Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications

Abstract

1. Introduction

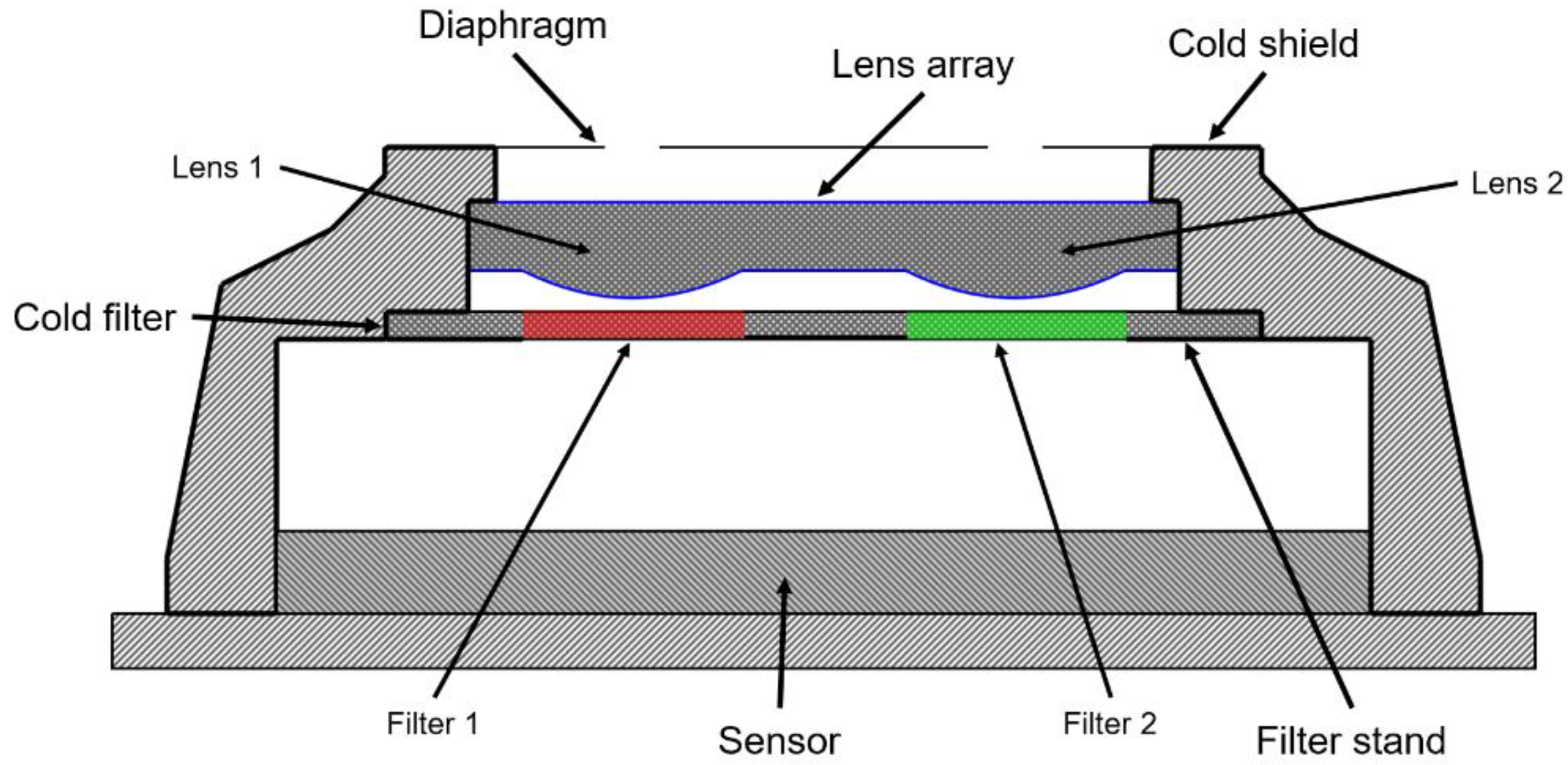

2. A gradient Index Plate in a Multispectral Camera

2.1. Multispectral Camera

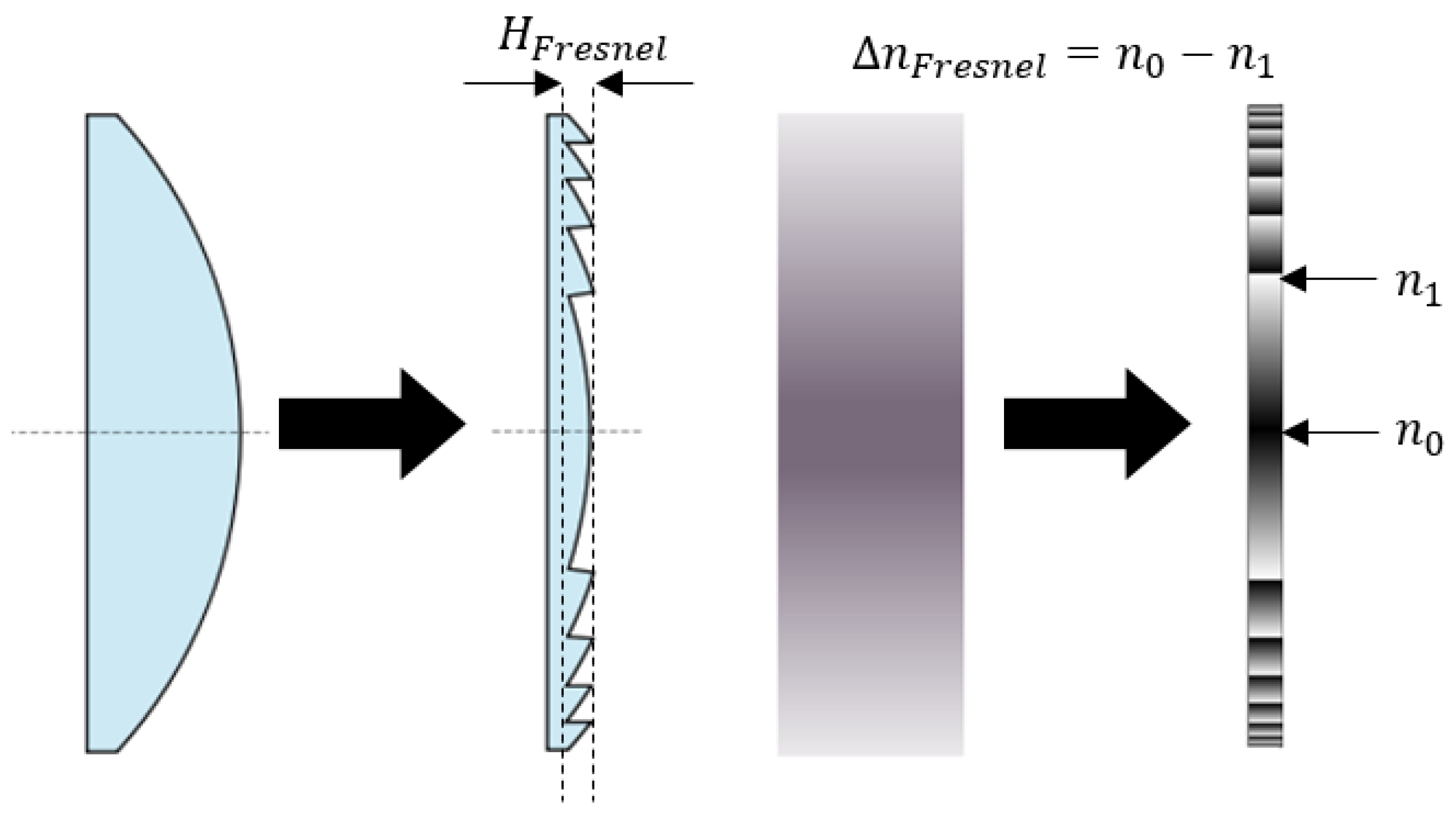

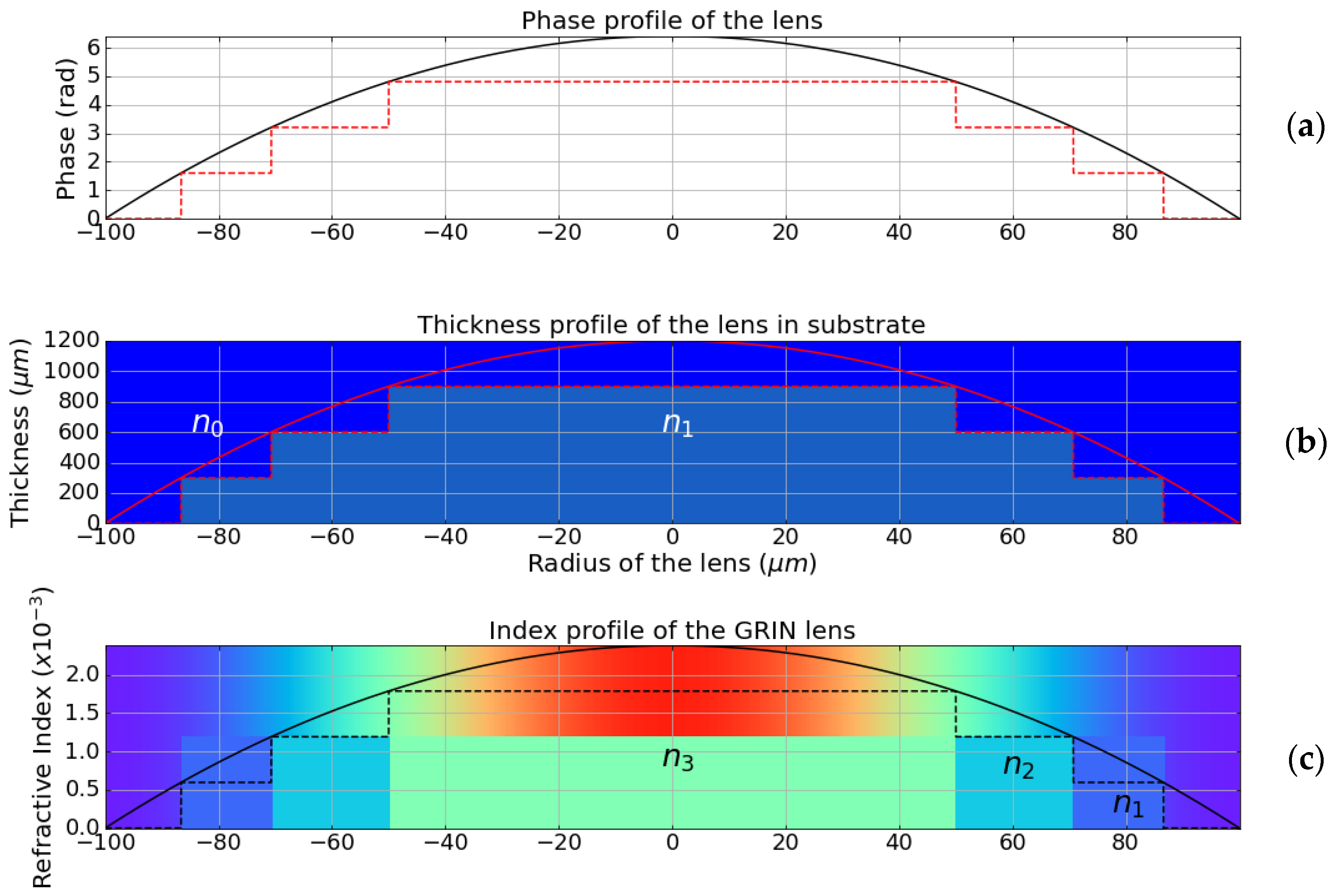

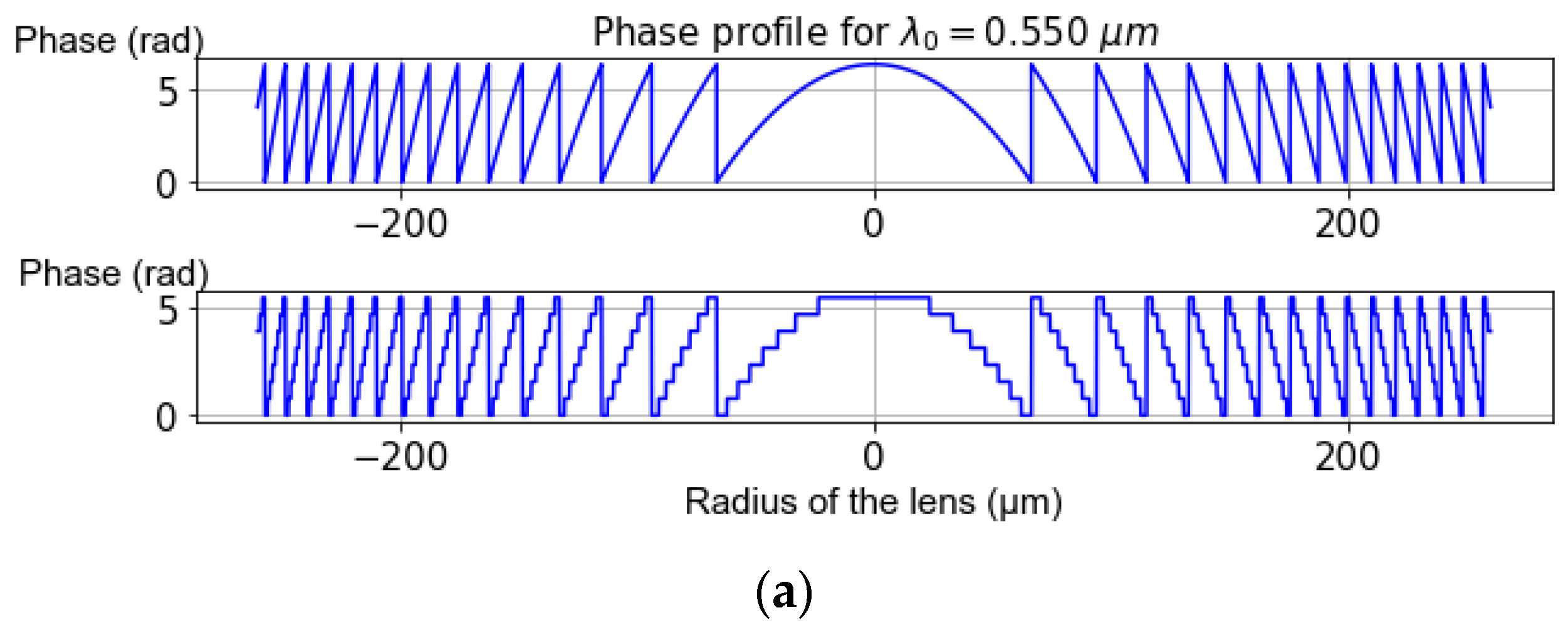

2.2. GRIN Fresnel Lenses

3. Femtosecond Laser Direct Writing of Gradient Index Flat Lens

3.1. Experimental Details

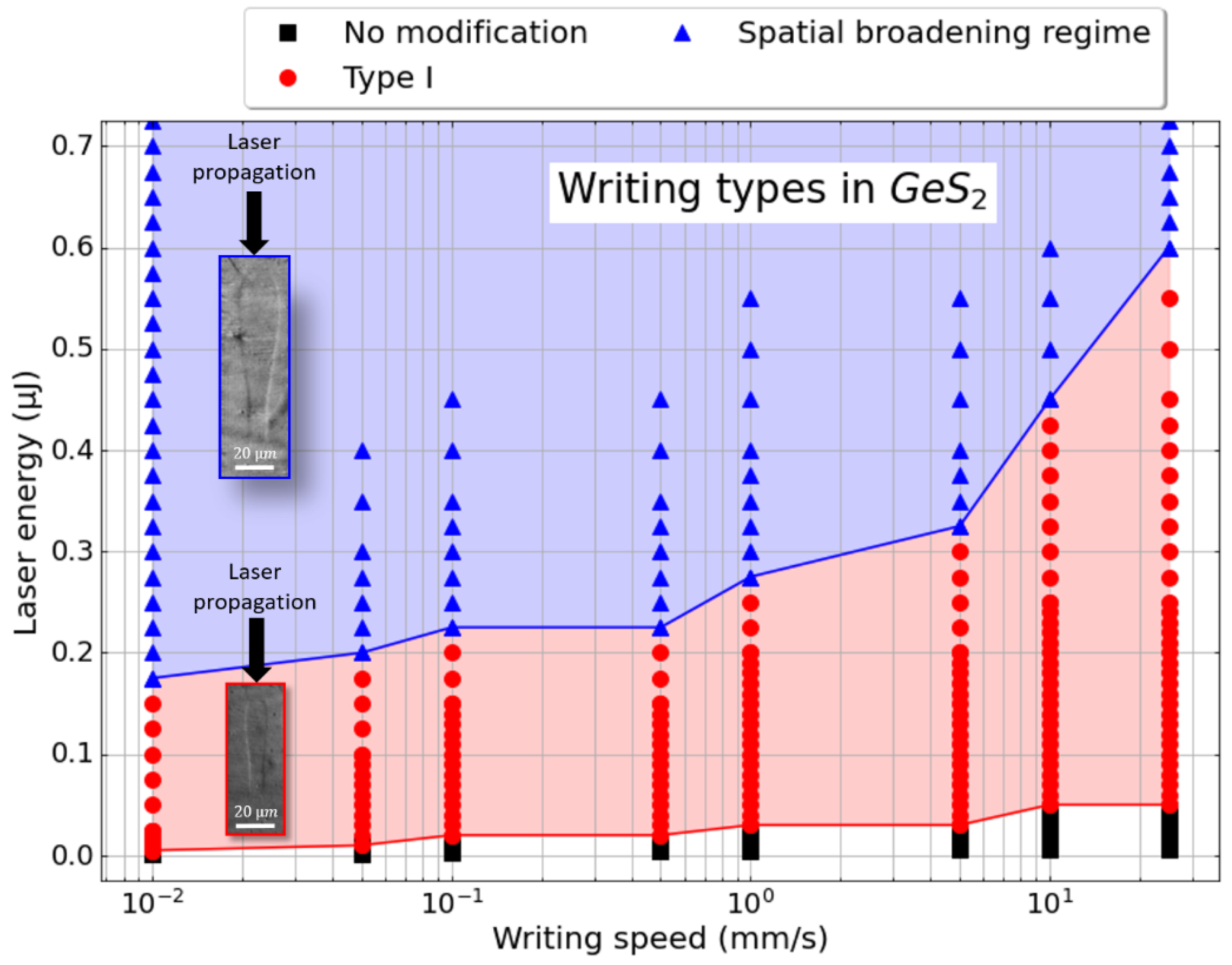

3.2. Identification of Different Kinds of Permanent Modifications in GeS2-Based Glass

