Optimization Model for Selective Harvest Planning Performed by Humans and Robots

Abstract

:1. Introduction

2. Literature Review

- Time window constraints—The model should consider the optimal time for harvesting and the quality decay resulting from harvesting outside of that time window, as well as its effect on revenues.

- Resource limitations—These include capacity and productivity constraints, together with labor and machine availability.

- Yield perishability—The deterioration of fresh products during the post-harvest period must be taken into account. Yield perishability can be modeled in several ways, including continuous deterioration curves, a loss factor for each period after harvesting, and the effect of product deterioration on customer demand.

- Uncertainty—There is uncertainty in the harvest yield (quantity and quality), due to unknown weather conditions and the inherent variability of agricultural processes.

- Inventory control—The inventory should be considered in terms of holding costs, duration of keeping in the inventory constraints, or as a decision variable.

3. Problem Description and Formulation

3.1. Growth Function

3.2. Model Formulation

- —number of periods

- —number of maturity levels

- —number of days after anthesis

- —min days after anthesis of maturity level j

- —max days after anthesis of maturity level j

- —number of peppers d DAA available to harvest in the first period

- —number of peppers at anthesis each day

- —harvester capablities in one period

- —price per kilogram of pepper fresh weight

- —fresh weight (kilogram) of pepper d days after anthesis

- —harvester’s salary/rental cost through all planning horizons

- —total fixed expenses through all of planning horizons, including utilities, land, water, fertilization, planting, and taxes

- —number of harvesters (hired workers or equivalent numbers of robots see Section 5.2.2) (decision variable)

- —peppers harvested from maturity class j in period t (decision variable)

- —total harvest weight of the peppers in period t (fresh weight in kilograms)

- —peppers from class j available to harvest at the beginning of period t

- —peppers d days after anthesis that are harvested in period t

- —peppers available to harvest d days after anthesis at the beginning of period t

3.3. Dealing with Uncertainty

- Distribute the harvested peppers uniformly among the different DAAs.

- Distribute the harvested peppers in proportion to the available peppers of each DAA.

- Create a worst-case scenario in which the peppers with the lowest weight (lower DAA) available in a maturity class will be harvested.

- Create a best-case scenario in which the peppers with the highest weight (highest DAA) available in a maturity class will be harvested.

