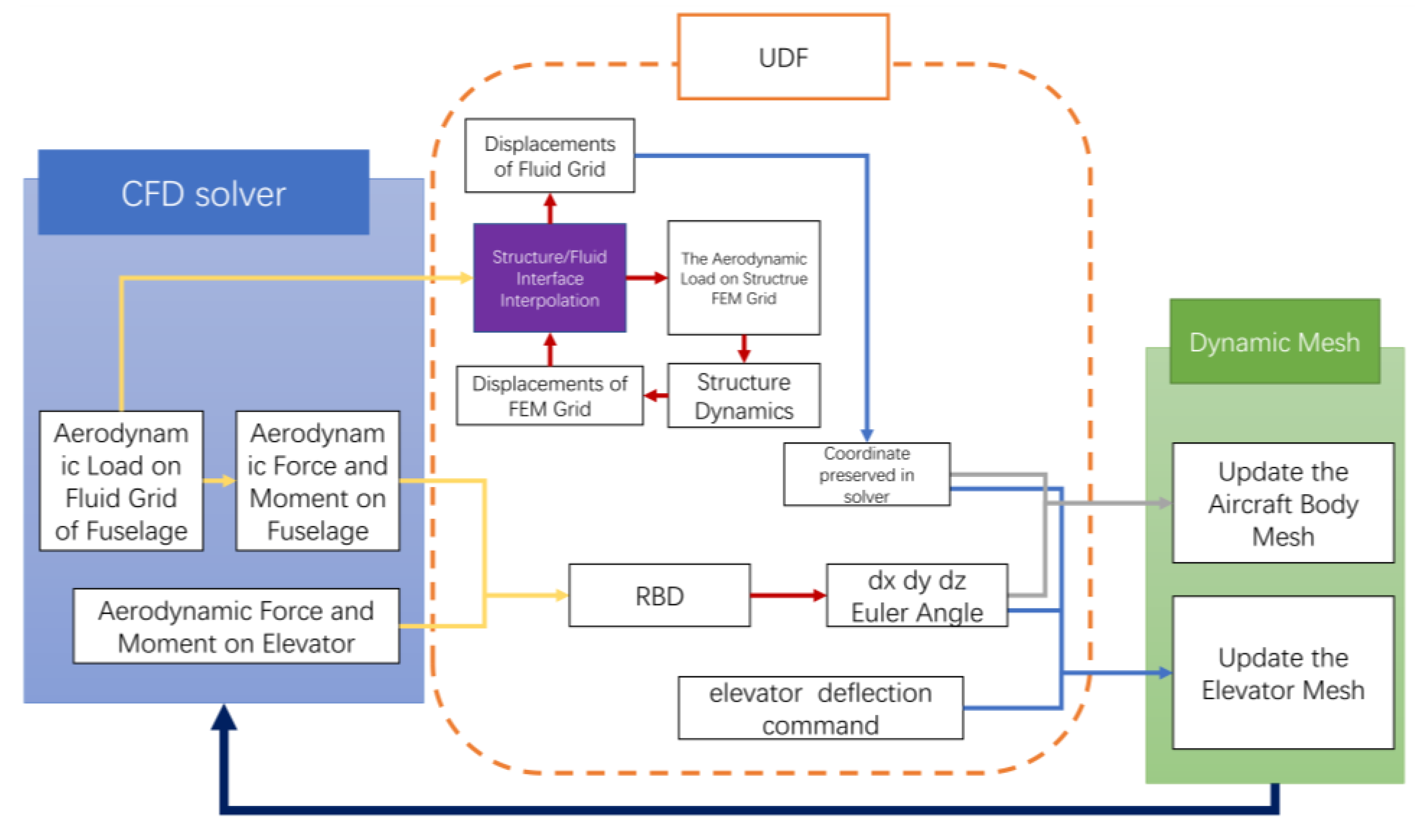

5. Co-Simulation of CFD/CSD/RBD

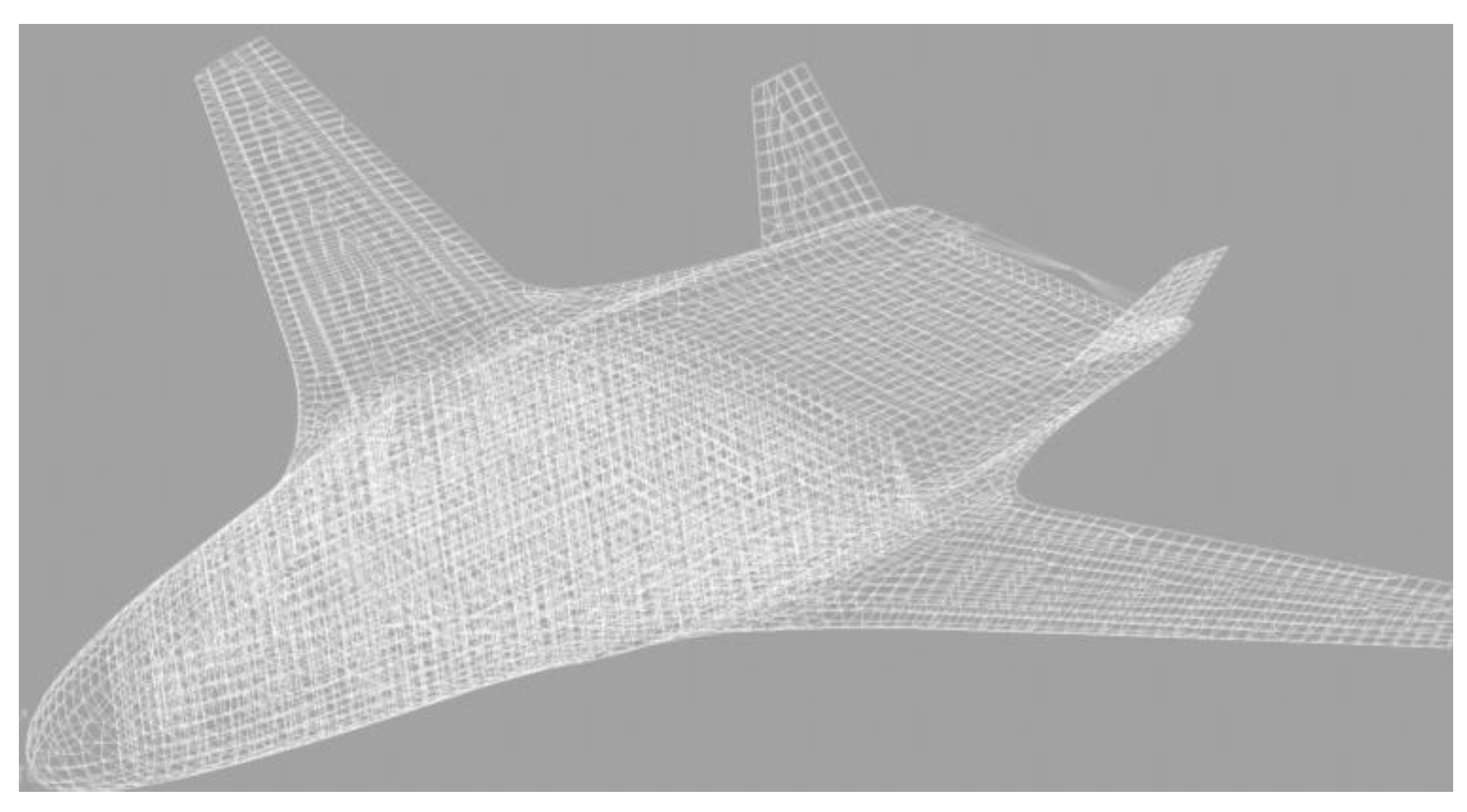

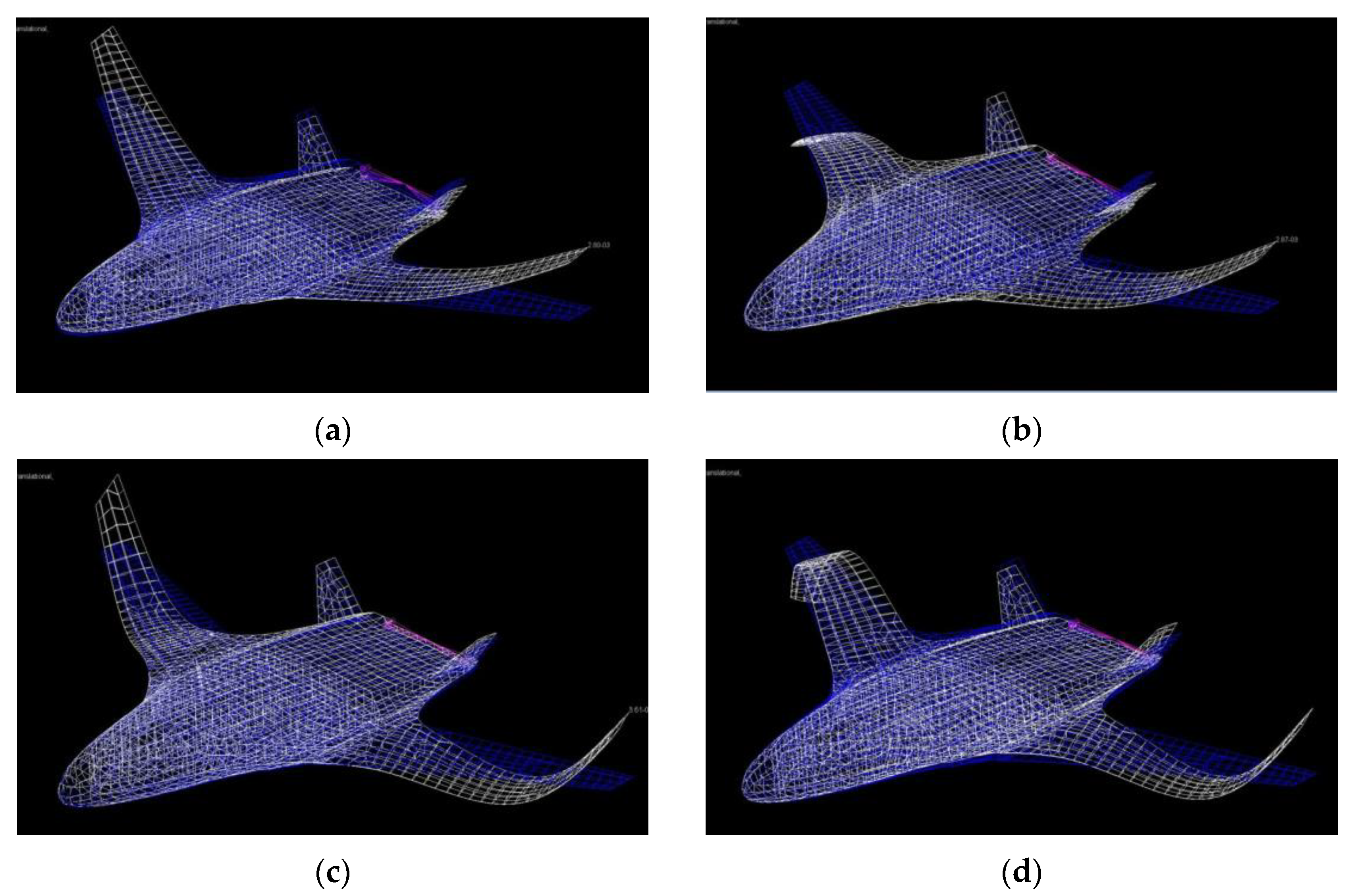

5.1. Structural Model of HWB

5.2. Procedure of Co-Simulation of CFD/CSD/RBD

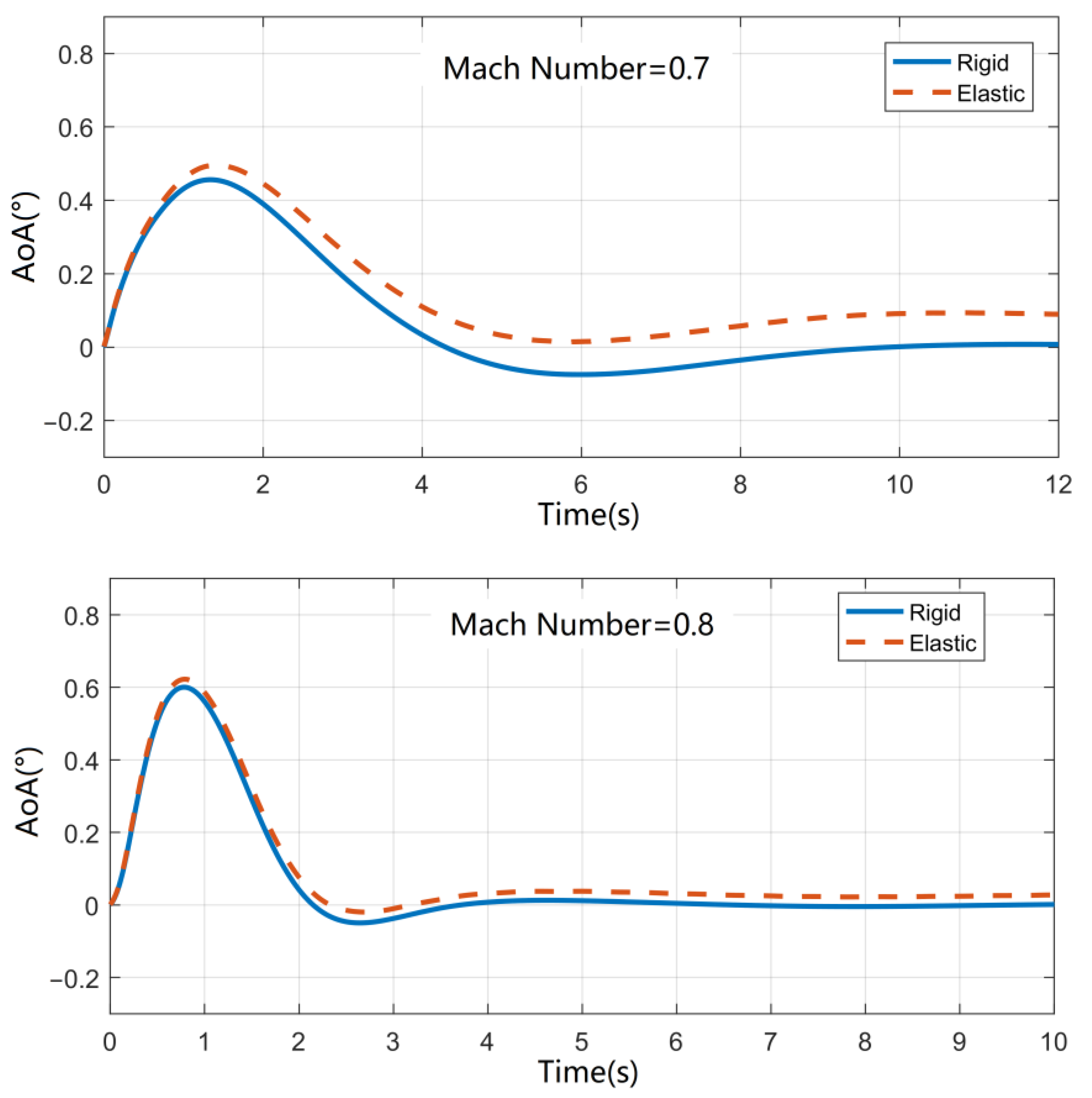

5.3. Results of Co-Simulation of CFD/CSD/RBD

5.4. Discussion on the Results of Co-Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| HWB | Hybrid Wing Body |

| AOA | Angle of Attack |

| CFD | Computational Fluid Dynamics |

| CSD | Computational Structure Dynamics |

| RBD | Rigid-Body Dynamics |

| RANS | Reynolds-averaged Navier–Stokes equations |

| MN | Mach Number |

| AVL | Athena Vortex Lattice |

| FSI | Flutter Speed Index |

| FEM | Finite Element |

| UDF | User Defined Function |

| DLM | Double-let Lattice Method |

| Matrix of Mode Shape | |

| Matrix of Mass | |

| Matrix of Damping | |

| Matrix of Stiffness | |

| Component of Velocity relative to body frame | |

| Component of Angular Velocity relative to body frame | |

