Abstract

The term “Industry 4.0” relates broadly to intelligent digitization, products, and value chain processes automation, an integration of real and virtual manufacturing worlds where products, factories, humans, and objects merge with embedded software in intelligent, distributed systems. The fourth industrial revolution currently encompasses many examples of application in several fields ranging from health to industry. However, despite this recent interest, the emergence of digitalization in the logistics industry has received little attention, especially in light of the fact that digitization is of increasing strategic importance for companies in a changing and highly competitive environment as it impacts their established processes, business models, and sector boundaries while also having an ecological impact. The new trade strategies put forward by the United Nations in their development plan revolve around sustainability, especially in the industrial sector. Technological advances related to the fourth industrial revolution represent the best approach to ensure sustainability, especially if these technologies are applied to the Logistics 4.0 paradigm within manufacturing companies. The focus of our research method, solely based on a bibliography study over a span of the last five years, is on the digitalization of manufacturing companies, while our selection of screened paper is based on a qualitative criterion further discussed in this paper. The purpose of this paper is to first shed light on the link between the last industrial revolution and its impact on the evolution of logistics and then to present the various optimization opportunities and risks, with a focus on efficiency performance.

1. Introduction

The phenomenon of globalization and technological advances linked to information are a medallion with two sides, a reality with both risks and opportunities for companies in general and especially for manufacturers [1].

The fourth industrial revolution, commonly known as “Industry 4.0”, represents the newest era of industrial transformation by introducing the digitalization of processes and the automation of production models; this new phase of manufacturing industry merges the latest information technologies with the various production processes and more precisely the logistics ones [2].

Barreto et. al. argue that the heart of the Industry 4.0 paradigm is to make a significant contribution to the management of the various aspects of logistics. Interestingly, shortly after the emergence of the concept of Industry 4.0, the term “Logistics 4.0” came along and was coined to signal a flexible implementation of logistics processes aimed at managing production [3].

The current global context is full of competitive environments and ecological concerns, accompanied by the evolution of the needs expressed by customers as well as by new technologies; companies find themselves struggling to reconsider their way of doing things, and to make the most of competitive advantages of digitizing their activities, processes, and supply chain while establishing the vision of sustainability with little harmful impact on the environment. Industry 4.0 has brought much turbulence and disruption to the strategic and organizational visions of entities [4].

The digital technologies offered by the fourth industrial revolution increase, among other things, responsiveness in the event of fluctuations in demand and improve flexibility in the face of limited capacities while reducing lead times thanks to additive manufacturing and at the same time increasing the control of stocks. This further proves the inherent impact of Industry 4.0 on industrial logistics [5].

With the COVID-19 pandemic, digital technologies have concretely demonstrated their importance and above all their potential in the industrial sector, playing an active and crucial role in the provision of the necessary logistics and transport services by managing supply and demand medical equipment, a limited resource in times of crisis; geographic information systems (GIS) and big data analytics have been used to support decision-making [6,7].

The impact of Industry 4.0 technologies on the various logistics operations can be felt on several links, ranging from optimized resource planning and warehouse management systems to intelligent transport systems, where the security of information and data is becoming increasingly important [8,9].

The adoption of technologies within logistics, a transversal function of companies, arouses great interest, especially with the digitization of manufacturing, marketing, transport, and warehousing processes based on the interconnectivity and integration technologies of Industry 4.0 [10].

At the level of this new phase of the industrial revolution, there has been a migration towards the digitization of production processes, transport systems, sourcing, and procurement by relying on intelligent and connected digital technologies such as cloud computing, IoT, big data analytics, and blockchain, which facilitate the development of intelligent supply chains [5,11].

Table 1 portrays a brief overview of previous studies that have analyzed and examined the impact of digital technologies on the logistics performance of companies.

Table 1.

Referral studies [11,12,13,14,15,16,17].

Table 1.

Referral studies [11,12,13,14,15,16,17].

| Micro-Logistic | Country Level (Competitiveness) | Commercial and Logistical Performance | Environment and Logistics Performance | Incoterms Clauses and Logistics Performance |

|---|---|---|---|---|

| Kayikci, 2018; | Çemberci et al., 2015; | Gani, 2017 | Liu et al., 2018 | Stojanović and Ivetić, 2020 |

| Lin and Ho, 2009 | Ekici et al., 2019 |

According to Philipp (2020), the efficiency of logistics operations represents one of the main enablers of digital transformation and the economic development of countries and regions [18]. The guiding question of our research focuses on the link between Industry 4.0 and Logistics 4.0? Does Logistics 4.0 require the exploitation of Industry 4.0 technologies? Does the adoption of Logistics 4.0 allow companies to migrate to Industry 4.0?

This paper represents an attempt to identify the latest current advances in research on the relationship between two paradigms, notably the fourth industrial revolution and Logistics 4.0 and their felt potential within the manufacturing sector.

Its aim is to demonstrate that the evolution of the logistics paradigm is closely linked to and influenced by the industrial revolutions, and to highlight the different opportunities brought by the digitization of logistics processes while emphasizing the most recent additions to the equation: sustainability factors.

This paper is structured as follows: Section 2 is devoted to a literature review carried out with a two-time step, which allows us to have two sets of data whose purpose is to analyze the concept of Logistics 4.0 between 2018 and 2022, as well as delimiting the articles appropriate to our theme. Then, Section 3 includes a discussion on the link between industrial evolution and logistics over the years, the different dimensions of intelligent logistics, the solutions offered by the advent of Logistics 4.0, and its opportunities and risks, and then a conclusion presenting possible limits to this paper, and a perspective to consider.