- The first method, distributing uniformly, will set ,

- The second method, distributing in proportion, will set ,

- The third method, the worst-case scenario, will set ,

- The fourth method, the best-case scenario, will set ,

4. Model Extensions

4.1. Limiting the Harvested Rows and Deciding on the Rows to Harvest

4.2. Modeling the Change in Pepper Price

5. Numerical Studies—Harvesters with Different Capabilities to Classify Pepper Maturity Levels

5.1. Analysis of the Type of Worker

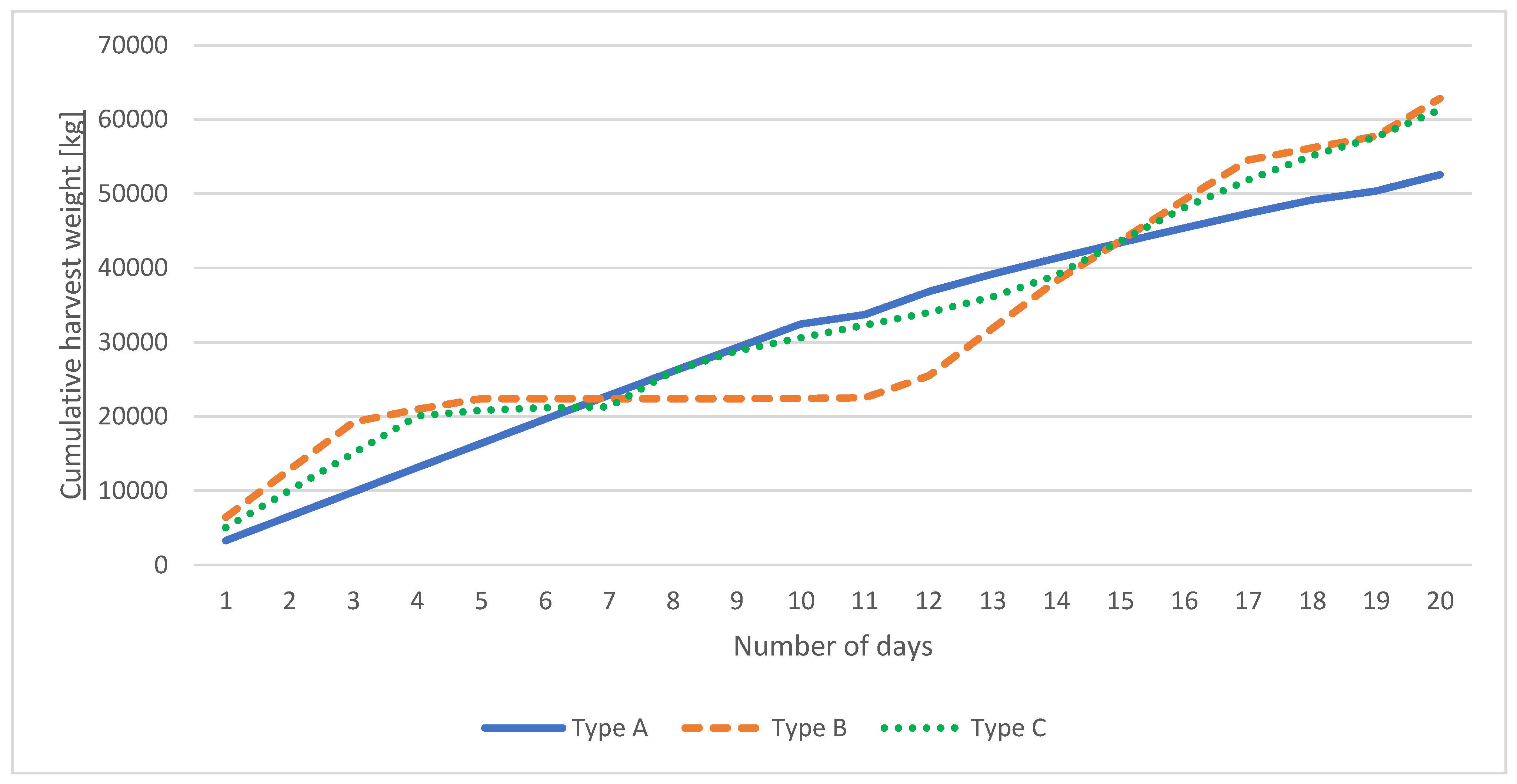

5.1.1. Number of Workers Is a Decision Variable

5.1.2. Fixed Number of Workers

5.2. Analysis of the Robotic Harvester Capability

5.2.1. Difference in the Total Harvest Weight between Robotic and Human Harvesters with the Same Capabilities

5.2.2. Required Cycle Time for the Harvester Robot

5.3. Payback Period and Rate-of-Return Analysis

- The cost of the robot is set at 100,000, 130,000, or 160,000 €

- The harvest season lasts 35 weeks per year

- Manual harvesting requires 3 s/pepper

- Robot harvesting requires 10 s/pepper

- Manual harvesters work five months, five days/week, 8 h/day

- A robotic harvester works 20 h/day, six days/week

- Manual harvest hourly rates of 16.5 (corresponding to rates in the Netherlands) and 9.97 € (corresponding to rates in Israel) result in 23,100 and 14,000 €/year, respectively

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kusumastuti, R.D.; Van Donk, D.P.; Teunter, R. Crop-related harvesting and processing planning: A review. Int. J. Prod. Econ. 2016, 174, 76–92. [Google Scholar] [CrossRef]

- Soto-Silva, W.E.; Nadal-Roig, E.; González-Araya, M.C.; Pla-Aragones, L.M. Operational research models applied to the fresh fruit supply chain. Eur. J. Oper. Res. 2016, 251, 345–355. [Google Scholar] [CrossRef]

- Perlman, Y. Establishing a dual food supply chain for organic products in the presence of showrooming—A game theoretic analysis. J. Clean. Prod. 2021, 321, 128816. [Google Scholar] [CrossRef]

- Ahumada, O.; Villalobos, J.R. Operational model for planning the harvest and distribution of perishable agricultural products. Int. J. Prod. Econ. 2011, 133, 677–687. [Google Scholar] [CrossRef]

- Ahumada, O.; Villalobos, J.R. Application of planning models in the agri-food supply chain: A review. Eur. J. Oper. Res. 2009, 196, 1–20. [Google Scholar] [CrossRef]

