Abstract

The quarrying of marble and its processing to produce building materials often generates a negative impact on the environment. In the Apuan Alps marble district, a renowned quarrying area in Italy since ancient times, the aquatic pollution of water bodies, caused by the presence of marble waste in the form of powder or sludge, represents a significant and current environmental problem. Depending on the different national and international regulations on waste management, the marble waste can be classified as a special non-hazardous industrial waste. If marble waste has been managed according to environmental international and national laws, it can be reused as a by-product. For this, the present work aims to evaluate the reuse of marble waste as a material in replacement for cement for producing mortars. Subsequently, the mechanical and physical tests were carried out to evaluate the specific properties of the obtained materials during and after the curing time. The results showed that replacement of cement into mortars by marble waste always causes a decrease of mechanical properties, with still acceptable values for many applications up to a substitution of less than 25%. From the collected data, the use of marble waste in the production of cement mortars represents an adequate and sustainable destination of this by-product.

1. Introduction

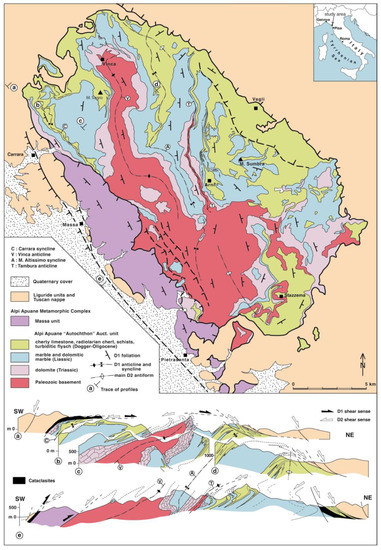

Since ancient times, marble has been one of the most used materials for construction and decorative purposes [1,2,3]. The marble industry is characterized by both high energy consumption, significant production of waste materials and environmental pollution due to gaseous and particulate emissions, dust, noise, and disturbance of natural habitats [4,5]. As reported by Founti et al. [6] for Greek marble, and particularly for the marble of the Island of Thassos, a building and ornamental material appreciated worldwide, the marble of high quality has been estimated only ca. 30% of the rock excavated, while a further 20–30% may be commercialized as a low-quality product and everything else is classified as a waste material and deposited in the quarries. To give a global overview of the environmental problem related to the extraction and cutting of marble, about 200 million tons of marble waste, coming from marble processing industries as waste powders or sludges, has been produced worldwide [7]. Therefore, proper management of marble wastes is necessary to protect the environment, including soil, water, and air, from a possible contamination [8,9]. Focusing on the Apuan Alps (Figure 1, marble and dolomitic marble), a quarrying marble area in Italy where the famous marble has been excavated since Roman times [10,11,12], the waste products resulting from the recent extraction and/or sawing of marble, commonly known as marmettola, are a worrying environmental problem (Figure 2) that should at least be reduced, if not eliminated. Generally, marble waste is a very fine white powder, in the case of dry cutting, or a sludge, in the case of wet cutting; the sludge is composed of water and very fine particles of rocks (often almost pure calcium carbonate) and, sometimes, traces of earth, oils and/or greases, used to lubricate/cool the cutting tools, hydrocarbons accidentally leaking from the cutting machines or traces of metal resulting from the wear of cutting tools.

Figure 1.

Geological sketch map of the Apuan Alps area (modified after Conti et al., 2004) [13].

Figure 2.

On the right (black arrow), the Carrione torrent turns whitish after a rain for the presence of marmettola, coming from the upstream quarrying area (Carrara, Italy); on the left, blue arrow indicates clear water coming from an area without quarries.

Depending on the different international and national environmental laws, the marble waste can be classified as an interesting by-product and it can be used in other production cycles [14,15,16,17,18,19,20,21,22,23,24,25,26]. If it is not usable as a by-product, marble powder or marble sludge becomes waste material and, therefore, must be treated according to local waste management laws [27]. In the Apuan Alps marble district, the marble waste produced by the quarrying and/or by the other processing activities amounts approximately to 200,000 t/year, and the pollution of water bodies caused by the presence of marble waste represents a current problem [28]. Generally speaking, there are three types of negative environmental effects on water bodies: (a) Biological effect: the marble waste causes body abrasion and occlusion of the gills of macroinvertebrates and a decrease in food availability due to reduced photosynthesis, because of the turbidity of water. Following the sedimentation of marble waste, carbonate material can be found on the riverbeds, which hinders colonization, buries the eggs and the life stages attached to the substrate, and destroys the variety of microenvironments; (b) Physical effect: marble waste increases the degree of turbidity of the river waters. Furthermore, marble waste sometimes becomes compact, waterproofing the riverbed and preventing the exchange with the aquifer; (c) Chemical effect: waterways, deprived of the biological populations responsible for their self-purifying power, also carry a large part of the organic pollutant load unaltered.