2. Literature Review

2.1. Methodology

The approach as represented in Figure 1 is a review of the literature; we focused on the relationship between Industry 4.0 and logistics, and the different advantages it offers. Relevant information was extracted from research papers published over the past five years.

Figure 1.

Our approach steps.

The research topic was defined using the terms “Logistics 4.0”, “Smart Logistics”, and the more generic term “Industry 4.0”.

Our main choice of database was Scopus; through the literature, many authors identified it as a pertinent database of scientific publications for systemic queries in various fields, especially those that share an interest in our approach, industrial engineering, and management sciences [19].

Our research approach was carried out in two stages:

The first stage focused on collecting data for a comprehensive general assessment of the field using descriptive statistics to provide insight into current research interests. The Scopus database was exploited to extract interesting articles related to Logistics 4.0 published over the last 5 years (2018–2022).

The second step focused on a bibliometric analysis of the documents considered after using the inclusion and exclusion criteria.

The first stage, a preliminary study, resulted in 126 documents. Keywords exploited for data collection are composed of “Industry 4.0” and “Logistics”. The relevant data were recorded in an Excel spreadsheet to perform the preliminary statistics presented in Section 2.2.

During the second step, a new selection was necessary and was carried out by adopting the criteria of inclusion and exclusion as listed in Table 2 and Table 3 while carefully reading the abstracts to assess the compatibility of the document with the research topic, including keywords such as smart logistics and industrial revolution, and specifying the fields of engineering, business, and computer science as the main areas of interest. The new metasearch query was phrased as follows: TI-TLE-ABS-KEY (“Logistics 4.0” OR “Smart Logistics” AND “Industry 4.0”) AND PUBYEAR > 2017 AND (LIMIT-TO (OA, “all ”)) AND (LIMIT-TO (SUB-JAREA, “ENGI”) OR LIMIT-TO (SUBJAREA, “COMP”) OR LIMIT-TO (SUBJAREA, “BUSI”)) AND (LIMIT-TO (LANGUAGE, “English”)).

Table 2.

Exclusion and inclusion criteria.

Once this second filter was set up, we identified a total of 47 articles, including 23 journal articles and 19 conference papers. In the next step, the 47 papers were ranked by examining the title and abstract showing “high relevance” and “low relevance” with respect to the predefined objective of this article.

Table 3.

Articles.

Table 3.

Articles.

| Title | Authors | Level of Appropriatness |

|---|---|---|

| Lagorio, A.; Cimini, C.; Pirola, F.; and Pinto, R. | High |

| Vukićević, A.; Mladineo, M.; Banduka, and N.; Mačužić; I. | Low |

| Sahal, R.; Alsamhi, S.H.; Brown, K.N.; (...); McCarthy, C.; and Guizani, M. | Low |

| Silva, N.; Barros, J.; Santos, M.Y.; (...); Carvalho, M.S.; and Gonçalves, J.N.C. | High |

| Khatib, E.J.; Barco, R. | Low |

| Bigliardi, B.; Casella, G.; and Bottani, E. | High |

| Zoubek, M.; Simon, M. | High |

| Woschank, M.; Dallasega, P. | High |

| Cano, J.A.; Salazar, F.; Gómez-Montoya, R.A.; and Cortés, P. | High |

| Moshood, T.D.; Sorooshian, S. | Low |

| Atzeni, G.; Vignali, G.; Tebaldi, L.; and Bottani, E. | Low |

| Machado, B.; Teixeira, L.; Ramos, A.L.; and Pimentel, C. | Low |

| Zoubek, M.; Poór, P.; Broum, T.; and Šimon, M. | Low |

| Zwolińska, B.; Tubis, A.A.; Chamier-Gliszczyński, N.; and Kostrzewski, M. | Low |

| Corrêa, J.S.; Sampaio, M.; and de Castro Barros, R. | High |

| Markov, K.; Vitliemov, P. | High |

| Winkelhaus, S.; Grosse, E.H. | High |

| Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S.; Stahre, J. | High |

| Bongomin, O.; Yemane, A.; Kembabazi, B.; (...); Sheron Mpofu, N.; and Tigalana, D. | Low |

| Dossou, P.-E.; Rafael, P.; Cristiane, S.; and Joao, C.J. | Low |

| Plakas, G.; Ponis, S.T.; Agalianos, K.; Aretoulaki, E.; and Gayalis, S.P. | Low |

| Woschank, M.; Pacher, C. | Low |

| Woschank, M.; Pacher, C. | Low |

| Woschank, M.; Pacher, C. | Low |

| Dharmasiri, P.; Kavalchuk, I.; and Akbari, M. | Low |

| Sgarbossa, F.; Peron, M.; and Fragapane, G. | Low |

| Matt, D.T.; Modrák, V.; and Zsifkovits, H. | High |

| Bigliardi, B.; Bottani, E.; and Casella, G. | High |

| Correa, J.S.; Sampaio, M.; de Casto Barros, R.; de Castro Hilsdorf, W. | High |

| Dallasega, P.; Woschank, M.; Zsifkovits, H.; Tippayawong, K.; and Brown, C.A. | High |