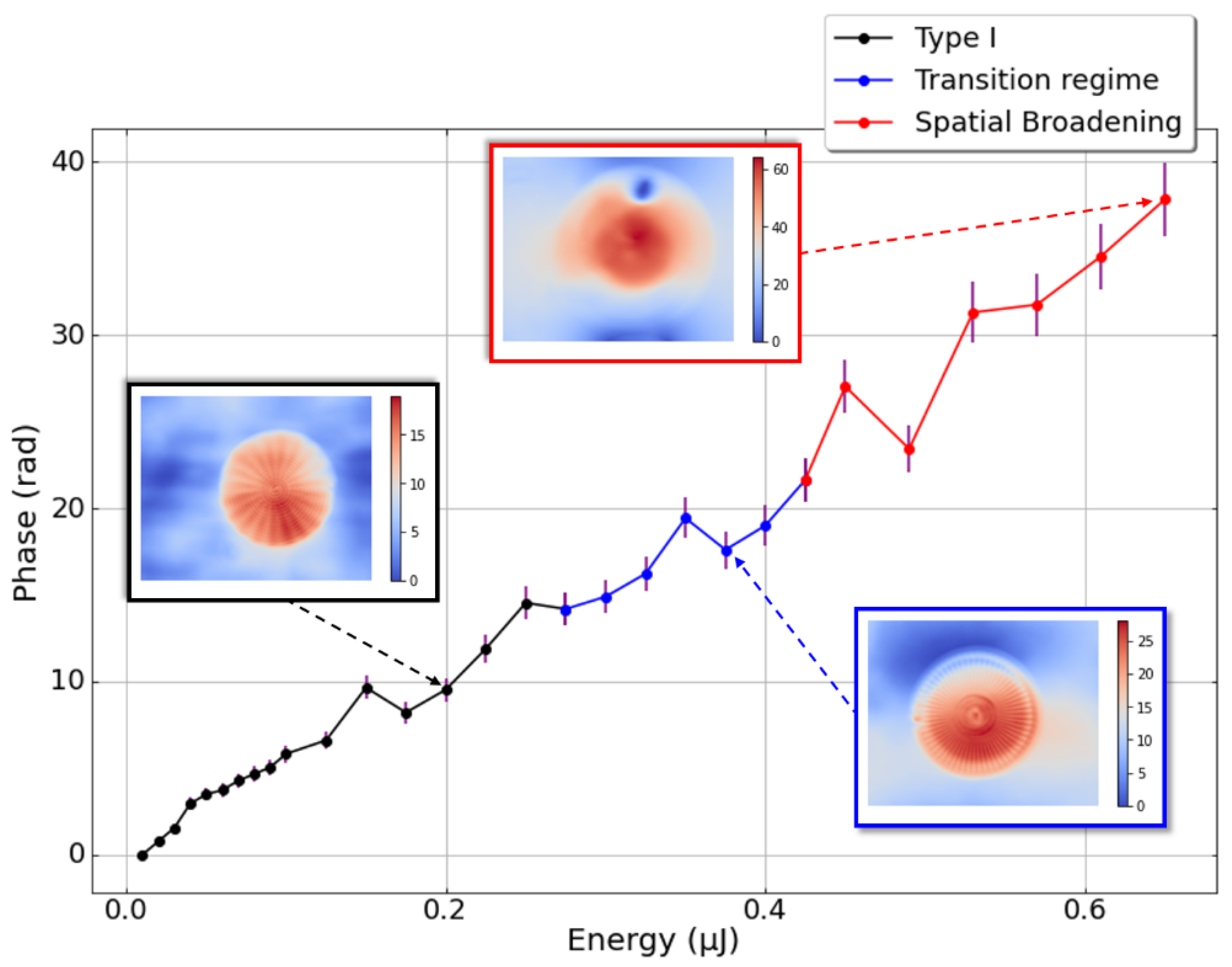

3.3. Phase Variation with Laser Energy and Writing Speed

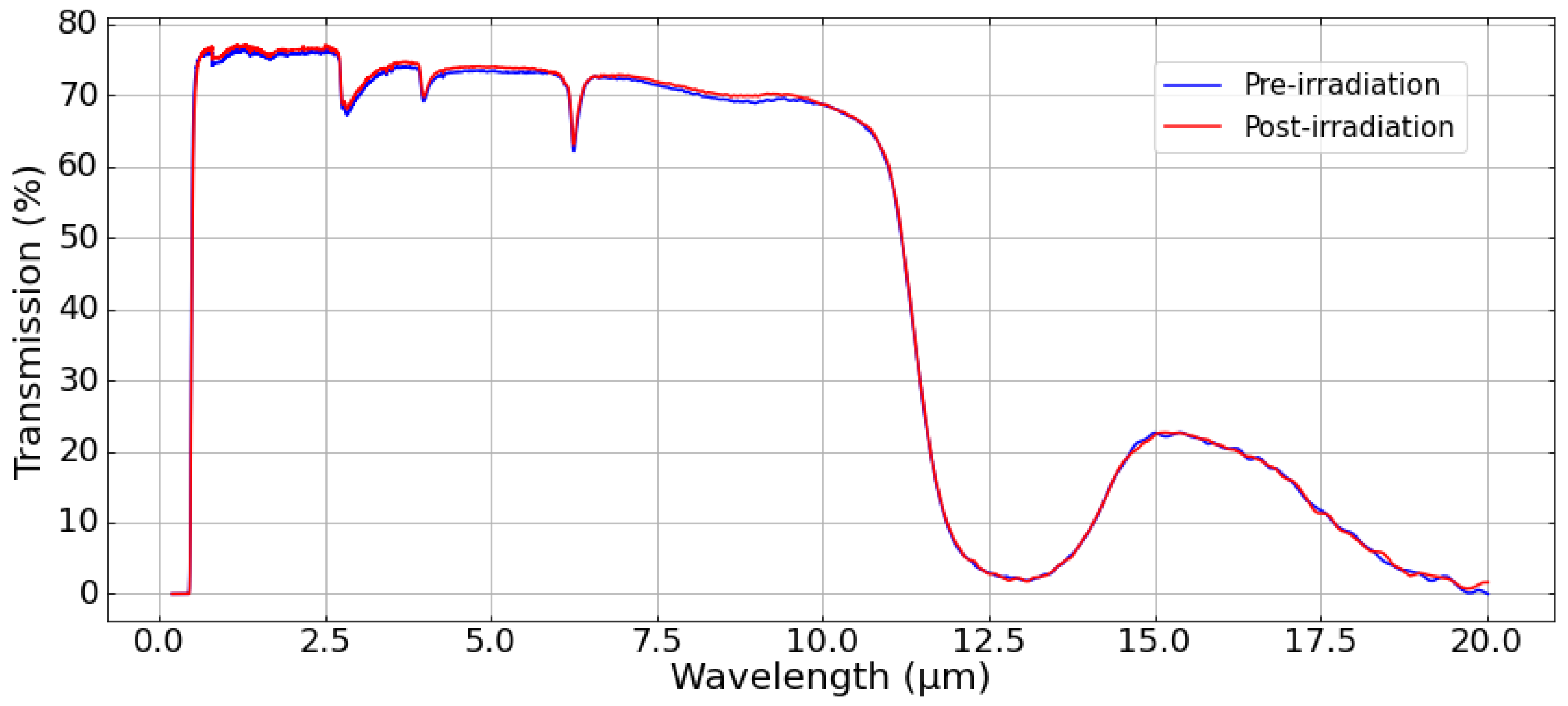

3.4. Optical Losses Pre- and Post-Irradiation

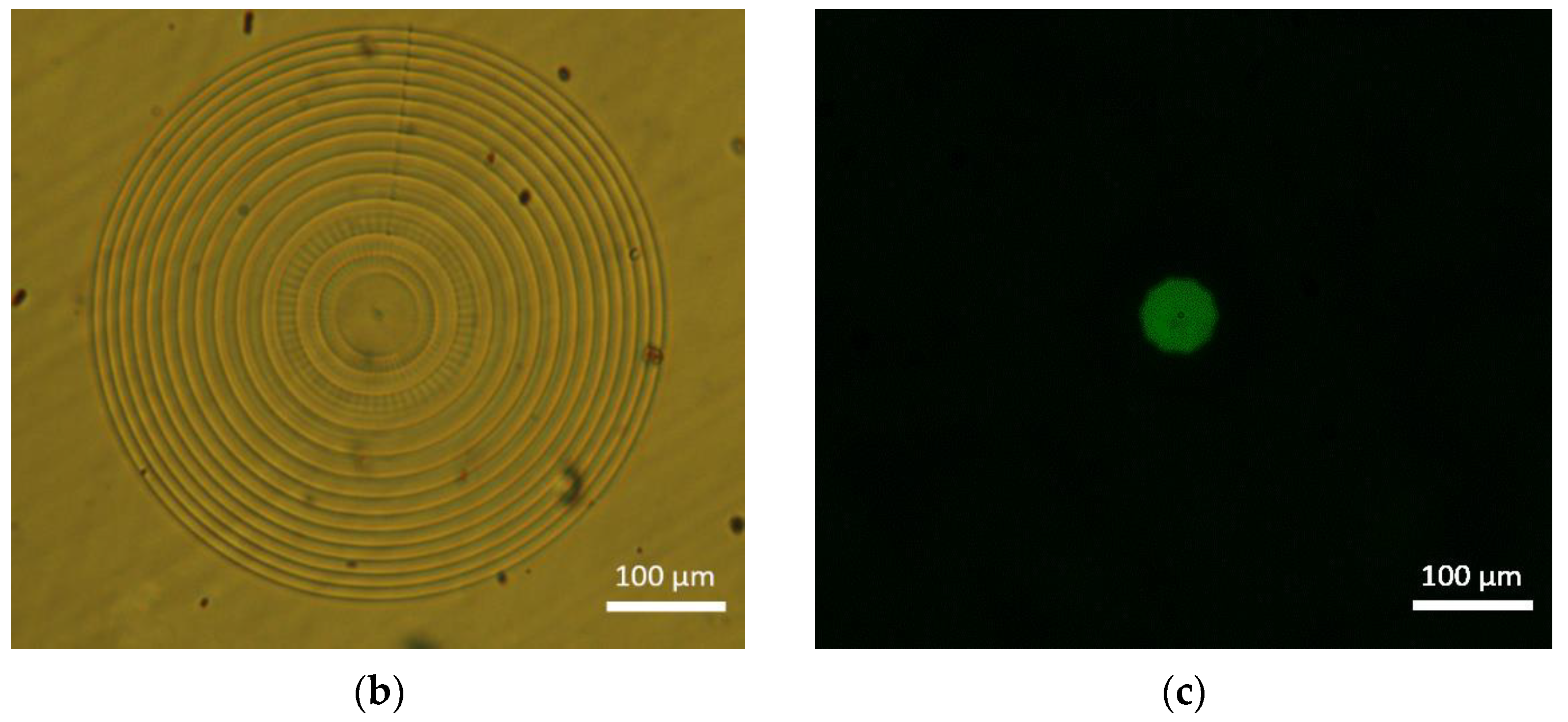

4. Fabrication and Characterization of a Fresnel GRIN Plate

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rolland, J.P.; Davies, M.A.; Suleski, T.J.; Evans, C.; Bauer, A.; Lambropoulos, J.C.; Falaggis, K. Freeform Optics for Imaging. Optica 2021, 8, 161. [Google Scholar] [CrossRef]

