Probability-Based Crack Width Estimation Model for Flexural Members of Underground RC Box Culverts

Abstract

:1. Introduction

2. Control of Crack Width

3. Experimental Work

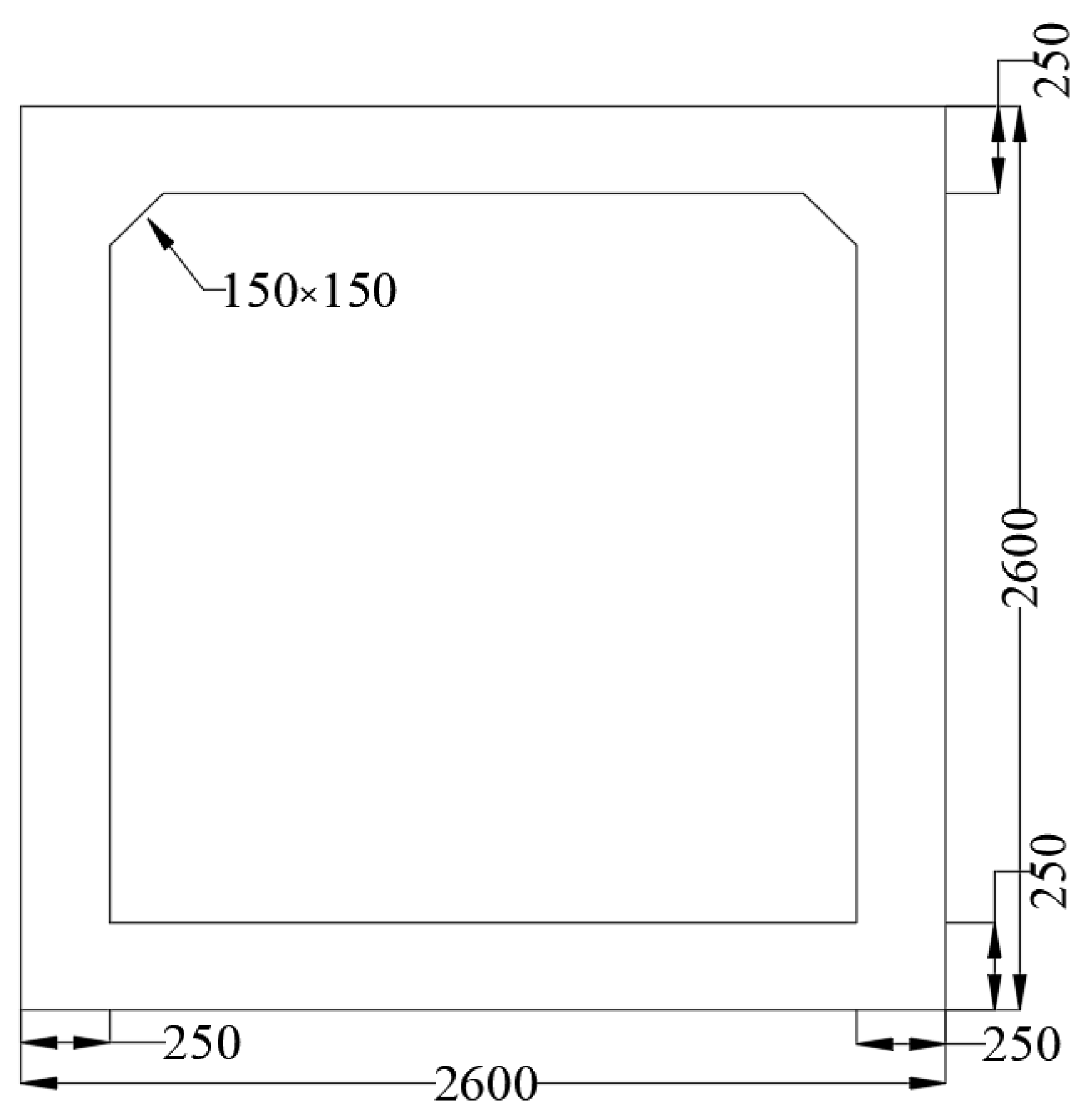

3.1. Fabrication of Specimens and Material Properties

