Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing †

Abstract

:Featured Application

Abstract

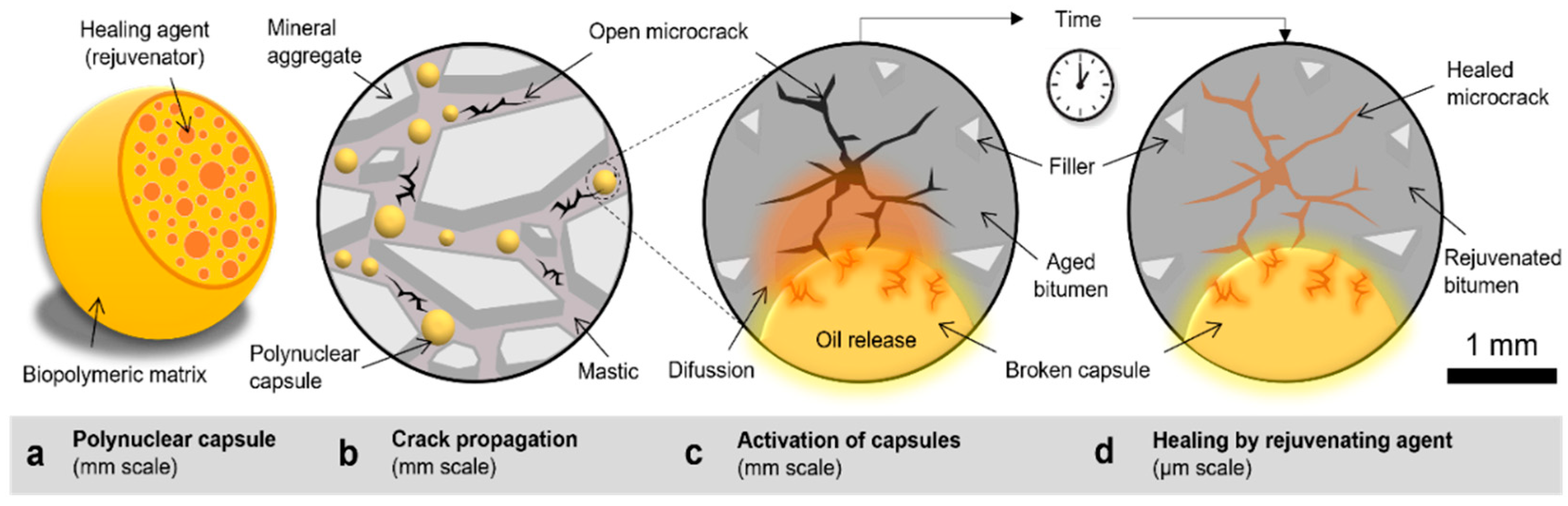

1. Introduction

2. Materials and Methods

2.1. Materials

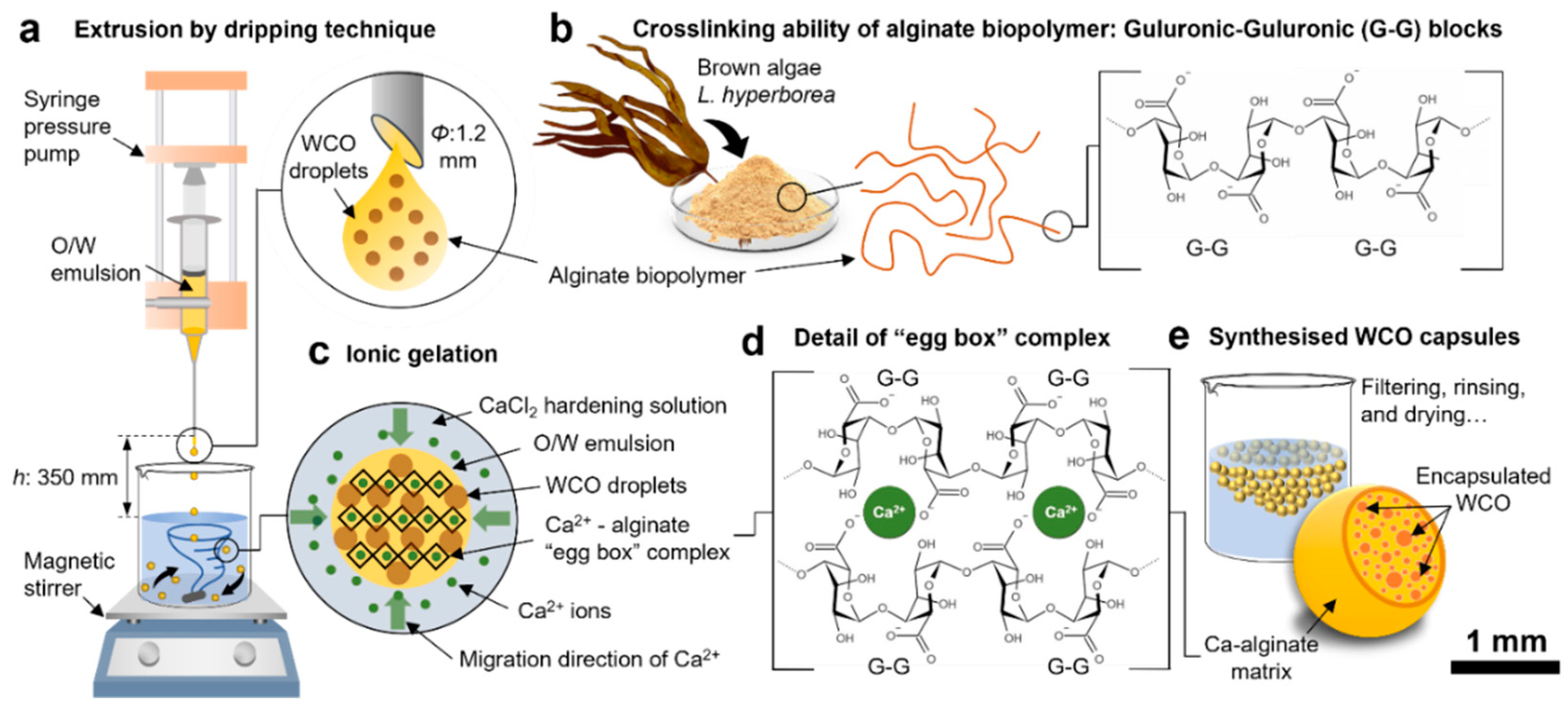

2.2. Synthesis of WCO Capsules by Dripping Method

2.3. Experimental Characterisation of the WCO Capsules and Their Components

3. Results and Discussion

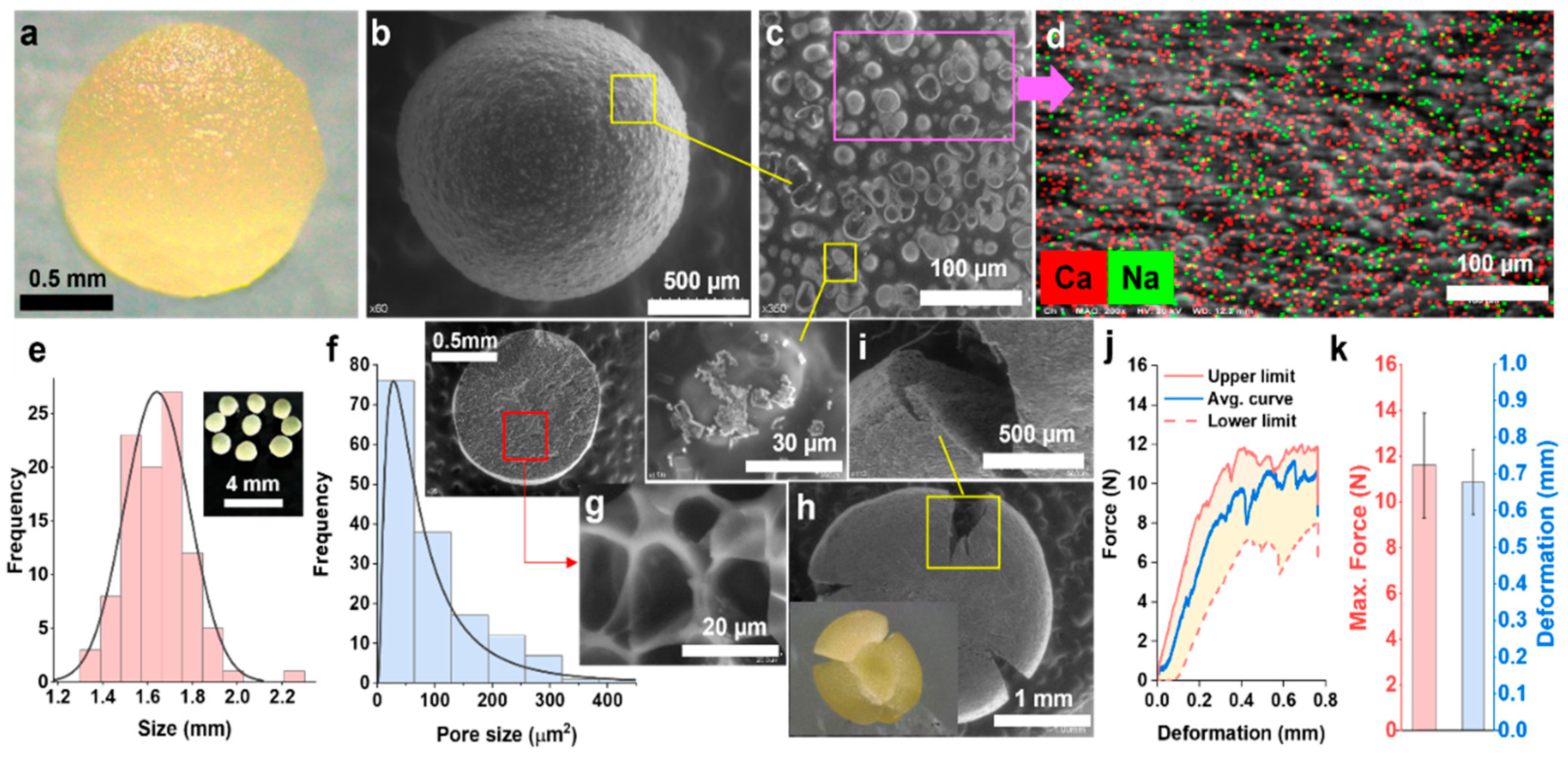

3.1. Physical-Mechanical Properties of the Synthesised Capsules

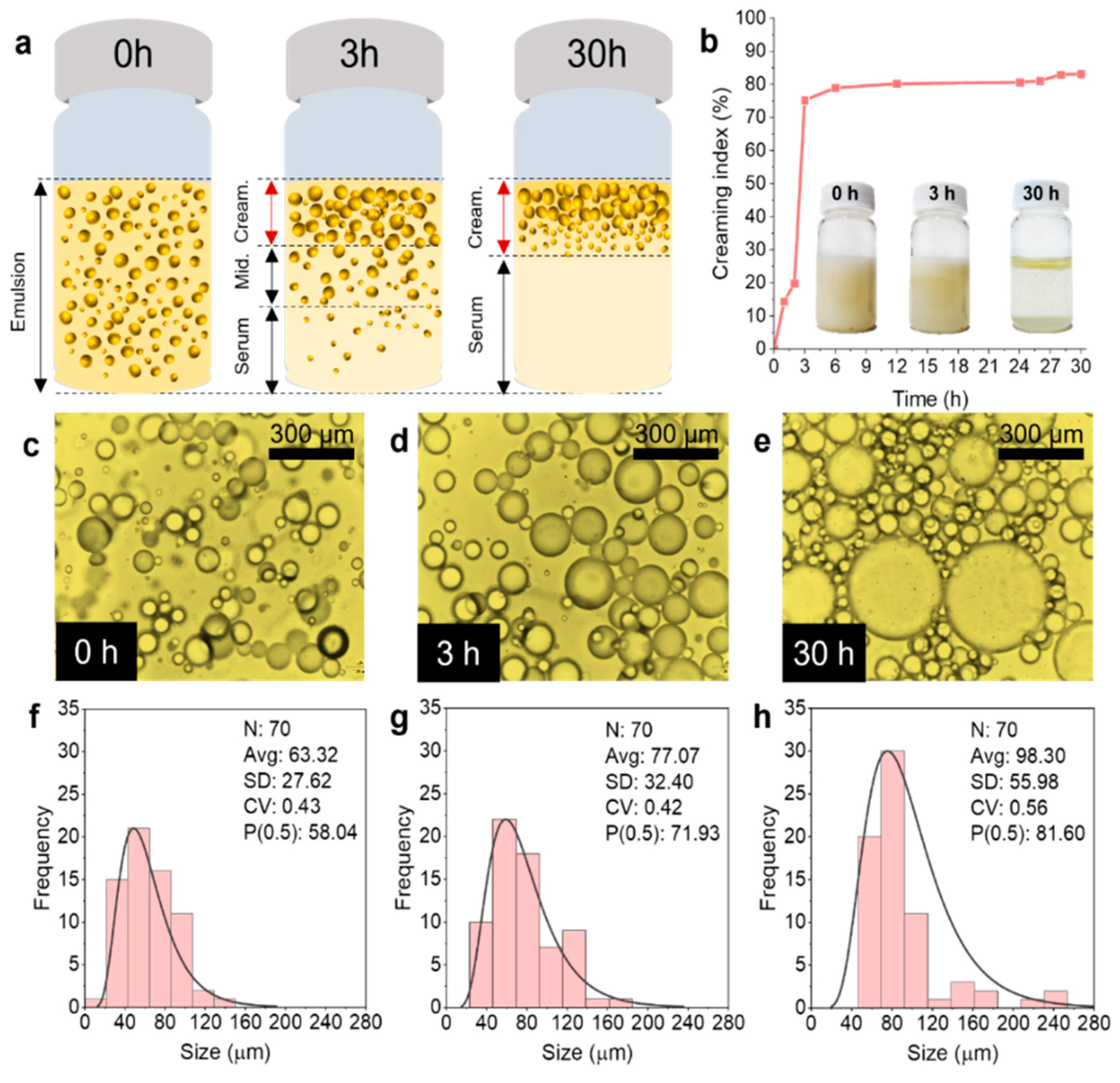

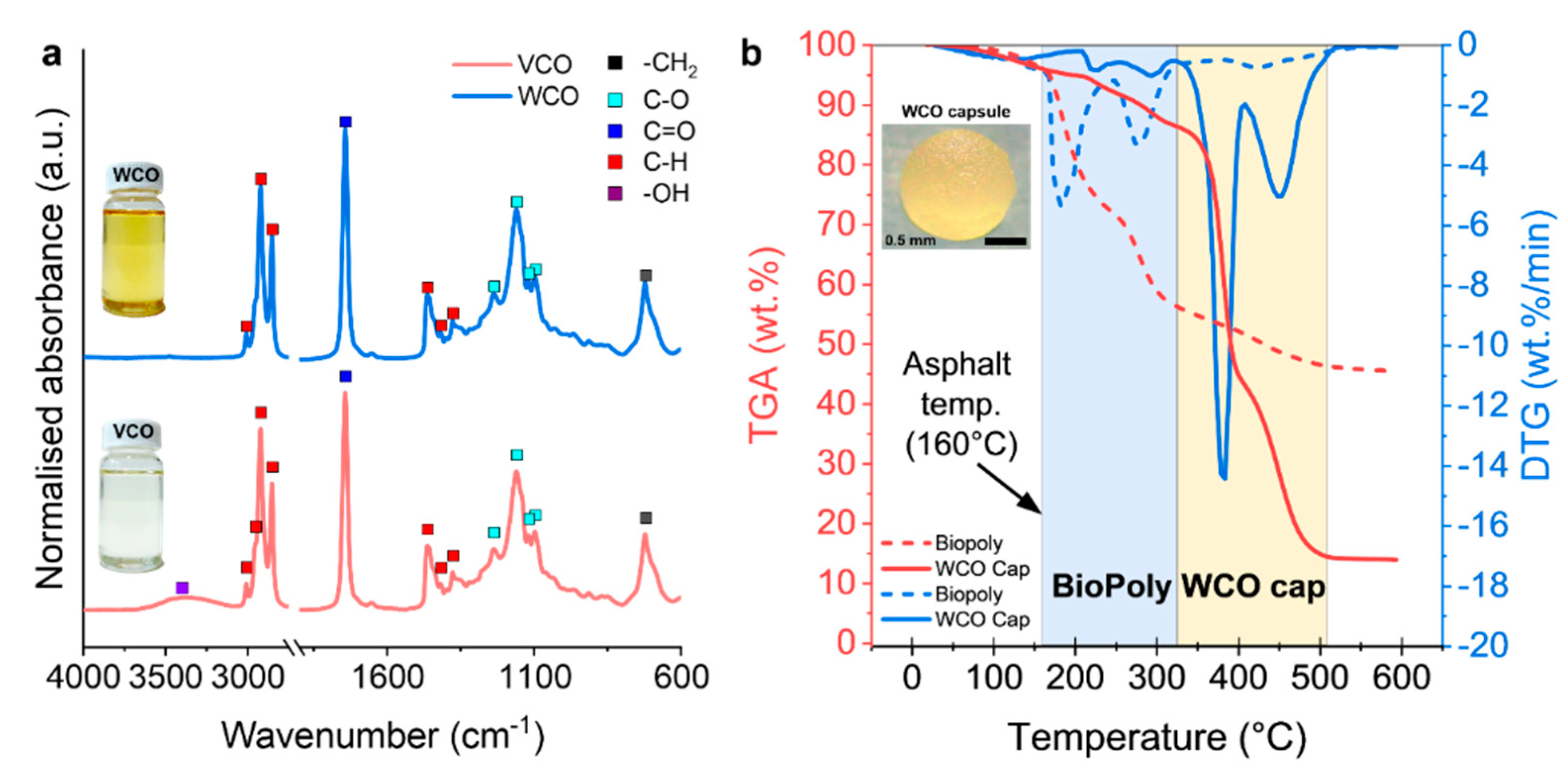

3.2. Physical Stability of Components of the Capsules

3.3. Thermal Stability of Capsule and Their Components

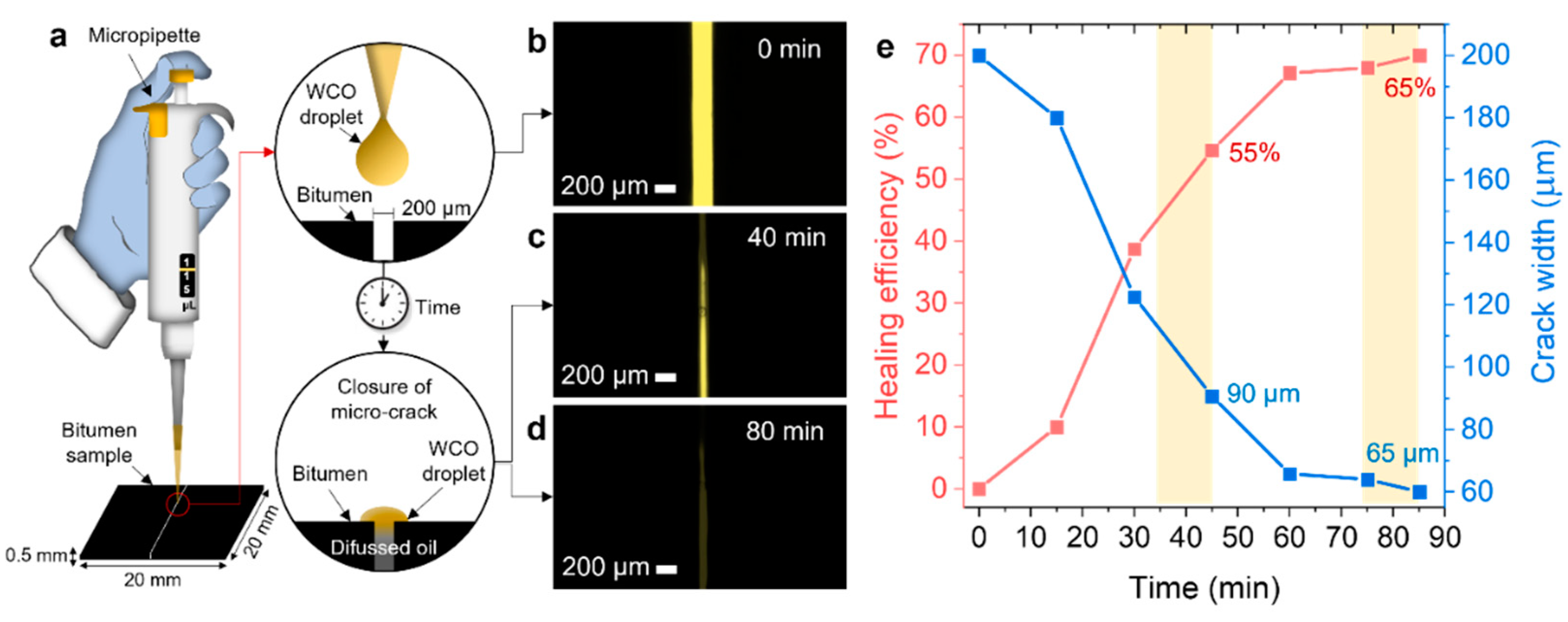

