Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints

Abstract

1. Introduction

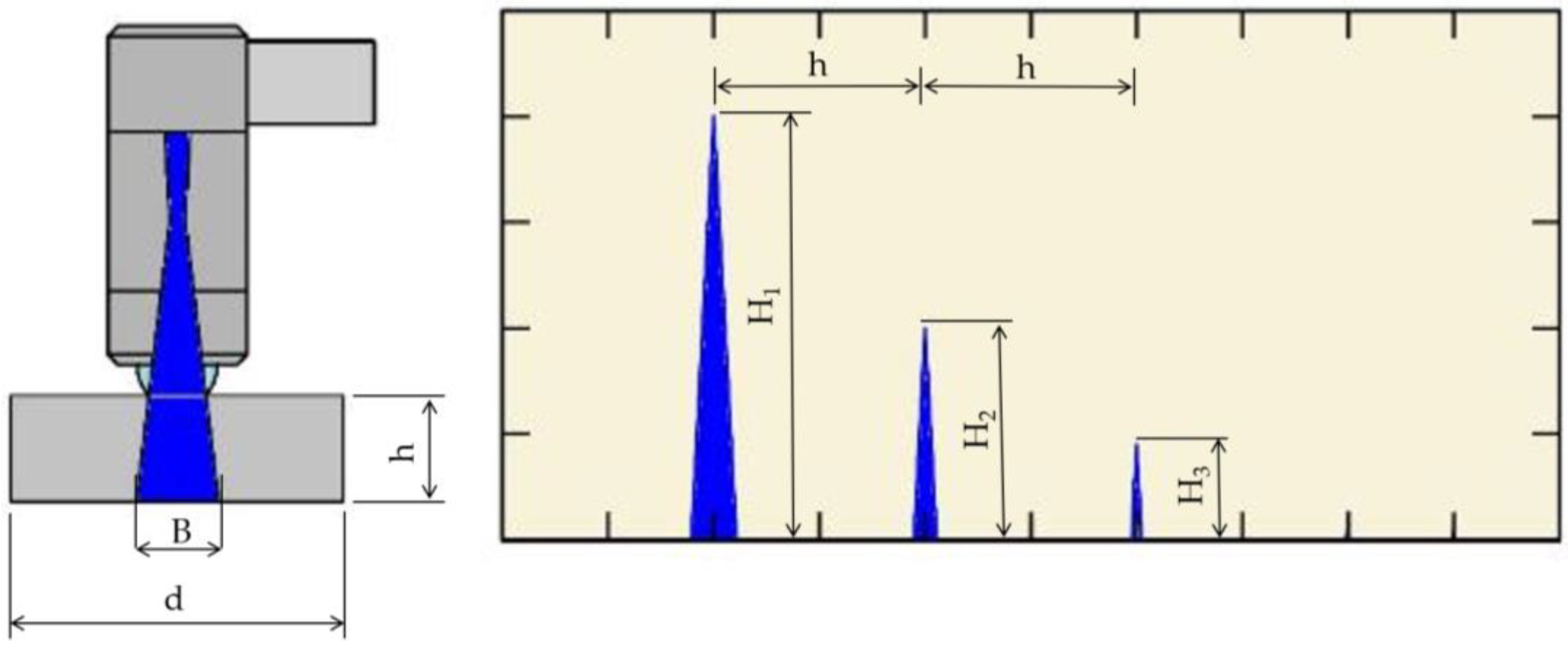

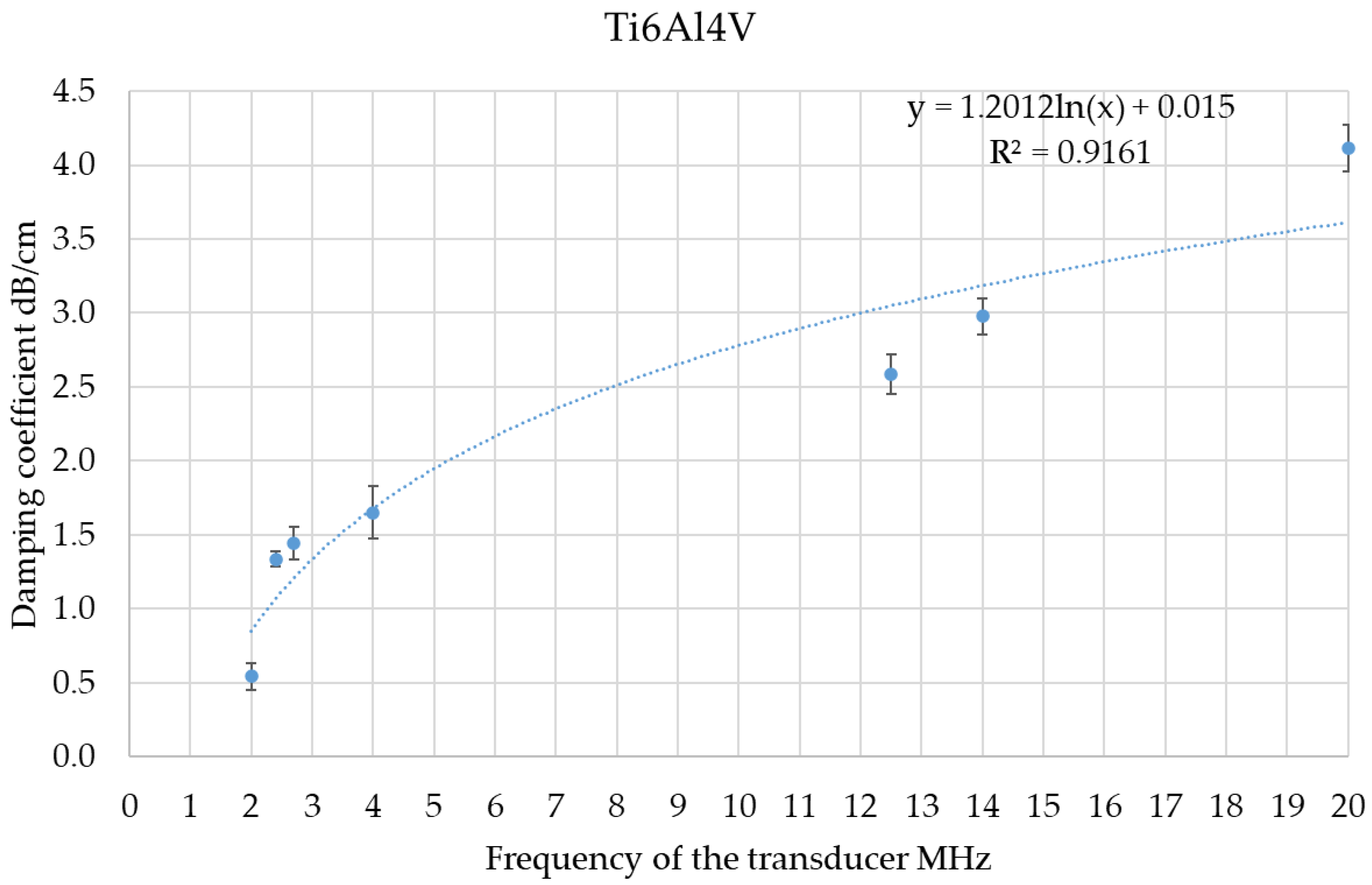

