The Effect of Clamping Force on the Wear Behavior of a Steam Generator Tube

Abstract

1. Introduction

2. Experiment

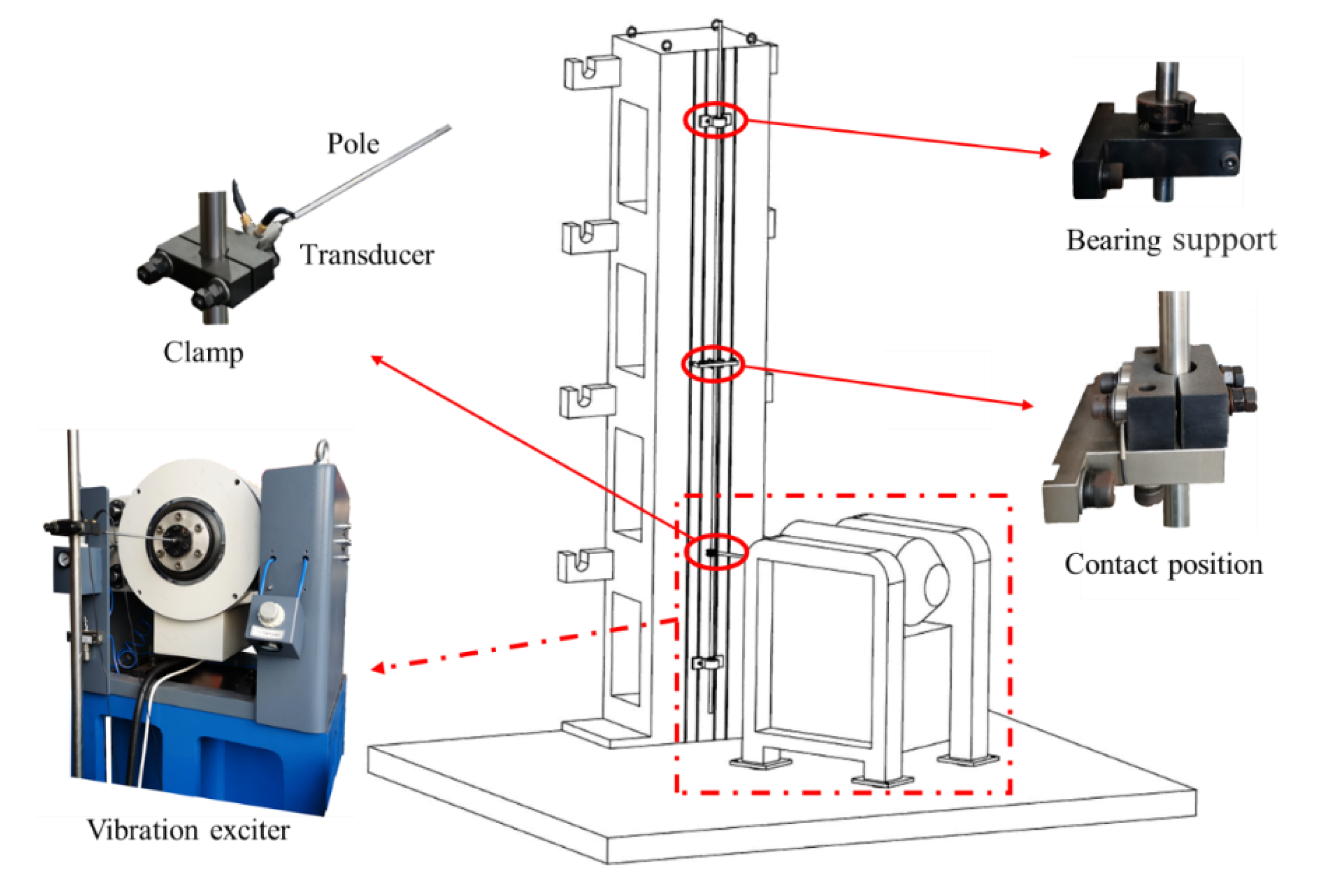

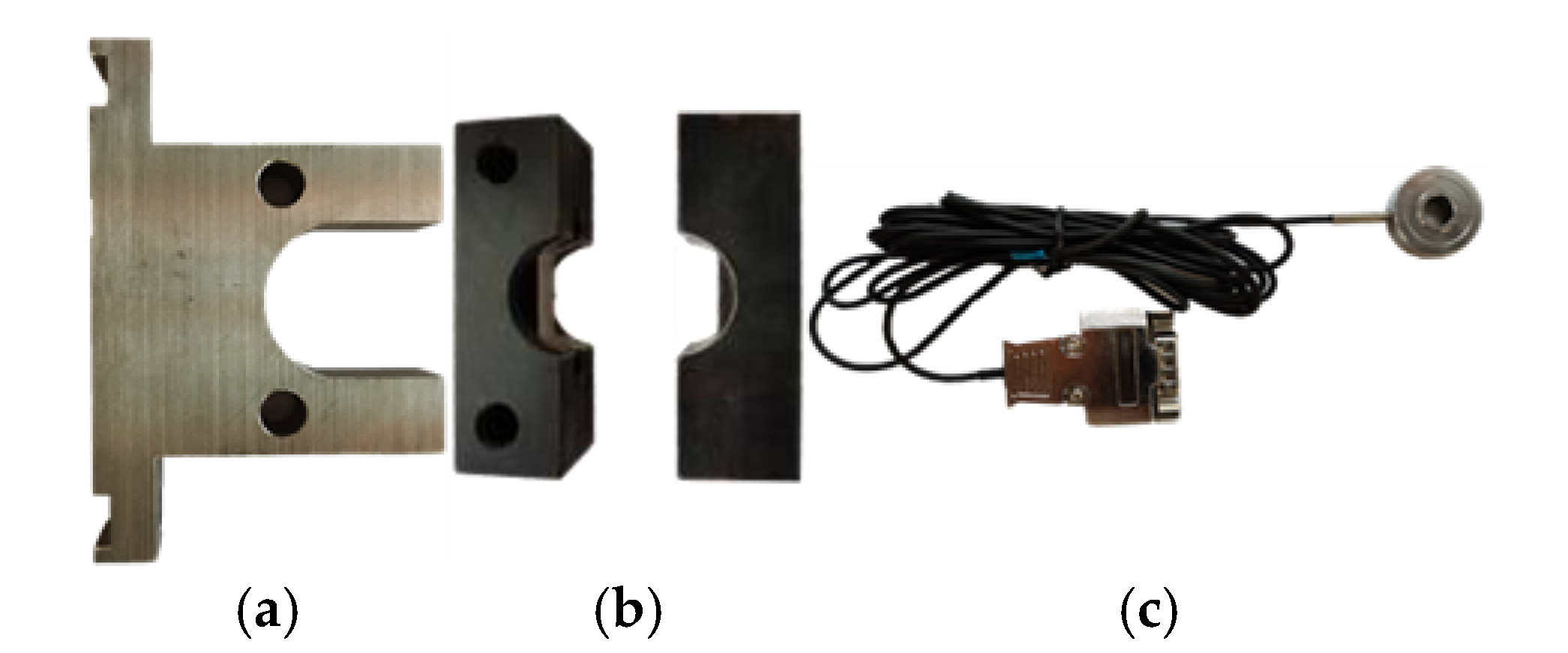

2.1. Experimental Setup

