Research on a PSO-H-SVM-Based Intrusion Detection Method for Industrial Robotic Arms

Abstract

:Featured Application

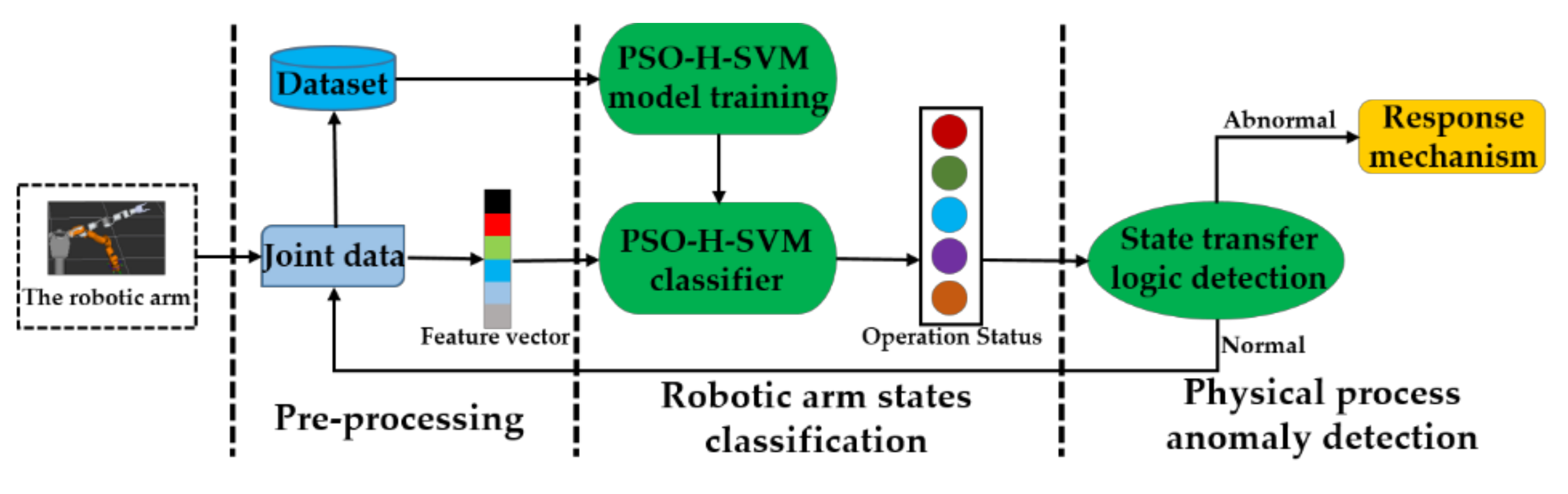

Abstract

1. Introduction

- The intrusion detection model for hierarchical support vector machines is established based on the particle swarm optimization algorithm (PSO-H-SVM) and response mechanism.

