CFD-DEM Simulation of the Transport of Manganese Nodules in a Vertical Pipe

Abstract

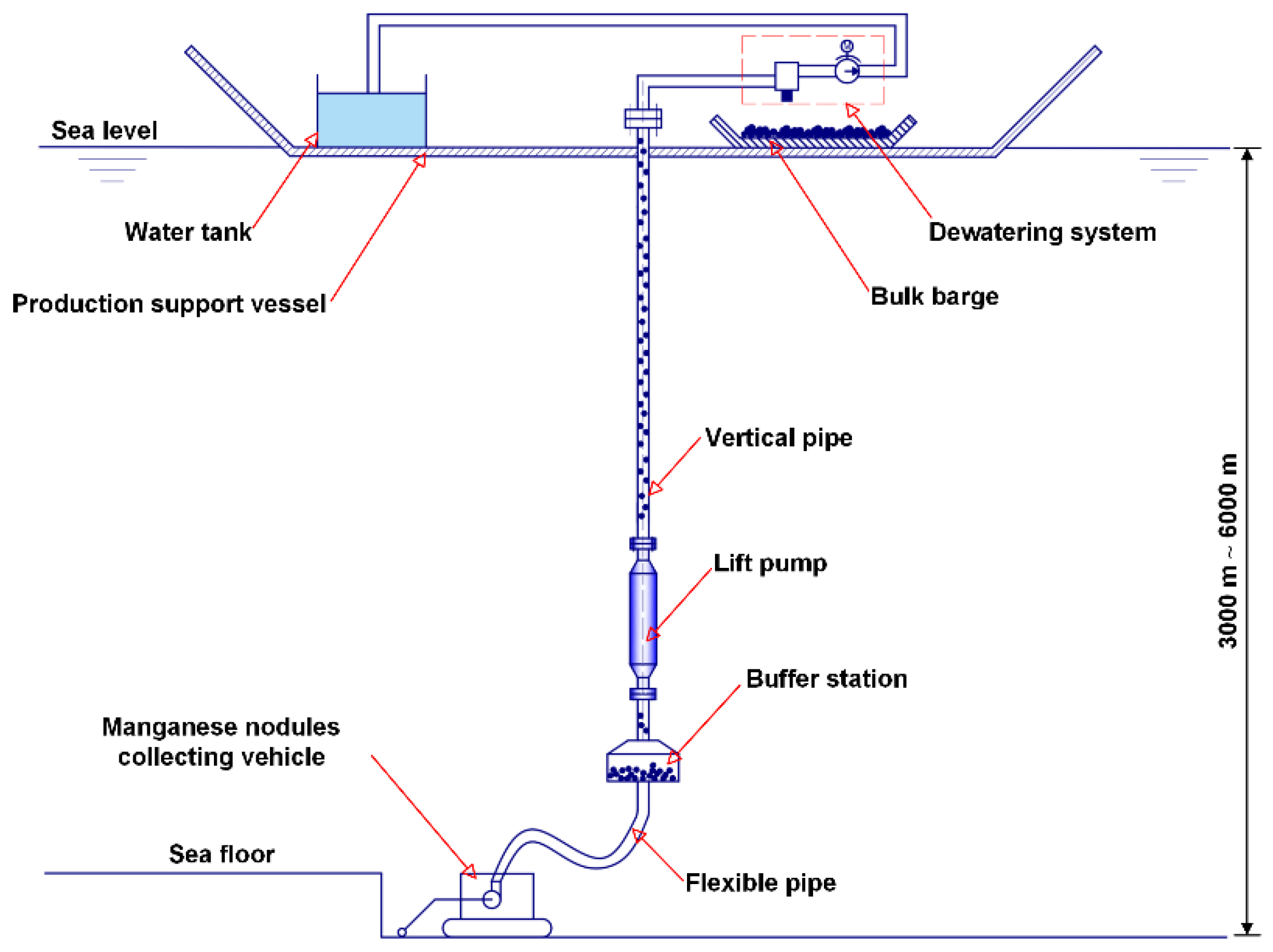

:1. Introduction

2. Geometry Model and Operating Parameters

2.1. Geometry Model

2.2. Flow Parameters

3. Mathematical Models

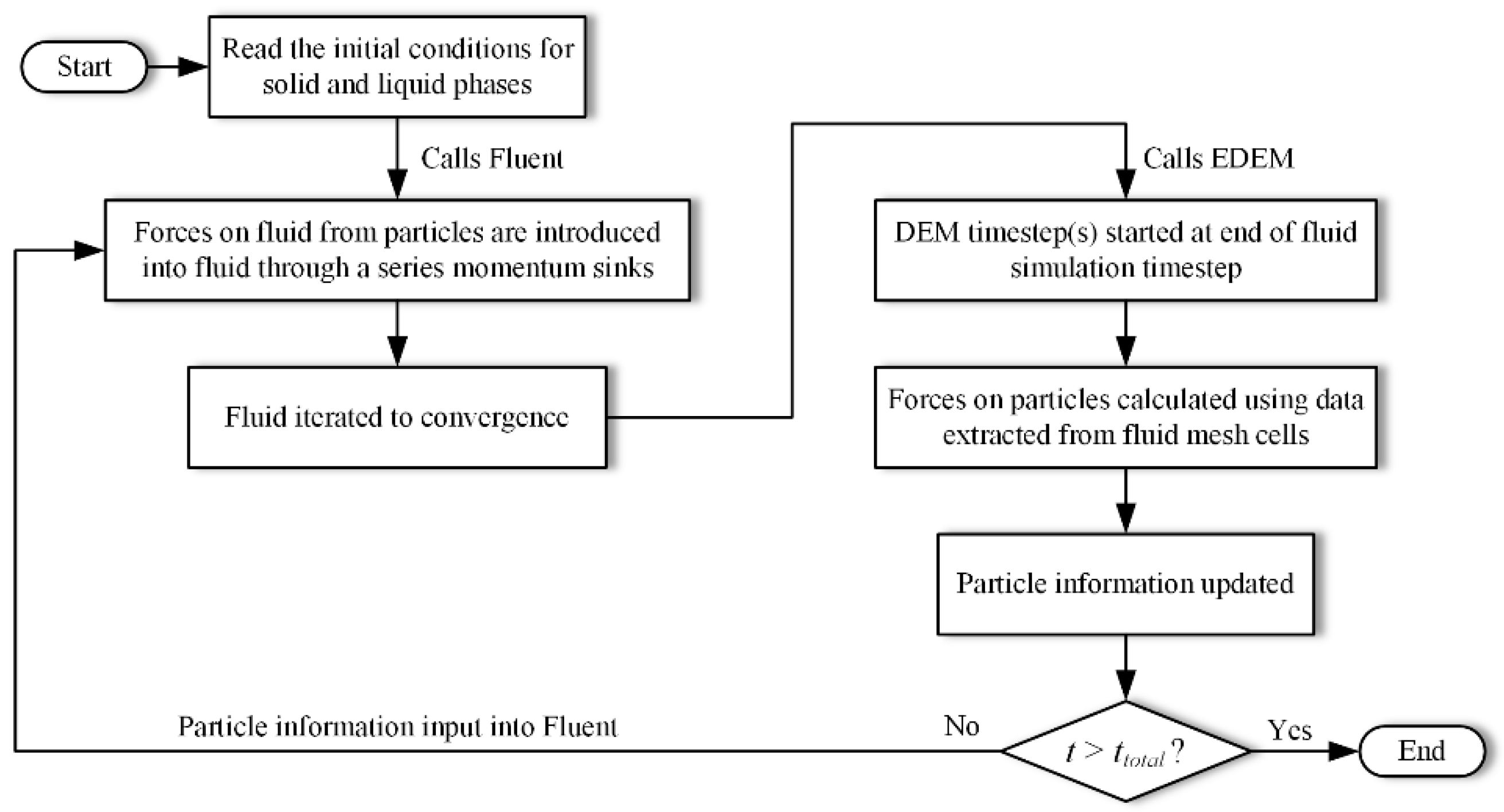

3.1. Computational Model

