Abstract

Augmented Reality (AR) has gradually become a mainstream technology enabling Industry 4.0 and its maturity has also grown over time. AR has been applied to support different processes on the shop-floor level, such as assembly, maintenance, etc. As various processes in manufacturing require high quality and near-zero error rates to ensure the demands and safety of end-users, AR can also equip operators with immersive interfaces to enhance productivity, accuracy and autonomy in the quality sector. However, there is currently no systematic review paper about AR technology enhancing the quality sector. The purpose of this paper is to conduct a systematic literature review (SLR) to conclude about the emerging interest in using AR as an assisting technology for the quality sector in an industry 4.0 context. Five research questions (RQs), with a set of selection criteria, are predefined to support the objectives of this SLR. In addition, different research databases are used for the paper identification phase following the Preferred Reporting Items for Systematic Reviews and Meta-Analysis (PRISMA) methodology to find the answers for the predefined RQs. It is found that, in spite of staying behind the assembly and maintenance sector in terms of AR-based solutions, there is a tendency towards interest in developing and implementing AR-assisted quality applications. There are three main categories of current AR-based solutions for quality sector, which are AR-based apps as a virtual Lean tool, AR-assisted metrology and AR-based solutions for in-line quality control. In this SLR, an AR architecture layer framework has been improved to classify articles into different layers which are finally integrated into a systematic design and development methodology for the development of long-term AR-based solutions for the quality sector in the future.

1. Introduction

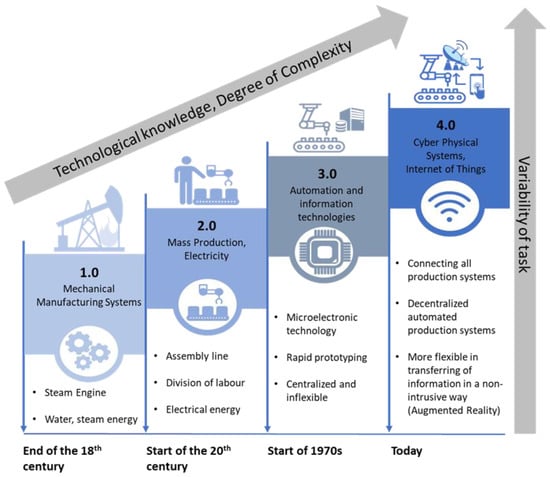

The industry 4.0 revolution has enabled many improvements and benefits for manufacturing as well as service systems (see Figure 1). However, the rapid and remarkable changes that appeared in manufacturing also led to higher requirements in technological knowledge, increasing the degree of task complexity or variability of tasks on the shop-floor level for the operators [1,2,3]. This leads to the demands of systems that intensively adopt the enabling technologies of industry 4.0 to reduce those burdens for the operators.

Figure 1.

Industrial revolutions and their characteristics based on [1].

The latest key facilitating technologies of Industry 4.0 are Advanced Simulation, Advanced robotics, Industrial “Internet of Things” (IoT), Cloud computing, Additive manufacturing, Horizontal and vertical system integration, Cybersecurity, Big Data and analytics, Digital-twin, Blockchain, Knowledge Graph and Augmented Reality (AR) [4].

Besides these key technologies, there are some fundamental technologies such as sensors and actuators, Radio Frequency Identification (RFID) and Real-Time Locating Solution (RTLS) technologies, etc. to support them. For the long-term adaptation progress of Industry 4.0, seven design principles need to be considered when designing and developing a solution in general and for manufacturing specifically [5]. These principles are real-time data management, interoperability, virtualization, decentralization, agility, service orientation and integrated business processes. An important aspect of Industry 4.0 is the synthesis of the physical environment and the virtual elements [6], which can be achieved by the advantages of AR together with the Cyber-Physical System (CPS).

In the last few years, Augmented Reality (AR) has been constantly adapted by key companies on industrial innovation, such as General Electrics, Airbus [7] and Boeing. It has been employed for productivity improvement, product and process quality advancement (reducing error rates) [8] or higher ergonomics in diverse manufacturing phases to boost the transformation of Industry 4.0. AR studies in the quality sector have emerged, and have shown potential results in enhancing human performance in technical quality control tasks, supporting the Total quality management (TQM) and autonomizing operators’ decision making. Despite the mentioned advantages, there are still limited examples of AR’s concrete implementation in manufacturing, especially for the quality sector.

For this reason, the main objective of this paper is to conduct a state-of-the-art review of AR systematically in terms of technology used, applications and limitations, focusing on the quality context. This is to prepare for the digital transformation of Industry 4.0, which also leads to the change in the quality sector, known as Quality 4.0, and the adaptation of AR for quality control. However, not only the studies focusing on quality context but also the other relevant studies in the manufacturing context are considered to build a long-term roadmap for AR-based applications supporting Quality 4.0. To achieve this, a Systematic Literature Review (SLR) was performed to assure the reproducibility and scalability of the study, together with the objectivity of the results [9]. An investigation of the status of AR-based manufacturing applications on the shop-floor level in the context of Industry 4.0 was carried out to give a holistic view about future challenges and to propose roadmaps to implement AR technology for the quality control sector in the short term and Quality 4.0 in the long term.

The paper is structured in four sections. Section 1 introduces the project, AR technology and Quality 4.0. Section 2 describes the methodology applied for the SLR. Section 3 reports on the results and answers the research questions (RQs) to provide a holistic view about the current AR-based manufacturing in general and AR-based quality control in particular. The final Section 4 concludes and proposes future works.

