A BIM Based Framework for Damage Segmentation, Modeling, and Visualization Using IFC

Abstract

:1. Introduction

2. Background

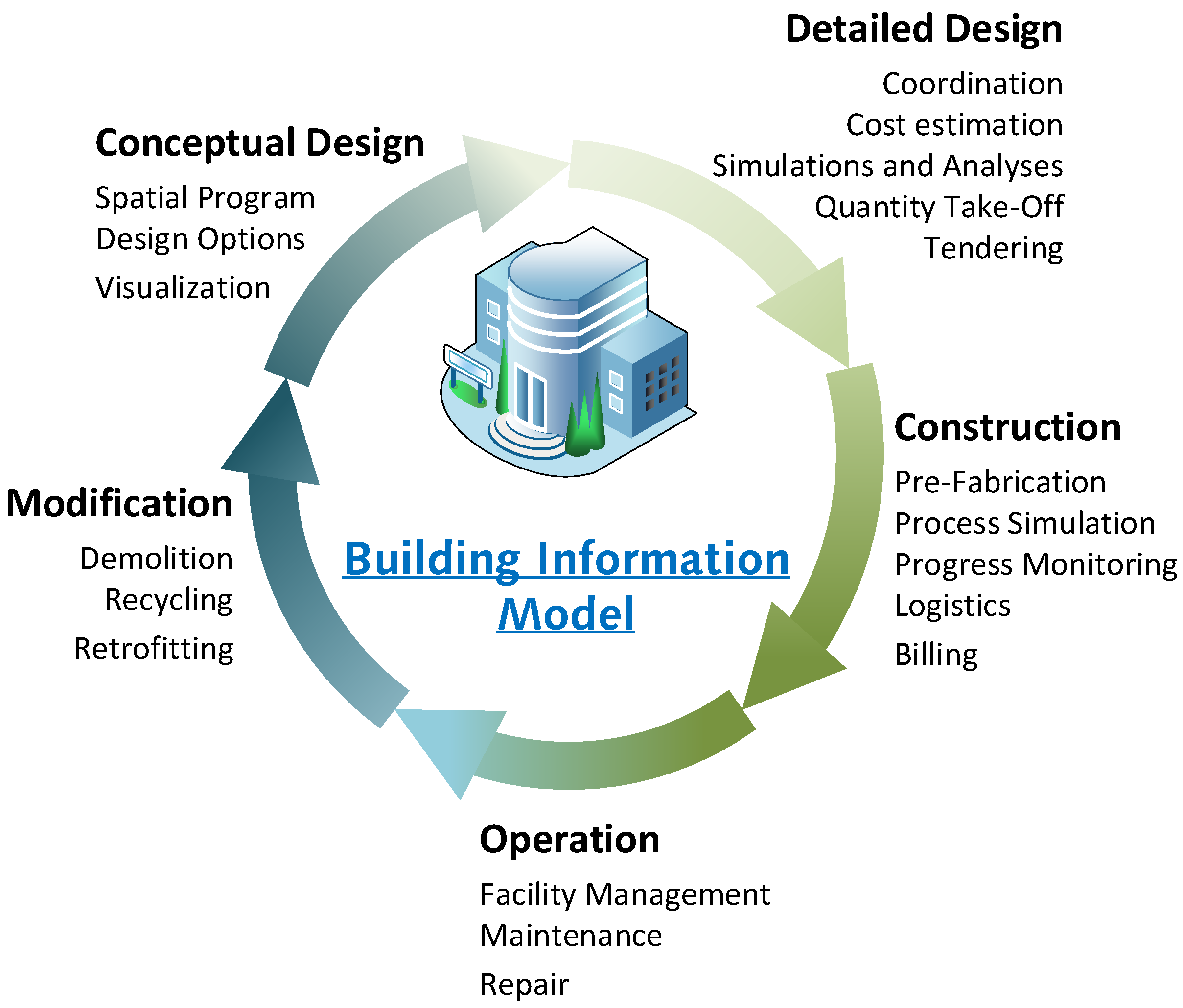

2.1. Building Information Modeling

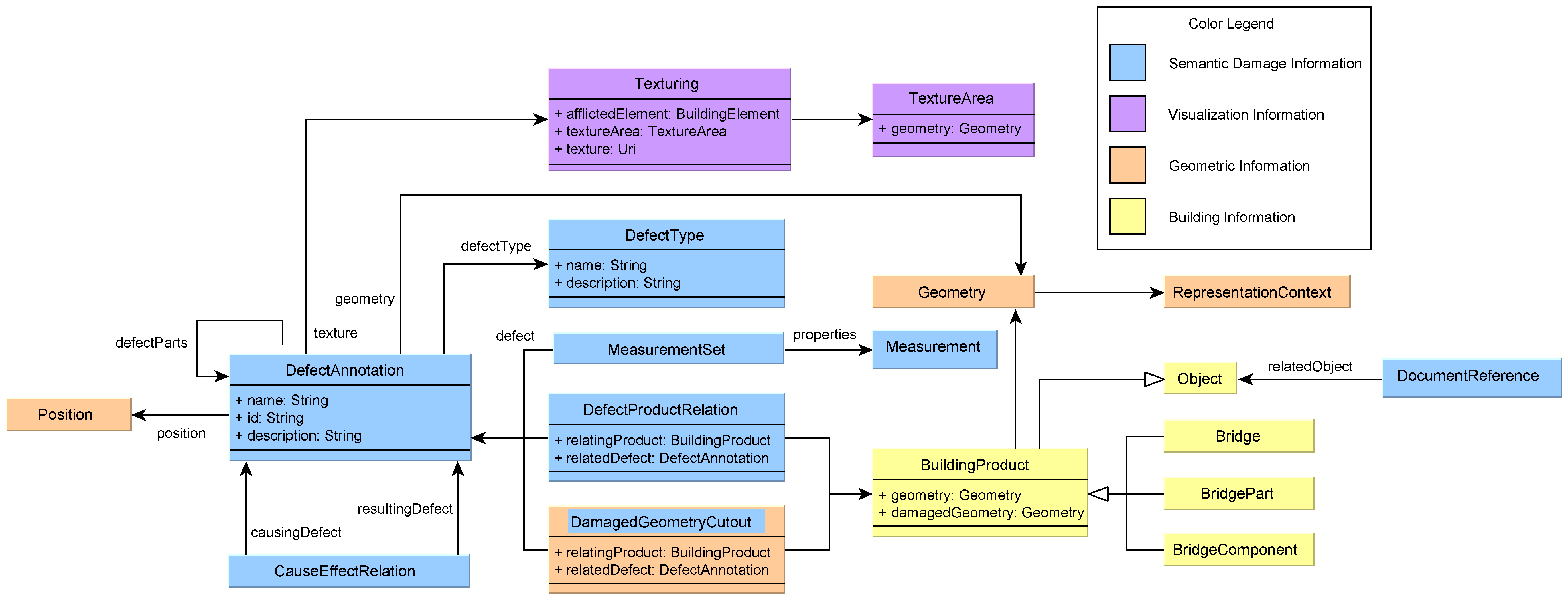

2.2. Damage Data Model

2.3. Damage Data Acquisition

2.4. Damage Data Applications

2.5. Problem Statements and Objectives

- How are damage geometries generated on the basis of photos?

- How are geometric as-damaged BIM models generated?

