CO2 Sorption and Regeneration Properties of K2CO3/Al2O3-Based Sorbent at High Pressure and Moderate Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the CO2 Sorbent and Analysis

2.2. Apparatus and Procedure

3. Results

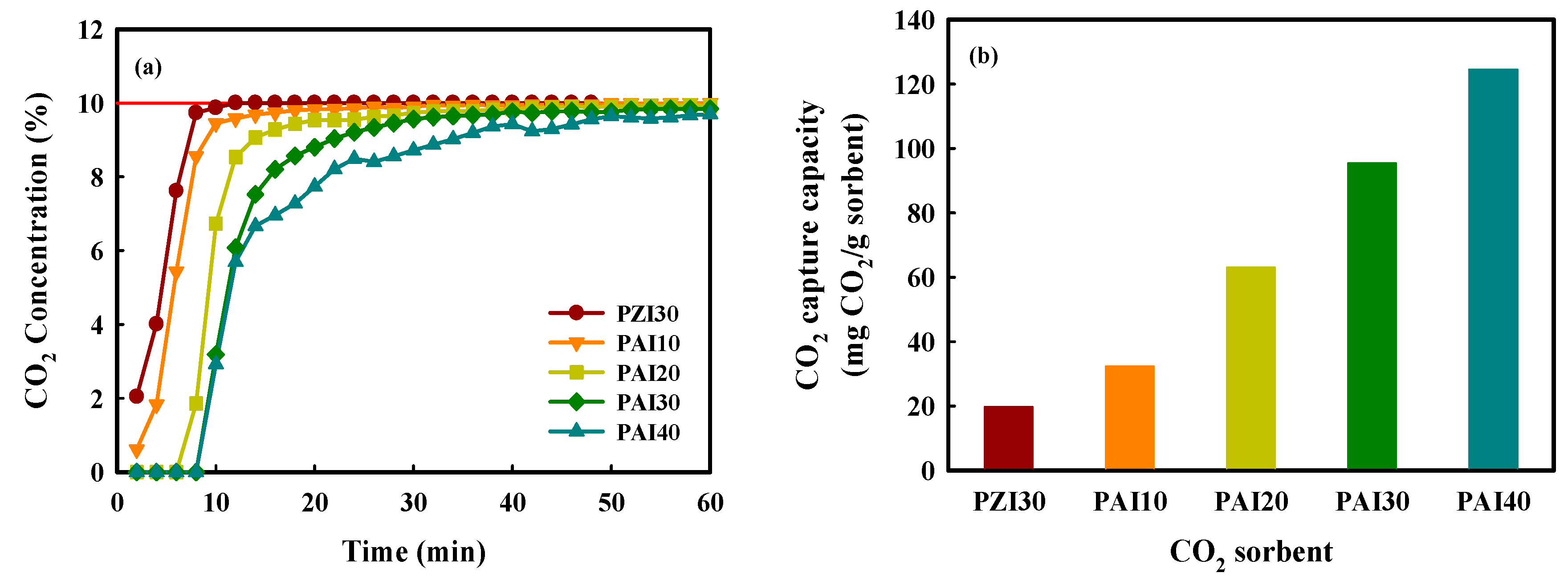

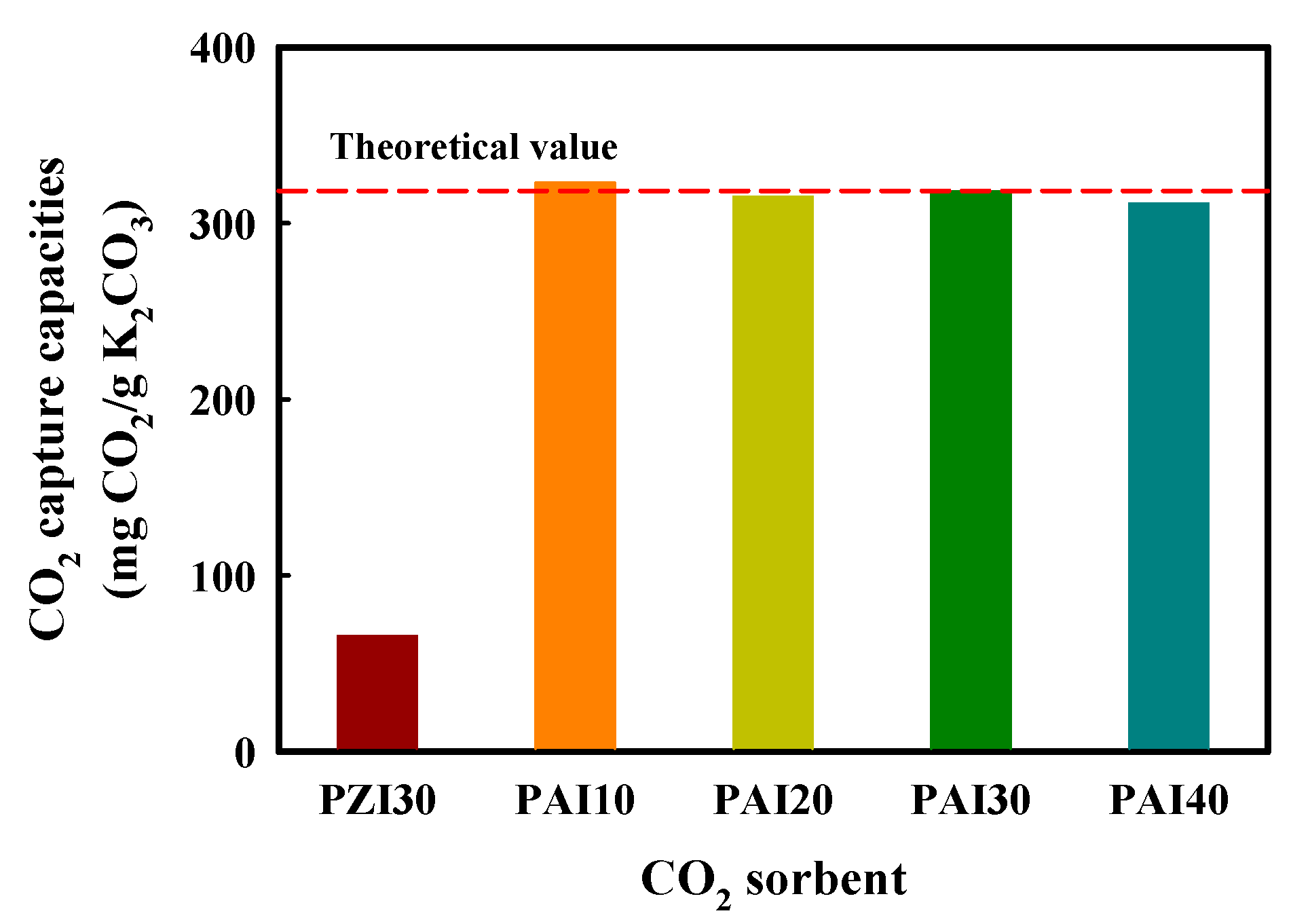

3.1. CO2 Capture Capacity of a CO2 Sorbent

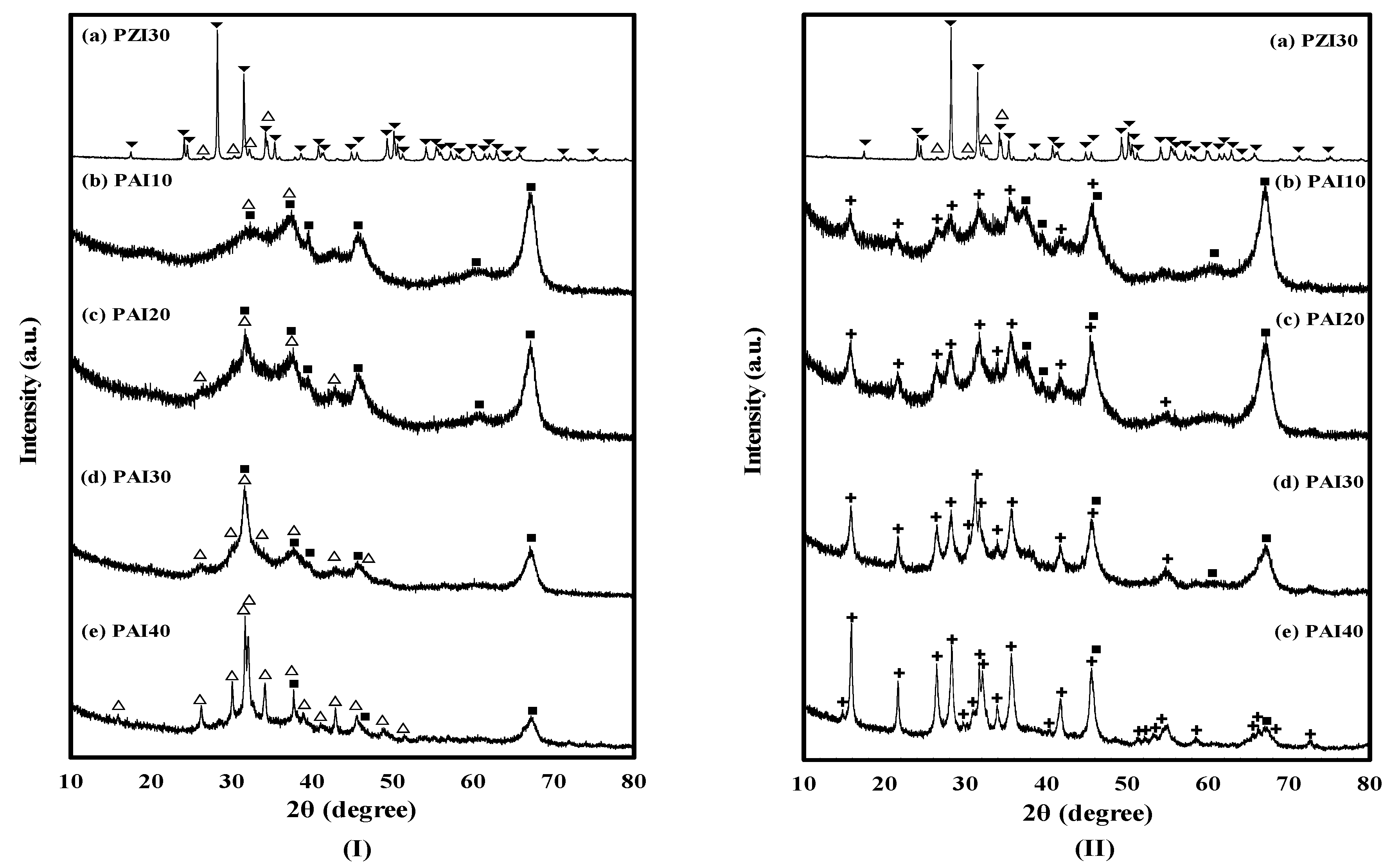

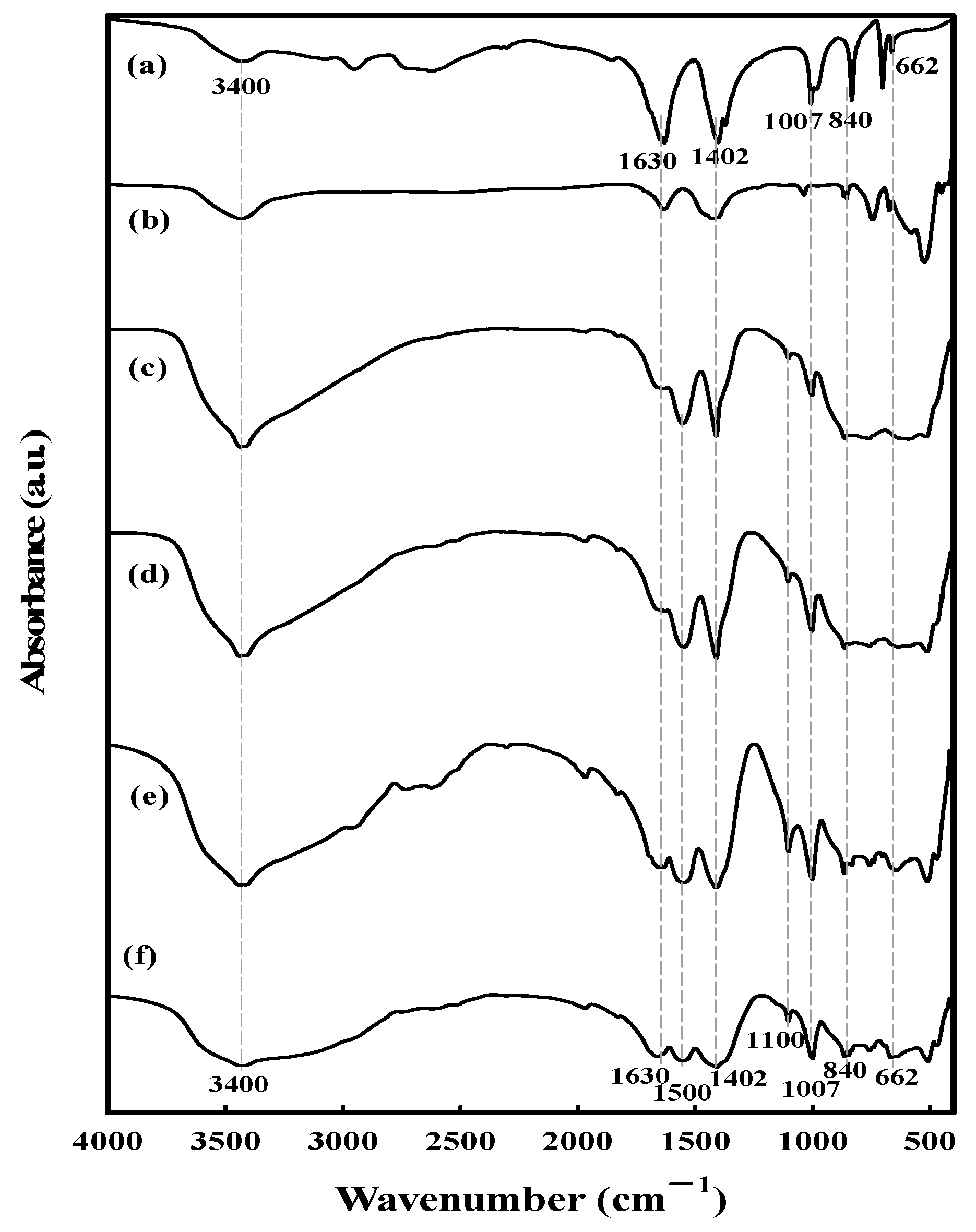

3.2. Physical Characteristic Analysis after CO2 Sorption

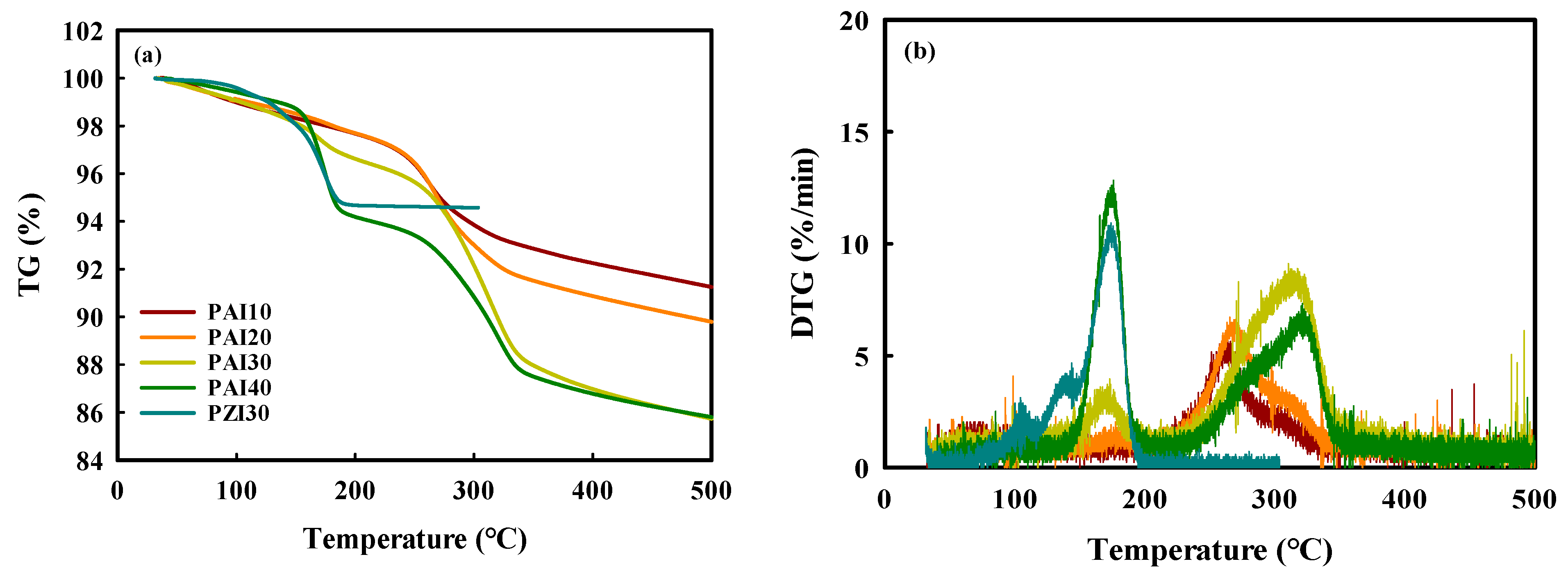