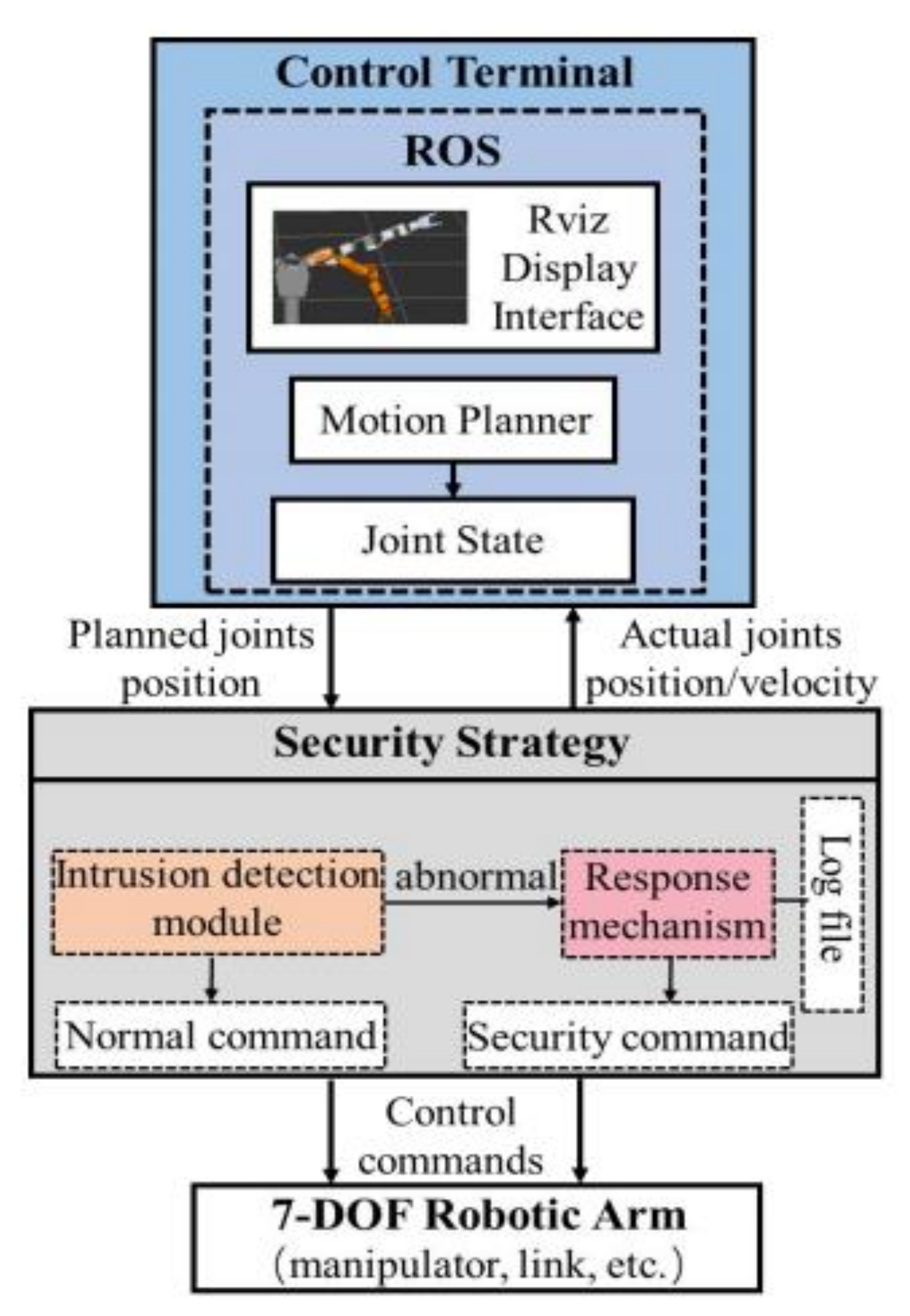

- The composition of the robotic arm system based on the EtherCAT protocol and the logical attack of the physical process are analyzed.

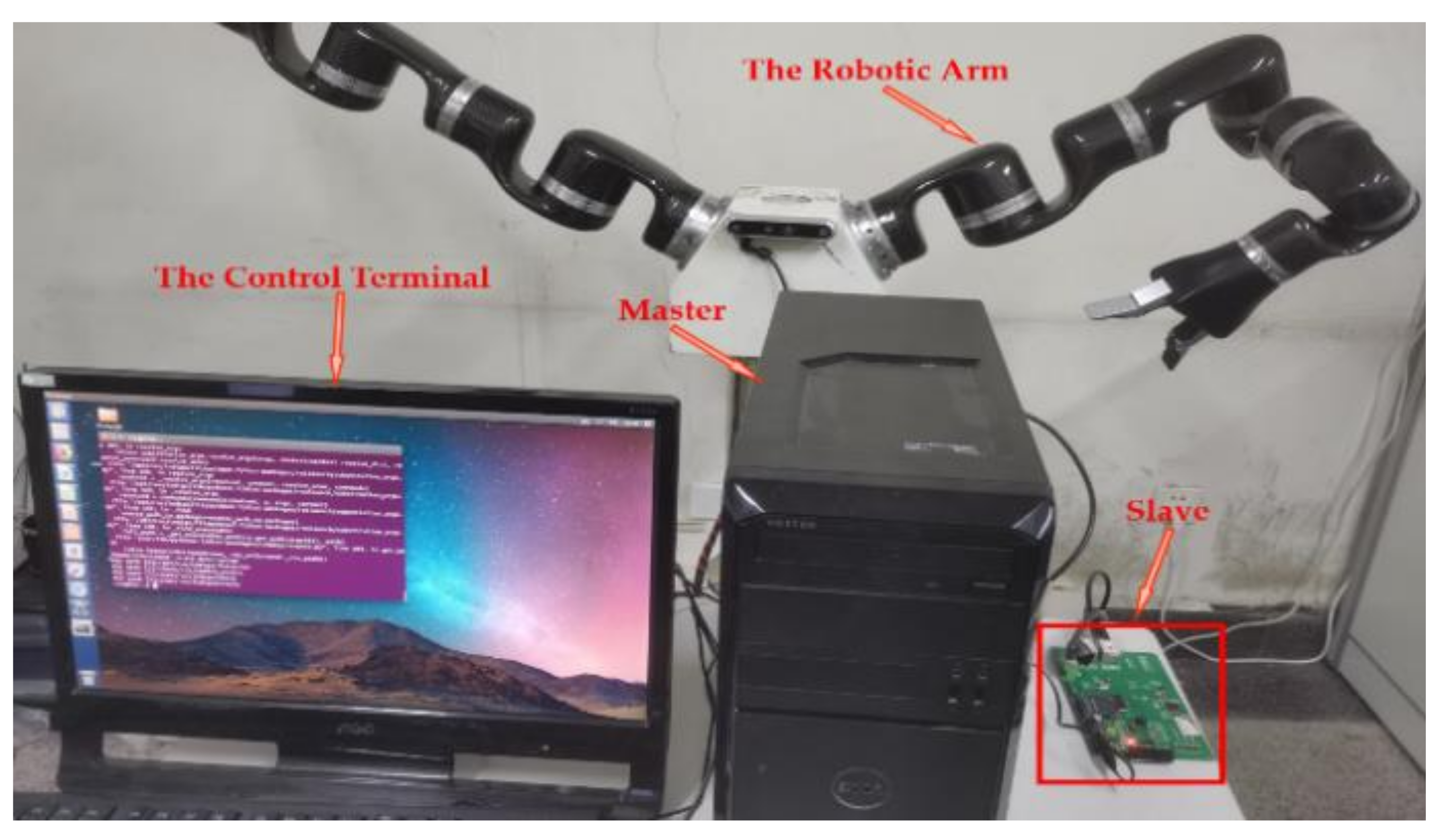

- A physical experiment platform is built to test the performance of the established intrusion detection model and verify its effectiveness.

