Life Cycle Assessment of Waste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case

Abstract

:1. Introduction

2. Materials and Methods

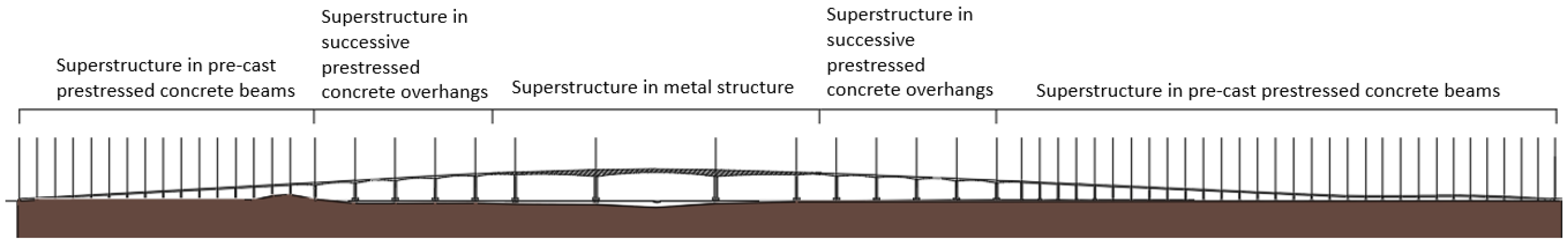

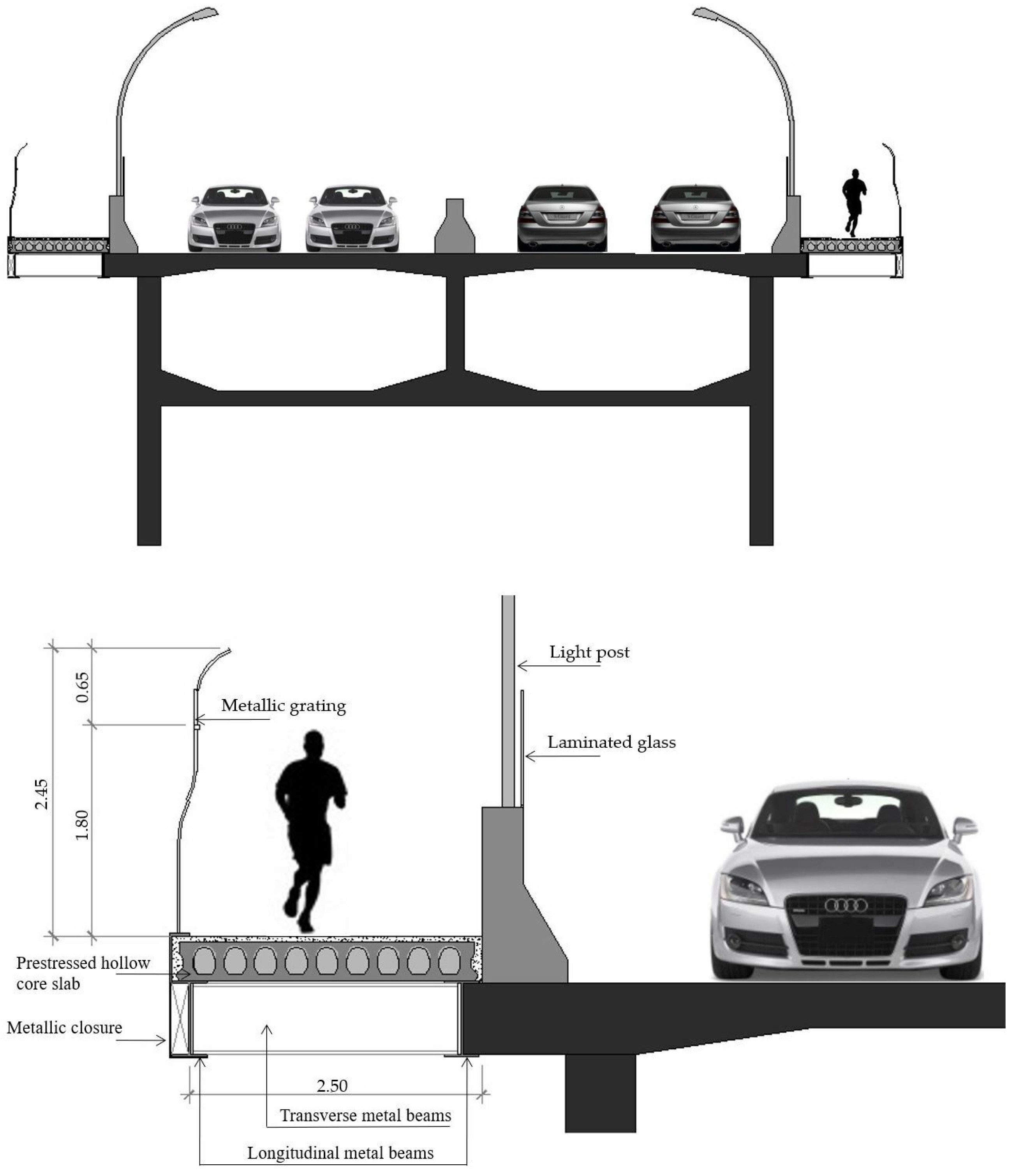

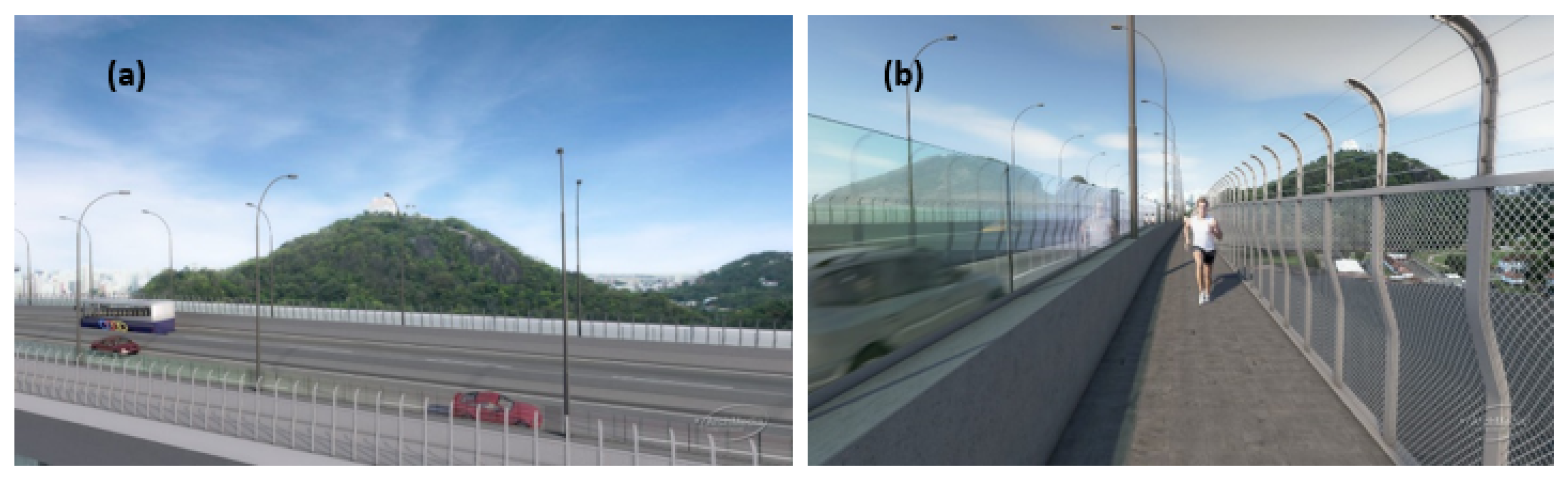

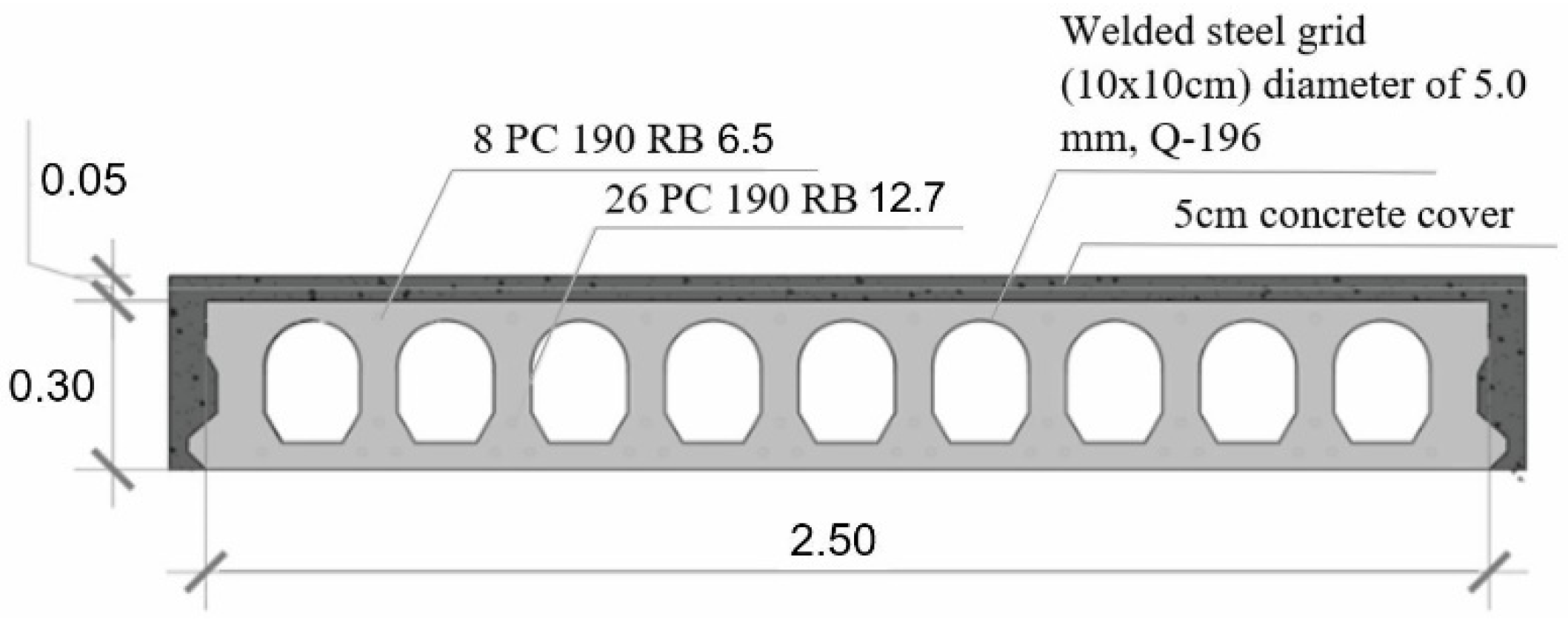

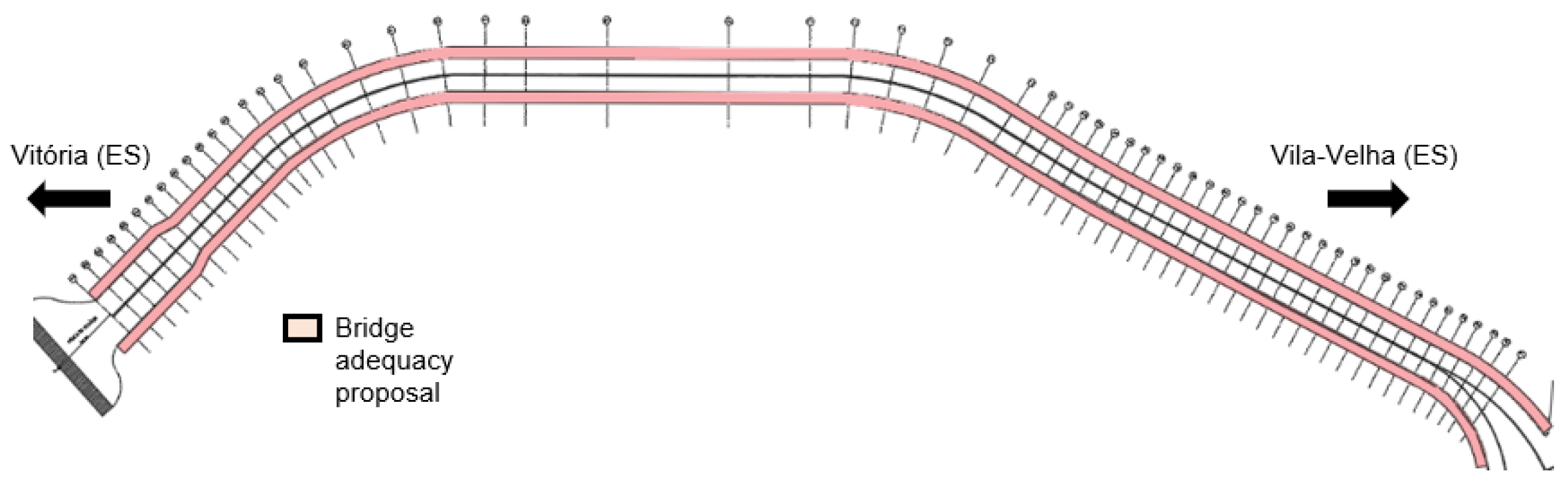

2.1. Third Bridge VIXBR Technical Characteristics

2.2. Premises for the Technical Solution

2.3. Quantity Evaluation for the Proposal Execution

2.4. Materials and Experimental Methods

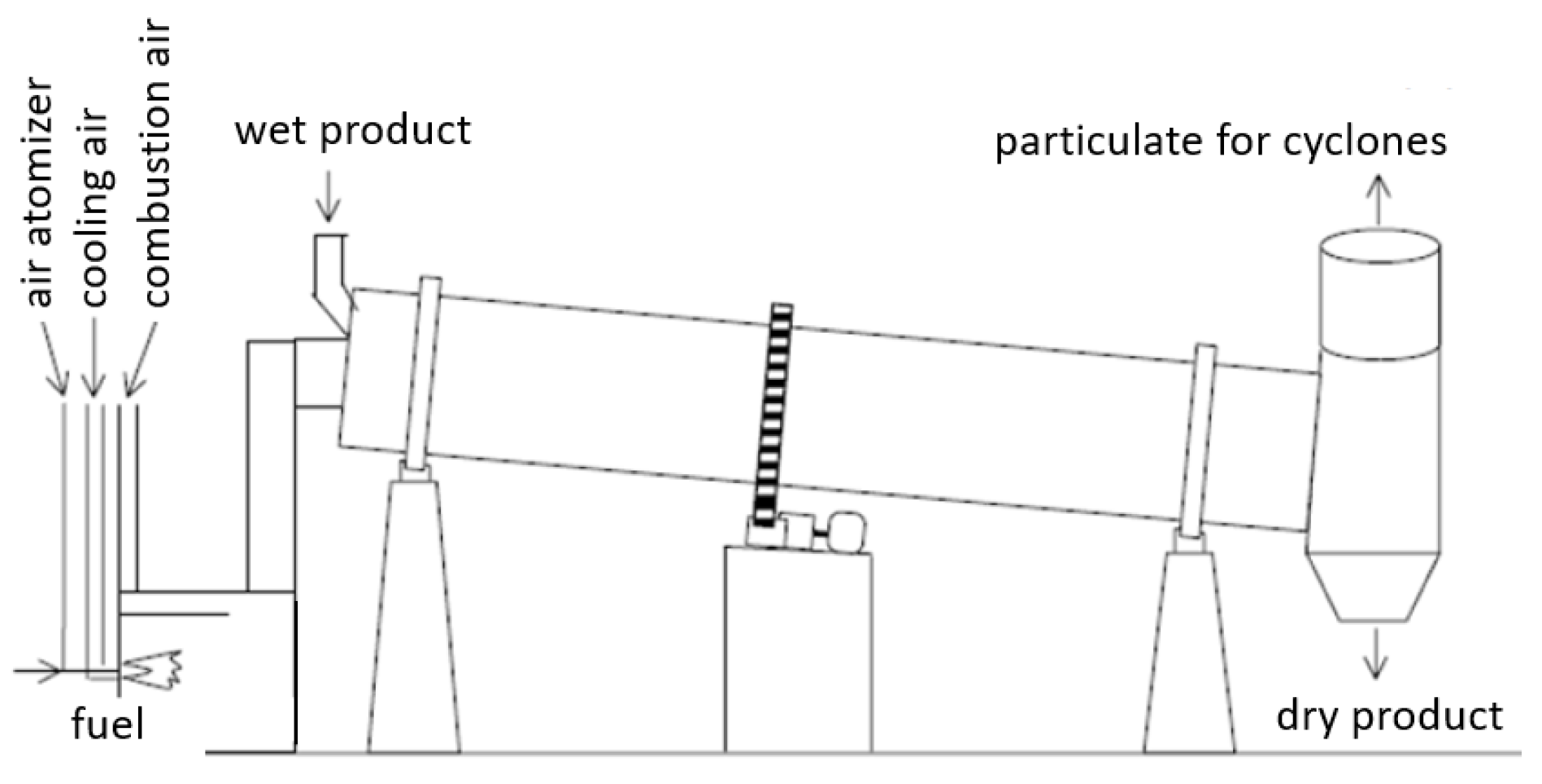

2.4.1. Waste Glass Powder

2.4.2. Laboratory Methods for Material–Technical Requirements

2.5. Analytical Methods

Service Life Prediction

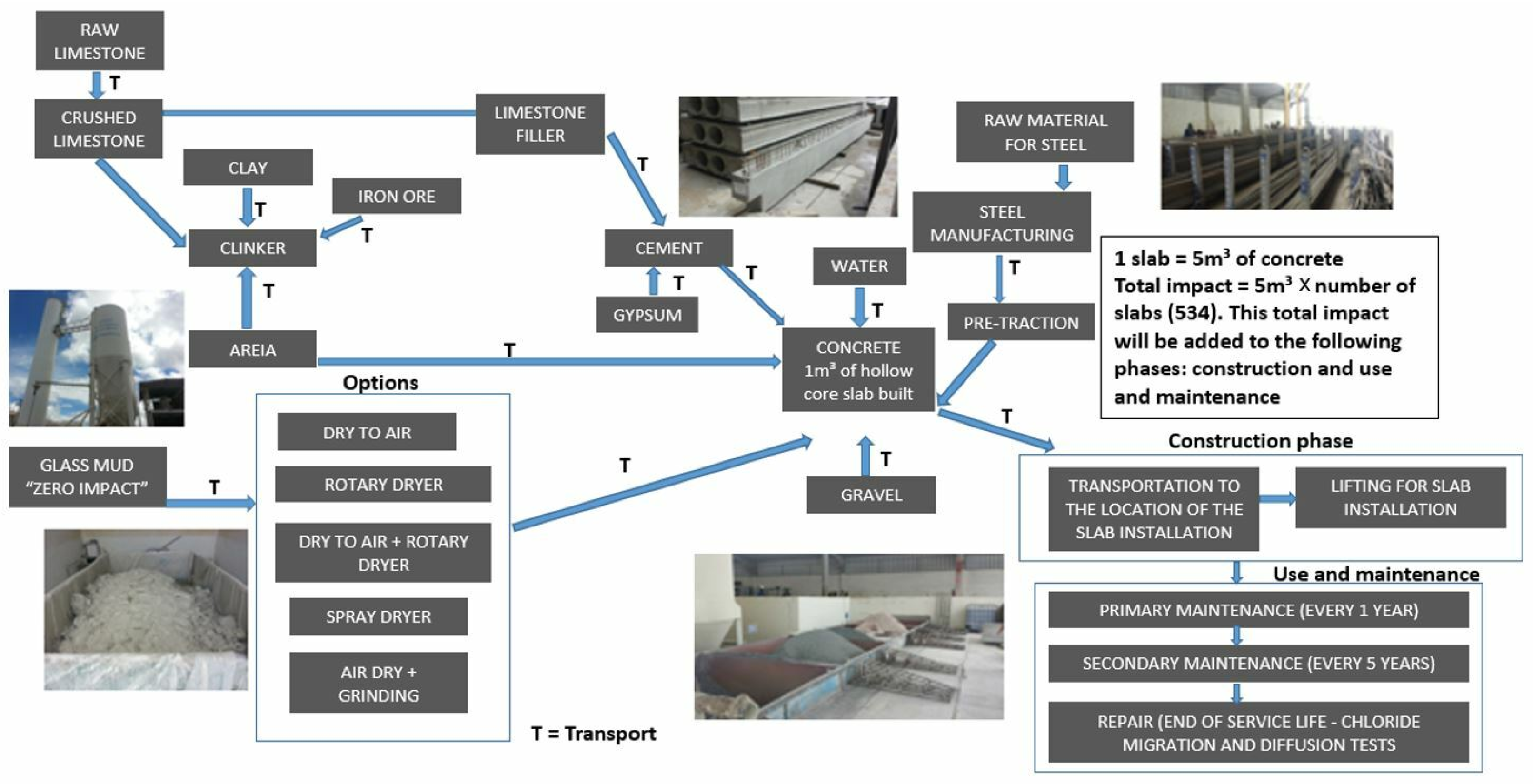

2.6. Life Cycle Assessment