3.2. Direction of Casting and Testing of Slab Specimens

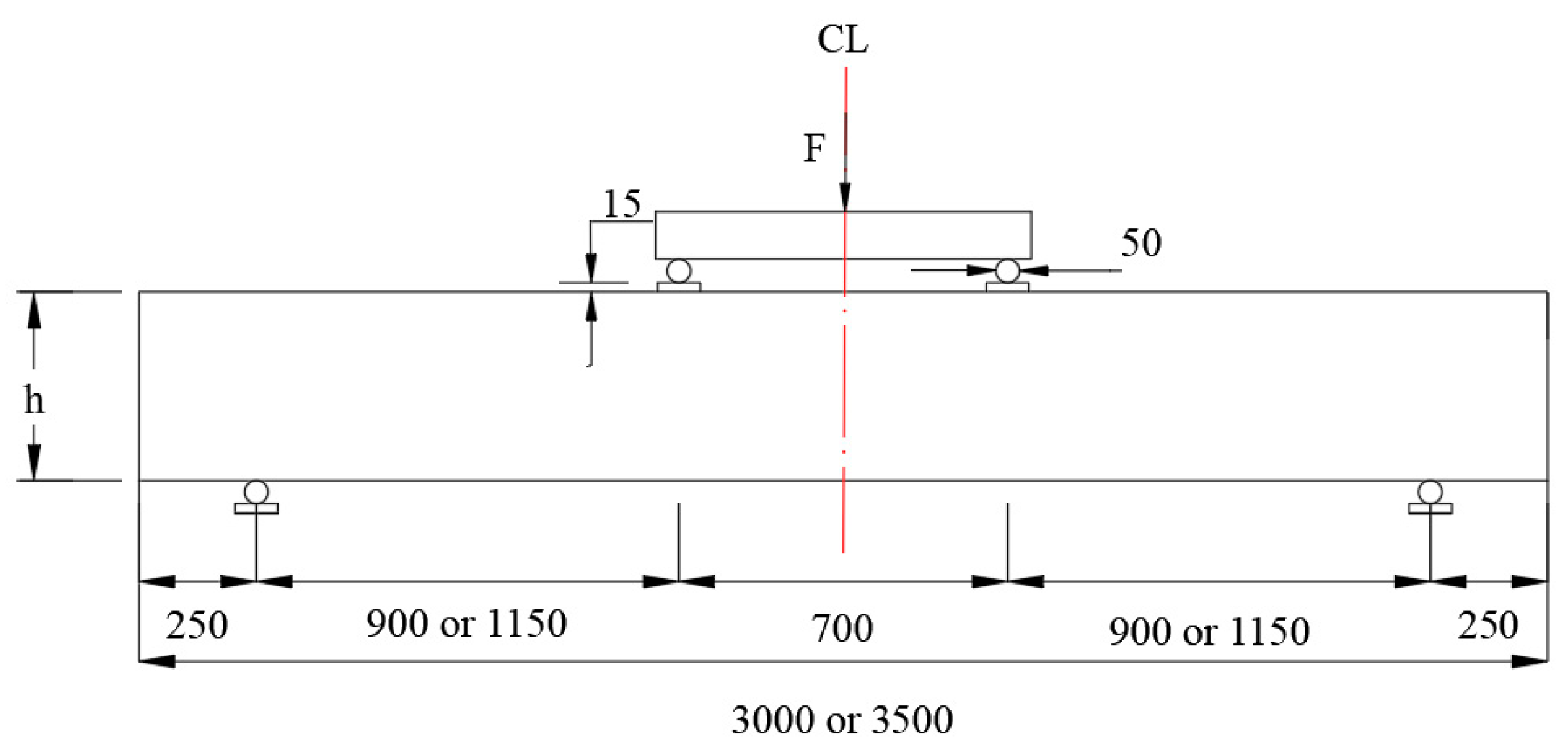

3.3. Experimental Setup

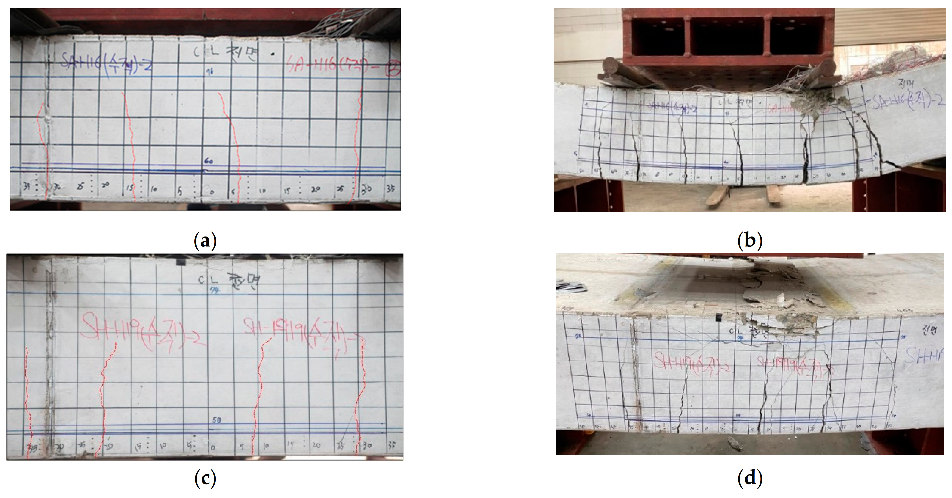

4. Analysis of Crack Width

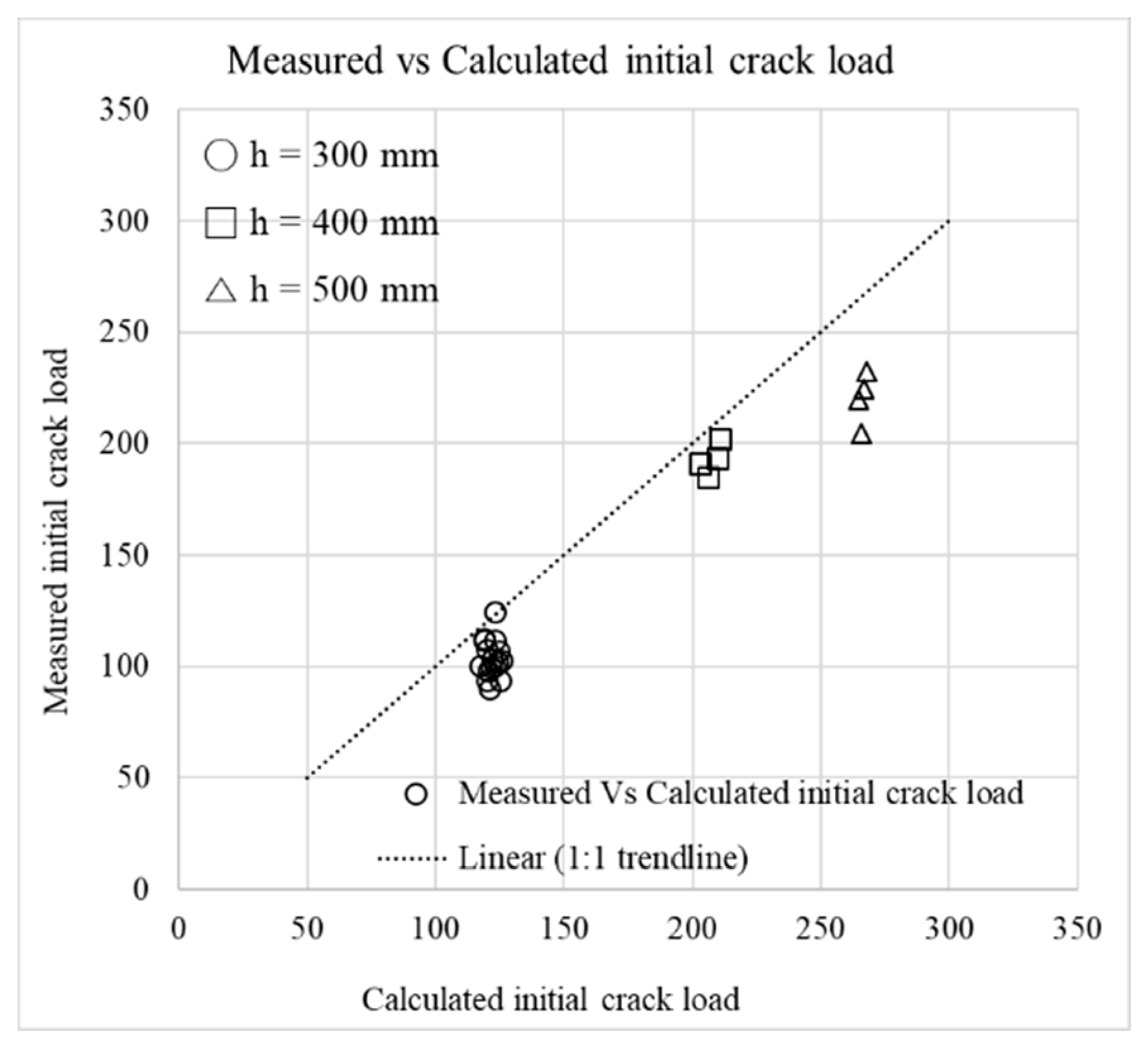

4.1. Moment at First Cracking