3.4. Healing Ability of the Encapsulated Rejuvenator

4. Conclusions

- The encapsulation process by simple extrusion-dripping yielded alginate-based WCO capsules with an adequate encapsulation efficiency and multicavity morphology for asphalt self-healing applications.

- WCO polynuclear capsules and their components presented a good thermal stability and physical-chemical properties. Creaming results showed that encapsulation of the O/W emulsion should be addressed during the first 2 h.

- TGA and FTIR tests suggested that the encapsulation process leads to a thermally stable material with potential to be mixed with hot asphalt mixtures for asphalt healing purposes.

- Mechanical characterisation proved that alginate-based WCO capsules can break and partially release the encapsulated WCO oil through an external force trigger effect.

- It was proven through transient oil-bitumen diffusion tests that the encapsulated rejuvenating agent WCO can be diffused in long-term aged bitumen test samples, reducing their viscosity, and hence, healing microcracks present in the asphalt matrix.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gonzalez-Torre, I.; Norambuena-Contreras, J. Recent advances on self-healing of bituminous materials by the action of encapsulated rejuvenators. Constr. Build. Mater. 2020, 258, 119568. [Google Scholar] [CrossRef]

- Airey, G.D. State of the art report on ageing test methods for bituminous pavement materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Investigations on bitumen rejuvenator diffusion and structural stability (with discussion). J. Assoc. Asphalt. Pav. 2003, 72, 463–501. [Google Scholar]

- Garcia, A.; Jelfs, J.; Austin, C.J. Internal asphalt mixture rejuvenation using capsules. Constr. Build. Mater. 2015, 101, 309–316. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E. Synthesis and physicochemical properties of high compact microcapsules containing rejuvenator applied in asphalt. Chem. Eng. J. 2012, 198–199, 289–300. [Google Scholar] [CrossRef]

- Su, J.F.; Qiu, J.; Schlangen, E.; Wang, Y.Y. Investigation the possibility of a new approach of using microcapsules containing waste cooking oil: In situ rejuvenation for aged bitumen. Constr. Build. Mater. 2015, 74, 83–92. [Google Scholar] [CrossRef]