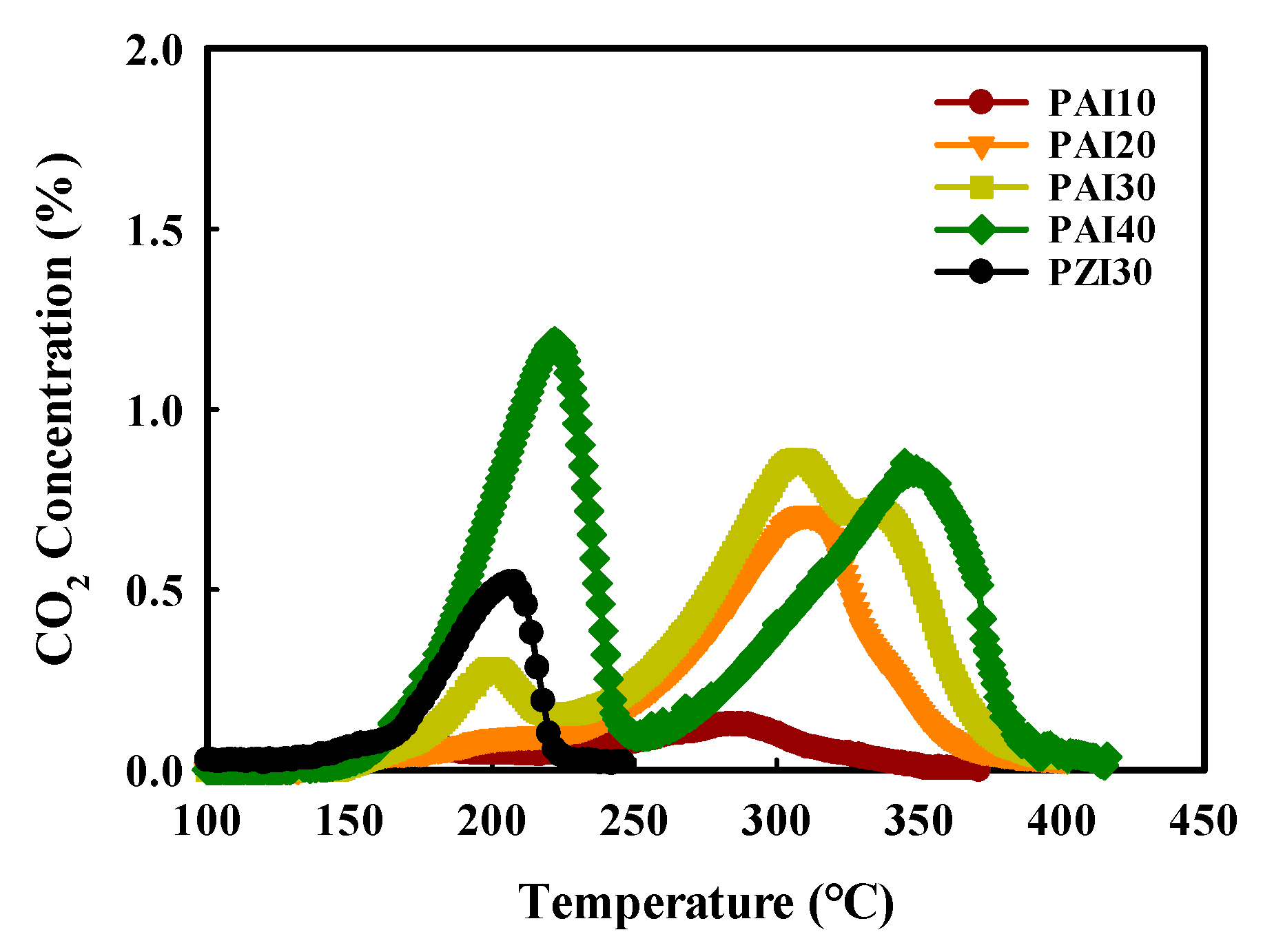

3.3. TPD at 20 atm of PZI30 and PAI10–40 Sorbents

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orr, F.M., Jr. CO2 capture and storage: Are we ready? Energy Environ. Sci. 2009, 2, 449–458. [Google Scholar] [CrossRef]

- Xiao, G.; Singh, R.; Chaffee, A.; Webley, P. Advanced adsorbents based on MgO and K2CO3 for capture of CO2 at elevated temperatures. Int. J. Greenhouse Gas Control. 2011, 5, 634–639. [Google Scholar] [CrossRef]

- Fisher, J.C.; Siriwardane, R.V.; Stevens, R.W., II. Process for CO2 Capture from