4.2. Estimation of Crack Widths

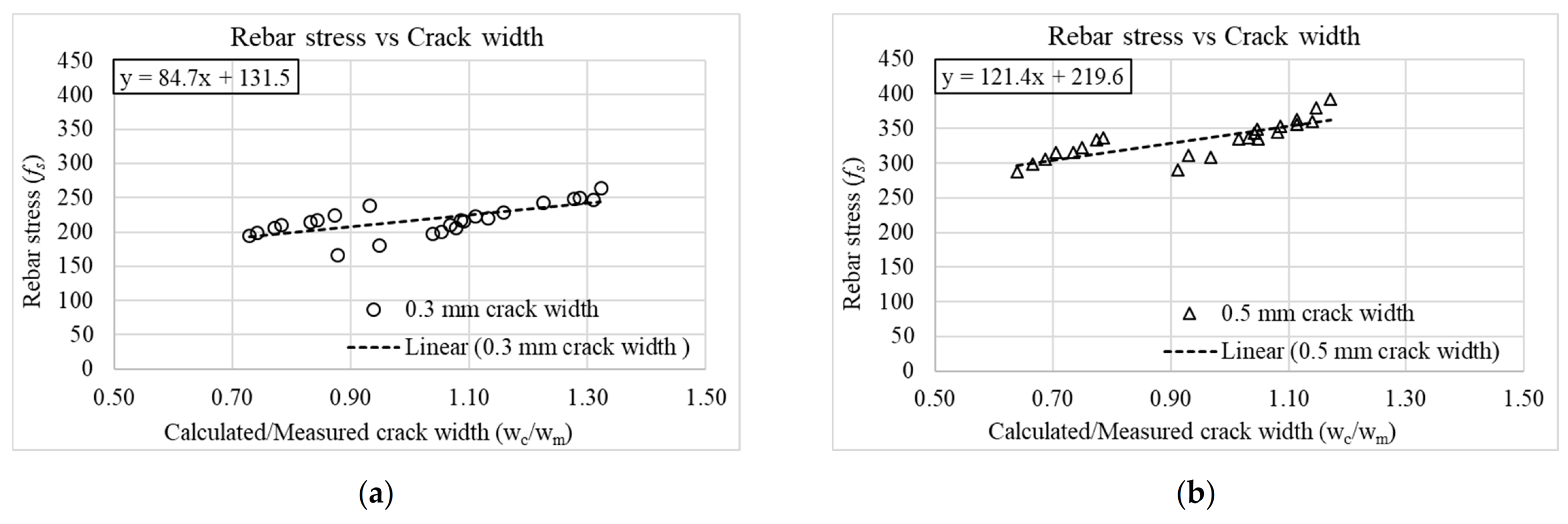

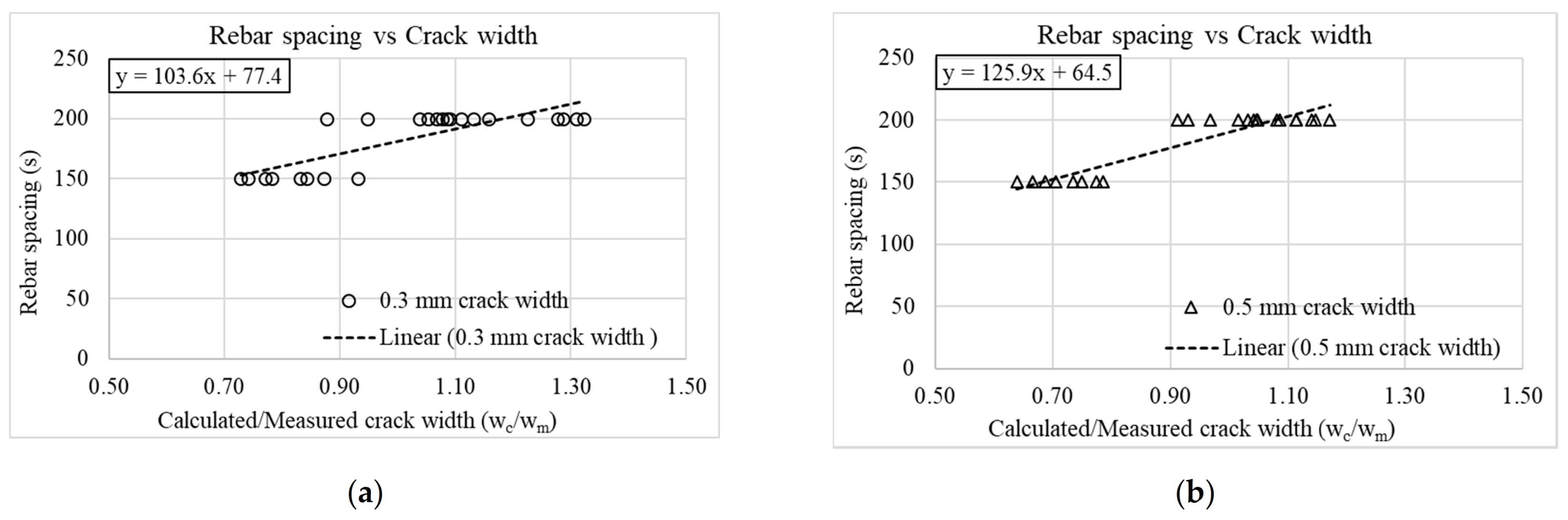

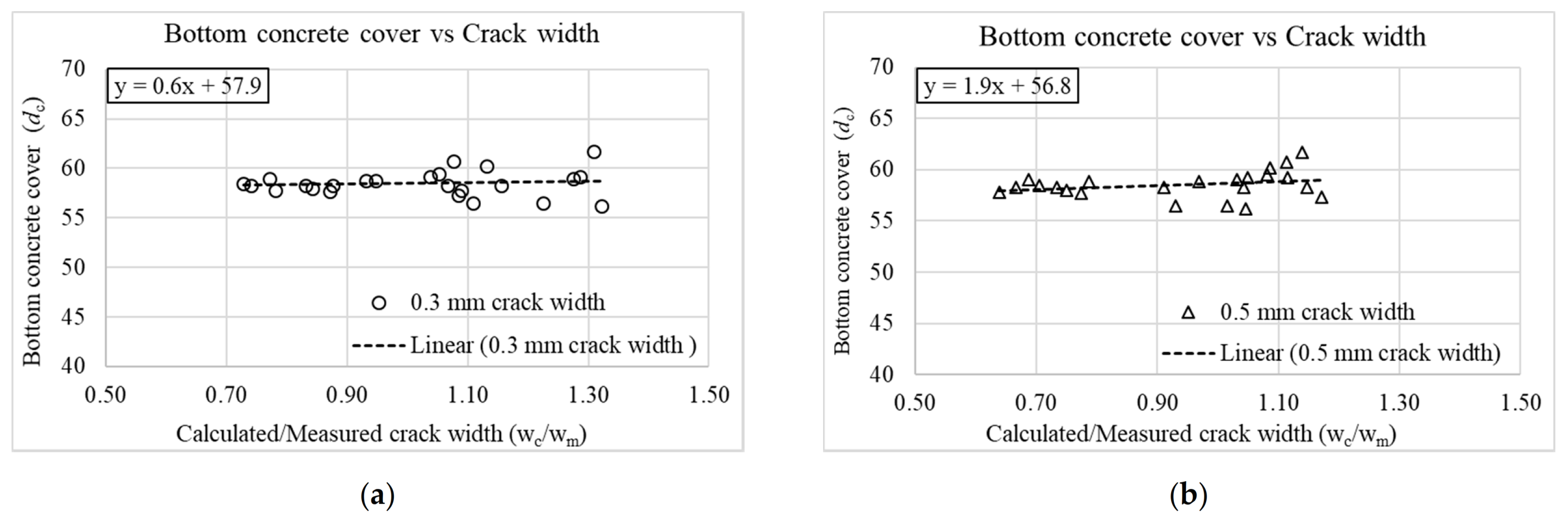

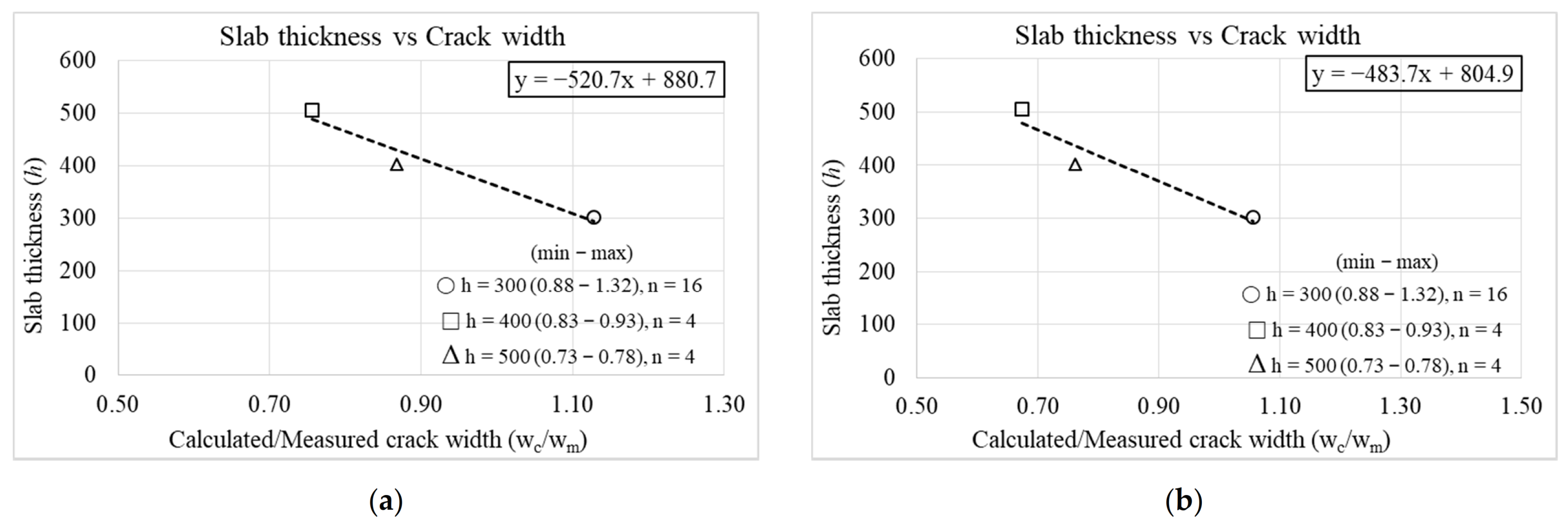

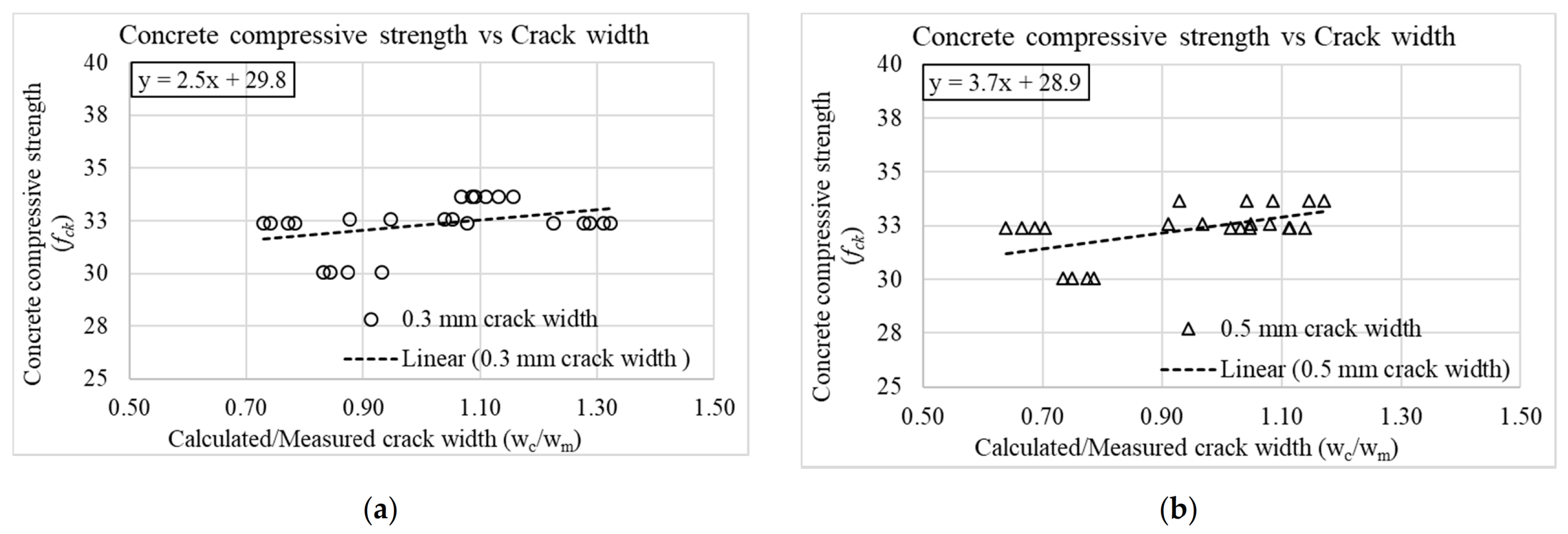

4.3. Effect of Design Variables on Crack Width