- Lippman, D.H.; Kochan, N.S.; Yang, T.; Schmidt, G.R.; Bentley, J.L.; Moore, D.T. Freeform Gradient-Index Media: A New Frontier in Freeform Optics. Opt. Express 2021, 29, 36997. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Bandyopadhyay, S.; Liu, Y.; Shao, L. A Review on Metasurface: From Principle to Smart Metadevices. Front. Phys. 2021, 8, 586087. [Google Scholar] [CrossRef]

- Manhart, P.K. Fundamentals of Macro Axial Gradient Index Optical Design and Engineering. Opt. Eng. 1997, 36, 1607. [Google Scholar] [CrossRef]

- Gibson, D.; Bayya, S.; Nguyen, V.; Sanghera, J.; Beadie, G.; Kotov, M.; McClain, C.; Vizgaitis, J. Multispectral IR Optics and GRIN. In Advanced Optics for Imaging Applications: UV through LWIR IV; Marasco, P.L., Sanghera, J.S., Vizgaitis, J.N., Eds.; SPIE: Baltimore, MD, USA, 2019; p. 12. [Google Scholar]

- Gibson, D.; Bayya, S.; Nguyen, V.; Myers, J.; Fleet, E.; Sanghera, J.; Vizgaitis, J.; Deegan, J.; Beadie, G. Diffusion-Based Gradient Index Optics for Infrared Imaging. Opt. Eng. 2020, 59, 1. [Google Scholar] [CrossRef]