3.2. Particle Collision Model

3.3. Particle–Wall Collision Model

3.4. Forces Acting on Particles by Seawater

4. Numerical Preparations

4.1. Numerical Setup

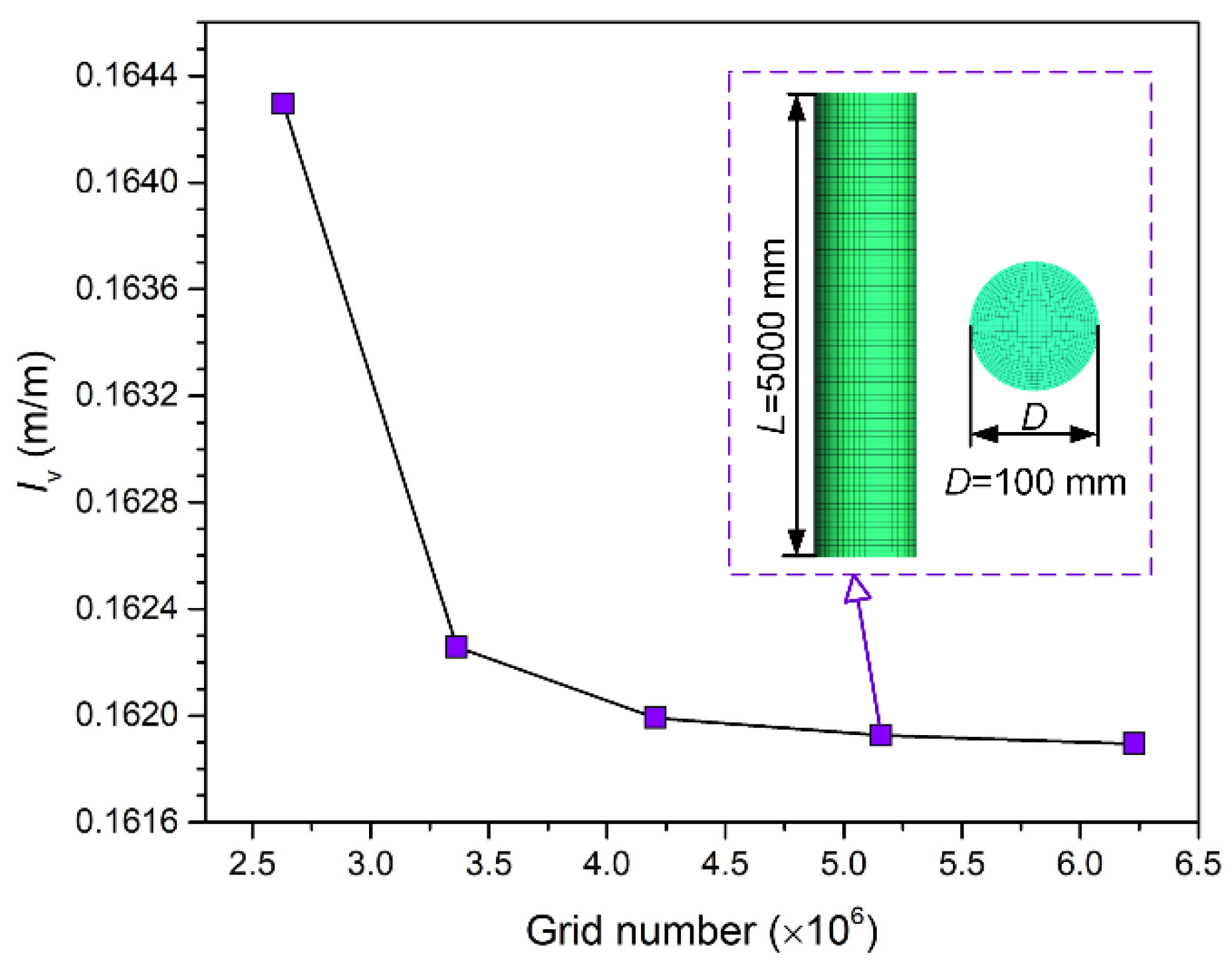

4.2. Grid Generation

4.3. Experimental Validation

5. Results and Discussion

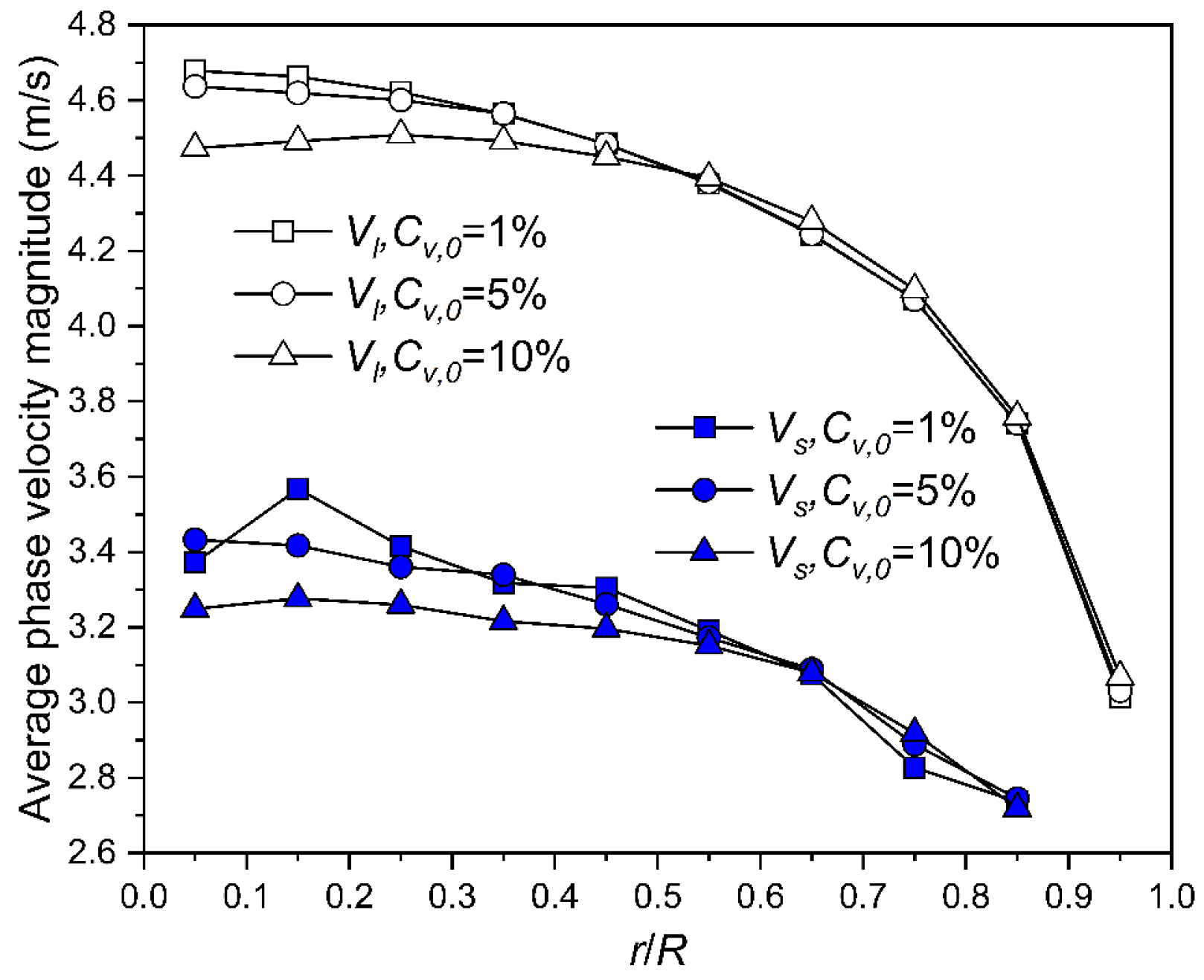