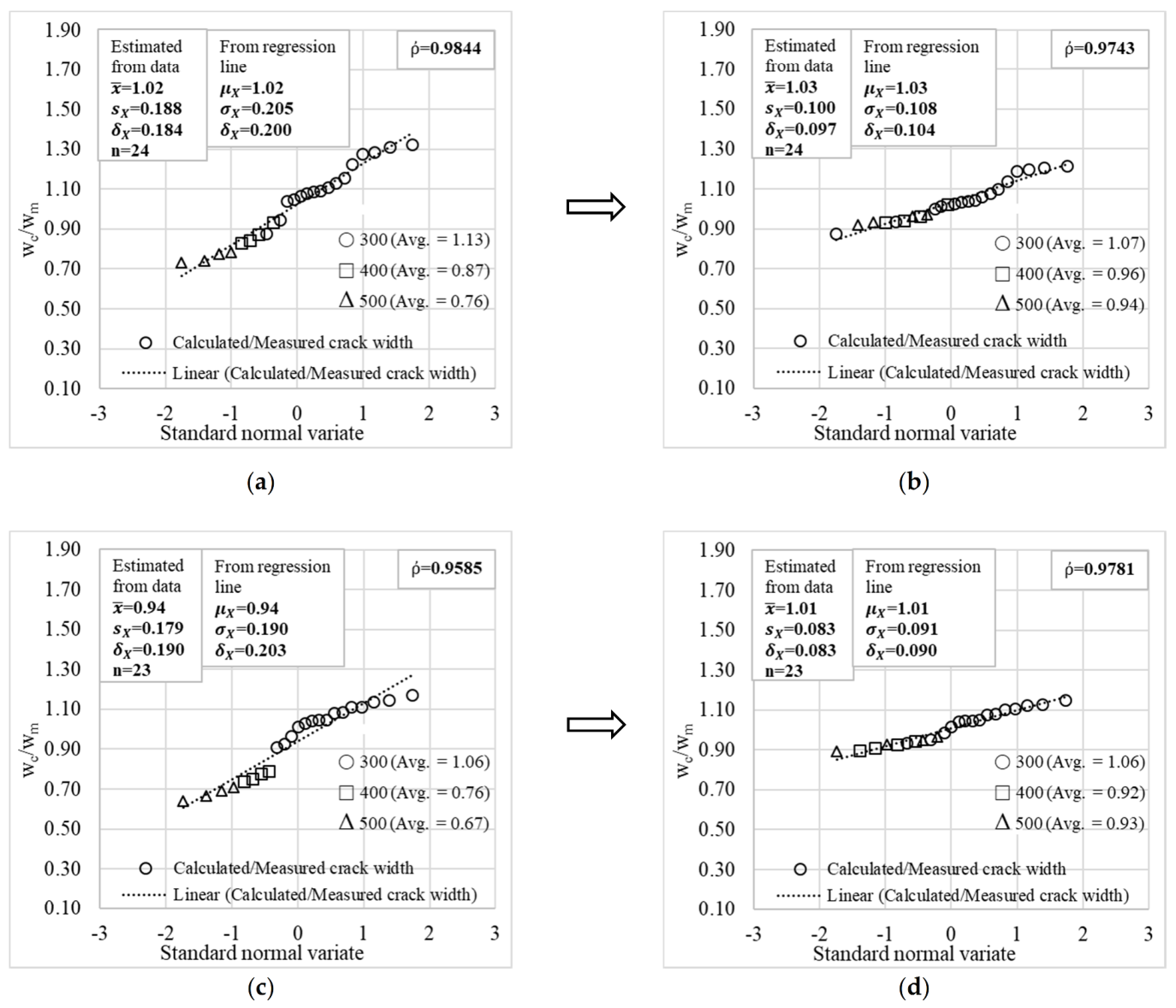

4.4. Correction Factor for Frosch’s Crack Width Estimation Equation

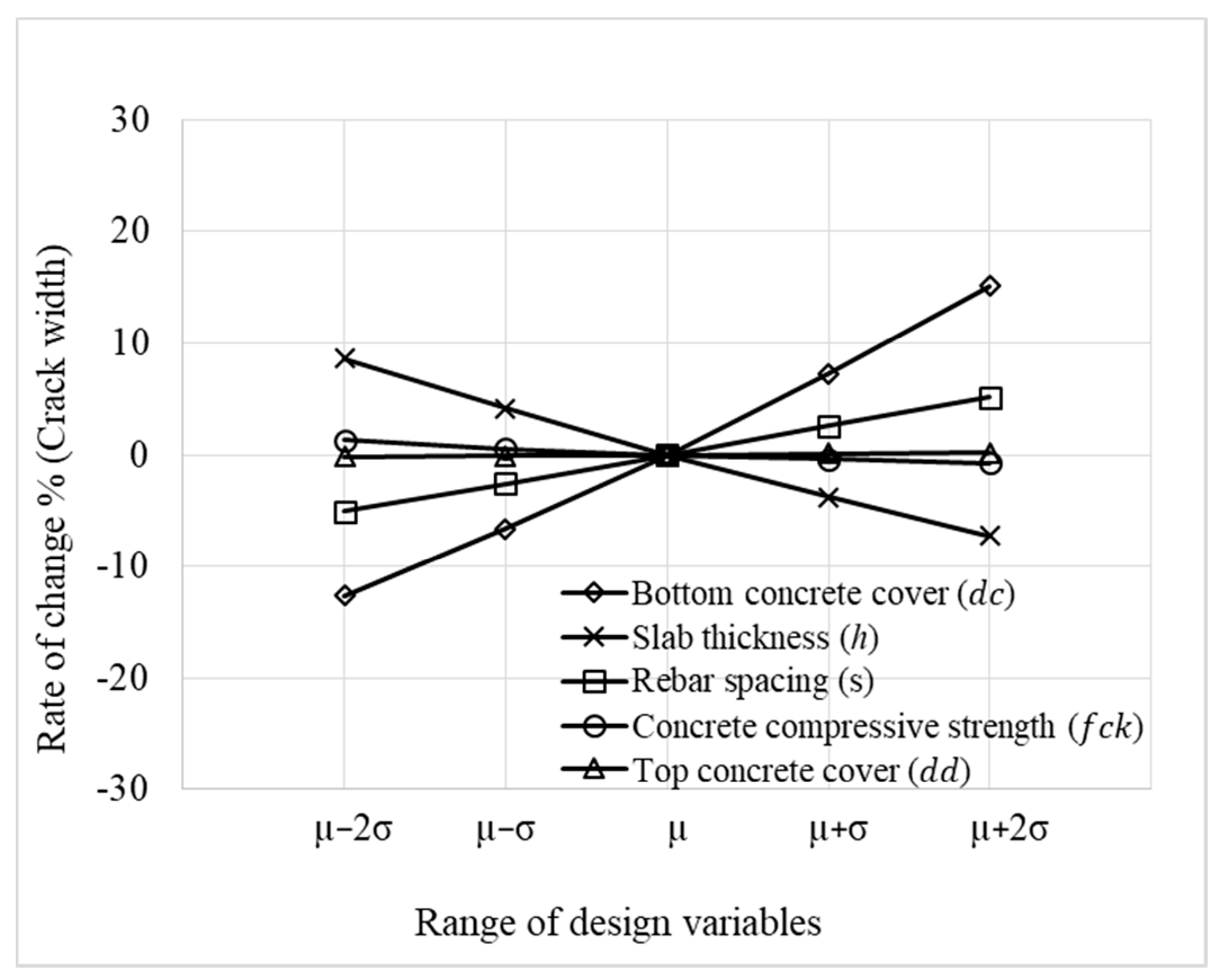

4.5. Sensitivity Analysis of Crack Width

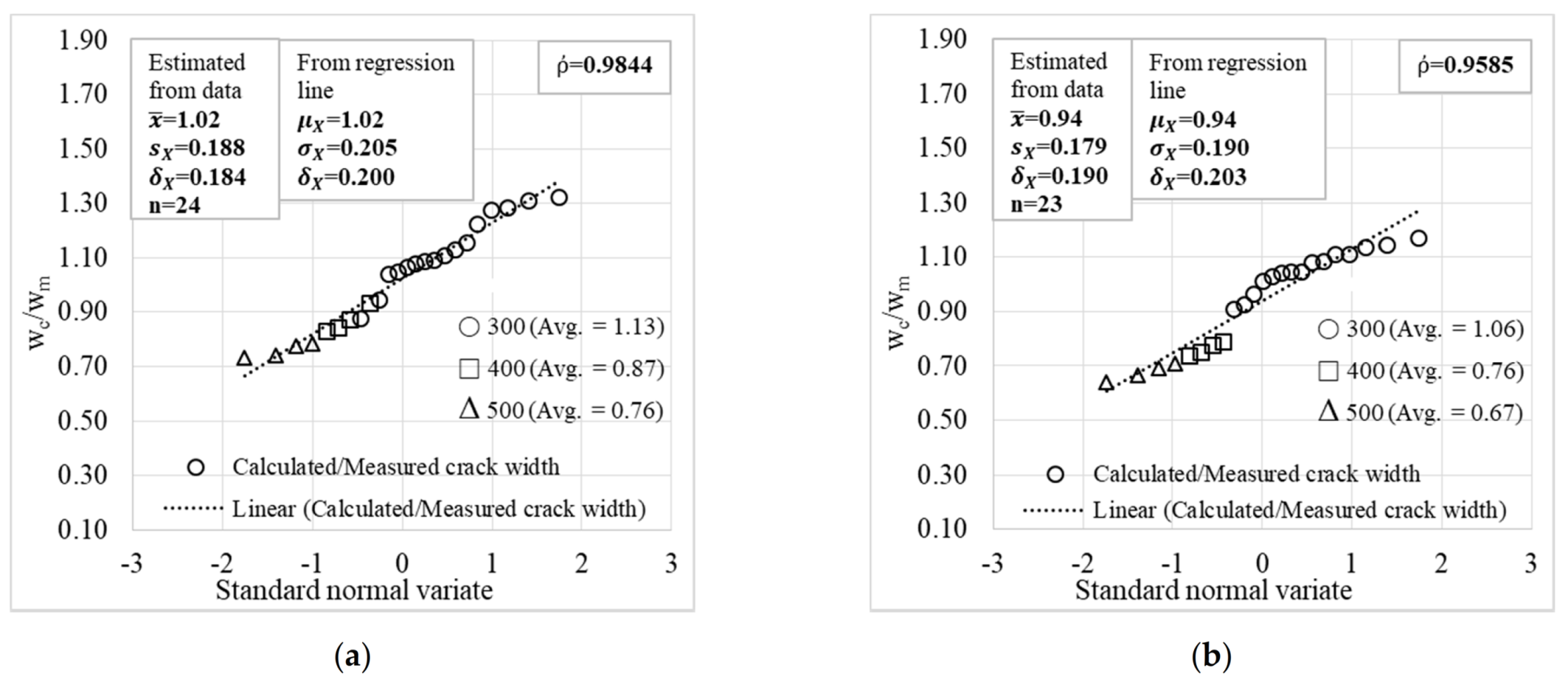