2.6.1. Goal and Scope Definition

2.6.2. Life Cycle Boundaries

2.6.3. Data Quality Indicators

2.6.4. LCI, Materials’ Life Cycle Inventory, and Waste Glass Powder Life Cycle Inventory

2.6.5. Concrete Production

2.6.6. Prestressing Slab Procedure

2.6.7. Construction: Slab Installation

2.6.8. Use and Maintenance

- Maintenance

- Repairs

2.6.9. Transportation Distances

2.6.10. Life Cycle Impact Analysis (LCIA)

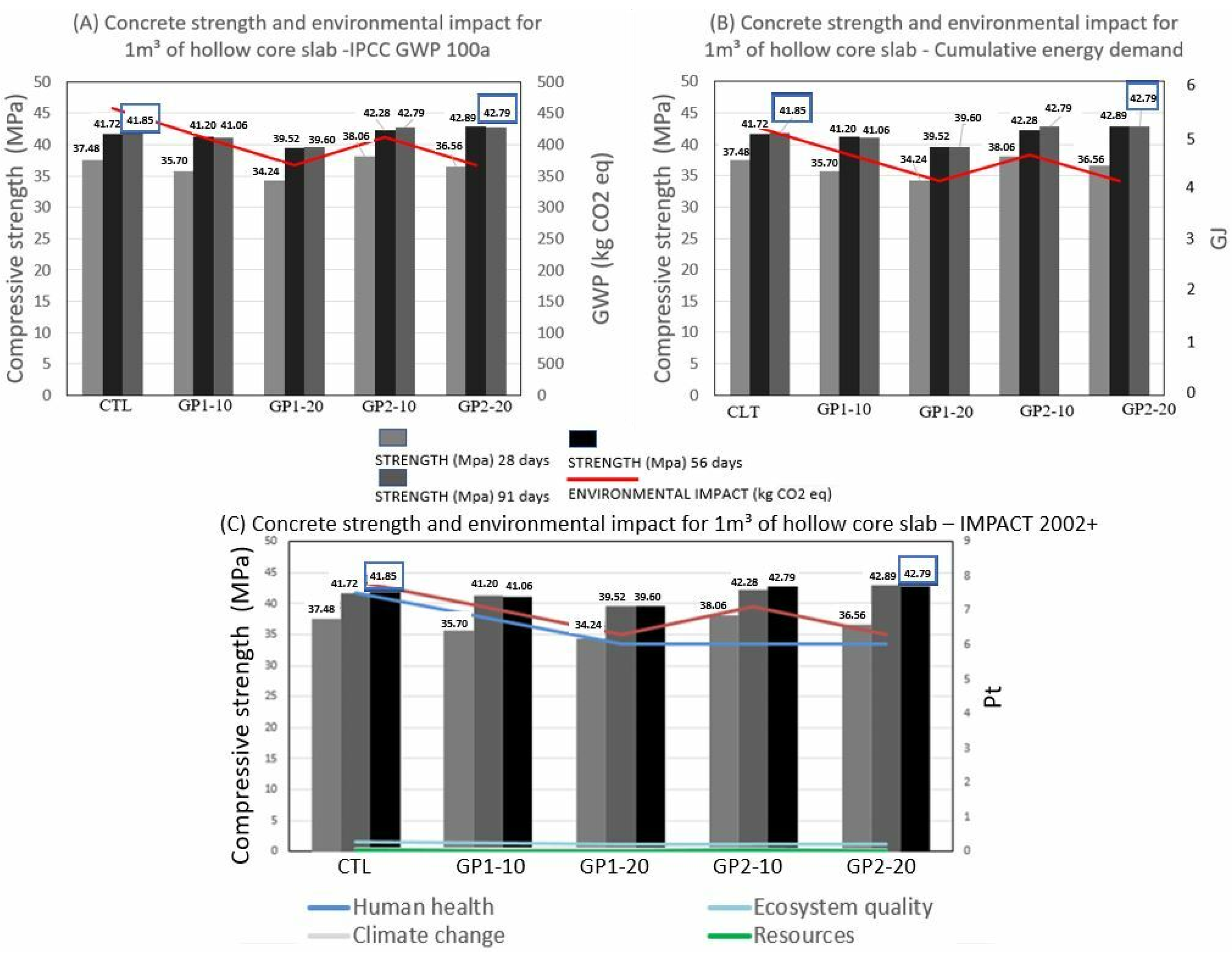

3. Results and Discussion

3.1. Drying Options for GP

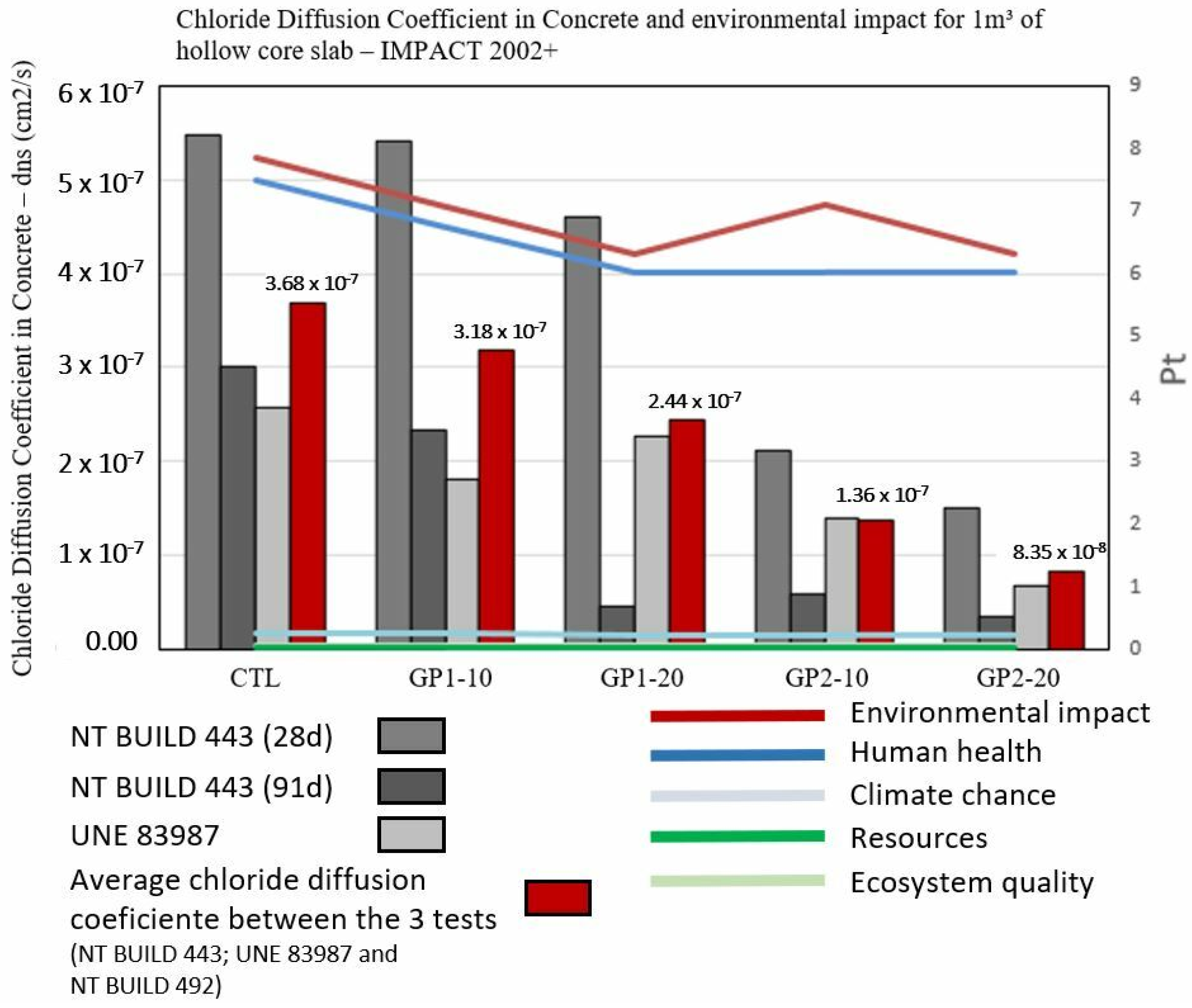

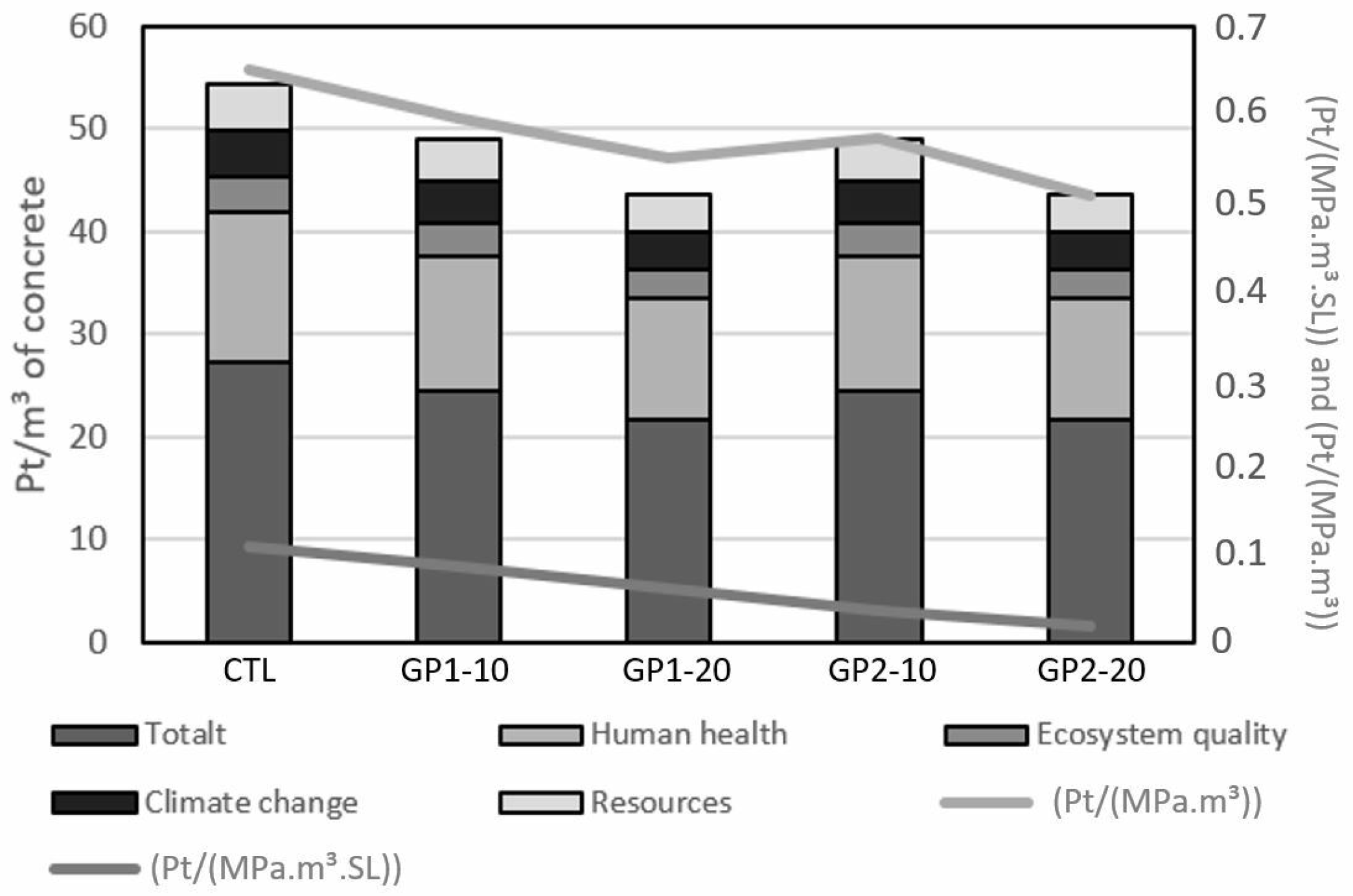

3.2. Concrete Environmental Performance Comparison

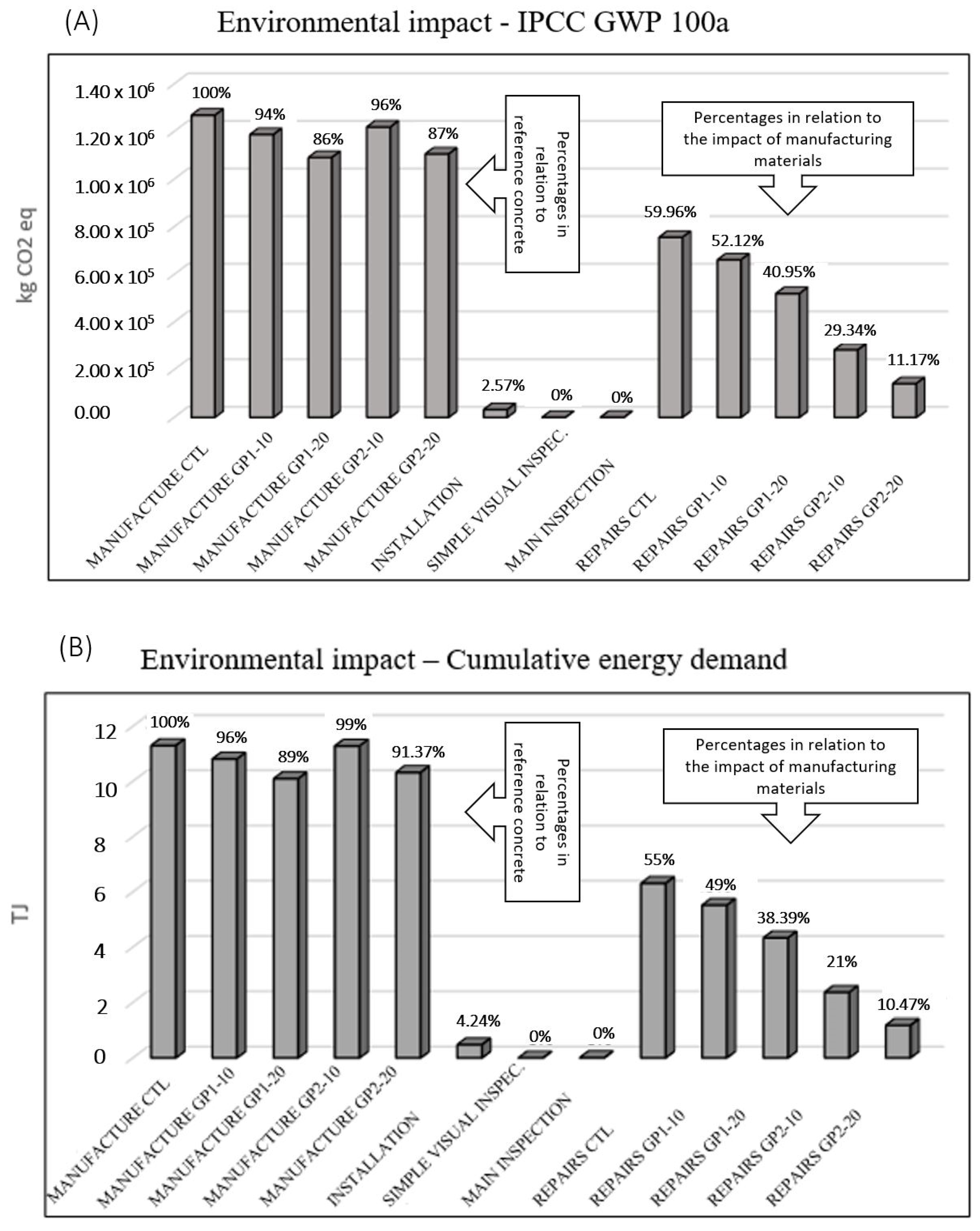

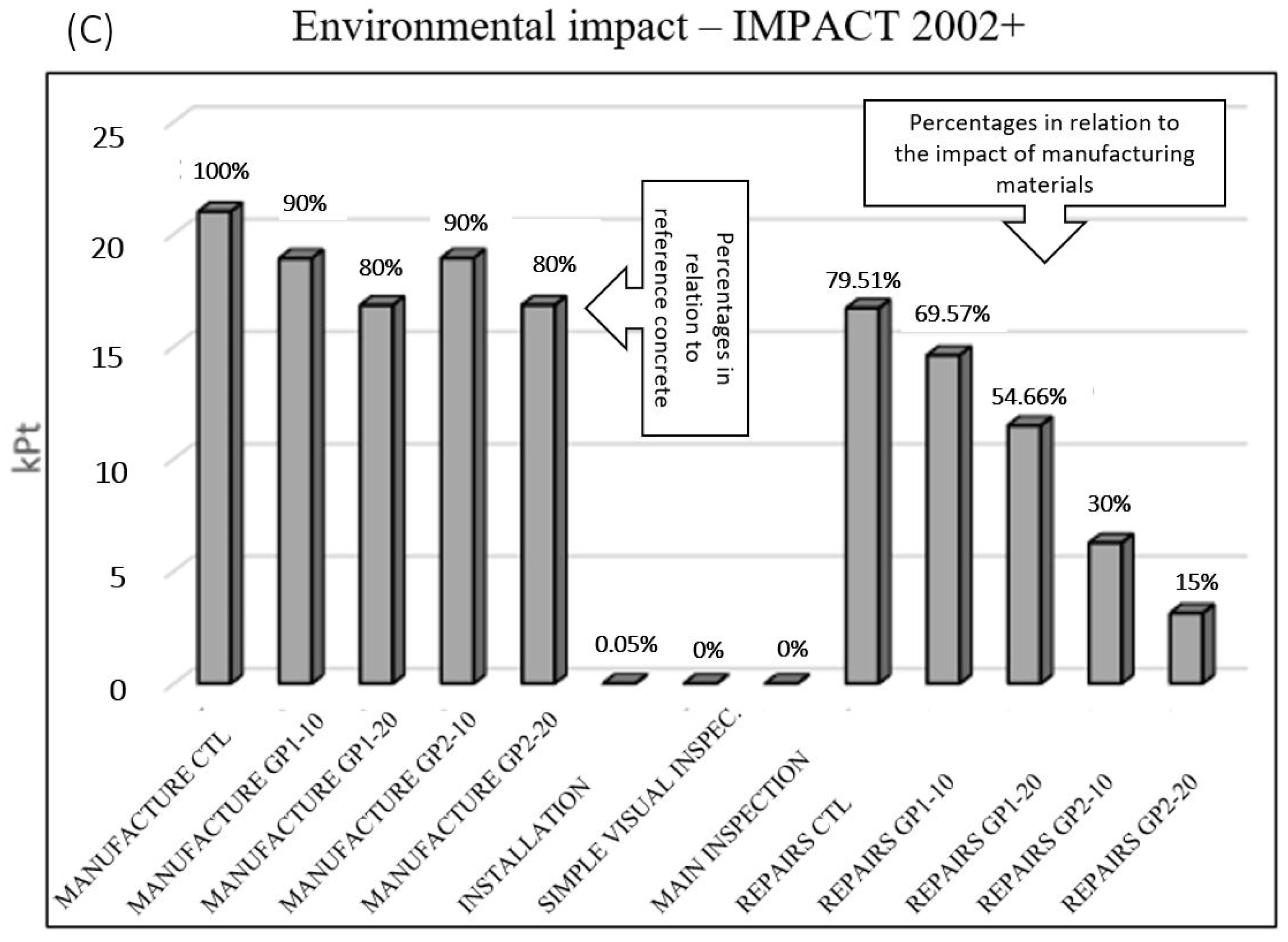