- Perlman, Y.; Ozinci, Y.; Westrich, S. Pricing decisions in a dual supply chain of organic and conventional agricultural products. Ann. Oper. Res. 2019, 1–16. [Google Scholar] [CrossRef]

- Ozinci, Y.; Perlman, Y.; Westrich, S. Competition between organic and conventional products with different utilities and shelf lives. Int. J. Prod. Econ. 2017, 191, 74–84. [Google Scholar] [CrossRef]

- Grisso, R.D.; McCullough, D.; Cundiff, J.S.; Judd, J.D. Harvest schedule to fill storage for year-round delivery of grasses to biorefinery. Biomass Bioenergy 2013, 55, 331–338. [Google Scholar] [CrossRef]

- Carpente, L.; Casas-Méndez, B.; Jácome, C.; Puerto, J. A model and two heuristic approaches for a forage harvester planning problem: A case study. TOP 2010, 18, 122–139. [Google Scholar] [CrossRef]

- Starbird, S.A. Optimal loading sequences for fresh-apple storage facilities. J. Oper. Res. Soc. 1988, 39, 911–917. [Google Scholar] [CrossRef]

- Higgins, A.J.; Muchow, R.C.; Rudd, A.V.; Ford, A.W. Optimising harvest date in sugar production: A case study for the Mossman mill region in Australia I. Development of operations research model and solution. Field Crops Res. 1998, 57, 153–162. [Google Scholar] [CrossRef]

- Higgins, A.J.; Neville, D.W. Australian sugar mills optimize harvester rosters to improve production. Interfaces 2002, 32, 15–25. [Google Scholar] [CrossRef]

- Kootstra, G.; Wang, X.; Blok, P.M.; Hemming, J.; van Henten, E. Selective Harvesting Robotics: Current Research, Trends, and Future Directions. Curr. Robot. Rep. 2021, 2, 95–104. [Google Scholar] [CrossRef]

- Edan, Y.; Adamides, G.; Oberti, R. Agriculture automation. In Handbook of Automation; Springer: Cham, Switzerland, 2022. [Google Scholar]

- De-An, Z.; Jidong, L.; Wei, J.; Ying, Z.; Yu, C. Design and control of an apple harvesting robot. Biosyst. Eng. 2011, 110, 112–122. [Google Scholar] [CrossRef]

- Silwal, A.; Davidson, J.R.; Karkee, M.; Mo, C.; Zhang, Q.; Lewis, K. Design, integration, and field evaluation of a robotic apple harvester. J. Field Robot. 2017, 34, 1140–1159. [Google Scholar] [CrossRef]

- Mehta, S.S.; Burks, T.F. Vision-based control of robotic manipulator for citrus harvesting. Comput. Electron. Agric. 2014, 102, 146–158. [Google Scholar] [CrossRef]

- Hu, X.; Yu, H.; Lv, S.; Wu, J. Design and experiment of a new citrus harvesting robot. In Proceedings of the International Conference on Control Science and Electric Power Systems (CSEPS), Shangai, China, 28–30 May 2021; pp. 179–183. [Google Scholar] [CrossRef]

- Feng, Q.; Zou, W.; Fan, P.; Zhang, C.; Wang, X. Design and test of robotic harvesting system for cherry tomato. Int. J. Agric. Biol. Eng. 2018, 11, 96–100. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Edan, Y.; Rogozin, D.; Flash, T.; Miles, G.E. Robotic melon harvesting. IEEE Trans. Robot. Autom. 2000, 16, 831–835. [Google Scholar] [CrossRef]

- Leu, A.; Razavi, M.; Langstadtler, L.; Ristic-Durrant, D.; Raffel, H.; Schenck, C.; Graser, A.; Kuhfuss, B. Robotic green asparagus selective harvesting. IEEE/ASME Trans. Mechatron. 2017, 22, 2401–2410. [Google Scholar] [CrossRef]

- Bac, C.W.; van Henten, E.J.; Hemming, J.; Edan, Y. Harvesting robots for high-value crops: State-of-the-art review and challenges ahead. J. Field Robot. 2014, 31, 888–911. [Google Scholar] [CrossRef]

- Harel, B.; Parmet, Y.; Edan, Y. Maturity classification of sweet peppers using image datasets acquired in different times. Comput. Ind. 2020, 121, 103274. [Google Scholar] [CrossRef]