| Kodym, O.; Kubáč, L.; and Kavka, L. | High |

| Bukowski, L. | Low |

| Cimini, C.; Lagorio, A.; Pirola, F.; and Pinto, R. | High |

| Krykavskyy, Y.; Pokhylchenko, O.; and Hayvanovych, N. | High |

| Kostrzewski, M.; Kosacka-Olejnik, M.; and Werner-Lewandowska, K. | High |

| Pinheiro, J.C.; Dossou, P.-E.; and Junior, J.C. | Low |

| Jordon, K.; Dossou, P.-E.; and Junior, J.C. | Low |

| Werner-Lewandowska, K.; Kosacka-Olejnik, M. | Low |

| Dossou, P.-E. | High |

| Issaoui, Y.; Khiat, A.; Bahnasse, A.; and Ouajji, H. | High |

| Krowas, K.; Riedel, R. | Low |

| Ellefsen, A.P.T.; Oleśków-Szłapka, J.; Pawłowski, G.; and Toboła, A. | Low |

| Mukku, V.D.; Lang, S.; and Reggelin, T. | Low |

| Selma, C.; Tamzalit, D.; Mebarki, N.; (...); Bruggeman, L.; and Thiériot, D. | High |

| Lee, C.K.M.; Lv, Y.; Ng, K.K.H.; Ho, W.; and Choy, K.L. | High |

| Teucke, M.; Broda, E.; Börold, A.; and Freitag, M. | Low |

| Chong, Z.Q.; Low, C.Y.; Mohammad, U.; Rahman, R.A.; and Shaari, M.S.B. | High |

It is important to note:

- ➢

- That we focused on this study of recent literature on digitization initiatives in the specific field of logistics in industrial companies.

- ➢

- That the relevance criterion addressed in Table 2 is linked to the presence of an attempt to define Logistics 4.0s, an endeavor to highlight the relation between the fourth industrial revolution and the evolution of logistics, an attempt at the I4.0 technologies used in logistics field, and a display of the impact of 4.0 on companies’ performances.

The subjects and the abstracts were analyzed according to the criterion of “high relevance”, which led to the exclusion of 24 articles because of their low or non-relevance for the study, followed by the extraction of articles 15 and 17 since only their abstract is English and available.

The process resulted in 45% of highly suitable studies (21 documents) for subsequent full-text analysis.

2.2. Data Analysis

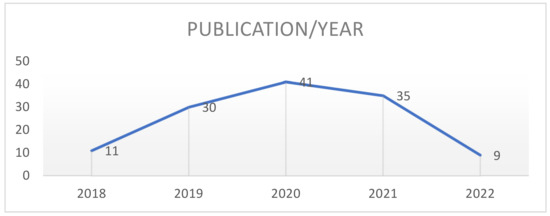

In this section, from Figure 2, Figure 3, Figure 4 and Figure 5, the set of data analyzed is a result of the first filter “126 Documents” from 2018 to 2022, which will help us get an overview of recent studies in the field of intelligent logistics. According to our latest use of the Scopus database, the results below are from the date 24 February 2022.

Figure 2.

A view of Logistics 4.0-related publications within the last 5 years.

Interestingly, in Figure 2, the peak of 2020 is intrinsically related to the momentum of the COVID-19 pandemic; much more attention has been paid to Industry 4.0 and consequently to Logistics 4.0, which further proves that the two paradigms are closely linked. As for the low rate perceived in 2022, it comes down to the fact that we are still at the start of the year; these results will inevitably fluctuate, and they are worth researching.

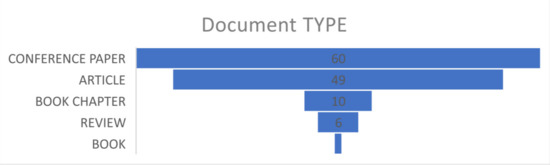

Figure 3.

A breakdown of publications by type of document.

Figure 3 represents the breakdown of the first set of data that resulted from the initial filter; out of the 126 documents, 60 are from conferences, while 49 are from journal articles; what remains is divided between book chapter, book, and review.

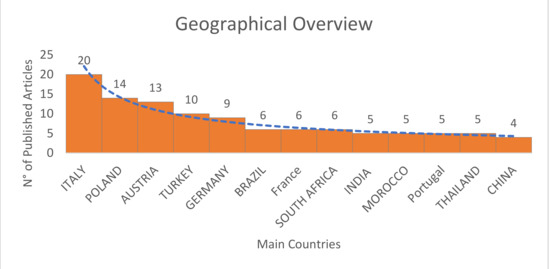

Figure 4.

Geographical breakdown of publications.

Figure 4 is a portrait of the main geographical distribution of the articles published. We notice two interesting points: the first is a concentration on the European continent (Italy taking the lead, followed by Poland then Austria), whereas Germany is in the top 5; the second is the lack of representation on the North American continent, which leads us to validate that the terminology chosen for our study raises a limit.

On the other hand, to inspect the global trend about Logistics 4.0, a quick overview of the interest in Logistics 4.0 on google trend was sufficient; in the last five years, Germany has been ranked first, with a value of 100, which indicates the popularity of the specific term, followed by India with a value of 44 and then the United States with a value of 19. This classification leans on the scientific interests of the researchers of these countries, for example, German researchers have more publications on the concepts of smart factories and intelligent plants, and Americans focus more on Industrial IoT. These results do not in any way prove that Logistics 4.0 is not a subject discussed scientifically in other countries besides Germany, they just show that the browser does not have enough data.

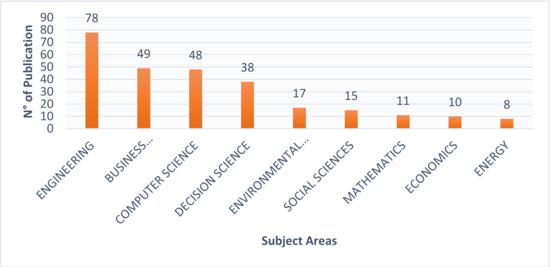

Figure 5.

The main breakdown of subject areas.

In Figure 5, we find the areas most represented by scientific research related to the Logistics 4.0 paradigm. It would be wise to pay attention to the fact that several research projects have been carried out in several interrelated fields; nevertheless, engineering and business management take precedence over the others, closely followed by computer sciences, whereas the environmental sciences come in at fifth place.