2. Related Work

3. Intrusion Detection Method and Response Mechanism

3.1. Particle Swarm Optimization Algorithm

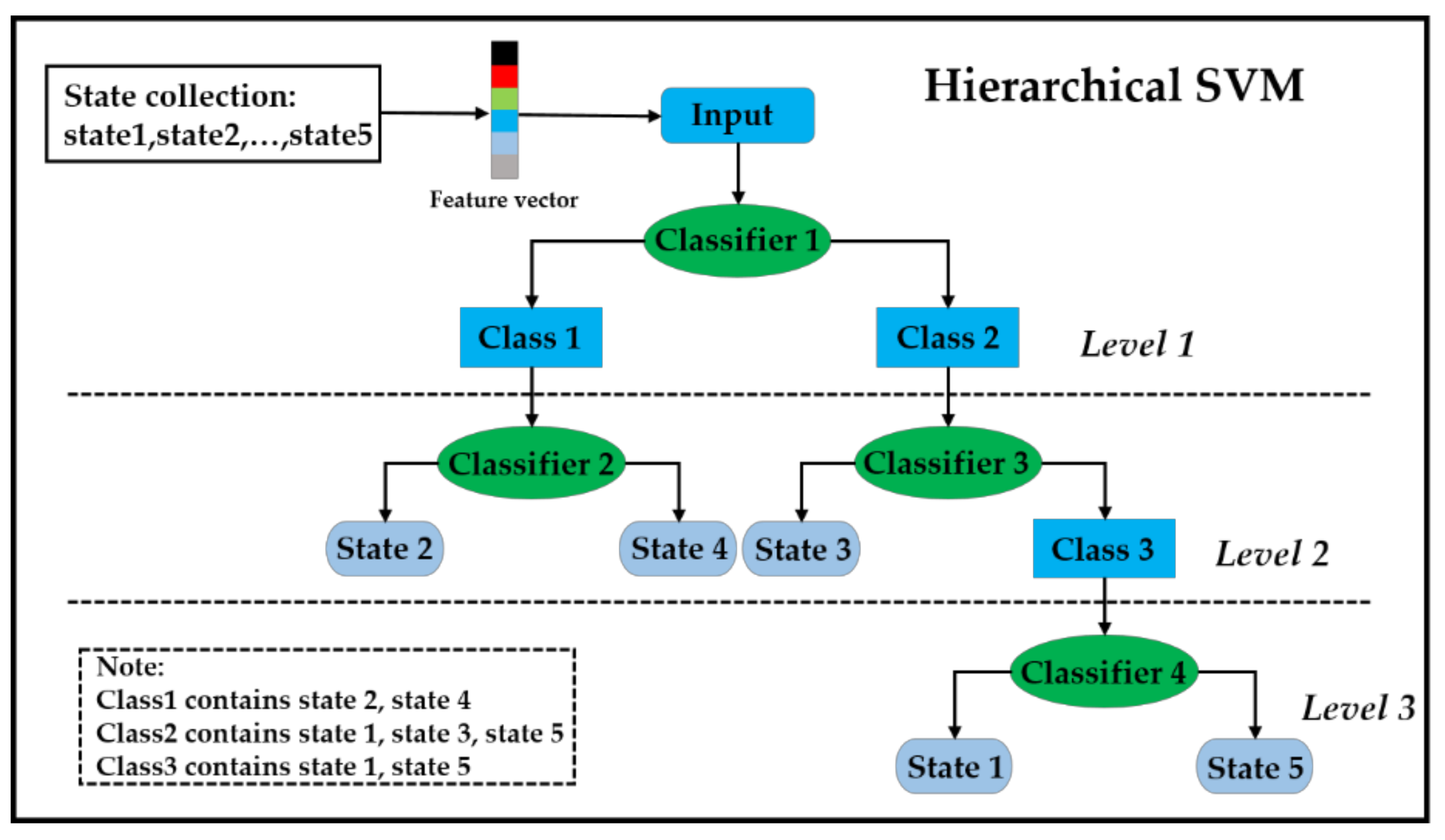

3.2. Hierarchical Support Vector Machine Based on PSO Algorithm

| Algorithm 1 Hierarchical Support Vector Machine Based on PSO Algorithm |

| procedure optimizing each classifier in H-SVM using PSO algorithm Input: X, Y // X is the eigenvector, Y is the result label for classifier_i in (k − 1) do particle_init = [(random(), random())*m] // m is the number of particles g = 0 while g < gmax do for i in m do position = particle_init[i] SC = SVC(kernel = ‘RBF’, C = position[0], gamma = position[1]).fit(X, Y) // Creat SVM CM = confusion_matrix(Y_true, SC.predict(X)) // Calculate the confusion matrix fv = sum(CM[i][j]) (i ≠ j) // Calculate the fitness value if pbest_fv > fv and gbest_fv > fv then Update individual and global optimal solutions w = wmax − itrea*(wmax − wmin)/gmax // Update inertia weight Update the position and velocity of each particle C, gamma = gbest_position[0], gbest_position[1] Combine classifiers and calculate accuracy Output: The values of C, gamma and accuracy |