High-Pressure and Moderate-Temperature Gas Streams. Ind. Eng. Chem. Res. 2012, 51, 5273–5281. [Google Scholar] [CrossRef]

- Siriwardane, R.V.; Stevens, R.W., Jr. Novel regenerable magnesium hydroxide sorbents for CO2 capture at warm gas temperatures. Ind. Eng. Chem. Res. 2009, 48, 2135–2141. [Google Scholar] [CrossRef]

- Lee, S.C.; Kwon, Y.M.; Chae, H.J.; Jung, S.Y.; Lee, J.B.; Ryu, C.K.; Yi, C.K.; Kim, J.C. Improving regeneration properties of potassium-based alumina sorbents for carbon dioxide capture from flue gas. Fuel 2013, 104, 882–885. [Google Scholar] [CrossRef]

- Yong, Z.; Mata, V.; Rodrigues, A.E. Adsorption of carbon dioxide at high temperature—A review. Sep. Purif. Technol. 2002, 26, 195–205. [Google Scholar] [CrossRef]

- Hwang, B.W.; Lim, J.H.; Chae, H.J.; Ryu, H.-J.; Lee, D.; Lee, J.B.; Kim, H.; Lee, S.C.; Kim, J.C. CO2 capture and regeneration properties of MgO-based sorbents promoted with alkali metal nitrates at high pressure for the sorption enhanced water gas shift process. Process Saf. Environ. Prot. 2018, 116, 219–227. [Google Scholar] [CrossRef]