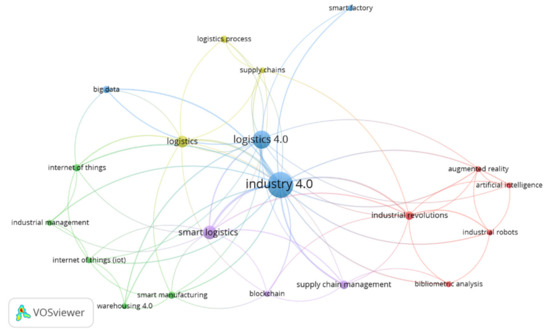

Figure 6.

Keywords mapping.

VOSviewer is the creation of Nees Jan van Eck and Ludo Waltman; the tool represents a computer program that makes it possible to establish, visualize, and explore bibliometric maps.

This tool is available free of charge on www.vosviewer.com, accessed on 24 February 2022. It can be used to analyze all kinds of bibliometric network data, including co-occurrence relationships between scientific terms.

In Figure 6, the set of data used is the result of the second filter (47 Articles) before considering the inclusion and exclusion criteria. While using the tool VOSviewer edition 1.6.17, the chosen analysis’s type is “co-occurrence”; our unit of analysis is “all keywords”, and the counting method is “full-counting”, with a minimum number of occurrences of a keyword at 2. The result is of the 256 keywords; only 28 meet the threshold, divided into 5 clusters, as follows:

- ✓

- Cluster 1: Industrial Revolutions, Augmented Reality, and Artificial Intelligence.

There are 4 occurrences of industrial revolutions, while AR and AI each have 2 occurrences.

- ✓

- Cluster 2: Internet of Things and Smart Manufacturing.

There are 5 occurrences of IoT, whereas there are 2 of Smart Manufacturing.

- ✓

- Cluster 3: Industry 4.0 and Logistics 4.0 (main cluster).

There are 36 occurrences of I4.0, and there are 17 of Logistics 4.0.

- ✓

- Cluster 4: Logistics and Supply Chain.

There are 7 occurrences of Logistics, whereas there are 2 of SC.

- ✓

- Cluster 5: Smart Logistics and Blockchain.

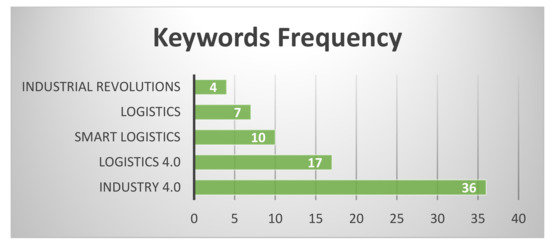

Figure 7.

The main keywords occurrences.

There are 10 occurrences of Smart Logistics, whereas there are two of Blockchain.

Clearly the term “Industry 4.0” has proven to be the most frequent as seen in Figure 7, as it was main component of the search query and to identify studies to include, followed by “Logistics 4.0”, “Smart Logistics” and Fourth Industrial Revolution Key Technologies.

Of the 21 articles screened and read, 4 core ideas were identified as portrayed in Table 4:“definition of Logistics 4.0, its dimensions and technologies” with 6 articles; “Industry 4.0 technologies and application areas” with 10 articles; “potential of logistics evolution in companies, and sustainability” with 4 articles; and “Human factor in Logistics 4.0” with 3 articles; this classification of the articles by axis eases their analysis, with the objective of deducing the arguments that may validate the orientation questions mentioned beforehand.

Table 4.

The main ideas screened in the second set of data after the inclusion and exclusion criteria were considered [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37].

2.3. Industry 4.0: Technologies

In the current era, artificial systems are experiencing unprecedented complexity, which drives the creation of new opportunities while presenting the possibility of the emergence of increased challenges for companies that create and use these systems in an environment influenced by the following conditions:

- ✓

- The context of globalization, an example of connected knowledge.

- ✓

- Information flows become more important and diverse.

- ✓

- The method and speed of dissemination of information and communication technologies.

- ✓

- The involvement of information systems in improving business performance and their impact as a major asset related to business survival.

Industry 4.0 personifies the next generation of industrial production (the actual phase for most developed countries), a manufacturing era where real-time data can be captured, shared, and used to drive rapid decision-making.

Table 5.

The genesis of the paradigm.

Table 5.

The genesis of the paradigm.

| Mark Weiser 1988 1999 | Kagermann 2010 2011 |

|---|---|

|

|

|

|

The German Manifesto as a result of the first publication of the new industrial paradigm, as cited in Table 5, triggered a multitude conference and seminars on “Industry 4.0” worldwide. I4.0 is about connecting the physical and digital worlds, which is expressed by an influx of the volume, velocity, and variety of data.

Today, a large part of the critical assets of manufacturing companies are part of the physical world. The latest advances in technology are giving manufacturers the ability to use the data produced by these physical assets to generate data-driven insights.

Some of these advanced technologies are: cyber physical systems, big data analytics, Internet of Things, cloud computing, Artificial Intelligence, augmented reality:

-

- CPS: A cyber-physical system is a system where computer elements collaborate for the control and command of physical entities.

-

- IoT: as its name designates ‘connected objects to internet’, this technology represents the interconnection between the Internet and physical objects, places, and environments, therefore allowing for communication between our so-called physical goods and their digital existences.

-

- Big Data: a term used to refer to a massive amount of data, or a large set of data that no conventional database management or information management tool can really work with. Big data analytics is all about helping businesses make better informed decisions.

