Optimization on Linkage System for Vehicle Wipers by the Method of Differential Evolution

Abstract

1. Introduction

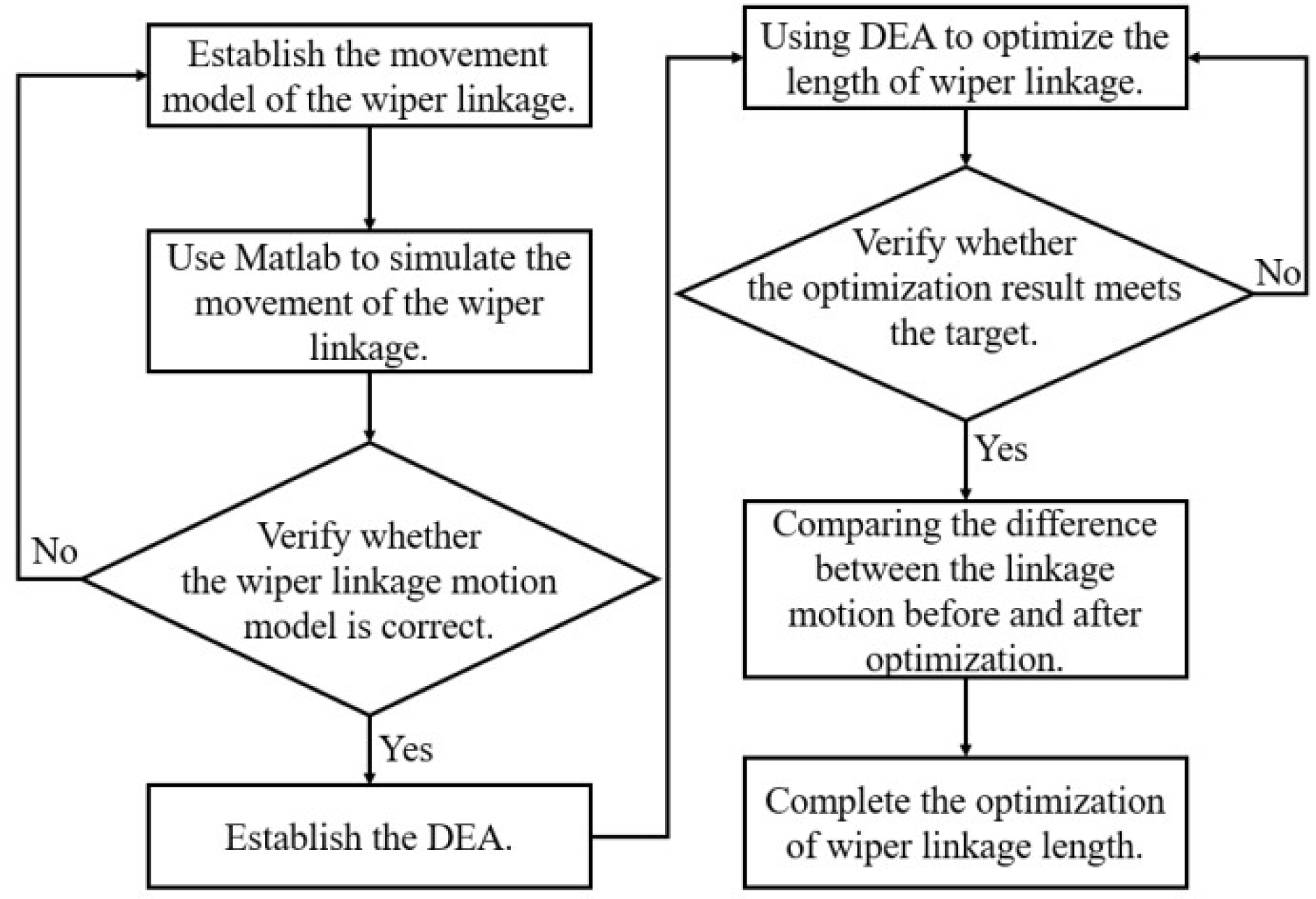

2. Materials and Methods

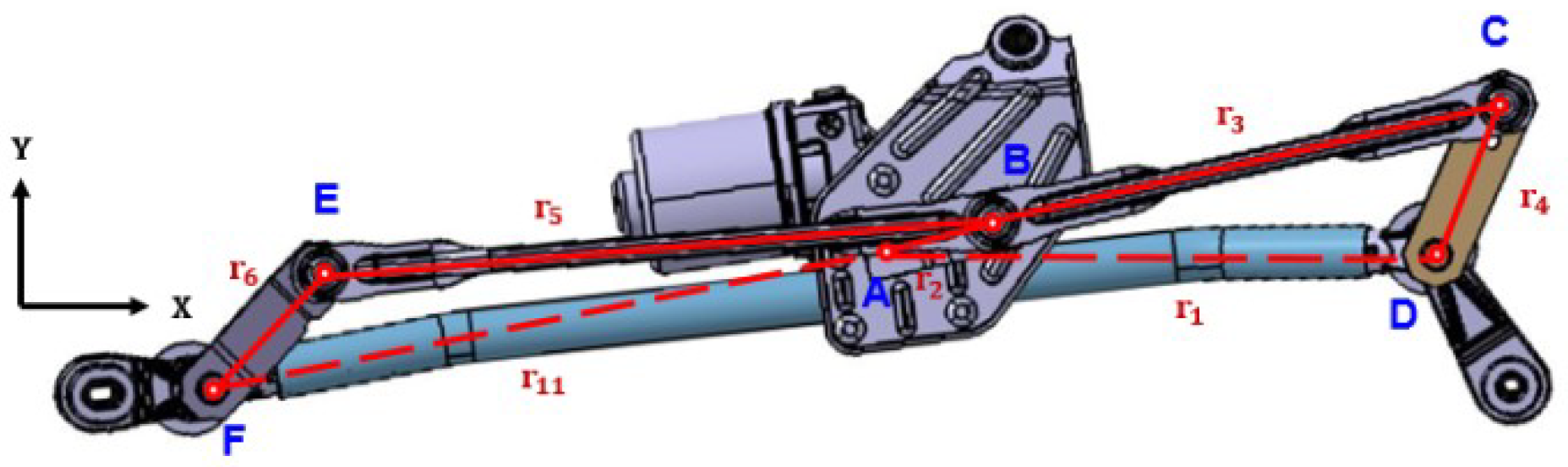

2.1. Establishing the Wiper Linkage Motion Model

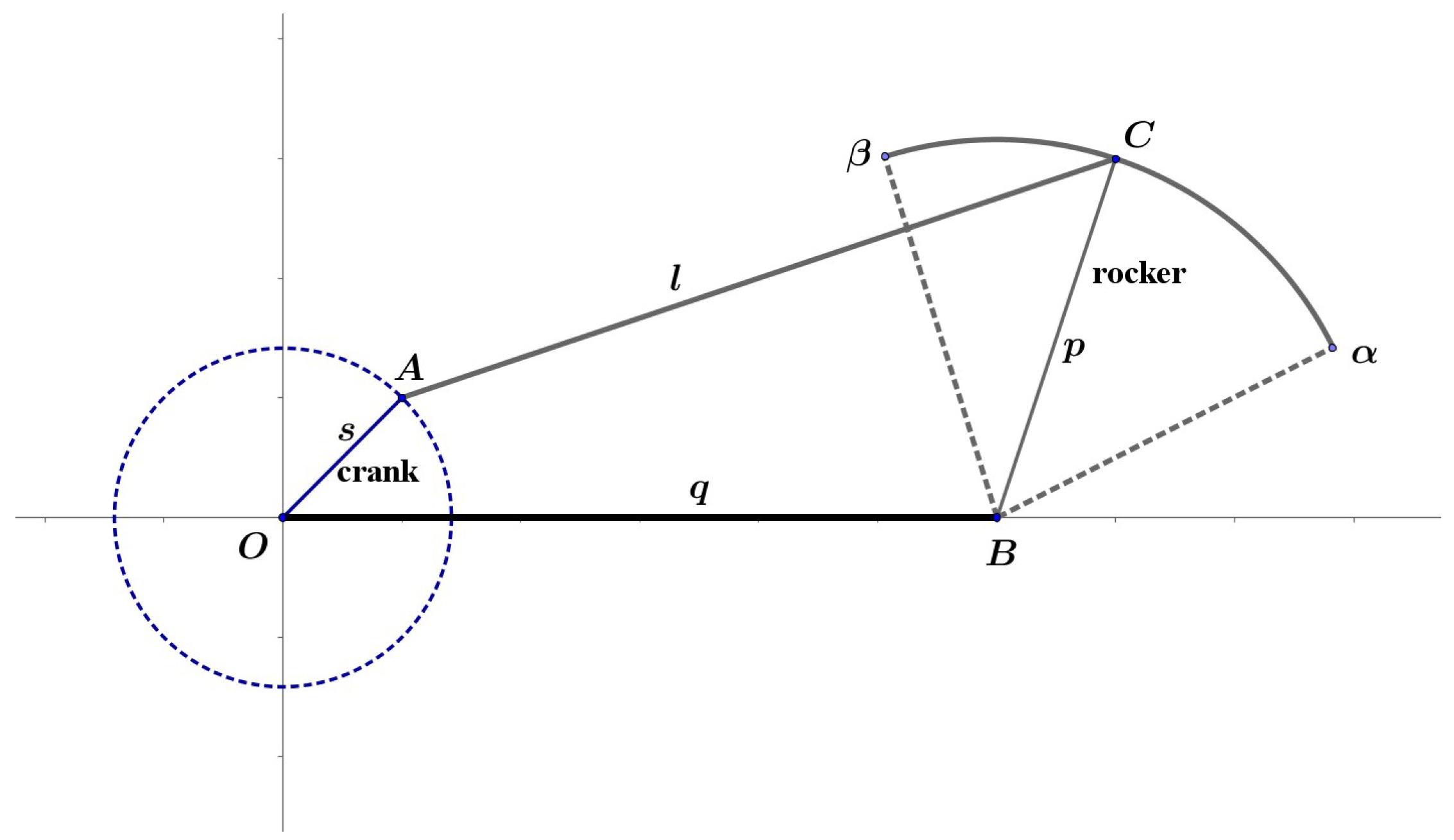

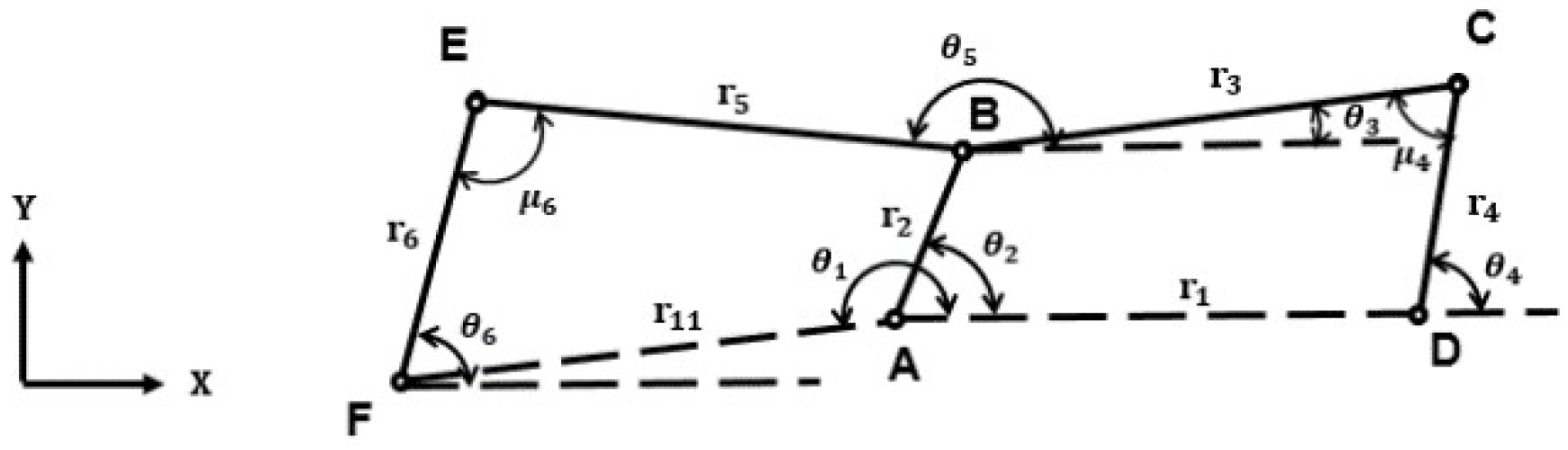

2.1.1. Motion of the Driver Side Linkage of CDLS

2.1.2. Motion of the Passenger Side Linkage of CDLS

2.2. Method of Differential Evolution

2.2.1. Initialization of Population

2.2.2. Mutation

2.2.3. Crossover

2.2.4. Selection Process

2.3. Optimization on the Angular acceleration of Output Links of CDLS

3. Results

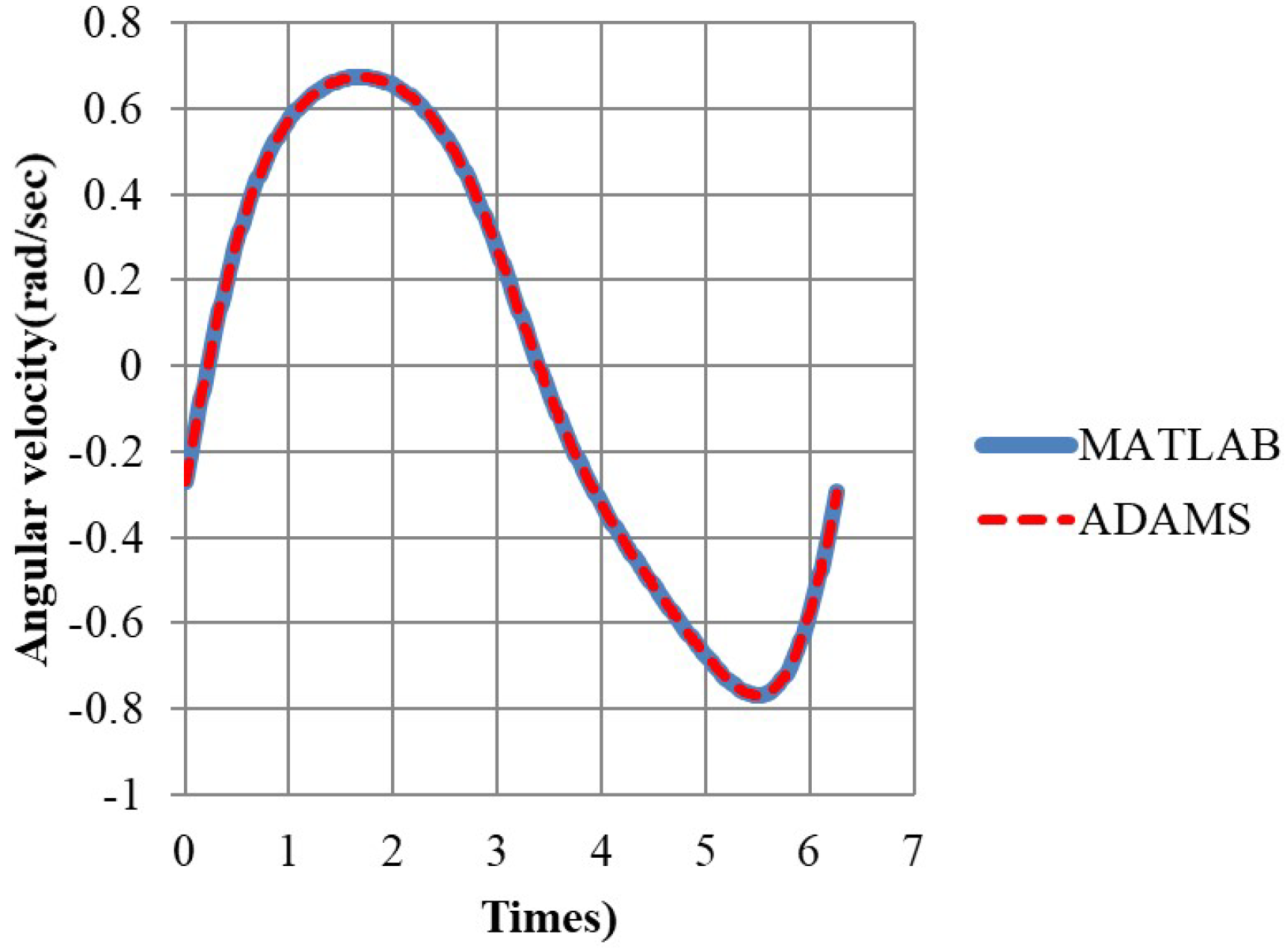

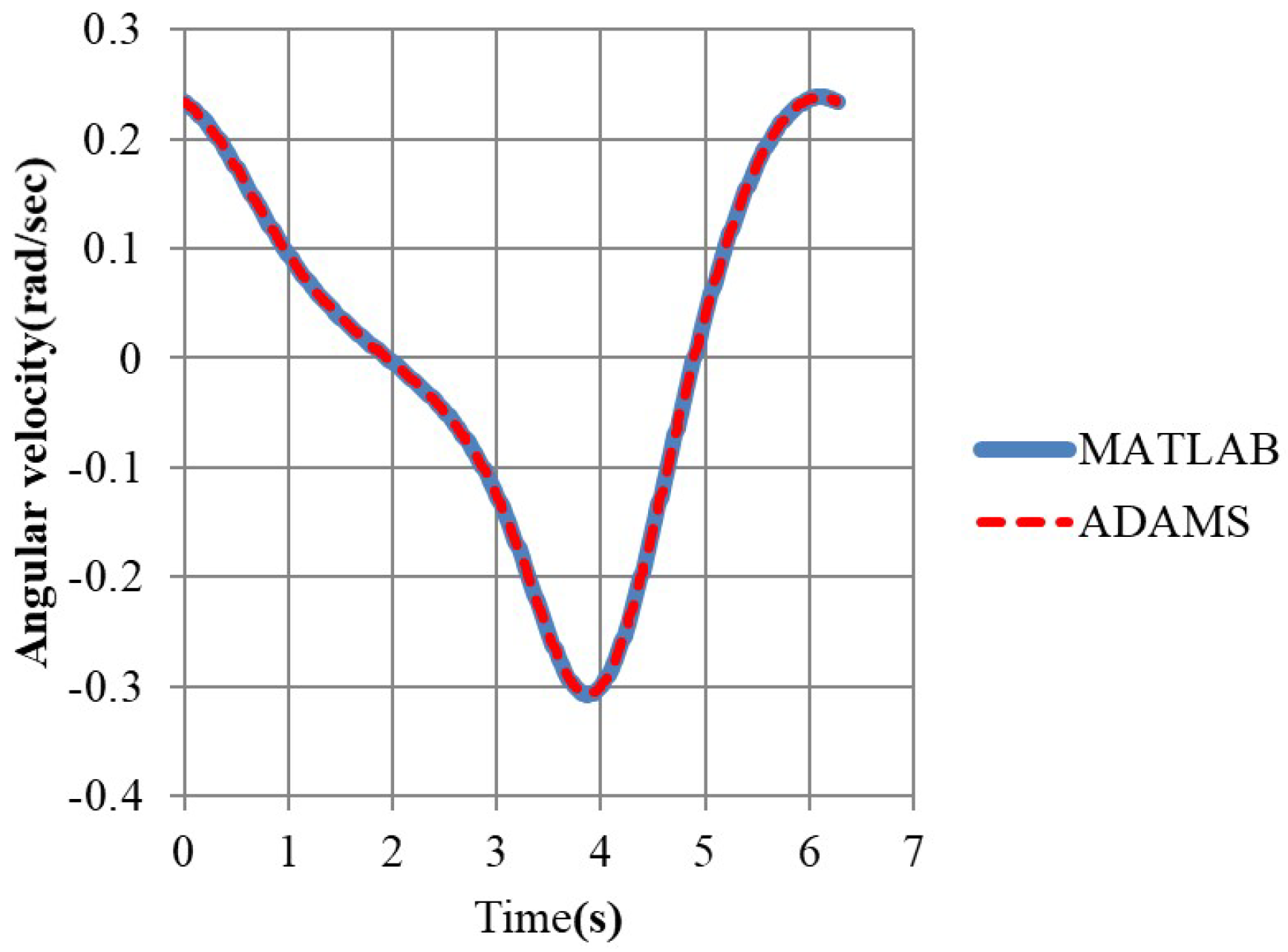

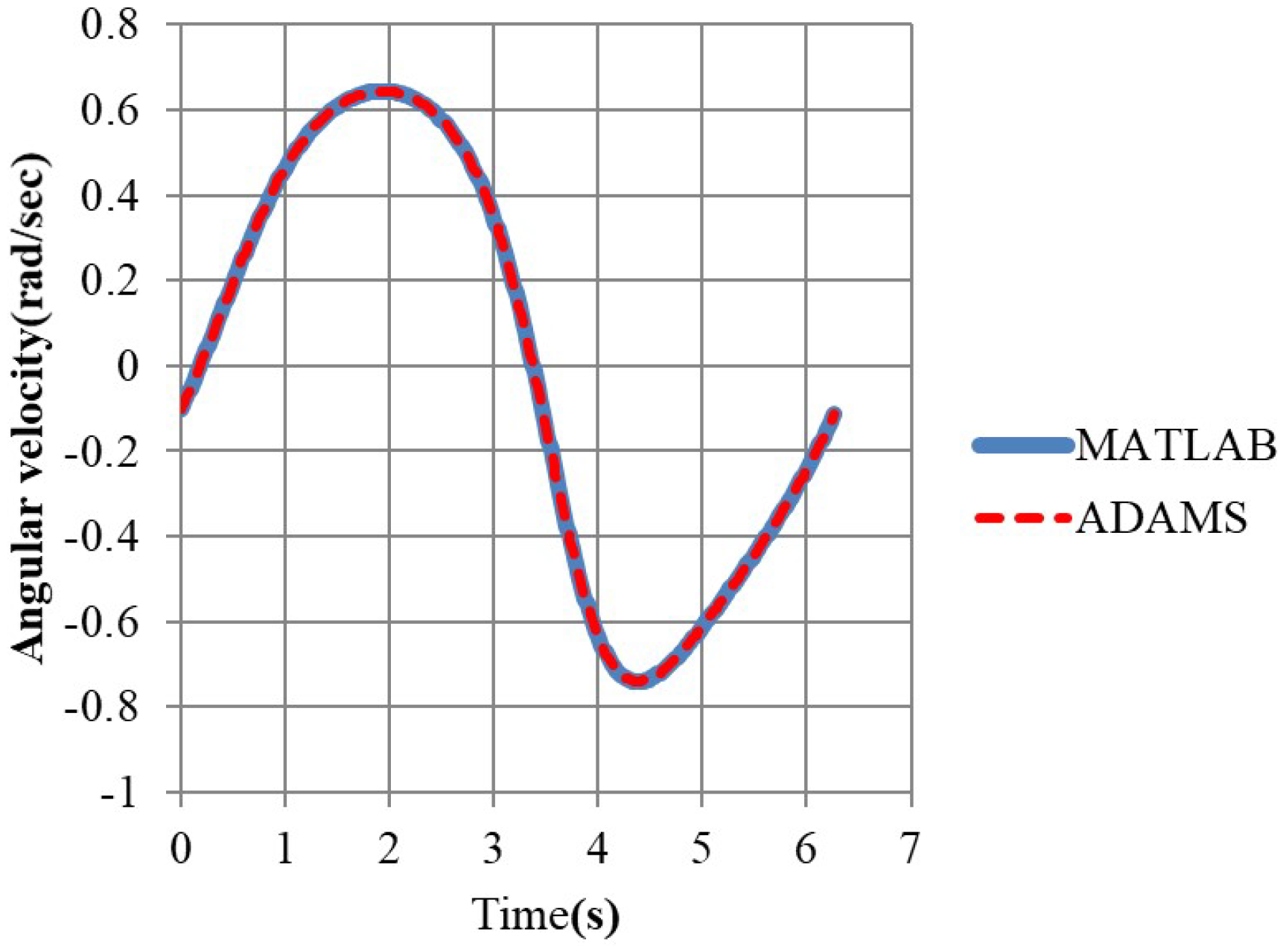

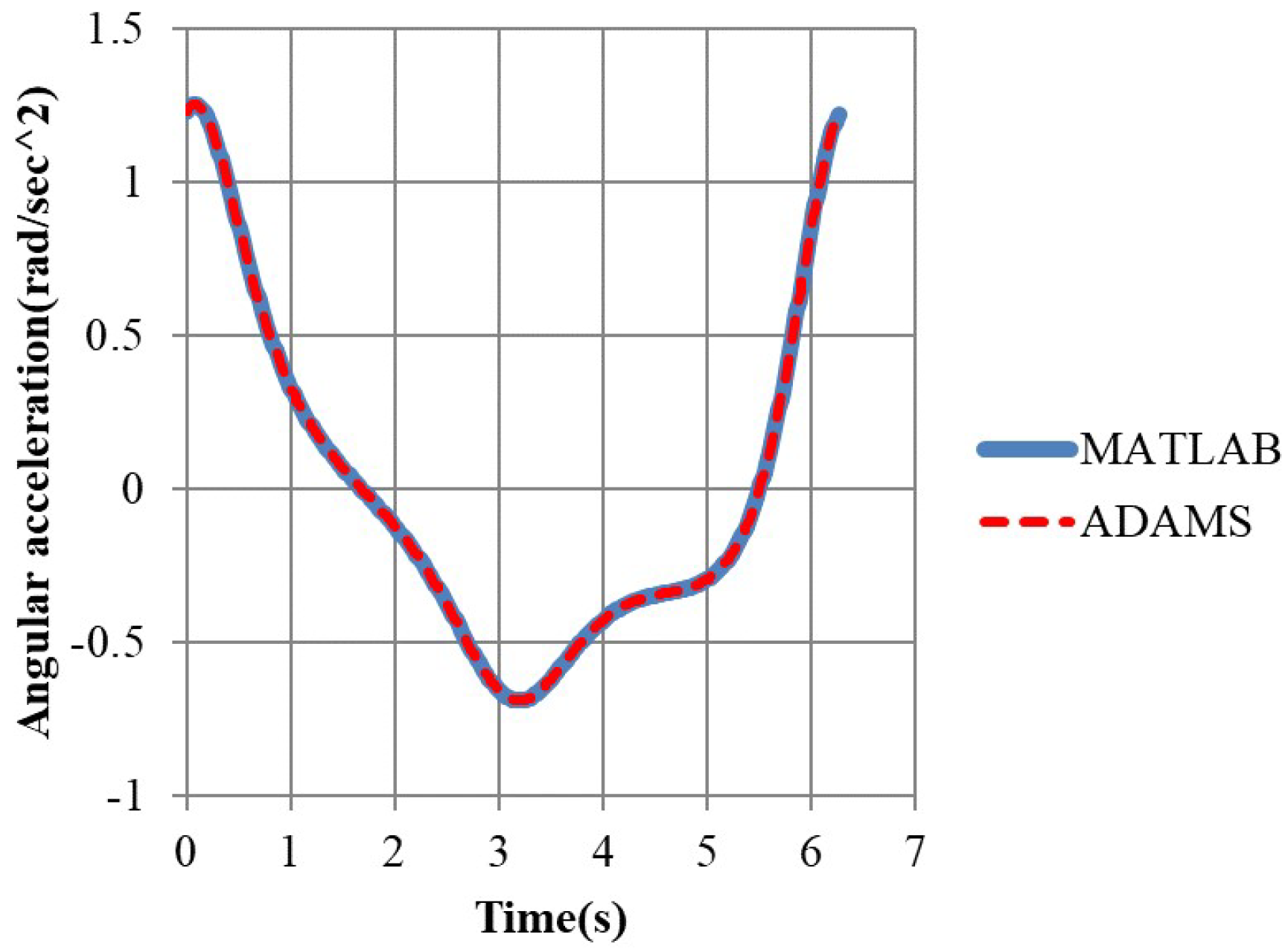

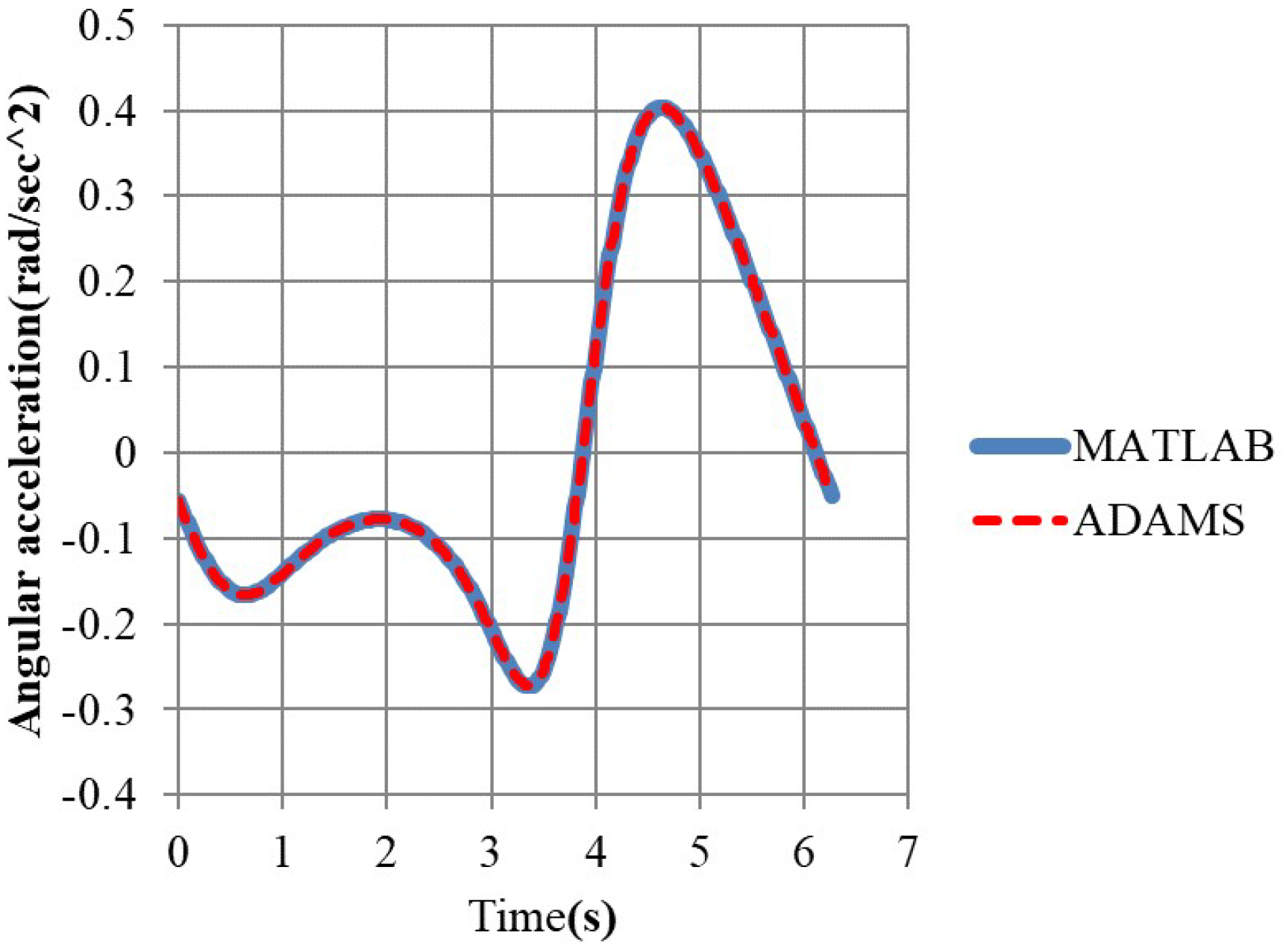

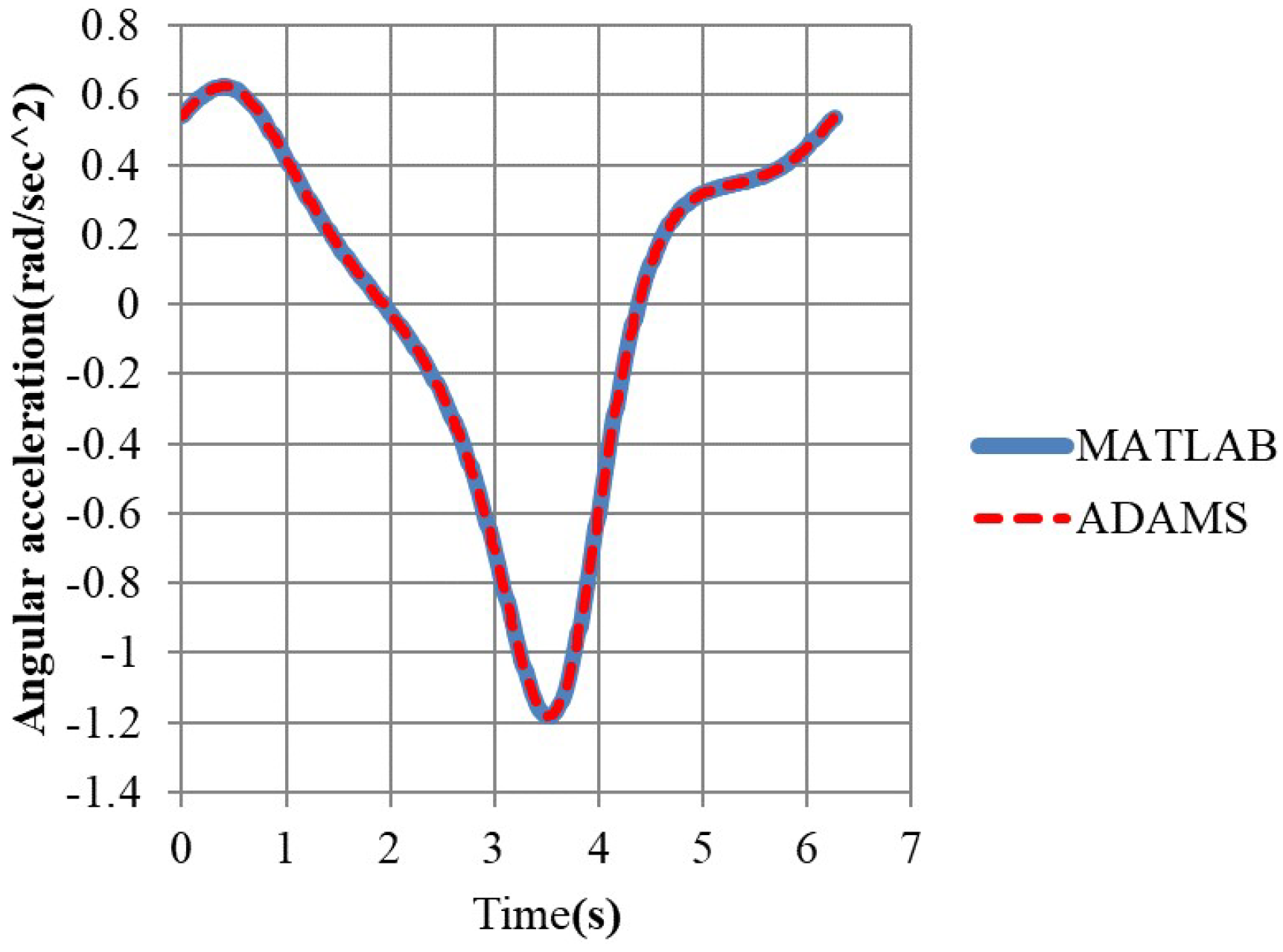