| Thin Plate Spline Basic Function | |

| Solid/Fluid Interface Interpolation Matrix | |

| Center of Mass of Aircraft in Inertial Frame | |

| Attitude angle of Aircraft in Inertial Frame | |

| Center of Mass of Aircraft in CFD Frame | |

| Attitude angle of Aircraft in CFD Frame | |

| Coordinates of Fuselage Mesh in CFD Frame | |

| Coordinates of Elevator Mesh in CFD Frame | |

| Coordinates of Fuselage Mesh in body Frame | |

| Coordinates of Elevator Mesh in body Frame | |

| Coordinates of Deformed Fuselage Mesh in body Frame | |

| Coordinates of deflected Elevator Mesh in body Frame | |

| Displacement on Coordinates of Fuselage Mesh in body Frame | |

| Deflected Angle of Elevator |

References

- Dorian, F.C.; Nicholas, H.R. HALE Multidisciplinary Design Optimization Part II: Solar-Powered Flying-Wing Aircraft. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Daniel, P.; Simon, B. The Integration of an Efficient High Lift System in the Design Process of a Blended Wing Body Aircraft. In Proceedings of the 12th AIAA Aviation Technology, Integration, and Operations Conference, Indianapolis, IN, USA, 17–19 September 2012. [Google Scholar]

- Melike, N.; Bret, S. Impact of Aeroelastic Uncertainties on the Sonic Boom Signature of a Commercial Supersonic Transport Configuration. In Proceedings of the AIAA Scitech 2017 Forum, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Molong, D.; Carlos, E. Nonlinear Control-oriented Modeling for Very Flexible Aircraft. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–15 & 19–21 January 2021. [Google Scholar]

- Wang, X.R.; Tigran, M. Nonlinear Incremental Control for Flexible Aircraft Trajectory Tracking and Load Alleviation. J. Guid. Control Dyn. 2022, 45, 39–57. [Google Scholar] [CrossRef]

- Flávio, J.S.; Antônio, B.G. Aircraft Control Based on Flexible Aircraft Dynamics. J. Aircr. 2018, 54, 262–271. [Google Scholar]

- Wu, Z.G.; Yang, C. Flight Loads and Dynamics of Flexible Air Vehicles. Chin. J. Aeronaut. 2004, 17, 17–22. [Google Scholar] [CrossRef][Green Version]