-

- Cloud computing: defined as the access to computer services via the Internet from a provider; related to the delivery of on-demand resources and services over the Internet. It adverts to storing and accessing data via the Internet rather than via a computer hard drive.

-

- Augmented reality: is the superposition of reality and elements calculated by a computer system in real time. It often designates the various methods that make it possible to inlay virtual objects in a realistic way in a sequence of images.

-

- Artificial Intelligence: refers to systems or machines that mimic human intelligence to perform tasks and can improve based on information gathered through iteration.

3. Discussion

In this section, other references have been added, mainly drawn from Google scholar, to enrich the discussion and confirm the arguments put forward by the authors and researchers of the 21 papers screened in Section 2.

3.1. Industry 4.0 and Logistics 4.0

It is widely recognized that the actual industrial revolution will bring forth opportunities related to global logistics, such as efficiency, sustainability, or responsiveness to customers [22].

With the digitalization of manufacturing processes, “Logistics 4.0” has been receiving increasing attention in recent years, especially since the evolution of Logistics’ concept is deeply related to the industrial revolution as described in Table 6, which accentuates the fact that logistics processes are the central function that plays a crucial role in the digital migration of the manufacturing sector, and therefore the underlying vision of fourth industrial revolution. [34,35,38,39].

Table 6.

The impact of industrial revolutions on the evolution of logistics.

Some of the front-end technologies of Industry 4.0, such as Cyber-Physical Systems (CPS) and Internet of Things, Services, and People, can support the real-time tracking and tracing of materials from point of origin to the last mile, enabling a better internal and external logistics management.

According to Hofmann and Rüsch (2017), Industry 4.0 presents an opportunity for more efficient logistics management. The authors pointed out that the connectivity of products and services through the Internet or other network applications such as blockchain technology will enable the decentralized control of value chains. These same authors state that digital connectivity offers the possibility of improving automated production as well as the self-optimized production of goods and services, including delivery without the presence of the human agent [40].

Witkowski (2017) emphasizes the importance of IoT, especially in the logistics and transport sector since the integration of the respective solutions provides operational data on location and status [41].

Barreto (2017) argue that the IoT is the solution to challenges of transparency or visibility in supply chains processes, thus boosting customer satisfaction by reducing costs due to reduced cycles of logistics processes, joining the famous quote of logistics—the right products at the right time, in the right place, in right quantity, and at the right cost [3].

Liu et al. (2019) suggest another potential benefit of IoT— the real-time activated state detection of logistics vehicles for improved logistics services, which will enable cost reduction through controlled and optimized fuel consumption [42].

By starting the shift to Industry 4.0, companies will undertake the digitization of all their processes, ranging from planning, to supply, to manufacturing, to delivery, and to return, which will positively impact logistics processes by improving flows, optimizing work, and reducing lead times.

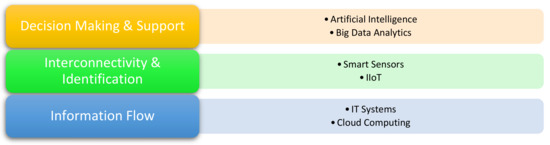

We can deduce that the Industry 4.0 technologies as shown in Figure 8 support the logistics paradigm on two fronts: physical operations and resource management.

Figure 8.

Industry 4.0 technologies applied to Logistics [32,33].

Artificial Intelligence (AI) and big data analytics play an important role in automating decision-making processes; they provide a way to support human decisions in a data-driven approach. In addition, Industrial Internet of Things (IIoT) technologies and smart sensors facilitate product and material identification processes and improve product tracking throughout the chain. As for computer systems, they provide real-time access to data and information from multiple sources; therefore, they allow for production planning in real time and in a reactive manner [28,43].

Industry 4.0 technologies adopted by logistics operations will enable new features that facilitate the optimization of resources and energy, such as the constant transparency of the complete supply chain, for all participants in the process.

3.2. Logistics 4.0 Characteristics

Industrial logistics in manufacturing companies focuses mainly on the processes of planning, implementation, control, and the continuous optimization of physical and informational flows, with the aim of satisfying customer requirements [20,44].

The dimensions presented in Table 7 highlight the components of each type of flow linked to the Logistics 4.0 paradigm:

Table 7.

Logistics 4.0 dimensions [24,45].

It is interesting to note that among these components, we find technologies related to Industry 4.0. These Industry 4.0 solutions must adapt to the maturity of the existing logistics processes in enterprises, so that the transition towards Logistics 4.0 is on the right track [46].

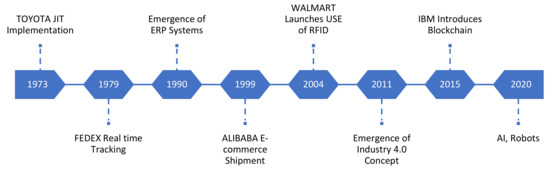

Figure 9 depicts the main phases in the evolution of logistics ‘concept; the most recent approach is called Logistics 4.0, which is supposed to increase the efficiency of logistics services, thus allowing manufacturing companies to shift to the concept of Industry 4.0. Some of the possible solutions would include support for the planning/scheduling process, warehouse operation management, the management of the intelligent transport system, and the management of secure information flows [3]. The figure also reflects the scientific interest of researchers in relation to the emergence of each new solution related to logistics.

Figure 9.

Worldwide historical logistic evolution events.

The figure above also reflects the scientific interest of researchers in relation to the emergence of each new solution related to logistics [23].

Smart Logistics modifies the actual solutions already in operation in classical logistics and brings out new technologies, some of which are presented in Table 8, such as cyber-physical systems, which consent to the networking and automation of the transport, the storage system, the sustainable fulfillment of individualized customer demands without increasing costs, and decentralized software control among others [47,48,49].