3.1. Comparison of Our Simulation Results with That by ADAMS

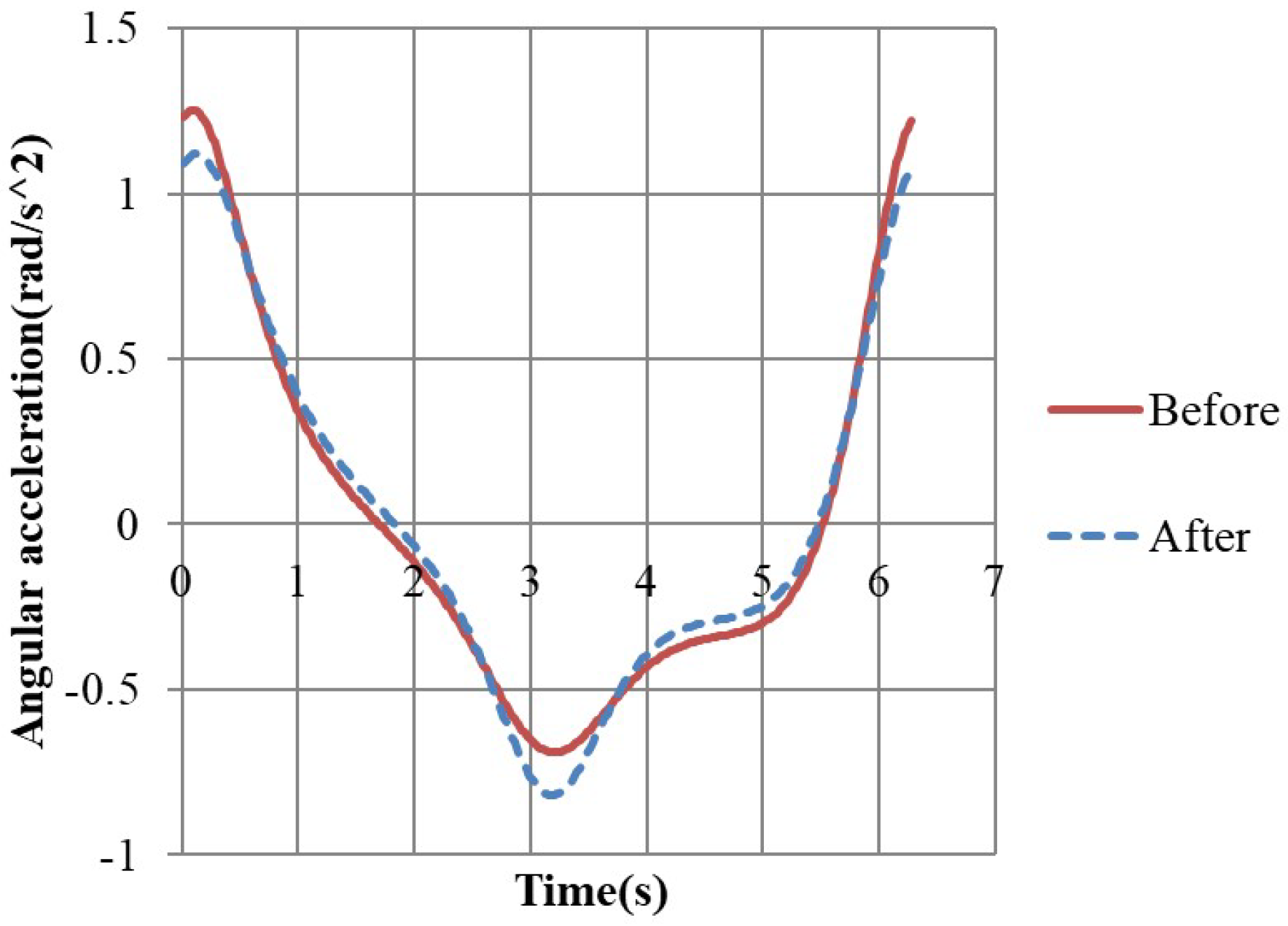

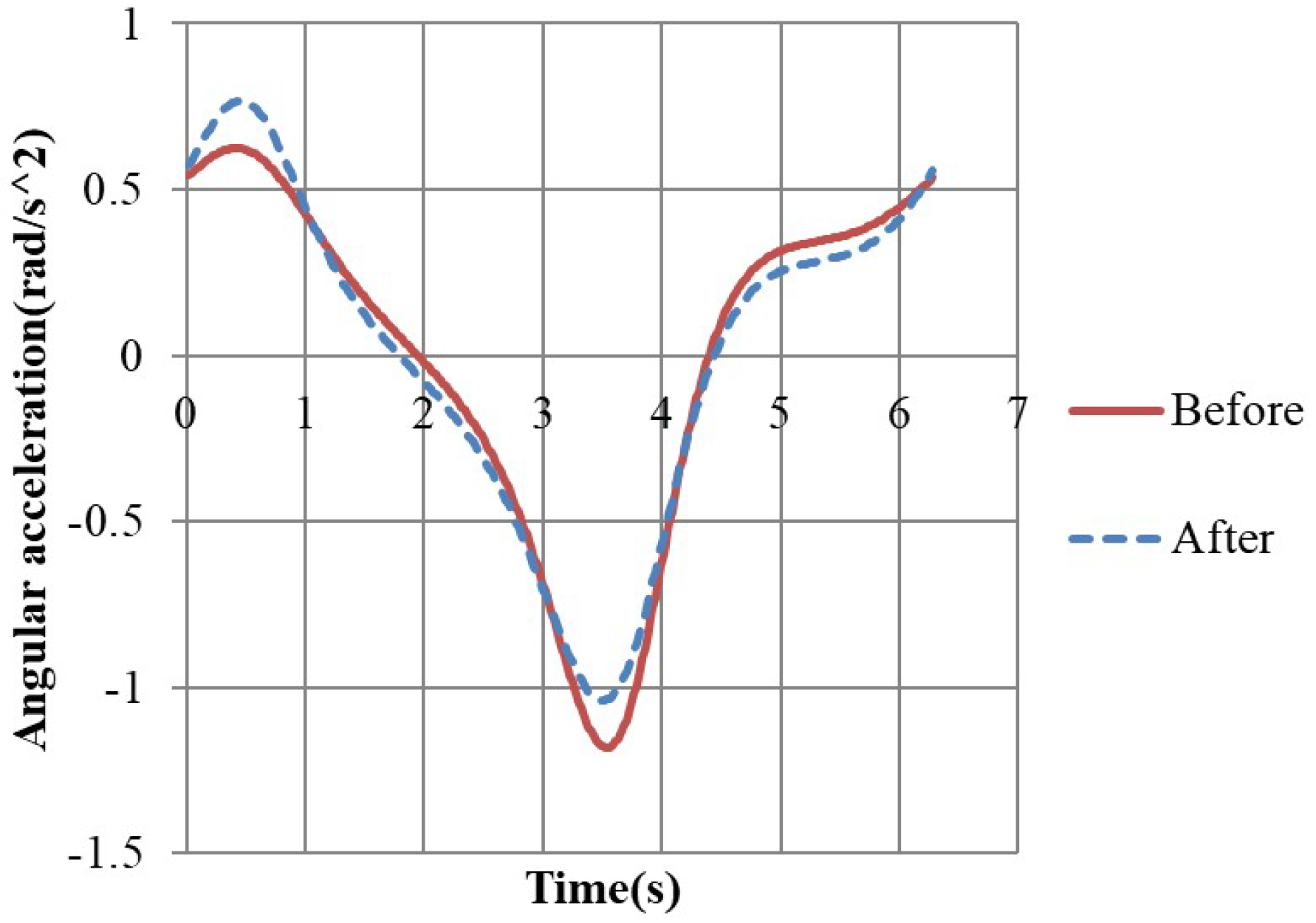

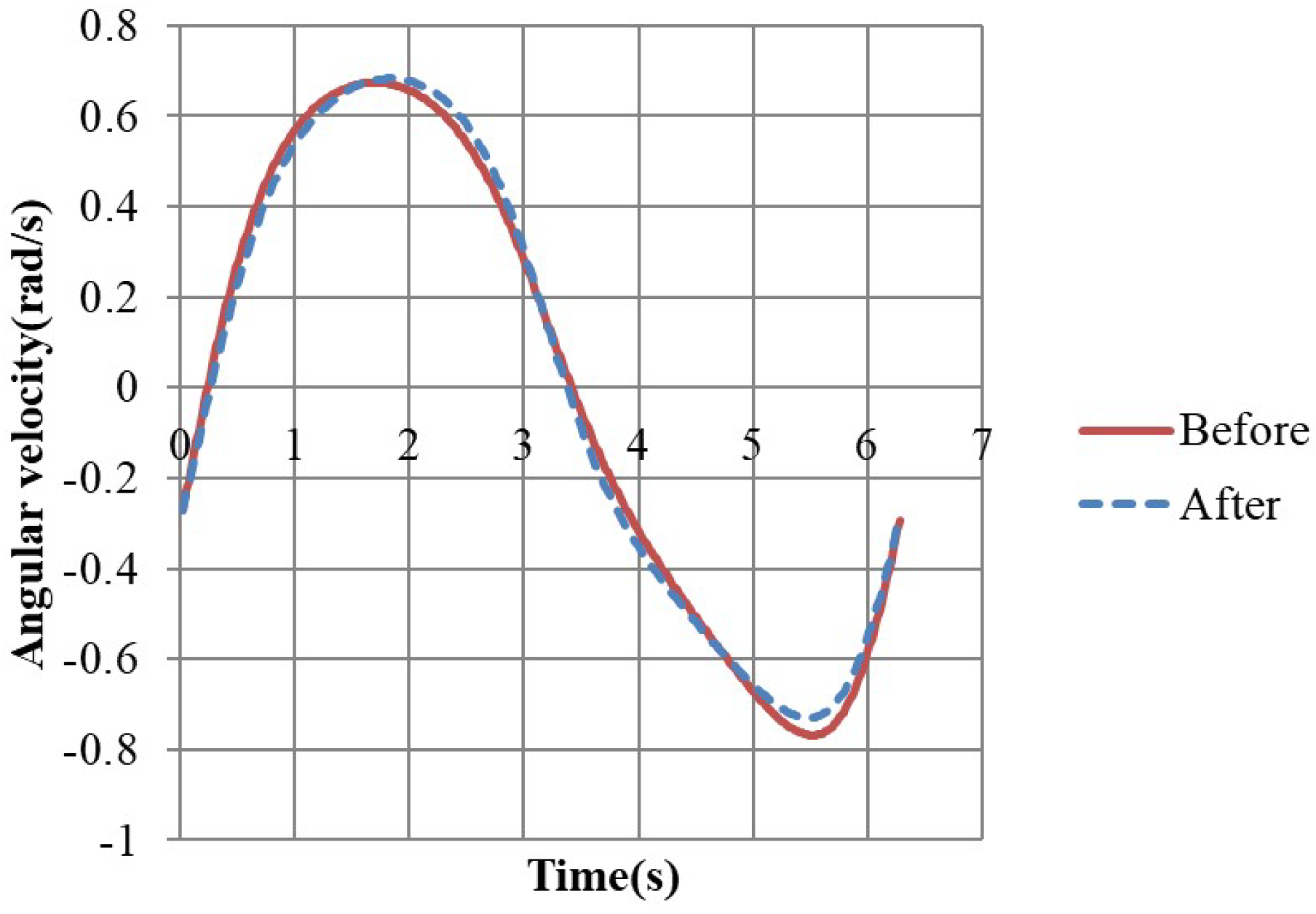

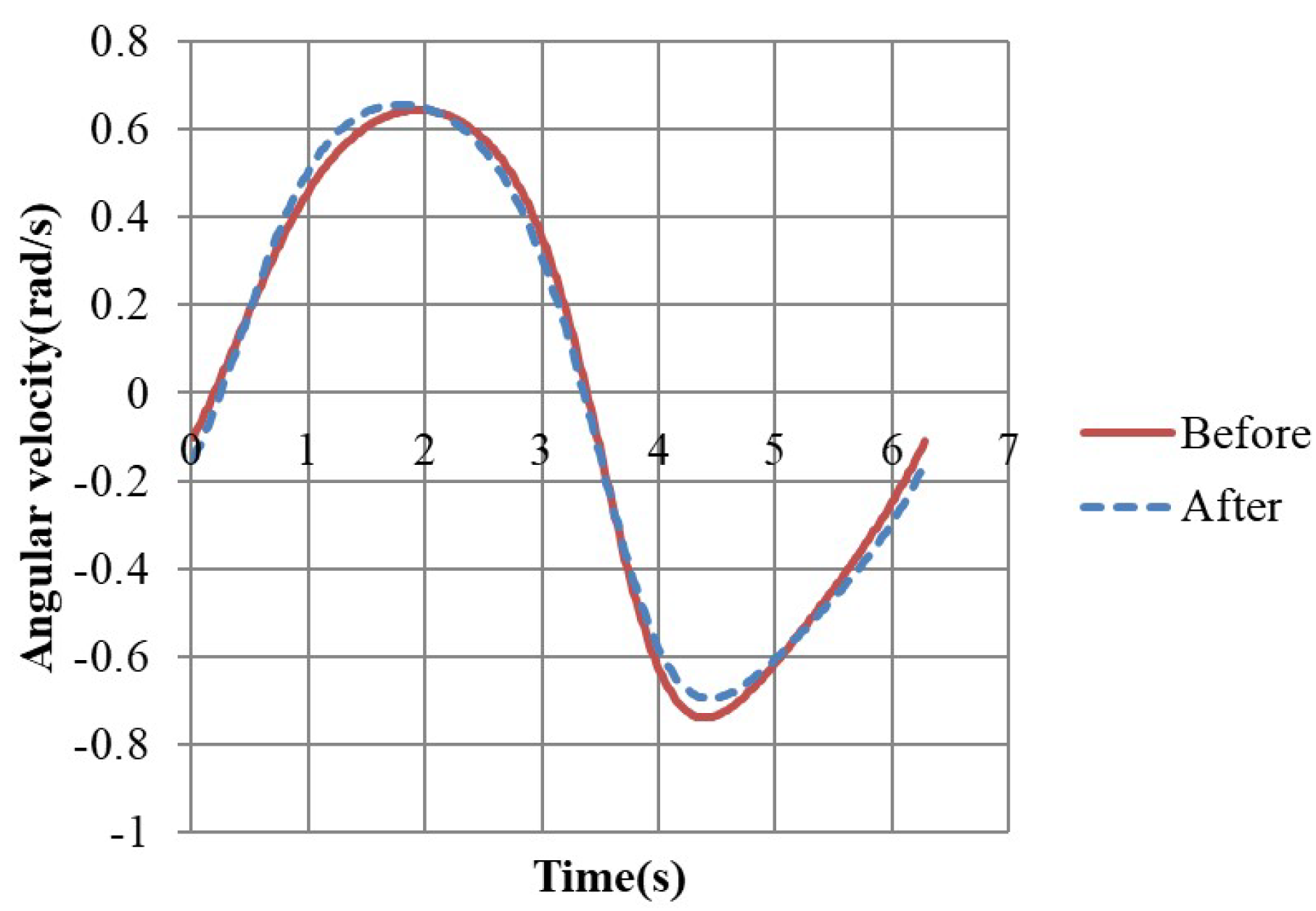

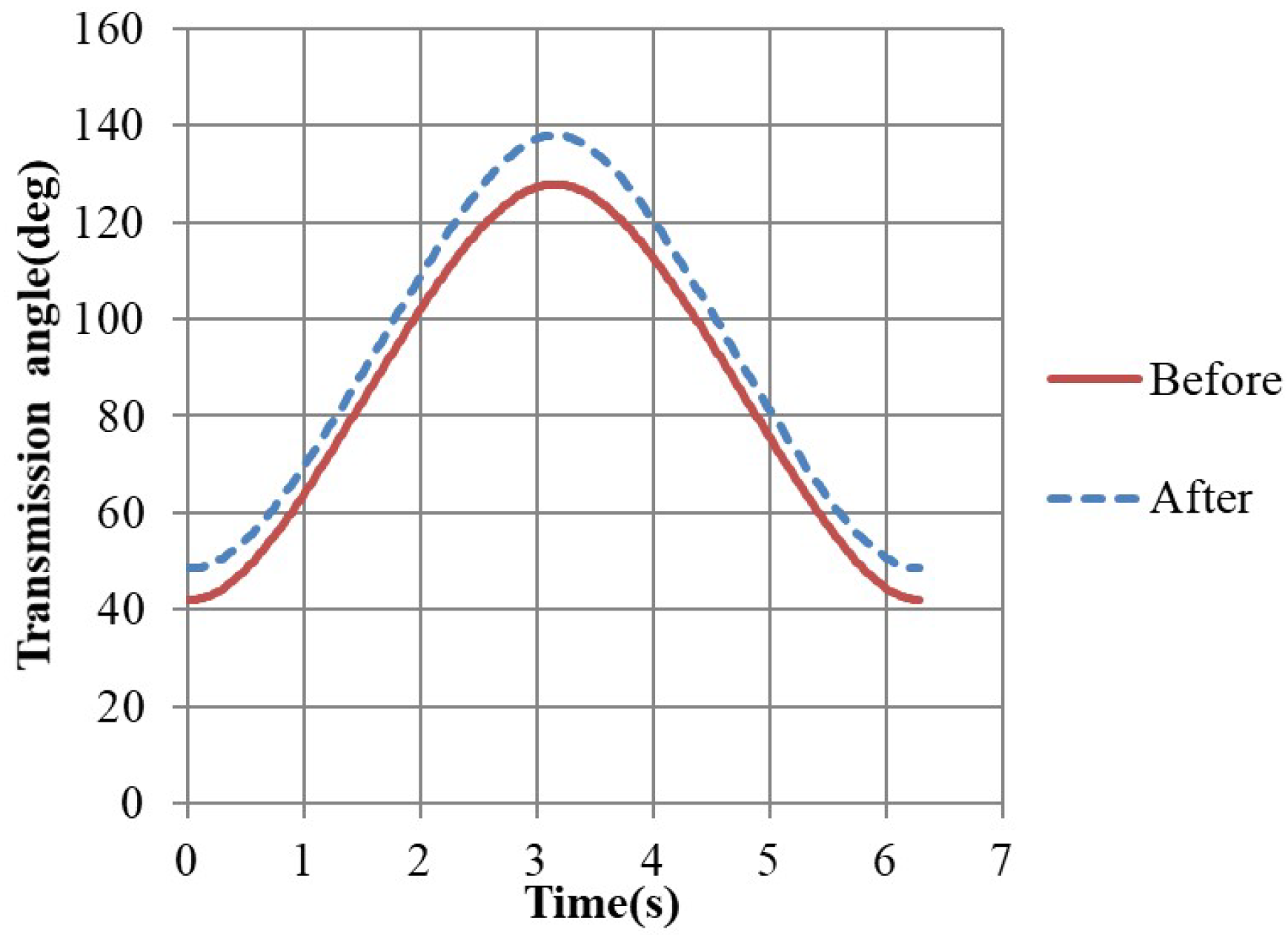

3.2. Comparison of the Linkage Lengths before DE Optimization with That after DE Optimization

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McCarthy, J.M.; Soh, G.S. Geometric Design of Linkages, 2nd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Storn, R.; Price, K.V. Differential Evolution—A Simple and Efficient Adaptive Scheme for Global Optimization over Continuous Spaces; Technical Report, TR-95-012; International Computer Science Institute (ICSI) of University of California: Berkeley, CA, USA, 1995. [Google Scholar]