3.3. Intrusion Detection and Response Mechanism

- Step 1: The initial position of the robotic arm

- Step 2: Move towards the target object position and reach the target object

- Step 3: Execute the grasping action

- Step 4: Move towards the placement position and reach the placement position

- Step 5: Execute the placing action

- Step 6: Reset the robotic arm.

| Algorithm 2 Physical Process Logic Intrusion Detection |

| procedure Detect exception and return alert Input: Joint_data // The eigenvector of joint position, velocity, etc. pre_state = state 1 detection_value = True // Detection result SC = load_SVM() // Load the created classifier while detection_value == True do Joint_data = data_capture() // Obtaining joint data cur_state = SC.predict(Joint_data) if pre_sate->cur_state not in SDS then // Print error messages and trigger the response mechanism Debug.log(alert) Start (response_ mechanism) detection_value = False log(normal) pre_state = cur_state Output: detection_value is True or False |

4. Experiments and Evaluation of Results

4.1. System Components

4.2. Data Collection and Processing

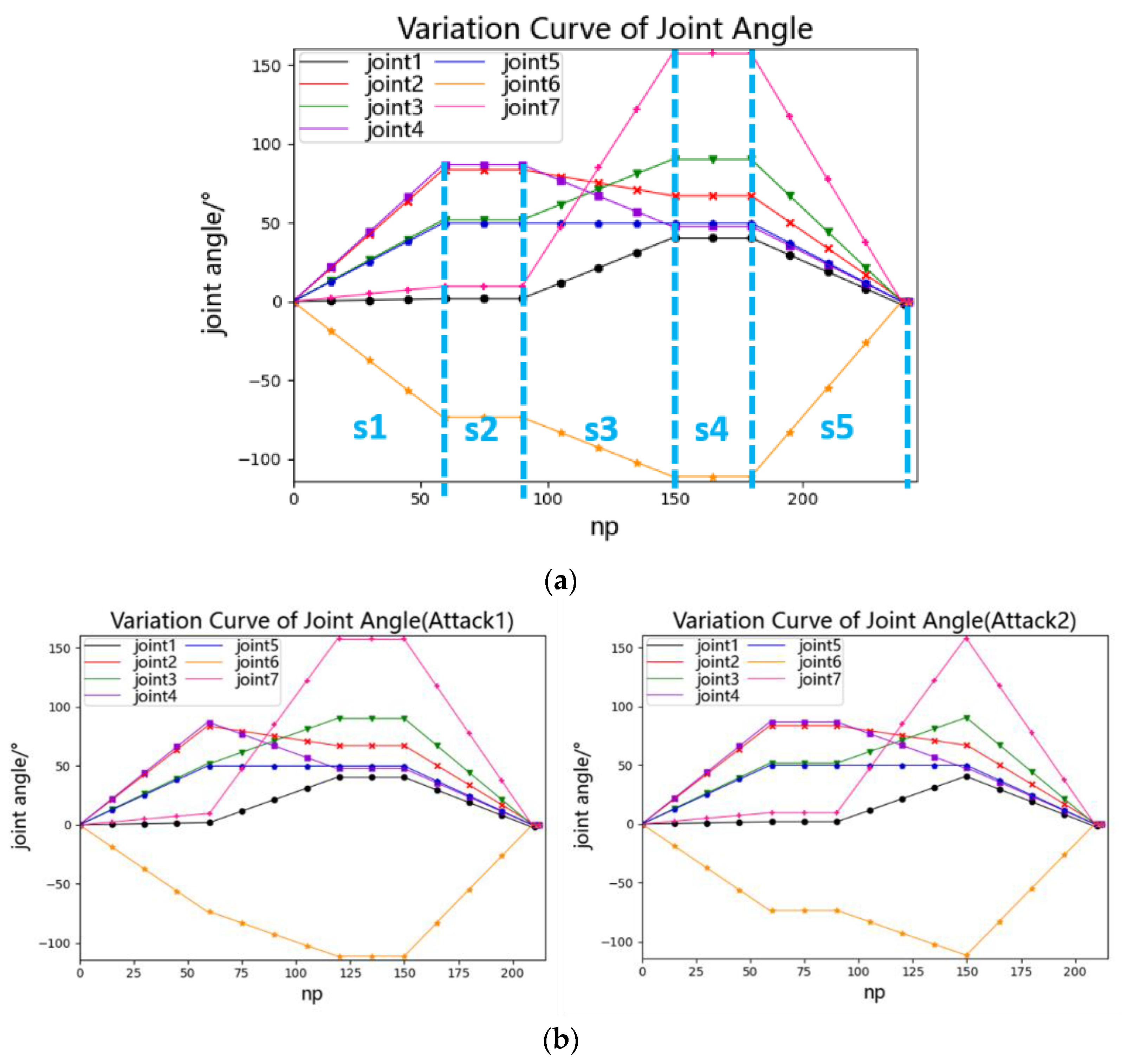