Table 8.

Solutions in Logistics 4.0 [25,30,33,34,36].

It is important to note that without technological infrastructure such as IoT, CPS, cloud computing, and big data, it will not be possible to take full advantage of Logistics 4.0 programs.

IoT not only helps improve the aspect of transparency in the supply chain but also supports certain activities such as packaging and order picking.

Scientific publications in the literature point out that big data technologies can process information with new statistical tools and manage them in a centralized way via cloud computing and decentralized in autonomous systems.

Human capital/managers are responsible for improving the ability to analyze big data to make the operational decision-making process more efficient. Big data can add significant value and bring monetary gains to businesses [50,51].

The latest technology to be added in operations management is the application of blockchain technologies, the latter being used for processing transactions, which allows one to transform supply chains, providing better visibility, guaranteeing security and privacy, and contributing to operational improvements [52].

The digitalization phase of traditional logistics solutions makes the logistics system more efficient and flexible in the face of changes in the market and customer needs.

Digitized internal and external logistics will provide an interconnected system, advanced information analysis and prediction tools, a smart warehouse, and an intelligent transport system.

Industry 4.0 technologies assimilated into logistics operations will offer better cooperation between the different actors in the chain, which will minimize energy consumption, among other benefits.

The application of technologies such as cyber-physical systems and big data within the framework of Logistics 4.0 for the purpose of production process management can be an ideal way to improve the efficiency of logistics processes while enabling compliance with the principles of sustainable development [53].

Another component that has shown up recently with Logistics 4.0 concept is none other than the notion of sustainability, achievable through the intelligent management of the various active elements of the logistics process (such as the management of delivery areas, the estimation and monitoring of air pollution, and energy consumption in shop floors) [54].

3.3. Logistics 4.0 between Opportunities and Risks

We thought it is appropriate to report the most specific comments from the literature review concerning the various advantages and risks of Logistics 4.0:

- Among the most redundant ideas shared by more than several authors is that after the adoption of Industry 4.0 technologies by the current logistics process, the new purposes of resource planning; warehouse management systems, intelligent transport systems; and security information are reduced time to market, prevention of stockouts, increased return on investment, and the sustainability of operations [29,55].

- Another benefit is the reduction of physical workload when using programmable logic controllers in production processes and logistics operations [56].

- A third benefit is the growth of customer satisfaction, thanks to two essential factors: better analysis of the implicit need, thanks to real-time information and analysis of data shared between all participants in the supply chain, and transparency of production and cost savings [57].

- A fourth advantage is the possibility of capacity sharing between many companies [58].

- A fifth benefit is renewable energy, resource efficiency, and waste reduction.

- A sixth benefit is higher product quality and personalized products that entail increased customer loyalty.

- A seventh benefit is that assistance systems will increase workplace safety for employees [30,59].

With each change or evolution, new opportunities appear in parallel with new threats; we have mentioned above some examples of the advantages that Logistics 4.0 brings, but the latter also recognizes disadvantages:

- As for the other side of the medallion, the risks incurred are numerous; the most serious will be those linked to cyberattacks on assembly lines connected to the Internet, which will lead to a halt in production processes.

- Secondly, another challenge will concern incorrect data in blockchain portals, which will have a direct impact on the investment cost of implementing this technology.

- According to (Verma et al., 2020), security is always the first concern, followed by confidentiality and trust, important installation and implementation costs, lack of technical skills and roadmaps, lack of adequate infrastructure, the digital transformation of the legacy system, and resistance to change [60].

4. Conclusions

The main objective of this article was to identify the influence of Industry 4.0 on the evolution of logistics; subsequently to determine whether the impact of the relationship between the two paradigms goes in one way or in both ways; and then to list the main opportunities and risks of Logistics 4.0.

In this paper, apart from the first dataset used for descriptive statistics, 21 articles published between 2018 and February 2022 were screened based on defined inclusion and exclusion criteria and fully read.

The concept of Industry 4.0 is capable of significantly changing production processes and associated logistics processes.

This paper presents the link between Industry 4.0 and Logistics 4.0, as well as the role of technologies and their contributions during their adoption in the logistics process. A few benefits of Logistics 4.0 are improved information visibility and connectivity, in combination with a physical network with fast and reliable delivery options, as well as logistics productivity efficiency and a reduced negative impact on the environment.

We are aware that Logistics 4.0 is a relatively new concept, and little research is available in this area. Logistics 4.0 remains quite difficult to define, and digitalization within industrial logistics may also have other influences and is shaped by different actors.

In this paper, we have restricted the choice of terms used to “Smart Logistics” and “Logistics 4.0” which could prove to be a limit to detecting the different opportunities possible with this recent paradigm.

Another limit, which could also be the subject of a new scientific study, is the role of humans in Logistics 4.0. Several authors mention that certain job skills, mainly manual activities, will be replaced by machines due to problems of efficiency, safety, and quality, which induces a growing fear of job loss and therefore loss of income among many workers; this fear, whether justified or not, negatively affects staff motivation and causes resistance to change. On the other hand, the lack of qualifications of workers and the absence of computer security skills represent major risks to be considered more seriously.

As a perspective of future research, we could focus on the environmental, economic, and social sustainability dimensions in logistics.

Author Contributions

Conceptualization, methodology, analysis, writing—review and editing, S.E.H. and Supervision, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tsai, W.C.; Tang, L.L. A model of the adoption of radio frequency identification technology: The case of logistics service firms. J. Eng. Technol. Manag. 2012, 29, 131–151. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Bericht der Promotorengruppe Kommu-Nikation Im Fokus: Das Zukunftsprojekt Industrie 4.0—Handlungsempfehlungen zur Umsetzung. Available online: https://www.bmbf.de/pub_hts/kommunikation_bericht_2012-1 (accessed on 15 July 2021).

