Investigation on Functional, Thermo-Mechanical and Bread-Making Properties of Some White and Black Rice Flours

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Physico-Chemical Characteristics of Rice Flours

2.3. Functional Properties of Rice Flours

2.4. The Thermo-Mechanical Properties of Rice Flours

2.5. Bread-Making Procedure and Bread Characterization

2.6. Statistical Analysis

3. Results and Discussion

3.1. Physico-Chemical Characteristics of the Rice Flours

3.2. Functional Properties of Rice Flours

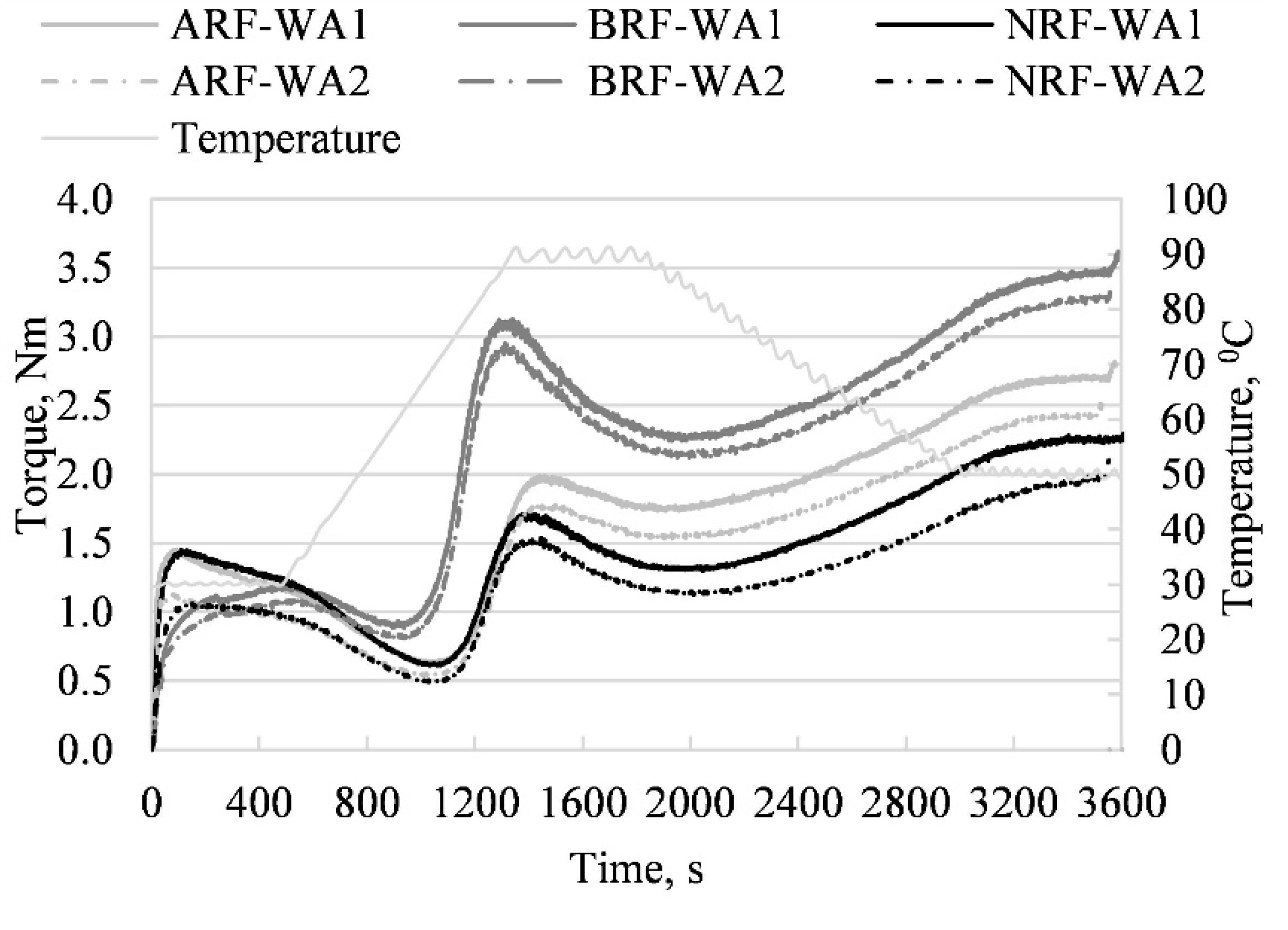

3.3. The Thermo-Mechanical Properties of Rice Flours

3.4. Bread Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ferreira, A.R.; Oliveira, J.; Pathania, S.; Almeida, A.S.; Brites, C. Rice quality profiling to classify germplasm in breeding programs. J. Cereal Sci. 2017, 76, 17–27. [Google Scholar] [CrossRef]