- How could additional data, for instance, documents or photos, be added to the geometric as-damaged BIM model?

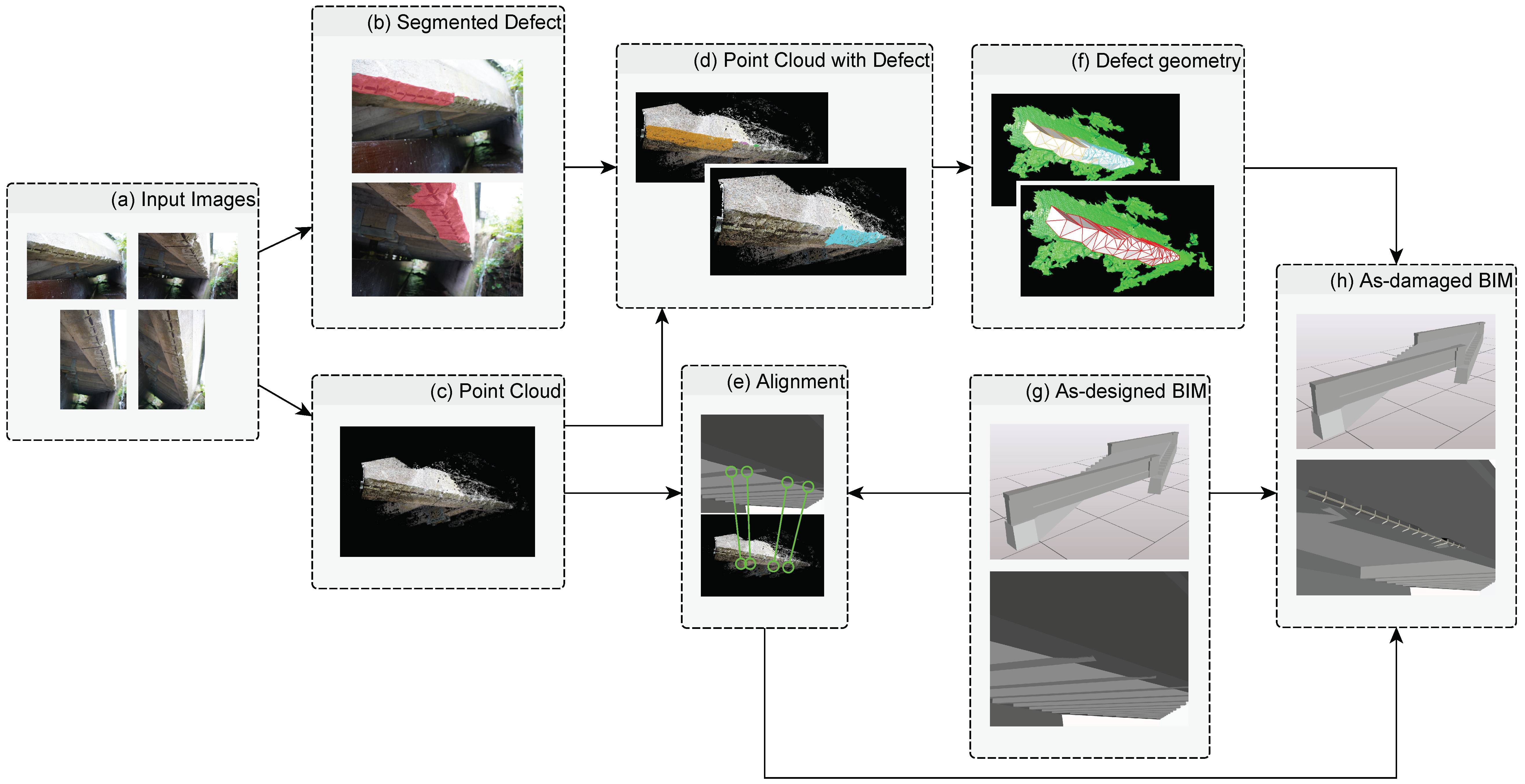

3. Methodology

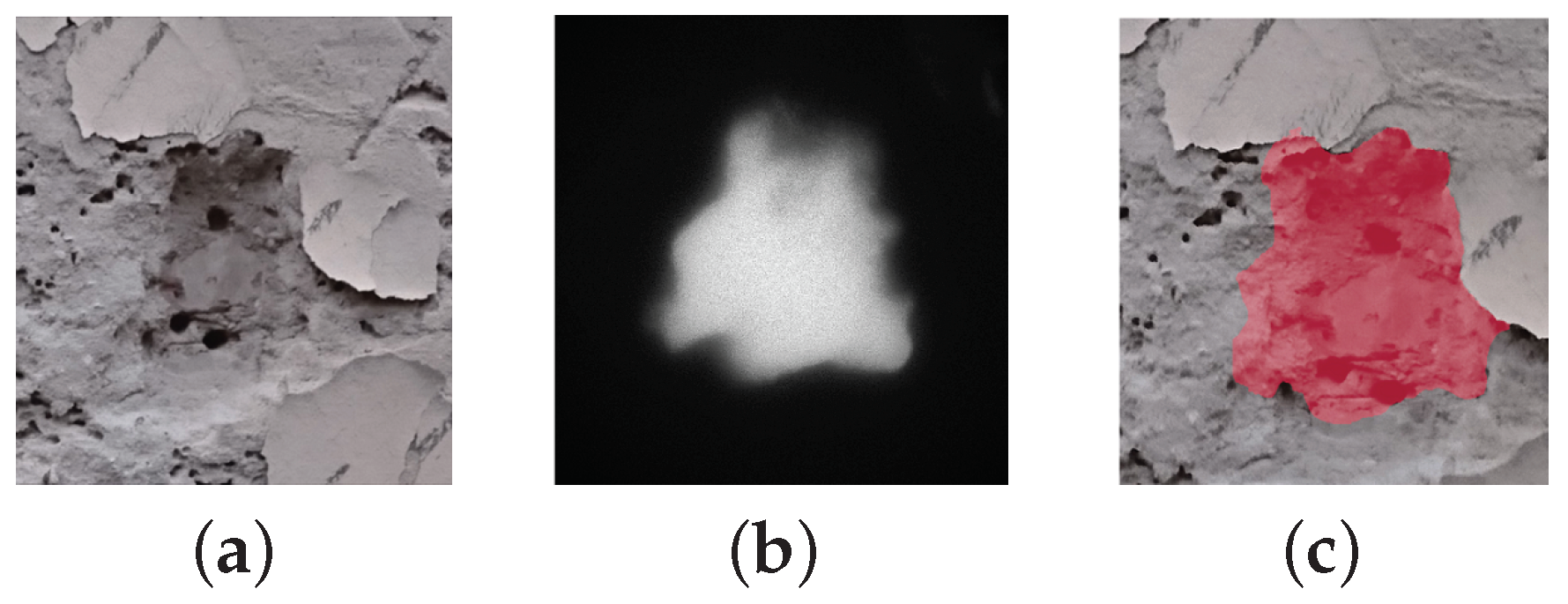

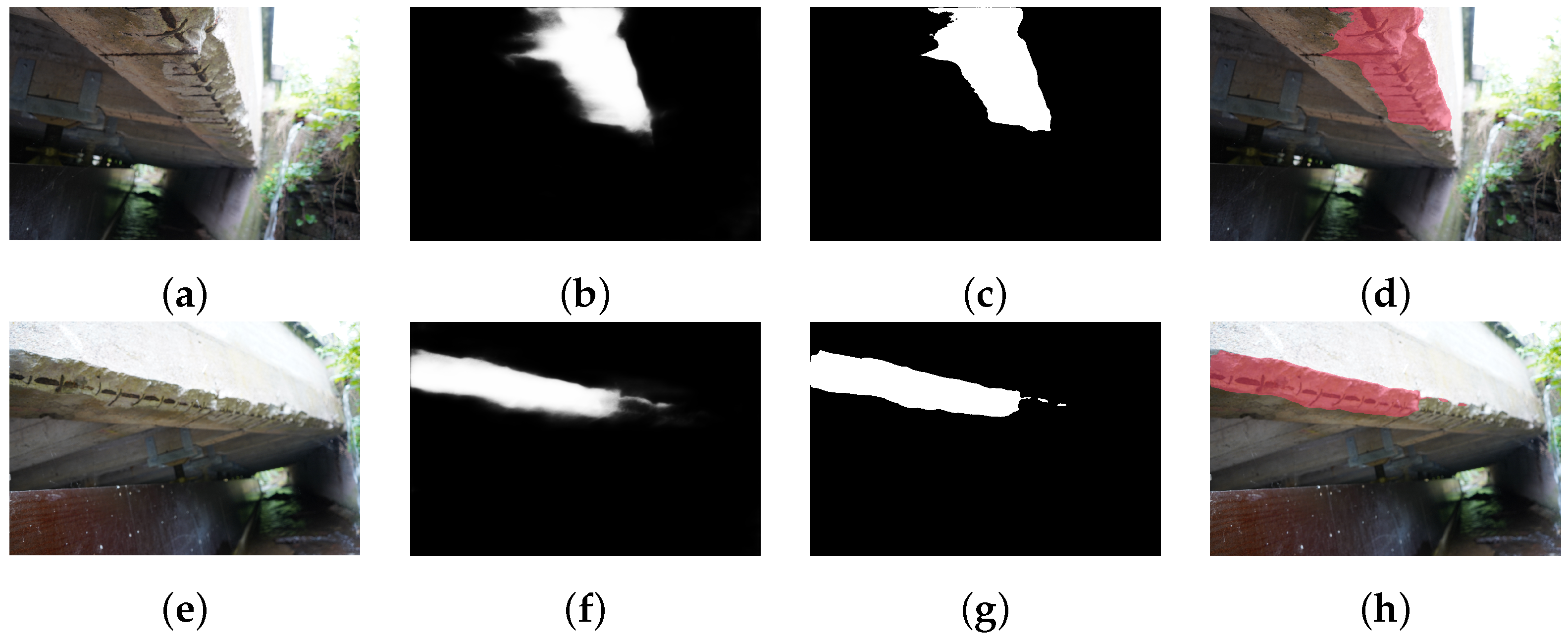

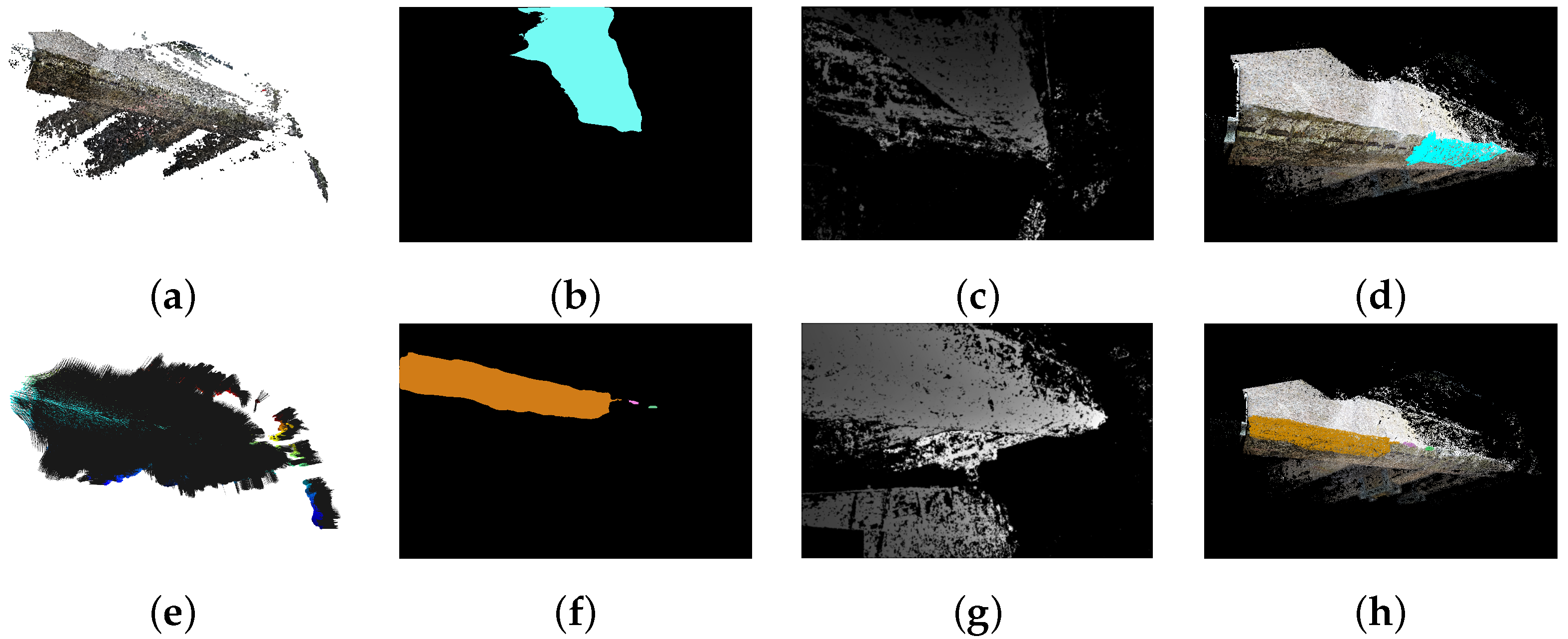

3.1. Damage Segmentation

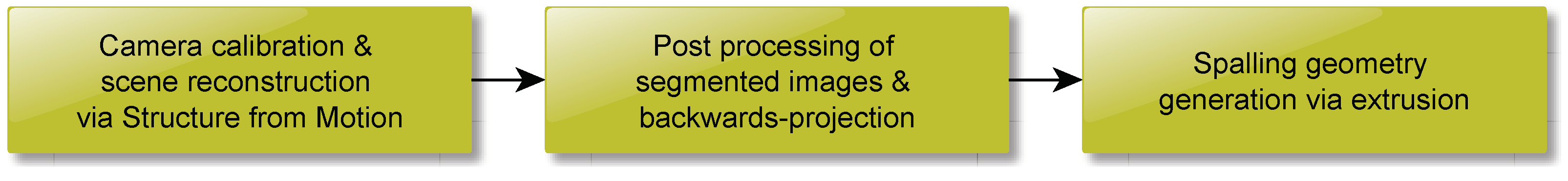

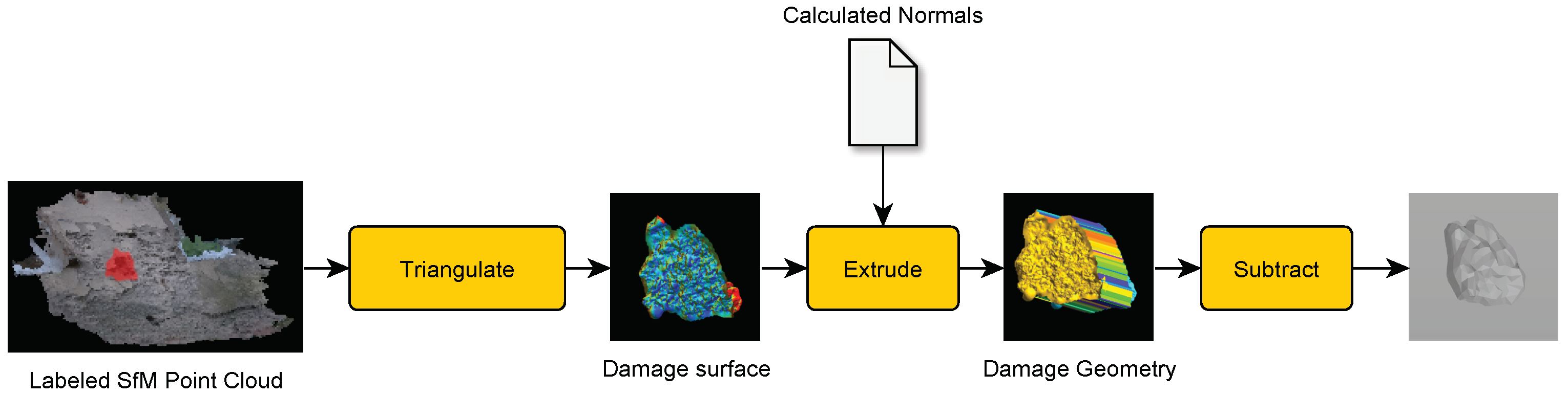

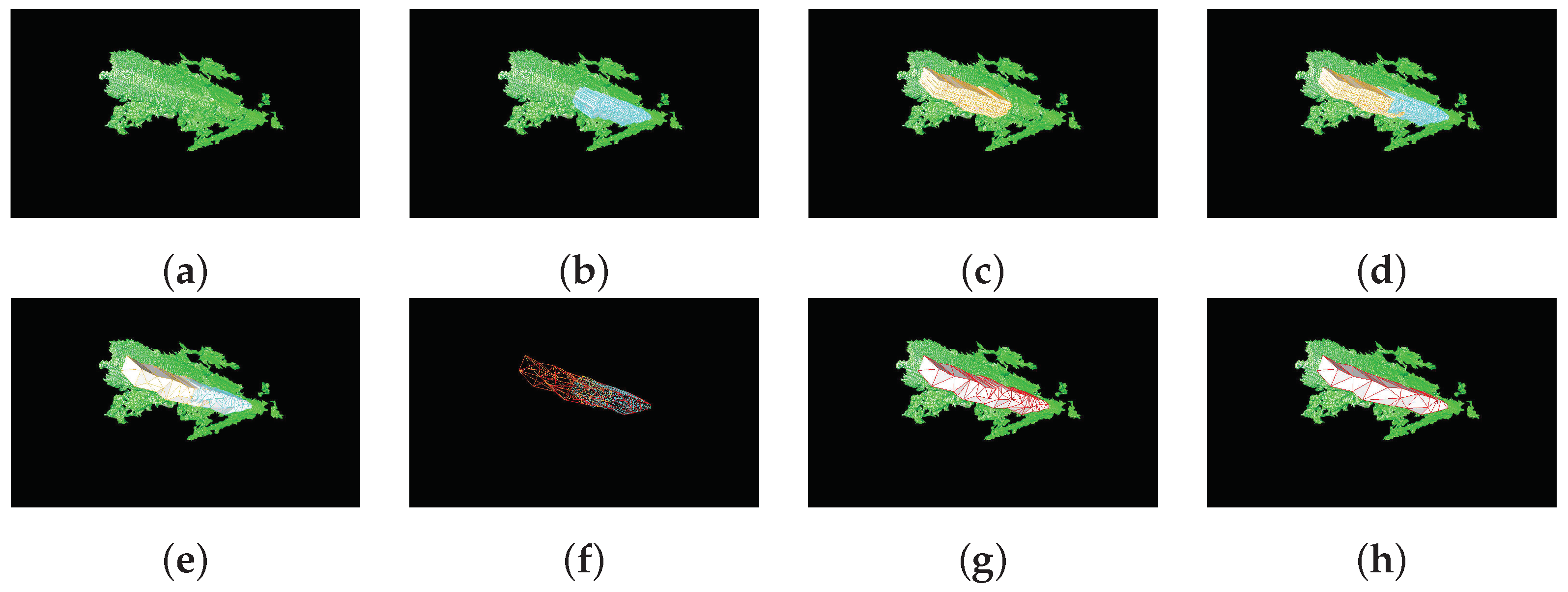

3.2. Damage Geometry Generation

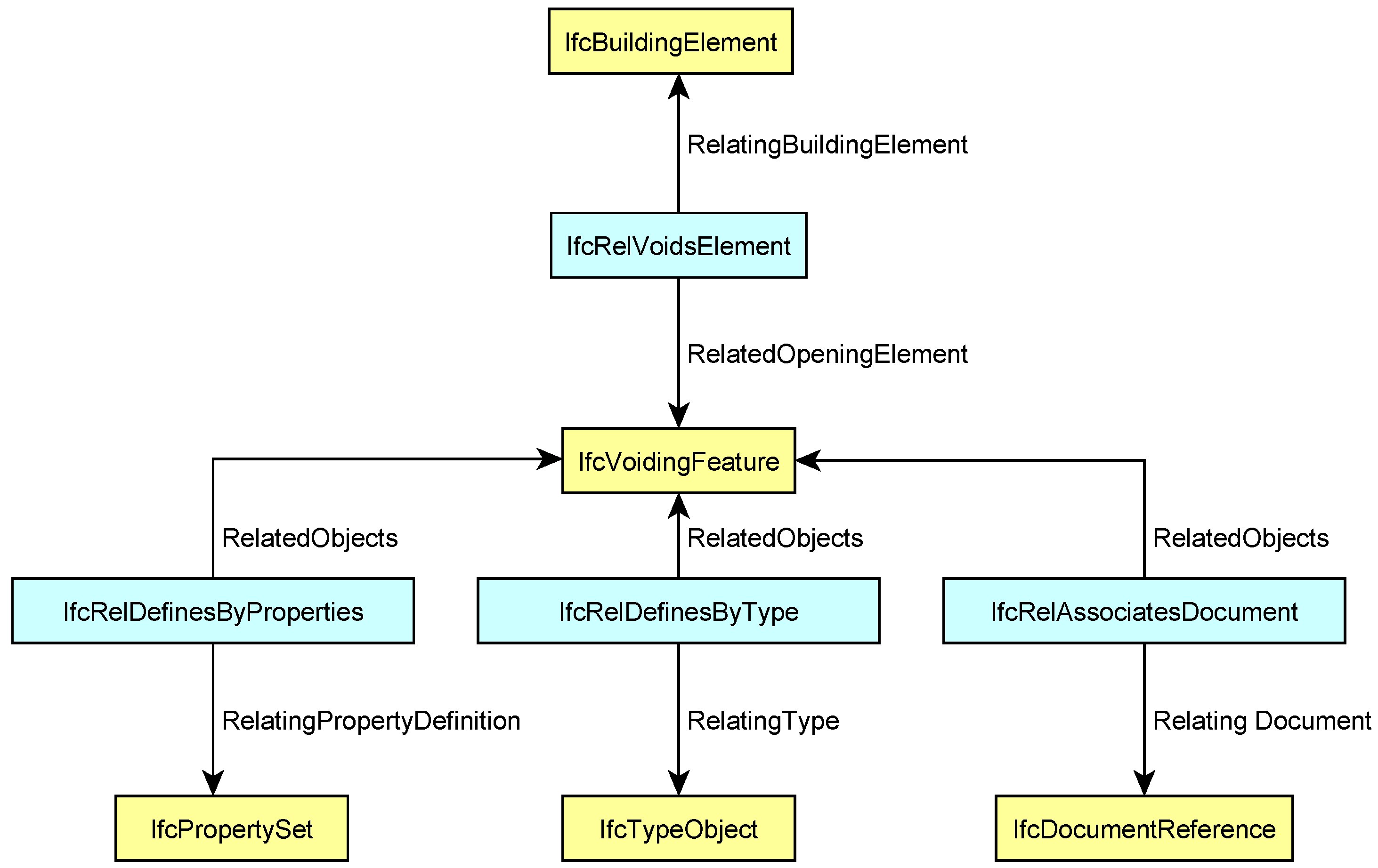

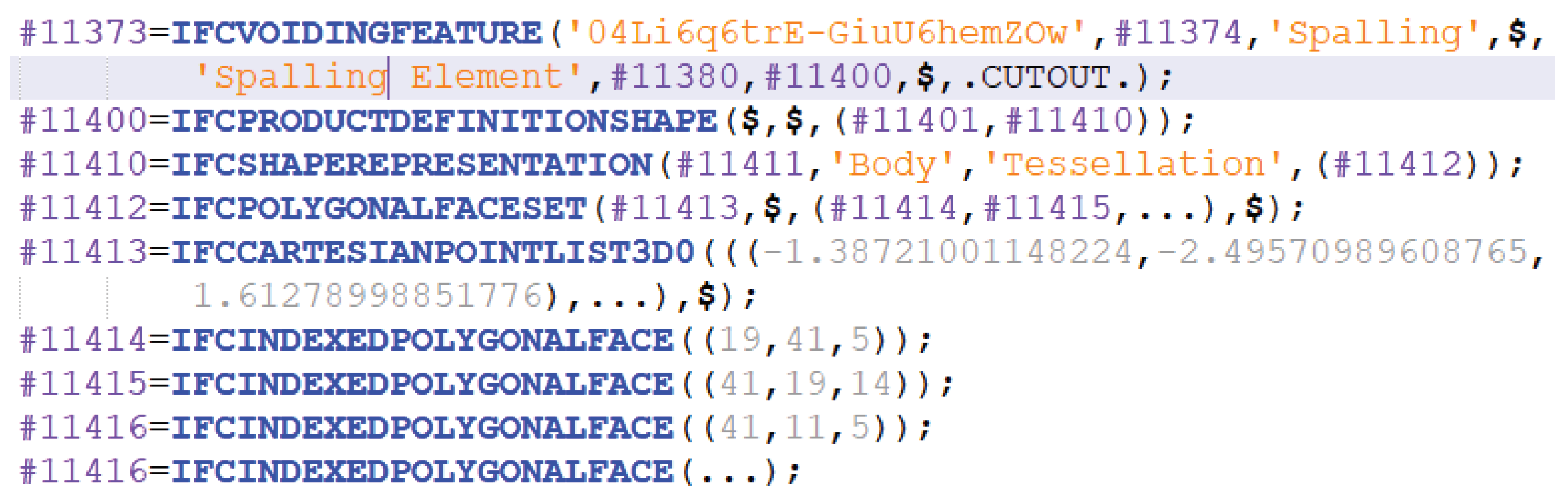

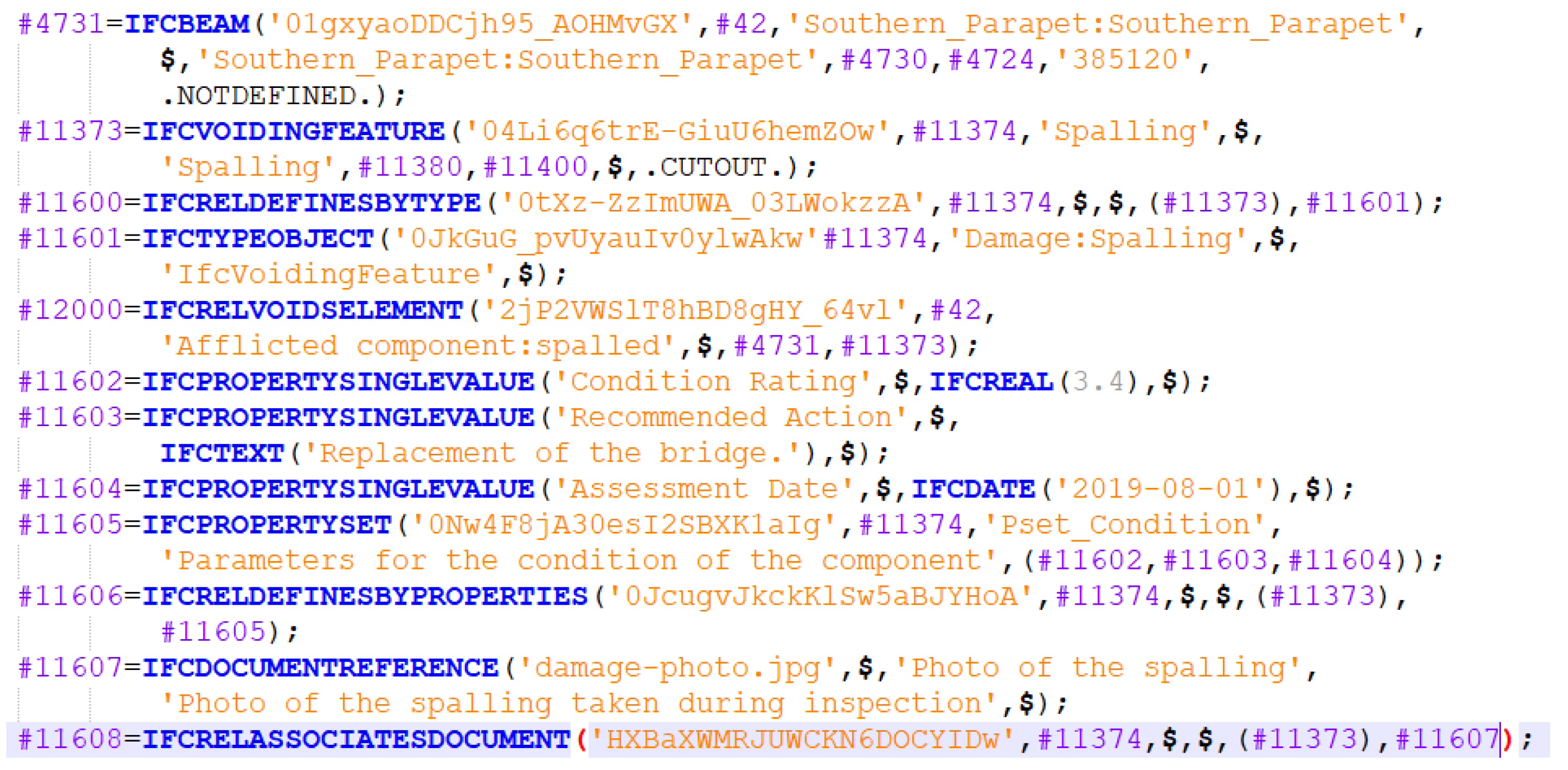

3.3. Damage Modeling

3.4. Use Cases

4. Implementation

4.1. Defect Geometry Generation and Alignment