4.3. Physical Process Logic Attack

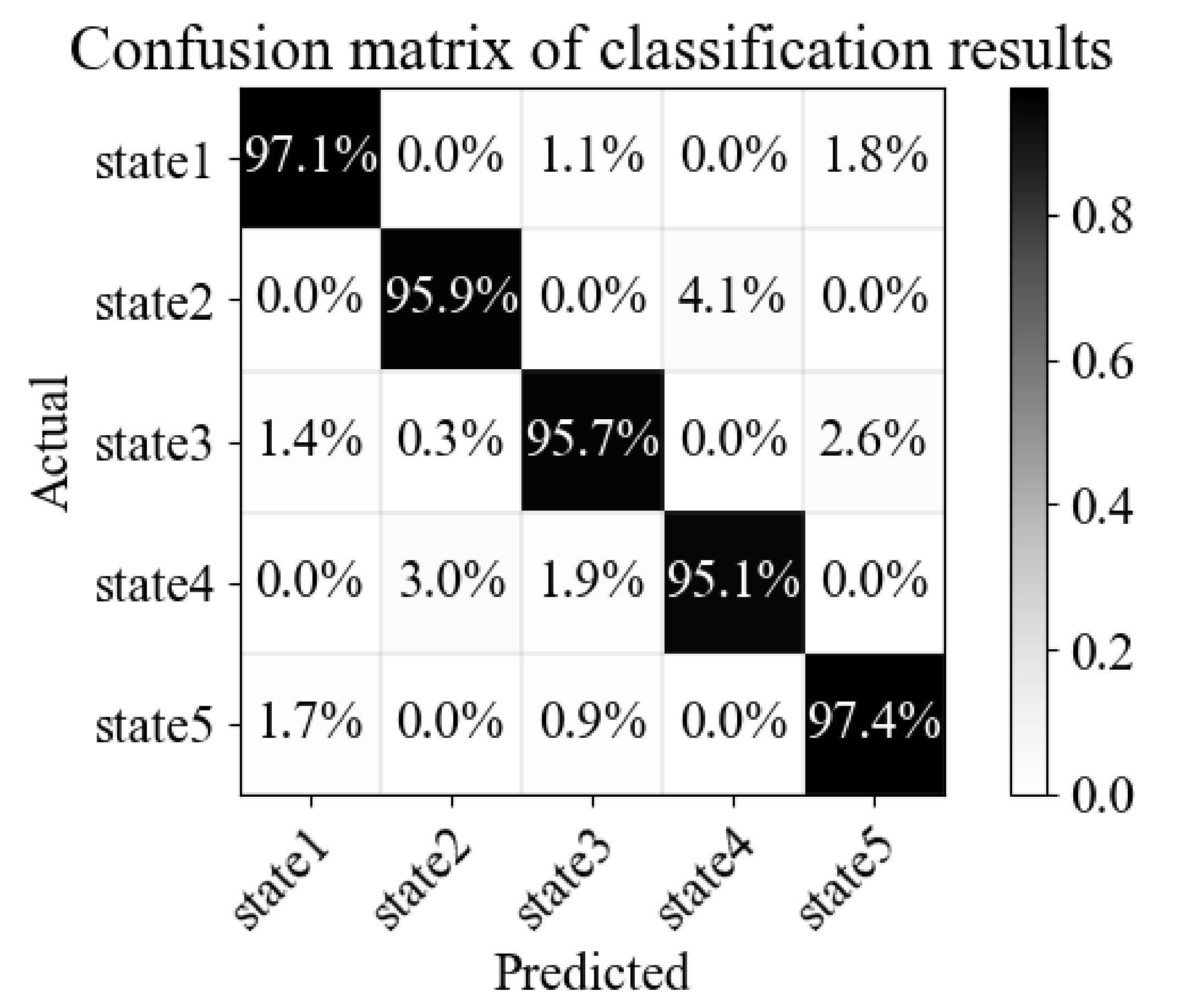

4.4. Analysis of Results

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sobhan, N.; Shaikat, A.S. Implementation of Pick & Place Robotic Arm for Warehouse Products Management. In Proceedings of the 2021 IEEE 7th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Bandung, Indonesia, 23–25 August 2021. [Google Scholar]

- Yenorkar, R.; Chaskar, U.M. GUI Based Pick and Place Robotic Arm for Multipurpose Industrial Applications. In Proceedings of the 2018 Second International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018. [Google Scholar]

- Silva, M.Z.; Brito, T.; Lima, J.L.; Silva, M.F. Industrial Robotic Arm in Machining Process Aimed to 3D Objects Reconstruction. In Proceedings of the 22nd IEEE International Conference on Industrial Technology (ICIT), Valencia, Spain, 10–12 March 2021. [Google Scholar]

- Vihonen, J.; Mattile, J.; Visa, A. Joint-Space Kinematic Model for Gravity-Referenced Joint Angle Estimation of Heavy-Duty Manipulators. IEEE Trans. Instrum. Meas. 2017, 66, 3280–3288. [Google Scholar] [CrossRef]

