1. Introduction

Various participants are involved in the construction process, including clients, contractors, and technical supervisors. A project develops according to the achievement of goals that considers the requirements of the client and also ensures the qualifications of the chosen contractor and suppliers. A successful project requires appropriate contractor selection. Failing to select an adequate contractor often leads to price changes, a delayed project schedule, and substandard quality. However, the prequalified bidding process is the only step to regulate the selection of the qualified contractor, and each client conceives the evaluation criteria differently.

Most project leaders in construction underestimate and neglect the importance of the contractor selection process [

1,

2]. It is challenging to analyze a wide variety of uncertainties presented by conditional considerations in decision making. Problems in selecting contractors include insufficient time for execution, complex procedures, and poor information channels [

3]. The evaluation is usually performed by the general contractor’s management based on intuition and experience [

4]. In most cases, a selection process called “prequalification” is used to screen out contractors with inferior skills, leaving the contracting officer to select only from the remaining qualified bidders.

The prequalification process attempts to identify a group of eligible contractors after bids are received to avoid wasting resources evaluating contractors. In the current literature, prequalification is defined more generally [

5,

6,

7,

8,

9], according to which the process includes contractor registration and project-specific prequalification. Registration may include an initial evaluation and periodic updates to higher-level labor categories from a list of registered contractors according to their capabilities [

10].

Therefore, it is essential for contractors to implement a systematic mechanism to improve the performance of the bidding process for construction projects. A multicriteria approach solves this problem by allowing contractors to be evaluated on their financial and technological aspects, quality standards, technical performance, and other tangible and intangible characteristics. This helps to reduce the number of unsuccessful tenders [

11], integrates prequalification in the selection of candidates, introduces a second standard to study contractors, and generates a final evaluation, taking into account the total tender cost to propose the best bidder [

12]. In this study, a new contractor selection model is proposed for owners that extends beyond the traditional contractor management model.

The remainder of this paper is organized as follows:

Section 2 reviews the literature on contractor evaluation models and the prequalification criteria.

Section 3 describes the interpretive structural modeling methodology for solving the problem.

Section 4 reveals the implementation of the proposed approach to identify the key criteria in contractor prequalification.

Section 5 and

Section 6 analyze and discuss the results, respectively. Finally,

Section 7 draws conclusions.

2. Literature Review

Many studies have established evaluation models to appraise and supervise construction contractors in the bidding process. This section discusses the evaluation models and prequalification criteria for selecting qualified contractors.

2.1. Contractor Selection Models

The contractor selection is indeed a multicriteria problem. Many studies on contractor selection dedicated their efforts to analyzing prequalification criteria and the weighting factors and describing the palpable applications. Several methodologies are involved in the prequalification process. Holt [

13] presented a thorough methodology review in both stages of the contractor selection process, shown in

Table 1.

Other methodologies have also been suggested in the literature, such as multicriteria decision making (MCDM) [

14], case-based reasoning (CBR) [

15], and graph theory (GT) [

16]. Most of these models are built on schematic conceptions. Russell and Skibniewski [

17] developed a dimensional weighting aggregation model where the input rating of each decision criterion can generate an aggregated weighting for each contractor. Russell et al. [

18] employed decision rules when choosing the contractor prequalification by constructing a knowledge-based expert system. Hatush [

6] used the program evaluation and review technique (PERT) considering the probabilities of the criteria to assess contractor data as opposed to client goals (time, cost, and quality). Zavadskas et al. [

19] presented a multiattribute analysis applicable to many economic, managerial, and constructional problems. They studied global bridge and road quality management by examining investment support tools, such as cost–benefit analysis and multiattribute analysis. Huang et al. [

20] appraised contractor financial capacities as financial prequalification using a cash flow-based (CFB) credit model.

Linguistic assessments are often used in contractor selection instead of numerical values. The fuzzy set theory helps address decision making with unspecific and general terms. It can suggest decisions based on preliminary data [

21]. Nguyen [

22] proposed a bidder selection procedure considering three criteria: cost, bidding presentation and experience, and client preferences. Plebankiewicz [

23] presented a two-staged contractor prequalification schema: on a standing list and per project. The author described a per-project evaluation model employing the fuzzy set theory. Palaneeswaran and Yu [

24] developed an SVM prequalification model.