4.2. As-Damaged BIM with IFC

5. Case Study

5.1. Generation of BIM with Physical Defects

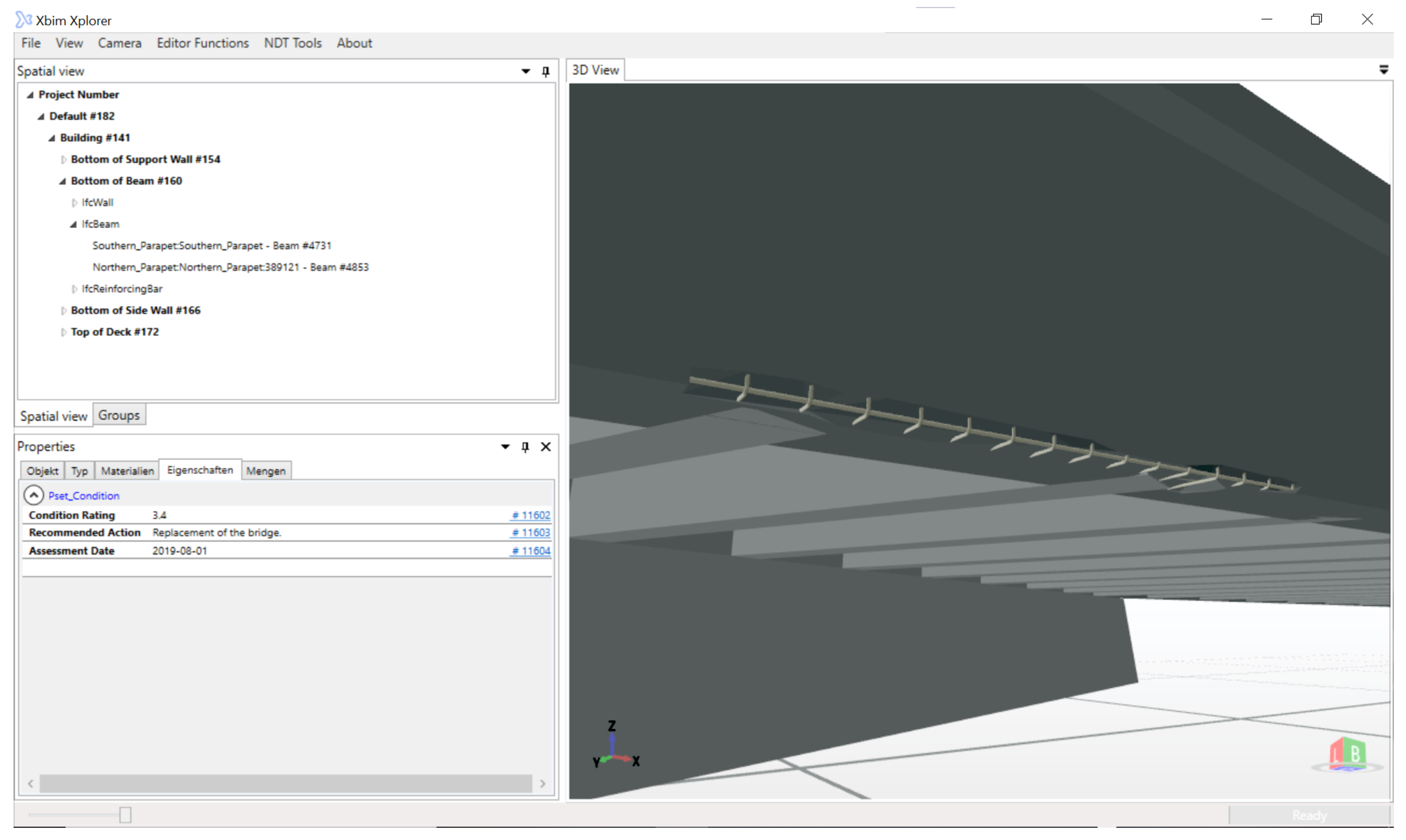

5.2. Semantic Data

5.3. Lessons Learned

6. Summary

- Development and implementation of an image based processes for:

- -

- Defect geometry generation

- -

- Defect alignment to BIM models

- Development of an inspection framework based on open file formats

- Providing a case study to test practical usability of the data acquisitions and storage

7. Discussion and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEC | Architecture, Engineering and Construction |

| BIM | Building Information Modeling |

| CNN | Convolutional Neural Network |

| CSG | Constructive Solid Geometry |