3.3. Total Environmental Impact of Each Life Cycle Stage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maywald, C.; Riesser, F. Sustainability-The art of modern architecture. International Symposium on “Novel Structural Skins: Improving sustainability and efficiency through new structural textile materials and designs”. Procedia Eng. 2016, 155, 238–248. [Google Scholar] [CrossRef] [Green Version]

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. IPCC Report; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- World Business Council for Sustainable Development (WBCSD). Cement Technology Roadmap 2009: Carbon Emissions Reductions Up to 2050; WBCSD: Geneva, Switzerland, 2009. [Google Scholar]

- USGS. Cement-Mineral Commodity Summaries. In Cement Statistics and Information-Annual Publications; U.S. Department of the Interior, U.S. Geological Survey: Washington, DC, USA, 2011. [Google Scholar]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the ultrahigh performances concrete containing metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Duan, P.; Zhonghe, S.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concret. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

- Guignone, G.; Vieira, G.; Zulcão, R.; Degen, M.; Mittri, S.H. Incorporation of glass powder and metakaolin as cement partial replacement to improve concrete mechanical properties and increase service life. J. Compos. Mater. 2020, 54, 2965–2983. [Google Scholar] [CrossRef]

- Mittri, S.H.M.; Vieira, G.L.; Guignone, G.C.; Degen, M.K.; Teles, C.R.; Zulcão, R. Utilization of heat-treated ornamental stone processing waste as an addition to concretes to improve compressive strength and reduce chloride ion penetration. Constr. Build. Mater. 2018, 118, 444–455. [Google Scholar] [CrossRef]

- Samad, S.; Shah, A. Role of binary cement including Supplementary Cementitious Material (SCM), in production of environmentally sustainable concrete: A critical review. Int. J. Sustain. Built Environ. 2017, 6, 663–674. [Google Scholar] [CrossRef]

- Nassar, R.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Tariq, S.; Scott, A.N.; Mackechnie, J.R.; Shah, V. Durability of High Volume Glass Powder Self-Compacting Concrete. Appl. Sci. 2020, 10, 8058. [Google Scholar] [CrossRef]

- Jurczak, R.; Szmatuła, F. Evaluation of the Possibility of Replacing Fly Ash with Glass Powder in Lower-Strength Concrete Mixes. Appl. Sci. 2021, 11, 396. [Google Scholar] [CrossRef]