- Yamaç, Ö.E.; Yilmaz, M.; Yalçın, E.; Kök, B.V.; Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mastic using capsules containing waste oils. Constr. Build. Mater. 2021, 270, 121417. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Yalcin, E.; Garcia, A.; Al-Mansoori, T.; Yilmaz, M.; Hudson-Griffiths, R. Effect of mixing and ageing on the mechanical and self-healing properties of asphalt mixtures containing polymeric capsules. Constr. Build. Mater. 2018, 175, 254–266. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Arteaga-Perez, L.E.; Guadarrama-Lezama, A.Y.; Briones, R.; Vivanco, J.F.; Gonzalez-Torre, I. Microencapsulated bio-based rejuvenators for the self-healing of bituminous materials. Mater 2020, 13, 1446. [Google Scholar] [CrossRef] [Green Version]

- Norambuena-Contreras, J.; Arteaga-Pérez, L.E.; Concha, J.L.; Gonzalez-Torre, I. Pyrolytic oil from waste tyres as a promising encapsulated rejuvenator for the extrinsic self-healing of bituminous materials. Road Mater. Pavement Des. 2021, 22, S117–S133. [Google Scholar] [CrossRef]

- Xu, S.; Tabaković, A.; Liu, X.; Schlangen, E. Calcium alginate capsules encapsulating rejuvenator as healing system for asphalt mastic. Constr. Build. Mater. 2018, 169, 379–387. [Google Scholar] [CrossRef] [Green Version]

- Puscaselu, R.G.; Lobiuc, A.; Dimian, M.; Covasa, M. Alginate: From food industry to biomedical applications and management of metabolic disorders. Polymers 2020, 12, 2417. [Google Scholar] [CrossRef] [PubMed]