- Ding, D.; Han, Q.L.; Xiang, Y.; Ge, X.; Zhang, X.M. A survey on security control and attack detection for industrial cyber-physical systems. Neurocomputing 2018, 275, 1674–1683. [Google Scholar] [CrossRef]

- Haddadin, S.; De Luca, A.; Albu-Schäffer, A. Robot Collisions: A Survey on Detection, Isolation, and Identification. IEEE Trans. Robot. 2017, 33, 1292–1312. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Xie, L.; Hao, B.; Yang, L.; Hu, T.; Wang, Z. Data Logic Attack on Heavy-Duty Industrial Manipulators. IEEE Access. 2020, 8, 17419–17433. [Google Scholar] [CrossRef]

- Kim, T.; Kim, C.H.; Choi, H.; Kwon, Y.; Xu, D. Revarm: A Platform-Agnostic Arm Binary Rewriter for Security Applications. In Proceedings of the 33rd Annual Computer Security Applications Conference, Orlando, FL, USA, 4–8 December 2017. [Google Scholar]

- Jeong, S.; Choi, I.; Kim, Y.; Shin, Y.; Kim, K. A Study on ROS Vulnerabilities and Countermeasure. In Proceedings of the Companion of the 2017 ACM/IEEE International Conference on Human-Robot Interaction, Vienna, Austria, 6–9 March 2017. [Google Scholar]

- Li, W.; Xie, L.; Deng, Z.; Wang, Z. False sequential logic attack on SCADA system and its physical impact analysis. Comput. Secur. 2016, 58, 149–159. [Google Scholar] [CrossRef]

- Zhu, G.; Yuan, H.; Zhuang, Y.; Guo, Y.; Zhang, X.; Qiu, S. Research on Network Intrusion Detection Method of Power System Based on Random Forest Algorithm. In Proceedings of the 13th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Beihai, China, 16–17 January 2021. [Google Scholar]

- Liu, Z.; Yin, X.; Hu, Y. CPSS LR-DDoS Detection and Defense in Edge Computing Utilizing DCNN Q-Learning. IEEE Access. 2020, 8, 42120–42130. [Google Scholar] [CrossRef]

- Li, H.; Chasaki, D. Ensemble Machine Learning for Intrusion Detection in Cyber-Physical Systems. In Proceedings of the IEEE INFOCOM 2021—IEEE Conference on Computer Communications Workshops (INFOCOM WKSHPS), Vancouver, BC, Canada, 10–13 May 2021. [Google Scholar]

- Yimeng, D.; Gupta, N.; Chopra, N. On content modification attacks in bilateral teleoperation systems. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 6–8 July 2016. [Google Scholar]

- Albu-Schäffer, A.; Ott, C.; Hirzinger, G. A Unified Passivity-based Control Framework for Position, Torque and Impedance Control of Flexible Joint Robots. Int. J. Robot. Res. 2007, 26, 23–39. [Google Scholar] [CrossRef]

- Shang, W.; Xie, F.; Zhang, B.; Cong, S.; Li, Z. Adaptive Cross-Coupled Control of Cable-Driven Parallel Robots With Model Uncertainties. IEEE Robot. Autom. Lett. 2020, 5, 4110–4117. [Google Scholar] [CrossRef]

- Park, J.H.; Uhm, T.Y.; Bae, G.D.; Choi, Y.H. Stability Evaluation of Outdoor Unmanned Security Robot in Terrain Information. In Proceedings of the 2018 18th International Conference on Control, Automation and Systems (ICCAS), PyeongChang, Korea, 17–20 October 2018. [Google Scholar]

- Singh, P.K.; Singh, R.; Nandi, S.K.; Ghafoor, K.Z.; Nandi, S. An efficient blockchain-based approach for cooperative decision making in swarm robotics. Internet Technol. Lett. 2019, 3, 140–145. [Google Scholar] [CrossRef] [Green Version]

- Azzalini, D. Modeling and Comparing Robot Behaviors for Anomaly Detection. In Proceedings of the 19th International Conference on Autonomous Agents and MultiAgent Systems (AAMAS), Auckland, New Zealand, 9–13 May 2020. [Google Scholar]

- Li, X.J.; Shen, X.Y. A Data-Driven Attack Detection Approach for DC Servo Motor Systems Based on Mixed Optimization Strategy. IEEE Trans. Industr. Inform. 2020, 16, 5806–5813. [Google Scholar] [CrossRef]

- Bezemskij, A.; Loukas, G.; Gan, D.; Anthony, R.J. Detecting Cyber-Physical Threats in an Autonomous Robotic Vehicle Using Bayesian Networks. In Proceedings of the 2017 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Exeter, UK, 21–23 June 2017. [Google Scholar]

- Guerrero, H.; Ángel, M.; Noemí, D.G.; Vicente, M. Detection of Cyber-attacks to indoor real time localization systems for autonomous robots. Robot. Auton. Syst. 2018, 99, 75–83. [Google Scholar] [CrossRef]

- Pang, Z.H.; Liu, G.P.; Zhou, D.; Hou, F.; Sun, D. Two-Channel False Data Injection Attacks Against Output Tracking Control of Networked Systems. IEEE Trans. Ind. Electron. 2016, 63, 3242–3251. [Google Scholar] [CrossRef]