- Sompong, R.; Siebenhandl-Ehn, S.; Linsberger-Martin, G.; Berghofer, E. Physicochemical and antioxidative properties of red and black rice varieties from Thailand, China and Sri Lanka. Food Chem. 2011, 124, 132–140. [Google Scholar] [CrossRef]

- Kumar, I.; Khush, G.S. Genetic analysis of different amylose levels in rice. Crop Sci. 1987, 27, 1167–1172. [Google Scholar] [CrossRef]

- Kraithong, S.; Lee, S.; Rawdkuen, S. Physicochemical and functional properties of Thai organic rice flour. J. Cereal Sci. 2018, 79, 259–266. [Google Scholar] [CrossRef]

- Ye, L.; Wang, C.; Wang, S.; Zhou, S.; Liu, X. Thermal and rheological properties of brown flour from Indica rice. J. Cereal Sci. 2016, 70, 270–274. [Google Scholar] [CrossRef]

- Kadan, R.S.; Bryant, R.J.; Miller, J.A. Effects of milling on functional properties of rice flour. J. Food Sci. 2008, 73, 151–154. [Google Scholar] [CrossRef]

- Soriguer, F.; Colomo, N.; Olveira, G.; García-Fuentes, E.; Esteva, I.; Ruiz de Adana, M.S.; Morcillo, S.; Porras, N.; Valdes, S.; Rojo-Martínez, G. White rice consumption and risk of type 2 diabetes. Clin. Nutr. 2013, 32, 481–484. [Google Scholar] [CrossRef]

- Ito, V.C.; Lacerda, L.G. Black rice (Oryza sativa L.): A review of its historical aspects, chemical composition, nutritional and functional properties, and applications and processing technologies. Food Chem. 2019, 301, 125304. [Google Scholar] [CrossRef]

- Ranilla, L.G.; Kwon, Y.I.; Apostolidis, E.; Shetty, K. Phenolic compounds, antioxidant activity and in vitro inhibitory potential against key enzymes relevant for hyperglycemia and hypertension of commonly used medicinal plants, herbs and spices in Latin America. Bioresour. Technol. 2010, 101, 4676–4689. [Google Scholar] [CrossRef]

- Tanaka, J.; Nakamura, S.; Tsuruma, K.; Shimazawa, M.; Shimoda, H.; Hara, H. Purple rice (Oryza sativa L.) Eetract and its constituents Inhibit VEGF-induced angiogenesis. Phytother. Res. 2012, 26, 214–222. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, F.; Sun, X.; Bao, J.; Beta, T. Identification and quantification of phenolic acids and anthocyanins as antioxidants in bran, embryo and endosperm of white, red and black rice kernels (Oryza sativa L.). J. Cereal Sci. 2014, 59, 211–218. [Google Scholar] [CrossRef]

- SR 91:2007, SR ISO 2171/2002, SR ISO 712:2005; Romanian Standards Catalog for Cereal and Milling Products Analysis. ASRO: Bucharest, Romania, 2008.

- AACC International. Approved Methods of Analysis, 11th ed.; Methods 56-11.02 and 76-31.01; American Association of Cereal Chemists International: St. Paul, MN, USA, 2000. [Google Scholar]

- Godon, B.; Wilhm, C. Primary Cereal Processing a Comprehensive Sourcebook; VCH: New York, NY, USA, 1994; pp. 129–130. [Google Scholar]

- Niu, Q.; Pu, Y.; Li, X.; Ma, Z.; Hu, X. Solvent retention capacities of oat flour. Int. J. Mol. Sci. 2017, 18, 590. [Google Scholar] [CrossRef]

- Xie, L.; Chen, N.; Tang, S.; Lu, J.; Jiao, G.; Hu, P. Use of Mixolab in predicting rice quality. Cereal Chem. 2011, 88, 333–337. [Google Scholar] [CrossRef]