1.1. Augmented Reality (AR)

From a technical point of view, AR is a technology superimposing digital, computer-generated information onto the physical world to enrich humans’ perspectives about the surrounding environment. This innovates regarding the interaction of humans with digital information and the real world. There are different types of augmented information, which are visual augmentation [8], audio [10], haptic feedback [11] and multimodal feedback [12]. AR applications based on visual augmentation are currently dominant in the manufacturing context. However, there is an emerging interest in multimodal AR applications, which mainly implement visual augmentation with another sensing feedback.

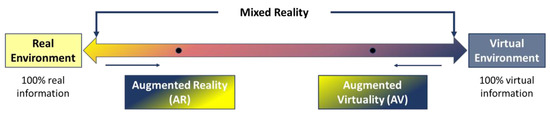

Although the research interest in AR technology has rapidly evolved and been intensively investigated over the past 20 years, the first immersive reality prototype can be dated back to 1968. In that year, the first head-mounted display (HMD) device connecting to the computer, which provided the earliest of humankind’s experience into augmented reality named “Sword of Damocles”, was invented by Ivan Sutherland [13]. The way humans interact with industrial AR today is influenced by this invention. However, the term Augmented Reality was first officially formulated years later in 1992 by Thomas Caudell, who was a Boeing researcher. He implemented a heads-up display (HUD) application to demonstrate his idea of designing and prototyping an application to support the manual manufacturing process [14]. In 1996, immersive reality was classified by different levels of immersive experience, which depends on the type of dominant content—reality information or virtual information—and was introduced into the Reality-Virtuality Continuum (RV continuum) by Milgram et al. [15] as shown in Figure 2.

Figure 2.

Reality-Virtuality Continuum adapted from [15].

One year later, Azuma defined the three main technical characteristics of AR based on its technology, which are combining real and virtual objects, interacting with real/virtual objects in real-time and registering (aligning) virtual objects with real objects [16].

Technically, a general AR system is constructed of software built on a selection of four fundamental hardware components: a processing unit, a tracking device, a display device and an input device. The processing unit creates augmentation models, controls devices’ connections and adjusts the position of superimposed information into the real world with respect to the pose and position of the user by employing the information coming from a tracking device. The tracking device is used to track the exact position and orientation of the user to align/register the augmentations accurately to the desired positions. This device usually consists of at least one element of image capture (a Charge-Coupled Device CCD, stereo, or depth-sensing camera Kinect) [17]. Regarding the tracking technology of AR, depending on the selected tracking devices and tracking methods, it can be classified into three groups: computer vision-based tracking (CV-based tracking), sensor-based tracking and hybrid tracking. The input device is used to obtain the stimulation of the environment or users to trigger the augmentation functionalities. However, the input device is optional because there are some built-in input methods integrated with display devices, especially HMD and HHD. In some cases, the activating elements (images, GPS positions, sensor values, markers, etc.) are pre-defined, thus an input device is not essential in those cases. The current input techniques for HMD are hand-tracking, head/eye-gaze and voice. The processing data are visualized onto the display device via a user interface (UI) enhancing two-way communication between the user and the system. The current display devices can be classified into two groups: in situ display (desktop monitor, projection-based augmentation, spatial augmentation, etc.) and mobile display (hand-held device HHD, head-mounted device HMD).

Depending on the selection of devices, the overlaying augmentations technique onto the user’s scene can be different. Currently, there are three superimposing techniques. With the first technique, the augmentation can be directly projected to the field of view (FoV) of the user. This one is called optical combination and is implemented with an optical see-through HMD (OST-HMD). The second technique is known as video mixing. The user’s scene is taken by the camera and processed by a computer. After inserting the augmentations on the processed scene, the result is displayed on a display device, on which the user views the real scene indirectly. The last technique is image projection, which directly projects the augmentations onto the physical objects.

Tracking and registration are the crucial and challenging aspects of AR applications. The accuracy in tracking and registration determines the alignment quality of augmentations. According to [18], the tracking and registration algorithms are divided into three groups: (1) Marker-based algorithms, (2) Markerless (or Natural feature-based) algorithms and (3) Model-based algorithms. For marker-based tracking, the 2D markers having unique shapes/patterns are placed on the real objects, where the digital information is planned to be overlayed. A digital augmentation is programmatically assigned for each marker in the workplace. When the camera recognizes the markers, the pre-assigned augmentation is displayed onto the marker. In some situations, the markers are occluded and it is not efficient. Thus, natural feature-based tracking (NFT) is more commonly used in computer vision-based tracking. Some well-known natural feature-based tracking algorithms are Speeded Up Robust Features (SURF), Scale Invariant Feature Transform (SIFT) and Binary Robust Independent Elementary Features (BRIEF). This technique extracts the characteristic points in images to train the AR system’s real-time detection of those points. Despite providing the seamless integration of augmentations into the real world, natural feature tracking (NFT) intensively depends on computational power and is slower and less effective at long distances. Therefore, small artificial markers knowns as fiducial markers are used to mitigate the disadvantages of NFT by accelerating the initial recognition, decreasing the computational requirements and improving the system’s performance. Model-based tracking algorithms utilize a predefined list of models, which are then compared with the real-time extracted features.

In general, a basic pipeline of AR system/application consists of image capturing, digital image processing, tracking, interaction handling, information management, rendering and displaying [17]. It starts by capturing a frame with the device’s camera. Then comes the Digital Image Processing step of AR software to process the captured image in order to estimate the camera position in relation to a reference point/object (a marker, an optical target, etc.). This estimation can also utilize the internal sensors, which help in tracking the reference object. The camera positioning accuracy is crucial for displaying AR content because it needs to be scaled and rotated according to the scenarios. After that, the processed image is rendered for the relevant perspective and is shown to the user on a display device. In some cases, when certain remote or local information is required, the Information Management module is responsible for accessing it. The interaction handling module is to enable the users’ interaction with the image.

