Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration

Abstract

:1. Introduction

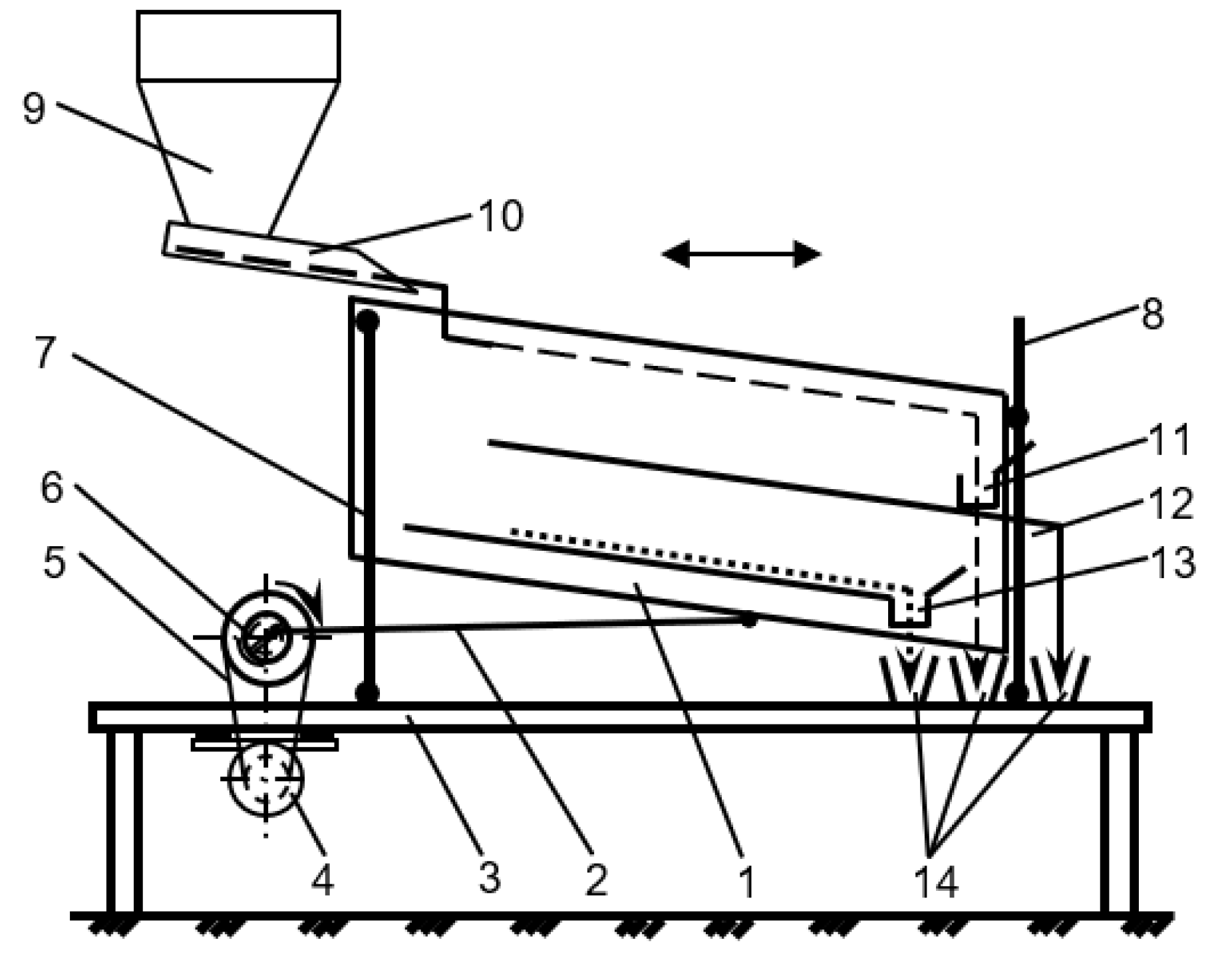

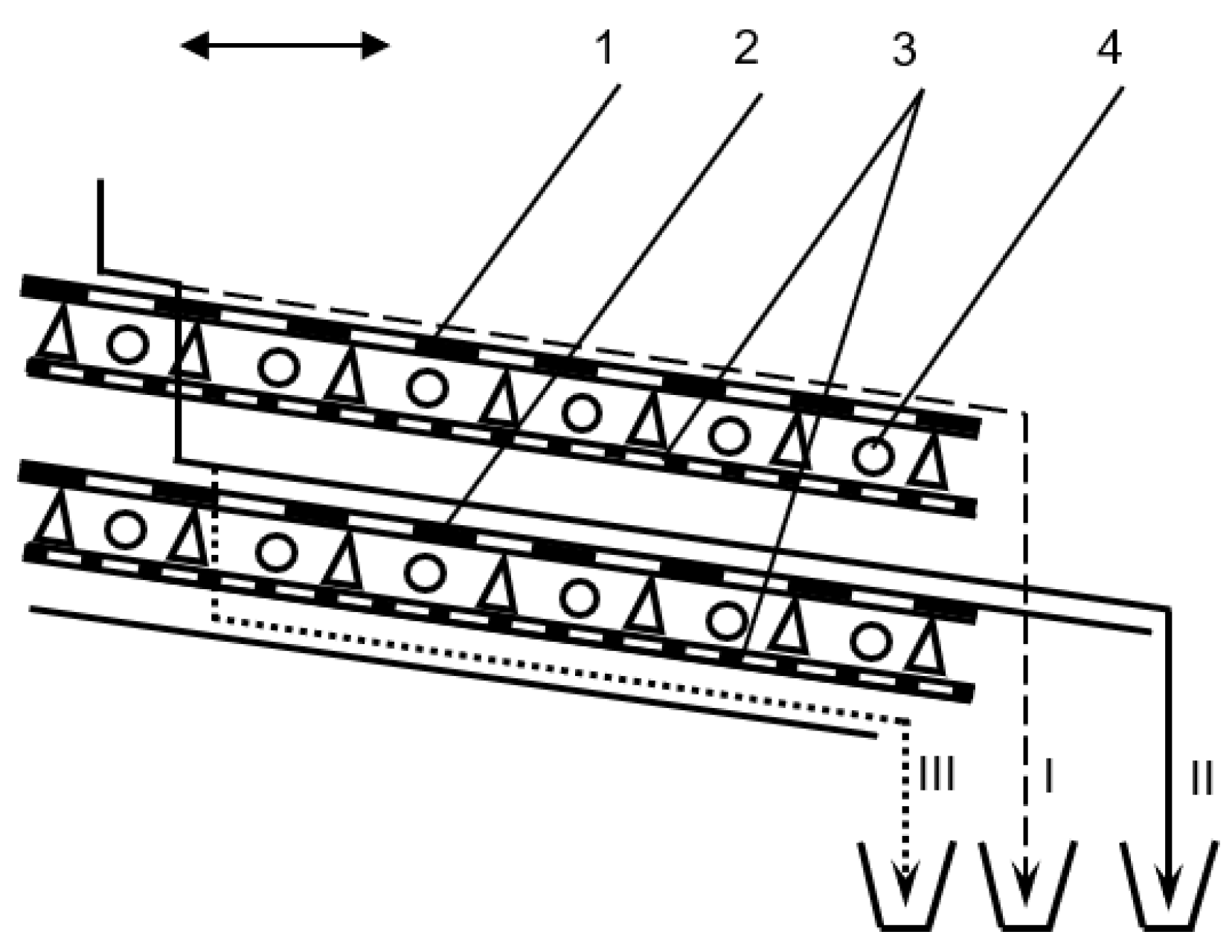

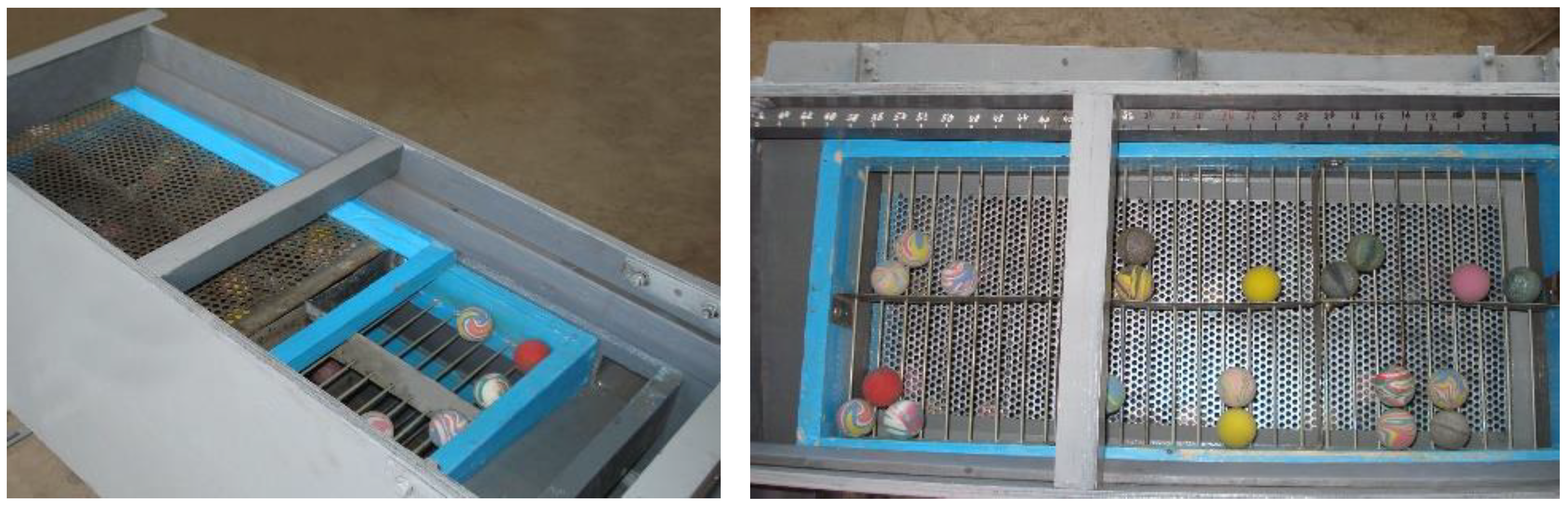

2. Materials and Methods

- Moving the bones on the working surface of the sieve;

- Sifting through the holes of the sieve;

- Cleaning the sieves’ openings from the bones stuck.