2.2. Prequalification Criteria

Contractor selection research often focuses on developing methods and tools similar to supplier selection. In these types of studies, emphasis has been placed on investigating clients’ criteria in contractor prequalification and selection. Doloi et al. [

25] established a hierarchical structural model attempting to understand the preemptive qualification criteria and their links to contractor performance. Their model adopts 29 technical attributes over five confirmatory factors according to structural equation modeling: overall project success (OPS), past performance (PP), quality performance (QP), planning and control (PC), and soundness of business and workforce (SBW). Alarcon and Mourgues [

26] stated that contractors’ quality performance is typically gauged by safety, query response time, quality assurance programs and quality control, safety records, tender timeliness, and tender quality. Ko et al. [

27] developed a framework based on 12 criteria to evaluate sub-contractor performance. Hatush and Skitmore [

5] found substantial variation in contractor selection criteria expression and classified the criteria into five categories: reputation, safety, managerial capability, technical ability, and financial soundness.

A wide variety of criteria have been proposed based on the literature (

Table 2). Although contractor prequalification has common characteristics, distinct projects can exhibit different criteria. The following 12 criteria are most considered in prequalification:

Financial stability (C1): The general financial situation and performance of a contractor must be known to the contracting authority;

Credit rating (C2): A credit rating indicated the probability that a company or government entity will become insolvent. It is usually performed by a credit rating agency;

Engineering experience (C3): The contractor must demonstrate previous participation, especially in similar bidding projects;

Personnel qualification (C4): The qualification of personnel requires adequate knowledge of the technical principles underlying the nondestructive tests to be performed;

Engineering ability (C5): Engineering ability is a professional discipline that addresses the designing, planning, construction, and managing of infrastructure;

Performance and quality (C6): Quality affects project performance. Defects or failures in constructed facilities require reconstruction and can result in degraded operations and high costs;

Project management organization (C7): This ensures that required tasks are completed in a timely manner and reports a company’s business requirements and staffing levels;

Management knowledge (C8): This is the process of gathering, developing, sharing, and effectively using corporate information;

Safety (C9): This includes promoting the organization and maintenance of risk management systems for employee safety and health;

Management accountability (C10): This sets expectations for sound management practices and performance in the public sector;

Breach of contract (C11): A breach of contract by either obstructing another party’s obligations or failing to meet its contractual obligations;

Past client–contractor relationships (C12): The customer needs to understand the contractor’s relationships with other parties.

3. Methodology

The ISM methodology is based on graph theory. Its mathematical development can be found in [

34,

35]. ISM has been used for criteria or factor analysis in various fields, such as sustainable supply chain management [

36,

37], supplier selection [

38], supply chain risk analysis [

39], Industry 4.0 implementation [

40], Building Information Modeling (BIM) implementation [

41], total quality management implementation [

42], and service quality improvement [

43].