- Dubat, A.; Boinot, N. Mixolab Applications Handbook. Rheological and Enzymes Analyses; Chopin Technology: Villenueve, France, 2012; pp. 12, 101, 102, 131, 132, 146. [Google Scholar]

- Hadnadev, T.D.; Torbica, A.; Hadnadev, M. Rheological properties of wheat flour substitutes/alternative crops assessed by Mixolab. Procedia Food Sci. 2011, 1, 328–334. [Google Scholar] [CrossRef]

- Pătraşcu, L.; Banu, I.; Vasilean, I.; Aprodu, I. Effect of gluten, egg and soy proteins on the rheological and thermo-mechanical properties of wholegrain rice flour. Food Sci. Technol. Int. 2017, 23, 142–155. [Google Scholar] [CrossRef] [PubMed]

- Phuwadolpaisarn, P. Comparison of β-glucan content in milled rice, rice husk and rice bran from rice cultivars grown in different locations of Thailand and the relationship between β-glucan and amylose contents. Molecules 2021, 26, 6368. [Google Scholar] [CrossRef] [PubMed]

- Cappa, C.; Lucisano, M.; Barbosa-Cánovas, G.V.; Mariotti, M. Physical and structural changes induced by high pressure on corn starch, rice flour and waxy rice flour. Food Res. Int. 2016, 85, 95–103. [Google Scholar] [CrossRef]

- Mariotti, M.; Lucisano, M.; Pagani, M.A.; Perry, K.W.N. Effects of dispersing media and heating rates on pasting profiles of wheat and gluten-free samples in relation to their solvent retention capacities and mixing properties. LWT Food Sci. Technol. 2016, 66, 201–210. [Google Scholar] [CrossRef]

- Lai, V.; Lu, S.; Hsien He, W.; Han Chen, H. Non-starch polysaccharide compositions of rice grains with respect to rice variety and degree of milling. Food Chem. 2006, 101, 1205–1210. [Google Scholar] [CrossRef]

- Cao, X.; Wen, H.; Li, C.; Gu, Z. Differences in functional properties and biochemical characteristics of congenetic rice proteins. J. Cereal Sci. 2009, 50, 184–189. [Google Scholar] [CrossRef]

- Kang, M.-Y.; Kim, J.-H.; Rico, C.; Nam, S.-H. A Comparative study on the physicochemical characteristics of black rice varieties. Int. J. Food Prop. 2011, 14, 1241–1254. [Google Scholar] [CrossRef][Green Version]

- Liu, P.; Li, Y.; Gao, L.; Zhou, X.; Ma, P.; Wang, Q. Effect of different carbohydrates on the functional properties of black rice glutelin (BRG) modified by the maillard reaction. J. Cereal Sci. 2020, 93, 102979. [Google Scholar] [CrossRef]

- Kosik, O.; Romero, M.; Bandonill, E.; Abilgos-Ramos, R.; Sreenivasulu, N.; Shewry, P.; Lovegrove, A. Diversity of content and composition of cell wall-derived dietary fibre in polished rice. J. Cereal Sci. 2020, 96, 103122. [Google Scholar] [CrossRef]

- Chen, J.-J.; Lii, C.-Y.; Lu, S. Physicochemical and morphological analyses on damaged rice starches. J. Food Drug Anal. 2003, 11, 283–289. [Google Scholar] [CrossRef]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016, 191, 45–51. [Google Scholar] [CrossRef]

- Chung, H.-J.; Liu, Q.; Wei, D. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocoll. 2011, 25, 968–975. [Google Scholar] [CrossRef]

- Varavinit, S.; Shobsngob, S.; Varanyanond, W.; Chinachoti, P.; Naivikul, O. Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of Thai rice. Starke 2003, 55, 410–415. [Google Scholar] [CrossRef]

- Cai, J.; Man, J.; Huanga, J.; Liua, Q.; Wei, W.; Wei, C. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydr. Polym. 2015, 125, 35–44. [Google Scholar] [CrossRef]

- Marco, C.; Rosell, C. Breadmaking performance of protein enriched, gluten-free breads. Eur. Food Res. Technol. 2008, 227, 1205–1213. [Google Scholar] [CrossRef]