- ball diameter D = 33 mm;

- distance between the rods t = 23 mm;

- height of space under sieve H = 40 mm.

- oscillation frequencies of the sieve part (n);

- oscillation amplitudes of the sieve part (A);

- the angle of inclination of the sieves and ball cleaners (β).

- where

- —the mass of the obtained bones fraction;

- —total mass of bones.

- oscillation frequency n from 200 to 500 rpm;

- the amplitude of oscillations A from 5 to 10 mm;

- angle of sieves and ball cleaners β from 0 to 20°.

- where

- x—opposite leg, mm;

- y—adjacent leg, mm.

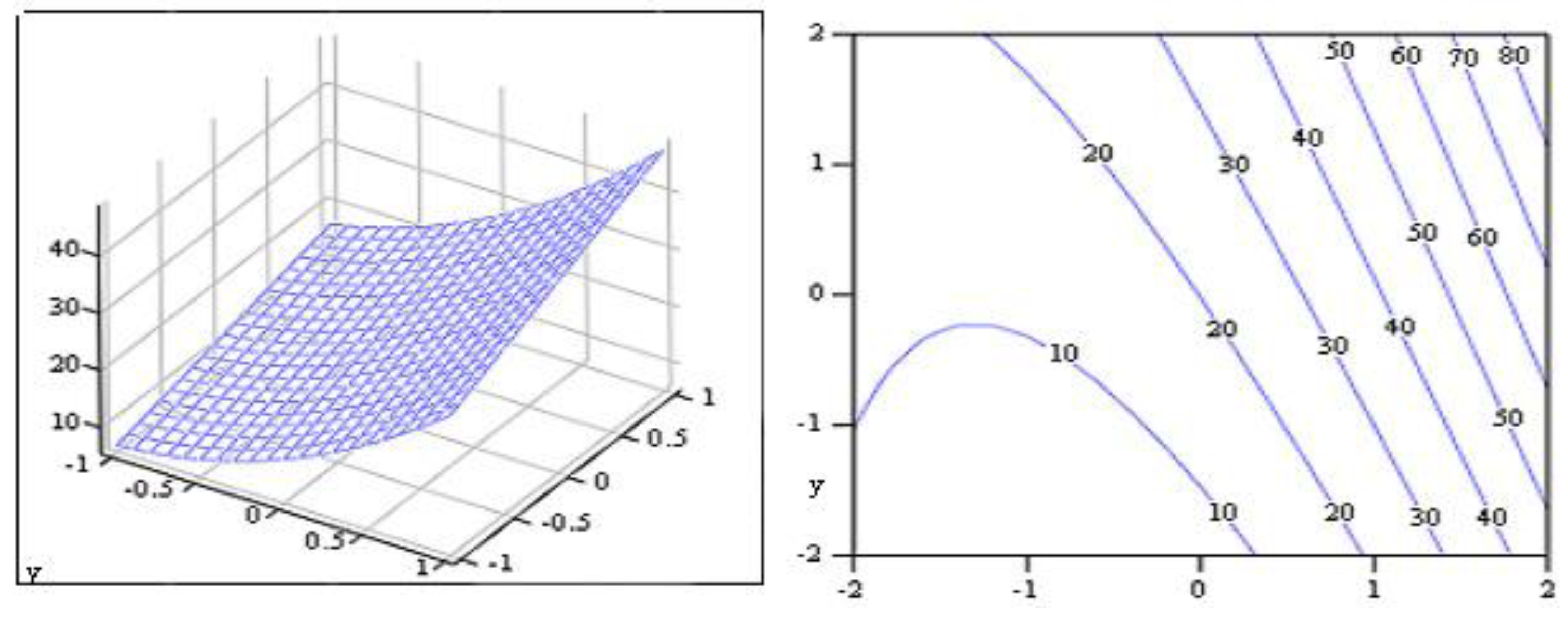

3. Results and Discussion

- Student criterion—checking the significance of regression coefficients;

- Kohren’s criterion—checking the reproducibility of experiments;

- Fisher criterion—checking the adequacy of the model.

- variance characterizing the error of the experiment was determined Dα (Table 3);

- variance of reproducibility by the results of the experiments in the center of the de-sign was calculated Dm (Table 3);

- variances characterizing the errors in determining the coefficients of the regression equation were found;

- the confidence interval of the regression coefficients was calculated using Student’s t-criterion, with the number of degrees of freedom . Its value is found from the tables [31]; in our case it is tcr = 2.05;

- confidence intervals are compared to the values of regression coefficients.