2.2. Experimental Procedure

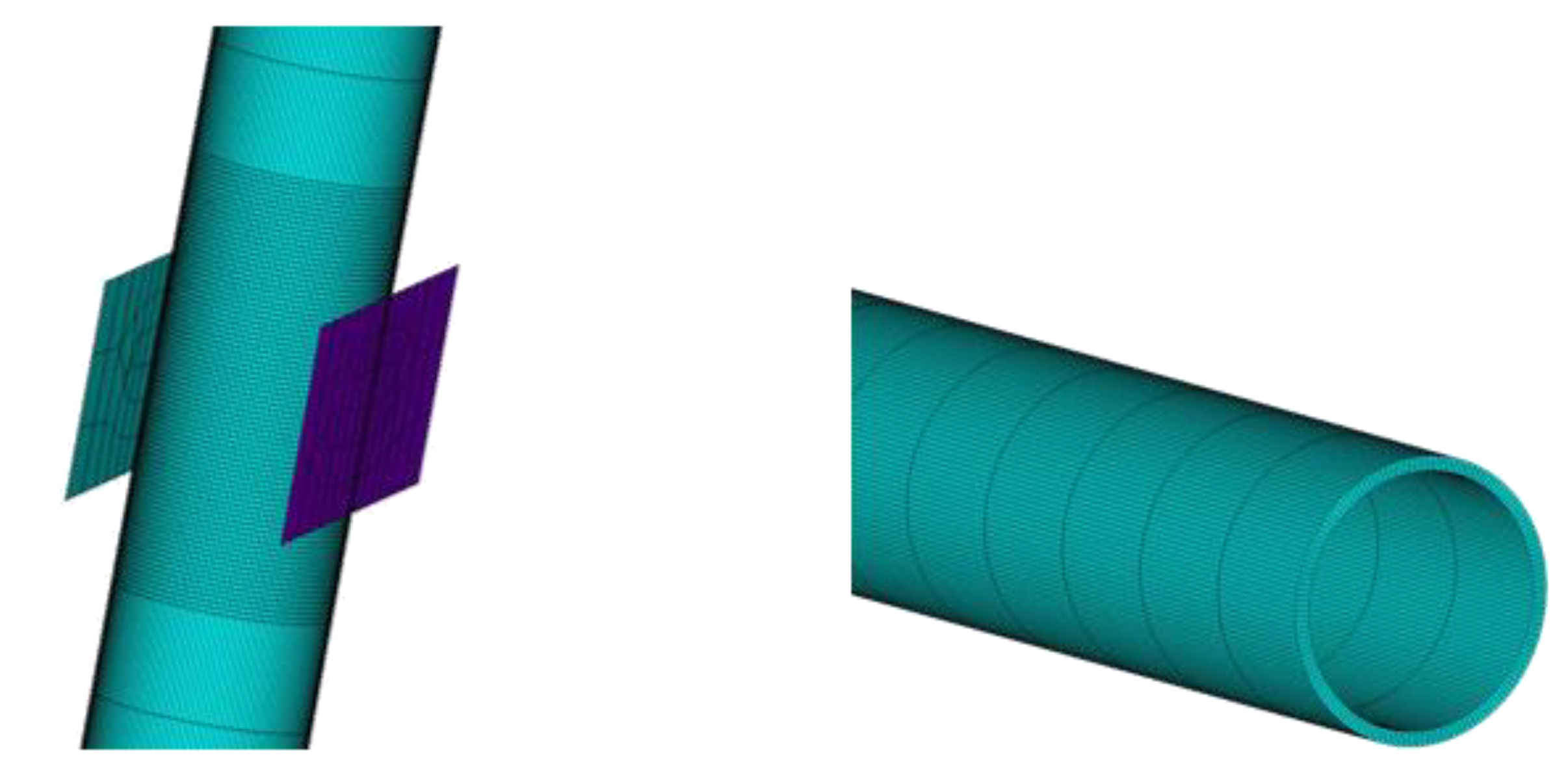

3. Finite Element Modeling

4. Results and Discussion

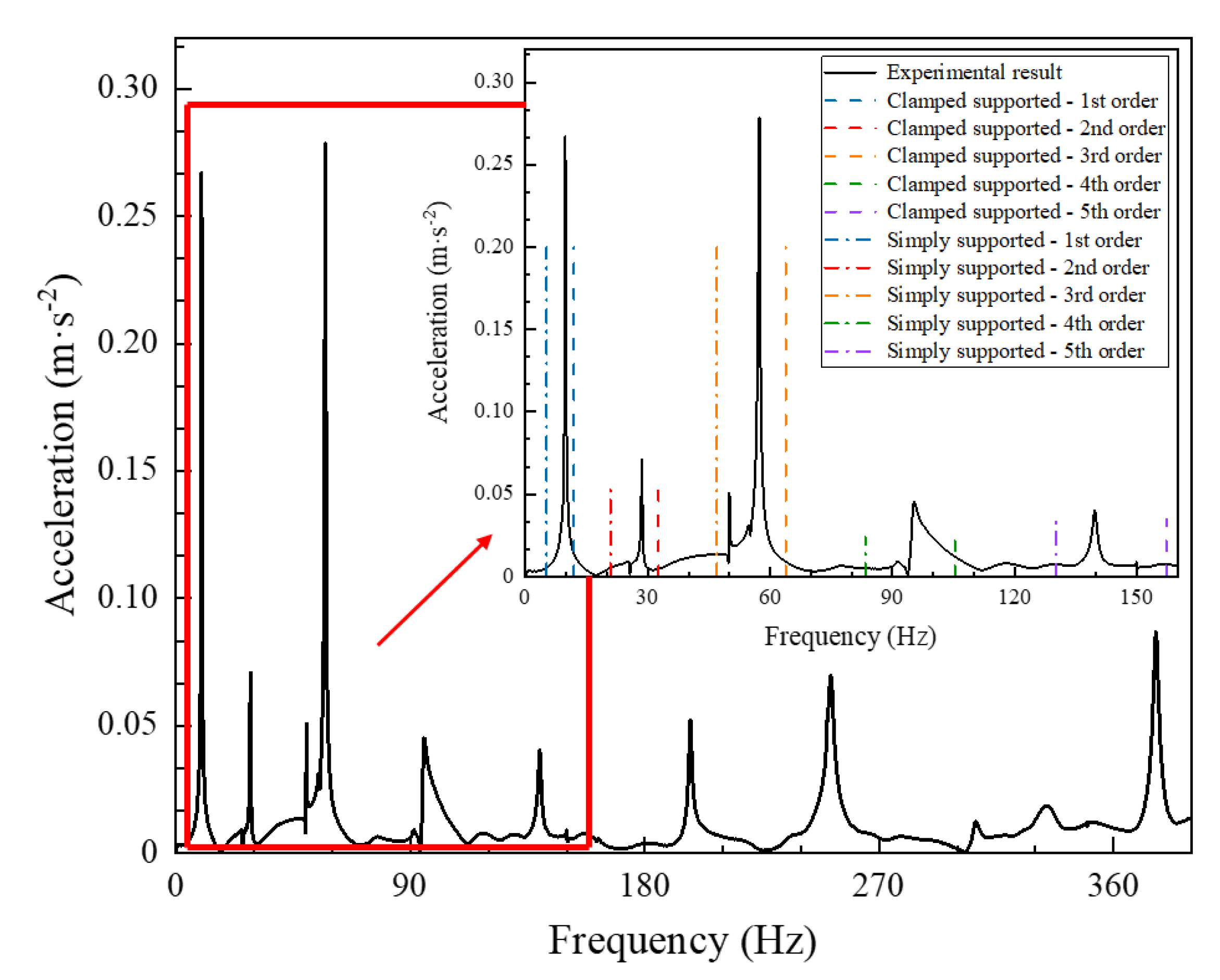

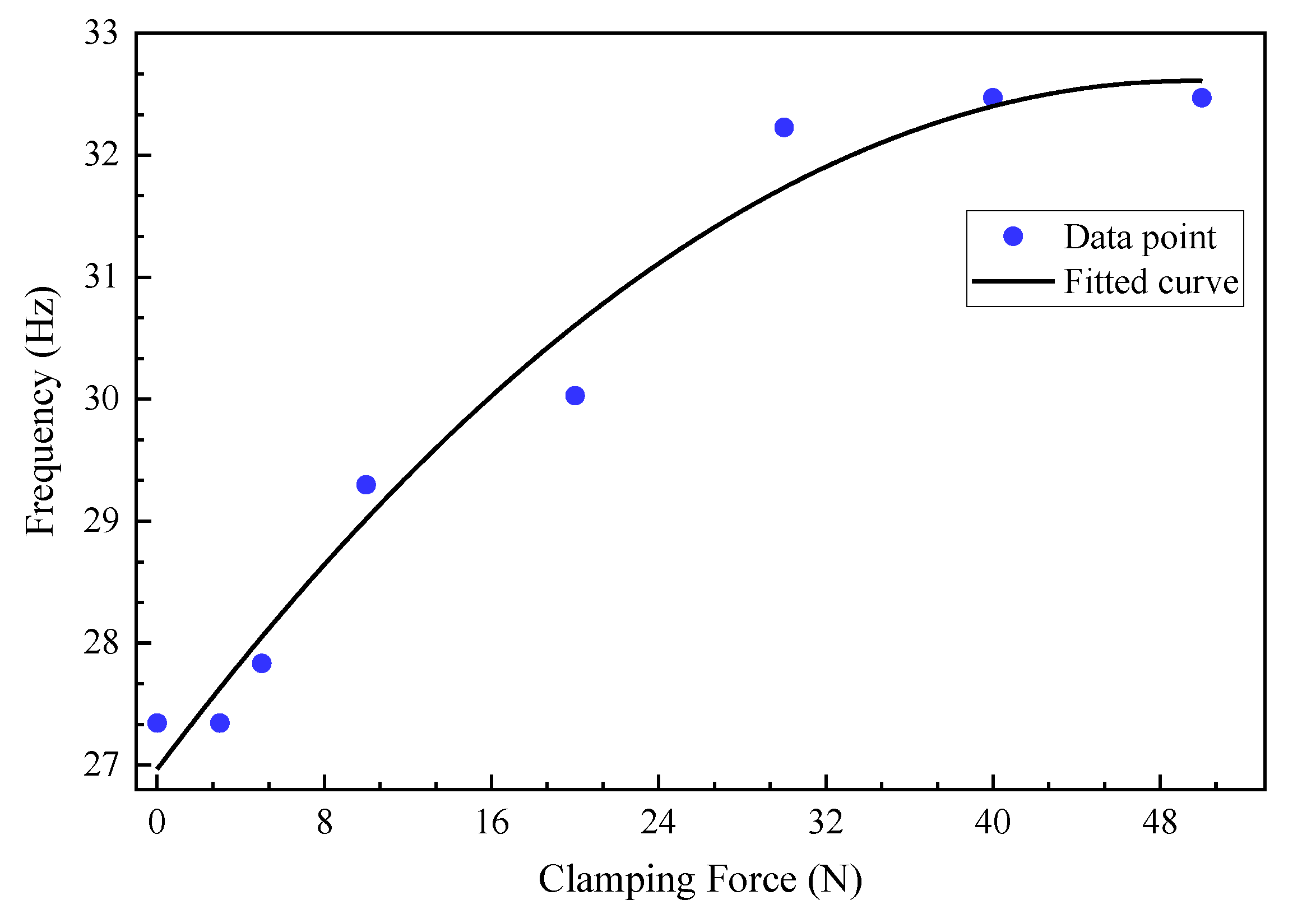

4.1. Natural Frequencies under Different Clamping Forces