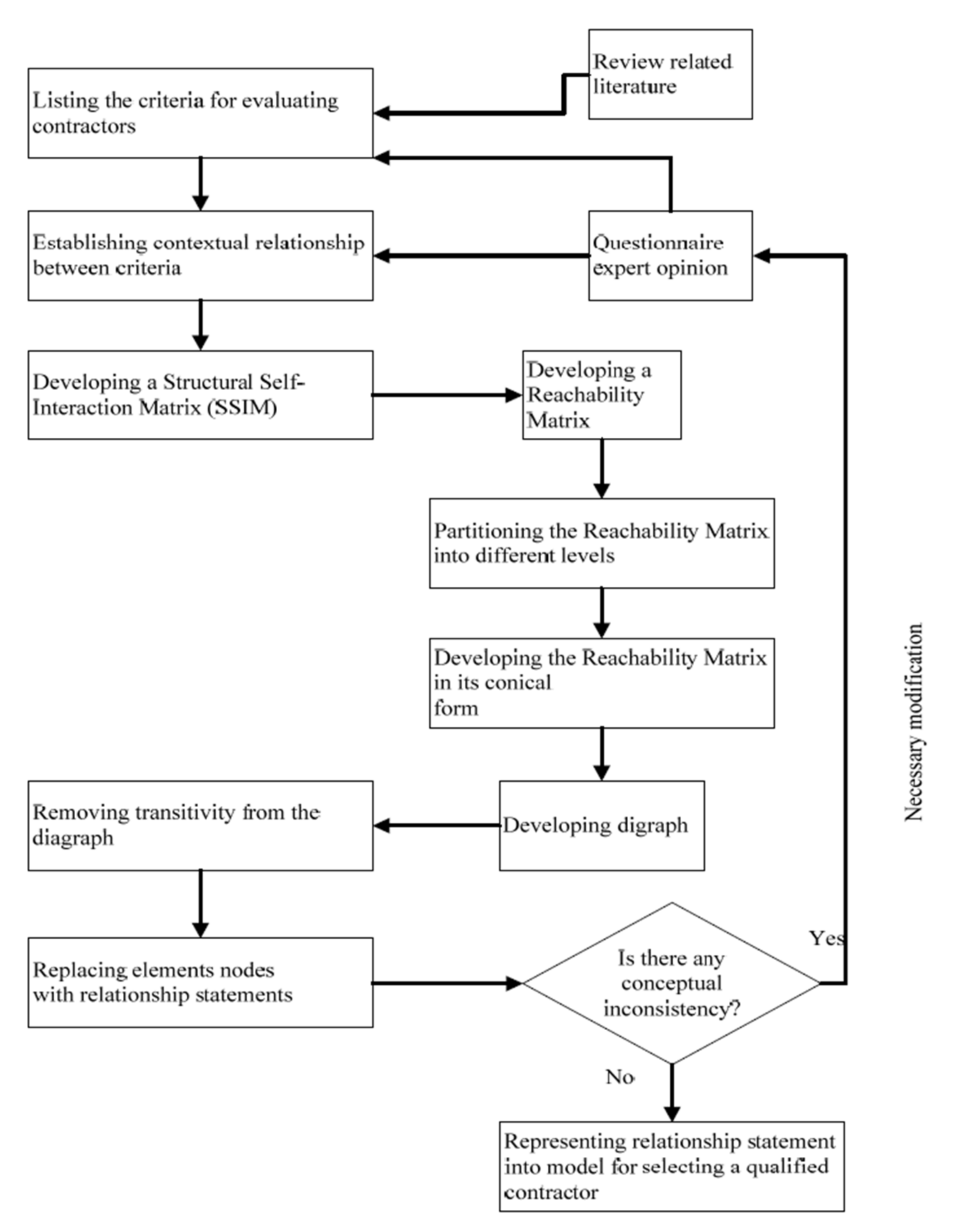

The concept of ISM is to build a hierarchical relational structure model based on complex element relationships. After analyzing the relational structure model using experts’ professional knowledge to describe the contextual relationships between elements, a directed graph is plotted. ISM identifies and analyzes the relationships between specific variables describing a problem, topic, system, or area of study in a carefully designed pattern that includes graphs and words. After a pairwise comparison of the variables, a structural self-interaction matrix (SSIM) is created and transformed into a reachability matrix whose transitivity is checked. When the transitivity embedding is completed, a matrix model is obtained. The steps of the ISM method are listed below.

- Step 1

List the elements that are relevant to the system;

- Step 2

Develop the contextual relationship between the elements identified in Step 1;

- Step 3

Use the pairwise comparison between the elements to develop an SSIM;

- Step 4

Generate a reachability matrix based on the SSIM and check the transitivity of the matrix;

- Step 5

Divide the matrix into different levels;

- Step 6

Draw a relational graph according to the reachability matrix in Step 3 and remove the transitive links;

- Step 7

Replace transitive nodes with statements to convert the directed graph obtained in Step 6 into an ISM model;

- Step 8

Check the conceptual inconsistency of the ISM model and modify the model if necessary.

Figure 1 illustrates the process of ISM modeling.

4. Implementation of the Proposed Approach

This section presents an application of the model conducted for the construction industry to validate the proposed approach for analyzing issues of qualified contractors. Lacking effective selection approaches, this focus grants us better insights into developing a qualified contractor in the construction industry. The methodology steps and qualified contractor analyses are shown below.