- Frank, G. Finite Element Based HWB Centerbody Structural Optimization and Weight Prediction. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Cai, Y.; Xie, J.C. Assessment of Longitudinal Stability-and-Control Characteristics of Hybrid Wing Body Aircraft in Conceptual Design. In Proceedings of the AIAA Aviation 2021 Forum, Virtual Event, 2–6 August 2015. [Google Scholar]

- Mardanpour, P.; Richards, W.P.; Nabipour, O.; Hodges, D.H. Effect of Multiple Engine Placement on Aeroelastic Trim and Stability of Flying Wing Aircraft. J. Fluids Struct. 2014, 44, 67–86. [Google Scholar] [CrossRef]

- Mardanpour, P.; Hodges, D.H.; Neuhart, R.; Graybeal, N. Engine Placement Effect on Nonlinear Trim and Stability of Flying Wing Aircraft. J. Aircr. 2013, 50, 1716–1725. [Google Scholar] [CrossRef]

- Giulio, A.; Francesco, N. Reduced-Order Short-Period Model of Flexible Aircraft. J. Guid. Control Dyn. 2017, 40, 2017–2029. [Google Scholar]

- Xie, C.C.; Yang, L. Stability of Very Flexible Aircraft with Coupled Nonlinear Aeroelasticity and Flight Dynamics. J. Aircr. 2018, 55, 862–874. [Google Scholar]

- Antônio, B.G.; Guilherme, C. Flexible Aircraft Simulation Validation with Flight Test Data. AIAA J. 2021, 61, 1–20. [Google Scholar]

- Antônio, B.G.; Roberto, G.A. Formulation of the Flight Dynamics of Flexible Aircraft Using General Body Axes. J. Aircr. 2016, 54, 3517–3534. [Google Scholar]

- Lars, R.; Markus, R. CFD-based Gust Load Analysis for a Free-flying Flexible Passenger Aircraft in Comparison to a DLM-based Approach. In Proceedings of the AIAA Aviation 2015 Forum, Dallas, TX, USA, 22–26 June 2015. [Google Scholar]

- Gul, D.; Altan, K. Aeroelastic Model Corrections of a Very Light Aircraft; Implications on Static Trim, Flutter and Gust Response. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Michele, C.; Jonathan, E.C. Nonlinear Static Aeroelasticity of High-Aspect-Ratio-Wing Aircraft by Finite Element and Multibody Methods. J. Aircr. 2017, 54, 548–560. [Google Scholar]