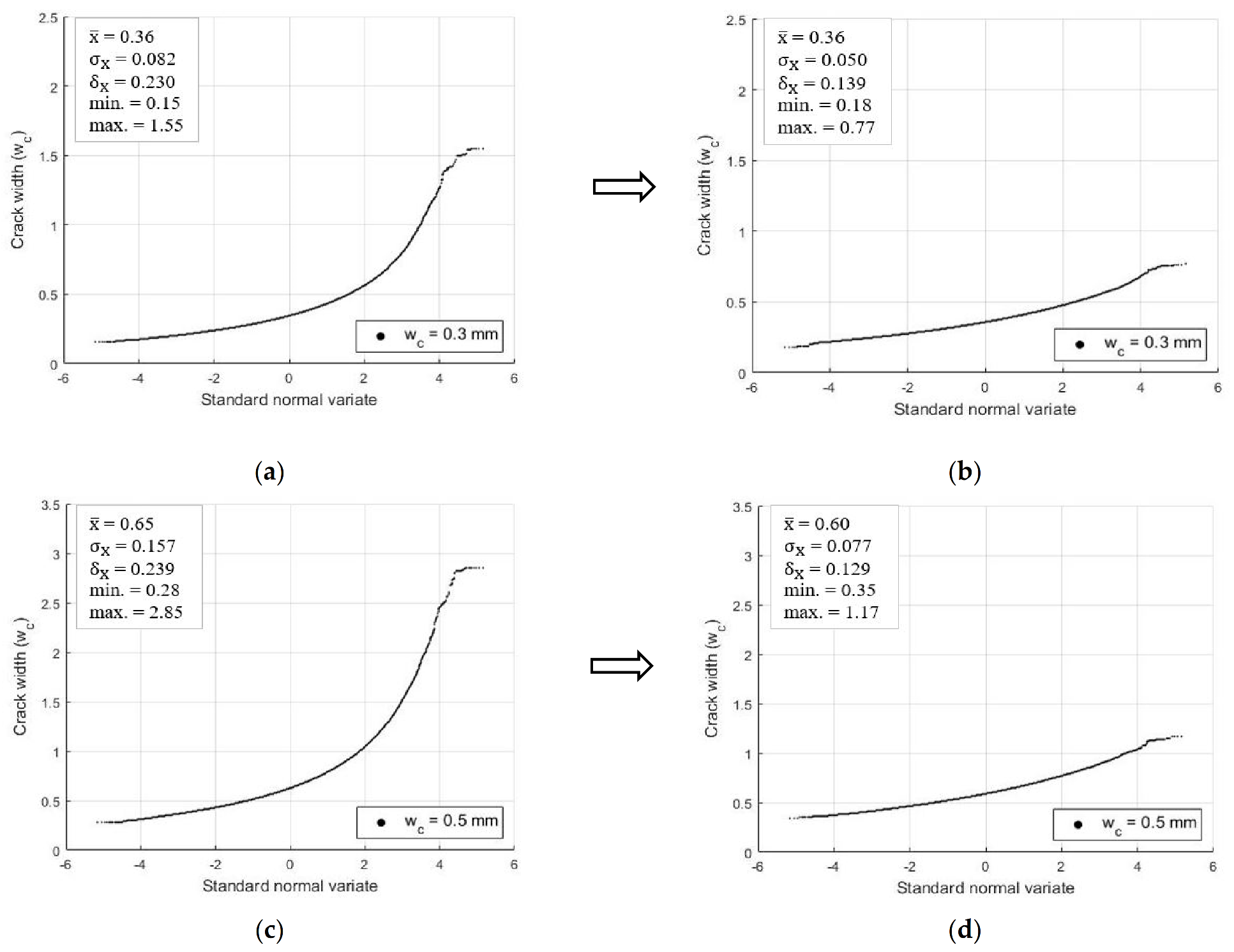

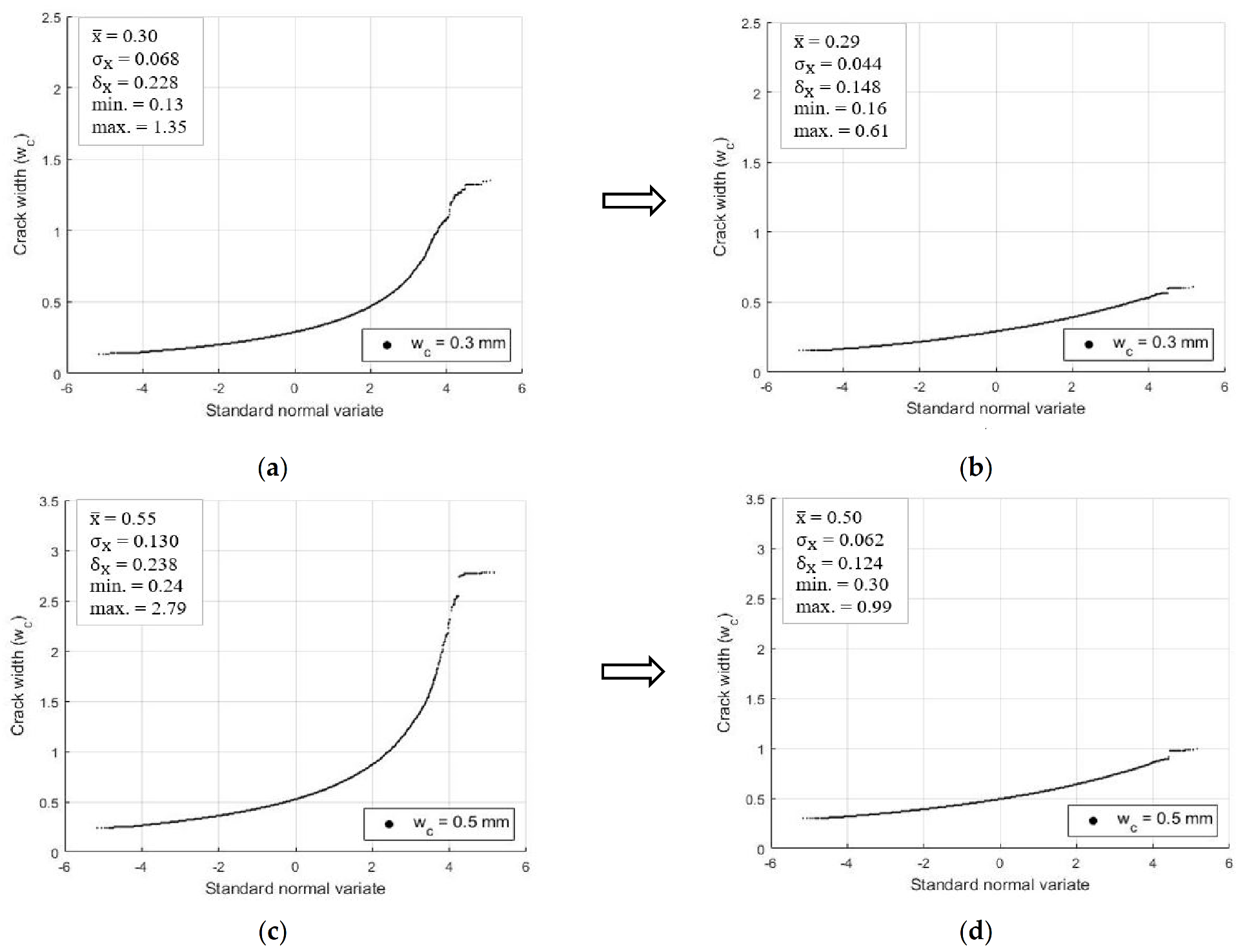

5. Probability-Based Crack Width Factors

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clark, A.P. Cracking in reinforced concrete flexural members. ACI J. Proc. 1956, 52, 851–862. [Google Scholar]