In addition to damaging surface and groundwater, the marmettola can also cause a negative environmental impact on the soil. The marble waste influences the morphology and the hydrology of the soil, reducing its porosity and permeability. Furthermore, soil fertility can become poor due to the increase in alkalinity caused by the presence of calcium carbonate [29]. As the marble industry is a growing sector, it is therefore necessary to find sustainable destinations for its waste to mitigate or eliminate pollution, transforming it into materials with an added economic value [30]. European Directive 2008/98/EC [31], implemented in Italy with Legislative Decree 205/2010 [32], has set the goal of achieving the recycling of 70% of construction materials since 2020. The development of technologies and research in this sector has made products deriving from recycling competitive with others, both from a technical and economic point of view [31,32,33,34,35,36]. In this context, the reuse of marble waste as a partial replacement of cement or aggregate in mortars can bring the double benefit of giving a new value to this by-product and, at the same time, partially eliminate the environmental problem caused by it, without a significant loss of mechanical properties of mortars [37,38,39,40,41,42,43,44,45,46,47]. The replacement of the cement with marble dust leads to a decrease in the mechanical characteristics, but not to the point of making them unusable for structural purposes. The comparison with mortars, where a pozzolanic material has been used, shows how these maintain if not improve the properties, thanks to the double action of filler, for the fineness of the powders used and for the chemical reactions that are triggered with the binder [48,49,50,51,52].

The main purpose of this research is to evaluate the effects of Apuan Alps marble waste as a cement replacement on the physical and mechanical properties of hardening mortars.

2. Experimental Procedures

2.1. Materials

To produce the specimens used in this work, Portland cement 52.5 grade, normalized sand, Apuan Alps white-marble powder, demineralized water, and superplasticizer additive were mixed in opportune proportions (Table 1).

Table 1.

List of materials used for making the specimens analyzed in this work.

2.2. Mortar Mixes

Seven mortar samples (two control mortar-MS and -0MS, respectively with and without superplasticizer, and five different mortar mixtures), with nine specimens for each sample, were produced according to the EN 196-1 [53].

The mortar mixtures were placed in standard specimen holders, each of them composed of three molds of 40 mm × 40 mm × 160 mm.

The control mortar sample with superplasticizer (MS) was produced with the recommended ratio among all the components of the mixture, and a control mortar sample without superplasticizer (0 MS) was produced to consider the effect of not adding it in mortar mixture, as reported in Table 2.

Table 2.

Composition of control mortar samples with and without superplasticizer.

The five different mortar mixtures were produced by replacing a portion of cement with marble powder (M5, M10, M15, M20, M25), without exceeding 25 wt.%, as reported in Table 3.

Table 3.

Mortar mixture compositions.

2.3. Methods

The determination of major and minor chemical components (Na2O, MgO, Al2O3, SiO2, P2O5, K2O, CaO, TiO2, MnO, Fe2O3) was performed by X-ray fluorescence analysis, according to the procedure suggested by Franzini et al. [54], and considering the measurement accuracies as reported in Lezzerini et al. [55]. Loss on ignition (LOI) was determined as mass loss in the temperature range 20–950 °C.

The qualitative mineralogical compositions of the samples were obtained by X-ray powder-diffraction (XRPD), using a Bragg–Brentano geometry and Ni-filtered CuKα radiation, obtained at 40 kV and 20 mA.

Simultaneous Thermogravimetric/Differential scanning calorimetry analysis (TG/DSC) was used to measure the total volatile components in the marble-powder samples. TG/DSC was obtained on about 25 mg of sample, using a thermal analyzer Netzsch 449 C Jupiter in the following experimental conditions: open alumina crucibles, heating rate of 10 °C/min, and 30 mL/min nitrogen gas flow.

The particle size distributions of selected materials were determined by dry sieve analysis, according to EN 933-1 [56] and EN 933-2 [57].

The water absorption coefficient by capillarity and the amount of water absorbed by total immersion were determined after 28 days of curing on 40 mm × 40 mm × 80 mm parallelepiped specimens, following the procedures reported in the EN 15801 [58] and EN 13755 [59], respectively. The apparent density was determined in accordance with the EN 1015-10 [60] after 28 days of curing. The volume of each specimen was measured by using a hydrostatic balance, and the accuracy of volume determinations was better than 0.02% by vol. for specimens larger than 30 cm3 [61].

Uniaxial compressive strength tests were performed using a Tecnotest KL 300/CE press following the EN 1015-11 [62]. Tests were carried out at 2, 7 and 28 days of curing. Determination of the propagation speed of ultrasonic pulses was carried out on samples at 28 days of curing. The ultrasonic pulses velocity was measured by a Proceq Pundit PL-200 instrument, using the transmission technique, in accordance with EN 12504-4 [63].