4.2. Dynamic Behavior Analysis Based on the Finite Element Method

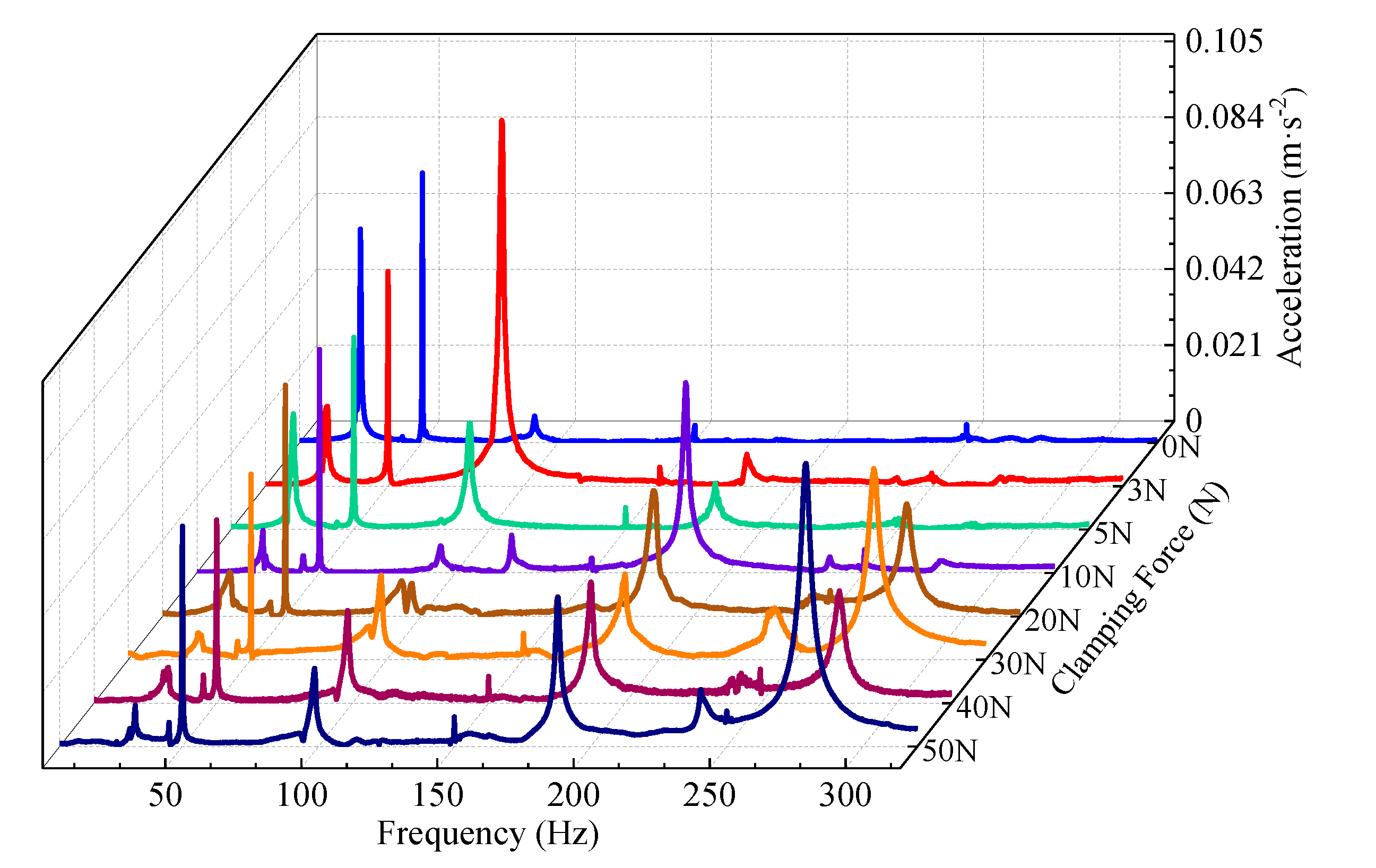

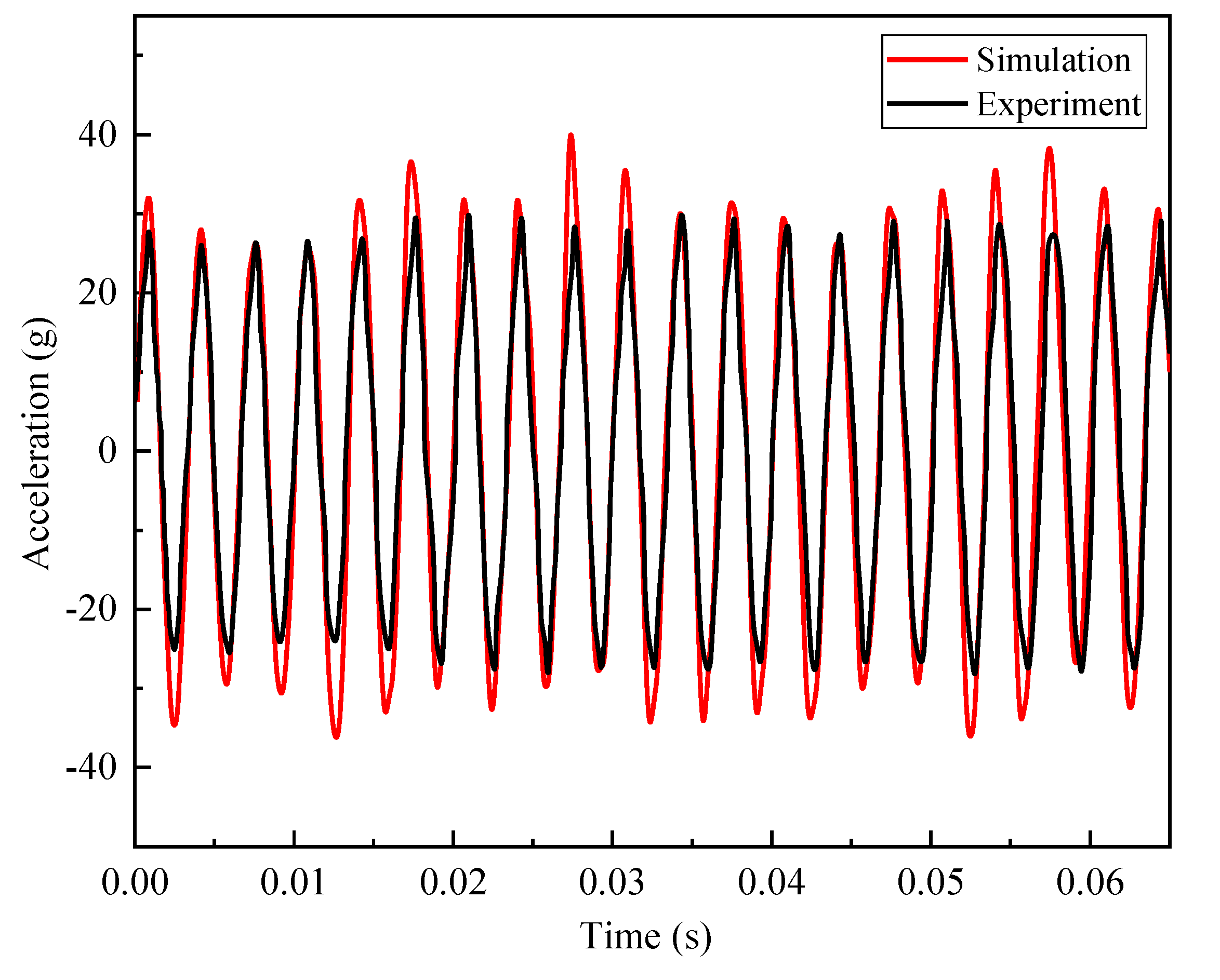

4.3. Experimental Validation

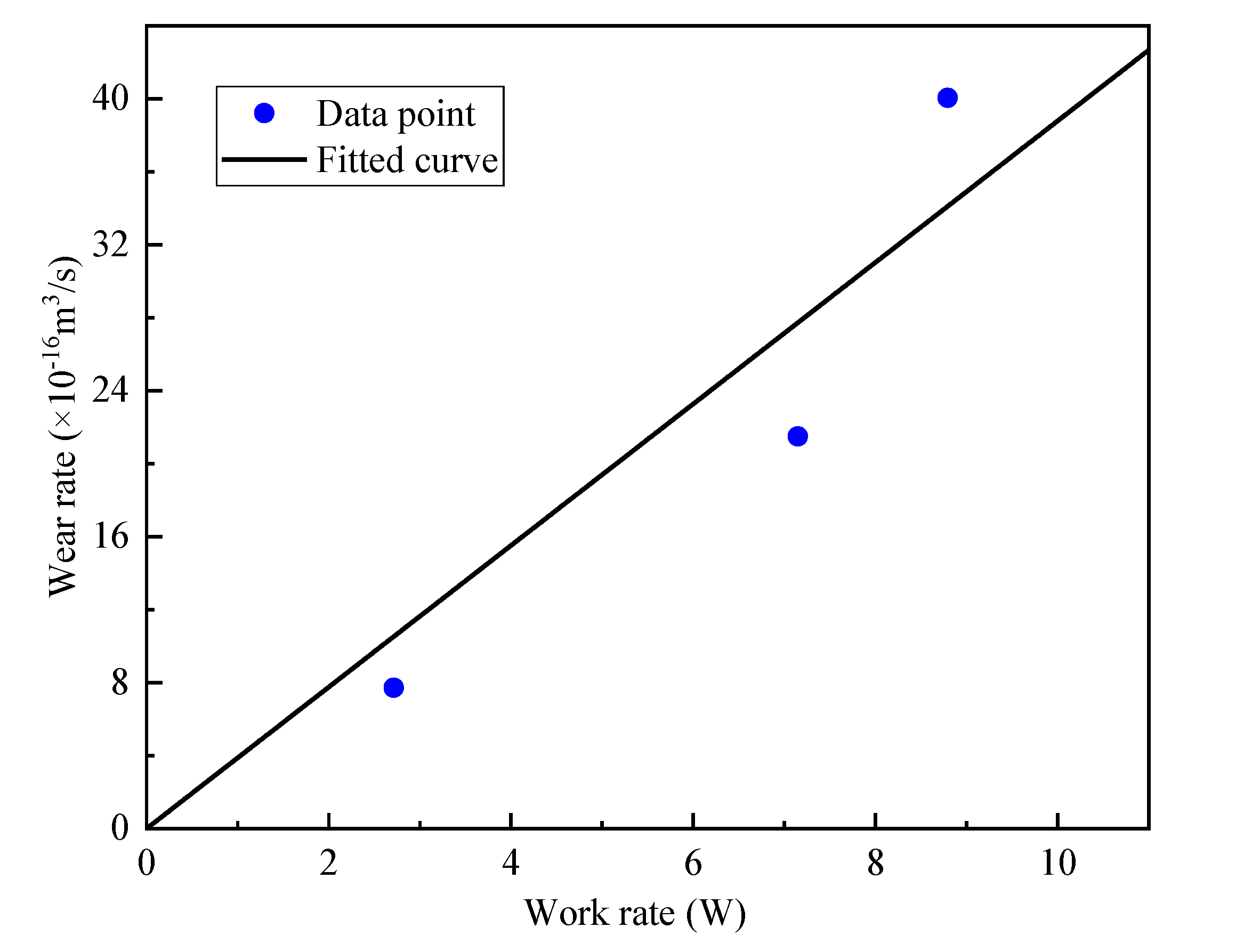

4.4. Wear Coefficient

5. Conclusions

- The main frequency of the double-span tube shifts to a higher frequency while the clamping force increases. Moreover, the first-order natural frequency of the tube grows under an increasing clamping force.

- The sliding distance of the tube is affected by the clamping force from results of dynamic behavior analysis. As the clamping force increases, both the sliding distance of the tube and friction energy decrease.