- Corsetti, J.A.; McCarthy, P.; Moore, D.T. Color Correction in the Infrared Using Gradient-Index Materials. Opt. Eng. 2013, 52, 112109. [Google Scholar] [CrossRef]

- Bowen, J.P.; Caldwell, J.B.; Gardner, L.R.; Haun, N.; Houk, M.T.; Kindred, D.S.; Moore, D.T.; Shiba, M.; Wang, D.Y.H. Radial Gradient-Index Eyepiece Design. Appl. Opt. 1988, 27, 3170. [Google Scholar] [CrossRef]

- Boyd, A.M. Optical Design of Athermal, Multispectral, Radial Gradient-Index Lenses. Opt. Eng. 2018, 57, 1. [Google Scholar] [CrossRef]

- Richardson, K.A.; Kang, M.; Sisken, L.; Yadav, A.; Novak, S.; Lepicard, A.; Martin, I.; Francois-Saint-Cyr, H.; Schwarz, C.M.; Mayer, T.S.; et al. Advances in Infrared Gradient Refractive Index (GRIN) Materials: A Review. Opt. Eng. 2020, 59, 1. [Google Scholar] [CrossRef]

- Lavanant, E.; Calvez, L.; Cheviré, F.; Rozé, M.; Hingant, T.; Proux, R.; Guimond, Y.; Zhang, X.-H. Radial Gradient Refractive Index (GRIN) Infrared Lens Based on Spatially Resolved Crystallization of Chalcogenide Glass. Opt. Mater. Express 2020, 10, 860. [Google Scholar] [CrossRef]