- Storn, R.; Price, K.V. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Storn, R.; Price, K.V. Differential Evolution: A Practical Approach to Global Optimization; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Fan, Y.-F.; Lampinen, J. A Trigonometric Mutation Operation to Differential Evolution. J. Glob. Optim. 2003, 27, 105–129. [Google Scholar] [CrossRef]

- Tizhoosh, H.R. Opposition-Based Learning: A New Scheme for Machine Intelligence. In Proceedings of the International Conference on Computational Intelligence for Modeling Control and Automation—CIMCA, Vienna, Austria, 28–30 November 2005. [Google Scholar]

- Tizhoosh, H.R. Reinforcement Learning based on Actions and Opposite Actions. In Proceedings of the ICGST International Conference on Artificial Intelligence and Machine Learning (AIML-05), Cairo, Egypt, 10–21 December 2005. [Google Scholar]

- Tizhoosh, H.R. Opposition-based Reinforcement Learning. J. Adv. Comput. Intell. Intell. Inform. 2006, 10, 578–585. [Google Scholar] [CrossRef]

- Rahnamayan, S.; Tizhoosh, H.R.; Salama, M.M.A. Opposition Based Differential Evolution. IEEE Trans. Evol. Comput. 2008, 12, 64–79. [Google Scholar] [CrossRef]

- Das, S.; Abraham, A.; Chakraborty, U.K.; Konar, A. Differential Evolution using a Neighborhood Based Mutation Operator. IEEE Trans. Evol. Comput. 2009, 13, 526–553. [Google Scholar] [CrossRef]

- Qin, A.K.; Huang, V.L.; Suganthan, P.N. Differential Evolution Algorithm with Strategy Adaptation for Global Numerical Optimization. IEEE Trans. Evol. Comput. 2009, 13, 398–417. [Google Scholar] [CrossRef]

- Brest, J.; Sepesy Maučec, M. Self-Adaptive Differential Evolution Algorithm Using Population Size Reduction and Three Strategies. Soft Comput. 2011, 15, 2157–2174. [Google Scholar] [CrossRef]

- Lou, Y.; Yuen, S.Y.; Chen, G. Non-Revisiting Stochastic Search Revisited: Results, Perspectives, and Future Directions. Swarm Evol. Comput. 2021, 61, 100828. [Google Scholar] [CrossRef]