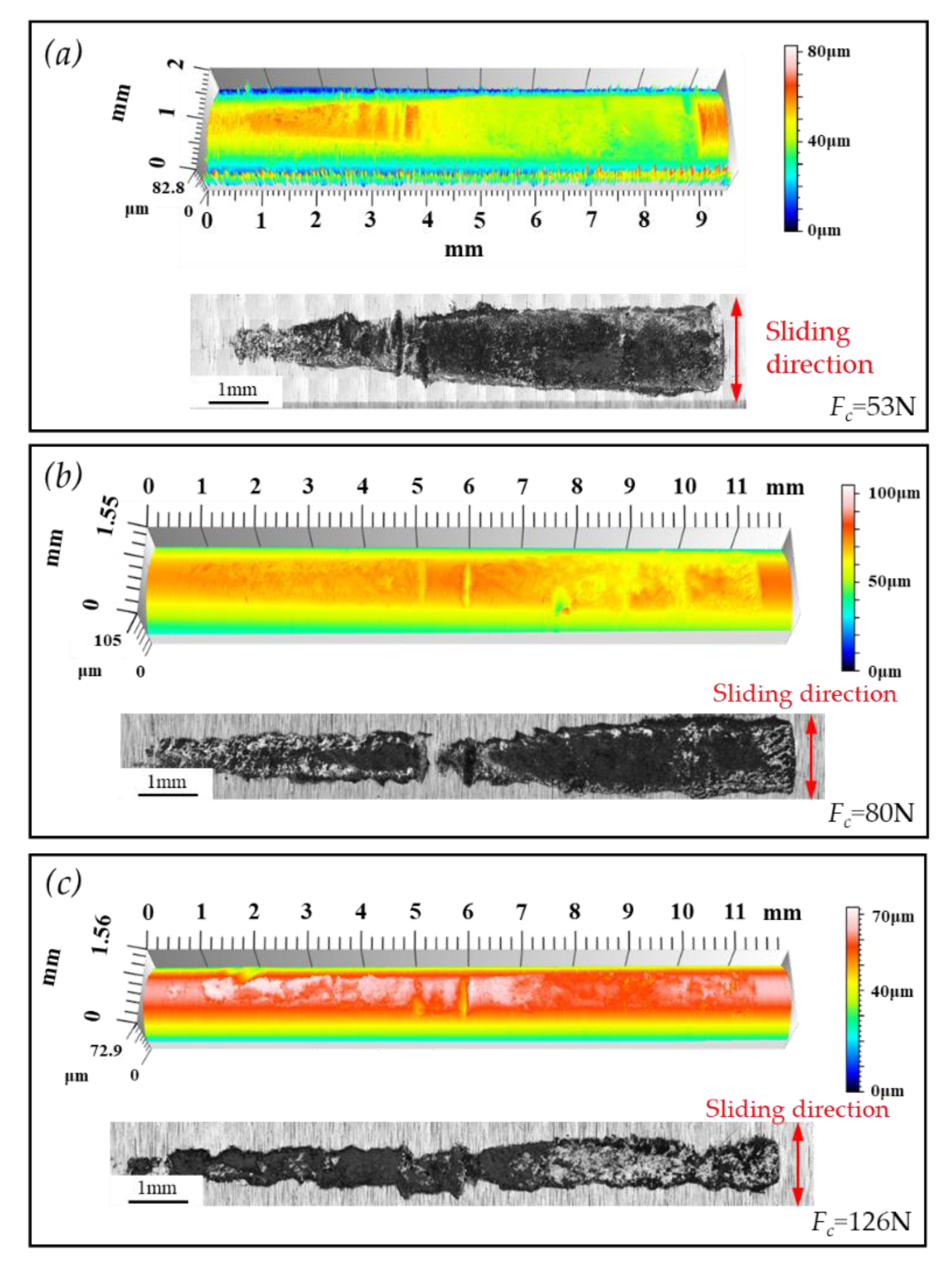

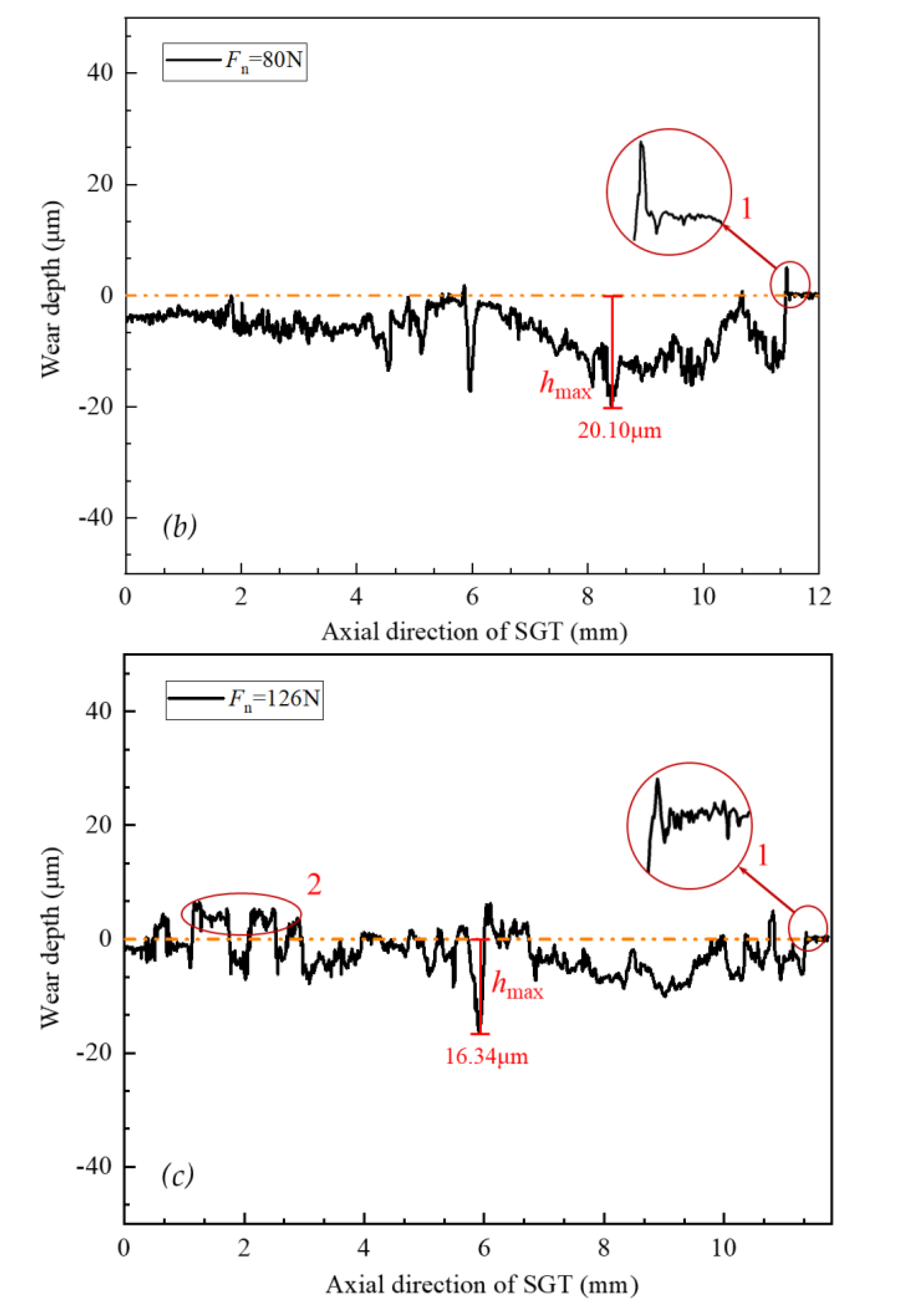

- Both maximum wear depth and wear volume reduce while the clamping force increases from 53 N to 126 N under a constant excitation frequency. Furthermore, the conclusion of the experiment is consistent with that of dynamic behavior analysis.

- Considering that the contact force of the tube is not easy to measure in the experiment, we estimate the wear coefficient through the contact force obtained by the finite element model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Auvinen, A.; Jokiniemi, J.K.; Lähde, A.; Routamo, T.; Lundström, P.; Tuomisto, H.; Dienstbier, J.; Güntay, S.; Suckow, D.; Dehbi, A.; et al. Steam generator tube rupture (SGTR) scenarios. Nucl. Eng. Des. 2005, 235, 457–472. [Google Scholar] [CrossRef]

- Chen, X.; He, X.; Tang, L.; Li, Y.; Zhou, M.; Jin, W.; Gao, Z. A heat transfer tube wear reliability analysis method based on first-order reliability method. J. Comput. Des. Eng. 2020, 7, 803–815. [Google Scholar] [CrossRef]

- Phalippou, C.; Ruffet, F.; Herms, E.; Balestreri, F. PWR steam generator tube and AVB wear under perpendicular impacting. In Proceedings of the Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013. [Google Scholar]