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Marinagi, C.; Trivellas, P.; Sakas, D.P. The impact of information technology on the development of supply chain competitive advantage. Procedia-Soc. Behav. Sci. 2014, 147, 586–591. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Zhou, C.; Su, F.; Pei, T.; Zhang, A.; Du, Y.; Luo, B.; Song, C. COVID-19: Challenges to GIS with Big Data. Geogr. Sustain. 2020, 1, 77–87. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulationbased analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, R. Impact of technology on logistics and supply chain management. IOSR J. Bus. Manag. 2014, 2, 19–24. [Google Scholar]

- Choy, K.L.; Gunasekaran, A.; Lam, H.Y.; Chow, K.H.; Tsim, Y.C.; Ng, T.W.; Lu, X.A. Impact of information technology on the performance of logistics industry: The case of Hong Kong and Pearl Delta region. J. Oper. Res. Soc. 2014, 65, 904–916. [Google Scholar] [CrossRef]

- Lai, K.H.; Wong, C.W.; Cheng, T.C.E. Bundling digitized logistics activities and its performance implications. Ind. Mark. Manag. 2010, 39, 273–286. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability impact of digitization in logistics. Procedia Manuf. 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Lin, C.Y.; Ho, Y.H. RFID technology adoption and supply chain perfor-mance: An empirical study in China’s logistics industry. Supply Chain Manag. 2009, 14, 369–378. [Google Scholar] [CrossRef]

- Çemberci, M.; Civelek, M.E.; Canbolat, N. The moderator effect of global competitiveness index on dimensions of logistics performance index. Procedia-Soc. Behav. Sci. 2015, 195, 1514–1524. [Google Scholar] [CrossRef] [Green Version]

- Ekici, Ş.Ö.; Kabak, Ö.; Ülengin, F. Improving logistics performance by reforming the pillars of Global Competitiveness Index. Transp. Policy 2019, 81, 197–207. [Google Scholar] [CrossRef]

- Gani, A. The logistics performance effect in international trade. Asian J. Shipp. Logist. 2017, 33, 279–288. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, C.; Hafeez, M.; Yuan, Q. The relationship between environ-ment and logistics performance: Evidence from Asian countries. J. Clean. Prod. 2018, 204, 282–291. [Google Scholar] [CrossRef]

- Stojanović, Đ.; Ivetić, J. Possibilities of using Incoterms clauses in a country logistics performance assessment and benchmarking. Transp. Policy 2020, 98, 217–228. [Google Scholar] [CrossRef]

- Philipp, R. Digital readiness index assessment towards smart port development. In Sustainability Management Forum|Nachhaltigkeits Management Forum; Springer: Berlin/Heidelberg, Germany, 2020; Volume 28, pp. 49–60. [Google Scholar] [CrossRef]

- Woschank, M.; Rauch, E.; Zsifkovits, H. A Review of Further Directions for Artificial Intelligence, Machine Learning, and Deep Learning in Smart Logistics. Sustainability 2020, 12, 3760. [Google Scholar] [CrossRef]

- Lagorio, A.; Cimini, C.; Pirola, F.; Pinto, R. A Taxonomy of Technologies for Human-Centred Logistics 4.0. Appl. Sci. 2021, 11, 9661. [Google Scholar] [CrossRef]

- Silva, N.; Barros, J.; Santos, M.Y.; Costa, C.; Cortez, P.; Carvalho, M.S.; Gonçalves, J.N.C. Advancing Logistics 4.0 with the Implementation of a Big Data Warehouse: A Demonstration Case for the Automotive Industry. Electronics 2021, 10, 2221. [Google Scholar] [CrossRef]

- Bigliardi, B.; Casella, G.; Bottani, E. Industry 4.0 in the logistics field: A bibliometric analysis. IET Collab. Intell. Manuf. 2021, 3, 4–12. [Google Scholar] [CrossRef]

- Zoubek, M.; Šimon, M. The Framework for Logistics 4.0 Maturity Model with a Specification for Internal Logistics. MM Sci. J. 2021, 2021, 4264–4274. [Google Scholar] [CrossRef]

- Woschank, M.; Dallasega, P. The Impact of Logistics 4.0 on Performance in Manufacturing Companies: A Pilot Study. Procedia Manuf. 2021, 55, 487–491. [Google Scholar] [CrossRef]

- Cano, J.A.; Salazar-Arrieta, F.; Gómez Montoya, R.A.; Cortés, P. Disruptive and Conventional Technologies for the Support of Logistics Processes: A Literature Review. Int. J. Technol. 2021, 12, 448–460. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S.; Stahre, J. Smart logistics and the logistics operator 4.0. IFAC-PapersOnLine 2020, 53, 10615–10620. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Correa, J.S.; Sampaio, M.; Barros, R.D.C.; Hilsdorf, W.D.C. IoT and BDA in the Brazilian future logistics 4.0 scenario. Production 2020, 30. [Google Scholar] [CrossRef] [Green Version]

- Kodym, O.; Kubáč, L.; Kavka, L. Risks associated with Logistics 4.0 and their minimization using Blockchain. Open Eng. 2020, 10, 74–85. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Pirola, F.; Pinto, R. Exploring human factors in Logistics 4.0: Empirical evidence from a case study. IFAC-Pap. 2019, 52, 2183–2188. [Google Scholar] [CrossRef]