3. Results and Discussion

3.1. Physical and Chemical Characteristics of the Selected Materials

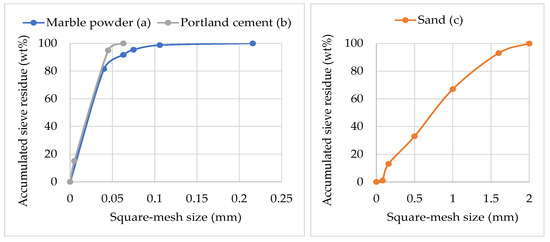

The powder of Apuan Alps white marble, the Portland cement, and the normalized sand are characterized by different particle-size distribution. As shown in Figure 3, Portland cement and marble powder are finer than the normalized sand.

Figure 3.

Particle-size distribution of (a) Marble powder, (b) Portland cement, and (c) Normalized sand, according to EN 196-1 [53].

Before mixing, marble powder was dried at room temperature for 48 h. Chemical composition and specific gravity of the mortar components were examined before mixing (Table 4).

Table 4.

Chemical compositions (wt.%) and specific gravity of the selected materials used in the production of the specimens.

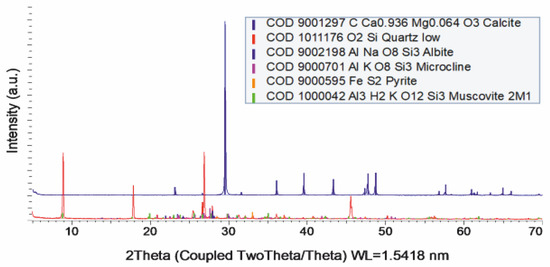

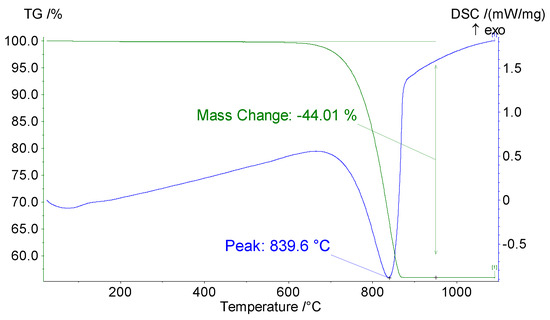

In Figure 4 and Figure 5, XRPD and TG/DSC analyses of white marble powder (M) are shown. The crystalline phases identified through XRPD are essentially calcite, and traces of quartz, feldspars, and phyllosilicates for the total sample, and muscovite, quartz, K-feldspar, plagioclase, and pyrite for the insoluble residue (R), which amount to less than 0.2 wt.% of the total sample. TG/DSC analysis confirms that the analyzed marble powder is a calcite-rich material (loss on ignition = 44.01 wt.% in the range 105–950 °C).

Figure 4.

XRPD of both white marble powder (M, blue line) and residue insoluble to acid attack (R, red line).

Figure 5.

Thermogravimetry (TG, green line) and differential scanning calorimetry (DSC, blue line) of marble powder (M).

3.2. Mechanical Properties of Mortars

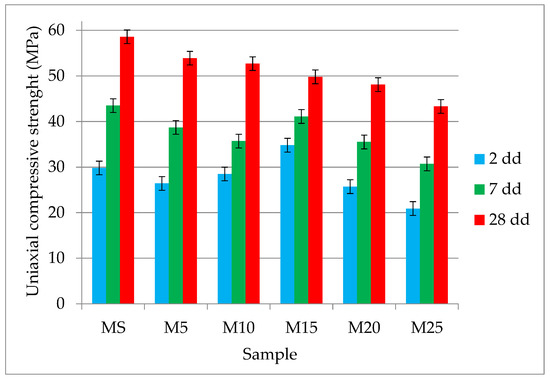

The mechanical properties of the mortar specimens were determined by uniaxial compressive strength tests. Table 5 and Figure 6 show the uniaxial compressive strengths of the mortar specimens 0MS, MS, M5, M10, M15, M20 and M25 mixtures at 2, 7, and 28 days of curing. The mean of the standard deviations of the compressive strength was equal to 2.0 MPa.

Table 5.

Compressive strength of the specimens 0MS, MS, M5, M10, M15, M20, and M25 mixtures, at 2, 7, and 28 days of curing.

Figure 6.

Compressive strength histogram of the specimens MS, M5, M10, M15, M20, and M25 mixtures at 2, 7, and 28 days of curing.

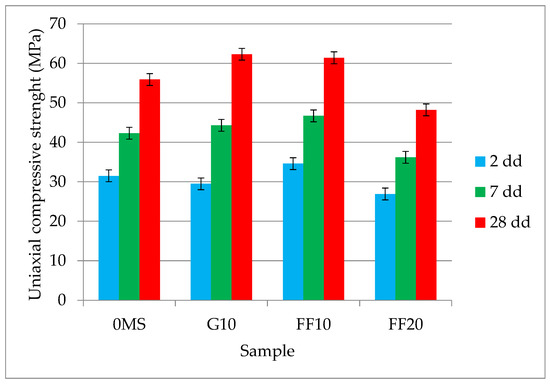

In Figure 7, the uniaxial compressive strengths measured on 0MS mortar sample are compared with those obtained on mortars made by using pozzolanic materials (G = garnet; FF = diatomaceous earth) instead of marble powder. The number of the alphanumeric abbreviation indicates the percentage of cement replacement.