- Wu, S.F.; Li, Q.H.; Kim, J.N.; Yi, K.B. Properties of a Nano CaO/Al2O3 CO2 sorbent. Ind. Eng. Chem. Res. 2008, 47, 180–184. [Google Scholar] [CrossRef]

- Ma, J.; Xu, Y.; Wu, Y.; Chen, X.; Cai, T.; Liu, D. Continuous CO2 capture performance of K2CO3/Al2O3 sorbents in a novel integrated bubbling-transport fluidized reactor. Ind. Eng. Chem. Res. 2019, 58, 19733–19740. [Google Scholar] [CrossRef]

- Koirala, R.; Gunugunuri, K.R.; Pratsinis, S.E.; Smirniotis, P.G. Effect of zirconia doping on the structure and stability of CaO-based sorbents for CO2 capture during extended operating cycles. J. Phys. Chem. C. 2011, 115, 24804–24812. [Google Scholar] [CrossRef]

- Mastin, J.; Aranda, A.; Meyer, J. New synthesis method for CaO-based synthetic sorbents with enhanced properties for high-temperature CO2-capture. Energy Procedia. 2011, 4, 1184–1191. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Qi, Y.; Xie, M.; Cheng, Z.; Yuan, W. Synthesis of CaO-based sorbents through incorporation of alumina/aluminate and their CO2 capture performance. Chem. Eng. Sci. 2012, 74, 172–180. [Google Scholar] [CrossRef]