- He, X.; Xu, X.; Tian, W.; Li, Y.; Jin, W.; Zhou, M. Markov stochastic process modeling for evolution of wear depth in steam generator tubes. Adv. Mech. Eng. 2019, 11, 1–9. [Google Scholar] [CrossRef]

- Connors, H.J. Flow-induced vibration and wear of steam generator tubes. Nucl. Technol. 1981, 55, 311–331. [Google Scholar] [CrossRef]

- Diercks, D.; Shack, W.; Muscara, J. Overview of steam generator tube degradation and integrity issues. Nucl. Eng. Des. 1999, 194, 19–30. [Google Scholar] [CrossRef]

- Pettigrew, M.J.; Taylor, C.E. Vibration analysis of shell-and-tube heat exchangers: An overview—Part 2: Vibration response, fretting-wear, guidelines. J. Fluids Struct. 2003, 18, 485–500. [Google Scholar] [CrossRef]

- Fricker, A.J. Numerical analysis of the fluidelastic vibration of a steam generator tube with loose supports. J. Fluids Struct. 1992, 6, 85–107. [Google Scholar] [CrossRef]

- Lalonde, V.; Ross, A.; Pettigrew, M.J.; Nowlan, I. Experimental Study of Dynamic Interaction Between a Steam Generator Tube and an Anti-Vibration Bar. In Proceedings of the ASME 2010 3rd Joint US-European Fluids Engineering Summer Meeting collocated with 8th International Conference on Nanochannels, Microchannels, and Minichannels, Montreal, QC, Canada, 1–5 August 2010. [Google Scholar]