- for cherries Gp = 0.21;

- for sweet cherries Gp = 0.31;

- for plum cherries Gp = 0.2;

- for apricots Gp = 0.29;

- for almonds Gp = 0.27.

- coefficient of multiple correlation R;

- coefficient of determination R2 (r-square).

- for cherries Fp = 1.71 < Fcr = 2.19;

- for sweet cherries Fp = 1.03 < Fcr = 2.19;

- for plum cherries Fp = 2.01 < Fcr = 2.19;

- for apricots Fp = 1.80 < Fcr = 2.19;

- for almonds Fp = 1.92 < Fcr = 2.19.

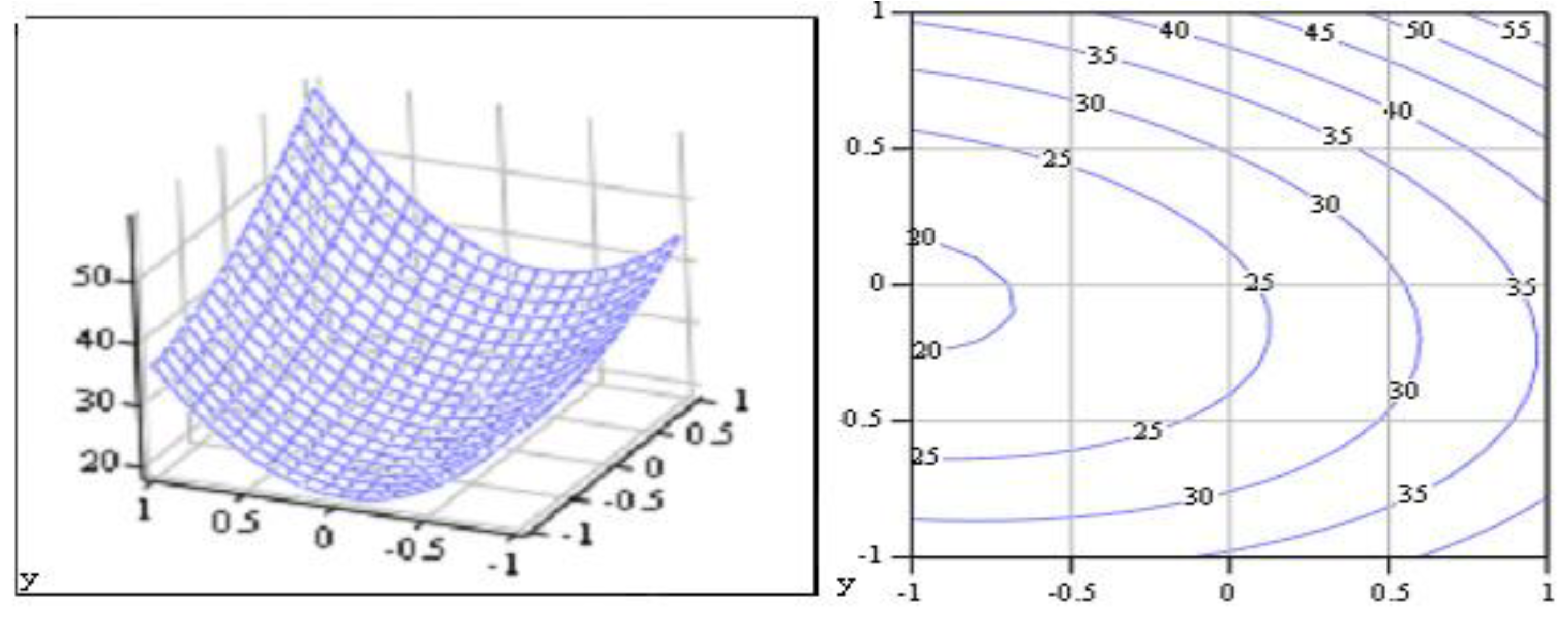

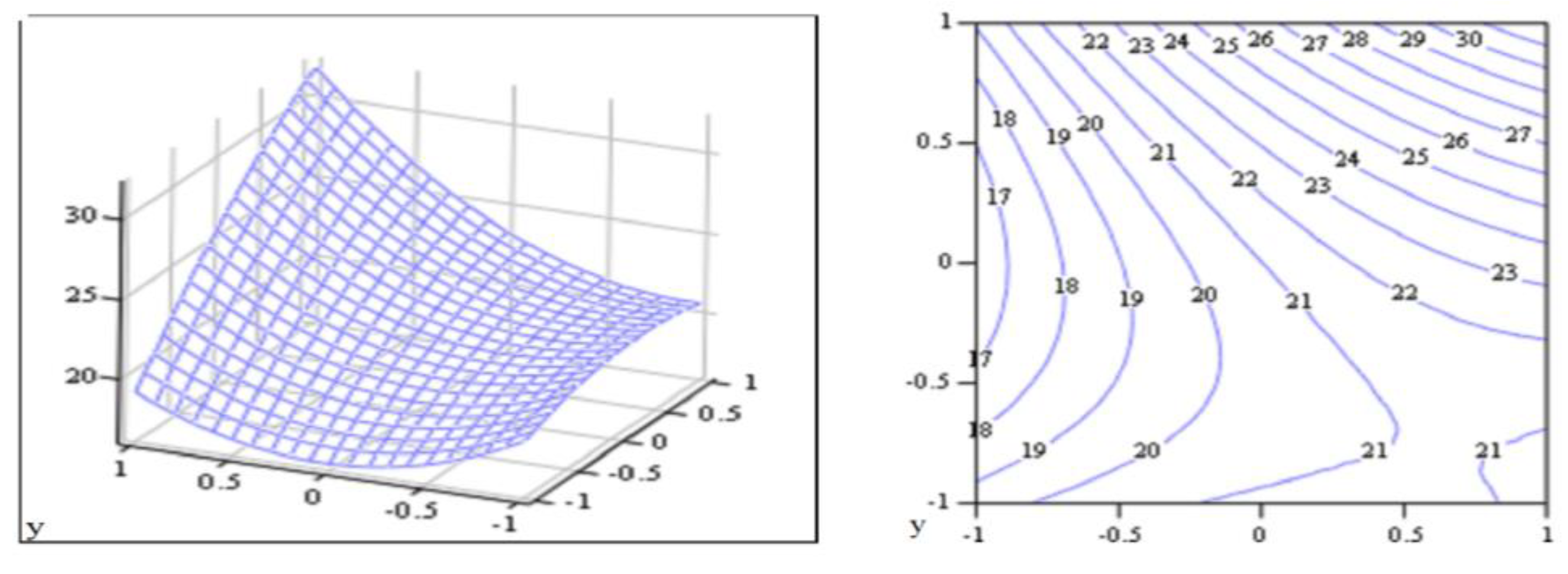

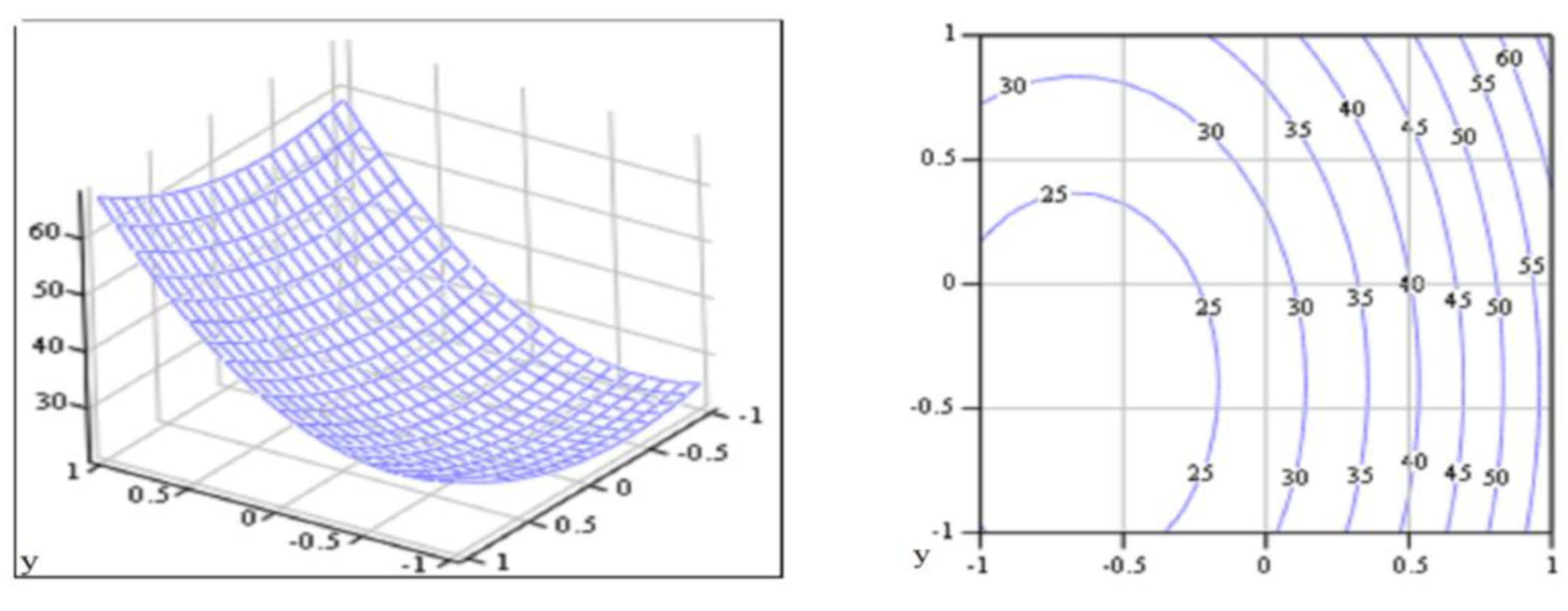

- for cherries

- for plum cherries ;

- for apricots ;

- for almonds .