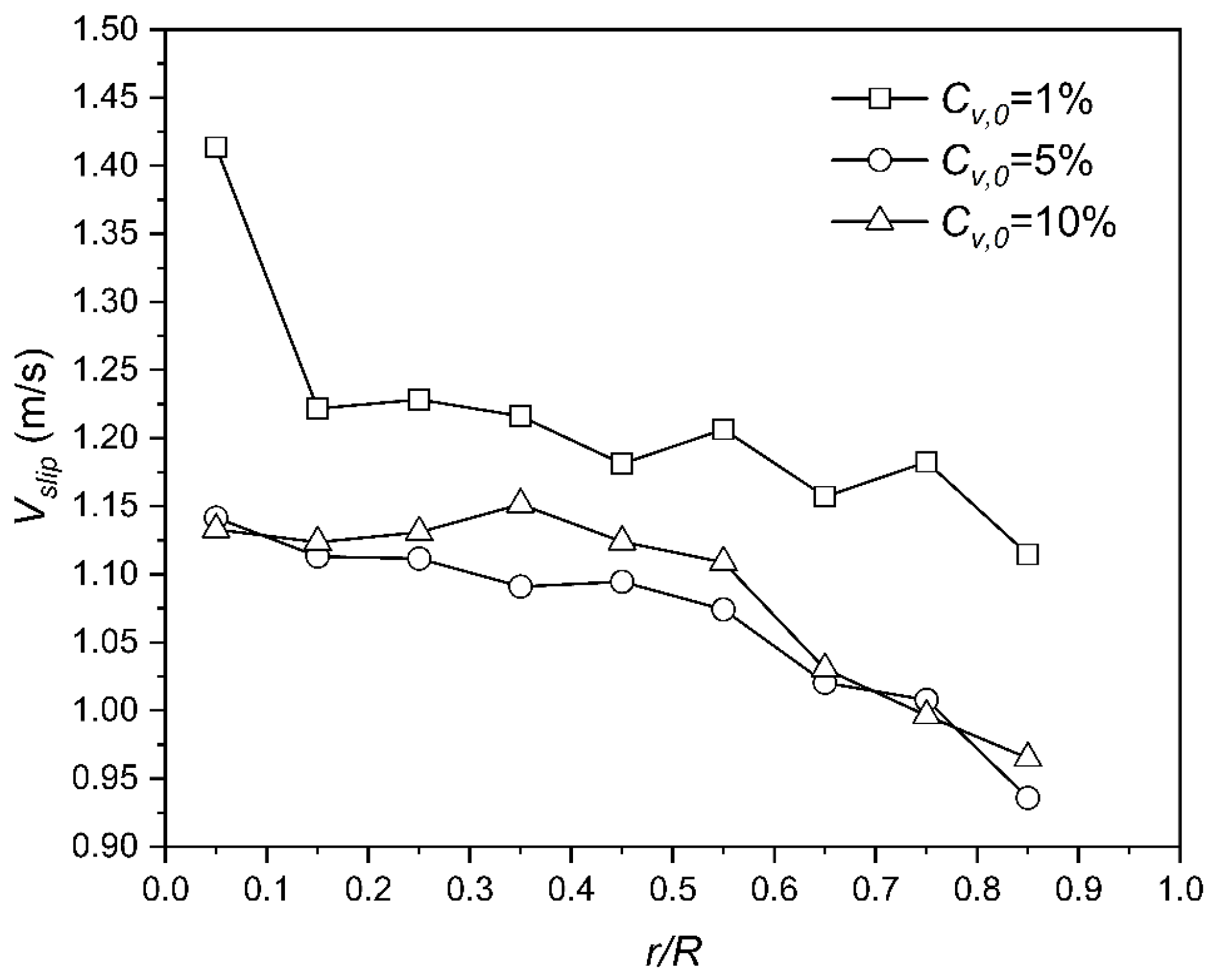

5.1. Effect of Initial Solid Volume Fraction

5.1.1. Distribution of Instantaneous Particle Velocity

5.1.2. Average Parameters

5.1.3. Total Pressure Drop

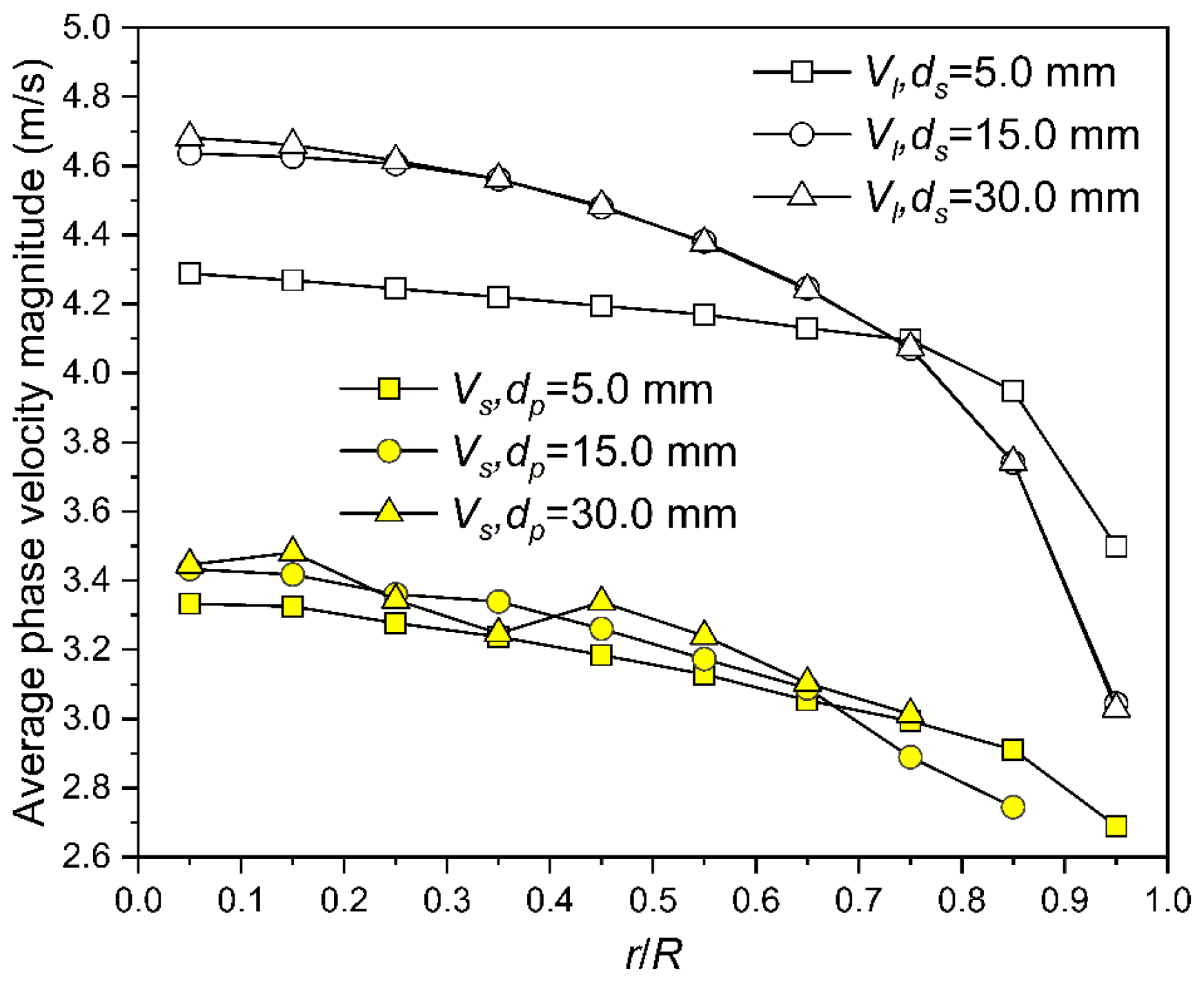

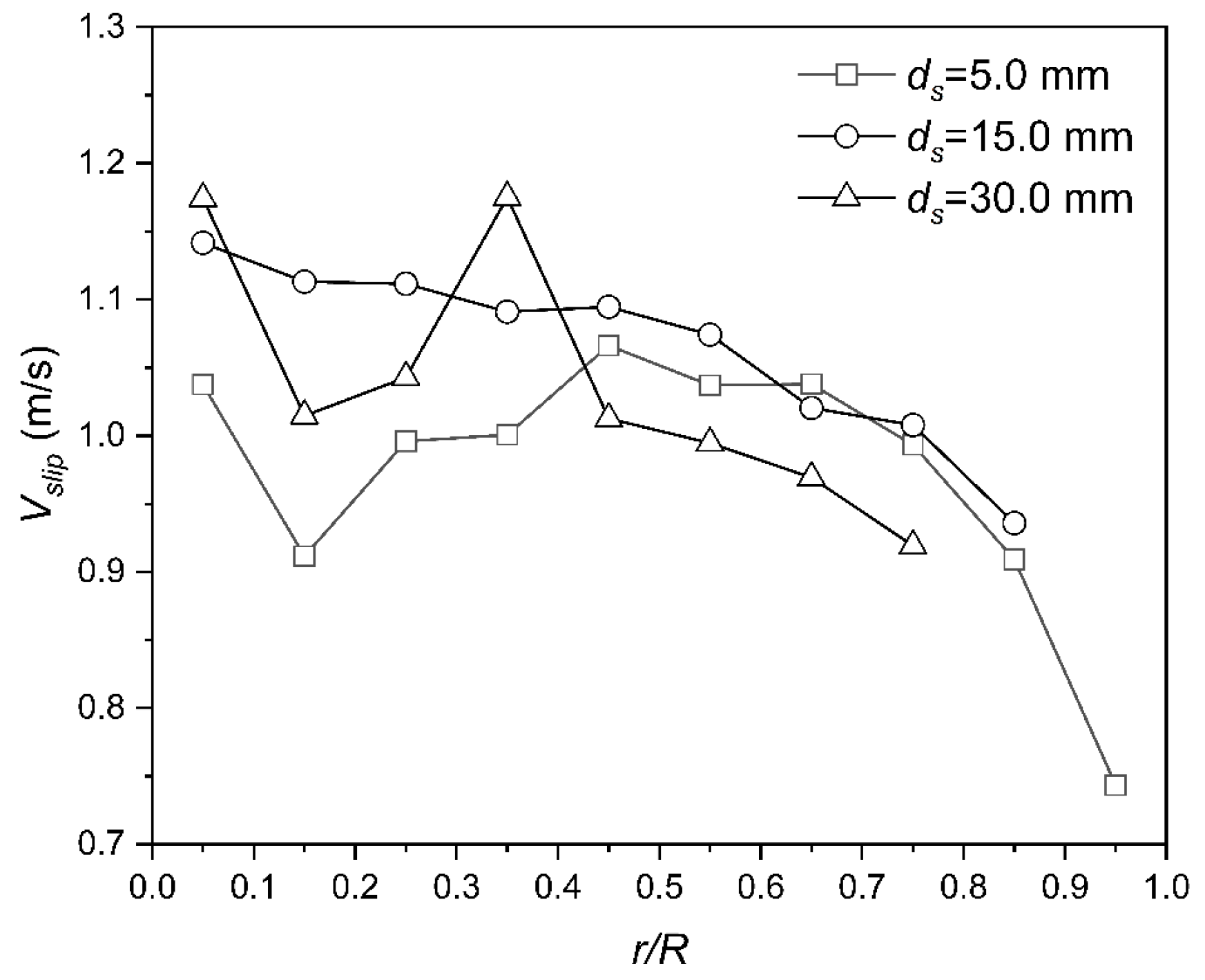