- Valverde, J.M. Ca-based synthetic materials with enhanced CO2 capture efficiency. J. Mater. Chem. A. 2013, 1, 447–468. [Google Scholar] [CrossRef]

- Tripoonsuk, C.; Maneewatthanakulphol, T.; Khantiudom, W.; Chalermsinsuwan, B.; Piumsomboon, P. Potassium Carbonate Supported on gamma-Alumina Sorbent Regeneration in Fluidized Bed Reactor for Carbon Dioxide Capture Technology. Eng. J. 2021, 25, 45–55. [Google Scholar] [CrossRef]

- Choi, S.H.; Drese, J.H.; Jones, C.W. Adsorbent materials for carbon dioxide capture from large anthropogenic point sources. ChemSusChem 2009, 2, 796–854. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Wang, X.; Zhong, C.; Li, L. Synthesis and CO2 capture property of high aspect-ratio Li2ZrO3 nanotubes arrays. Appl. Surf. Sci. 2011, 257, 8106–8109. [Google Scholar] [CrossRef]

- Walspurger, S.; Cobden, P.D.; Haije, W.G.; Westerwaal, R.; Elzinga, G.D.; Safonova, O.V. In situ XRD detection of reversible dawsonite formation on alkali promoted alumina: A cheap sorbent for CO2 capture. Eur. J. Inorg. Chem. 2010, 2010, 2461–2464. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, X.; Zhao, C.; Wu, Y.; Wu, D. K2CO3/Al2O3 for capturing CO2 in flue gas from power plants. Part 3: CO2 Capture Behaviors of K2CO3/Al2O3 in a Bubbling Fluidized-Bed Reactor. Energy Fuels 2012, 26, 3062–3068. [Google Scholar] [CrossRef]

- Li, L.; Li, Y.; Wen, X.; Wang, F.; Zhao, N.; Xiao, F.; Wei, W.; Sun, Y. CO2 capture over K2CO3/MgO/Al2O3 dry sorbent in a fluidized bed. Energy Fuels 2011, 25, 3835–3842. [Google Scholar] [CrossRef]

- Lee, S.C.; Kwon, Y.M.; Ryu, C.Y.; Chae, H.J.; Ragupathy, D.; Jung, S.Y.; Lee, J.B.; Ryu, C.K.; Kim, J.C. Development of new alumina-modified sorbents for CO2 sorption and regeneration at temperatures below 200 °C. Fuel 2011, 90, 1465–1470. [Google Scholar] [CrossRef]

- Lee, S.C.; Cho, M.S.; Jung, S.Y.; Ryu, C.K.; Kim, J.C. Effects of alumina phases on CO2 sorption and regeneration properties of potassium-based alumina sorbents. Adsorption 2014, 20, 331–339. [Google Scholar] [CrossRef]

- Lee, S.C.; Kim, J.C. Dry potassium-based sorbents for CO2 capture. Catal. Surv. Asia. 2007, 11, 171–185. [Google Scholar] [CrossRef]

- Lee, S.C.; Choi, B.Y.; Lee, T.J.; Ryu, C.K.; Ahn, Y.S.; Kim, J.C. CO2 absorption and regeneration of alkali metal-based solid sorbents. Cat. Today 2006, 111, 385–390. [Google Scholar] [CrossRef]

- Lee, S.C.; Chae, H.J.; Lee, S.J.; Park, Y.H.; Ryu, C.K.; Yi, C.K.; Kim, J.C. Novel regenerable potassium-based dry sorbents for CO2 capture at low temperatures. J. Mol. Catal. B Enzym. 2009, 56, 179–184. [Google Scholar] [CrossRef]

- Lee, S.C.; Cho, M.S.; Kwon, Y.M.; Chae, H.J.; Jung, S.Y.; Ryu, C.K. Dhanusuraman Ragupathy, K.J.C. CO2 sorption properties of nano-sized zirconia-based sorbents promoted with alkali metal carbonates. J. Nanoelectron. Optoelectron. 2012, 7, 460–465. [Google Scholar] [CrossRef]

- Lee, S.C.; Kwon, Y.M.; Jung, S.Y.; Lee, J.B.; Ryu, C.K.; Kim, J.C. Excellent thermal stability of potassium-based sorbent using ZrO2 for post combustion CO2 capture. Fuel 2014, 115, 97–100. [Google Scholar] [CrossRef]