Figure 7.

Compressive strength histogram of the specimens of the 0MS, G10, G20, FF10, FF20 at 2, 7, and 28 days of curing.

The comparison with mortars containing garnets and diatomaceous earth is useful to demonstrate that substitution of cement in increasing percentages does not necessarily lead to a decrease in the mechanical properties of the mortar. This is true if the aggregate is made up of a substantially inert material (marmettola), the addition of which inevitably leads to a decrease of the physical–mechanical properties.

Regarding the addition of pozzolanic materials (G and FF) that can react with the binder, it leads to an increase of the uniaxial compressive strength for relative low cement replacement (10 wt.%), and the maintenance of the physical–mechanical properties up to quite high substitution levels (about 20 wt.%).

The use of pozzolanic materials in manufacturing mortars and their hydraulic effects are well known since ancient times, and several examples can be found in the literature, in which different pozzolanic materials are used to make mortars with high mechanical strength [50,51,62,63,64,65,66,67,68,69,70].

At 2 days of curing, the values of the compressive strengths of the specimens of both the reference mixture (MS) and the specimens of the mixture made without the superplasticizer additive MasterGlenium SKY 698 (0MS) are quite similar, 29.8 MPa in respect to 31.5 MPa. Even after 7 days of curing, very similar compressive strength values are observed, 43.5 MPa in the reference mixture (MS) and 42.3 MPa in the mixture made without additive (0MS), respectively. At 28 days of curing, the compressive strength of the specimens of the MS reference mixture is 58.6 MPa, while that of the mixture made without additive (0MS) is 55.9 MPa. Considering the standard deviation value of 1.5 MPa, no significant differences are observed in the uniaxial compressive strength of the specimens MS and 0MS at 2, 7, and 28 days of curing. This result indicates that the superplasticizer additive MasterGlenium SKY 698 does not change the mechanical properties of the samples.

At 28 days of curing, the highest values of compressive strength were measured on specimens of the reference mixture (MS, 58.6 MPa), while the lowest values were found in the mixture containing 25 wt.% of marble powder (M25, 43.3 MPa) as cement replacement. From the data reported in Table 5, it can be observed that, at 28 days of curing, there is a decrease in compressive strength due to the increase in the percentage of marble powder used to replace the cement. The mechanical resistances of the specimens of the mixtures containing 5% (M5) and 10% of marble powder (M10) are quite similar, respectively 53.9 MPa and 52.7 MPa, as well as those of the mixtures made with 15% (M15) and 20% (M20) of marble powder, respectively 49.8 MPa and 48.1 MPa. It is also interesting to note that the uniaxial compressive strength (σ) vs. cement replacement (r) with marble powder can be explained by the following inverse linear relationship:

σ = −0.5531·r + 57.981, R2 = 0.97.

Vardan et al. [33] and Li et al. [21], by using Portland cement 42.5 grade, obtained at 28 days a decrease in the compressive strength values with the increase of replacement percentage of cement. The trend of the compressive strength versus the percentage of marble powder replacing cement observed by analyzing the data of this study is quite like that obtained by Li et al. [21], but differs substantially from the values obtained by Vardan et al. [33] that, for example, by replacing 20% by weight of the cement with marble powder, achieved a 5% decrease in resistance compared to the reference samples, while in this study and in that one conducted by Li et al. [21] the decrease in mechanical resistances was 18% and 20%, respectively.

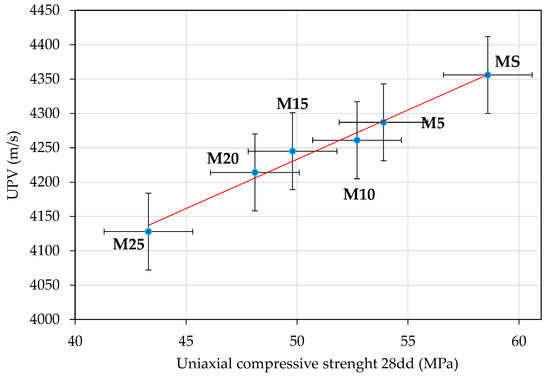

Table 6 shows the propagation speed of the ultrasonic pulse (UPV—Ultrasonic Pulse Velocity) measured on the mortar samples of the MS, M5, MP10, M15, M20, and M25 mortar mixtures at 28 days of curing. The mean of the standard deviations of the ultrasonic pulse propagation speed is 56 m/s.