- Li, B.; Lecourt, J.; Bishop, G. Advances in non-destructive early assessment of fruit ripeness towards defining optimal time of harvest and yield prediction—A review. Plants 2018, 7, 3. [Google Scholar] [CrossRef] [Green Version]

- Harel, B.; van Essen, R.; Parmet, Y.; Edan, Y.; van Essen, R.; Parmet, Y.; Edan, Y. Viewpoint Analysis for Maturity Classification of Sweet Peppers. Sensors 2020, 20, 3783. [Google Scholar] [CrossRef]

- Kurtser, P.; Edan, Y. Statistical models for fruit detectability: Spatial and temporal analyses of sweet peppers. Biosyst. Eng. 2018, 171, 272–289. [Google Scholar] [CrossRef]

- Džidiæ, A.; Halachmi, I.; Havranek, J.L. Prediction of Milking Robot Utilization Predvidanje iskoristenja robota za strojnu muznju. Agric. Conspec. Sci. 2001, 66, 137–143. [Google Scholar]

- Halachmi, I.; Metz, J.H.M.; van’t Land, A.; Halachmi, S.; Kleijnen, J.P.C. Case Study: Optimal facility allocation in a robotic milking barn. Trans. ASAE 2002, 45, 1539–1546. [Google Scholar] [CrossRef] [Green Version]

- Halachmi, I.; Metz, J.H.M.; Maltz, E.; Dijkhuizen, A.A.; Speelman, L. Designing the optimal robotic milking barn, Part 1: Quantifying facility usage. J. Agric. Eng. Res. 2000, 76, 37–49. [Google Scholar] [CrossRef]

- van Herck, L.; Kurtser, P.; Wittemans, L.; Edan, Y. Crop design for improved robotic harvesting: A case study of sweet pepper harvesting. Biosyst. Eng. 2020, 192, 294–308. [Google Scholar] [CrossRef]

- Edan, Y.; Engel, B.A.; Miles, G.E. Intelligent control system simulation of an agricultural robot. J. Intell. Robot. Syst. 1993, 8, 267–284. [Google Scholar] [CrossRef]

- Johnson, L.K.; Bloom, J.D.; Dunning, R.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Farmer harvest decisions and vegetable loss in primary production. Agric. Syst. 2019, 176, 102672. [Google Scholar] [CrossRef]

- Temu, A.E.; Temu, A.A. High value agricultural products for smallholder markets in sub-saharan Africa: Trends, opportunities and research priorities. In Proceedings of the High Value Agricultural Products Workshop, Cali, Columbia, 3–5 October 2005; pp. 1–37. [Google Scholar]

- Kapach, K.; Barnea, E.; Mairon, R.; Edan, Y.; Ben-Shahar, O. Computer vision for fruit harvesting robots-state of the art and challenges ahead. Int. J. Comput. Vis. Robot. 2012, 3, 4–34. [Google Scholar] [CrossRef] [Green Version]

- Landahl, S.; Terry, L.A. Non-destructive discrimination of avocado fruit ripeness using laser Doppler vibrometry. Biosyst. Eng. 2020, 194, 251–260. [Google Scholar] [CrossRef]

- Saranwong, S.; Sornsrivichai, J.; Kawano, S. Prediction of ripe-stage eating quality of mango fruit from its harvest quality measured nondestructively by near infrared spectroscopy. Postharvest Biol. Technol. 2004, 31, 137–145. [Google Scholar] [CrossRef]

- Azarmdel, H.; Jahanbakhshi, A.; Mohtasebi, S.S.; Muñoz, A.R. Evaluation of image processing technique as an expert system in mulberry fruit grading based on ripeness level using artificial neural networks (ANNs) and support vector machine (SVM). Postharvest Biol. Technol. 2020, 166, 111201. [Google Scholar] [CrossRef]

- Ratprakhon, K.; Neubauer, W.; Riehn, K.; Fritsche, J.; Rohn, S. Developing an Automatic Color Determination Procedure for the Quality Assessment of Mangos (Mangifera indica) Using a CCD Camera and Color Standards. Foods 2020, 9, 1709. [Google Scholar] [CrossRef] [PubMed]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V.; Blackmore, S. Economics of robots and automation in field crop production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef] [Green Version]

- Allen, S.J.; Schuster, E.W. Controlling the risk for an agricultural harvest. Manuf. Serv. Oper. Manag. 2004, 6, 225–236. [Google Scholar] [CrossRef] [Green Version]