4.1. Step 1: Collecting and Defining the Selection Criteria

The first step is to gather and establish evaluation criteria for selecting a qualified contractor. Our team asked five construction managers and experts in the field for their opinions on the issues they face. This was carried out through emails, phone inquiries, and face-to-face meetings. We also examined the existing literature from respected journals such as Springer, Elsevier, and Emerald. Finally, with the help of experts from the field and the literature, we identified important issues in contractor selection.

4.2. Step 2: Questionnaire Development Based on the Evaluation Criteria

A questionnaire was designed and circulated to construction managers to decide the effect and priority of various criteria. All industrial manager contacts were accomplished through e-inquiries and meetings. According to the replies received, we assembled the most prominent factors in the qualified contractor process and began to compare them.

4.3. Step 3: Analyzing the Qualified Contractor Using the ISM Approach

The implementation steps of the ISM are as follows:

ISM is an interactive learning process involving different and directly related variables. The model can explicitly characterize the structure of a complicated problem. The first stage of the ISM method builds the contextual relationship among all factors through expert opinions. Four symbols were used to indicate the relationships among the criteria: V, A, X, and O. We can produce the following assessments considering and as the criteria:

A: Criterion causes criterion ;

V: Criterion causes criterion ;

X: Criterion causes criterion , and criterion j causes criterion ;

O: Criteria and are not related.

One factor “causes” another indicates one leads to another. An SSIM is built on expert comments on the relationship between two factors. The experts certify the inclusion of crucial agile factors pivoting on their relationship and elucidating their intent. This process ends when all the experts approve the listed relations. In this study, the experts formed pairwise comparisons. After the pairwise comparisons were formed, we constructed the SSIM, as shown in

Table 3.

The SSIM is transformed into the initial reachability matrix, a binary matrix, by substituting 1 and 0 for V, A, X, and O, respectively. The rules for substituting 1 s and 0 s are shown in

Table 4. The resulting initial reachability matrix is given in

Table 5. The final reachability matrix is generated by Equations (1) and (2).

where

represents the identity matrix,

symbolizes the powers,

denotes the reachability matrix, and

is the stable reachability matrix. The reachability matrix is calculated based on the addition law and Boolean multiplication (i.e.,

,

,

,

, and

). The transitivity checks from the criteria in the ISM approach yield the final reachability matrix in

Table 6.

- 2.

Level partitions

By continuously evaluating the reachability and prior sets for each criterion, a partition of the reachability matrix was created. The reachability set included the reachable criteria. The antecedent set included the criteria and the others that could contribute to their fulfillment. The intersection of these sets was created for all criteria. The criteria could be categorized in the first level of the ISM hierarchy if they gravitated toward both the reachability set and intersection set in the same fashion. The criteria cannot be used to determine the others above their level. The next level criteria were identified through the same process.

Table 7 exhibits the criteria, their levels, intersection set, antecedent set, and reachability set.

4.4. Step 4: Analyzing a Qualified Contractor Using the ISM Approach

The results acquired were substantiated through inquiring field experts and industrial managers and reviewing the published literature. Complications in feedback results can be further analyzed for the cause of the complication. The cross-impact matrix multiplication applied to classification (MICMAC) method [

44] was used for response simplification. The calculations are shown in

Table 6, and the results are illustrated in

Figure 3.

5. MICMAC Analysis

A number of previous studies integrated ISM and MICMAC to assess the criteria of multicriteria decision-making problems in construction-related fields, to rank the alternatives or select the most suitable alternative [

45,

46,

47]. MICMAC was proposed to handle complicated problems [

35]. It comprises four clusters according to two factors: driving power and dependence power. A variable shows driving power if its action might drive the variables before it and significantly impact the system. Meanwhile, if the action of a variable depends on other variables, this variable presents dependence power. The fourth cluster contains independent factors having hefty driving power but weak dependence. The driving power-dependence matrix discloses the following results:

Cluster I (autonomous): The variables are autonomous variables and have weak dependence and weak driving power in cluster I. These variables can be tackled autonomously throughout the intervention and have a lower influence on the overall system. Thus, few direct linkages have been found throughout the system.

Cluster II (dependent): The variables have high dependence power and low driving power in cluster II and are dependent variables. They are lower priorities to be addressed since they are weak drivers.