- Ahmad, J.; Martínez-García, R.; de-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Cassar, J.; Camiller, J. Utilization of imploded glass in structural concrete. Constr. Build. Mater. 2012, 29, 299–307. [Google Scholar] [CrossRef]

- Matos, A.M.; Souza-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Frederico, L.M.; Chidiac, S.E. Waste glass as a supplementary cementitious material in concrete—Critical review of treatment methods. Cem. Concr. Res. 2009, 31, 606–610. [Google Scholar] [CrossRef]

- ISO 14040:2006; Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental management-Life cycle assessement-Requirements and guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Panesar, D.; Kanraj, D.; Abualrous, Y. Effect of transportation of fly ash: Life cycle assessment and life cycle cost analysis of concrete. Cem. Concr. Compos. 2019, 99, 214–224. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Zulcão, R.; Calmon, J.L.; Rebello, T.A.; Vieira, D.R. Life cycle assessment of the ornamental stone processing waste use in cement-based building materials. Constr. Build. Mater. 2020, 257, 119–523. [Google Scholar] [CrossRef]

- Mohan, J.; Chen, X.; Rajabipour, F.; Hendrickson, T.C. Comparative Life Cycle Assessment of Conventional, Glass Powder, and AlkaliActivated Slag Concrete and Mortar. J. Infrastruct. Syst 2014, 20, 04014020. [Google Scholar]

- Tucker, E.L.; Ferraro, C.C.; Laux, S.J.; Townsend, T.G. Economic and life cycle assessment of recycling municipal glass as a pozzolan in Portland cement concrete prodution, Resources. Conserv. Recycl. 2018, 129, 240–247. [Google Scholar] [CrossRef]

- Deschamps, J.; Simon, B.; Tagnit-Hamou, A.; Amor, B. Is open-loop recycling the lowest preference in a circular economy? Answering through LCA of glass powder in concrete. J. Clean. Prod. 2018, 185, 14–22. [Google Scholar] [CrossRef]

- Vieira, D.R.; Moreira, A.L.R.; Calmon, J.L.; Dominicini, W.K. Service life modeling of a bridge in a tropical marine environment for durable design. Constr. Build. Mater. 2018, 163, 315–325. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, W.X.; Abududdin, M.; Canning, L. Environmental Evaluation of FRP in UK Highway Bridge Deck Replacement Applications Based on Comparative LCA Study. Adv. Mater. Res. 2012, 374–377, 43–48. [Google Scholar] [CrossRef]

- San Martin, L.G. LCA of a Spanish Railway Bridge. Master’s Thesis, KTH, Stockholm, Sweden, 2011. [Google Scholar]

- Dequidt, T.C.E. Life Cycle Assessment of a Norwegian Bridge. Master’s Thesis, Norwegian Universitu of Science and Technology, Department of Civil and Transport Engineering, Trondheim, Norway, 2012. [Google Scholar]

- Gervásio, H.; Da Silva, L.S. Comparative life-cycle analysis of steel-concrete composite bridges. Struct. Infrastruct. Eng. 2008, 4, 251–269. [Google Scholar] [CrossRef]

- Du, G.; Karoumi, R. Life cycle assessment of a railway bridge: Comparison of two superstructure designs. Struct. Infrastruct. Eng. 2012, 9, 1149–1160. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Preventing Suicide: How to Start a Survivors’ Group; World Health Organization: Geneva, Switzerland, 2016. [Google Scholar]

- Helene, P. Contribuição ao Estudo da Corrosão em Armaduras de Concreto Armado. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 1993. [Google Scholar]

- Helene, P.; Terzian, P. Manual de Dosagem e Controle do Concreto; PINI: São Paulo, Brazil, 1992. [Google Scholar]

- ABNT NBR 12653; Pozzolanic Materials–Requirements. ABNT (Technical Standards Brazilian Association): Rio de Janeiro, Brazil, 2015.

- Guignone, G.; Vieira, G.; Zulcão, R.; Degen, M.; Mittri, S.; Teles, C. Desempenho de concretos com a incorporação de resíduo do processo de lapidação e polimento do vidro como substituto parcial ao cimento. Rev. Ibracon De Estrut. E Mater. 2020, 13, 613–627. [Google Scholar] [CrossRef]

- ABNT NBR 5751; Pozzolanic Materials–Determination of Pozzolanic Activity with Lime at Seven Days. ABNT (Technical Standards Brazilian Association): Rio de Janeiro, Brazil, 2015.

- ABNT NBR 5752; Pozzolanic Materials–Determination of the Performance Index with Portland Cement at 28 Days. ABNT (Technical Standards Brazilian Association): Rio de Janeiro, Brazil, 2014.

- American Society for Testing and Materials—ASTM. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration-ASTM C 1202; ASTM: Philadelphia, PA, USA, 2012. [Google Scholar]

- UNE 83987-14. Durabilidad Del Hormigón. Métodos de Ensayo. Determinación de los Coeficientes de Difusion de los Iones Cloruro em el Hormigón Endurecido. Método Multirrégimen. 2014. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0053184 (accessed on 25 January 2022).

- Nordtest Method. Nt Build 443-Concrete, Hardened: Accelerated Chloride Penetration; Nordtest: Oslo, Norway, 1995. [Google Scholar]

- Nordtest Method. Nt Build 492-Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest: Oslo, Norway, 1999. [Google Scholar]

- Ribeiro, D.V. Corrosão em Estruturas de Concreto Armado: Teoria, Controle e Métodos de Análise; Elsevier: Rio de Janeiro, Brazil, 2014. [Google Scholar]

- CEB. Durable Concrete Structures–Design Guide, Comite’ Euro-International du Beto´ n. CEB Bulletin d’Information, Thomas Telford, London; Thomas Telford Ltd.: London, UK, 1992; p. 183. ISBN 978-0-7277-1620-0. [Google Scholar]

- ABNT NBR 6118; Design of Concrete Structures–Procedure. ABNT (Technical Standards Brazilian Association): Rio de Janeiro, Brazil, 1968; rev. April 2014.

- American Concrete Institute. Committee 318. Building Code Requirements for Structural Concrete (ACI 318- and Commentary (ACI 318R-95); American Concrete Institute: Detroit, Michigan, 1995; p. 369. [Google Scholar]

- Nunes, J.L.O.; Guimarães, A.T.C.; Silveira, B.P.; Guimarães, D.L.C.; Oliveira, M.T.; Rodrigues, N.D. Intensidade de ataque de cloretos: Consideração es sobre a distância do concreto em relacão à agua do mar. In Seminário e Workshop em Engenharia Oceânica-SEMENGO; FURG: Rio Grande, Brazil, 2004. [Google Scholar]

- Guimarães, A.T.C.; Castro, P.; Nunes, J.L.O. Teor de Cloretos Próximos à Superfície do Concreto em Ambientes Marítimos. In Anais do 49° Congresso Brasileiro do Concreto-IBRACON, Bento Gonçalves; IBRACON: Rio Grande do Sul, Brasil, 2007. [Google Scholar]

- Younis, A.; Ebead, U.; Judd, S. Life cycle cost analysis of structural concrete using seawater, recycled concrete aggregate, and GFRP reinforcement. Constr. Build. Mater. 2018, 175, 152–160. [Google Scholar] [CrossRef]

- Van Den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- BRASIL. Resolução CONAMA N° 436, de 22 de Dezembro de 2011. 2011. Available online: http://www.mma.gov.br/port/conama/legislacao/CONAMA_RES_CONS_2006_382.pdf (accessed on 7 October 2021).

- MCTIC. Estimativas Anuais de Emissões de Gases de Efeito Estufa no Brasil, Brasília. Ministério da Ciência, Tecnologia, Inovações e Comunicações-MCTIC. 2016. Available online: https://www.gov.br/mcti/pt-br/acompanhe-o-mcti/sirene/publicacoes/estimativas-anuais-de-emissoes-gee/arquivos/estimativas_3ed.pdf (accessed on 7 October 2021).

- Carvalho, J.O. A Indústria do Cimento e a Infraestrutura no Brasil, Comissão de serviços de infraestrutura. Senado Federal. Sindicato Nacional da Indústria do Cimento. SNIC. 2009. Available online: http://www.senado.gov.br/web/comissoes/ci/ap/AP20090511_jo-seotaviocarvalho.pdf (accessed on 7 October 2021).

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- EFCA. EFCA Environmental Declaration; EFCA: Minneapolis, MN, USA, 2002. [Google Scholar]

- Kellenberger, D.; Althaus, H.J. Life Cycle Inventories of Building Products. Final Report Ecoinvent Data v2.0 No.7 EMPA Dübendorf, Dübendorf, CH. 2007. Available online: www.ecoinvent.org (accessed on 25 January 2022).