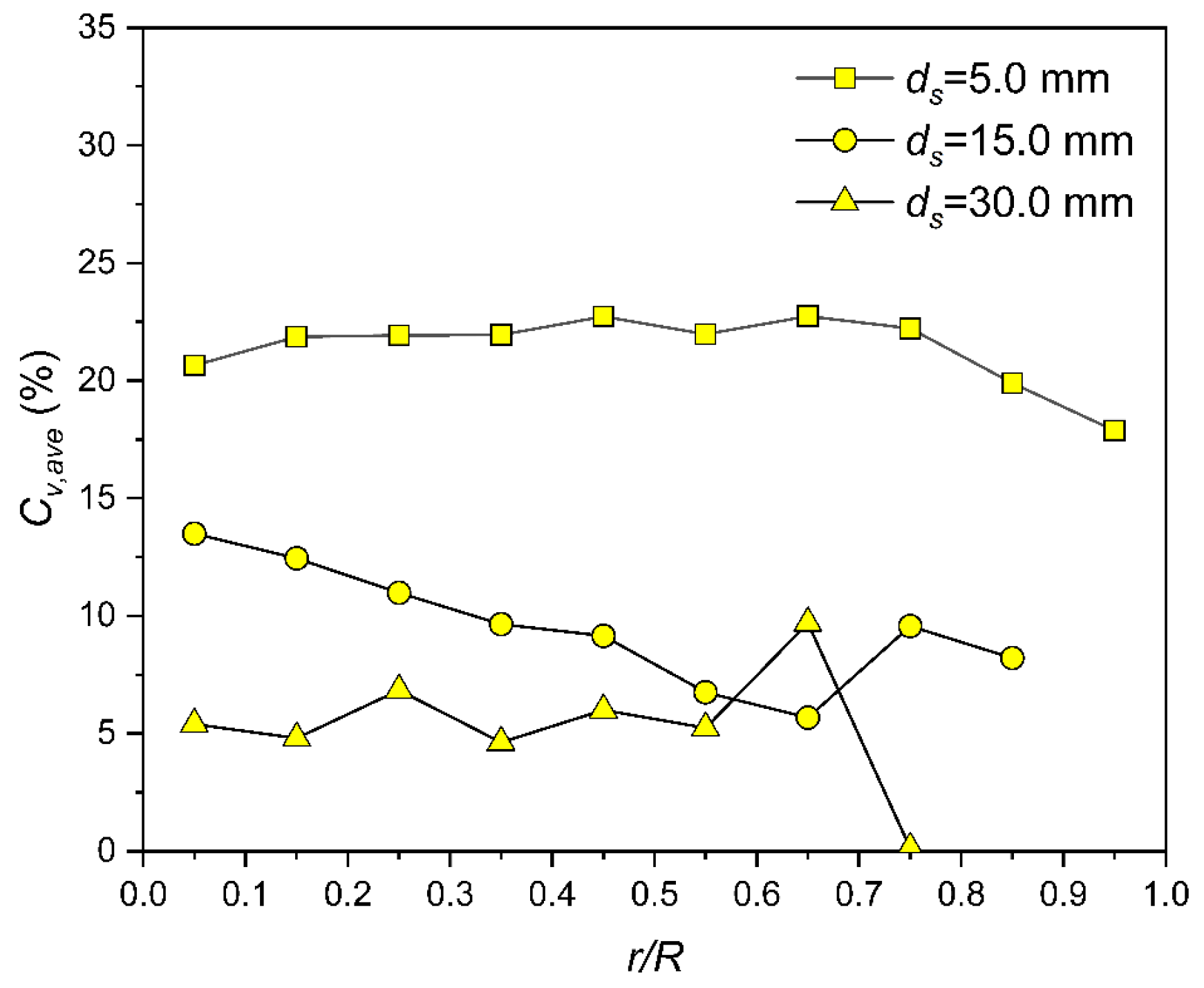

5.2. Effect of Particle Diameter

5.2.1. Distribution of Instantaneous Particle Velocity

5.2.2. Average Parameters

5.2.3. Total Pressure Drop

5.3. Effect of Initial Mixture Velocity

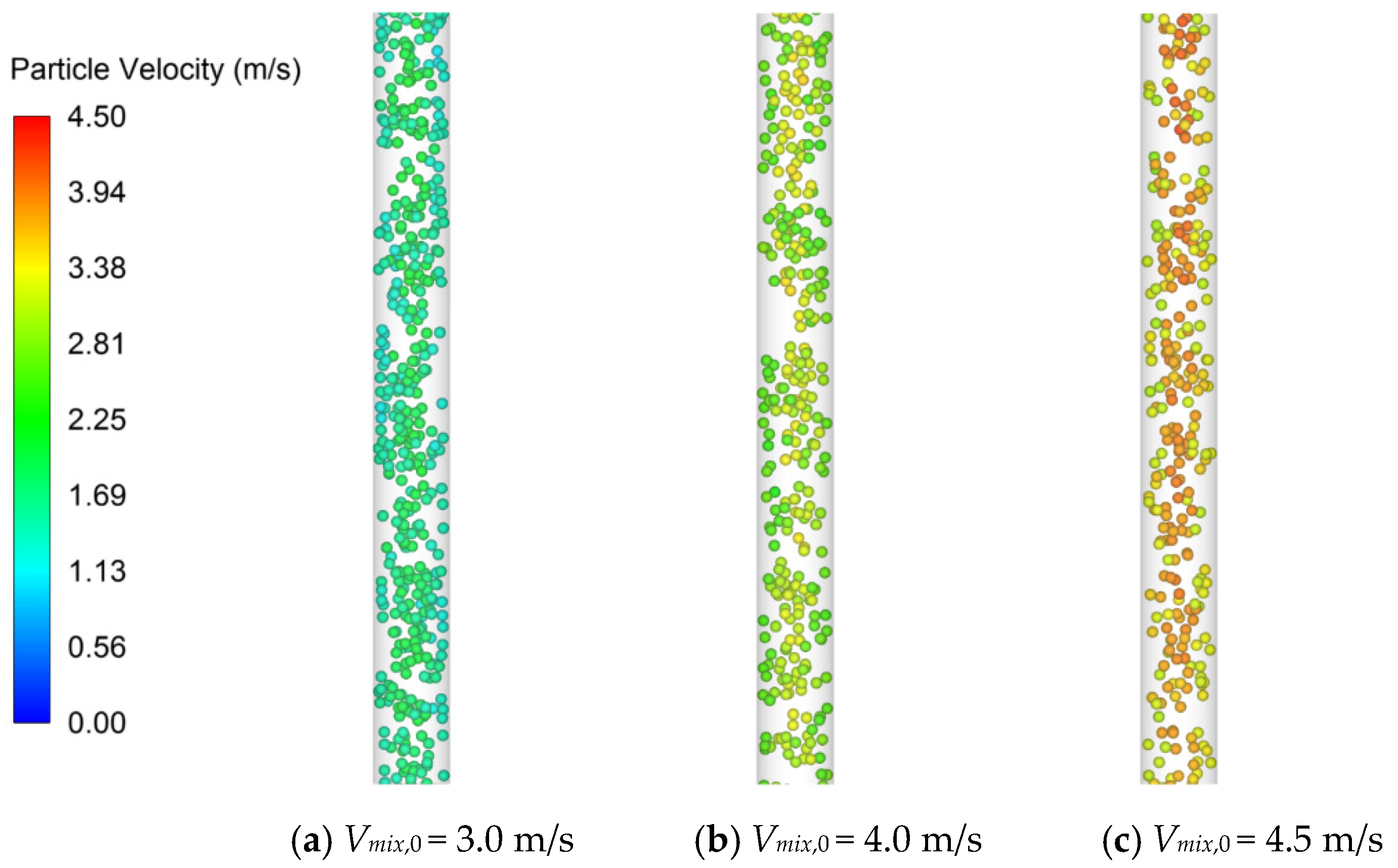

5.3.1. Distribution of Instantaneous Particle Velocity