- Zion, B.; Mann, M.; Levin, D.; Shilo, A.; Rubinstein, D.; Shmulevich, I. Harvest-order planning for a multiarm robotic harvester. Comput. Electron. Agric. 2014, 103, 75–81. [Google Scholar] [CrossRef]

- Amaruchkul, K. Planning migrant labor for green sugarcane harvest: A stochastic logistics model with dynamic yield prediction. Comput. Ind. Eng. 2021, 154, 107016. [Google Scholar] [CrossRef]

- Ferrer, J.C.; Mac Cawley, A.; Maturana, S.; Toloza, S.; Vera, J. An optimization approach for scheduling wine grape harvest operations. Int. J. Prod. Econ. 2008, 112, 985–999. [Google Scholar] [CrossRef]

- Plà-Aragonés, L.M. Handbook of Operations Research in Agriculture and the Agri-Food Industry; Springer: Cham, Switzerland, 2015; ISBN 9781493924820. [Google Scholar]

- Ampatzidis, Y.G.; Vougioukas, S.G.; Whiting, M.D.; Zhang, Q. Applying the machine repair model to improve efficiency of harvesting fruit. Biosyst. Eng. 2014, 120, 25–33. [Google Scholar] [CrossRef]

- Arnaout, J.P.M.; Maatouk, M. Optimization of quality and operational costs through improved scheduling of harvest operations. Int. Trans. Oper. Res. 2010, 17, 595–605. [Google Scholar] [CrossRef]

- Maatman, A.; Schweigman, C.; Ruijs, A.; Van Der Vlerk, M.H.; Maatman, A.; Schweigman, C.; Ruijs, A.; Van Der Vlerk, M.H. Modeling farmers’ response to uncertain rainfall in Burkina Faso: A stochastic programming approach. Oper. Res. 2002, 50, 399–414. [Google Scholar] [CrossRef] [Green Version]

- Annetts, J.E.; Audsley, E. Multiple objective linear programming for environmental farm planning. J. Oper. Res. Soc. 2002, 53, 933–943. [Google Scholar] [CrossRef]

- Golenko-Ginzburg, D.; Sinuany-Stern, Z.; Kats, V. A multilevel decision-making system with multiple resources for controlling cotton harvesting. Int. J. Prod. Econ. 1996, 46–47, 55–63. [Google Scholar] [CrossRef]

- Albornoz, V.M.; Araneda, L.C.; Ortega, R. Planning and scheduling of selective harvest with management zones delineation. Ann. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Maaike Wubs, A.; Ma, Y.T.; Heuvelink, E.; Hemerik, L.; Marcelis, L.F.M. Model selection for nondestructive quantification of fruit growth in pepper. J. Am. Soc. Hortic. Sci. 2012, 137, 71–79. [Google Scholar] [CrossRef] [Green Version]

- Elkoby, Z.; Van Ooster, B.; Edan, Y. Simulation analysis of sweet pepper harvesting. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Ajaccio, France, 20–24 September 2014; pp. 441–448. [Google Scholar]

- Melamed, Z. Analysis of Human-Robot Harvesting Operations in Sweet Pepper Greenhouses. Master’s Thesis, Ben Gurion University of the Negev, Beersheba, Israel, 2016. [Google Scholar]

- Nof, S.Y. Handbook of Industrial Robotics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Sweeper Project Workpackages Overview. Available online: http://www.sweeper-robot.eu/workpackages (accessed on 1 December 2021).

| General | Workers | Yield | Growth Function | ||||

|---|---|---|---|---|---|---|---|

| Type A: m = 2 | Type B: m = 3 | Type C: m = 4 | ||||||

|---|---|---|---|---|---|---|---|---|

| Class | d Start | d End | Class | d Start | d End | Class | d Start | d End |

| 1 | 31 | 45 | 1 | 31 | 40 | 1 | 31 | 40 |

| 2 | 46 | 60 | 2 | 41 | 50 | 2 | 41 | 45 |

| 3 | 51 | 60 | 3 | 46 | 50 | |||

| 4 | 51 | 60 | ||||||

| Variable Number of Workers | Fixed Number of Workers | |||||

|---|---|---|---|---|---|---|

| N | Profit | THW | N | Profit | THW | |

| Type A: m = 2 | 2 | 98,066.7 | 52,553.37 | 2 | 98,066.7 | 52,553.37 |

| Type B: m = 3 | 4 | 111,593 | 62,836.68 | 2 | 107,918 | 57,478.77 |

| Type C: m = 4 | 3 | 112,049 | 61,304.32 | 2 | 108,022 | 57,531.19 |

| Harvester Type | Robot | 6 Type A Workers | 6 Type B Workers | 6 Type C Workers |