1.2. Quality 4.0

Besides cost, time and flexibility, quality is one crucial dimension of manufacturing attributes in terms of products and processes [19]. Its objective is to assure that the service or final product meets the specifications and satisfies the customers’ requirements.

Total quality management (TQM) is the current highest level of quality in an organization context, which holistically considers internal and external customers’ needs, cost of quality and system development to organize and assist quality improvement. Quality control (QC) is a part of TQM, playing an essential role in fulfilling technical specifications with inspection applying techniques such as statistical process control (SPS), which is statistical sampling to manage the in-line quality on the shop-floor manufacturing level [20]. Contrastingly, Quality assurance (QA) concentrates more on the pre-manufacturing phases, such as planning, design, prototyping, etc., to ensure the achievement of quality requirements for manufacturing products. The international standard ISO 9001:2015 describes the specific standards of the quality management system [21]. Many organizations have employed various methods and approaches to improve quality performance such as TQM, Lean Six-Sigma, Failure mode and effect analysis (FMEA), quality function deployment (QFD) and benchmarking [22]. Furthermore, certain behaviors in the factories, such as process management, customer focus, involvement in the quality of supply and small group activity, are required for the successful application of quality management [23].

Industry 4.0 is a new industrial digitization paradigm that may be seen at all levels of modern industry. Quality 4.0 can be considered an integral part of Industry 4.0 when the status of quality and industry 4.0 are combined. It is the digitalization of TQM or the application of Industry 4.0 technology to improve quality. The value propositions for Quality 4.0 include the augmentation or improvement of human intelligence; the enhancement of productivity and quality for decision-making; the improvement of transparency and traceability; human-centered learning; change prediction and management [24,25,26].

In a holistic view of a smart factory, Big Data, in conjunction with CPS, can be applied to manage the data understanding. Big data analytics play a critical role in supporting early failure detection during the manufacturing process, providing valuable insight into factory management such as productivity enhancement [27]. IoT provides a superior global vision for the industrial network (including intelligent sensors and humans) as well as the ability to take real-time actions based on data comprehension [28]. Then it comes to AI, which is currently used to perform visual inspections of products towards quality control evaluation. One of the most critical issues in manufacturing is the ability to visually assess product quality [29]. AI methods (Machine learning techniques) proved their advancement in assisting inspections based on data analysis. This latter is frequently taken as images collected from sensors/cameras inside manufacturing environments. Finally, AR technologies can be applied to facilitate the inspection process with an immersive experience by superimposing digital information onto the working environment [30].

At the time of conducting this study, most enabling technologies of Industry 4.0, especially AR technology, have reached a mature point that could enhance the transformation of quality 4.0. This means that a systematic literature review about AR applied in the quality sector is essential and crucial not only for the digital transformation in quality 4.0 but also for the long-term integration of AR technology in quality sector. All relevant AR-assisted quality control solutions in the manufacturing context are considered for this SLR to observe how the cutting edge AR technology has been applied and evolved in quality sector. The findings of this SLR then can be used as references for further improvement and implementation of AR in quality 4.0. to save costs and resources, as well as to improve productivity, accuracy and autonomy

2. Research Methodology

The literature methodology is demonstrated in this section. Two successive searches were carried out following the Preferred Reporting Items for Systematic Reviews and Meta-analyses (PRISMA) [31], which is a straightforward reporting framework for systematic reviews that supports authors to develop their reviews and meta-analysis reporting. The primary search was done on 15 September 2020 and the extended search on 13 August 2021.

Then, the predefined inclusion and exclusion criteria were allocated into relevant stages of the PRISMA flowchart to support the paper selection process (see Section 2.2 Paper selection).

2.1. Planning

The initial step was to identify exactly which areas the study should cover and which are excluded. To fill an essential gap in the AR-based quality control sector, as well as to provide a road map for the further implementation of AR technology to support Quality 4.0 in the future, this study focuses on AR systems and their applications in manufacturing, especially shop-floor processes that require intensive involvement of operators’ activities such as assembly, maintenance and quality control. Hence, the following five research questions are defined (see Table 1).

Table 1.

Research questions.

RQ1: What is the current state of AR-based applications in manufacturing?

The motivation of this question is to understand the current industry adoption status of AR-based applications, and to determine the gap between applications that were tested in the industry through field experiments and the ones that were still in the novel stage as pilot projects or only tested in a laboratory context.

RQ2: How does AR-based quality control benefit manufacturing in the context of Industry 4.0?

The objective is to observe the evolution of AR-based quality control applications in the manufacturing context. In addition, it is to understand how AR technology is currently applied to support each specific case in the quality sector.

Thus, a holistic identification of application areas for AR-based quality control in industrial manufacturing based on technology suitability can be carried out in the future.

RQ3: What are available tools to develop AR-based applications for quality sector?

The objective is to systemize the current development tools and frameworks supporting in the AR-assisted manufacturing process development. Thus, when it comes to developing AR-based quality control applications in the future, a useful set of tools and frameworks would be available to consider.

RQ4: How can AR-based applications for the quality sector be evaluated?

The motivation is to know which metrics, indicators and methods are utilized to evaluate effectiveness and improvement when applying AR technology to support a quality-related activity.

RQ5: How to develop an AR-based solution for long-term benefits of quality in manufacturing?

Based on the results concerning previous RQs (RQ1, RQ2, RQ3, RQ4), a concept of development framework for AR-assisted quality can be generalized and used to answer this question.

The next step was choosing the databases for document identification. Four well-known technology research databases, which are Scopus, Web of Science (WoS), SpringerLink and ScienceDirect, were used for finding high-quality literature resources. Those databases were selected due to their broad coverage of journals and disciplines. Mendeley was used as a reference manager software. This program is chosen due to its user-friendly aspects such as fast processing of large numbers of references, word citation add-in, integrated pdf-viewer and teamwork collaboration. Microsoft Excel was used for data extraction and evaluation.