- Nyquist, R.A.; Kagel, R.O. The Handbook of Infrared and Raman Spectra of Inorganic Compounds and Organic Salts; Academic Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Jo, S.B.; Lee, S.C.; Chae, H.J.; Cho, M.S.; Lee, J.B.; Baek, J.I.; Kim, J.C. Regenerable potassium-based alumina sorbents prepared by CO2 thermal treatment for post-combustion carbon dioxide capture. Korean J. Chem. Eng. 2016, 33, 3207–3215. [Google Scholar] [CrossRef]

- Ma, J.; Zhong, J.; Bao, X.; Chen, X.; Wu, Y.; Cai, T.; Liu, D.; Liang, C. Continuous CO2 capture performance of K2CO3/Al2O3 sorbents in a novel two-stage integrated bubbling-transport fluidized reactor. Chem. Eng. J. 2021, 404, 126465. [Google Scholar] [CrossRef]

- Amiri, M.; Shahhosseini, S. Optimization of CO2 capture from simulated flue gas using K2CO3/Al2O3 in a Micro fluidized bed reactor. Energy Fuels 2018, 32, 7978–7990. [Google Scholar] [CrossRef]

- Lucazeau, G.; Novak, A. Low temperature Raman spectra of KHCO3 single crystal. J. Raman Spectrosc. 1973, 1, 573–586. [Google Scholar] [CrossRef]

- Dembowski, M.; Loring, J.S.; Bowden, M.E.; Reynolds, J.G.; Graham, T.R.; Rosso, K.M.; Pearce, C.I. The controlling role of atmosphere in dawsonite versus gibbsite precipitation from tetrahedral aluminate species. Dalton Trans. 2021, 50, 13438–13446. [Google Scholar] [CrossRef] [PubMed]

| Sample | Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Size (nm) |

|---|---|---|---|

| ɣ-Al2O3 | 157.65 | 0.31 | 4.91 |

| ZrO2 | 8.04 | 0.03 | 3.83 |

| PZI30 | 3.92 | 0.02 | 3.82 |

| PAI10 | 134.98 | 0.22 | 4.32 |

| PAI20 | 69.67 | 0.17 | 4.32 |

| PAI30 | 44.26 | 0.17 | 4.32 |

| PAI40 | 27.37 | 0.09 | 4.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, D.-Y.; Jo, S.; Kim, T.-Y.; In, S.-Y.; Woo, J.-H.; Lee, J.-H.; Chae, H.-J.; Kim, J.-K.; Hwang, J.-E.; Kim, J.-C.; et al. CO2 Sorption and Regeneration Properties of K2CO3/Al2O3-Based Sorbent at High Pressure and Moderate Temperature. Appl. Sci. 2022, 12, 2989. https://doi.org/10.3390/app12062989

Ryu D-Y, Jo S, Kim T-Y, In S-Y, Woo J-H, Lee J-H, Chae H-J, Kim J-K, Hwang J-E, Kim J-C, et al. CO2 Sorption and Regeneration Properties of K2CO3/Al2O3-Based Sorbent at High Pressure and Moderate Temperature. Applied Sciences. 2022; 12(6):2989. https://doi.org/10.3390/app12062989

Chicago/Turabian StyleRyu, Do-Yeong, Seongbin Jo, Tae-Young Kim, Soo-Yeong In, Jin-Hyeok Woo, Jong-Heon Lee, Ho-Jin Chae, Jae-Kuk Kim, Jae-Eun Hwang, Jae-Chang Kim, and et al. 2022. "CO2 Sorption and Regeneration Properties of K2CO3/Al2O3-Based Sorbent at High Pressure and Moderate Temperature" Applied Sciences 12, no. 6: 2989. https://doi.org/10.3390/app12062989

APA StyleRyu, D.-Y., Jo, S., Kim, T.-Y., In, S.-Y., Woo, J.-H., Lee, J.-H., Chae, H.-J., Kim, J.-K., Hwang, J.-E., Kim, J.-C., & Lee, S.-C. (2022). CO2 Sorption and Regeneration Properties of K2CO3/Al2O3-Based Sorbent at High Pressure and Moderate Temperature. Applied Sciences, 12(6), 2989. https://doi.org/10.3390/app12062989