- Broms, B.B. Crack width and crack spacing in reinforced concrete members. ACI J. Proc. 1965, 62, 1237–1256. [Google Scholar]

- Gergely, P.; Lutz, L.A. Maximum crack width in reinforced concrete flexural members. Am. Concr. Inst. 1968, 20, 87–117. [Google Scholar]

- Nawy, E.G.; Blair, K.W. Further studies on flexural crack control in structural slab systems. ACI Spec. Publ. 1971, 30, 1–41. [Google Scholar]

- Beeby, A.W. The prediction of crack widths in hardened concrete. Struct. Eng. 1979, 57, 9–17. [Google Scholar]

- Balázs, G.L. Cracking analysis based on slip and bond stresses. ACI Mater. J. 1993, 90, 340–348. [Google Scholar]

- Makhlouf, H.M.; Malhas, F.A. The effect of thick concrete cover on the maximum flexural crack width under service load. ACI Struct. J. 1996, 93, 257–265. [Google Scholar]

- ACI Committee 318; Building Code Requirements for Structural Concrete: (ACI 318-95) and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 1995.

- BS 8110-2; Structural Use of Concrete, Part 2: Code of Practice for Special Circumstances. British Standard Institution: London, UK, 1985.

- Park, R.; Paulay, T. Reinforced Concrete Structures; John Wiley & Sons: New York, NY, USA, 1975. [Google Scholar]

- ACI Committee 224; 224R-01: Control of Cracking in Concrete Structures (Reapproved 2008). ACI: Farmington Hills, MI, USA, 2001.

- Colotti, V.; Spadea, G. An analytical model for crack control in reinforced concrete elements under combined forces. Cem. Concr. Compos. 2005, 27, 503–514. [Google Scholar] [CrossRef]

- Kwak, H.G.; Song, J.Y. Cracking analysis of RC members using polynomial strain distribution function. Eng. Struct. 2002, 24, 455–468. [Google Scholar] [CrossRef]

- Visintin, P.; Sturm, A.B.; Oehlers, D.J. Long- and short-term serviceability behavior of reinforced concrete beams: Mechanics models for deflections and crack widths. Struct. Concr. 2018, 19, 489–507. [Google Scholar] [CrossRef]

- Kim, S.H.; Boldoo, T.; Kim, D.Y.; Chu, I.; Woo, S.K. Probabilistic Moment Capacity Models of RC Slab Members for Underground Box Culverts. Appl. Sci. 2021, 11, 8520. [Google Scholar] [CrossRef]

- Frosch, R.J. Another look at cracking and crack control in reinforced concrete. ACI Struct. J. 1999, 96, 437–442. [Google Scholar]

- ACI Committee 318; Building Code Requirements for Structural Concrete: (ACI 318-19) and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Kaar, P.B.; Mattock, A.B. High strength bars as concrete reinforcement, Part 4, Control of cracking. J. PCA Res. Dev. Lab. 1963, 5, 15–38. [Google Scholar]

- Beeby, A.W. The prediction and control of flexural cracking in reinforced concrete members. Cracking, deflection, and ultimate load of concrete slab systems. Am. Concr. Inst. 1971, 20, 55–76. [Google Scholar]

- CEB. CEB-FIP Model. Code 90; CEB: London, UK, 1992. [Google Scholar]

- EN1992-1-1; Eurocode 2–1992, Design of Concrete Structures, Part 1.1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

| Parameter | Specimens | |||||

|---|---|---|---|---|---|---|

| SA-H16 | SA-H19 | SA-H22 | SA-H25 | SH-H19 | SK-H22 | |

| Number of specimens | 6 | 6 | 2 | 2 | 4 | 4 |

| (mm) | 80 | 80 | 80 | 80 | 80 | 80 |

| (mm) | 160 | 160 | 160 | 160 | 260 | 360 |

| (mm) | 60 | 60 | 60 | 60 | 60 | 60 |

| (mm) | 300 | 300 | 300 | 300 | 400 | 500 |

| (mm) | 240 | 240 | 240 | 240 | 340 | 440 |

| (mm) | 3000 | 3000 | 3000 | 3000 | 3000 | 3500 |

| Rebar diameter (mm) | 16 | 19 | 22 | 25 | 19 | 22 |

| Tensile reinforcement ratio (%) | 0.41 | 0.60 | 0.81 | 1.06 | 0.59 | 0.62 |

| Parameter | Specimens | |||||

|---|---|---|---|---|---|---|

| SA-H16 | SA-H19 | SA-H22 | SA-H25 | SH-H19 | SK-H22 | |

| Experimental data (MPa) | 31.5, 34.2, 35.2 | 30.3, 32.5, 34.4 | 33.4, 32.3, 32.2 | 30.1, 31.5, 28.6 | 33.7, 32.1, 31.5 | |

| Average strength (MPa) | 33.7 | 32.4 | 32.6 | 30.1 | 32.4 | |

| Specimen Name | Thickness | Rebar Stress | Bottom Concrete Cover | Rebar Spacing | Neutral Axis Factor | Calculated Crack Width Using Measured Load | Calculated-To- Measured Crack Width Ratio |

|---|---|---|---|---|---|---|---|

| H | |||||||

| Unit: | (mm) | (MPa) | (mm) | (mm) | - | (mm) | - |

| SA-H16 (PL)-1 | 297.8 | 216.1 | 57.8 | 200 | 1.31 | 0.33 | 1.09 |

| SA-H16 (OP)-1 | 303.5 | 229.5 | 58.3 | 200 | 1.31 | 0.35 | 1.16 |

| SA-H16 (PR)-1 | 304.7 | 217.6 | 57.3 | 200 | 1.30 | 0.33 | 1.08 |

| SA-H16 (PL)-2 | 300.0 | 223.1 | 56.5 | 200 | 1.30 | 0.33 | 1.11 |

| SA-H16 (OP)-2 | 301.7 | 211.2 | 58.3 | 200 | 1.31 | 0.32 | 1.07 |

| SA-H16 (PR)-2 | 304.0 | 220.8 | 60.2 | 200 | 1.32 | 0.34 | 1.13 |

| SA-H19 (PL)-1 | 297.3 | 242.8 | 56.5 | 200 | 1.32 | 0.37 | 1.22 |

| SA-H19 (OP)-1 | 302.5 | 206.2 | 60.7 | 200 | 1.34 | 0.32 | 1.08 |

| SA-H19 (PR)-1 | 305.7 | 250.9 | 59.2 | 200 | 1.32 | 0.39 | 1.29 |

| SA-H19 (PL)-2 | 301.0 | 264.0 | 56.2 | 200 | 1.31 | 0.40 | 1.32 |

| SA-H19 (OP)-2 | 301.5 | 248.1 | 61.7 | 200 | 1.35 | 0.39 | 1.31 |

| SA-H19 (PR)-2 | 304.5 | 249.1 | 59.0 | 200 | 1.32 | 0.38 | 1.28 |

| SA-H22 (PL)-1 | 300.3 | 201.0 | 59.5 | 200 | 1.35 | 0.32 | 1.05 |

| SA-H22 (PL)-2 | 297.8 | 198.5 | 59.2 | 200 | 1.35 | 0.31 | 1.04 |

| SA-H25 (PL)-1 | 298.7 | 167.2 | 58.3 | 200 | 1.36 | 0.26 | 0.88 |

| SA-H25 (PL)-2 | 303.8 | 180.9 | 58.8 | 200 | 1.35 | 0.28 | 0.95 |

| SH-H19 (PL)-1 | 401.5 | 217.5 | 58.0 | 150 | 1.23 | 0.25 | 0.84 |

| SH-H19 (PR)-1 | 405.7 | 214.3 | 58.3 | 150 | 1.22 | 0.25 | 0.83 |

| SH-H19 (PL)-2 | 398.0 | 225.3 | 57.7 | 150 | 1.23 | 0.26 | 0.87 |

| SH-H19 (PR)-2 | 403.7 | 238.6 | 58.8 | 150 | 1.23 | 0.28 | 0.93 |

| SK-H22 (PL)-1 | 507.3 | 199.3 | 58.3 | 150 | 1.17 | 0.22 | 0.74 |

| SK-H22 (PR)-1 | 505.3 | 206.2 | 59.0 | 150 | 1.18 | 0.23 | 0.77 |

| SK-H22 (PL)-2 | 504.8 | 211.2 | 57.8 | 150 | 1.17 | 0.23 | 0.78 |

| SK-H22 (PR)-2 | 505.0 | 195.8 | 58.5 | 150 | 1.17 | 0.22 | 0.73 |

| 0.31 | 1.02 | ||||||

| Standard deviation, | 0.056 | 0.188 | |||||

| cov, δ | 0.184 | 0.184 | |||||

| Maximum | 0.40 | 1.32 | |||||

| Minimum | 0.22 | 0.73 | |||||

| Number of measurements | 24 | 24 |

| Specimen Name | Thickness | Rebar Stress | Bottom Concrete Cover | Rebar Spacing | Neutral Axis Factor | Calculated Crack Width Using Measured Load | Calculated-To- Measured Crack Width Ratio |