2.2. Paper Selection

For the systematic search of documents, a set of search strings was determined to search the databases mentioned in the planning phase. The Search strings and search syntax for each database are listed in Table 2.

Table 2.

Database query strings.

Comparing to assembly and maintenance, the AR-based applications supporting the quality sector have not been comprehensively investigated in the last few years. Thus, assembly and maintenance sectors can be considered as good references for the development of AR-based quality control applications. In addition, assembly, maintenance and quality control are normally carried out in similar working conditions and all require intensive involvement of the operators. Therefore, keywords such as “assembly” and “maintenance” are included in the search strings besides keywords such as “manufacturing”, “industrial application”, etc.

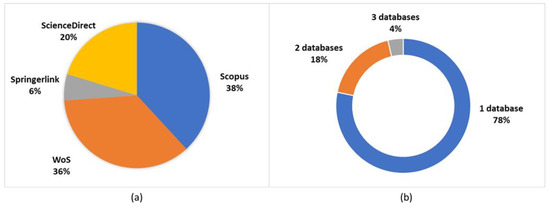

After systematically searching with the above search strings on respective databases, there were 1248 documents found (see Table 3). On the left side of Figure 3, a chart referring to the numbers of publications is illustrated, which were systematically found on databases. The large number of articles found using databases were from Scopus (38%) and WoS (36%). Regarding duplication, 78% of found articles only belong to one single database, 18% to two databases and 4% to three databases shown on the right side of Figure 3. In addition, the manual search resulted in 48 more articles by scanning cited references of influential review papers.

Table 3.

Identified papers by database.

Figure 3.

Search by database: (a) Database distribution; (b) Database duplication.

The AR articles were selected and approved based on the following criteria described in Table 4: Inclusion and exclusion criteria. The number of publications excluded referring to specific criteria were also included in the table.

Table 4.

Selection criteria.

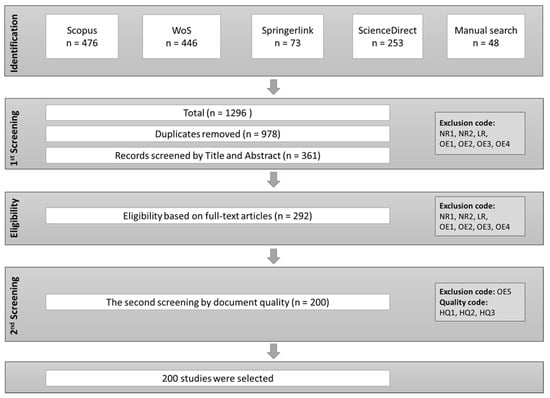

The relevant exclusion criteria were applied for each stage of paper selection flowing PRISMA flowchart as in Figure 4.

Figure 4.

Search results following PRISMA flow chart adapted from [31].

The main strategy for paper selection following the adapted PRISMA flowchart is intensively applying exclusion criteria for the first screening and full-text eligibility evaluation. If a paper meets any exclusion criteria, it would be immediately excluded from the search results. The inclusion criteria were used for the second screening to check the quality of articles.

In the document identification step, there were a total number of 1296 papers found from both systematic searches on the aforementioned databases and a manual search. After removing duplicated documents (318 papers), 978 publications were analyzed by Title and Abstract, referring to exclusion criteria to identify the relevant papers supporting the study’s objective. After the first screening, 361 publications were remaining, which were carefully considered following the exclusion code (NR1, NR2, LR, OE1, OE2, OE3, OE4). A total of 69 publications were rejected, including five papers that could not be accessed as a full text. There were 292 articles qualified for the next screening. The quality assessment at the second screening phase was achieved by evaluating each document through binary decision compliance with a set of criteria HQ1, HQ2, HQ3. If a paper did not satisfy the quality check, it was listed as an exclusion result regarding the OE5 code. The quality check criteria were:

HQ1: The full text of the article provides a clear methodology

HQ2: The full text of the article provides results

HQ3: The article is relevant to the research questions

However, there were some exceptions, namely that a paper was not required to fulfill all the quality check criteria. If a document did not provide methodology or results but exhibited an interesting concept or potential development, it could be accepted. For example, paper [8] provides a clear methodology and implementation of in-line quality assessment of polished surfaces in a real manufacturing context, but there is no test or evaluation to validate the results. However, the prototype in the paper was built on a robust development approach, which can be further improved to adopt for long-term implementation. Besides that, most of the remote collaboration articles focusing more on the Human-Computer Interaction (HCI) and human cognition fields, which do not support the RQs of this study, rather than the AR context were also excluded at this step. As a result of paper selection, a total of 200 studies were selected to conduct the systematic review. Figures and tables summing up these papers and their research are provided in the following sections.

2.3. Data Extraction and Analysis

2.3.1. Classification Framework

The classification framework used to analyze AR-based publications in manufacturing and extracting relevant information for answering RQs consists of three parts:

- Application area in manufacturing mixed categories of papers:

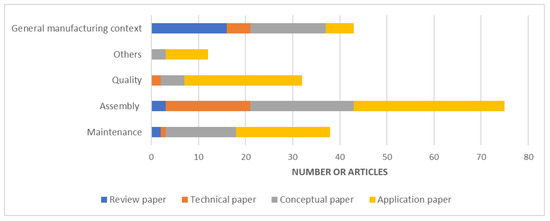

At the beginning of the 200 selected publications, each can be allocated into five solution groups according to their application field in an industry 4.0 context: (1) Maintenance, (2) Assembly, (3) Quality, (4) Others and (5) General manufacturing context. Next, they were classified into 4 different categories of papers following the benchmark in [32]: review papers, technical papers, conceptual papers and application papers (see Table 5).

Table 5.

Literature retrieved and organized based on the classification framework.