4. Conclusions

- − Cherry: n = 440 fluct/min, A = 5.0 mm; α = 7 deg;

- − Sweet cherry: n = 420 fluct/min, A = 5.0 mm; α = 7 deg;

- − Cherry plum: n = 440 fluct/min, A = 5.0 mm; α = 4 deg;

- − Apricot: n = 400 fluct/min, A = 7.0 mm; α = 6 deg;

- − Almond: n = 400 fluct/min, A = 6.0 mm; α = 7 deg.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karaiev, O.H. Scientific Bases of Creation of Mechanized Technological Complexes for Production Systems of Seedlings of Fruit Crops. Ph.D. Thesis, Dmytriy Motornyi Tavria State Agrotechnological University, Melitopol, Ukraine, 2017. [Google Scholar]

- Karaiev, O.; Bondarenko, L.; Halko, S.; Miroshnyk, O.; Vershkov, O.; Karaieva, T.; Shchur, T.; Findura, P.; Prístavka, M. Mathematical Modelling of the fruit-stone culture seeds calibration process using flat sieves. Acta Technol. Agric. 2021, 24, 119–123. [Google Scholar] [CrossRef]

- Myhan, R.; Jachimczyk, E. Grain separation in a straw walker unit of a combine harvester: Process model. Biosyst. Eng. 2016, 145, 93–107. [Google Scholar] [CrossRef]

- Bondarenko, L.Y. Investigation of size and mass parameters of seed material of fruit stones. Pr. Tavriiskoi Derzhavnoi Ahrotekhnichnoi Akad. 2006, 35, 111–117. [Google Scholar]

- Bondarenko, L.Y. Correlation-regression analysis of size-mass parameters of seeds of fruit stones. Pr. Tavriiskoi Derzhavnoi Ahrotekhnichnoi Akad. 2006, 36, 105–110. [Google Scholar]

- Sadek, M.A.; Chen, Y. Discrete element modeling of hemp particle separation using a 3D vibratory separator. Can. Biosyst. Eng. 2013, 55, 2.23–2.31. [Google Scholar] [CrossRef]

- Bracacescu, C.; Pirna, I.; Sorica, C.; Popescu, S.; Stan, O. Experimental researches on influence of functional parameters of gravity separator on quality indicators of separation process with application on cleaning of wheat seeds. Eng. Rural Dev. 2012, 11, 16–21. [Google Scholar]

- Xu, L.; Li, Y.; Li, Y.; Chai, X.; Qiu, J. Research Progress on Cleaning Technology and Device of Grain Combine Harvester. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–16. [Google Scholar]

- Wang, L.; Duan, L.; Zheng, Z.; Li, Y.; Zhao, H. Optimization and Experiment on Driving Mechanism of Vibrating Screen with Three Translations and Two Rotations. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 138–145. [Google Scholar]

- Shi, L.; Ma, Z.; Zhao, W.; Yang, X.; Sun, B.; Zhang, J. Calibration of simulation parameters of flaxed seeds using discrete element method and verification of seed-metering test. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2019, 35, 25–33. [Google Scholar]

- Tabor, S.; Lezhenkin, A.; Halko, S.; Miroshnyk, A.; Kovalyshyn, S.; Vershkov, A.; Hryhorenko, O. Mathematical simulation of separating work tool technological process. In Proceedings of the International Scientific Conference on Progress of Mechanical Engineering Supported by Information Technology, Czajowice, Poland, 19 September 2019; p. 132. [Google Scholar]

- Havrylenko, Y.; Kholodniak, Y.; Halko, S.; Vershkov, O.; Miroshnyk, O.; Suprun, O.; Dereza, O.; Shshur, T.; Śrutek, M. Representation of a monotone curve by a contour with regular change in curvature. Entropy 2021, 23, 923. [Google Scholar] [CrossRef]

- Struchaiev, N.; Bondarenko, L.; Vershkov, O.; Chaplinskiy, A. Improving the efficiency of fruit tree sprayers. Mod. Dev. Paths Agric. Prod. Trends Innov. 2019, 1, 3–10. [Google Scholar]

- Lezhenkin, A.; Lezhenkin, I.; Vershkov, A.; Kolomiyets, S. Agrobiological as well as mechanical and technological framework of development of the harvesting technology with the method of grain crops combing in standing position. Mod. Dev. Paths Agric. Prod. Trends Innov. 2019, 1, 85–91. [Google Scholar]

- Lezhenkin, O.M.; Halko, S.V.; Miroshnyk, O.O.; Vershkov, O.O.; Lezhenkin, I.O.; Suprun, O.M.; Shchur, T.G.; Kruszelnicka, W.; Kasner, R. Investigation of the separation of combed heap of winter wheat. J. Phys. 2021, 1781, 012016. [Google Scholar] [CrossRef]

- Havrylenko, Y.; Kholodniak, Y.; Halko, S.; Vershkov, O.; Bondarenko, L.; Suprun, O.; Miroshnyk, O.; Shchur, T.; Śrutek, M.; Gackowska, M. Interpolation with Specified Error of a Point Series Belonging to a Monotone Curve. Entropy 2021, 23, 493. [Google Scholar] [CrossRef] [PubMed]