- Ji, S.; Yin, K.; Mackey, M.; Brister, A.; Ponting, M.; Baer, E. Polymeric Nanolayered Gradient Refractive Index Lenses: Technology Review and Introduction of Spherical Gradient Refractive Index Ball Lenses. Opt. Eng. 2013, 52, 112105. [Google Scholar] [CrossRef]

- Arriola, A.; Gross, S.; Ams, M.; Gretzinger, T.; Le Coq, D.; Wang, R.P.; Ebendorff-Heidepriem, H.; Sanghera, J.; Bayya, S.; Shaw, L.B.; et al. Mid-Infrared Astrophotonics: Study of Ultrafast Laser Induced Index Change in Compatible Materials. Opt. Mater. Express 2017, 7, 698. [Google Scholar] [CrossRef]

- Musgraves, J.D.; Richardson, K.; Jain, H. Laser-Induced Structural Modification, Its Mechanisms, and Applications in Glassy Optical Materials. Opt. Mater. Express 2011, 1, 921. [Google Scholar] [CrossRef]

- Davis, K.M.; Miura, K.; Sugimoto, N.; Hirao, K. Writing Waveguides in Glass with a Femtosecond Laser. Opt. Lett. 1996, 21, 1729. [Google Scholar] [CrossRef] [PubMed]

- Yamada, K.; Watanabe, W.; Li, Y.; Itoh, K.; Nishii, J. Multilevel Phase-Type Diffractive Lenses in Silica Glass Induced by Filamentation of Femtosecond Laser Pulses. Opt. Lett. 2004, 29, 1846. [Google Scholar] [CrossRef]

- Drevinskas, R.; Beresna, M.; Gecevičius, M.; Khenkin, M.; Kazanskii, A.G.; Matulaitienė, I.; Niaura, G.; Konkov, O.I.; Terukov, E.I.; Svirko, Y.P.; et al. Giant Birefringence and Dichroism Induced by Ultrafast Laser Pulses in Hydrogenated Amorphous Silicon. Appl. Phys. Lett. 2015, 106, 171106. [Google Scholar] [CrossRef]

- Gandara-Montano, G.A.; Ivansky, A.; Savage, D.E.; Ellis, J.D.; Knox, W.H. Femtosecond Laser Writing of Freeform Gradient Index Microlenses in Hydrogel-Based Contact Lenses. Opt. Mater. Express 2015, 5, 2257. [Google Scholar] [CrossRef]

- Roux, F.S. Geometric Phase Lens. J. Opt. Soc. Am. A 2006, 23, 476. [Google Scholar] [CrossRef]

- Eaton, S.M.; Ng, M.L.; Osellame, R.; Herman, P.R. High Refractive Index Contrast in Fused Silica Waveguides by Tightly Focused, High-Repetition Rate Femtosecond Laser. J. Non-Cryst. Solids 2011, 357, 2387–2391. [Google Scholar] [CrossRef]

- Khalid, M.; Chen, G.Y.; Ebendorff-Heidepreim, H.; Lancaster, D.G. Femtosecond Laser Induced Low Propagation Loss Waveguides in a Lead-Germanate Glass for Efficient Lasing in near to Mid-IR. Sci. Rep. 2021, 11, 10742. [Google Scholar] [CrossRef]

- Morris, J.M.; Demetriou, G.; Lancaster, A.; Kar, A.K.; Bookey, H.T. 3D Optical Waveguides in Ge22As20Se58 Glass—A Highly Nonlinear Material for the Mid-IR. In Conference on Lasers and Electro-Optics; OSA Technical Digest (online) (Optica Publishing Group): San Jose, CA, USA, 2016; p. JTh2A.82. [Google Scholar] [CrossRef]

- Bérubé, J.P.; Messaddeq, S.H.; Bernier, M.; Skripachev, I.; Messaddeq, Y.; Vallée, R. Tailoring the Refractive Index of Ge-S Based Glass for 3D Embedded Waveguides Operating in the Mid-IR Region. Opt. Express 2014, 22, 26103. [Google Scholar] [CrossRef] [PubMed]

- Gross, S.; Jovanovic, N.; Sharp, A.; Ireland, M.; Lawrence, J.; Withford, M.J. Low Loss Mid-Infrared ZBLAN Waveguides for Future Astronomical Applications. Opt. Express 2015, 23, 7946. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.; Zaiter, R.; Cavillon, M.; Sapaly, B.; Calzavara, F.; Delullier, P.; Cardinal, T.; Dai, Y.; Poumellec, B.; Lancry, M. Photosensitivity of Barium Germano-Gallate Glasses under Femtosecond Laser Direct Writing for Mid-IR Applications. Ceram. Int. 2021, 47, 34235–34241. [Google Scholar] [CrossRef]

- Delullier, P.; Druart, G.; de la Barrière, F.; Calvez, L.; Lancry, M. Femtosecond Laser Direct Writing of a Fresnel Zone Plate in Glasses for Mid-Infrared Imaging Applications. In SPIE Optifab 2021; DeGroote Nelson, J., Unger, B.L., Eds.; SPIE: Rochester, NY, USA, 2021; p. 36. [Google Scholar]

- Druart, G.; de la Barriere, F.; Guérineau, N.; Deschamps, J.; Fendler, M.; Lhermet, N.; Rulliere, J.; Magli, S.; Reibel, Y.; Moullec, J.-B. Towards Infrared DDCA with an Imaging Function. In SPIE Defense, Security, and Sensing 2011; Andresen, B.F., Fulop, G.F., Norton, P.R., Eds.; SPIE: Orlando, FL, USA, 2011; p. 801228. [Google Scholar]