- Thiemo, M.K.; Bret, S. Comparison of Unsteady Aerodynamic Modelling Methodologies with Respect to Flight Loads Analysis. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference and Exhibit, San Francisco, CA, USA, 9–13 August 2005. [Google Scholar]

- Pau, C.M.; Christophe, P. Simulation of Flexible Aircraft Response to Gust and Turbulence for Flight Dynamics Investigations. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Martin, L.; Andreas, K. Flight Dynamics Modeling of a Body Freedom Flutter Vehicle for Multidisciplinary Analyses. In Proceedings of the AIAA Scitech 2015 Forum, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Ethan, C.; Matthew, F. Transient CFD/CSD Tiltrotor Stability Analysis. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Amine, A.; Muhammed, K.Y. CFD/CSD Coupling for Camber Morphed Rotor Blades. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Chen, G.; Zhou, Q. Computational-Fluid-Dynamics-Based Aeroservoelastic Analysis for Gust Load Alleviation. J. Aircr. 2018, 55, 1620–1628. [Google Scholar] [CrossRef]

- Amin, F.; Anant, G. Computational Aeroelastic Analysis using an Enhanced OpenFOAM-based CFD-CSD Solver. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Nidhi, D.S.; Klaus, A.H. Trajectory Prediction Using Coupled CFD-RBD with Dynamic Meshing. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Jubaraj, S.; Frank, F. Computational and Experimental Free-Flight Motion of a Subsonic Canard-Controlled Body. In Proceedings of the AIAA Aviation 2017 Forum, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Cui, P.; Han, J.L. Numerical investigation of the effects of structural geometric and material nonlinearities on limit-cycle oscillation of a cropped delta wing. J. Fluids Struct. 2011, 27, 611–622. [Google Scholar]

- Wang, N.H.; Ma, R. Numerical Virtual Flight Simulation of Quasi-Cobra Maneuver of a Fighter Aircraft. J. Aircr. 2021, 58, 139–152. [Google Scholar] [CrossRef]

- Zhang, L.P.; Zhao, Z.L.; Chang, X.H. Validation of Numerical Virtual Flight System with Wind-Tunnel Virtual Flight Testing. AIAA J. 2020, 58, 1566–1579. [Google Scholar]

- Carson, Y. AGARD Standard Aeroelastic Configurations for Dynamic Response I-Wing 445.6; NASA Langley Research Center: Hampton, VA, USA, 1988. [Google Scholar]

- Victor, L.; Kim, L. Hybrid Wing Body (HWB) Aircraft Design and Optimization Using Stitched Composites. In Proceedings of the AIAA Aviation 2015 Forum, Dallas, TX, USA, 22–26 June 2015. [Google Scholar]

| Material Properties | Value |

|---|---|

| Longitudinal Young’s modulus | 3.1511 Gpa |

| Lateral Young’s modulus | 0.4162 Gpa |

| Poisson’s ratio | 0.31 |

| Density | 381.98 kg/m3 |

| Mode 1 | Mode 2 | Mode 3 | Mode 4 | |

|---|---|---|---|---|

| Experiment | 9.6 | 38.1 | 50.7 | 98.5 |

| Simulation | 8.8 | 39.4 | 51.6 | 100.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, G. Research on Rigid–Elastic Coupling Flight Dynamics of Hybrid Wing Body Based on a Multidiscipline Co-Simulation. Appl. Sci. 2023, 13, 410. https://doi.org/10.3390/app13010410

Wang Y, Liu G. Research on Rigid–Elastic Coupling Flight Dynamics of Hybrid Wing Body Based on a Multidiscipline Co-Simulation. Applied Sciences. 2023; 13(1):410. https://doi.org/10.3390/app13010410

Chicago/Turabian StyleWang, Yucheng, and Gang Liu. 2023. "Research on Rigid–Elastic Coupling Flight Dynamics of Hybrid Wing Body Based on a Multidiscipline Co-Simulation" Applied Sciences 13, no. 1: 410. https://doi.org/10.3390/app13010410

APA StyleWang, Y., & Liu, G. (2023). Research on Rigid–Elastic Coupling Flight Dynamics of Hybrid Wing Body Based on a Multidiscipline Co-Simulation. Applied Sciences, 13(1), 410. https://doi.org/10.3390/app13010410