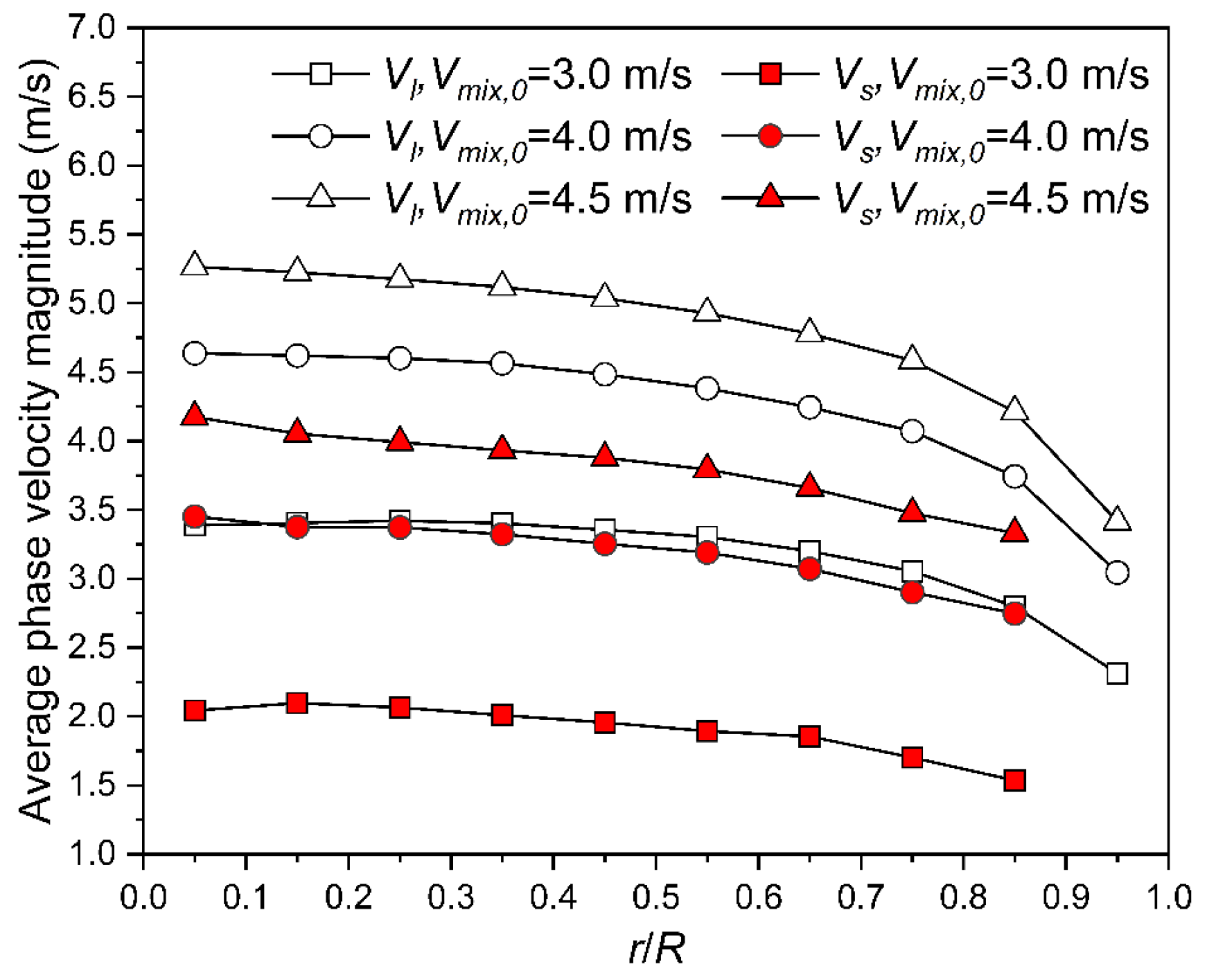

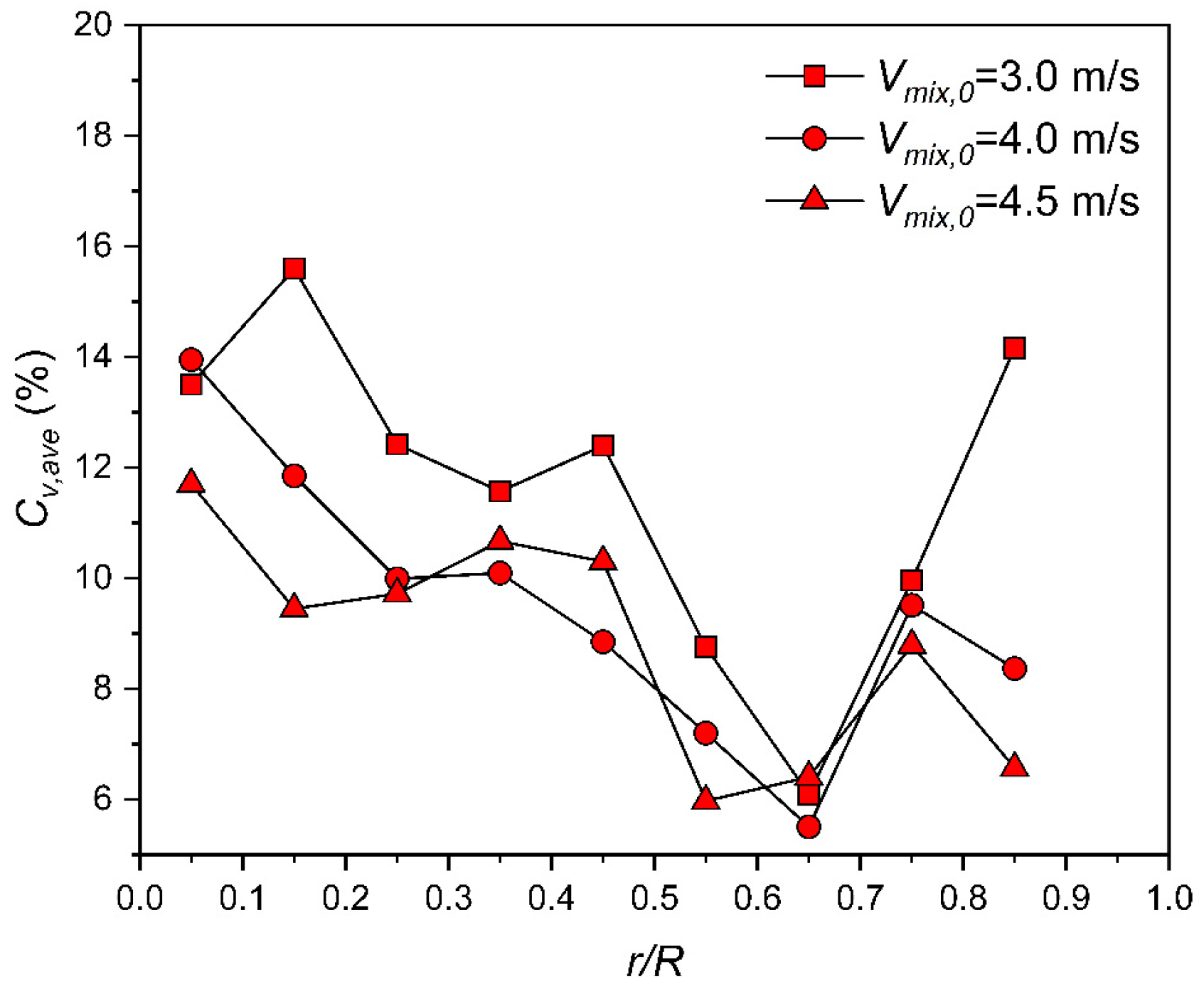

5.3.2. Average Parameters

5.3.3. Total Pressure Drop

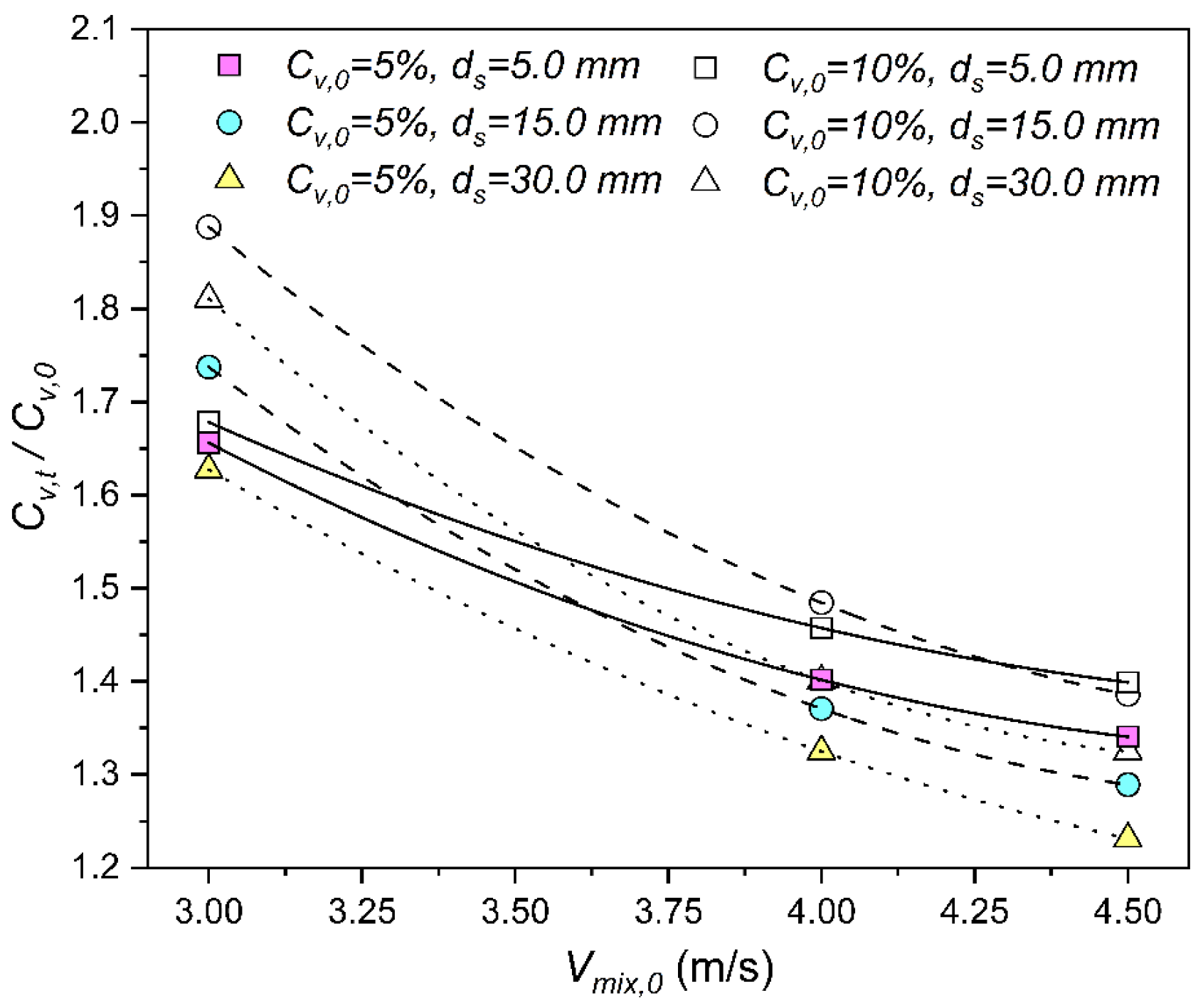

5.4. Retention Ratio

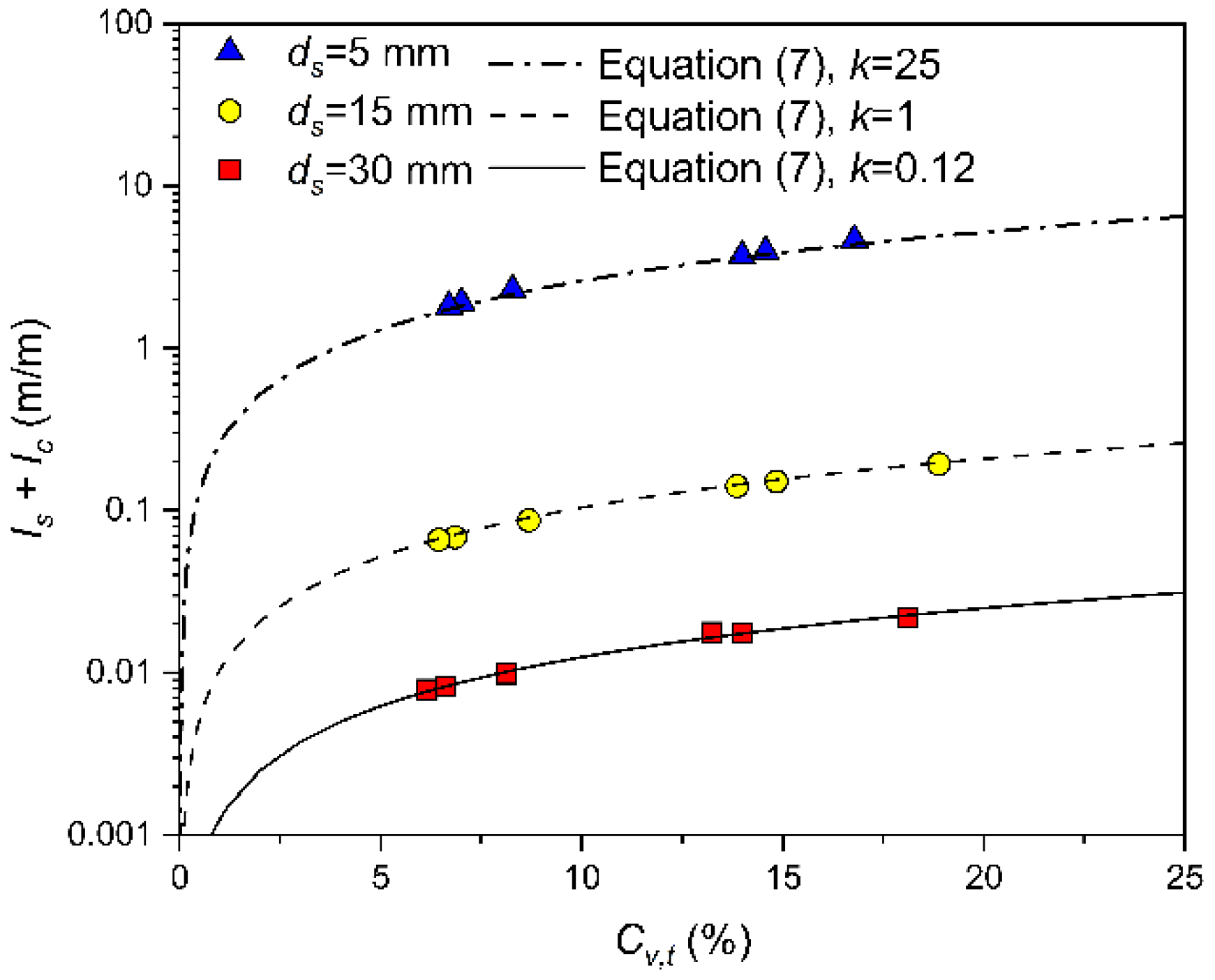

5.5. Relationship between Is + Ic and Local SVF

6. Conclusions

- (1)

- With increasing initial solid volume fraction, the energy consumption is enhanced, which leads to the decreases in both seawater and manganese nodule velocities at the central part of the pipe. This effect attenuates near the wall. Moreover, a high initial solid volume fraction results in an increase in total pressure drop.