| DIM | Damage Information Modeling |

| FEA | Finite Element Analysis |

| GoICP | Golbally optimal Iterative Closest Point |

| GPR | Ground Penetrating Radar |

| HBIM | Historic Building Information Model |

| ICP | Iterative Closest Point |

| IDM | Information Delivery Manual |

| IFC | Industry Foundation Classes |

| NDT | Nondestructive Testing |

| SfM | Structure from Motion |

| SHM | Structural Health Monitoring |

| UML | Unified Modeling Language |

| URI | Unified Resource Identifier |

| VGG | Visual Geometry Group |

References

- Schach, R.; Otto, J.; Häupel, H.; Fritzsche, M. Lebenszykluskosten von Brücken. Bauingenieur 2006, 81, 7–14. Available online: https://tu-dresden.de/bu/bauingenieurwesen/ibb/ressourcen/dateien/publikationen/periodika/2006/bauing08_2006.pdf?lang=de (accessed on 20 December 2021).

- Nagel, L.M.; Pauly, M.; Mucha, V.; Setzer, J.; Wilhelm, F. Wettlauf Gegen den Verfall. 2016. Available online: http://www.welt.de/politik/interaktiv/bruecken/deutschlands-bruecken-wettlauf-gegen-den-verfall.html (accessed on 27 September 2018).

- Sacks, R.; Eastman, C.M.; Lee, G.; Teicholz, P.M. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers, 3rd ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Borrmann, A.; König, M.; Koch, C.; Beetz, J. (Eds.) Building Information Modeling: Technology Foundations and Industry Practice, 2nd ed.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Sacks, R.; Kedar, A.; Borrmann, A.; Ma, L.; Brilakis, I.; Hüthwohl, P.; Daum, S.; Kattel, U.; Yosef, R.; Liebich, T.; et al. SeeBridge as next generation bridge inspection: Overview, Information Delivery Manual and Model View Definition. Autom. Constr. 2018, 90, 134–145. [Google Scholar] [CrossRef] [Green Version]

- Adrien Coquet. Damage. 2020. Available online: https://thenounproject.com/term/damage/4211556/ (accessed on 20 December 2021).

- Nawicon. Demolition. 2020. Available online: https://thenounproject.com/term/demolition/3364573/ (accessed on 20 December 2021).

- Eucalyp. Maintenance. 2019. Available online: https://thenounproject.com/term/maintenance/3050592/ (accessed on 20 December 2021).