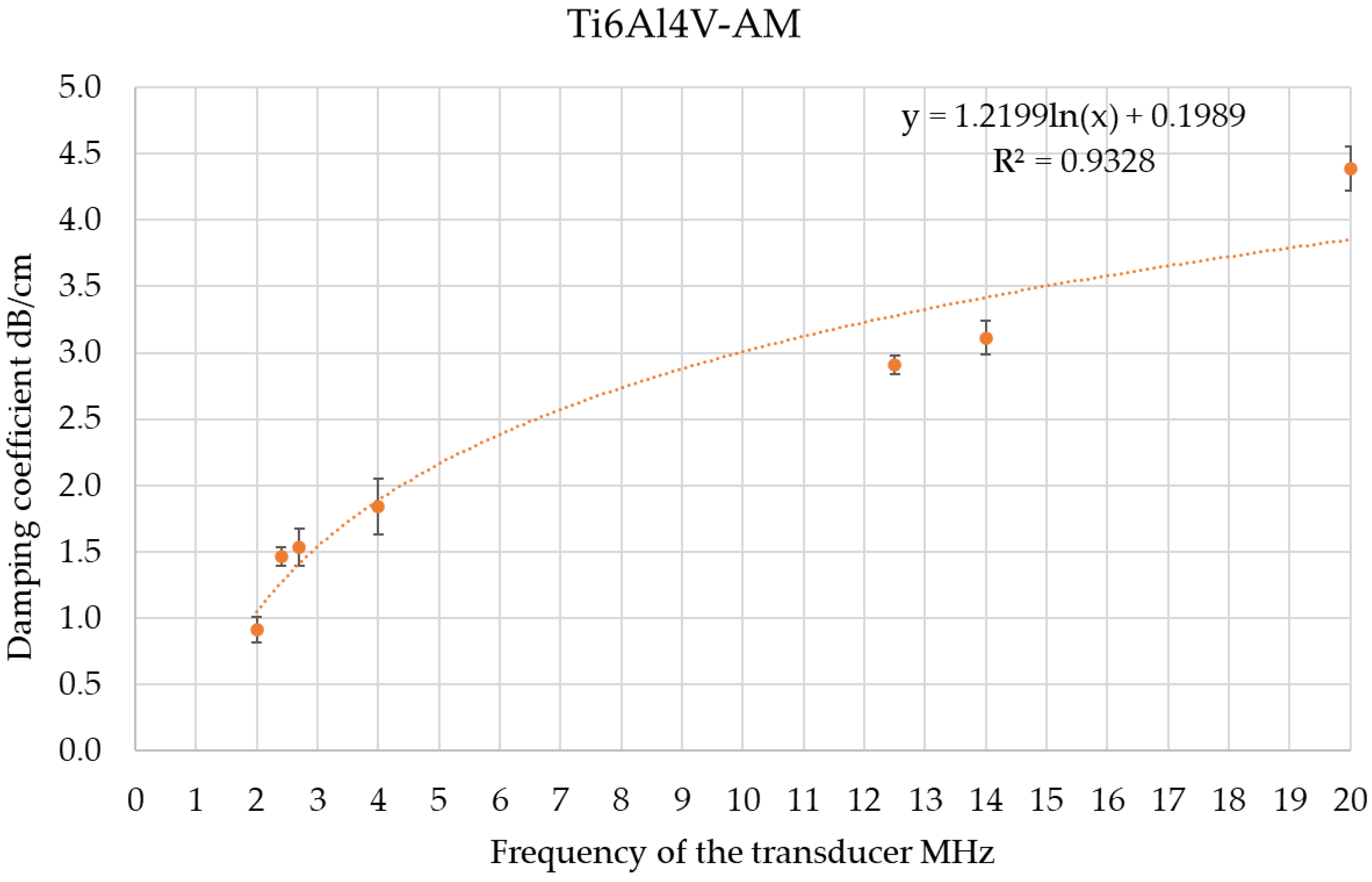

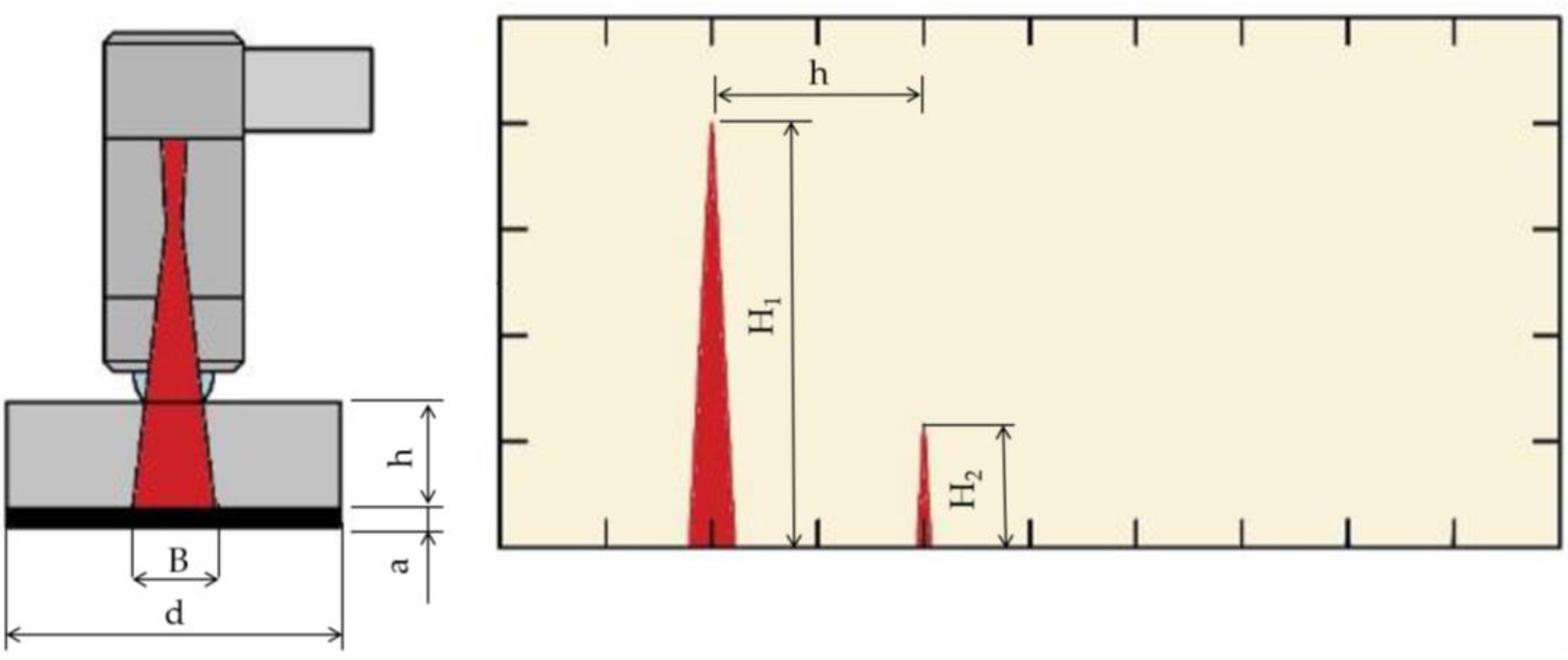

2. Ultrasonic Testing of Materials

- B—beam diameter mm,

- s—distance from the ultrasonic transducer mm,

- k—coefficient of amplitude decrease across the beam width by 6 dB (k = 0.5) and by 10 dB (k = 0.87),

- c—wave velocity in the material m/s,

- f—head frequency 1/s,

- D—transducer diameter mm.