The correlation between these two classifications formed a matrix giving an overview of the current interest in AR-based solutions in the industry. In more detail, review papers are the ones summing up the current literature on a specific topic to provide the state of the art of that area. Technical papers are mainly about solutions and algorithms for the development of hardware/software and AR systems. Conceptual papers consider specific characteristics of AR solutions to propose advanced concepts for their further practical adoption. Finally, application papers provide works that develop and test AR solutions in a case study or real environment.

With this classifying approach, the results in Figure 5 show that there is currently no systematic review paper about AR technology enhancing quality sector.

Figure 5.

Type of papers and application field.

The general manufacturing context has the highest number of review papers, while Assembly has the highest number of application papers. Although the total number of publications of AR-based quality is less than the total number of articles in AR-based maintenance, AR-based application papers in quality are slightly higher than in maintenance. Considering that the investigation for AR-based quality solution was behind maintenance in the past, this proves that the interest for implementing AR technology in quality sector has significantly grown in recent years.

- 2.

- The architecture layer framework of AR systems in manufacturing

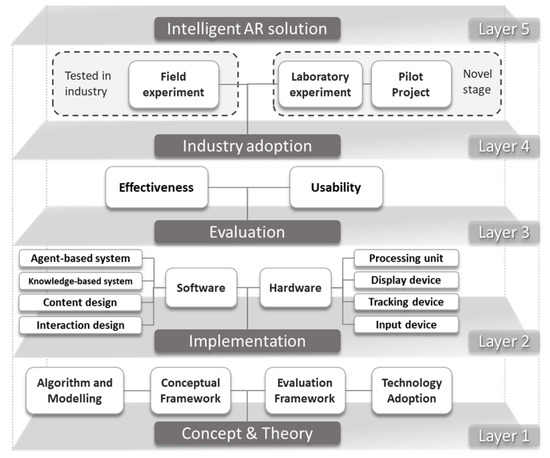

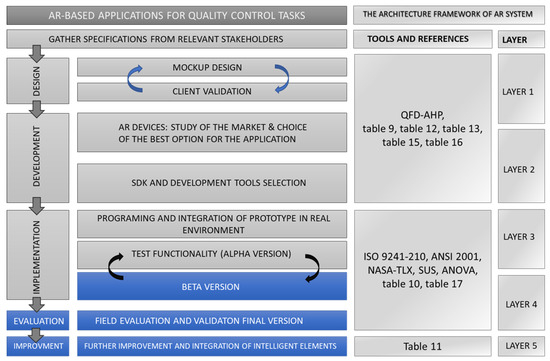

After the first classification, each paper’s content was analyzed following the architecture layer framework of the AR system adapted from [226], as in Figure 6, to extract relevant data for answering the RQs.

Figure 6.

The architecture layer framework of an AR system, adopted from [226].

This architecture layer framework of AR systems was adapted and improved from a study in the built environment sector. The framework was chosen for the analysis step because its architecture was constructed in accordance with the standard architecture layer criteria for developing information technology concepts and tools. Besides that, it could cover all essential aspects of an AR application based on system point of view (layer 1, 2), industry point of view (layer 4, 5) and user point of view (layer 3: usability, layer 2: interaction design, content design).

In more detail, the framework in the study consists of five layers covering most of the important characteristics of AR-based solutions, from fundamental aspects to advanced intelligent solutions, as in the following:

- Concept & Theory

- Implementation

- Evaluation

- Industry adoption

- Intelligent AR solution

Layer 1: Concept & Theory

This layer includes Algorithm, Conceptual Framework, Evaluation Framework and Technology Adoption. Algorithm relates to technical aspects of AR/Registration/Tracking methodology. Conceptual Framework supports the development or proposal of AR solutions for proof-of-concept cases. Evaluation Framework assists in grading and selecting the right enabling elements for an AR concept or AR systems. Finally, Technology adoption is relevant to the papers that point out the current challenges, limitations and gaps which needs to be solved to facilitate a wide adoption of AR-based solutions.

Layer 2: Implementation

This layer consists of two sublayers, which are Software and Hardware layers.

Hardware sublayer includes the fundamental elements of an AR system, which are a Processing Unit, an Input device, a Tracking device and a Display device.

Due to the fact that the Processing Unit can be flexibly selected depending on the computing workloads of the desired tracking methods and the chosen display techniques, this paper does not consider extracting this information. Besides that, the input device is an optional element of the system because it depends on the system design and specific use case. The stimuli to trigger the AR modules could be automatically included (sensors data, camera, tracking algorithms) in the approach itself. Therefore, the paper aims to concentrate more on extracting the data regarding the Display device and Tracking methods to support for RQs.

In this paper, the display devices are classified into 2 groups: In-situ display and Mobile display. An In-situ display involves a Spatial display/Projector and a Monitor/Large screen. Mobile display involves HHD and HMD. Tracking methods are categorized into 3 groups: Computer vision-based tracking (CV-based), including marker-based; markerless (NFT), model-based tracking; Sensor-based tracking and Hybrid tracking.

Software sublayer consists of Interaction design and Content design, as well as Agent-based and Knowledge-based elements.

Content design is relevant to those papers that focus more on demonstrating how the AR information is constructed and used. In this, there is no interaction between the user and the virtual information; no external database is required.

Interaction design focuses more on developing and enhancing the interaction between the user and virtual objects/contents.

An Agent-based system (ABS) applies an agent or multi-agent system, which originates from Artificial Intelligent (AI), enabling the autonomous, adaptive/learning, intelligent characteristics of a system. Agent-based software is a higher evolution of object-oriented software [227,228,229].