- Črepinšek, M.; Liu, S.-H.; Mernik, M.; Ravber, M. The Trap of Sisyphean Work in Differential Evolution and How to Avoid It. In Differential Evolution: From Theory to Practice, 1st ed.; Vinoth Kumar, B., Oliva, D., Suganthan, P.N., Eds.; Springer: Singapore, 2022; pp. 137–174. [Google Scholar]

- Das, S.; Suganthan, P.N. Differential Evolution: A Survey of the State-of-the-Art. IEEE Trans. Evol. Comput. 2011, 15, 4–31. [Google Scholar] [CrossRef]

- Das, S.; Mullick, S.S.; Suganthan, P.N. Recent Advances in Differential Evolution—An Updated Survey. Swarm Evol. Comput. 2016, 27, 1–30. [Google Scholar] [CrossRef]

- Karol R.Opara, K.O.; Arabas, J. Differential Evolution: A Survey of Theoretical Analyses. Swarm Evol. Comput. 2019, 44, 546–558. [Google Scholar] [CrossRef]

- Rudolph, G. Convergence of Evolutionary Algorithms in General Search Spaces. Proceedings of IEEE International Conference on Evolutionary Computation, Nagoya, Japan, 20–22 May 1996. [Google Scholar]

- Hu, Z.; Su, Q.; Yang, X.; Xiong, Z. Not Guaranteeing Convergence of Differential Evolution on a Class of Multimodal Functions. Appl. Soft Comput. 2016, 41, 479–487. [Google Scholar] [CrossRef]

- Hu, Z.; Xiong, S.; Su, Q.; Fang, Z. Finite Markov Chain Analysis of Classical Differential Evolution Algorithm. J. Comput. Appl. Math. 2014, 268, 121–134. [Google Scholar] [CrossRef]

- Chen, T.-J.; Hong, Y.-J. Geometric Analysis of the Vibration of Rubber Wiper Blade. Taiwan. J. Math. 2021, 25, 491–516. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, Z.; He, B. Optimization Design for Crank-rocker Mechanism Based on Genetic Algorithm. In Proceedings of the 2012 Second International Conference on Intelligent System Design and Engineering Application, Sanya, China, 6–7 January 2012. [Google Scholar]

- Balli, S.S.; Chand, S. Transmission angle in mechanisms. Mech. Mach. Theory 2002, 37, 175–195. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, Z.; Hang, Q. Differential Evolution with Composite Trial Vector Generation Strategies and Control Parameters. IEEE Trans. Evol. Comput. 2011, 15, 55–66. [Google Scholar] [CrossRef]

- Ma, C.-F. Optimization Methods and MATLAB Programming; Science Press, Chinese Academy of Sciences: Beijing, China, 2010. [Google Scholar]

- Arafa, M.; Sallam, E.A.; Fahmy, M.M. An enhanced differential evolution optimization algorithm. In Proceedings of the 2014 Fourth International Conference on Digital Information and Communication Technology and its Applications (DICTAP), Bangkok, Thailand, 6–8 May 2014. [Google Scholar]

- Electronic Code of Federal Regulations. Available online: https://www.ecfr.gov/cgi-bin/text-idx?SID=7d443eb75ceba033fed91e90f816b574&node=se49.6.571_1104&rgn=div8 (accessed on 10 October 2020).