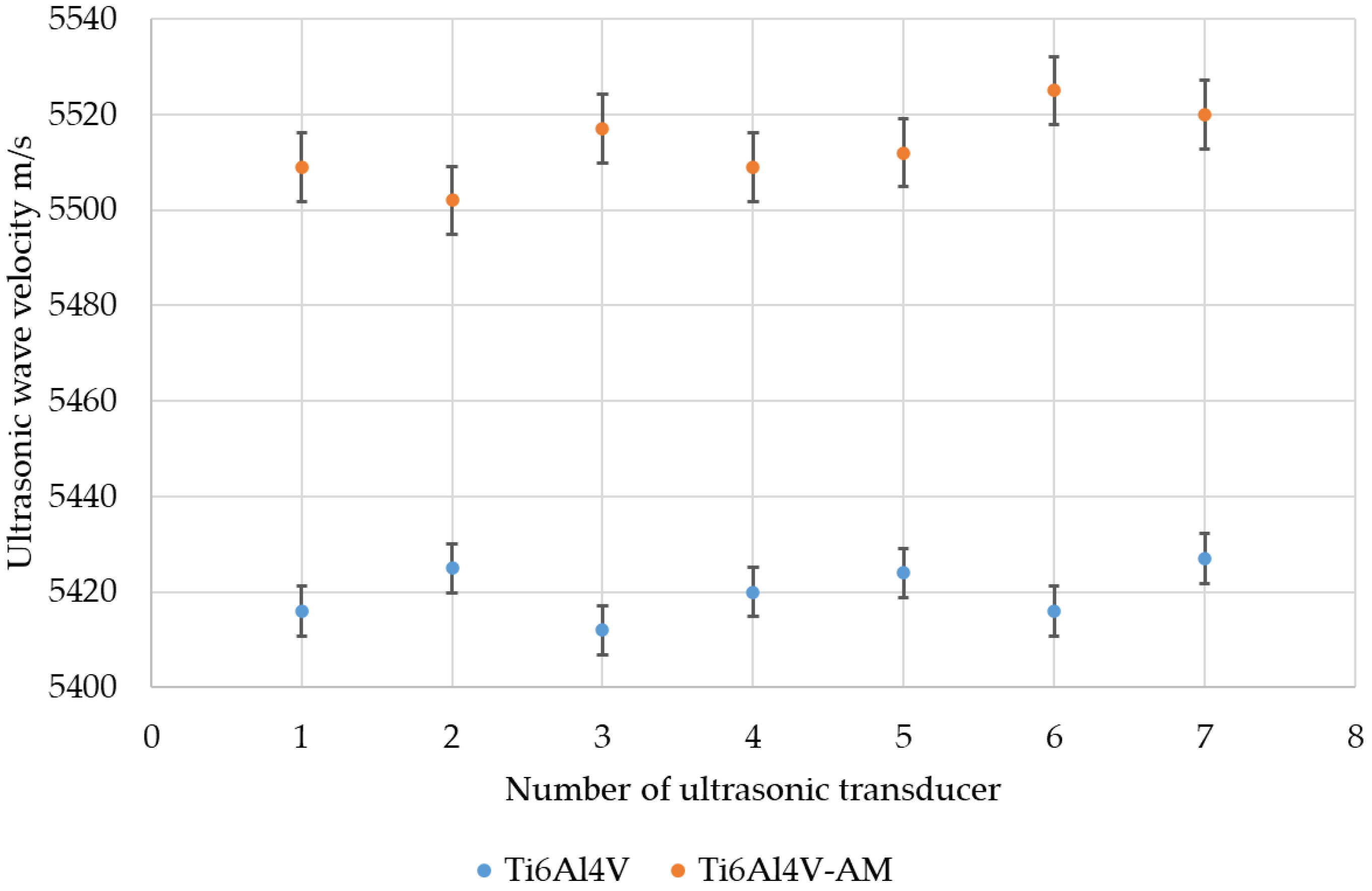

| Parameter/Head Name | MB2S | KD1-6 | KD0.8-3 | MB4S | KD4-12 | KD6-16 | GE20 |

|---|---|---|---|---|---|---|---|

| Number of Ultrasonic Transducer | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| frequency MHz | 2.00 | 2.40 | 2.75 | 4.00 | 12.5 | 14.00 | 20.00 |

| transducer diameter mm | 10.00 | 12.00 | 12.00 | 10.00 | 6.00 | 3.00 | 3.00 |

| effective diameter of the beam mm | 9.70 | 11.64 | 11.64 | 9.70 | 5.82 | 2.91 | 2.91 |

| mean wave velocity in tested material m/s | 5418 | 5418 | 5418 | 5418 | 5418 | 5418 | 5418 |

| wavelength mm | 2.71 | 2.26 | 1.97 | 1.36 | 0.43 | 0.39 | 0.27 |

| near field mm | 8.00 | 14.40 | 16.70 | 17.00 | 19.40 | 5.40 | 7.70 |

| decibel drop ratio K | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 |

| sin beam divergence angle | 0.24 | 0.17 | 0.15 | 0.12 | 0.06 | 0.12 | 0.08 |

| divergence angle° | 14.06 | 9.71 | 8.47 | 6.98 | 3.71 | 6.64 | 4.65 |

| Parameter/Head Name | MB2S | KD1-6 | KD0.8-3 | MB4S | KD4-12 | KD6-16 | GE20 |

|---|---|---|---|---|---|---|---|

| Number of Ultrasonic Transducer | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| frequency MHz | 2.00 | 2.40 | 2.75 | 4.00 | 12.5 | 14.00 | 20.00 |