Cluster III (linkage): Cluster III includes linkage variables with high dependence and high driving force. These variables are unstable; they influence the other variables and receive feedback from them.

Cluster IV (independent): The variables have weak dependence power and strong driving power in cluster IV. They influence the system significantly and drive the variables above them. Early intervention helps establish a solid foundation for addressing the remaining variables.

6. Discussion

Figure 2 illustrates that engineering experience (C3), management knowledge (C8), and management accountability (C10) play significant driving roles in developing a qualified contractor, and they form the base of the ISM hierarchy. Therefore, these variables help management increase know-how, develop trust between business associates, and minimize the aversion to change. This also helps in improving personnel qualifications (C4) and engineering ability (C5). Meanwhile, client–contractor relationship (C12) and credit rating (C2) illustrate the significant dependence on other variables for contractors’ development. These variables situate close to the top of the hierarchy. A credit rating (C2) for a qualified contractor is enhanced as a result of an excellent reputation.

Health and safety (C9) are achieved with higher levels of engineering ability (C5) and the project management organization (C7). Raising financial stability (C1), performance and quality (C6), and breach of contract (C11) help management concentrate on increasing the credit rating of the contractor. Credit rating provides better trust, which results in an improved client–contractor relationship (C12). ISM also illustrates that, while searching for a qualified contractor, top management should deploy strategies for sufficient management knowledge (C8) and management accountability (C10) and raise engineering experience (C3).

In this study, we analyzed the characteristics of a qualified contractor using the ISM approach. Based on the MICMAC analysis (

Figure 3), financial stability (C1), engineering ability (C5), and project management organization (C7) exhibit both feeble dependence and driving power in cluster I. These autonomous variables can mostly be handled independently during the intervention and affect the overall system moderately. However, the inclusion of financial stability (C1) indicates that this variable is important but has few direct linkages throughout the system. Financial stability has notable effects on any intervention’s credit rating (C2) and client–contractor relationship (C12), and the variable’s location in the influence diagram testifies to its importance.

The issues of credit rating (C2), performance and quality (C6), health and safety (C9), breach of contract (C11), and client–contractor relationship (C12) in cluster II participate in interrelationships and show strong dependence and weak driving power. They should have lower priorities than the variables on which they depend. Later intervention perks up the organization’s performance by forming strong foundations.

No issue is depicted in cluster III even if the elements are unstable. None of them has both strong dependence and strong driving power, which means that the action of all 12 variables and their feedback do not affect others.

Engineering experience (C3), management knowledge (C8), and management accountability (C10) are the issues in cluster IV that dominate the bottom portion of the diagram (

Figure 2). As indicated by the MICMAC analysis (

Figure 3), these independent variables significantly drive the variable above them and affect the system. Early intervention produces a sturdy foundation and boosts contractor performance due to their low dependence and high driving power. For example, management knowledge depends on a few of the other variables but drives personnel qualification, engineering ability, project organization, health and safety, etc.

7. Conclusions

This study has searched for suitable criteria to evaluate contractors in a construction project prequalification process. The criteria presented in this paper can be used to evaluate the impacts of various capabilities and management activities to monitor the performance of firms in the construction industry. The objective was to accurately and thoroughly assess the contractor prequalification criteria in the construction project bidding process to help project managers understand the relationships between critical criteria and facilitate the decision-making process. Moreover, experts have commented on the merits and drawbacks of the proposed solutions. As it does not depend on structural equation models and statistical approaches, the ISM method does not resemble the traditional hierarchical model due to its complex dependence relations. It is superior in hierarchical modeling and dependence solutions, thus providing more valuable information for selective strategies. The central contributions of this research cover the following observations:

First, we attempted to identify the significant criteria for contractor prequalification in a contractor prequalification process as a framework. Several studies are available on contractor prequalification criteria, but no study has examined the interactions between major criteria. There is also no model development study on contractor prequalification criteria that could help us understand the relationship among the criteria. The ISM model assists practitioners and project managers of contractor prequalification in understanding the kernel of the relationships. Hence, this research seizes importance in this context.

Second, this study’s key finding is that engineering experience, management knowledge, and management accountability are significant variables. The ISM model implies higher driving power for these three variables in the lower hierarchy. Therefore, project managers should focus on these three variables during contractor prequalification.