- Oleksandr Panasovskyi. Elastic Material. 2020. Available online: https://thenounproject.com/term/elastic-material/3636285/ (accessed on 20 December 2021).

- Oleksandr Panasovskyi. Deformation. 2020. Available online: https://thenounproject.com/term/deformation/2753612/ (accessed on 20 December 2021).

- Nithinan Tatah. Sustainable. 2020. Available online: https://thenounproject.com/term/sustainable/3031205/ (accessed on 20 December 2021).

- Shocho. Inspection. 2020. Available online: https://thenounproject.com/term/inspection/2851743/ (accessed on 20 December 2021).

- Artus, M.; Koch, C. State of the art in damage information modeling for RC bridges—A literature review. Adv. Eng. Inform. 2020, 46, 101171. [Google Scholar] [CrossRef]

- Autodesk. Revit. 2019. Available online: https://www.autodesk.de/products/revit/overview (accessed on 14 October 2019).

- Graphisoft. Archicad. 1984. Available online: https://graphisoft.com/us (accessed on 20 December 2021).

- Ward, A.; Benghi, C.; Černý, M.; Lockley, S. xBIM XbimWindowsUI. 2007. Available online: https://github.com/xBimTeam/XbimWindowsUI (accessed on 15 October 2019).

- Java IFC Viewer. 2012. Available online: http://www.apstex.com (accessed on 14 October 2019).

- Lebegue, E. IFC-Bridge & IFC for Roads at BuildingSmart Infrastructure Room, Held on 08.10.2013 in Munich. Available online: http://iug.buildingsmart.org/resources/itm-and-iug-meetings-2013-munich/infra-room/ifc-bridge-ifc-for-roads (accessed on 9 August 2018).

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Barazzetti, L.; Banfi, F.; Brumana, R.; Previtali, M.; Roncoroni, F. BIM from Laser Scans… not just for Buildings: Nurbs-Based Parametric Modeling of a Medieval Bridge. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, III-5, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Kropp, C.; Koch, C.; König, M. Interior construction state recognition with 4D BIM registered image sequences. Autom. Constr. 2018, 86, 11–32. [Google Scholar] [CrossRef]

- Hearn, G. Bridge Inspection Practices; Transportation Research Board. 2007. Available online: https://www.researchgate.net/publication/298792603_Bridge_Inspection_Practices (accessed on 11 May 2020).

- Hüthwohl, P.; Brilakis, I.; Borrmann, A.; Sacks, R. Integrating RC Bridge Defect Information into BIM Models. J. Comput. Civ. Eng. 2018, 32, 1–14. [Google Scholar] [CrossRef]

- Hamdan, A.H.; Scherer, J.R. Modular Concatenation of Reference Damage Patterns. In EWork and EBusiness in Architecture, Engineering and Construction; Karlshoj, J., Scherer, R., Eds.; Chapman and Hall/CRC: Milton, MA, USA, 2018. [Google Scholar]

- Tanaka, F.; Tsuchida, M.; Onosato, M.; Date, H.; Kanai, S.; Hada, Y.; Nakao, M.; Kobayashi, H.; Hasegawa, E.; Sugawara, T.; et al. Bridge Information Modeling based on IFC for supporting maintenance management of existing bridges. In Proceedings of the ICCCBE 2018 Conference Proceedings, Tampere, Finland, 5–7 June 2018; pp. 778–785. [Google Scholar]

- German, S.; Brilakis, I.; DesRoches, R. Rapid entropy-based detection and properties measurement of concrete spalling with machine vision for post-earthquake safety assessments. Adv. Eng. Inform. 2012, 26, 846–858. [Google Scholar] [CrossRef]

- Paal, S.G.; Brilakis, I.; DesRoches, R. Automated Damage Index Estimation of Reinforced Concrete Columns for Post-Earthquake. J. Struct. Eng. 2015, 141, 04014228. [Google Scholar] [CrossRef] [Green Version]

- Dawood, T.; Zhu, Z.; Zayed, T. Machine vision-based model for spalling detection and quantification in subway networks. Autom. Constr. 2017, 81, 149–160. [Google Scholar] [CrossRef]

- Wu, H.; Ao, X.; Chen, Z.; Liu, C.; Xu, Z.; Yu, P. Concrete Spalling Detection for Metro Tunnel from Point Cloud Based on Roughness Descriptor. J. Sens. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Hoang, N.D.; Nguyen, Q.L.; Tran, X.L. Automatic Detection of Concrete Spalling Using Piecewise Linear Stochastic Gradient Descent Logistic Regression and Image Texture Analysis. Complexity 2019, 2019, 5910625. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Gkioxari, G.; Dollar, P.; Girshick, R. Mask R-CNN. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017. [Google Scholar] [CrossRef]

- Borin, P.; Cavazzini, F. Condition Assessment of RC Bridges. Integrating Machine Learning, Photogrammetry and BIM. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, 42, 201–208. [Google Scholar] [CrossRef] [Green Version]

- Jeong, S.; Byun, J.; Kim, D.; Sohn, H.; Bae, I.H.; Law, K.H. A data management infrastructure for bridge monitoring. In SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring; Lynch, J.P., Ed.; SPIE: Bellingham, WA, USA, 2015. [Google Scholar] [CrossRef] [Green Version]

- Mousavi, M.; Gandomi, A.H. Prediction error of Johansen cointegration residuals for structural health monitoring. Mech. Syst. Signal Process. 2021, 160, 107847. [Google Scholar] [CrossRef]

- Bruno, S.; de Fino, M.; Fatiguso, F. Historic Building Information Modelling: Performance assessment for diagnosis-aided information modelling and management. Autom. Constr. 2018, 86, 256–276. [Google Scholar] [CrossRef]

- Torok, M.M.; Golparvar-Fard, M.; Kochersberger, K.B. Image-Based Automated 3D Crack Detection for Post-disaster Building Assessment. J. Comput. Civ. Eng. 2014, 28, A4014004. [Google Scholar] [CrossRef]

- Chan, B.; Guan, H.; Hou, L.; Jo, J.; Blumenstein, M.; Wang, J. Defining a conceptual framework for the integration of modelling and advanced imaging for improving the reliability and efficiency of bridge assessments. J. Civ. Struct. Health Monit. 2016, 6, 703–714. [Google Scholar] [CrossRef] [Green Version]

- McGuire, B.M. Using Building Information Modeling to Track and Assess the Structural Condition of Bridges. Master’s Thesis, Colorado State University, Fort Collins, CO, USA, 2014. [Google Scholar]

- McGuire, B.; Atadero, R.; Clevenger, C.; Ozbek, M. Bridge Information Modeling for Inspection and Evaluation. J. Bridge Eng. 2016, 21, 04015076. [Google Scholar] [CrossRef]

- Hamdan, A.H.; Taraben, J.; Helmrich, M.; Mansperger, T.; Morgenthal, G.; Scherer, R.J. A semantic modeling approach for the automated detection and interpretation of structural damage. Autom. Constr. 2021, 128, 103739. [Google Scholar] [CrossRef]

- Isailović, D.; Stojanovic, V.; Trapp, M.; Richter, R.; Hajdin, R.; Döllner, J. Bridge damage: Detection, IFC-based semantic enrichment and visualization. Autom. Constr. 2020, 112, 103088. [Google Scholar] [CrossRef]