| transducer diameter mm | 10.00 | 12.00 | 12.00 | 10.00 | 6.00 | 3.00 | 3.00 |

| effective diameter of the beam mm | 9.70 | 11.64 | 11.64 | 9.70 | 5.82 | 2.91 | 2.91 |

| mean wave velocity in tested material m/s | 5513 | 5513 | 5513 | 5513 | 5513 | 5513 | 5513 |

| wavelength mm | 2.80 | 2.30 | 2.00 | 1.40 | 0.40 | 0.40 | 0.30 |

| near field mm | 7.80 | 14.20 | 16.40 | 16.70 | 19.10 | 5.30 | 7.60 |

| decibel drop ratio K | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 |

| sin beam divergence angle | 0.25 | 0.17 | 0.15 | 0.12 | 0.07 | 0.12 | 0.08 |

| divergence angle° | 14.31 | 9.89 | 8.62 | 7.10 | 3.78 | 6.76 | 4.73 |

- MB2S → 67.87%,

- KD1-6 → 9.84%,

- KD0.8-3 → 6.12%,

- MB4S → 11.60%,

- KD4-12 → 12.46%,

- KD6-16 → 4.60%,

- GE20 → 6.67%.

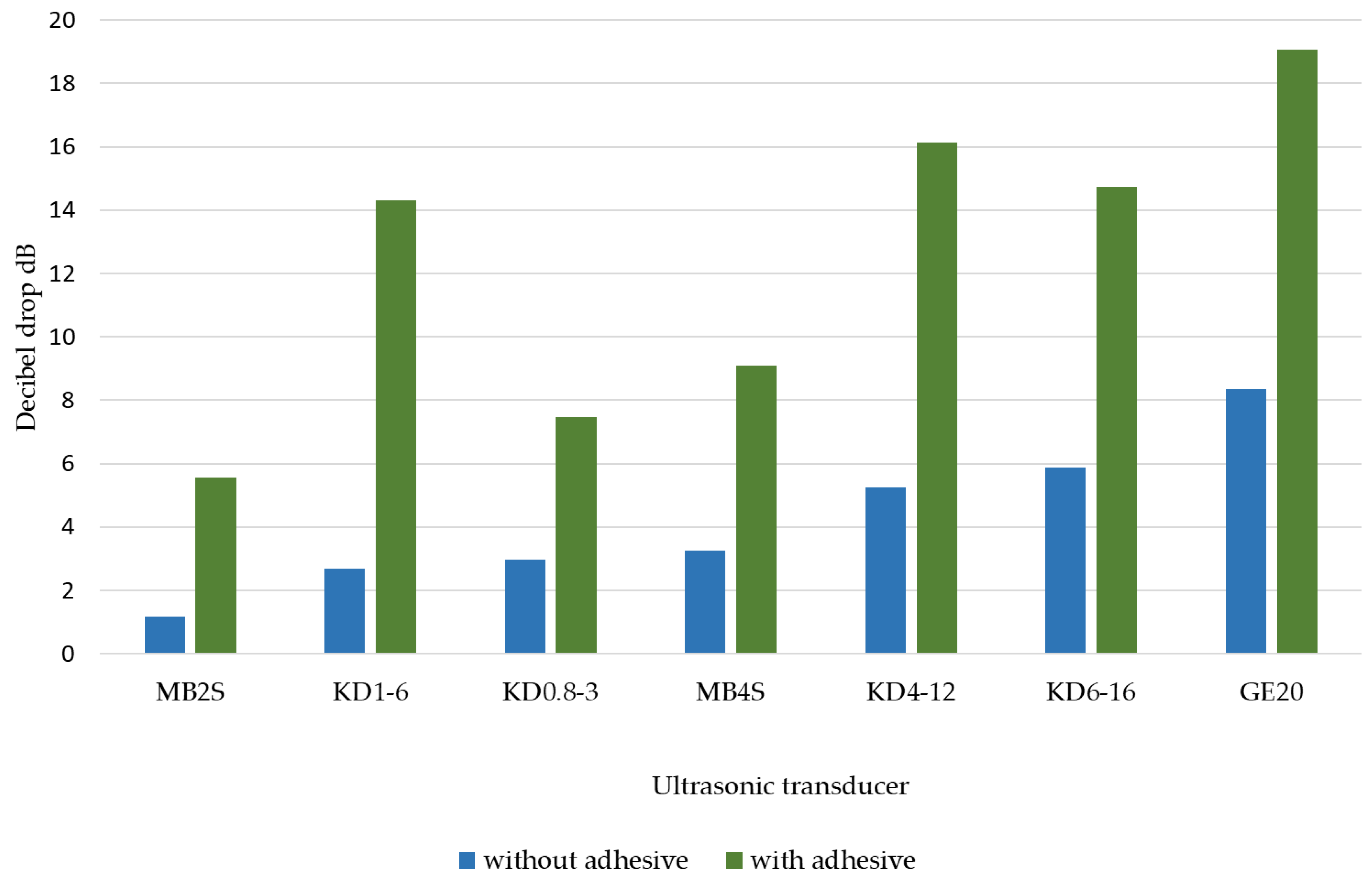

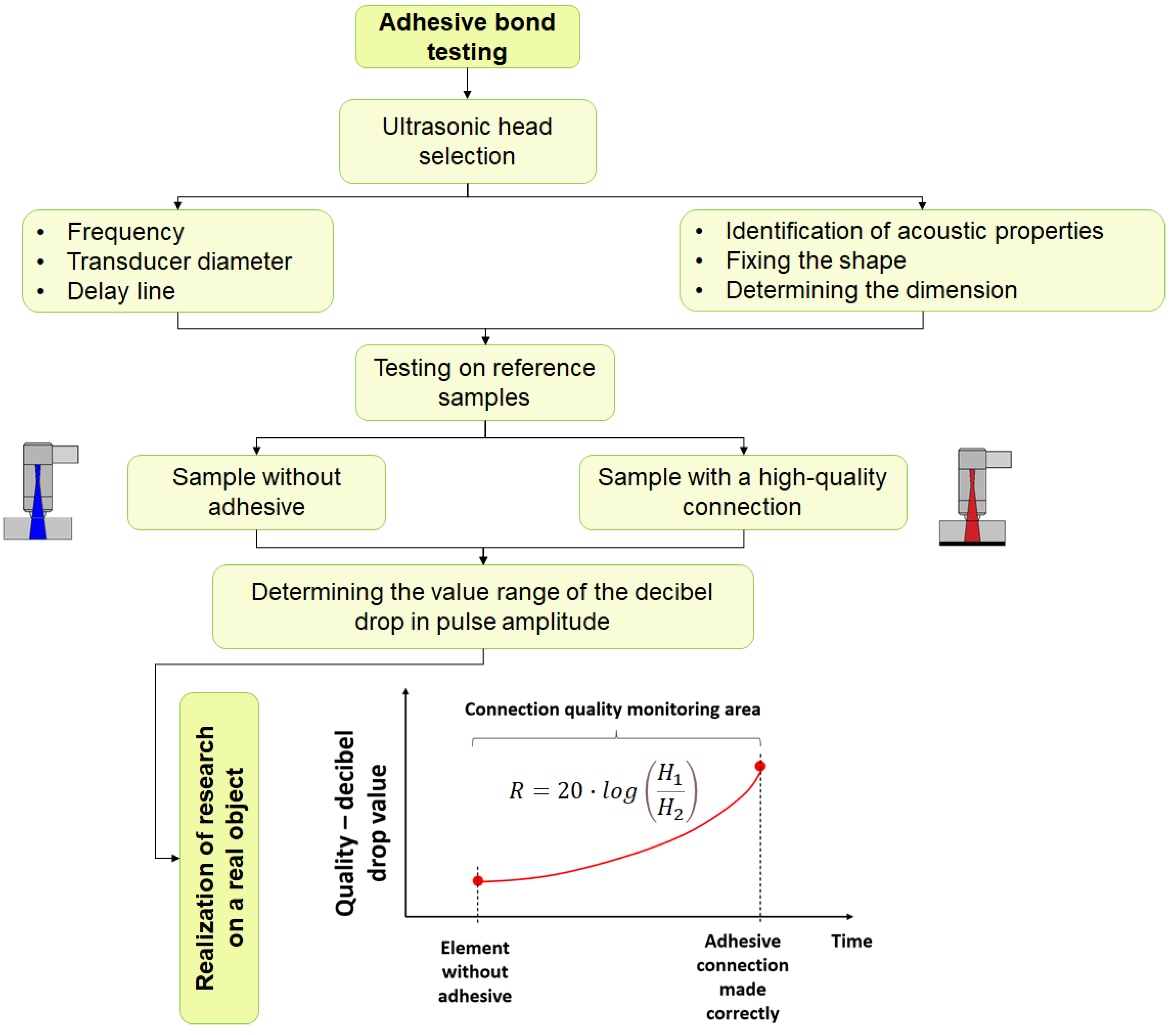

3. Evaluation of Adhesive Joints by Ultrasonic Method

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sanchez, A.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kaczmarzyk, P. Legal Regulations of Restrictions of Air Pollution Made by Mobile Positive Pressure Fans—The Case Study for Europe: A Review. Energies 2022, 15, 7672. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Wieczorek, B.; Krawiec, P. Energy consumption of the wood size reduction processes with employ-ment of a low-power machines with various cutting mechanisms. Renew. Energy 2022, 181, 630–639. [Google Scholar] [CrossRef]

- Bartkowski, D.; Bartkowska, A.; Jurči, P.; Przestacki, D. Influence of Manufacturging Parameters on Microstructure, Chemical Composition, Microhardness, Corrosion and Wear Resistance of ZrC Coatings Produced on Monel®400 Using Laser Processing Technology. Coatings 2022, 12, 651. [Google Scholar] [CrossRef]