|---|---|---|---|---|---|---|---|

| H | |||||||

| Unit: | (mm) | (MPa) | (mm) | (mm) | - | (mm) | - |

| SA-H16 (PL)-1 | 297.8 | - | 57.8 | 200 | 1.31 | - | - |

| SA-H16 (OP)-1 | 303.5 | 379.2 | 58.3 | 200 | 1.31 | 0.57 | 1.15 |

| SA-H16 (PR)-1 | 304.7 | 391.6 | 57.3 | 200 | 1.30 | 0.59 | 1.17 |

| SA-H16 (PL)-2 | 300.0 | 311.6 | 56.5 | 200 | 1.30 | 0.46 | 0.93 |

| SA-H16 (OP)-2 | 301.7 | 343.9 | 58.3 | 200 | 1.31 | 0.52 | 1.04 |

| SA-H16 (PR)-2 | 304.0 | 353.2 | 60.2 | 200 | 1.32 | 0.54 | 1.09 |

| SA-H19 (PL)-1 | 297.3 | 335.6 | 56.5 | 200 | 1.32 | 0.51 | 1.02 |

| SA-H19 (OP)-1 | 302.5 | 355.5 | 60.7 | 200 | 1.34 | 0.56 | 1.11 |

| SA-H19 (PR)-1 | 305.7 | 362.4 | 59.2 | 200 | 1.32 | 0.56 | 1.11 |

| SA-H19 (PL)-2 | 301.0 | 348.3 | 56.2 | 200 | 1.31 | 0.52 | 1.05 |

| SA-H19 (OP)-2 | 301.5 | 359.9 | 61.7 | 200 | 1.35 | 0.57 | 1.14 |

| SA-H19 (PR)-2 | 304.5 | 335.8 | 59.0 | 200 | 1.32 | 0.52 | 1.03 |

| SA-H22 (PL)-1 | 300.3 | 344.3 | 59.5 | 200 | 1.35 | 0.54 | 1.08 |

| SA-H22 (PL)-2 | 297.8 | 334.4 | 59.2 | 200 | 1.35 | 0.52 | 1.05 |

| SA-H25 (PL)-1 | 298.7 | 289.8 | 58.3 | 200 | 1.36 | 0.46 | 0.91 |

| SA-H25 (PL)-2 | 303.8 | 308.3 | 58.8 | 200 | 1.35 | 0.48 | 0.97 |

| SH-H19 (PL)-1 | 401.5 | 322.3 | 58.0 | 150 | 1.23 | 0.37 | 0.75 |

| SH-H19 (PR)-1 | 405.7 | 315.7 | 58.3 | 150 | 1.22 | 0.37 | 0.73 |

| SH-H19 (PL)-2 | 398.0 | 333.3 | 57.7 | 150 | 1.23 | 0.39 | 0.77 |

| SH-H19 (PR)-2 | 403.7 | 335.9 | 58.8 | 150 | 1.23 | 0.39 | 0.79 |

| SK-H22 (PL)-1 | 507.3 | 298.7 | 58.3 | 150 | 1.17 | 0.33 | 0.67 |

| SK-H22 (PR)-1 | 505.3 | 306.2 | 59.0 | 150 | 1.18 | 0.34 | 0.69 |

| SK-H22 (PL)-2 | 504.8 | 287.7 | 57.8 | 150 | 1.17 | 0.32 | 0.64 |

| SK-H22 (PR)-2 | 505.0 | 315.4 | 58.5 | 150 | 1.17 | 0.35 | 0.70 |

| 0.47 | 0.94 | ||||||

| Standard deviation, | 0.089 | 0.179 | |||||

| cov, δ | 0.190 | 0.190 | |||||

| Maximum | 0.59 | 1.17 | |||||

| Minimum | 0.32 | 0.64 | |||||

| Number of measurements | 23 | 23 |

| Variables | 0.3 mm Crack Width | 0.5 mm Crack Width | ||

|---|---|---|---|---|

| Original Equation (1) | Modified Equation (3) | Original Equation (1) | Modified Equation (3) | |

| 1.02 | 1.03 | 0.94 | 1.01 | |

| 0.188 | 0.100 | 0.179 | 0.083 | |

| cov, δ | 0.184 | 0.097 | 0.190 | 0.083 |

| Maximum | 1.32 | 1.22 | 1.17 | 1.15 |

| Minimum | 0.73 | 0.87 | 0.64 | 0.89 |

| Specimen Name | Thickness | Rebar Stress | Bottom Concrete Cover | Rebar Spacing | Neutral Axis Factor | Calculated Crack Width Using Measured Load | Calculated-To- Measured Crack Width Ratio | Ratio | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| h | |||||||||||||||

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | 1st | 2nd | 3rd | 2nd/ 1st | 3rd/ 1st | |||||

| Unit: | (mm) | (MPa) | (mm) | (mm) | - | (mm) | - | - | |||||||

| SA-H16 (PR)-2 | 304.0 | 220.8 | 246.9 | 250.9 | 60.2 | 200 | 1.32 | 0.33 | 0.33 | 0.33 | 1.08 | 1.18 | 1.19 | 1.09 | 1.11 |

| SA-H19 (PR)-1 | 305.7 | 250.9 | 270.4 | 283.0 | 59.2 | 200 | 1.32 | 0.33 | 0.34 | 0.34 | 1.20 | 1.27 | 1.32 | 1.06 | 1.10 |

| SA-H19 (PR)-2 | 304.5 | 249.1 | 251.9 | 275.7 | 59.0 | 200 | 1.32 | 0.33 | 0.33 | 0.34 | 1.19 | 1.20 | 1.29 | 1.01 | 1.08 |

| SA-H22 (PL)-1 | 300.3 | 201.0 | 221.3 | - | 59.5 | 200 | 1.35 | 0.33 | 0.33 | - | 1.01 | 1.09 | - | 1.08 | - |

| SH-H19 (PL)-1 | 217.5 | 217.5 | 242.4 | 246.7 | 58.0 | 150 | 1.23 | 0.33 | 0.33 | 0.33 | 0.94 | 1.02 | 1.04 | 1.09 | 1.11 |

| SH-H19 (PR)-1 | 214.3 | 214.3 | 239.6 | 246.7 | 58.3 | 150 | 1.22 | 0.33 | 0.33 | 0.33 | 0.93 | 1.02 | 1.04 | 1.09 | 1.12 |

| SH-H19 (PL)-2 | 225.3 | 225.3 | 237.6 | 259.2 | 57.7 | 150 | 1.23 | 0.33 | 0.33 | 0.33 | 0.96 | 1.00 | 1.08 | 1.04 | 1.12 |

| SH-H19 (PR)-2 | 238.6 | 238.6 | 256.3 | 261.3 | 58.8 | 150 | 1.23 | 0.33 | 0.34 | 0.34 | 1.02 | 1.08 | 1.10 | 1.06 | 1.08 |

| SK-H22 (PL)-1 | 199.3 | 199.3 | 213.7 | 283.3 | 58.3 | 150 | 1.17 | 0.32 | 0.31 | 0.33 | 0.93 | 0.98 | 1.23 | 1.06 | 1.32 |

| SK-H22 (PR)-1 | 206.2 | 206.2 | 217.1 | 224.9 | 59.0 | 150 | 1.18 | 0.32 | 0.32 | 0.32 | 0.96 | 1.00 | 1.03 | 1.04 | 1.07 |

| SK-H22 (PL)-2 | 211.2 | 211.2 | 240.1 | 253.6 | 57.8 | 150 | 1.17 | 0.31 | 0.32 | 0.32 | 0.97 | 1.07 | 1.12 | 1.11 | 1.16 |

| SK-H22 (PR)-2 | 195.8 | 195.8 | 227.3 | - | 58.5 | 150 | 1.17 | 0.32 | 0.32 | - | 0.92 | 1.03 | - | 1.13 | - |

| 0.32 | 0.33 | 0.33 | 1.01 | 1.08 | 1.14 | 1.07 | 1.13 | ||||||||

| Standard deviation, | 0.007 | 0.008 | 0.008 | 0.097 | 0.091 | 0.107 | 0.033 | 0.074 | |||||||

| cov, δ | 0.021 | 0.026 | 0.024 | 0.097 | 0.085 | 0.094 | 0.031 | 0.066 | |||||||