- Statens Vegvesen (Public Roads Company, Norway): “Inspeksjonshåndbok for bruer (Inspection reference manual for bridges, in Norwegian),” Handbook No. 136, Statens vegvesen, Oslo, Norway. No. 136; Vegdirektoratet and Vegkontorene Publications. 2000. Available online: https://vegvesen.brage.unit.no/vegvesen-xmlui/handle/11250/195976 (accessed on 7 October 2021).

- Mujumdar, A.S. Chapter 1. Principles, classification, and selection of dryers. In Handbook of Industrial Drying; Mujumdar, A.S., Ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 3–30. [Google Scholar]

- Rebello, T.A.; Zulcão, R.; Calmon, J.L.; Gonçalves, R.F. Comparative life cycle assessment of ornamental stone processing waste recycling, sand, clay and limestone filler. Waste Manag. Res. 2019, 37, 186–195. [Google Scholar] [CrossRef]

- Alves, H.J.; Melchiades, F.G.; Boschi, A.O. Levantamento inicial do consumo de energias térmica e elétrica na indústria brasileira de revestimentos cerâmicos. Cerâmica Ind. 2017, 12, 17–21. [Google Scholar]

- Bushi, L.; Finlayson, G.; Meil, J. A Cradle-to-Gate Life Cycle Assessment of Ready-Mixed Concrete Manufacture by NRMCA Members; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2014; 39p. [Google Scholar]

- Marceau, M.L.; Nisbet, M.; Vangeem, M.G. Life Cycle Inventory of Portland Cement Concrete; Portland Cement Association: Skokie, IL, USA, 2007; 121p. [Google Scholar]

- Phrommarat, B.; Arromdee, P. A life cycle assessment study of prestressed concrete poles in Thailand. Int. J. Constr. Manag. 2019. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-specific Life Cycle Assessment of ready mix concrete: Comparison between a recycled and na ordinary concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

- Steinmann, Z.J.N.; Schipper, A.M.; Hauck, M.; Huijbregts, M.A.J. How many environmental impact indicators are needed in the evaluation of product life cycles? Environ. Sci. Technol. 2016, 50, 3913–3919. [Google Scholar] [CrossRef] [PubMed]

- IPCC. IPCC Fifth Assessment Report. The Physical Science Basis. 2013. Available online: http://www.ipcc.ch/report/ar5/wg1/ (accessed on 25 January 2022).

- Frischknecht, R.; Jungbluth, N.; Althaus, H.J.; Doka, G.; Dones, R.; Hischier, R.; Dones, R.; Nemecek, T.; Hellweg, S.; Humbert, S.; et al. Implementation of Life Cycle Impact Assessment Methods: Data v2.0. Ecoinvent Report No. 3, Swiss Centre for Life Cycle Inventories. 2007. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/41/028/41028089.pdf (accessed on 7 October 2021).

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G. Presenting a new method IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef] [Green Version]

- Hauschild, M.J. 2003 Potting, Spatial Differentiation in Life Cycle Impact Assessment–The EDIP2003 Methodology; Institute for Product Development, Technical University of Denmark: Kongens Lyngby, Denmark, 2003. [Google Scholar]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part I: Utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2014, 98, 272–281. [Google Scholar] [CrossRef] [Green Version]

- ABNT NBR 16697; Portland Cement-Requirements. ABNT (Technical Standards Brazilian Association): Rio de Janeiro, Brazil, 2018.

| Material Quantity | Control | GP1-10 | GP1-20 | GP2-10 | GP2-20 |

|---|---|---|---|---|---|

| Steel strand, 26 PC-190 RB 12.7 (kg) | 51.48 | 51.48 | 51.48 | 51.48 | 51.48 |

| Steel strand, 8 PC-190 RB 6.5 (kg) | 3.44 | 3.44 | 3.44 | 3.44 | 3.44 |

| Concrete (m³) | 1 | 1 | 1 | 1 | 1 |

| Cement (kg) | 302.85 | 272.57 | 242.28 | 272.57 | 242.28 |

| Glass powder (GP) (kg) | 0 | 24.77 | 49.57 | 24.77 | 49.57 |

| Gravel (kg) | 1133 | 1133 | 1133 | 1133 | 1133 |

| Sand (kg) | 875.24 | 875.24 | 875.24 | 875.24 | 875.24 |

| Water (kg) | 181.71 | 181.71 | 181.71 | 181.71 | 181.71 |

| Properties | Limits ABNT NBR 12653 [37] Class E | Limits ABNT NBR 12653 [37] Class N | Glass Powder (GP1) (Class E) | Ground Glass Powder (GP2) (Class E) | Metakaolin (ME) (Class N) |

|---|---|---|---|---|---|

| Fineness by sieve #325 (45 µm) (% retained) | <20 | <20 | 19.65 | 7.64 | 8.14 |

| Pozzolanic activity with lime (MPa) [39] | ≥6 | ≥6 | 4.14 | 6.28 | 11.53 |

| Pozzolanic activity with cement (%) [40] | ≥90 | ≥90 | 83 | 90 | 137 |

| SiO2 + Al2O3 + Fe2O3 (%) | ≥50 | ≥70 | 68.02 | 68.02 | 93.6 |

| SO3 (%) | ≤5 | ≤4 | 0.21 | 0.21 | 0.2 |

| Loss on ignition (%) | ≤6 | ≤10 | 0.55 | 0.55 | 2.5 |

| Available alkalis in Na2Oeq * (%) | ≤1.5 | ≤1.5 | 19.43 | 19.43 | 1.38 |

| Properties | Standard | Dimensions of Specimen | Number of Samples | Age of Testing | Category |

|---|---|---|---|---|---|

| Compressive strength | ABNT NBR 5739-07 | Cylinder 100 mm in diameter and 200 mm in length | 3 | 28, 56, and 91 days | Concrete |

| Rapid chloride permeability test (RCPT) | ASTM C 1202-12 [41] | Cylinder 100 mm in diameter and 50 mm in length | 3 | 28 and 91 days | Concrete |

| Multi-regime method | UNE 83987-14 [42] | Cylinder 100 mm in diameter and 20 mm in length | 3 | 28 days | Concrete |

| Bulk diffusion test (BDT) | NT BUILD 443-95 [43] | Cylinder 100 mm in diameter and 50 mm in length | 3 | 28 days curing and 60, 120, and 180 days of exposure | Concrete |

| Rapid migration test (RMT) | NT BUILD 492 [44] | Cylinder 100 mm in diameter and 50 mm in length | 3 | 91 days | Concrete |

| Slump | ASTM C143 | - | 3 | At mixing | Fresh concrete |

| Density | ASTM C143 | - | 3 | At mixing | Fresh concrete |

| Pozzolanic activity with lime (MPa) | ABNT NBR 5751-2015 | Cylinder 50 mm in diameter and 100 mm in length | 3 | 7 days | Mortar |

| Pozzolanic activity cement (%) | ABNT NBR 5752-14 | Cylinder 50 mm in diameter and 100 mm in length | 3 | 28 days | Mortar |

| Analysis Type/Aim | Mass Functional Unit (1 kg) | Volume Functional Unit (1 m³) | Total Construction (534 Slabs) | Compressive Strength (1 MPa) | Compressive Strength and Service Life (years·MPa) |

|---|---|---|---|---|---|

| Comparison between drying methodologies (natural or artificial) | X | ||||

| Comparison between milling scenarios (milling or not milling) | X | ||||

| Comparative analysis of the product fabrication for different mixes | X | ||||

| Comparative analysis of the complete cradle-to-grave bridge retrofit, considering different mixes and slab installations as well as the maintenance for a period of 100 years | X | ||||

| Comparative analysis of how different compressive strengths can affect the total impact | X | ||||

| Comparative analysis of how different compressive strengths and service life can affect the total impact | X |