- Bazaluk, O.; Struchaiev, N.; Halko, S.; Miroshnyk, O.; Bondarenko, L.; Karaiev, O.; Nitsenko, V. Ways to Improve the Efficiency of Devices for Freezing of Small Products. Mater. This Link Is Disabl. 2022, 15, 2412. [Google Scholar] [CrossRef]

- Craessaerts, G.; Saeys, W.; Missotten, B.; De Baerdemaeker, J. Identification and control of the cleaning section on a combine harvester. VDI Ber. 2007, 106, 359–365. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, Y.; Zhu, J.; Yin, X.; Wang, W.; Peng, Q.; Li, J.; Wang, B. Direct calibration of discrete element method simulation parameters of seed metering device. Int. Agric. Eng. J. 2020, 29, 181–189. [Google Scholar]

- Huang, W.-Y.; Sheu, S.-J. Separation and identification of the fifteen constituents in forsythiae fructus. J. Food Drug Anal. 2007, 15, 33–39. [Google Scholar] [CrossRef]

- Heise, H.M.; Damm, U.; Lampen, P.; Davies, A.N.; Mcintyre, P.S. Spectral variable selection for partial least squares calibration applied to authentication and quantification of extra virgin olive oils using Fourier transform Raman spectroscopy. Appl. Spectrosc. 2005, 59, 1286–1294. [Google Scholar] [CrossRef]

- Zeng, Z.; Ma, X.; Cao, X.; Li, Z.; Wang, X. Critical Review of Applications of Discrete Element Method in Agricultural Engineering. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar] [CrossRef]

- Korenko, M.; Bulgakov, V.; Kurylo, V.; Ihnatiev, Y.; Matušeková, E. Formation of crop yields of energy crops depending on the soil and weather conditions. Acta Technol. Agric. 2021, 24, 42–47. [Google Scholar] [CrossRef]

- Bondarenko, L.Y.; Tsymbal, V.I. Investigation of the shape and size of the openings of the sieve for the calibration of the seed material of fruit stones. Mech. Electrif. Agric. 2008, 92, 176–180. [Google Scholar]

- Kiurchev, S.; Verkholantseva, V.; Yeremenko, O.; Al-Nadzhar, F. Research and changes in berries using technology of freezing during storage. Eng. Rural Dev. 2020, 19, 997–1002. [Google Scholar]

- Hrytsaienko, H.; Hrytsaienko, I.; Bondar, A.; Zhuravel, D. Mechanism for the maintenance of investment in agriculture. Mod. Dev. Paths Agric. Prod. Trends Innov. 2019, 1, 29–40. [Google Scholar]

- Zhuravel, D.; Samoichuk, K.; Petrychenko, S.; Gródek-Szostak, Z.; Sorokin, D. Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels. Energies 2022, 15, 1795. [Google Scholar] [CrossRef]

- Piven, M.V. Substantiation of the Parameters of the Grating Separation Process of Grain Mixtures. Ph.D. Thesis, Kharkiv Petro Vasylenko National Technical University of Agricultur, Kharkiv, Ukraine, 2006. [Google Scholar]

- Qawaqzeh, M.; Szafraniec, A.; Halko, S.; Miroshnyk, O.; Zharkov, A. Modelling of a household electricity supply system based on a wind power plant. Przegląd Elektrotechniczny 2020, 96, 36–40. [Google Scholar] [CrossRef]

- X200 Series Frequency Converters Quick Reference Guide. Available online: http://vened.kiev.ua/pr/X200_QRG.pdf (accessed on 22 February 2022).

- Mencher, J.M.; Zemshman, A.J. Fundamentals of Experiment Planning with Elements of Mathematical Statistics in Viticulture Research; Shtiintsa: Kishinev, Moldova, 1986; p. 238. [Google Scholar]

- Lawinska, K.; Wodzinski, P.; Modrzewski, R. Verification of the mathematical model of the screen blocking process. Powder Technol. 2014, 256, 506–511. [Google Scholar] [CrossRef]