- Martins, E.; Poncelet, D.; Rodrigues, R.C.; Renard, D. Oil encapsulation techniques using alginate as encapsulating agent: Applications and drawbacks. J. Microencapsul. 2017, 34, 754–771. [Google Scholar] [CrossRef] [PubMed]

- Eqbal, M.D.; Gundabala, V. Controlled fabrication of multi-core alginate microcapsules. J. Colloid Interface Sci. 2017, 507, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Norambuena-Contreras, J.; Yalcin, E.; Hudson-Griffiths, R.; García, A. Mechanical and Self-Healing Properties of Stone Mastic Asphalt Containing Encapsulated Rejuvenators. J. Mater. Civ. Eng. 2019, 31, 04019052. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Liu, Q.; Zhang, L.; Wu, S.; Yalcin, E.; Garcia, A. Influence of encapsulated sunflower oil on the mechanical and self-healing properties of dense-graded asphalt mixtures. Mater. Struct. Constr. 2019, 52, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Riancho, N.; Garcia, A.; Grossegger, D.; Saadoon, T.; Hudson-Griffiths, R. Properties of Ca-alginate capsules to maximise asphalt self-healing properties. Constr. Build. Mater. 2021, 284, 122728. [Google Scholar] [CrossRef]

- ASTM D6521-19; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurised Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2019.

- Guadarrama-Lezama, A.Y.; Dorantes-Alvarez, L.; Jaramillo-Flores, M.E.; Pérez-Alonso, C.; Niranjan, K.; Gutiérrez-López, G.F.; Alamilla-Beltrán, L. Preparation and characterization of non-aqueous extracts from chilli (Capsicum annuum L.) and their microencapsulates obtained by spray-drying. J. Food Eng. 2012, 112, 29–37. [Google Scholar] [CrossRef]

- ASTM D792-13; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D695-02a; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2002.

- McClements, D.J. Critical review of techniques and methodologies for characterisation of emulsion stability. Crit. Rev. Food Sci. Nutr. 2007, 47, 611–649. [Google Scholar] [CrossRef]

- Concha, J.L.; Arteaga-Pérez, L.; Gonzalez-Torre, I.; Norambuena-Contreras, J. Biocapsules Containing Low-Cost Rejuvenators for Asphalt Self-Healing. RILEM Tech. Lett. 2021, 6, 1–7. [Google Scholar] [CrossRef]

- Rayhan, B.A.; Kamal, H. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar]

- Atabani, A.E.; Shobana, S.; Mohammed, M.N.; Uğuz, G.; Kumar, G.; Arvindnarayan, S.; Aslam, M.; Al-Muhtaseb, A.H. Integrated valorization of waste cooking oil and spent coffee grounds for biodiesel production: Blending with higher alcohols, FT–IR, TGA, DSC and NMR characterizations. Fuel 2019, 244, 419–430. [Google Scholar] [CrossRef]

- Zhao, W.; Qi, Y.; Wang, Y.; Xue, Y.; Xu, P.; Li, Z.; Li, Q. Morphology and Thermal Properties of Calcium Alginate/Reduced Graphene Oxide Composites. Polymers 2018, 10, 990. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norambuena-Contreras, J.; Concha, J.L.; Arteaga-Pérez, L.E.; Gonzalez-Torre, I. Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing. Appl. Sci. 2022, 12, 2739. https://doi.org/10.3390/app12052739

Norambuena-Contreras J, Concha JL, Arteaga-Pérez LE, Gonzalez-Torre I. Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing. Applied Sciences. 2022; 12(5):2739. https://doi.org/10.3390/app12052739

Chicago/Turabian StyleNorambuena-Contreras, Jose, Jose L. Concha, Luis E. Arteaga-Pérez, and Irene Gonzalez-Torre. 2022. "Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing" Applied Sciences 12, no. 5: 2739. https://doi.org/10.3390/app12052739

APA StyleNorambuena-Contreras, J., Concha, J. L., Arteaga-Pérez, L. E., & Gonzalez-Torre, I. (2022). Synthesis and Characterisation of Alginate-Based Capsules Containing Waste Cooking Oil for Asphalt Self-Healing. Applied Sciences, 12(5), 2739. https://doi.org/10.3390/app12052739