A Knowledge-based system (KBS) is a type of AI targeting that captures human experts’ knowledge to support the autonomy of decision-making. The typical architecture of a KBS consists of a knowledge base, which contains a collection of information in each field, and an inference engine, which deduces insights from the information captured/encoded in the knowledge base. Depending on the KBS problem-solving method/approach, it can be referred as a rule-based reasoning (RBS) system that encodes expert knowledge as rules, or a case-based reasoning (CBS) system that substitutes cases for rules [230,231,232].

Layer 3: Evaluation

This layer consists of Effectiveness and/or Usability categories that involve a user study. There is a close relationship between these two categories. The more usable a system is, the more effective it could become.

Effectiveness evaluation is designed to measure the system’s capability of getting the desired result for a specific task or activity. For example: reducing assembly time, enhancing productivity, etc. [30].

Usability evaluation utilizes expert evaluations, needs analysis, behaviors measures, user interviews, surveys, etc. to measure the ease of adaption of AR-based systems. Thus, the system flaws can be identified at the early stages of development [194].

Layer 4 Industry adoption

This layer considers whether an AR prototype/application is tested in industry or not. A prototype/application can be classified into two classes depending on its industry adoption status, which are “Tested in the industry” and “Novel stage”. If the field experiment is carried out for a prototype, it is classified into the “Tested in industry” class. The “novel stage” is relevant to applications, which focus on solving specific issues of AR technology such as tracking, calibration, etc., rather than finding holistic solutions for real industrial case studies, or are only tested in a laboratory environment. A pilot project solves real case studies and has the potential to be applied in the manufacturing environment, but there were no in-depth experiments carried out for it to verify/validate the results. Thus, pilot projects are also classified into the “novel stage” category.

Layer 5 Intelligent AR solution

To support this layer, an article should satisfy at least one of the following questions.

- Does the prototype or application integrate with another industry 4.0 technology such as AI, IoT, CPS, Digital Twin, etc.?

- Does the solution/concept potentially establish the fundamental base for the further integration of AI, IoT, etc. in AR environment to support manufacturing?

- Do the algorithms try to solve a limitation in AI-supporting AR systems?

- 3.

- Categories of current AR assisted quality sector

All the AR-based solutions for the quality sector can be classified into 3 groups:

- AR supporting quality as a virtual Lean tool for error prevention (virtual Poka Yoke)

- AR-based applications for metrology

- AR-based solutions for in-line quality control (process, product, machine, human)

Metrology: Applied metrology is a subset of metrology and a measuring science created to ensure the appropriateness of measurement devices, as well as their calibration and quality control, in manufacturing and other operations. Nowadays, measurement technologies are utilized not only for assuring the completed product, but also for proactive management of the entire production process. With AR’s superimposition advantage and metrology’s power, metrology integrated AR might be a promising research area for the long-term success of quality 4.0.

2.3.2. Analysis

Based on the proposed classification framework, a pilot datasheet was designed using Excel to extract relevant data for RQs (see Table 6). All the selected publications were systematically scanned and extracted by the main author. Two main reviewers were used, as well as a third to resolve any disagreements. Mendeley was used to keep track of references. The final decision to modify, keep or remove any defined categories was made by cross-checking each step of the reviewers, who also verified the extracted information.

Table 6.

Example of data extraction from selected papers for the SLR.

3. Results and Discussion

In this section, the results of the SLR are reported and the analyzed papers are synthesized. The objective of the SLR is to answer the defined RQs. In order to guarantee the requirement of the PRISMA method in terms of transparency, there is a table providing all relevant articles of specific classification criteria at the end of each subsection.

These RQs are discussed, analyzed and answered in the following subsections. While the RQ1 and RQ2 utilized all selected papers to provide a holistic picture about current AR-based applications in manufacturing and their benefits to the quality sector, the RQ3 to RQ5 focus more comprehensively on finding the practical answers to support AR solutions development for the quality field.

3.1. Answering RQ1 and RQ2

RQ1: What is the current state of AR-based applications in manufacturing?

RQ2: How does AR-based quality control benefit manufacturing in the context of Industry 4.0?

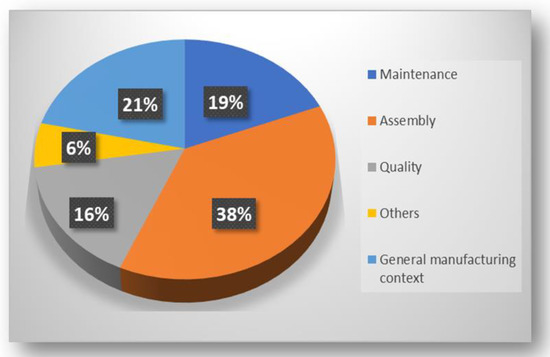

The distribution of AR-based solutions in the Maintenance, Assembly, Quality, Other and General manufacturing contexts are 19%, 38%, 16%, 6% and 21%, respectively, as depicted in Figure 7. In more detail, the number of AR articles in each application field considered within this paper’s objectives from the year 2010 to 2021 is illustrated in Figure 8, which provides a longitudinal viewpoint for analyzing patterns, themes and trends concerning the application field in the quantity of publication. The timeframe from 2010 to 2021 is extensive enough to determine the evolution of literature in each field.

Figure 7.

Distribution of application field in manufacturing.

Figure 8.

Distribution of AR solutions in different fields over years.