- Begout, M. Les Problèmes Liés au Frottement Élastomère-Verre dans L’Automobile. Ph.D. Thesis, Université Paul Sabatier de Toulouse, Toulouse, France, 1979. [Google Scholar]

- Okura, S.; Sekiguchi, T.; Oya, T. Dynamic Analysis of Blade Reversal Behavior in a Windshield Wiper System; SAE 2000 World Congress 2000, Technical Paper 2000-01-0127; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Goto, S.; Takahashi, H.; Oya, T. Investigation of wiper blade squeal noise reduction measures. In SAE 2001 Noise & Vibration Conference & Exposition; Technical Paper 2001-01-1410; SAE International: Warrendale: Warrendale, PA, USA, 2001. [Google Scholar]

- Goto, S.; Takahashi, H.; Oya, T. Clarification of the Mechanism of Wiper Blade Rubber Squeal Noise Generation. JSAE Rev. 2001, 22, 57–62. [Google Scholar] [CrossRef]

- Grenouillat, R.; Leblanc, C. Simulation of chatter vibrations for wiper systems. In SAE 2002 World Congress & Exhibition; Technical Paper 2002-01-1239; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Berger, S.; Sinou, J.-J.; Aubry, E. Model of Chatter Vibrations and Stability Analysis of a Non-linear Wiper System. Int. Rev. Mech. Eng. 2008, 2, 349–356. [Google Scholar]

- Stein, G.J.; Zahoransky, R.; Múčka, P. On Dry Friction Modelling and Simulation in Kinematically Excited Oscillatory Systems. J. Sound Vib. 2008, 311, 74–96. [Google Scholar] [CrossRef]

- Bódai, G.; Goda, T.J. Friction Force Measurement at Windscreen Wiper/Glass Contact. Tribol. Lett. 2012, 45, 515–523. [Google Scholar] [CrossRef]

- Nechak, L.; Berger, S.; Aubry, E. Prediction of Random Self Friction-Induced Vibrations in Uncertain Dry Friction Systems Using a Multi-Element Generalized Polynomial Chaos Approach. J. Vib. Acoust. 2012, 134, 041015. [Google Scholar] [CrossRef]

- Min, D.; Jeong, S.; Yoo, H.H.; Kang, H.; Park, J. Experimental Investigation of Vehicle Wiperblade’s Squeal Noise Generation due to Windscreen Waviness. Tribol. Int. 2014, 80, 191–197. [Google Scholar] [CrossRef]

- Bódai, G.; Goda, T.J. Sliding Friction of Wiper Blade: Measurement, FE Modeling and Mixed Friction Simulation. Tribol. Int. 2014, 70, 63–74. [Google Scholar] [CrossRef]

- Lancioni, G.; Lenci, S.; Galvanetto, U. Dynamics of windscreen wiper blades: Squeal noise, reversal noise and chattering. Int. J. Non-Linear Mech. 2015, 80, 132–143. [Google Scholar] [CrossRef]

- Reddyhoff, T.; Dober, O.; Rouzic, J.L.; Gotzen, N.-A.; Parton, H.; Dini, D. Friction Induced Vibration in Windscreen Wiper Contacts. J. Vib. Acoust. 2015, 137, 041009. [Google Scholar] [CrossRef]

- Unno, M.; Shibata, A.; Yabuno, H.; Yanagisawa, D.; Nakano, T. Analysis of the Behavior of a Wiper Blade around the Reversal in Consideration of Dynamic and Static Friction. J. Sound Vib. 2017, 393, 76–91. [Google Scholar] [CrossRef]

- Viscardi, M.; Di Leo, R.; Ciminello, M.; Brandizzi, M. Preliminary Experimental/Numerical Study for the Vibration Annoyance Control of a Windshield Wiper Mechanical System through a Synchronized Switch Shunt Resonator (SSSR) Technology. J. Theor. Appl. Mech. 2018, 56, 283–296. [Google Scholar] [CrossRef]

- Muhr, A.H. Modeling the Stress-Strain Behavior of Rubber. Rubber Chem. Technol. 2005, 78, 391–425. [Google Scholar] [CrossRef]

- Wang, W.; Chen, S. Hyperelasticity, Viscoelasticity, and Nonlocal Elasticity Govern Dynamic Fracture in Rubber. Phys. Rev. Lett. 2005, 95, 144301. [Google Scholar] [CrossRef]

- Yang, C.; Persson, B.N.J. Molecular Dynamics Study of Contact Mechanics: Contact Area and Interfacial Separation from Small to Full Contact. Phys. Rev. Lett. 2008, 100, 024303. [Google Scholar] [CrossRef]

- Frankel, T. The Geometry of Physics; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Chaichian, M.; Merches, I.; Tureanu, A. Mechanics; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Ernst, E. The Boussinesq Form of Saint-Venant’s Principle. Math. Model. Methods Appl. Sci. 2000, 10, 863–875. [Google Scholar] [CrossRef]

- Gilbarg, D.; Trudinger, N.S. Elliptic Partial Differential Equations of Second Order; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Alinhac, S. Hyperbolic Partial Differential Equations; Springer: New York, NY, USA, 2009. [Google Scholar]

- Evans, L.C. Partial Differential Equations; American Mathematical Society: Providence, RI, USA, 2010. [Google Scholar]

- Serov, V. Fourier Transform and Their Applications to Mathematical Physics; Springer International Publishing AG: New York, NY, USA, 2017. [Google Scholar]

- Rossing, T.D.; Fletcher, N.H. Principles of Vibration and Sound; Springer: New York, NY, USA, 2004. [Google Scholar]

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (rad/s) | (rad/s2) |

|---|---|---|---|---|---|---|---|---|---|

| 210.5 | 206.8 | 209 | 66.8 | 206.0 | 69.9 | 45 | 1 | 0 |

| (mm) | (mm) | (mm) | (mm) | |

|---|---|---|---|---|

| Linkage length before DE | 209.0 | 66.8 | 206.0 | 69.9 |

| Linkage length after DE | 202.0 | 66.7 | 196.4 | 69.5 |

| Before DE | 0.8379(rad) | 0.8232(rad) |

| After DE | 0.8377(rad) | 0.8205(rad) |

| Before DE | 1.254 (rad/s2) | −0.690 (rad/s2) | 0.674 (rad/s2) | −0.769 (rad/s2) |

| After DE | 1.120 (rad/s2) | −0.819 (rad/s2) | 0.683 (rad/s2) | −0.730 (rad/s2) |

| Change | −10.69% | 18.70% | 1.34% | −5.07% |

| Before DE | 0.624(rad/s2) | −1.182(rad/s2) | 0.644(rad/s) | −0.739(rad/s) |

| After DE | 0.767(rad/s2) | −1.039(rad/s2) | 0.657(rad/s) | −0.696(rad/s) |

| Change | 22.92% | −12.10% | 2.02% | −5.82% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.-J.; Hong, Y.-J.; Lin, C.-H.; Wang, J.-Y. Optimization on Linkage System for Vehicle Wipers by the Method of Differential Evolution. Appl. Sci. 2023, 13, 332. https://doi.org/10.3390/app13010332

Chen T-J, Hong Y-J, Lin C-H, Wang J-Y. Optimization on Linkage System for Vehicle Wipers by the Method of Differential Evolution. Applied Sciences. 2023; 13(1):332. https://doi.org/10.3390/app13010332

Chicago/Turabian StyleChen, Tsai-Jung, Ying-Ji Hong, Chia-Han Lin, and Jing-Yuan Wang. 2023. "Optimization on Linkage System for Vehicle Wipers by the Method of Differential Evolution" Applied Sciences 13, no. 1: 332. https://doi.org/10.3390/app13010332

APA StyleChen, T.-J., Hong, Y.-J., Lin, C.-H., & Wang, J.-Y. (2023). Optimization on Linkage System for Vehicle Wipers by the Method of Differential Evolution. Applied Sciences, 13(1), 332. https://doi.org/10.3390/app13010332