Third, there are several criteria responsible for credit rating and client–contractor relationship. These contractor prequalification criteria have been studied with regard to their dependence and driving powers. Among these criteria, those with high driving power in ISM must be carefully prioritized, for they greatly affect the credit rating and the client–contractor relationship.

Finally, the proposed approach of criteria identification for contractor prequalification can provide project managers and practitioners with a more sensible depiction of the construction project bidding process. One major contribution developed by this research is the contextual relationships among various distinguished criteria for contractor prequalification using a single systemic framework.

In this study, 12 widely considered criteria were identified for construction projects, and a systematic framework was proposed for evaluating the criteria. However, the scope of construction projects includes road projects, bridge projects, building projects, etc. Therefore, additional criteria and expert opinions should be introduced into the ISM model according to the form and characteristics of the construction projects under study. The contractor prequalification criteria were analyzed with the resulting model, and the comparative significance and relationships amidst the criteria were illustrated in the driver dependence diagram. This method relies on the feedback opinions from experts and may generate some bias. Moreover, the numerical validation of the model is yet to be carried out. One may consider the analytical network process (ANP) to appraise the consistency ratio and consistency index. In fact, a linear structural relationship approach, also called structural equation modeling, can be used to validate hypothetical models. Hence, the validation and enhancement of this framework can be the subject of future research.

Author Contributions

Conceptualization, V.F.Y. and F.-Y.C.; methodology, F.-Y.C.; software, F.-Y.C.; validation, V.F.Y., F.-Y.C., T.H.A.L. and S.-W.L.; formal analysis, F.-Y.C.; investigation, F.-Y.C.; resources, V.F.Y.; data curation, F.-Y.C.; writing—original draft preparation, F.-Y.C.; writing—review and editing, V.F.Y., F.-Y.C., T.H.A.L. and S.-W.L.; supervision, V.F.Y. and S.-W.L.; project administration, V.F.Y.; funding acquisition, V.F.Y. and S.-W.L. All authors have read and agreed to the published version of the manuscript.

Funding

The research of the first author is partially supported by the Ministry of Science and Technology of the Republic of China (Taiwan) under Grant MOST 108-2221-E-011-051-MY3 and the Center for Cyber-Physical System Innovation from the Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education in Taiwan. The fourth author of this study is grateful to the Ministry of Science and Technology, Taiwan, and the Linkou Chang Gung Memorial Hospital for financially supporting this research grants MOST 109-2410-H-182-009MY3 and BMRPA19, respectively.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ng, S.T.; Wan, W.Y. Appraisal of subcontractor performance-criteria and their importance. In CIB2005-Advancing Facilities Management and Construction through Innovation; Finlandia Hall: Helsinki, Finland, 2005; pp. 305–314. [Google Scholar]

- Kumaraswamy, M.M.; Matthews, J. Improved subcontractor selection employing partnering principles. J. Manag. Eng. 2000, 16, 47–57. [Google Scholar] [CrossRef]

- Shiau, Y.C.; Tsai, T.P.; Wang, W.C.; Huang, M.L. Use questionnaire and AHP techniques to develop subcontractor selection system. In International Symposium on Automation and Robotics in Construction, 19th (ISARC); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2002; pp. 35–40. [Google Scholar]

- Luu, D.T.; Sher, W. Construction tender subcontract selection using case-based reasoning. Constr. Econ. Build. 2006, 6, 32–43. [Google Scholar] [CrossRef] [Green Version]

- Hatush, Z.; Skitmore, M. Criteria for contractor selection. Constr. Manag. Econ. 1997, 15, 19–38. [Google Scholar] [CrossRef] [Green Version]

- Hatush, Z.; Skitmore, M. Evaluating contractor prequalification data: Selection criteria and project success factors. Constr. Manag. Econ. 1997, 15, 129–147. [Google Scholar] [CrossRef] [Green Version]

- Holt, D.G.; Olomolaiye, P.O.; Harris, F.C. Evaluating performance potential in the selection of construction contractors. Eng. Constr. Archit. Manag. 1994, 1, 29–50. [Google Scholar] [CrossRef]

- Kumaraswamy, M.M.; Dissanayaka, S.M. Performance-oriented building procurement systems. Build. Technol. Manag. 1996, 22, 17–26. [Google Scholar]