- De la Hera, E.; Rosell, C.; Gomez, M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014, 151, 526–531. [Google Scholar] [CrossRef]

| Component | Flour Samples | ||

|---|---|---|---|

| ARF | BRF | NRF | |

| Moisture, % | 12.78 ± 0.11 a | 12.15 ± 0.15 b | 12.21 ± 0.09 b |

| Ash, % | 0.46 ± 0.01 b | 0.46 ± 0.01 b | 1.30 ± 0.03 a |

| Protein, % | 7.73 ± 0.11 c | 9.99 ± 0.10 b | 11.16 ± 0.05 a |

| Fat, % | 1.47 ± 0.03 b | 1.45 ± 0.03 b | 3.42 ± 0.07 a |

| Crude fiber, % | 2.06 ± 0.05 b | 1.46 ± 0.03 c | 4.75 ± 0.05 a |

| Starch, % | 88.28 ± 0.63 a | 86.64 ± 0.56 b | 79.37 ± 0.23 c |

| Starch damage, % | 9.71 ± 0.10 a | 5.34 ± 0.05 c | 6.26 ± 0.05 b |

| Amylose, % | 17.40 ± 0.17 a | 11.17 ± 0.11 b | 6.87 ± 0.16 c |

| Fineness module | 2.15 ± 0.05 a | 2.10 ± 0.10 a | 1.99 ± 0.04 a |

| SRC | Flour Samples | ||

|---|---|---|---|

| ARF | BRF | NRF | |

| W-SRC, % | 115.49 ± 0.50 b | 105.85 ± 0.30 c | 124.51 ± 0.36 a |

| Ca-SRC, % | 103.65 ± 0.41 c | 110.84 ± 0.30 b | 134.33 ± 0.25 a |

| Na-SRC, % | 93.03 ± 0.26 c | 101.66 ± 0.35 b | 105.27 ± 0.23 a |

| SC-SRC, % | 104.10 ± 0.36 a | 84.89 ± 0.35 c | 90.18 ± 0.17 b |

| LA-SRC, % | 79.27 ± 0.15 c | 95.33 ± 0.25 b | 106.01 ± 0.34 a |

| Su-SRC, % | 88.36 ± 0.23 b | 82.53 ± 0.21 c | 124.57 ± 0.35 a |

| Properties | Flour Samples | |||||

|---|---|---|---|---|---|---|

| ARF-WA1 | ARF-WA2 | BRF-WA1 | BRF-WA2 | NRF-WA1 | NRF-WA2 | |

| WA, % | 65.00 | 70.30 | 65.00 | 66.00 | 65.00 | 69.70 |

| C1, Nm | 1.44 ± 0.10 aA | 1.12 ± 0.10 bX | 1.18 ± 0.01 aB | 1.08 ± 0.01 bY | 1.43 ± 0.01 aA | 1.05 ± 0.01 bZ |

| Time C1, min | 1.45 ± 0.02 aC | 1.28 ± 0.01 bZ | 8.30 ± 0.03 bA | 8.68 ± 0.01 aX | 1.97 ± 0.01 bB | 2.48 ± 0.01 aY |

| S, min | 4.50 ± 0.10 bC | 6.10 ± 0.10 aZ | 9.10 ± 0.01 aA | 8.60 ± 0.01 bX | 6.10 ± 0.10 bB | 8.30 ± 0.10 aY |

| CS, Nm | 1.17 ± 0.02 aB | 0.96 ± 0.01 bY | 1.17 ± 0.01 aB | 1.07 ± 0.02 bX | 1.24 ± 0.01 aA | 0.97 ± 0.01 bY |

| C2, Nm | 0.63 ± 0.02 aB | 0.54 ± 0.01 bY | 0.90 ± 0.02 aA | 0.82 ± 0.01 bX | 0.62 ± 0.01 aB | 0.49 ± 0.02 bZ |

| TMW, % | 37.46 ± 0.27 aB | 37.14 ± 0.78 aY | 22.81 ± 0.81 aC | 23.15 ± 1.04 aZ | 43.37 ± 1.10 aA | 45.58 ± 2.12 aX |

| C3, Nm | 1.97 ± 0.02 aB | 1.77 ± 0.01 bY | 3.09 ± 0.03 aA | 2.91 ± 0.01 bX | 1.70 ± 0.02 aC | 1.51 ± 0.01 bZ |