It is not surprising that assembly is the leading adopter with 75 articles, or 38% of the total. This demonstrates a sustained interest in AR-assisted assembly, which peaked in 2019. Undoubtedly, assembly is the dominant sector in manufacturing to embrace AR technology. This is due to the nature of manual and semi-manual assembly activities that required the intensive involvement of operators, whose work is visual-oriented and who are in need of visual aid supporting. Next, when it comes to AR-based industrial applications in a specific field, maintenance is the second dominant sector, with 38 articles, or 19% of the total. Although the amount of AR-based maintenance applications fluctuates over time, they get the consistent consideration in 3 consecutive years from 2017 to 2019. Despite the investigation of AR solutions for the quality sector, this area is still far behind with 32 articles, or 16% of the total. Recently, this area has significantly emerged, reaching its peak in 2019, catching up with the AR articles for maintenance sector. Other sectors consisting of AR-assisted robot programming [211,214], machine tool setup [213], real-time manufacturing modeling and simulation [121] have slowly been considered. General manufacturing context solutions are relevant to those articles investigating generic AR-based solutions that can be customized and adopted for any particular field later to support the objectives of that field [123,221].

Virtual and real context fusion, as well as the intuitive display, is the main advantage of implementing AR-based solutions for maintenance and assembly instructions. Thus, media representation in the forms of text, symbols, indicators, 2D symbols, 3D models, etc. could be directly projected on the relevant objects [100,104,144,147,165]. A comparative study for AR-based assisted maintenance was conducted to compare maintenance efficiency in using different assisting tools such as video instructions, AR instructions and paper manuals. The results showed that AR technology could help in productivity enhancement, maintenance time reduction and quality assurance of maintenance tasks compared to other traditional tools [233]. Similarly, Fiorentino et al. [147] and Uva et al. [142] conducted a series of studies comparing AR-based instructions to 2D documents for assembly, finding that AR-based instructions dramatically increased assembly efficiency [147]. Nevertheless, AR-assisted instructions also enhanced the assembly order memorization of operators [142].

Considering the quality field, the AR-supported quality process has evolved from a basic indicating tool of projecting 2D information onto processed parts to support in situ quality inspection of welding spots using Spatial AR (SAR) [209] to a higher level that combines real-time 3D metrology data and the MR glasses HoloLens for in-line assessing of the quality of parts’ polished surfaces [8]. In another scenario, SAR is also applied to improve the repeatability of manual spot-welding in the automotive industry to assure the precision and accuracy of the process [201]. Several types of cues visualized with different sizes and colors (red, green, white, yellow and blue) are defined and superimposed on the welding area to support operators in focusing the weld guns onto the correct welding spot. In a real case at the Igamo company in Spain, AR technology was adopted to work as an innovative Poka-Yoke tool. In the packaging sector, setting up the die cutters is crucial to ensuring the final quality of the cardboard. However, this process is error-prone, causing defects and low-quality products. Thus, correction templates, which are made of paper marked with tapes using different colors, are applied to balance the press differences of die cutters. These correction templates are made based on the traditional Poka-Yoke method for error prevention. The templates are then digitalized and directly projected onto the die cutter, resulting in warehouse cost reduction, which comes from storing correction templates, and data loss prevention, which is caused by damaged templates [198]. Additionally, 3D models or CAD are implemented into AR tools for design discrepancies [206] and design variations inspection [195]. In a quality assurance of sheet metal parts in the automotive industry, an interactive SAR system integrating point cloud data is implemented and validated [234].

In recent studies [30,210], an AR-based solution for improving the original quality control procedure used on the shop floor to check error deviation in several key points of an automotive part has been investigated and developed to automatically generate virtual guidance content for operators during measuring tasks. The main problem of the original procedure is that quality control consists of repetitive and precise tasks, which are frequently complex, requiring a high mental workload for the operator. Although quality control tests are facilitated with documents of static media such as video recording, photos or diagrams to support the operators, they still need to divide the attention between the task and the documents, which also lack in-time feedback. This leads to a slowing of the processes as well as movement waste due to the operator’s need to move between a workstation and a computer to validate measuring results after a certain number of tests. In detail, the original quality control is to measure deviation errors of an automotive part at specific positions in accordance with the essential specification of clients. A wireless measurement device (a comparator) is manually positioned by operators at specific locations for evaluation. During the nine measures, the operators need to move back and forth between the working cell and a display device to verify the measurements. For the AR-based solution, a camera is mounted on a tripod, pointing downwards at the gauge where the test takes place. The correct position for the comparator in each step indicated by green boxes is augmented onto the RGB-D live video stream using the same screen with other methods. In this method, whenever the comparator is detected in the correct position, the measure is taken automatically. The validation of the correct comparator positioning is also used to trigger the transition to the next assembly stage. With this approach, an AR-based quality control system provides automatic in-process instructions for the next steps of measuring and accurate guidance to speed up the workers’ efficiency. A test is carried out with seven operators: four inexperienced users and three experienced users. As a result, the experienced participants performed faster in both non-AR and AR-based methods, but the difference was smaller with the AR-based method. After implementation in an industrial setup by operators working on the shop floor in the metal industry, it was shown that AR-based systems help to reduce by 36% the execution time of a complex quality control procedure, allowing an increase of 57% in the number of tests performed in a certain period of time. It is also concluded that the AR system can prevent users from making costly errors during peak production times, though this has not been tested yet. Besides that, the risk of human errors is also reduced. In another scenario, an AR inspection tool is developed based on a user-centered design approach, following the standard ISO 9241-210:2019 to support workers during assembly error detection in an industry 4.0 context [188]. Once again, it is mentioned that the inspection activities naturally require high mental concentration and time when using traditional paper-based detection methods. Besides that, when the geometric complexity of the product grows, the probability that an operator makes mistakes also increases. In order to solve this, the research proposed and developed a novel AR tool to assist operators during inspection activities by overlaying 3D models onto real prototypes. When errors are detected, the users can add an annotation by using the virtual 3D models. The AR tool is then tested in a case study of assembly inspection of an auxiliary baseplate system (14 m long and 6 m wide) used for providing oil lubrication of turbine bearings and managing oil pressure and temperature. 16 engineers and factory workers of the Baker Hughes plant, skilled in the use of smartphone and tablet devices but novices to AR technology, were selected for the test. Five markers (rigid plastic QR code size of 150mm x 150mm x 1mm) were placed 1.5 m apart, along with the system for the tracking method. The users went through a demo, performed training steps and indicated a set of six tasks: framing a marker and visualizing the AR scene; detecting a design discrepancy and adding the relative 3D annotation; taking a picture of design discrepancies detected during the task; changing the size of the 3D annotations added during task 2; framing marker 4 and hiding the 3D model of the filter component; sending a picture and 3D annotations to the technical office. By adopting multiple markers to minimize tracking errors, freedom of movement for the user when inspecting large-size products is ensured. Analysis of Variance (ANOVA) is used to evaluate the number of errors and completion time, while System Usability Scale (SUS) and NASA Task Load Index (NASA-TLX) are applied to evaluate user acceptance. The ANOVA and SUS results showed that a low number of errors occurred during the interaction of the user with the proposed tool, which means that the AR tool is easy and intuitive to use. Thus, the AR tool could be efficiently adopted to support workers during the inspection activities for detecting design discrepancies. Nevertheless, the NASA-TLX test proved that the developed AR tool minimizes the cognitive load of divided attention induced to both the physical prototype and the related design data.