- Sharma, S.K.; Grewal, H.S.; Saxena, K.K.; Mohammed, K.A.; Prakash, C.; Davim, J.P.; Buddhi, D.; Raju, R.; Mohan, D.G.; Tomków, J. Advancements in the Additive Manufacturing of Magnesium and Aluminum Alloys through Laser-Based Approach. Materials 2022, 15, 8122. [Google Scholar] [CrossRef]

- Bhavar, V.; Kattire, P.; Patil, V.; Khot, S.; Gujar, K.; Singh, R. A review on powder bed fusion technology of metal additive manufacturing. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 251–261. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- du Preez, W.B. Towards Qualification of Additively Manufactured Ti6Al4V (ELI) Medical Implants. JOM 2018, 71, 655–661. [Google Scholar] [CrossRef]

- Ramosena, L.A.; Dzogbewu, T.C.; du Preez, W. Direct Metal Laser Sintering of the Ti6Al4V Alloy from a Powder Blend. Materials 2022, 15, 8193. [Google Scholar] [CrossRef]

- Liu, Z.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V. Process.-Microstruct.-Prop. Relatsh. Addit. Manuf. Ti Alloys 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Olmo, J.A.; Alosno, J.M.; Ronco-Campana, A.; Saez-Martinez, V.; Perez-Gonzalez, R.; Rothie, A.J.; Tighe, B.J.; Vilas-Vilela, J.L.; Perez-Avarez, L. Effectiveness of physicochemical techniques on the activation of Ti6Al4V surface with improved bio-compatibility and antibacterial properties. Surf. Coat. Technol. 2022, 447, 128821. [Google Scholar] [CrossRef]

- Bocchetta, P.; Chen, L.-Y.; Tardelli, J.; Reis, A.; Almeraya-Calderón, F.; Leo, P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings 2021, 11, 487. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Shukla, K.A.; Balasubramaniam, R. Effect of surface treatment on electrochemical behavior of CP Ti, Ti–6Al–4V and Ti–13Nb–13Zr alloys in simulated human body fluid. Corros. Sci. 2006, 48, 1696–1720. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T.; Fukui, H.; Toda, H. Corrosion resistance and biocompatibility of Ti–Ta alloys for bio-medical applications. Mater. Sci. Eng. A 2005, 398, 28–36. [Google Scholar] [CrossRef]

- Attanasio, A.; Gelfi, M.; Pola, A.; Ceretti, E.; Giardini, C. Influence of Material Microstructures in Micromilling of Ti6Al4V Alloy. Materials 2013, 6, 4268–4283. [Google Scholar] [CrossRef]

- Lekkala, R.; Bajpai, V.; Singh, R.K.; Joshi, S.S. Characterization and modeling of burr formation in micro-end milling. Precis. Eng. 2011, 35, 625–637. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S. Effects of cutting conditions on the milling process of titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2014, 77, 2235–2240. [Google Scholar] [CrossRef]

- Li, K.-M.; Chou, S.-Y. Experimental evaluation of minimum quantity lubrication in near micro-milling. J. Mater. Process. Technol. 2010, 210, 2163–2170. [Google Scholar] [CrossRef]

- da Costa, P.R.; Sardinha, M.; Reis, L.; Freitas, M.; Fonte, M. Ultrasonic fatigue testing in as-built and polished Ti6Al4V alloy manufactured by SLM. Forces Mech. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Spierings, A.; Starr, T.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured Ti–6Al–4V and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Mian, J.; Razmi, J.; Ladani, L. Defect analysis and fatigue strength prediction of as-built Ti6Al4V parts, produced using electron beam melting (EBM) AM technology. Materialia 2021, 16, 101041. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Y.; Li, L.; Wang, C.; Wang, Q.; Liu, Y. Interior defect-induced crack initiation mechanism and initial growth behavior for Ti6Al4V alloy fabricated using laser powder bed fusion. J. Mater. Res. Technol. 2022, 21, 2089–2104. [Google Scholar] [CrossRef]

- Szymanik, B.; Psuj, G.; Hashemi, M.; Lopato, P. Detection and Identification of Defects in 3D-Printed Dielectric Structures via Thermographic Inspection and Deep Neural Networks. Materials 2021, 14, 4168. [Google Scholar] [CrossRef]

- Kim, C.; Yin, H.; Shmatok, A.; Prorok, B.C.; Lou, X.; Matlack, K.H. Ultrasonic nondestructive evaluation of laser powder bed fusion 316L stainless steel. Addit. Manuf. 2021, 38, 101800. [Google Scholar] [CrossRef]

- Allam, A.; Alfahmi, O.; Patel, H.; Sugino, C.; Harding, M.; Ruzzene, M.; Erturk, A. Ultrasonic testing of thick and thin In-conel 625 alloys manufactured by laser powder bed fusion. Ultrasonics 2022, 125, 106780. [Google Scholar] [CrossRef]

- Lopez, A.; Bacelar, R.; Pires, I.; Santos, T.G.; Sousa, J.P.; Quintino, L. Non-destructive testing application of radiography and ultrasound for wire and arc additive manufacturing. Addit. Manuf. 2018, 21, 298–306. [Google Scholar] [CrossRef]