| TC3, °C | 80.50 ± 0.10 bA | 82.30 ± 0.10 aX | 77.80 ± 0.10 aC | 74.50 ± 0.10 bZ | 79.90 ± 0.10 aB | 78.80 ± 0.10 bY |

| C4, Nm | 1.75 ± 0.01 aB | 1.55 ± 0.02 bY | 2.27 ± 0.02 aA | 2.14 ± 0.01 bX | 1.31 ± 0.01 aC | 1.14 ± 0.01 bZ |

| C5, Nm | 2.77 ± 0.02 aB | 2.47 ± 0.01 bY | 3.54 ± 0.01 aA | 3.33 ± 0.01 aX | 2.26 ± 0.02 aC | 2.01 ± 0.01 bZ |

| C3-C2, Nm | 1.36 ± 0.03 aB | 1.23 ± 0.01 bY | 2.19 ± 0.04 aA | 2.09 ± 0.01 bX | 1.08 ± 0.03 aC | 1.02 ± 0.02 bZ |

| C3-C4, Nm | 0.22 ± 0.01 aC | 0.22 ± 0.03 aZ | 0.82 ± 0.04 aA | 0.77 ± 0.02 aX | 0.39 ± 0.03 aB | 0.37 ± 0.02 aY |

| C5-C4, Nm | 1.03 ± 0.03 aB | 0.92 ± 0.01 bY | 1.27 ± 0.01 aA | 1.19 ± 0.02 bX | 0.95 ± 0.02 aC | 0.88 ± 0.01 bZ |

| Beta, Nm/min | 0.38 ± 0.01 aB | 0.38 ± 0.01 aY | 0.65 ± 0.01 aA | 0.60 ± 0.02 bX | 0.37 ± 0.01 aB | 0.34 ± 0.01 bZ |

| Properties | Samples | |||||

|---|---|---|---|---|---|---|

| ARF | BRF | NRF | ||||

| WA1 | WA2 | WA1 | WA2 | WA1 | WA2 | |

| Specific volume, g/cm3 | 193.82 ± 1.60 aA | 196.89 ± 1.84 aX | 181.53 ± 1.50 aB | 183.36 ± 1.52 aY | 195.51 ± 1.33 bA | 199.76 ± 1.65 aX |

| Firmness, g force | 1444.5 ± 42.0 aB | 1302.1 ± 20.3 bY | 1845.4 ± 45 aA | 1573.9 ± 29.6 bX | 1308.0 ± 35.4 aC | 1219.9 ± 26.5 bZ |

| L* | 60.61 ± 0.01 bB | 61.04 ± 0.11 aY | 60.96 ± 0.05 bA | 61.45 ± 0.11 aX | 14.26 ± 0.06 bC | 14.50 ± 0.02 aZ |

| a* | 1.64 ± 0.01 bB | 1.68 ± 0.01 aY | 1.43 ± 0.01 bC | 1.58 ± 0.01 aZ | 5.51 ± 0.01 bA | 5.95 ± 0.01 aX |

| b* | 11.30 ± 0.01 bA | 12.36 ± 0.01 aX | 10.58 ± 0.04 bB | 10.85 ± 0.01 aY | -1.53 ± 0.01 bC | -1.38 ± 0.01 aZ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banu, I.; Aprodu, I. Investigation on Functional, Thermo-Mechanical and Bread-Making Properties of Some White and Black Rice Flours. Appl. Sci. 2022, 12, 4544. https://doi.org/10.3390/app12094544

Banu I, Aprodu I. Investigation on Functional, Thermo-Mechanical and Bread-Making Properties of Some White and Black Rice Flours. Applied Sciences. 2022; 12(9):4544. https://doi.org/10.3390/app12094544

Chicago/Turabian StyleBanu, Iuliana, and Iuliana Aprodu. 2022. "Investigation on Functional, Thermo-Mechanical and Bread-Making Properties of Some White and Black Rice Flours" Applied Sciences 12, no. 9: 4544. https://doi.org/10.3390/app12094544

APA StyleBanu, I., & Aprodu, I. (2022). Investigation on Functional, Thermo-Mechanical and Bread-Making Properties of Some White and Black Rice Flours. Applied Sciences, 12(9), 4544. https://doi.org/10.3390/app12094544