- Russell, S.J.; Hancher, D.E.; Skibniewski, M.J. Contractor prequalification data for construction owners. Constr. Manag. Econ. 1992, 10, 117–135. [Google Scholar] [CrossRef]

- Palaneeswaran, E.; Kumaraswamy, M. Recent advances and proposed improvements in contractor prequalification methodologies. Build. Environ. 2001, 36, 73–87. [Google Scholar] [CrossRef]

- Ng, S.T.; Skitmore, R.M. Client and consultant perspectives of prequalication criteria. Build. Environ. 1999, 34, 607–621. [Google Scholar] [CrossRef] [Green Version]

- Holt, G.D.; Olomolaiye, P.O.; Harris, F.C. A review of contractor selection practice in the UK construction industry. Build. Environ. 1995, 30, 553–561. [Google Scholar] [CrossRef]

- Holt, G.D. Which contractor selection methodology? Int. J. Proj. Manag. 1998, 16, 153–164. [Google Scholar] [CrossRef]

- Mahdi, I.M.; Riley, M.J.; Fereig, S.M.; Alex, A.P. A multi-criteria approach to contractor selection. Eng. Constr. Archit. Manag. 2002, 9, 29–37. [Google Scholar]

- Ng, S.T. EQUAL: A case-based contractor prequalifier. Autom. Constr. 2001, 10, 443–457. [Google Scholar] [CrossRef]

- Darvish, M.; Yasaei, M.; Saeedi, A. Application of the graph theory and matrix methods to contractor ranking. Int. J. Proj. Manag. 2009, 27, 610–619. [Google Scholar] [CrossRef]

- Russell, J.S.; Skibniewski, M.J. QUALIFIER-1: Contractor prequalification model. J. Comput. Civ. Eng. 1990, 4, 77–90. [Google Scholar] [CrossRef]

- Russell, J.S.; Skibniewski, M.J.; Cozier, D.R. QUALIFIER-2: Knowledge-based system for contractor prequalification. J. Constr. Eng. Manag. 1990, 116, 157–171. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Liias, R.; Turskis, Z. Multi-attribute decision-making methods for assessment of quality in bridges and road construction: State-of-the-art sur-veys. Balt. J. Road Bridge Eng. 2008, 3, 152–160. [Google Scholar] [CrossRef]

- Huang, W.-H.; Tserng, H.P.; Liao, H.-H.; Yin, S.Y.L.; Chen, P.-C.; Lei, M.C. Contractor financial prequalification using simulation method based on cash flow model. Autom. Constr. 2013, 35, 254–262. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Nguyen, V.U. Tender evaluation by fuzzy sets. J. Constr. Eng. Manag. 1985, 111, 231–243. [Google Scholar] [CrossRef]

- Plebankiewicz, E. A fuzzy sets based contractor prequalification procedure. Autom. Constr. 2012, 22, 433–443. [Google Scholar] [CrossRef]

- Lam, K.C.; Palaneeswaran, E.; Yu, C. A support vector machine model for contractor prequalification. Autom. Constr. 2009, 18, 321–329. [Google Scholar] [CrossRef]

- Doloi, H.; Iyer, K.C.; Sawhney, A. Structural equation model for assessing impacts of contractor’s performance on project success. Int. J. Proj. Manag. 2011, 29, 687–695. [Google Scholar] [CrossRef]

- Alarcon, L.F.; Mourgues, C. Performance modeling for contractor selection. J. Manag. Eng. 2002, 18, 52–60. [Google Scholar] [CrossRef]

- Ko, C.-H.; Cheng, M.-Y.; Wu, T.-K. Evaluating sub-contractors performance using EFNIM. Autom. Constr. 2007, 16, 525–530. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Zidan, S.J.; Yehia, S.; Randolph, D. Hybrid prequalification-based innovative contracting model using AHP. J. Manag. Eng. 2007, 23, 88–96. [Google Scholar] [CrossRef]

- Arslan, G.; Kivrak, S.; Birgonul, M.T.; Dikmen, I. Improving sub-contractor selection process in construction projects: Web-based sub-contractor evaluation system (WEBSES). Autom. Constr. 2008, 17, 480–488. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Nie, X. Fuzzy pattern recognition approach to construction contractor selection. Fuzzy Optim. Decis. Mak. 2005, 4, 103–118. [Google Scholar]