- Clark, G.; Doran, M.; Glisson, W. A Malicious Attack on the Machine Learning Policy of a Robotic System. In Proceedings of the 17th IEEE International Conference on Trust, Security and Privacy in Computing and Communications/12th IEEE International Conference on Big Data Science and Engineering (TrustCom/BigDataSE), New York, NY, USA, 1–3 August 2018. [Google Scholar]

- Li, W.; Xie, L.; Wang, Z. Two-Loop Covert Attacks against Constant-Value Control of Industrial Control Systems. IEEE Trans Ind. Inform. 2018, 15, 663–676. [Google Scholar] [CrossRef]

- Khojasteh, M.J.; Khina, A.; Franceschetti, M.; Javidi, T. Learning-based attacks in cyber-physical systems. IEEE Trans. Control. Netw. Syst. 2020, 8, 437–449. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, Y.; Zhen, Z.; Li, Y. Data-Driven False Data-Injection Attack Design and Detection in Cyber-Physical Systems. IEEE Trans Cybern. 2020, 51, 6179–6187. [Google Scholar] [CrossRef] [PubMed]

- Hector, J.B.; Katsiaris, P.; Carey, N.E.; Cote, N.; Rawat, D.B. On the Security of Cyber-Physical Robotic Systems Using Dynamic Modeling and Simulation. In Proceedings of the 2021 IEEE International Conference on Communications Workshops (ICC Workshops), Montreal, QC, Canada, 14–23 June 2021. [Google Scholar]

- Tang, Y.; Zhang, D.; Ho, D.W.C.; Yang, W.; Wang, B. Event-Based Tracking Control of Mobile Robot With Denial-of-Service Attacks. IEEE Trans. Syst. Man. Cybern. 2020, 50, 3300–3310. [Google Scholar] [CrossRef]

- Hong, J.; Liu, C.; Govindarasu, M. Integrated Anomaly Detection for Cyber Security of the Substations. IEEE T Smart GRID. 2014, 5, 1643–1653. [Google Scholar] [CrossRef]

- Khaitan, S.K.; McCalley, J.D. Design Techniques and Applications of Cyberphysical Systems: A Survey. IEEE Syst J. 2015, 9, 350–365. [Google Scholar] [CrossRef]

- Ali Alheeti, K.M.; Al-Zaidi, R.; Woods, J.; McDonald-Maier, K. An intrusion detection scheme for driverless vehicles based gyroscope sensor profiling. In Proceedings of the 2017 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 8–10 January 2017. [Google Scholar]

- Zhou, C.; Hu, B.; Shi, Y.; Tian, Y.C.; Li, X.; Zhao, Y. A Unified Architectural Approach for Cyberattack-Resilient Industrial Control Systems. P IEEE. 2021, 109, 517–541. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, S.; Xiong, N. Design and Analysis of Multimodel-Based Anomaly Intrusion Detection Systems in Industrial Process Automation. IEEE Trans. Syst. Man. Cybern. 2015, 45, 1345–1360. [Google Scholar] [CrossRef]

- Akpinar, K.O.; Ozcelik, I. Anomaly Detection on EtherCAT Based Water Level Control Automation. In Proceedings of the 2020 5th International Conference on Computer Science and Engineering (UBMK), Diyarbakir, Turkey, 9–11 September 2020. [Google Scholar]

- Akpinar, K.O.; Ozcelik, I. Analysis of Machine Learning Methods in EtherCAT-Based Anomaly Detection. IEEE Access. 2019, 7, 184365–184374. [Google Scholar] [CrossRef]

- Qiu, C.; Shan, J.; Shandong, B. Research on intrusion detection algorithm based on BP neural network. Int. J. Secur. Its Appl. 2015, 9, 247–258. [Google Scholar] [CrossRef]

- Maushart, F.; Prorok, A.; Hsieh, M.A.; Kumar, V. Intrusion detection for stochastic task allocation in robot swarms. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017. [Google Scholar]

- Narayanan, V.; Bobba, R.B. Learning Based Anomaly Detection for Industrial Arm Applications. In Proceedings of the 2018 Workshop on Cyber-Physical Systems Security and PrivaCy–CPS-SPC ’18, Toronto, ON, Canada, 15–19 October 2018. [Google Scholar]

- Zihao, W.; Lan, L.; Zongyi, X.; Guangtao, C. The forecasting model of wheelset size based on PSO-SVM. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019. [Google Scholar]

- Nguyen, T.T.; Nguyen, V.H.; Nguyen, X.H. Comparing the Results of Applying DE, PSO and Proposed Pro DE, Pro PSO Algorithms for Inverse Kinematics Problem of a 5-DOF Scara Robot. In Proceedings of the 2020 International Conference on Advanced Mechatronic Systems (ICAMechS), Hanoi, Vietnam, 10–13 December 2020. [Google Scholar]

- Shi, Y.; Eberhart, R.C. Empirical study of particle swarm optimization. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999. [Google Scholar]

- Stockman, M.; Awad, M. Predicting microarchitectural power using Interval Based Hierarchical Support Vector Machine. In Proceedings of the 2010 International Conference on Energy Aware Computing, Cairo, Egypt, 16–18 December 2010. [Google Scholar]