Table 6.

Ultrasonic pulse velocity of the specimens MS, M5, M10, M15, M20, and M25 at 28 days of curing.

Figure 8 shows the uniaxial compressive strengths and the UPVs of the mortar specimens for MS, M5, M10, M15, M20, and M25 mortar mixtures at 28 days of curing. From the graph, it is possible to observe that the UPV linearly decreases as the mechanical compressive strength of the specimens decreases (it decreases as the percentage of replacement of cement with marble powder M increases). The best equation describing the relationship between UPV and compressive strength is:

UPV (m/s) = 14.344·σc (MPa) + 3516, R2 = 0.98.

Figure 8.

Compressive strength vs. ultrasonic pulse velocity (UPV) of the MS, M5, M10, M15, M20, and M25 mortar mixtures at 28 days of curing.

Table 7 reports the apparent density, the water absorption coefficient by capillarity, the water absorption by total immersion referred to weight and to volume, measured on the mortar specimens of the MS, M5, M10, M15, M20, and M25 mortar mixtures at 28 days of curing.

Table 7.

Apparent density, water absorption coefficient by capillarity, water absorption by total immersion referred to the weight and to the volume, measured in the MS, M5, M10, M15, M20, and M25 mortar mixtures at 28 days of curing.

The average of the standard deviations of apparent density, water absorption coefficient by capillarity, water absorption by total immersion referred to the weight, and to the volume, are 0.02 g/cm3, 1.2 g/m2 s0.5, 0.2 wt.% and 0.5% by volume, respectively.

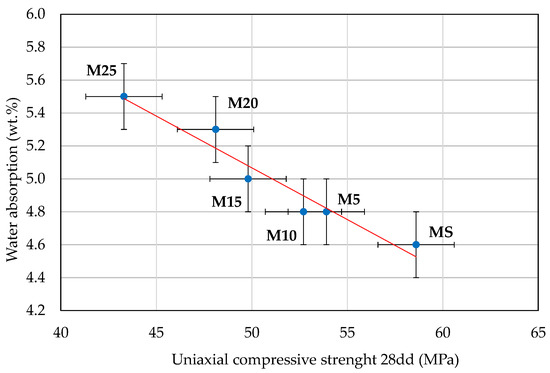

The highest apparent density value is that relating to specimens made with 5% marble powder (M5, 2.19 g/cm3), while the lowest value is relative to specimens made with 25% marble powder (M25, 2.13 g/cm3).

The highest value of the water absorption coefficient by capillarity is that measured on specimens made with cement replacement of 25% marble powder (M25, 18 g/m2 s0.5), while the lowest is that relating to mortar mixture made with 5% marble powder (M5, 13 g/m2 s0.5).

The values of water absorption by total immersion referred to the weight and to the volume were higher for the specimens of the M25 mixture, respectively 5.5% by weight and 11.8% by volume, while the lowest ones were those measured on the reference mixture, respectively 4.6% by weight and 10% by volume.

Figure 9 shows the uniaxial compressive strengths vs. the water absorption by total immersion referred to weight of the mortar specimens MS, M5, M10, M15, M20, and M25 at 28 days of curing.

Figure 9.

Uniaxial compressive strength vs. water absorption by total immersion referred to weight of the MS, M5, M10, M15, M20, and M25 mortar mixtures at 28 days of curing.

From the graph, it is possible to observe that the water absorption by total immersion referred to the weight decreases as the uniaxial compressive strength of the specimens increases (it increases with the increase in the percentage of cement replacement with marble powder).

The best equation describing the relationship between uniaxial compressive strength and water absorption by total immersion referred to the weight is as follows:

Water absorption (wt.%) = −0.0628·σc (MPa) + 8.208, R2 = 0.94.

4. Conclusions

In the production of mortars, marble waste can be used to replace the cement in various proportions. The collected data on mortar mixtures made by replacing 5%, 10%, 15%, 20%, and 25% of cement with a fine marble waste powder at 28 days of curing shows a reduction in the uniaxial compressive strength values compared to those of reference mortars, characterized by a reference value of 59 MPa. As shown by the comparison with mortars produced by partially replacing the cement with garnet and diatomaceous earth, the gradual decrease in mechanical properties by replacing the binder with marble powder is due to lower grain size than sand, but without pozzolanic activity. Marble powder used in this work is a material that could fill a few percent by volume of aggregate porosity, and by not reacting with the binding material, will inevitably lead to a decrease in the technical properties of the hardened product.

In conclusion, the mortar cement replacement with marmettola gives interesting results for waste recycling. For example, by replacing up to 25% of cement with fine marble waste, mortars with uniaxial compressive strength slightly higher than 43 MPa were obtained, which could also be used for structural purposes. Further studies should be conducted in the future to identify new sustainable destinations for this waste material and to reduce environmental pollution.