|---|---|---|---|---|

| THW (kg) in one month | 37,069.03 | 32,885.64 | 34,352.45 | 35,253.99 |

| THW (kg) in one year (35 harvest weeks) | 324,354 | 287,749.35 | 300,583.93 | 308,472.41 |

| Robot Cycle Time | Type A Workers | Type B Workers | Type C Workers |

|---|---|---|---|

| 0.5 | 25.4 | 24.0 | 23.1 |

| 1 | 12.7 | 12.0 | 11.6 |

| 2.5 | 5.1 | 4.8 | 4.6 |

| 5.5 | 2.3 | 2.2 | 2.1 |

| 7.5 | 1.7 | 1.6 | 1.5 |

| 10 | 1.3 | 1.2 | 1.2 |

| 12.5 | 1.0 | 1.0 | 0.9 |

| 15 | 0.8 | 0.8 | 0.8 |

| 20 | 0.6 | 0.6 | 0.6 |

| 25 | 0.5 | 0.5 | 0.5 |

| The Netherlands | Israel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Payback Periods | IRR in Five Years (%) | Payback Periods | IRR in Five Years (%) | |||||||||

| Pepper p (€)/ Robot Cost (€) | 100K | 130K | 160K | 100K | 130K | 160K | 100K | 130K | 160K | 100K | 130K | 160K |

| 1 | 3.72 | 4.58 | 5.50 | 10.5 | 2.9 | 0.0 | 4.89 | >6 | >6 | 0.0 | 0.0 | 0.0 |

| 1.25 | 3.21 | 3.99 | 4.72 | 16.2 | 7.8 | 1.9 | 4.05 | 5.00 | >6 | 7.3 | 0.0 | 0.0 |

| 1.5 | 2.89 | 3.52 | 4.19 | 21.1 | 12.4 | 5.9 | 3.46 | 4.29 | 5.08 | 13.3 | 5.2 | 0.0 |

| 1.75 | 2.63 | 3.17 | 3.76 | 25.7 | 16.6 | 9.8 | 3.05 | 3.76 | 4.46 | 18.5 | 9.9 | 3.8 |

| 2 | 2.42 | 2.91 | 3.40 | 30.3 | 20.3 | 13.6 | 2.76 | 3.33 | 3.98 | 23.3 | 14.5 | 7.8 |

| 2.25 | 2.24 | 2.70 | 3.14 | 34.7 | 24.0 | 16.8 | 2.53 | 3.04 | 3.58 | 27.9 | 18.3 | 11.6 |

| 2.5 | 2.08 | 2.52 | 2.93 | 39.0 | 27.6 | 19.8 | 2.33 | 2.81 | 3.27 | 32.4 | 22.1 | 15.1 |

| 2.75 | 1.95 | 2.36 | 2.75 | 43.2 | 31.0 | 22.8 | 2.16 | 2.61 | 3.03 | 36.7 | 25.7 | 18.2 |

| 3 | 1.82 | 2.23 | 2.59 | 47.4 | 34.5 | 25.8 | 2.02 | 2.45 | 2.84 | 41.0 | 29.2 | 21.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harel, B.; Edan, Y.; Perlman, Y. Optimization Model for Selective Harvest Planning Performed by Humans and Robots. Appl. Sci. 2022, 12, 2507. https://doi.org/10.3390/app12052507

Harel B, Edan Y, Perlman Y. Optimization Model for Selective Harvest Planning Performed by Humans and Robots. Applied Sciences. 2022; 12(5):2507. https://doi.org/10.3390/app12052507

Chicago/Turabian StyleHarel, Ben, Yael Edan, and Yael Perlman. 2022. "Optimization Model for Selective Harvest Planning Performed by Humans and Robots" Applied Sciences 12, no. 5: 2507. https://doi.org/10.3390/app12052507

APA StyleHarel, B., Edan, Y., & Perlman, Y. (2022). Optimization Model for Selective Harvest Planning Performed by Humans and Robots. Applied Sciences, 12(5), 2507. https://doi.org/10.3390/app12052507