- Gaohui, L.; Jiakun, C. Research on Modulation Recognition of OFDM Signal Based on Hierarchical Iterative Support Vector Machine. In Proceedings of the 2020 International Conference on Communications, Information System and Computer Engineering (CISCE), Kuala Lumpur, Malaysia, 3–5 July 2020. [Google Scholar]

- Dang-Ngoc, H.; Cao, T.N.M.; Dang-Nguyen, C. Citrus Leaf Disease Detection and Classification Using Hierarchical Support Vector Machine. In Proceedings of the 2021 International Symposium on Electrical and Electronics Engineering (ISEE), Ho Chi Minh, Vietnam, 15–16 April 2021. [Google Scholar]

- Attanasio, A.; Marahrens, N.; Scaglioni, B.; Valdastri, P. An Open Source Motion Planning Framework for Autonomous Minimally Invasive Surgical Robots. In Proceedings of the 2021 IEEE International Conference on Autonomous Systems (ICAS), Montreal, QC, Canada, 11–13 August 2021. [Google Scholar]

- Lawal, M.A.; Shaikh, R.A.; Hassan, S.R. Security Analysis of Network Anomalies Mitigation Schemes in IoT Networks. IEEE Access. 2020, 8, 43355–43374. [Google Scholar] [CrossRef]

- Brinkman, A.; Morris, J.; Chen, I.; Sheikh, N.; Warren, P. Fastcat: An Open-Source Library for Composable EtherCAT Control Systems. In Proceedings of the 2021 IEEE Aerospace Conference (50100), Big Sky, MT, USA, 6–13 March 2021. [Google Scholar]

- Pan, H.; Xie, L.; Lv, Z.; Li, J.; Wang, Z. Hierarchical support vector machine for facial micro-expression recognition. MTAP 2020, 79, 1–15. [Google Scholar] [CrossRef]

- Koizumi, Y.; Murata, S.; Harada, N.; Saito, S.; Uematsu, H. SNIPER: Few-shot Learning for Anomaly Detection to Minimize False-negative Rate with Ensured True-positive Rate. In Proceedings of the ICASSP 2019–2019 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Brighton, UK, 12–17 May 2019. [Google Scholar]

| No. | Attribute | Joint 1 | Joint 2 | Joint 3 | Joint 4 | Joint 5 | Joint 6 | Joint 7 |

|---|---|---|---|---|---|---|---|---|

| 1 | Position (rad) | 0.743 | 0.969 | −0.396 | 0.510 | −0.545 | 0.492 | −1.152 |

| Velocity (rad/s) | −0.218 | −0.291 | 0.288 | −0.314 | 0.297 | −0.316 | 0.330 | |

| Current (A) | 4.314 | 5.067 | 0.112 | 4.131 | 2.928 | 0.546 | 0.957 | |

| 2 | Position (rad) | 0.396 | 1.122 | −0.287 | 0.472 | −0.318 | 0.576 | −0.827 |

| Velocity (rad/s) | −0.237 | −0.300 | 0.279 | −0.316 | 0.274 | −0.324 | 0.336 | |

| Current (A) | 4.565 | 4.850 | 0.140 | 4.183 | 2.776 | 0.502 | 0.907 |

| Methods | Classifier | C | Gammma | Accuracy |

|---|---|---|---|---|

| SVM | classifier1 | 1.0 | ‘auto’ | 93.87% |

| PSO-SVM | classifier1 | 7.5592 | 0.0256 | 95.04% |

| PSO-H-SVM | classifier1 | 8.8983 | 0.0796 | 96.02% |

| classifier2 | 6.1910 | 0.0941 | ||

| classifier3 | 9.2709 | 0.0707 | ||

| classifier4 | 9.5290 | 0.0214 |

| No. | Steps under Attack | Attack Commands |

|---|---|---|

| 1 | Step 2 | Execute the placement command |

| 2 | Step 3 | Execute the abnormal movement command |

| 3 | Step 4 | Execute the grab command |

| Step 4 | Execute the reset command | |

| 4 | Step 5 | Execute the grab command |

| Step 5 | Execute the reset command |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Xie, L.; Pan, H. Research on a PSO-H-SVM-Based Intrusion Detection Method for Industrial Robotic Arms. Appl. Sci. 2022, 12, 2765. https://doi.org/10.3390/app12062765

Zhou Y, Xie L, Pan H. Research on a PSO-H-SVM-Based Intrusion Detection Method for Industrial Robotic Arms. Applied Sciences. 2022; 12(6):2765. https://doi.org/10.3390/app12062765

Chicago/Turabian StyleZhou, Yulin, Lun Xie, and Hang Pan. 2022. "Research on a PSO-H-SVM-Based Intrusion Detection Method for Industrial Robotic Arms" Applied Sciences 12, no. 6: 2765. https://doi.org/10.3390/app12062765

APA StyleZhou, Y., Xie, L., & Pan, H. (2022). Research on a PSO-H-SVM-Based Intrusion Detection Method for Industrial Robotic Arms. Applied Sciences, 12(6), 2765. https://doi.org/10.3390/app12062765