| Main Process | Flux Type | Flux | Value | Unit |

|---|---|---|---|---|

| Cement (1 kg) | Materials | Clinker | 0.9025 | kg |

| Plaster | 0.0475 | kg | ||

| Limestone filler | 0.05 | kg | ||

| Energy/Processing | Electricity | 0.0555 | kWh | |

| Packaging | 1 | kg | ||

| Emissions | Particulate matter | 0.09 | g | |

| Clinker (1 kg) | Materials | Limestone, crushed | 1.3 | kg |

| Clay | 0.2 | kg | ||

| Sand | 0.1 | kg | ||

| Iron ore | 0.03 | kg | ||

| Energy | Petroleum coke | 101.08 | g | |

| Charcoal | 3.46 | g | ||

| (Hard) Mineral coal | 3.45 | g | ||

| Firewood (bundle, energy wood) | 4.6 | g | ||

| Diesel oil (burned) | 59.1 | kJ | ||

| Natural gas | 0.33 | dm³ | ||

| (Heavy) Fuel oil | 0.22 | g | ||

| Electricity | 0.0555 | kWh | ||

| Emissions | Carbon dioxide | 0.947 | kg | |

| Carbon monoxide | 0.47 | g | ||

| Nitrogen oxides | 2.17 | g | ||

| Sulfur oxides | 0.32 | g | ||

| Limestone filler (1 kg) | Materials | Limestone, crushed | 1 | kg |

| Energy | Electricity | 0.06334 | kWh | |

| Limestone, crushed (1 kg) | Materials | Limestone | 1 | kg |

| Energy | Electricity | 0.000255 | kWh | |

| Diesel oil | 0.0034 | MJ | ||

| Emissions | Particulate matter < 2.5 μm | 1.75 × 10−5 | kg | |

| Particulate matter > 2.5 μm < 10 μm | 7.51 × 10−5 | kg | ||

| Particulate matter > 10 μm | 0.000148 | kg | ||

| Limestone, raw (1 kg) | Materials | Calcite (mineral) | 1 | kg |

| Water | 2.14 × 10−2 | dm³ | ||

| Soil | Occupation | 1.34 × 10−3 | m²a | |

| Energy/ Processing | Explosive (blasting) | 1.82 × 10−5 | kg | |

| Electricity | 2.73 × 10−5 | kWh | ||

| Diesel oil (burned) | 0.0333 | MJ | ||

| Emissions | Evaporated water | 2.14 × 10−2 | dm³ | |

| Particulate matter < 2.5 μm | 6.08 × 10−6 | kg | ||

| Particulate matter > 2.5 μm and <10 vm | 5.89 × 10−5 | kg | ||

| Particulate matter > 10 μm | 0.000159 | kg | ||

| Clay (1 kg) | Material | Clay mineral | 1 | kg |

| Soil | Occupation | 1.67 × 10−4 | m²a | |

| Energy | Diesel oil (burned) | 0.0288 | MJ | |

| Gypsum (1 kg) | Miscellaneous | Miscellaneous (unmodified inventory) | - | - |

| Iron ore | Miscellaneous | Miscellaneous (unmodified inventory) | - | - |

| Sand | Materials | Quartz sand | 1 | kg |

| Soil | Occupation | 1.25 × 10−3 | m²a | |

| Energy | Diesel oil (burned) | 0.0609 | MJ | |

| Gravel (1 kg) | Materials | Granite | 1.05 | kg |

| Groundwater | 8.07 × 10−3 | dm³ | ||

| Soil | Occupation | 1.34 × 10−3 | m²a | |

| Energy | Explosive (blasting) | 1.45 × 10−4 | kg | |

| Electricity | 3.72 × 10−3 | kWh | ||

| Diesel oil (burned) | 8.28 × 10−3 | MJ | ||

| Lubricant oil | 6.00 × 10−3 | g | ||

| Internal transportation | 1 | km | ||

| Emissions | Particulate matter < 2.5 μm | 6.08 × 10−6 | kg | |

| Particulate matter > 2.5 μm and <10 um | 5.89 × 105 | kg | ||

| Particulate matter > 10 μm | 1.59 × 10−4 | kg | ||

| Potable water | Miscellaneous | Miscellaneous (unmodified inventory) | - | - |

| Main Process | Flux Type | Flux | Value | Unit |

|---|---|---|---|---|

| GP, rotary dryer (1 kg) | Materials | GP (naturally dried) | 1.04 | kg |

| Energy | Heat, natural gas | 0.276 | MJ | |

| Emissions | Evaporated water | 0.04 | dm³ | |

| GP, spray dryer after press filter (1 kg) | Materials | GP, cake (press filter) | 1.15 | kg |

| Energy | Heat, natural gas | 1.2 | MJ | |

| Emissions | Evaporated water | 0.15 | dm³ | |

| GP, natural drying (1 kg) | Materials | GP, cake (press filter) | 1.106 | kg |

| Energy | Machine | 0.046 | s/kg | |

| Electricity | 0.000156 | kWh | ||

| Emissions | Evaporated water | 0.106 | dm³ | |

| GP, milling process (1 kg) | Materials | Glass waste | 1.0 | kg |

| Energy | Electricity | 0.01180 | kWh |

| Main Process | Flux Type | Flux | Value | Unit |

|---|---|---|---|---|

| Concrete mixer (1 m³) | Energy | Electricity | 5.05 | kWh |

| Diesel oil | 27.73 | MJ | ||

| Pre-tension, crane, and cut control system (1 m³) | Energy | Electricity | 0.770 | kWh |

| Steel production (1 m³) | Material | Hot rolling of steel | 1.000 | kg |

| Material | Steel, low league | 0.370 | kg | |

| Material | Steel, no league | 0.630 | kg | |

| Transportation | Internal transportation | 20 | km | |

| Construction–transport for installation on the bridge | Energy | Internal transportation | 11,520 | km |

| Construction–lifting | Energy | Electricity | 1920 | h |

| Simple visual inspection (once each year; 100 years) | Transportation | Internal transportation–low-weight vehicle | 3200 | km |

| Main inspection (5 times every year; 100 years) | Transportation of the elevator | Internal transportation | 1000 | km |

| Transportation | Internal transportation–low-weight vehicle | 400 | km | |

| Equipment | Elevator operation | 160 | h | |

| Repair–transportation to site (100 years) | Transportation | Internal transportation—low weight vehicle | 400 | km |

| Repair concrete–REF (100 years) | Material | Concrete (repair) | 2136 | m³ |

| Energy | Electricity (concrete demolition) | 2136 | kWh | |

| Repair concrete—RV1-10 (100 years) | Material | Concrete (repair) | 1869 | m³ |

| Energy | Electricity (concrete demolition) | 1869 | kWh | |

| Repair concrete—RV1-20 (100 years) | Material | Concrete (repair) | 1468.5 | m³ |

| Energy | Electricity (concrete demolition) | 1468.5 | kWh | |

| Repair concrete—RV2-10 (100 years) | Material | Concrete (repair) | 801 | m³ |

| Energy | Electricity (concrete demolition) | 801 | kWh | |

| Repair concrete—RV2-20 (100 years) | Material | Concrete (repair) | 400.5 | m³ |

| Energy | Electricity (concrete demolition) | 400.5 | kWh |

| Material Transported | Material Produced | Origin | Destination | Distance (km) |

|---|---|---|---|---|

| Clinker | Cement | Cachoeiro do Itapemirim, ES | Greater Vitória, ES | 160 |

| Limestone filler | Cement | Cachoeiro do Itapemirim, ES | Greater Vitória, ES | 170 |

| Gypsum | Cement | Araripe, CE | Greater Vitória, ES | 1700 |

| Sand | Clinker | Cachoeiro do Itapemirim, ES | Cachoeiro do Itapemirim, ES | 5 |

| Limestone raw material | Crushed limestone | Various sources | Clinker/Limestone filler | 5 |

| Clay | Clinker | Cachoeiro do Itapemirim, ES | Cachoeiro do Itapemirim, ES | 5 |

| Iron ore Cement | Clinker Concrete slab | Greater Vitória, ES Greater Vitória, ES | Cachoeiro do Itapemirim, ES Greater Vitória, ES | 160 5 |

| GP | Concrete slab | Greater Vitória, ES | Greater Vitória, ES | 6.5 |

| Sand and gravel | Concrete slab | Greater Vitória—ES | Greater Vitória—ES | 5 |

| Steel | Concrete slab | Greater Vitória—ES | Greater Vitória—ES | 20 |

| Concrete slab | Bridge | Greater Vitória—ES | Greater Vitória—ES | 21.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guignone, G.; Calmon, J.L.; Vieira, G.; Zulcão, R.; Rebello, T.A. Life Cycle Assessment of Waste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case. Appl. Sci. 2022, 12, 3353. https://doi.org/10.3390/app12073353

Guignone G, Calmon JL, Vieira G, Zulcão R, Rebello TA. Life Cycle Assessment of Waste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case. Applied Sciences. 2022; 12(7):3353. https://doi.org/10.3390/app12073353

Chicago/Turabian StyleGuignone, Guilherme, João Luiz Calmon, Geilma Vieira, Robson Zulcão, and Thais Ayres Rebello. 2022. "Life Cycle Assessment of Waste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case" Applied Sciences 12, no. 7: 3353. https://doi.org/10.3390/app12073353

APA StyleGuignone, G., Calmon, J. L., Vieira, G., Zulcão, R., & Rebello, T. A. (2022). Life Cycle Assessment of Waste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case. Applied Sciences, 12(7), 3353. https://doi.org/10.3390/app12073353