Author Contributions

Conceptualization, M.L. and L.L.; methodology, L.L. and S.P.; investigation, L.L. and G.G.; resources, M.L.; data curation, M.L., L.L., G.G., A.A. and S.P.; writing—original draft preparation, A.A.; writing—review and editing, S.P., G.G. and M.L.; visualization, S.P.; supervision, M.L.; project administration, M.L.; funding acquisition, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was supported by LABECA (Cultural and Environmental Heritage Lab.), University of Pisa (Italy).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Authors are grateful to Ing. Michele Romano and to Marcello Spampinato for their help in mortar sample preparation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Herz, N.; Waelkens, M. Classical Marble: Geochemistry, Technology, Trade; Brill Archive: Leiden, The Netherlands, 1988; Volume 153. [Google Scholar]

- Greenhalgh, M. Marble Past, Monumental Present: Building with Antiquities in the Mediaeval Mediterranean; Brill: Leiden, The Netherlands, 2009; Volume 80. [Google Scholar]

- Attanasio, D.; Platania, R.; Rocchi, P. The marble of the David of Michelangelo: A multi-method analysis of provenance. J. Archaeol. Sci. 2005, 32, 1369–1377. [Google Scholar] [CrossRef]

- Gazi, A.; Skevis, G.; Founti, M.A. Energy efficiency and environmental assessment of a typical marble quarry and processing plant. J. Clean. Prod. 2012, 32, 10–21. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Founti, M.A.; Giannopoulos, D.; Laskaridis, K. Environmental management aspects for energy saving in natural stone quarries. In Proceedings of the Global Stone Congress, Alicante, Spain, 2–5 March 2010. [Google Scholar]

- Montani, C. XXVII World Marble and Stones Report 2016; Aldus: Carrara, Italy, 2016. [Google Scholar]

- Giusti, L. A review of waste management practices and their impact on human health. Waste Manag. 2009, 29, 2227–2239. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Auda, E.M. Re-use of waste marble dust in the production of cement and concrete. Constr. Build. Mater. 2014, 50, 28–41. [Google Scholar] [CrossRef]

- Cantisani, E.; Fratini, F.; Malesani, P.; Molli, G. Mineralogical and petrophysical characterisation of white Apuan marble. Period. Mineral. 2005, 74, 117–138. [Google Scholar]

- Franzini, M.; Lezzerini, M. The Triassic marble from the Punta Bianca promontory (La Spezia, Italy). Did Romen quarrying of ‘lunensis marble’ begin here? Period. Mineral. 2002, 71, 137–144. [Google Scholar]

- Lezzerini, M.; di Battistini, G.; Zucchi, D.; Miriello, D. Provenance and compositional analysis of marbles from the medieval Abbey of San Caprasio, Aulla (Tuscany, Italy). Appl. Phys. A Mater. Sci. Process. 2012, 108, 475–485. [Google Scholar] [CrossRef]

- Conti, P.; Carmignani, L.; Giglia, G.; Meccheri, M.; Fantozzi, P.L. Evolution of geological interpretations in the Alpi Apuane Metamorphic Complex, and their relevance for the geology of the Northern Apennines. In The Regione Toscana Project of Geological Mapping; Morini, D., Bruni, P., Eds.; Regione Toscana-Servizio Geologica Regionale: Firenze, Italy, 2004; pp. 241–262. [Google Scholar]

- Demirel, B. The effect of the using waste marble dust as fine sand on the mechanical properties of the concrete. Int. J. Phys. Sci. 2010, 5, 1372–1380. [Google Scholar]

- Bilgin, N.; Yeprem, H.A.; Arslan, S.; Bilgin, A.; Günay, E.; Marşoglu, M. Use of waste marble powder in brick industry. Constr. Build. Mater. 2012, 29, 449–457. [Google Scholar] [CrossRef]

- Talah, A.; Kharchi, F.; Chaid, R. Influence of marble powder on high performance concrete behavior. Procedia Eng. 2015, 114, 685–690. [Google Scholar] [CrossRef] [Green Version]

- Sadek, D.M.; El-Attar, M.M.; Ali, H.A. Reusing of marble and granite powders in self-compacting concrete for sustainable development. J. Clean. Prod. 2016, 121, 19–32. [Google Scholar] [CrossRef]

- Li, L.G.; Huang, Z.H.; Tan, Y.P.; Kwan, A.K.H.; Liu, F. Use of marble dust as paste replacement for recycling waste and improving durability and dimensional stability of mortar. Constr. Build. Mater. 2018, 166, 423–432. [Google Scholar] [CrossRef]

- Ashish, D.K. Concrete made with waste marble powder and supplementary cementitious material for sustainable development. J. Clean. Prod. 2019, 211, 716–729. [Google Scholar] [CrossRef]