- (2)

- Particle diameter has a significant influence on the rising velocities of seawater and manganese nodules. At the central part of the pipe, the liquid velocity is relatively low for small particles, while high liquid velocity arises near the pipe wall for small particle flow compared to large particle flow. The total pressure drop decreases with the increase of particle size from 5.0 mm to 30.0 mm.

- (3)

- At different flow velocities, similar seawater velocity distributions are evidenced. The velocity of manganese nodules exhibits the same tendency, and the highest velocity is produced at the pipe axis and then decreases in a radial direction. Increasing initial mixture velocity is beneficial to the transport of manganese nodules, but it will consume more energy and result in the increase of total pressure drop.

- (4)

- For both small and large particles, the retention ratio declines with increasing initial mixture velocity and decreasing initial solid volume fraction. At an initial mixture velocity of 4.5 m/s, the particles of 30.0 mm in diameter are responsible for the lowest retention ratio, implying a significant effect of the initial mixture velocity on the transport performance.

- (5)

- A formula is proposed to describe the pressure drop due to the presence of solid particles and collisions. Combined with the pressure drop formula associated with clean water, the total pressure drop for the hydraulic transportation of solid particles can be well predicted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Cross-sectional area of the pipe |

| Bpipe | Volume of the pipe segment |

| Bs,t | Total volume of solid particles in a pipe segment at time t |

| CD | Drag coefficient |

| Cv,0 | Initial solid volume fraction |

| Cv,ave | Average solid volume fraction |

| Cv,t | Local solid volume fraction at time t |

| D | Pipe diameter |

| ds | Particle diameter |

| E* | Equivalent Young’s modulus |

| Fc,ij | Contact forces between particles i and j |

| Fcn,ij | Normal component of contact force |

| Normal stiffness force decomposed from contact force | |

| Normal damping force decomposed from contact force | |

| Fct,ij | Tangential component of contact force |

| Tangential stiffness force decomposed from contact force | |

| Tangential damping force decomposed from contact force | |

| FD | Drag force |

| Fg | Gravitational force |

| Fg,i | Body forces acting on particle i |

| Fls,i | Force acting on particle i by liquid phase |

| FM | Magnus lift force |

| Fnc,ik | Non-contact forces between particles i and k |

| Fp | Pressure gradient force |

| Fsl | Sum of the forces acted on the liquid phase by solid phase |

| FS | Saffman lift force |

| Ft | Turbulence force |

| g | Gravitational acceleration |

| Ic | Dimensionless pressure drop related to collisions |

| Il | Dimensionless pressure drop related to liquid |

| Ii | Inertia moment of particle i |

| Is | Dimensionless pressure drop related to solid |

| Iv | Dimensionless total pressure drop of vertical pipe |

| L | Pipe length |

| m* | Equivalent mass |

| mi | Mass of particle i |

| Equivalent mass of the wall | |

| mwall | Mass of the wall |

| Mr,ij | Normal friction moment between particles i and j |

| Mt,ij | Tangential friction moment between particles i and j |

| Qs | Volume flow rate of solid |

| Ql | Volume flow rate of liquid |

| r | Distance to the axis of the pipe |

| R | Radius of the pipe |

| R* | Equivalent radius |

| Radius of the particle i | |

| Equivalent radius of the wall | |

| Rwall | Radius of the wall |

| Sn | Normal stiffness |

| St | Tangential stiffness |

| t | Simulation time |

| ttotal | Total simulation time |

| ul | Liquid velocity |

| us | Solid velocity |

| vi | Velocity of particle i |

| Vl | Average liquid velocity |

| Vmix,0 | Initial mixture velocity |

| Relative tangential velocity | |

| Normal component of the relative velocity; | |

| Vs | Average solid velocity |

| Vslip | Average slip velocity |

| β | The coefficient of restitution |

| δt | Tangential overlap |

| δn | Normal overlap |

| ΔP | Pressure drop of vertical pipe |

| Δtl | CFD time step |

| ΔtR | Rayleigh time |

| Δts | DEM time step |

| ΔVcell | Volume of CFD grid cell |

| ∇P | Static pressure gradient |

| εl | Volume fraction of liquid phase |

| λl | Friction coefficient |

| μl | Dynamic viscosity of liquid |

| μr | The coefficient of rolling friction |

| ρl | Density of liquid |

| ρs | Density of solid particle |

| ωi | Angular velocity of particle i |

References

- Miller, K.A.; Thompson, K.F.; Johnston, P.; Santillo, D. An Overview of Seabed Mining Including the Current State of Development, Environmental Impacts, and Knowledge Gaps. Front. Mar. Sci. 2018, 4, 418. [Google Scholar] [CrossRef]

- Takahashi, H.; Masuyama, T.; Noda, K. Unstable Flow of a Solid-Liquid Mixture in a Horizontal Pipe. Int. J. Multiph. Flow 1989, 15, 831–841. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, S.; Kuang, S.; Luo, K.; Fan, J.; Yu, A. CFD-DEM Modelling of Hydraulic Conveying of Solid Particles in a Vertical Pipe. Powder Technol. 2019, 354, 893–905. [Google Scholar] [CrossRef]

- Singh, J.P.; Kumar, S.; Mohapatra, S.K. Modelling of Two Phase Solid-Liquid Flow in Horizontal Pipe Using Computational Fluid Dynamics Technique. Int. J. Hydrogen Energy 2017, 42, 20133–20137. [Google Scholar] [CrossRef]

- Xia, J.X.; Ni, J.R.; Mendoza, C. Hydraulic Lifting of Manganese Nodules Through a Riser. J. Offshore Mech. Arct. 2004, 126, 72–77. [Google Scholar] [CrossRef]

- Yoon, C.H.; Kang, J.S.; Park, Y.C.; Kim, Y.J.; Park, J.M.; Kwon, S.K. Solid-Liquid Flow Experiment with Real and Artificial Manganese Nodules in Flexible Hoses. In Proceedings of the Eighteenth (2008) International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6 July 2008. [Google Scholar]

- Doron, P.; Barnea, D. Pressure Drop and Limit Deposit Velocity for Solid-Liquid Flow in Pipes. Chem. Eng. Sci. 1995, 50, 1595–1604. [Google Scholar] [CrossRef]

- Doron, P.; Simkhis, M.; Barnea, D. Flow of Solid-Liquid Mixtures in Inclined Pipes. Int. J. Multiph. Flow 1997, 23, 313–323. [Google Scholar] [CrossRef]

- Song, Y.; Zhu, X.; Sun, Z.; Tang, D. Experimental Investigation of Particle-Induced Pressure Loss in Solid–Liquid Lifting Pipe. J. Cent. South Univ. 2017, 24, 2114–2120. [Google Scholar] [CrossRef]

- Ravelet, F.; Bakir, F.; Khelladi, S.; Rey, R. Experimental Study of Hydraulic Transport of Large Particles in Horizontal Pipes. Exp. Therm. Fluid Sci. 2013, 45, 187–197. [Google Scholar] [CrossRef] [Green Version]

- Shokri, R.; Nobes, D.S.; Ghaemi, S.; Sanders, R.S. Investigation of Particle-Fluid Interaction at High Reynolds-Number Using PIV/PTV Techniques. In Proceedings of the International Symposium on Turbulence and Shear Flow Phenomena (TSFP-9), Melbourne, Australia, 30 July 2015. [Google Scholar]