- Davis, G.; Nagarajah, R.; Palanisamy, S.; Rashid, R.A.R.; Rajagopal, P.; Balasubramaniam, K. Laser ultrasonic inspection of additive manufactured components. Int. J. Adv. Manuf. Technol. 2019, 102, 2571–2579. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, D.; Li, H.; Song, C.; Zhou, X.; Shen, S.; Zhang, G.; Yang, Y.; Wang, H. Detection of Internal Holes in Additive Manufactured Ti-6Al-4V Part Using Laser Ultrasonic Testing. Appl. Sci. 2020, 10, 365. [Google Scholar] [CrossRef]

- Chen, S.-L. Review of Laser-Generated Ultrasound Transmitters and Their Applications to All-Optical Ultrasound Transducers and Imaging. Appl. Sci. 2016, 7, 25. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, S.; Liu, X. Detection and Quantification of Damage in Metallic Structures by Laser-Generated Ultrasonics. Appl. Sci. 2018, 8, 824. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Wong, C.H. Additive manufacturing process monitoring and control by non-destructive testing techniques: Challenges and in-process monitoring. Virtual Phys. Prototyp. 2018, 13, 39–48. [Google Scholar] [CrossRef]

- Marks, R.; Clarke, A.; Featherston, C.; Paget, C.; Pullin, R. Lamb Wave Interaction with Adhesively Bonded Stiffeners and Disbonds Using 3D Vibrometry. Appl. Sci. 2016, 6, 12. [Google Scholar] [CrossRef]

- Leiderman, R.; Braga, A.M. Scattering of guided waves by defective adhesive bonds in multilayer anisotropic plates. Wave Motion 2017, 74, 93–104. [Google Scholar] [CrossRef]

- Leiderman, R.; Figueroa, J.C.; Braga, A.M.B.; Rochinha, F.A. Scattering of ultrasonic guided waves by heterogeneous inter-faces in elastic multi-layered structures. Wave Motion 2016, 63, 68–82. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrol-ogy for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Gomez, C.; Guardia, A.; Mantari, J.L.; Coronado, A.M.; Reddy, J.N. A contemporary approach to the MSE paradigm powered by Artificial Intelligence from a review focused on Polymer Matrix Composites. Mech. Adv. Mater. Struct. 2021, 29, 3076–3096. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef]

- Yang, C.H.; Jeyaprakash, N.; Chan, C.K. Inhomogeneous mechanical properties in additively manufactured parts characterized by nondestructive laser ultrasound technique. NDTE Int. 2020, 116, 102340. [Google Scholar] [CrossRef]

- Yilmaz, B.; Asokkumar, A.; Jasiūnienė, E.; Kažys, R.J. Air-Coupled, Contact, and Immersion Ultrasonic Non-Destructive Testing: Comparison for Bonding Quality Evaluation. Appl. Sci. 2020, 10, 6757. [Google Scholar] [CrossRef]

| Ti6Al4V—Beam Diameter mm | Ti6Al4V-AM—Beam Diameter mm | |||||

|---|---|---|---|---|---|---|

| Sample Height—h | 10 | 25 | 40 | 10 | 25 | 40 |

| MB2S | 5.0 | 12.5 | 20.0 | 5.1 | 12.8 | 20.4 |

| KD1-6 | 3.4 | 8.6 | 13.7 | 3.5 | 8.7 | 13.9 |

| KD0.8-3 | 3.0 | 7.4 | 11.9 | 3.0 | 7.6 | 12.1 |

| MB4S | 2.4 | 6.1 | 9.8 | 2.5 | 6.2 | 10.0 |

| KD4-12 | 1.3 | 3.2 | 5.2 | 1.3 | 3.3 | 5.3 |

| KD6-16 | 2.3 | 5.8 | 9.3 | 2.4 | 5.9 | 9.5 |

| GE20 | 1.6 | 4.1 | 6.5 | 1.7 | 4.1 | 6.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalczyk, J.; Ulbrich, D.; Nowak, M.; Sędłak, K.; Gruber, K.; Kurzynowski, T.; Jósko, M. Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints. Appl. Sci. 2023, 13, 371. https://doi.org/10.3390/app13010371

Kowalczyk J, Ulbrich D, Nowak M, Sędłak K, Gruber K, Kurzynowski T, Jósko M. Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints. Applied Sciences. 2023; 13(1):371. https://doi.org/10.3390/app13010371

Chicago/Turabian StyleKowalczyk, Jakub, Dariusz Ulbrich, Michał Nowak, Kamil Sędłak, Konrad Gruber, Tomasz Kurzynowski, and Marian Jósko. 2023. "Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints" Applied Sciences 13, no. 1: 371. https://doi.org/10.3390/app13010371

APA StyleKowalczyk, J., Ulbrich, D., Nowak, M., Sędłak, K., Gruber, K., Kurzynowski, T., & Jósko, M. (2023). Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints. Applied Sciences, 13(1), 371. https://doi.org/10.3390/app13010371