- Nieto-Morote, A.; Ruz-Vila, F. A fuzzy multi-criteria decision-making model for construction contractor prequalification. Autom. Constr. 2012, 25, 8–19. [Google Scholar] [CrossRef] [Green Version]

- Alzahrani, J.I.; Emsley, M.W. The impact of contractors’ attributes on construction project success: A post construction evaluation. Int. J. Proj. Manag. 2013, 31, 313–322. [Google Scholar] [CrossRef]

- Ng, S.T.; Tang, Z. Labour-intensive construction sub-contractors: Their critical success factors. Int. J. Proj. Manag. 2010, 28, 732–740. [Google Scholar] [CrossRef]

- Harary, F.; Norman, R.; Cartwright, Z. Structural Models: An Introduction to the Theory of Directed Graphs; Wiley: New York, NY, USA, 1965. [Google Scholar]

- Warfield, J.W. Developing interconnected matrices in structural modeling. IEEE Trans. Syst. Man Cybern. 1974, 4, 51–81. [Google Scholar]

- Zayed, E.O.; Yaseen, E.A. Barriers to sustainable supply chain management implementation in Egyptian industries: An interpretive structural modeling (ISM) approach. Manag. Environ. Qual. 2021, 32, 1192–1209. [Google Scholar] [CrossRef]

- Thamsatitdej, P.; Boon-itt, S.; Samaranayake, P.; Wannakarn, M.; Laosirihongthong, T. Eco-design practices towards sustainable supply chain management: Interpretive structural modelling (ISM) approach. Int. J. Sustain. Eng. 2017, 10, 326–337. [Google Scholar] [CrossRef]

- Ciliberti, F.; Pierpaolapontrandolfo, P.; Scozzi, B.B. Investigating corporate social responsibility in supply chains: A SME perspective. J. Clean. Prod. 2008, 16, 1579–1588. [Google Scholar] [CrossRef]

- Venkatesh, V.G.; Rathi, S.; Patwa, S. Analysis on supply chain risks in Indian apparel retail chains and proposal of risk prioritization model using Interpretive structural modeling. J. Retail. Consum. Serv. 2015, 26, 153–167. [Google Scholar] [CrossRef]

- Bakhtaria, A.R.; Waris, M.M.; Sanin, C.; Szczerbicki, E. Evaluating Industry 4.0 implementation challenges using Interpretive Structural Modeling and Fuzzy Analytic Hierarchy Process. Cybern. Syst. 2021, 52, 350–378. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W. Barriers to Building Information Modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Talib, F.; Rahman, Z.; Qureshi, M.N. Analysis of interaction among the barriers to total quality management implementation using interpretive structural modeling approach. Benchmarking 2011, 18, 563–587. [Google Scholar] [CrossRef]

- Yu, V.F.; Hu, K.-J. An integrated approach for prioritizing key factors in improving the service quality of nursing homes. Math. Probl. Eng. 2013, 2013, 563723. [Google Scholar] [CrossRef] [Green Version]

- Duperrin, J.C.; Godet, M. Methode de HierarChization des Elements D’um System; Rapport Economique de CEA: Paris, France, 1973; pp. 45–51. [Google Scholar]

- He, Z.; Chen, H. An ISM-based methodology for interrelationships of critical success factors for construction projects in ecologically fragile regions: Take Korla, China as an example. Appl. Sci. 2021, 11, 4668. [Google Scholar] [CrossRef]

- Farooq, U.; Rehman, S.K.U.; Javed, M.F.; Jameel, M.; Aslam, F.; Alyousef, R. Investigating BIM implementation barriers and issues in Pakistan using ISM approach. Appl. Sci. 2020, 10, 7250. [Google Scholar] [CrossRef]

- Ahmad, M.; Tang, X.-W.; Qiu, J.-N.; Ahmad, F. Interpretive Structural Modeling and MICMAC analysis for identifying and benchmarking significant factors of seismic soil liquefaction. Appl. Sci. 2019, 9, 233. [Google Scholar] [CrossRef] [Green Version]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).