- Moliner, C.; Marchelli, F.; Spanachi, N.; Martinez-Felipe, A.; Bosio, B.; Arato, E. CFD Simulation of a Spouted Bed: Comparison between the Discrete Element Method (DEM) and the Two Fluid Model (TFM). Chem. Eng. J. 2019, 377, 120466. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, J. A Comparison of Two-Fluid Model, Dense Discrete Particle Model and CFD-DEM Method for Modeling Impinging Gas–Solid Flows. Powder Technol. 2014, 254, 94–102. [Google Scholar] [CrossRef]

- Blais, B.; Lassaigne, M.; Goniva, C.; Fradette, L.; Bertrand, F. Development of an Unresolved CFD–DEM Model for the Flow of Viscous Suspensions and Its Application to Solid–Liquid Mixing. J. Comput. Phys. 2016, 318, 201–221. [Google Scholar] [CrossRef]

- Hua, L.; Lu, L.; Yang, N. Effects of Liquid Property on Onset Velocity of Circulating Fluidization in Liquid-Solid Systems: A CFD-DEM Simulation. Powder Technol. 2020, 364, 622–634. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Q.; Zheng, J.; Zhao, Y. Numerical Prediction of Erosion in Elbow Based on CFD-DEM Simulation. Powder Technol. 2016, 302, 236–246. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A. CFD-DEM Modelling of Multiphase Flow in Dense Medium Cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Sakai, M.; Abe, M.; Shigeto, Y.; Mizutani, S.; Takahashi, H.; Viré, A.; Percival, J.R.; Xiang, J.; Pain, C.C. Verification and Validation of a Coarse Grain Model of the DEM in a Bubbling Fluidized Bed. Chem. Eng. J. 2014, 244, 33–43. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, N.; Li, Z.; Dou, Y.; Cao, Y. Erosion Failure of Horizontal Pipe Reducing Wall in Power-Law Fluid Containing Particles via CFD–DEM Coupling Method. J. Fail. Anal. Prev. 2017, 17, 1067–1080. [Google Scholar] [CrossRef]

- Alobaid, F.; Ströhle, J.; Epple, B. Extended CFD/DEM Model for the Simulation of Circulating Fluidized Bed. Adv. Powder Technol. 2013, 24, 403–415. [Google Scholar] [CrossRef]

- Yang, X.-D.; Zhao, L.-L.; Li, H.-X.; Liu, C.-S.; Hu, E.-Y.; Li, Y.-W.; Hou, Q.-F. DEM Study of Particles Flow on an Industrial-Scale Roller Screen. Adv. Powder Technol. 2020, 31, 4445–4456. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Kuang, S.B.; Chu, K.W.; Yu, A.B. Discrete Particle Simulation of Particle–Fluid Flow: Model Formulations and Their Applicability. J. Fluid Mech. 2010, 661, 482–510. [Google Scholar] [CrossRef]

- Rubinow, S.I.; Keller, J.B. The Transverse Force on a Spinning Sphere Moving in a Viscous Fluid. J. Fluid Mech. 1961, 11, 447. [Google Scholar] [CrossRef]

- Saffman, P.G. The Lift on a Small Sphere in a Slow Shear Flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef] [Green Version]

- Okhovat-Alavian, S.M.; Shabanian, J.; Norouzi, H.R.; Zarghami, R.; Chaouki, J.; Mostoufi, N. Effect of Interparticle Force on Gas Dynamics in a Bubbling Gas–Solid Fluidized Bed: A CFD-DEM Study. Chem. Eng. Res. Des. 2019, 152, 348–362. [Google Scholar] [CrossRef]

- Burke, S.P.; Plummer, W.B. Gas Flow through Packed Columns. Ind. Eng. Chem. 1928, 20, 1196–1200. [Google Scholar] [CrossRef]

- Li, Y.W.; Liu, S.J.; Hu, X.Z. Research on Reflux in Deep-Sea Mining Pump Based on DEM-CFD. Mar. Georesour. Geotechnol. 2020, 38, 744–752. [Google Scholar]

- Liu, Y.; Chen, L. Numerical Investigation on the Pressure Loss of Coarse Particles Hydraulic Lifting in the Riser with the Lateral Vibration. Powder Technol. 2020, 367, 105–114. [Google Scholar] [CrossRef]

- Hong, S.; Choi, J.; Yang, C.-K. Experimental Study on Solid-Water Slurry Flow in Vertical Pipe by Using Ptv Method. In Proceedings of the Twelfth (2002) International Offshore and Polar Engineering Conference, Kitakyushu, Japan, 26 May 2002. [Google Scholar]

- Friman Peretz, M.; Levy, A. Bends Pressure Drop in Hydraulic Conveying. Adv. Powder Technol. 2019, 30, 1484–1493. [Google Scholar] [CrossRef]

| Pipe parameters | |

| Diameter (m) | 0.1 |

| Length (m) | 5 |

| Poisson’s ratio | 0.3 |

| Density (kg/m3) | 7980 |

| Shear modulus (Pa) | 7.0 × 107 |

| Particle–wall restitution coefficient | 0.52 |

| Particle–wall static friction coefficient | 0.16 |

| Particle–wall rolling friction coefficient | 0.01 |

| Liquid property | |

| Liquid density (kg/m3) | 1044 |

| Liquid temperature (°C) | 24 |

| Liquid viscosity (Pa·s) | 1.01 × 10−3 |

| Solid particle property | |

| Poisson’s ratio | 0.4 |

| Density (kg/m3) | 2040 |

| Shear modulus (Pa) | 2.13 × 107 |

| Particle–particle restitution coefficient | 0.45 |

| Particle–particle static friction coefficient | 0.28 |

| Particle–particle rolling friction coefficient | 0.01 |

| CFD reference pressure (Pa) | 101,325 |

| CFD time step (s) | 0.001 |

| CFD turbulence model | RNG k-ε |

| DEM time step (s) | 0.0001 |

| Total simulation time (s) | 3 |

| Operating Parameters | No. | Initial SVF, Cv,0 (%) | Particle Diameter, ds (mm) | Initial Mixture Velocity, Vmix,0 (m/s) |

|---|---|---|---|---|

| Effects of Cv,0 | Case 1 | 1 | 15 | 4 |

| Case 2 | 5 | 15 | 4 | |

| Case 3 | 10 | 15 | 4 | |

| Effects of Vmix,0 | Case 4 | 5 | 15 | 3 |

| Case 5 | 5 | 15 | 4 | |

| Case 6 | 5 | 15 | 4.5 | |

| Effects of ds | Case 7 | 5 | 5 | 4 |

| Case 8 | 5 | 15 | 4 | |

| Case 9 | 5 | 30 | 4 |

| Cv,0 (%) | 1 | 5 | 10 |

| Cv,t (%) | 1.3 | 6.8 | 14.8 |

| Iv (m/m) | 0.1753 | 0.2303 | 0.3127 |

| ds (mm) | 5.0 | 15.0 | 30.0 |

| Cv,t (%) | 7.0 | 6.8 | 6.6 |

| Iv (m/m) | 2.3730 | 0.2303 | 0.0986 |

| Vmix,0 (m/s) | 3.0 | 4.0 | 4.5 |

| Cv,t (%) | 8.6 | 6.8 | 6.4 |

| Iv (m/m) | 0.1756 | 0.2303 | 0.2736 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, S.; Kang, C.; Ding, K.; Li, C.; Zhang, S. CFD-DEM Simulation of the Transport of Manganese Nodules in a Vertical Pipe. Appl. Sci. 2022, 12, 4383. https://doi.org/10.3390/app12094383

Teng S, Kang C, Ding K, Li C, Zhang S. CFD-DEM Simulation of the Transport of Manganese Nodules in a Vertical Pipe. Applied Sciences. 2022; 12(9):4383. https://doi.org/10.3390/app12094383

Chicago/Turabian StyleTeng, Shuang, Can Kang, Kejin Ding, Changjiang Li, and Sheng Zhang. 2022. "CFD-DEM Simulation of the Transport of Manganese Nodules in a Vertical Pipe" Applied Sciences 12, no. 9: 4383. https://doi.org/10.3390/app12094383

APA StyleTeng, S., Kang, C., Ding, K., Li, C., & Zhang, S. (2022). CFD-DEM Simulation of the Transport of Manganese Nodules in a Vertical Pipe. Applied Sciences, 12(9), 4383. https://doi.org/10.3390/app12094383