| Maximum | 0.33 | 0.34 | 0.34 | 1.20 | 1.27 | 1.32 | 1.13 | 1.32 | |||||||

| Minimum | 0.31 | 0.31 | 0.32 | 0.92 | 0.98 | 1.03 | 1.01 | 1.07 | |||||||

| Specimen Name | Thickness | Rebar Stress | Bottom Concrete Cover | Rebar Spacing | Neutral Axis Factor | Calculated Crack Width Using Measured Load | Calculated-To- Measured Crack Width Ratio | Ratio | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| h | |||||||||||||||

| 1st | 2nd | 3rd | 1st | 2nd | 3rd | 1st | 2nd | 3rd | 2nd/ 1st | 3rd/ 1st | |||||

| Unit: | (mm) | (MPa) | (mm) | (mm) | - | (mm) | - | - | |||||||

| SA-H16 (PR)-2 | 304.0 | 353.2 | 393.4 | 415.5 | 60.2 | 200 | 1.32 | 0.50 | 0.51 | 0.51 | 1.08 | 1.18 | 1.23 | 1.09 | 1.14 |

| SA-H19 (PR)-1 | 305.7 | 362.4 | 377.7 | 404.2 | 59.2 | 200 | 1.32 | 0.50 | 0.50 | 0.51 | 1.11 | 1.15 | 1.21 | 1.03 | 1.09 |

| SA-H19 (PR)-2 | 304.5 | 335.8 | 359.6 | 379.2 | 59 | 200 | 1.32 | 0.50 | 0.50 | 0.50 | 1.04 | 1.10 | 1.15 | 1.06 | 1.10 |

| SA-H22 (PL)-1 | 300.3 | 344.3 | 347.5 | 363.6 | 59.5 | 200 | 1.35 | 0.51 | 0.51 | 0.51 | 1.07 | 1.08 | 1.12 | 1.01 | 1.04 |

| SH-H19 (PL)-1 | 401.5 | 322.3 | 331.6 | 355.1 | 58 | 150 | 1.23 | 0.51 | 0.50 | 0.50 | 0.91 | 0.93 | 0.98 | 1.02 | 1.08 |

| SH-H19 (PR)-1 | 405.7 | 315.7 | 324.2 | 332.7 | 58.3 | 150 | 1.22 | 0.51 | 0.51 | 0.51 | 0.90 | 0.92 | 0.93 | 1.02 | 1.04 |

| SH-H19 (PL)-2 | 398.0 | 333.3 | 351.3 | 358.5 | 57.7 | 150 | 1.23 | 0.50 | 0.50 | 0.50 | 0.93 | 0.97 | 0.98 | 1.04 | 1.06 |

| SH-H19 (PR)-2 | 403.7 | 335.9 | 340.1 | 350.8 | 58.8 | 150 | 1.23 | 0.51 | 0.51 | 0.51 | 0.94 | 0.95 | 0.98 | 1.01 | 1.04 |

| SK-H22 (PL)-1 | 507.3 | 298.7 | 303.9 | 306.4 | 58.3 | 150 | 1.17 | 0.49 | 0.49 | 0.49 | 0.92 | 0.94 | 0.94 | 1.01 | 1.02 |

| SK-H22 (PR)-1 | 505.3 | 306.2 | 307.8 | 321.2 | 59 | 150 | 1.18 | 0.49 | 0.49 | 0.49 | 0.94 | 0.95 | 0.98 | 1.00 | 1.04 |

| SK-H22 (PL)-2 | 504.8 | 287.7 | 315.2 | 341.6 | 57.8 | 150 | 1.17 | 0.50 | 0.49 | 0.48 | 0.89 | 0.96 | 1.02 | 1.08 | 1.15 |

| SK-H22 (PR)-2 | 505.0 | 315.4 | 328.3 | - | 58.5 | 150 | 1.17 | 0.49 | 0.49 | - | 0.96 | 1.00 | - | 1.03 | - |

| 0.50 | 0.50 | 0.50 | 0.98 | 1.01 | 1.05 | 1.03 | 1.07 | ||||||||

| Standard deviation, | 0.007 | 0.009 | 0.010 | 0.079 | 0.093 | 0.109 | 0.027 | 0.043 | |||||||

| cov, δ | 0.013 | 0.018 | 0.021 | 0.081 | 0.092 | 0.104 | 0.027 | 0.040 | |||||||

| Maximum | 0.51 | 0.51 | 0.51 | 1.11 | 1.18 | 1.23 | 1.09 | 1.15 | |||||||

| Minimum | 0.49 | 0.49 | 0.48 | 0.89 | 0.92 | 0.93 | 1.00 | 1.02 | |||||||

| Location | Variables | Nominal | Mean/Median | cov/Zeta | |

|---|---|---|---|---|---|

| 27 MPa | 30.4 | 0.222 | Normal | ||

| ) | - | 0.998 | 0.035 | Normal | |

| ) | - | 1.004 | 0.028 | Normal | |

| Positive moment region | ) | 60 mm | 71.5 | 0.065 | Normal |

| 80 mm | 78.6 | 0.068 | Log-Normal | ||

| Negative moment region | ) | 80 mm | 78.6 | 0.068 | Log-Normal |

| 60 mm | 71.5 | 0.065 | Normal |

| Variables | Rate of Change, (%) | ||||

|---|---|---|---|---|---|

| µ − 2σ | µ − σ | µ | µ + σ | µ + 2σ | |

| (mm) | −12.65 | −6.61 | 0.00 | 7.23 | 15.15 |

| (mm) | 8.64 | 4.12 | 0.00 | −3.77 | −7.24 |

| (mm) | −5.08 | −2.55 | 0.00 | 2.58 | 5.17 |

| (MPa) | 1.31 | 0.54 | 0.00 | −0.42 | −0.76 |

| (mm) | −0.17 | −0.08 | 0.00 | 0.08 | 0.17 |

| Equation | Variables | Mean/Median | cov/Zeta | |

|---|---|---|---|---|

| Original equation (Equation (1)) | (crack width biasness) (0.3) | 1.02 | 0.184 | Normal |

| (crack width biasness) (0.5) | 0.94 | 0.190 | Normal | |

| Modified equation (Equation (3)) | (crack width biasness) (0.3) | 1.03 | 0.097 | Normal |

| (crack width biasness) (0.5) | 1.01 | 0.083 | Normal |

| Thickness, h (mm) | ||||

|---|---|---|---|---|

| 993 | 1324 | 1910 | 2578 | |

| 300 | 12 | 20 | 4 | 1 |

| 350 | 4 | 16 | 8 | 1 |

| 400 | 4 | 4 | 4 | 1 |

| 500 | 1 | 1 | 1 | 1 |

| Crack Width Factor, | The Occurrence Probability of the Design Crack | |||

|---|---|---|---|---|

| 0.3 mm | 0.5 mm | 0.3 mm | 0.5 mm | |

| 1.00 | −1.24 | −1.27 | 0.8932 | 0.8973 |

| 1.25 | 0.21 | 0.30 | 0.4159 | 0.3824 |

| 1.50 | 1.18 | 1.34 | 0.1184 | 0.0896 |

| 1.75 | 1.88 | 2.09 | 0.0303 | 0.0184 |

| 2.00 | 2.40 | 2.65 | 0.0083 | 0.0041 |

| Crack Width Factor, | The Occurrence Probability of Design Crack | |||

|---|---|---|---|---|

| 0.3 mm | 0.5 mm | 0.3 mm | 0.5 mm | |

| 1.00 | 0.13 | 0.01 | 0.4486 | 0.4948 |

| 1.25 | 1.49 | 1.64 | 0.0682 | 0.0506 |

| 1.50 | 2.40 | 2.72 | 0.0083 | 0.0032 |

| 1.75 | 3.04 | 3.50 | 0.0012 | 0.0002 |

| 2.00 | 3.52 | 4.08 | 0.0002 | 0.00002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-H.; Shah, S.H.A.; Woo, S.-K.; Chu, I.; Sim, C. Probability-Based Crack Width Estimation Model for Flexural Members of Underground RC Box Culverts. Appl. Sci. 2022, 12, 2063. https://doi.org/10.3390/app12042063

Kim S-H, Shah SHA, Woo S-K, Chu I, Sim C. Probability-Based Crack Width Estimation Model for Flexural Members of Underground RC Box Culverts. Applied Sciences. 2022; 12(4):2063. https://doi.org/10.3390/app12042063

Chicago/Turabian StyleKim, Sang-Hyo, Syed Haider Ali Shah, Sang-Kyun Woo, Inyeop Chu, and Chungwook Sim. 2022. "Probability-Based Crack Width Estimation Model for Flexural Members of Underground RC Box Culverts" Applied Sciences 12, no. 4: 2063. https://doi.org/10.3390/app12042063

APA StyleKim, S.-H., Shah, S. H. A., Woo, S.-K., Chu, I., & Sim, C. (2022). Probability-Based Crack Width Estimation Model for Flexural Members of Underground RC Box Culverts. Applied Sciences, 12(4), 2063. https://doi.org/10.3390/app12042063