- Singh, M.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Bhunia, D. A study on environmental and economic impacts of using waste marble powder in concrete. J. Build. Eng. 2017, 13, 87–95. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Żak, A.; Ostrowski, K. The utilization of waste marble dust as a cement replacement in air-cured mortar. Sustainability 2019, 11, 2215. [Google Scholar] [CrossRef] [Green Version]

- Garbarino, E.; Orveillon, G.; Saveyn, H.G.M. Management of waste from extractive industries: The new European reference document on the Best Available Techniques. Resour. Policy 2020, 69, 101782. [Google Scholar] [CrossRef]

- Ma, B.; Wang, J.; Tan, H.; Li, X.; Cai, L.; Zhou, Y.; Chu, Z. Utilization of waste marble powder in cement-based materials by incorporating nano silica. Constr. Build. Mater. 2019, 211, 139–149. [Google Scholar] [CrossRef]

- Sufian, M.; Ullah, S.; Ostrowski, K.A.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A.A. An experimental and empirical study on the use of waste marble powder in construction material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef]

- Nayak, S.K.; Satapathy, A.; Mantry, S. Use of waste marble and granite dust in structural applications: A review. J. Build. Eng. 2022, 46, 103742. [Google Scholar] [CrossRef]

- Benjeddou, O.; Alyousef, R.; Mohammadhosseini, H.; Soussi, C.; Khadimallah, M.A.; Alabduljabbar, H.; Tahir, M.M. Utilisation of waste marble powder as low-cost cementing materials in the production of mortar. J. Build. Eng. 2020, 32, 101642. [Google Scholar] [CrossRef]

- Passarini, F.; Vassura, I.; Monti, F.; Morselli, L.; Villani, B. Indicators of waste management efficiency related to different territorial conditions. Waste Manag. 2011, 31, 785–792. [Google Scholar] [CrossRef] [PubMed]

- Drysdale, R.; Pierotti, L.; Piccini, L.; Baldacci, F. Suspended sediments in karst spring waters near Massa (Tuscany), Italy. Environ. Geol. 2001, 40, 1037–1050. [Google Scholar]

- Rizzo, G.; D’Agostino, F.; Ercoli, L. Problems of soil and groundwater pollution in the disposal of ‘marble’ slurries in NW Sicily. Environ. Geol. 2008, 55, 929–935. [Google Scholar] [CrossRef]

- Demirel, B.; Alyamaç, K.E. Waste marble powder/dust. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 181–197. [Google Scholar]

- L:2008:312:TOC; Directive 2008/98/EC of the European Parliament and of the Council on Waste and Repealing Certain Directives. Official Journal of the European Union: Brussels, Belgum, 2008; pp. 3–30.

- Law 205; Legislative Decree No.105 of the 08 July 2010, Urgent Measures on Energy. Official Journal of the European Union: Brussels, Belgum, 2010; pp. 1–78.

- Vardhan, K.; Goyal, S.; Siddique, R.; Singh, M. Mechanical properties and microstructural analysis of cement mortar incorporating marble powder as partial replacement of cement. Constr. Build. Mater. 2015, 96, 615–621. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Drzymała, T.; Zegardło, B.; Tofilo, P. Properties of concrete containing recycled glass aggregates produced of exploded lighting materials. Materials 2020, 13, 226. [Google Scholar] [CrossRef] [Green Version]

- Tomasz, D.; Bartosz, Z.; Wioletta, J.-R.; Daniel, S. The effect of high temperatures on the flexural strength of cement mortar modified by the addition of polypropylene fibres. Saf. Fire Technol. 2018, 51, 26–39. [Google Scholar]

- Oza, R.B.; Kangda, M.Z.; Agrawal, M.R.; Vakharia, P.R.; Solanki, D.M. Marble dust as a binding material in concrete: A review. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Ruiz-Sánchez, A.; Sánchez-Polo, M.; Rozalen, M. Waste marble dust: An interesting residue to produce cement. Constr. Build. Mater. 2019, 224, 99–108. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Arel, H.Ş. Recyclability of waste marble in concrete production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K.; Kumar, R.; Sharma, N. Properties of concrete incorporating sand and cement with waste marble powder. Adv. Concr. Constr. 2016, 4, 145. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G.; Naik, T.R. Characterization of marble powder for its use in mortar and concrete. Constr. Build. Mater. 2010, 24, 113–117. [Google Scholar] [CrossRef]

- Hebhoub, H.; Aoun, H.; Belachia, M.; Houari, H.; Ghorbel, E. Use of waste marble aggregates in concrete. Constr. Build. Mater. 2011, 25, 1167–1171. [Google Scholar] [CrossRef]

- Keleştemur, O.; Arıcı, E.; Yıldız, S.; Gökçer, B. Performance evaluation of cement mortars containing marble dust and glass fiber exposed to high temperature by using Taguchi method. Constr. Build. Mater. 2014, 60, 17–24. [Google Scholar] [CrossRef] [Green Version]