| Fruit Crop | Upper Sieve | Lower Sieve |

|---|---|---|

| Cherry | 6.5 | 5.0 |

| Sweet cherry | 8.0 | 6.5 |

| Cherry plum | 13.0 | 11.0 |

| Apricot | 20.0 | 15.0 |

| Almond | 22.0 | 15.0 |

| Fruit Crops | Factors | n, fluct/min | A, mm | , deg |

|---|---|---|---|---|

| The Coded Designation | X1 | X2 | X3 | |

| Cherry | Variation Interval | 45 | 2.5 | 2.5 |

| Basic level (0) | 455 | 7.5 | 9.5 | |

| Top level (+1) | 500 | 10.0 | 12.0 | |

| Lower level (−1) | 410 | 5.0 | 7.0 | |

| Sweet cherry | Variation Interval | 65 | 2.5 | 3.0 |

| Basic level (0) | 415 | 7.5 | 7.0 | |

| Top level (+1) | 480 | 10.0 | 10.0 | |

| Lower level (−1) | 350 | 5.0 | 4.0 | |

| Cherry plum | Variation Interval | 70 | 2.5 | 3.0 |

| Basic level (0) | 430 | 7.5 | 7.0 | |

| Top level (+1) | 500 | 10.0 | 10.0 | |

| Lower level (−1) | 360 | 5.0 | 4.0 | |

| Apricot | Variation Interval | 50 | 1.5 | 4.0 |

| Basic level (0) | 450 | 8.5 | 6.0 | |

| Top level (+1) | 500 | 10.0 | 9.0 | |

| Lower level (−1) | 400 | 7.0 | 3.0 | |

| Almond | Variation Interval | 50 | 2.0 | 2.0 |

| Basic level (0) | 430 | 8.0 | 5.0 | |

| Top level (+1) | 480 | 10.0 | 7.0 | |

| Lower level (−1) | 380 | 6.0 | 3.0 |

| Regression Statistics | Cherry | Sweet Cherry | Cherry Plum | Apricot | Almond |

|---|---|---|---|---|---|

| Adequacy variance, Dα | 0.600 | 0.941 | 2.413 | 1.850 | 2.290 |

| Average variance of the whole experiment, Dm | 0.200 | 0.314 | 0.800 | 0.617 | 0.765 |

| Multiple correlation coefficient, R | 0.964 | 0.897 | 0.999 | 0.950 | 0.870 |

| Determination coefficient, R2 | 0.930 | 0.804 | 0.997 | 0.900 | 0.750 |

| Parameters | n, fluct/min | A, mm | |

|---|---|---|---|

| Fruit Crops | |||

| Cherry | 440 | 5 | 7 |

| Sweet Cherry | 420 | 5 | 7 |

| Cherry Plum | 440 | 5 | 4 |

| Apricot | 400 | 7 | 6 |

| Almond | 400 | 6 | 7 |

| Fruit Crops | The Diameter of the Opening of the Sieve d, mm | n, fluct/min | A, mm | , beg |

|---|---|---|---|---|

| Cherry | Upper d = 6.5 MM Lower d = 5.0 MM | 435–445 | 5.0–5.5 | 6.5–7.0 |

| Sweet Cherry | Upper d = 8.0 MM Lower d = 6.5 MM | 415–425 | 5.0–5.5 | 6.5–7.0 |

| Cherry Plum | Upper d = 13.0 MM Lower d = 11.0 MM | 435–445 | 5.0–5.5 | 4.0–4.5 |

| Apricot | Upper d = 20.0 MM Lower d = 15.0 MM | 395–405 | 7.0–7.5 | 6.0–6.5 |

| Almond | Upper d = 22.0 MM Lower d = 15.0 MM | 395–405 | 5.5–6.0 | 6.5–7.0 |

| Fruit Crops | The Mass of Fraction, % | The Criterion of Optimization, % | Productivity, kg/h | |||||

|---|---|---|---|---|---|---|---|---|

| Large | Middle | Small | ||||||

| Ideal | Experimental | Ideal | Experimental | Ideal | Experimental | |||

| Cherry | 7.55 | 5.90 | 77.65 | 7.55 | 5.90 | 77.65 | 7.55 | 5.90 |

| Sweet Cherry | 12.45 | 14.10 | 85.45 | 12.45 | 14.10 | 85.45 | 12.45 | 14.10 |

| Cherry Plum | 15.40 | 19.20 | 75.00 | 15.40 | 19.20 | 75.00 | 15.40 | 19.20 |

| Apricot | 7.25 | 10.60 | 88.35 | 7.25 | 10.60 | 88.35 | 7.25 | 10.60 |

| Almond | 14.85 | 17.40 | 83.15 | 14.85 | 17.40 | 83.15 | 14.85 | 17.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bondarenko, L.; Halko, S.; Matsulevych, O.; Tetervak, I.; Vershkov, O.; Miroshnyk, O.; Nitsenko, V.; Havrysh, V. Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration. Appl. Sci. 2023, 13, 21. https://doi.org/10.3390/app13010021

Bondarenko L, Halko S, Matsulevych O, Tetervak I, Vershkov O, Miroshnyk O, Nitsenko V, Havrysh V. Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration. Applied Sciences. 2023; 13(1):21. https://doi.org/10.3390/app13010021

Chicago/Turabian StyleBondarenko, Larysa, Serhii Halko, Oleksandr Matsulevych, Illia Tetervak, Oleksandr Vershkov, Oleksandr Miroshnyk, Vitalii Nitsenko, and Valerii Havrysh. 2023. "Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration" Applied Sciences 13, no. 1: 21. https://doi.org/10.3390/app13010021

APA StyleBondarenko, L., Halko, S., Matsulevych, O., Tetervak, I., Vershkov, O., Miroshnyk, O., Nitsenko, V., & Havrysh, V. (2023). Experimental Research on Unit Operation for Fruit Crops’ Bones Calibration. Applied Sciences, 13(1), 21. https://doi.org/10.3390/app13010021