- Krykavskyy, Y.; Pokhylchenko, O.; Hayvanovych, N. Supply chain development drivers in industry 4.0 in Ukrainian enterprises. Oeconomia Copernic. 2019, 10, 273–290. [Google Scholar] [CrossRef]

- Kostrzewski, M.; Kosacka-Olejnik, M.; Werner-Lewandowska, K. Assessment of innovativeness level for chosen solutions related to Logistics 4.0. Procedia Manuf. 2019, 38, 621–628. [Google Scholar] [CrossRef]

- Dossou, P.E. Using industry 4.0 concepts and theory of systems for improving company supply chain: The example of a joinery. Procedia Manuf. 2019, 38, 1750–1757. [Google Scholar] [CrossRef]

- Issaoui, Y.; Khiat, A.; Bahnasse, A.; Ouajji, H. Smart logistics: Study of the application of blockchain technology. Procedia Comput. Sci. 2019, 160, 266–271. [Google Scholar] [CrossRef]

- Selma, C.; Tamzalit, D.; Mebarki, N.; Cardin, O.; Bruggeman, L.; Thiériot, D. Industry 4.0 and service. In International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing; Springer: Cham, Switzerland, 2018; pp. 436–447. [Google Scholar]

- Lee, C.K.; Lv, Y.; Ng, K.K.H.; Ho, W.; Choy, K.L. Design and application of Internet of things-based warehouse management system for smart logistics. Int. J. Prod. Res. 2018, 56, 2753–2768. [Google Scholar] [CrossRef]

- Chong, Z.Q.; Low, C.Y.; Mohammad, U.; Rahman, R.A.; Shaari, M.S.B. Conception of logistics management system for smart factory. IJET 2018, 7, 126–131. [Google Scholar] [CrossRef]

- Alibekova, G.Z.; Medeni, T.; Panzabekova, A.Z.; Mussaeva, D. Digital Transformation Enablers and Barriers in the Economy of Kazakhstan. J. Asian Financ. Econ. Bus. 2020, 7, 565–575. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for Industry 4.0. J. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Witkowski, K. Internet of things, big data, industry 4.0–innovative solutions in logistics and supply chains management. Procedia Eng. 2017, 182, 763–769. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Liu, Y.; Wang, L.; Wang, X.V. An ‘Internet of Things’ enabled dynamic optimization method for smart vehicles and logistics tasks. J. Clean. Prod. 2019, 215, 806–820. [Google Scholar] [CrossRef] [Green Version]

- Strandhagen, J.W.; Alfnes, E.; Strandhagen, J.O.; Vallandingham, L.R. The Fit of Industry 4.0 Applications in Manufacturing Logistics: A Multiple Case Study. Adv. Manuf. 2017, 5, 344–358. [Google Scholar] [CrossRef] [Green Version]

- Christopher, M. Logistics & Supply Chain Management, 5th ed.; FT Publishing International: Upper Saddle River, NJ, USA; Pearson: London, UK, 2016. [Google Scholar]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2020, 12, 86. [Google Scholar] [CrossRef] [Green Version]

- Ole’sków-Szłapka, J.; Stachowiak, A. The framework of logistics 4.0 maturity model. In Advances in Intelligent Systems and Computing; Springer: Wrocław, Poland, 2019. [Google Scholar]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. Using multi-objective optimization for the integrated energy efficiency improvement of a smart city public buildings’ portfolio. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 21–26. [Google Scholar]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Wamba, S.F.; Gunasekaran, A.; Papadopoulos, T.; Ngai, E. Big data analytics in logistics and supply chain management. Int. J. Logist. Manag. 2018, 29, 478–484. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Kauf, S. City logistics–A Strategic Element of Sustainable Urban Development. Transp. Res. Procedia 2016, 16, 158–164. [Google Scholar] [CrossRef] [Green Version]

- Torbacki, W.; Kijewska, K. Identifying Key Performance Indicators to be used in Logistics 4.0 and Industry 4.0 for the needs of sustainable municipal logistics by means of the DEMATEL method. Transp. Res. Procedia 2019, 39, 534–543. [Google Scholar] [CrossRef]

- Cuenca, R.I.; Tokars, R.L.; Warnecke, V.; Deschamps, F.; Valle, P.D. Systematic literature review on the use of the internet of things in industrial logistics. Adv. Transdiscipl. Eng. 2020, 12, 151–160. [Google Scholar]

- Dallasega, P.; Woschank, M.; Zsifkovits, H.; Tippayawong, K.; Brown, C.A. Requirement Analysis for the Design of Smart Logistics in SMEs. In Industry 4.0 for SMEs: Challenges, Opportunities and Requirements; Matt, D.T., Modrák, V., Zsifkovits, H., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 147–162. [Google Scholar]

- Markov, K.; Vitliemov, P. Logistics 4.0 and supply chain 4.0 in the automotive industry. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 878. [Google Scholar]

- Sgarbossa, F.; Peron, M.; Fragapane, G. Cloud material handling systems: Conceptual model and cloud-based scheduling of handling activities. In Scheduling in Industry 4.0 and Cloud Manufacturing; Springer: Cham, Switzerland, 2020; Volume 289, pp. 87–101. [Google Scholar]

- Schmidtke, N.; Behrendt, F.; Thater, L.; Meixner, S. Technical potentials and challenges within internal logistics 4.0. In In Proceedings of the 2018 4th International Conference on Logistics Operations Management (GOL), Le Havre, France, 10–12 April 2018; Volume 4, pp. 19–28. [Google Scholar]

- Verma, P.; Dixit, V.; Kushwaha, J. Risk and resilience analysis for industry 4.0 in achieving the goals of smart logistics: An overview. In In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, UAE, 10–12 March 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).