- Druart, G.; Foucher, P.-Y.; Doz, S.; Watremez, X.; Jourdan, S.; Vanneau, E.; Pinot, H. Test of SIMAGAZ: A LWIR Cryogenic Multispectral Infrared Camera for Methane Gas Leak Detection and Quantification. In Algorithms, Technologies, and Applications for Multispectral and Hyperspectral Imaging XXVII; Messinger, D.W., Velez-Reyes, M., Eds.; SPIE: Bellingham, WA, USA, 2021; p. 9. [Google Scholar]

- De la Barrière, F.; Druart, G.; Guérineau, N.; Champagnat, F.; Plyer, A.; Lasfargues, G.; Magli, S. Compact Multichannel Infrared Camera Integrated in an Operational Detector Dewar Cooler Assembly. Appl. Opt. 2018, 57, 4761. [Google Scholar] [CrossRef] [PubMed]

- Druart, G.; Guérineau, N.; Haïdar, R.; Thétas, S.; Taboury, J.; Rommeluère, S.; Primot, J.; Fendler, M. Demonstration of an Infrared Microcamera Inspired by Xenos Peckii Vision. Appl. Opt. 2009, 48, 3368. [Google Scholar] [CrossRef]

- Marchand, E.W. Gradient Index Optics; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Zoubir, A.; Richardson, M.; Rivero, C.; Schulte, A.; Lopez, C.; Richardson, K.; Hô, N.; Vallée, R. Direct Femtosecond Laser Writing of Waveguides in As_2S_3 Thin Films. Opt. Lett. 2004, 29, 748. [Google Scholar] [CrossRef]

- Grulois, T.; Druart, G.; Guérineau, N.; Crastes, A.; Sauer, H.; Chavel, P. Extra-Thin Infrared Camera for Low-Cost Surveillance Applications. Opt. Lett. 2014, 39, 3169. [Google Scholar] [CrossRef]

- Grulois, T.; Druart, G.; Sauer, H.; Chambon, M.; Guérineau, N.; Magli, S.; Lasfargues, G.; Chavel, P. Reduction of Material Mass of Optical Component in Cryogenic Camera by Using High-Order Fresnel Lens on a Thin Germanium Substrate. Appl. Opt. 2015, 54, 6313. [Google Scholar] [CrossRef]

- Grulois, T. Etude de L’apport des Lentilles de Fresnel Pour la Vision. Ph.D. Thesis, Université Paris-Saclay, Orsay, France, 2015. [Google Scholar]

- Druart, G.; Barriere, F.D.L.; Guerineau, N. Optiques binaires et application à l’imagerie—Optiques focalisantes. Tech. De L’ingénieur 2019, 20. Available online: https://hal.archives-ouvertes.fr/hal-02172250/ (accessed on 20 March 2022). [CrossRef]

- Wang, Y.; Lancry, M.; Cavillon, M.; Poumellec, B. Lifetime Prediction of Nanogratings Inscribed by a Femtosecond Laser in Silica Glass. Opt. Lett. 2022, 47, 1242. [Google Scholar] [CrossRef]

- McMillen, B.; Zhang, B.; Chen, K.P.; Benayas, A.; Jaque, D. Ultrafast Laser Fabrication of Low-Loss Waveguides in Chalcogenide Glass with 0.65 DB/cm Loss. Opt. Lett. 2012, 37, 3. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Shimotsuma, Y.; Kazansky, P.G.; Qiu, J.; Hirao, K. Self-Organized Nanogratings in Glass Irradiated by Ultrashort Light Pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef] [PubMed]

- Glezer, E.N.; Milosavljevic, M.; Huang, L.; Finlay, R.J.; Her, T.-H.; Callan, J.P.; Mazur, E. Three-Dimensional Optical Storage inside Transparent Materials. Opt. Lett. 1996, 21, 2023. [Google Scholar] [CrossRef]

- Lapointe, J.; Li, M.-J.; Kashyap, R. High Quality Photonic Devices Directly Written in Gorilla Glass Using a Fs Laser. In Workshop on Specialty Optical Fibers and Their Applications; OSA: Sigtuna, Sweden, 2013; p. W3.38. [Google Scholar]

- Bélanger, E.; Bérubé, J.-P.; de Dorlodot, B.; Marquet, P.; Vallée, R. Comparative Study of Quantitative Phase Imaging Techniques for Refractometry of Optical Waveguides. Opt. Express 2018, 26, 17498. [Google Scholar] [CrossRef] [PubMed]

- Zuo, C.; Li, J.; Sun, J.; Fan, Y.; Zhang, J.; Lu, L.; Zhang, R.; Wang, B.; Huang, L.; Chen, Q. Transport of Intensity Equation: A Tutorial. Opt. Lasers Eng. 2020, 135, 106187. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delullier, P.; Druart, G.; De La Barrière, F.; Calvez, L.; Lancry, M. Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications. Appl. Sci. 2022, 12, 4490. https://doi.org/10.3390/app12094490

Delullier P, Druart G, De La Barrière F, Calvez L, Lancry M. Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications. Applied Sciences. 2022; 12(9):4490. https://doi.org/10.3390/app12094490

Chicago/Turabian StyleDelullier, Pierre, Guillaume Druart, Florence De La Barrière, Laurent Calvez, and Matthieu Lancry. 2022. "Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications" Applied Sciences 12, no. 9: 4490. https://doi.org/10.3390/app12094490

APA StyleDelullier, P., Druart, G., De La Barrière, F., Calvez, L., & Lancry, M. (2022). Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications. Applied Sciences, 12(9), 4490. https://doi.org/10.3390/app12094490