- Nowlan, I.; Ross, A.; Pettigrew, M.J. Dynamic Interaction Between a Straight Tube and an Anti-Vibration Bar. In Proceedings of the Asme Pressure Vessels and Piping Division Conference, Prague, Czech Republic, 26–30 July 2009. [Google Scholar]

- Mi, X.; Bai, X.; Tang, P.; Xie, H.; Peng, J.; Zhu, M. The role of the third body in the fretting wear of 690 alloy. Int. J. Mod. Phys. B 2020, 34, 2050077. [Google Scholar] [CrossRef]

- Soria, S.R.; Tolley, A.; Yawny, A. Running condition and material response fretting maps of incoloy 800 steam generator tubes against AISI 304L pads in air and room temperature. Tribol. Int. 2019, 135, 408–420. [Google Scholar] [CrossRef]

- Mi, X.; Wang, W.; Xiong, X.; Qian, H.; Tang, L.; Xie, Y.; Peng, J.; Cai, Z.; Zhu, M. Investigation of fretting wear behavior of Inconel 690 alloy in tube/plate contact configuration. Wear 2015, 328, 582–590. [Google Scholar] [CrossRef]

- Tang, P.; Mi, X.; Zhang, J.; Xiong, F.R.; Zheng, B.; Shao, X.J.; Peng, J.F.; Zhu, M.H. Evolution of wear damage in 690 alloy tube mated with 405 stainless steel plate due to fretting conditions. Tribol. Int. 2021, 163, 107177. [Google Scholar] [CrossRef]

- Chung, I.; Lee, M. An experimental study on fretting wear behavior of cross-contacting Inconel 690 tubes. Nucl. Eng. Des. 2011, 241, 4103–4110. [Google Scholar] [CrossRef]

- McColl, I.R.; Ding, J.; Leen, S.B. Finite element simulation and experimental validation of fretting wear. Wear 2004, 256, 1114–1127. [Google Scholar] [CrossRef]

- Guan, H.; Cai, Z.; Ren, Y.; Jing, J.; Wang, W.; Zhu, M. Impact-fretting wear behavior of Inconel 690 alloy tubes effected by pre-compressive stress. J. Alloys Compd. 2017, 724, 910–920. [Google Scholar] [CrossRef]

- Ming, H.; Liu, X.; Lai, J.; Wang, J.; Gao, L.; Han, E. Fretting wear between Alloy 690 and 405 stainless steel in high temperature pressurized water with different normal force and displacement. J. Nucl. Mater. 2020, 529, 151930. [Google Scholar] [CrossRef]

- Zhang, W.; Cui, D.; Ying, Y. Nondestructive measurement of pear texture by acoustic vibration method. Postharvest Biol. Tec. 2014, 96, 99–105. [Google Scholar] [CrossRef]

- Archard, J.; Hirst, W. The wear of metals under unlubricated conditions. Proc. R. Soc. A 1956, 236, 397–410. [Google Scholar]

- Xin, L.; Yang, B.; Wang, Z.; Li, J.; Lu, Y.; Shoji, T. Effect of normal force on fretting wear behavior and mechanism of Alloy 690TT in high temperature water. Wear 2016, 368, 210–218. [Google Scholar] [CrossRef]

- Ming, H.; Liu, X.; Zhang, Z.; Wang, J.; Han, E. Effect of normal force on the fretting wear behavior of Inconel 690 TT against 304 stainless steel in simulated secondary water of pressurized water reactor. Tribol. Int. 2018, 126, 133–143. [Google Scholar] [CrossRef]

- Ryu, K.W.; Park, C.Y.; Kim, H.N.; Rhee, H. Prediction of Fretting Wear Depth for Steam Generator Tubes Based on Various Types of Wear Scars. J. Nucl. Sci. Technol. 2010, 47, 449–456. [Google Scholar] [CrossRef][Green Version]

| Parameter | Value | |

|---|---|---|

| Material property | Young’s modulus | E = 211 GPa |

| Poisson’s ratio | Υ = 0.3 | |

| Density | Ρ = 8190 kg/m3 | |

| Geometric parameter | Length | 2985 mm |

| Outer diameter | 17.48 mm | |

| Thickness | 1.01 mm |

| First-Order | Second-Order | Third-Order | δave | |

|---|---|---|---|---|

| Experimental result | 9.766 Hz | 28.564 Hz | 57.373 Hz | / |

| Clamped supported | 11.821 Hz | 32.567 Hz | 63.800 Hz | 0.160 |

| Simply supported | 5.2165 Hz | 20.860 Hz | 46.915 Hz | 0.328 |

| Fc (N) | hmax (μm) | Percentage of t | Vtotal (μm3) |

|---|---|---|---|

| 53 | 23.70 | 2.35% | 7.20894 × 107 |

| 80 | 20.10 | 1.99% | 3.86827 × 107 |

| 126 | 16.34 | 1.62% | 1.38893 × 107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Xu, K.; Zhou, M.; Li, Y.; Jin, W.; Gao, Z.; Tang, L. The Effect of Clamping Force on the Wear Behavior of a Steam Generator Tube. Appl. Sci. 2022, 12, 2163. https://doi.org/10.3390/app12042163

Dong X, Xu K, Zhou M, Li Y, Jin W, Gao Z, Tang L. The Effect of Clamping Force on the Wear Behavior of a Steam Generator Tube. Applied Sciences. 2022; 12(4):2163. https://doi.org/10.3390/app12042163

Chicago/Turabian StyleDong, Xuxin, Kunlun Xu, Mingjue Zhou, Yuebing Li, Weiya Jin, Zengliang Gao, and Lichen Tang. 2022. "The Effect of Clamping Force on the Wear Behavior of a Steam Generator Tube" Applied Sciences 12, no. 4: 2163. https://doi.org/10.3390/app12042163

APA StyleDong, X., Xu, K., Zhou, M., Li, Y., Jin, W., Gao, Z., & Tang, L. (2022). The Effect of Clamping Force on the Wear Behavior of a Steam Generator Tube. Applied Sciences, 12(4), 2163. https://doi.org/10.3390/app12042163