- Khyaliya, R.K.; Kabeer, K.I.S.A.; Vyas, A.K. Evaluation of strength and durability of lean mortar mixes containing marble waste. Constr. Build. Mater. 2017, 147, 598–607. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Żak, A. Effects of marble powder on the properties of the air-cured blended cement paste. J. Clean. Prod. 2018, 183, 858–868. [Google Scholar] [CrossRef]

- Yamanel, K.; Durak, U.; İlkentapar, S.; Atabey, I.; Karahan, O.; TİŞ, C.A. Influence of waste marble powder as a replacement of cement on the properties of mortar. Rev. Constr. 2019, 18, 290–300. [Google Scholar] [CrossRef]

- Nasr, M.S.; Shubbar, A.A.; Abed, Z.A.-A.R.; Ibrahim, M.S. Properties of eco-friendly cement mortar contained recycled materials from different sources. J. Build. Eng. 2020, 31, 101444. [Google Scholar] [CrossRef]

- Al Jaaf, H.J.M.; Al-Jadiri, R.S.; Abdulghani, H.A. A Review on the Influence of Introducing Waste Materials to the Properties of Cement Mortar. J. Constr. Build. Mater. Eng. 2022, 8, 19–24. [Google Scholar]

- Khan, M.N.N.; Jamil, M.; Karim, M.R.; Zain, M.F.M.; Kaish, A. Filler effect of pozzolanic materials on the strength and microstructure development of mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- Miriello, D.; Lezzerini, M.; Chiaravalloti, F.; Bloise, A.; Apollaro, C.; Crisci, G.M. Replicating the chemical composition of the binder for restoration of historic mortars as an optimization problem. Comput. Concr. 2013, 12, 553–563. [Google Scholar] [CrossRef]

- Torres, M.L.; García-Ruiz, P.A. Lightweight pozzolanic materials used in mortars: Evaluation of their influence on density, mechanical strength and water absorption. Cem. Concr. Compos. 2009, 31, 114–119. [Google Scholar] [CrossRef]

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Standard: Brussels, Belgium, 2016.

- Franzini, M.; Leoni, M.; Saitta, L. Revisione di una metodologia analitica per fluorescenza-X, basata sulla correzione completa degli effetti di matrice. Rend. Soc. Ital. Miner. Petrog. 1975, 31, 365–378. [Google Scholar]

- Lezzerini, M.; Tamponi, M.; Bertoli, M. Reproducibility, precision and trueness of X-ray fluorescence data for mineralogical and/or petrographic purposes. Atti Soc. Toscana Sci. Nat. Mem. Ser. A 2013, 120, 67–73. [Google Scholar] [CrossRef]

- EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Standard: Brussels, Belgium, 2012.

- EN 933-2; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. European Standard: Brussels, Belgium, 2020.

- EN 15801; Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity. European Standard: Brussels, Belgium, 2009.

- EN 13755; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. European Standard: Brussels, Belgium, 2008.

- EN 1015-10; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. European Standard: Brussels, Belgium, 1999.

- Franzini, M.; Lezzerini, M. A mercury-displacement method for stone bulk-density determinations. Eur. J. Mineral. 2003, 15, 225–229. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Standard: Brussels, Belgium, 2019.

- EN 12504-4; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. European Standard: Brussels, Belgium, 2004.

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Investigation of the technology of historic mortars. J. Cult. Herit. 2000, 1, 45–58. [Google Scholar] [CrossRef]

- Franzini, M.; Leoni, L.; Lezzerini, M.; Sartori, F. The mortar of the ‘Leaning Tower’ of Pisa: The product of a Medieval technique for preparing high-strength mortars. Eur. J. Mineral. 2000, 12, 1151–1163. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Jackson, M.; Deocampo, D.; Marra, F.; Scheetz, B. Mid-Pleistocene pozzolanic volcanic ash in ancient Roman concretes. Geoarchaeol. Int. J. 2010, 25, 36–74. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Fichera, G.V.; Ortolano, G.; Pezzino, A.; Visalli, R.; Zappalà, L. Image processing of the pozzolanic reactions in Roman mortars via X-Ray Map Analyser. Microchem. J. 2016, 125, 242–253. [Google Scholar] [CrossRef]

- Lezzerini, M.; Raneri, S.; Pagnotta, S.; Columbu, S.; Gallello, G. Archaeometric study of mortars from the Pisa’s Cathedral Square (Italy). Meas. J. Int. Meas. Confed. 2018, 126, 322–331. [Google Scholar] [CrossRef] [Green Version]

- Rispoli, C.; De Bonis, A.; Guarino, V.; Graziano, S.F.; Di Benedetto, C.; Esposito, R.; Morra, V.; Cappelletti, P. The ancient pozzolanic mortars of the Thermal complex of Baia (Campi Flegrei, Italy). J. Cult. Herit. 2019, 40, 143–154. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).