- Lindenberg, R.E.; McGormley, J.C. Visualizing Bridge Inspection with 2D + 1 Software. In Computing in Civil Engineering; Brilakis, I., Lee, S., Becerik-Gerber, B., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 857–864. [Google Scholar] [CrossRef]

- Artus, M.; Koch, C. Modeling Geometry and Semantics of Physical Damages using IFC. In EG-ICE 2020 Workshop on Intelligent Computing in Engineering; Ungureanu, L.C., Hartmann, T., Eds.; Universitätsverlag der TU Berlin: Berlin, Germany, 2020; pp. 144–153. [Google Scholar]

- Artus, M.; Koch, C. Modeling Physical Damages Using the Industry Foundation Classes—A Software Evaluation. In Proceedings of the 18th International Conference on Computing in Civil and Building Engineering, Sao Paulo, Brazil, 18–20 August 2021; Toledo Santos, E., Scheer, S., Eds.; Springer: Cham, Switzerland, 2021; Volume 98, pp. 507–518. [Google Scholar]

- Yang, L.; Li, B.; Li, W.; Liu, Z.; Yang, G.; Xiao, J. A robotic system towards concrete structure spalling and crack database. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macao, China, 5–8 December 2017; pp. 1276–1281. [Google Scholar] [CrossRef]

- Yang, L.; Li, B.; Li, W.; Jiang, B.; Xiao, J. Semantic Metric 3D Reconstruction for Concrete Inspection. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), Salt Lake City, UT, USA, 18–22 June 2018; pp. 1624–16248. [Google Scholar] [CrossRef]

- Shih, F.Y. Image Segmentation. In Encyclopedia of Database Systems; Liu, L., Özsu, M.T., Eds.; Springer: Boston, MA, USA, 2009; pp. 1389–1395. [Google Scholar]

- Faugeras, O.; Luong, Q.-T. The Geometry of Multiple Images: The Laws That Govern the Formation of Multiple Images of a Scene and Some of Their Applications; The MIT Press: Cambridge, MA, USA, 2001. [Google Scholar] [CrossRef]

- Förstner, W.; Wrobel, B.P. Photogrammetric Computer Vision; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Li, H.; Jia, Y. Go-ICP: Solving 3D Registration Efficiently and Globally Optimally. In Proceedings of the 2013 IEEE International Conference on Computer Vision, Sydney, Australia, 1–8 December 2013; pp. 1457–1464. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Li, H.; Campbell, D.; Jia, Y. Go-ICP: A Globally Optimal Solution to 3D ICP Point-Set Registration. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 2241–2254. [Google Scholar] [CrossRef] [Green Version]

- Fröhlich, J. On Systematic Approaches for Interpreted Information Transfer of Inspection Data from Bridge Models to Structural Analysis. Master’s Thesis, Bauhaus Universität Weimar, Weimar, Germany, 10 February 2020. [Google Scholar]

- Adhikari, R.S.; Moselhi, O.; Bagchi, A. Automated Prediction of Condition State Rating in Bridge Inspection. In Proceedings of the International Symposium on Automation and Robotics in Construction, Eindhoven, The Netherlands, 1 February 2012. [Google Scholar] [CrossRef] [Green Version]

- Wellalage, W.; Zhang, T.; Dwight, R.; El-Akruti, K. Bridge Deterioration Modeling by Markov Chain Monte Carlo (MCMC) Simulation Method. In Engineering Asset Management-Systems, Professional Practices and Certification; Lecture Notes in Mechanical Engineering; Tse, P.W., Mathew, J., Wong, K., Lam, R., Ko, C.N., Eds.; Springer: Cham, Switzerland, 2015; pp. 545–556. [Google Scholar]

- Cong, L.; Bin, H.; Zongjun, H.; Zhongrong, N. Analysis of multi-crack propagation by using the extended boundary element method. Eng. Anal. Bound. Elem. 2021, 132, 65–76. [Google Scholar] [CrossRef]

- Shvets, A.A.; Rakhlin, A.; Kalinin, A.A.; Iglovikov, V.I. Automatic Instrument Segmentation in Robot-Assisted Surgery using Deep Learning. In Proceedings of the 2018 17th IEEE International Conference on Machine Learning and Applications (ICMLA), Orlando, FL, USA, 17–20 December 2018; pp. 624–628. [Google Scholar] [CrossRef] [Green Version]

- Bradski, G.R.; Kaehler, A. Learning OpenCV: Computer Vision with the OpenCV Library, 1st ed.; Software That Sees; O’Reilly: Beijing, China, 2011. [Google Scholar]

- Mapillary AB. OpenSfM. 2014. Available online: https://opensfm.org (accessed on 18 November 2021).

- Blender Foundation. Blender v. 2.92. 1995. Available online: https://www.blender.org/ (accessed on 16 March 2021).

- buildingSMART International Ltd. IFC4 Add2: Addendum 2 [Official]. 2016. Available online: https://standards.buildingsmart.org/IFC/RELEASE/IFC4/ADD2_TC1/HTML/ (accessed on 1 June 2018).

- Zhou, Q.Y.; Park, J.; Koltun, V. Open3D: A Modern Library for 3D Data Processing. arXiv 2018, arXiv:1801.09847. [Google Scholar]

- Lockley, S.; Ward, A.; Cerny, M.; Artus, M. xBIM Xplorer. 2020. Available online: https://github.com/Noranius/XbimWindowsUI (accessed on 20 December 2021).

- ANSYS Inc. Ansys 2020 R2. 2020. Available online: https://www.ansys.com/en-us/products/ansys-workbench (accessed on 14 April 2021).

- Artus, M.; Alabassy, M.S.H.; Koch, C. IFC based Framework for Generating, Modeling and Visualizing Spalling Defect Geometries. In EG-ICE 2021 Workshop on Intelligent Computing in Engineering; Abualdenien, J., Borrmann, A., Ungureanu, L.C., Hartmann, T., Eds.; Universitätsverlag der TU Berlin: Berlin, Germany, 2021. [Google Scholar]

| Metric | Mean | Std |

|---|---|---|

| Dice (F1) | 0.8304 | 0.1754 |

| Jaccard (IoU) | 0.8326 | 0.2013 |

| Accuracy | 0.9196 | 0.0672 |

| Precision | 0.8755 | 0.1672 |

| Recall | 0.8136 | 0.2057 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Artus, M.; Alabassy, M.S.H.; Koch, C. A BIM Based Framework for Damage Segmentation, Modeling, and Visualization Using IFC. Appl. Sci. 2022, 12, 2772. https://doi.org/10.3390/app12062772

Artus M, Alabassy MSH, Koch C. A BIM Based Framework for Damage Segmentation, Modeling, and Visualization Using IFC. Applied Sciences. 2022; 12(6):2772. https://doi.org/10.3390/app12062772

Chicago/Turabian StyleArtus, Mathias, Mohamed Said Helmy Alabassy, and Christian Koch. 2022. "A BIM Based Framework for Damage Segmentation, Modeling, and Visualization Using IFC" Applied Sciences 12, no. 6: 2772. https://doi.org/10.3390/app12062772

APA StyleArtus, M., Alabassy, M. S. H., & Koch, C. (2022). A BIM Based Framework for Damage Segmentation, Modeling, and Visualization Using IFC. Applied Sciences, 12(6), 2772. https://doi.org/10.3390/app12062772