Another interesting AR-assisted quality study relevant to the automotive industry is investigated for car body fitting, correcting alignment errors [189]. Alignment car panels of exterior bodywork to satisfy the specific tolerances is a challenging task in automotive assembly. The workers need to be guided during the panel fitting operations to reduce errors and performance time. In addition, correcting the positioning of body work components is a key operation in automotive assembly, which is time-consuming and characterized by a strong dependence between the achievable results and the skill level of the worker performing the operation. To solve this, an AR prototype system is developed for supporting the operator during complex operations relating to the dedicated phase of panel fitting for car body assembly by providing gap and flushness information to correct the alignment errors. This system also provides the feature of converting the information on gap and flushness between car panels measured by sensors into AR instructions to support the workers for correcting alignment errors. The main elements of the solution consist of measuring sensors positioned on the wrist of a 6-axis articulated robot for gap and flushness data acquisitions and an AR system utilized for providing instructions and visual aids to the worker through a Head-Mounted Device (HMD). Gap and flush measurements of the component are first acquired for each control point (CP) and analyzed by comparing the extracted features with reference values to decide whether the component position needs correcting with further manual adjustments. Thus, the AR system starts guiding the operator by showing proper assembly instructions. During adjustment operations, gap and flushness are continuously measured and checked, creating, if necessary, further instructions until the assembly phase is completed. With this approach, the system has some outstanding features: immediate detection of alignment errors, in-process selection of the recovery procedure, accurate guidance for reduced time and procedural errors in task execution, real-time information without diverting the worker from the assembly process, fast feedback after adjusting and easy use, thanks to the integration of the real environment and the AR instructions in the user’s field of view. A verified step and a test is carried out for the developed system. The results show a potential for further integration and industry adoption. With the advantage of immediate detection of alignment errors, the same assembly procedure has been able to be completed almost 4 times faster with the AR tool. The data collected from 10 tests are also less dispersed, indicating the robustness of the procedure conducted with the support of the AR system. The gap and flushness are reduced from 12.77 mm and 3.05 mm to 7.17 mm and 0.33mm, respectively. Besides that, the AR system also helped in increasing assembly effectiveness and efficiency as well as reducing errors. The correct positioning of bodywork components no longer depends on the experience and dexterity of the operator. For further improvement, system setup time needs to be minimized, implementing an Artificial Neutral Network (ANN) to support the measurement for gap and flushness error detection as well as reducing the collected data.

At this point, it is found in this SLR that although the AR-based application proved its strength in assisting quality activities, there are still challenges and limitations. In general, the current AR-assist quality applications can be classified into three groups depending on the features and objectives of their approach: AR as a virtual Lean tool, AR-assisted metrology and AR-based solutions for in-line quality control. The details are included in the following Table 7:

Table 7.

Categories of current AR-assisted quality.

To continue answering RQ1, all the collected data reported are shown in Table 8:

Table 8.

Number of articles classified by the framework.

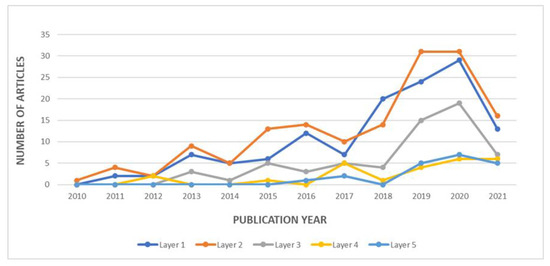

In terms of Layer 1, 63.5% (127 articles) of the selected publications provide important concepts and theory in their research (Layer 1). The largest percentage of AR articles is in Layer 2 Implementation (150 articles, 75%). This indicates that AR technology has matured to the point where it can be implemented using off-the-shelf commercial packages or self-development using less expensive software infrastructure. Significant assessment (Layer 3) of the Effectiveness and Usability studies using scientific and formal methods is found in 31% (62 articles) of the publications. 25 works, or 12.5% of the total, perform field experiments and have significant industry adoption context (Layer 4). An interesting point is that 20 articles, or 10% of the total, have contributed proof-of-concept or a conceptual framework supporting the current stage and further integration of intelligent elements for AR solutions (Layer 5). These five layers’ percentage distribution have already illustrated a holistic view of the ongoing stage and the trend of AR-based application for the manufacturing context. They also depicted a general view of what AR-based solutions for manufacturing context have accomplished (see Figure 9). The AR technology has rapidly evolved and reached its mature point to be integrated into manufacturing, equipping operators with immersive interaction tools on the shop-floor level and providing essential manufacturing information for decision making in a short time.

Figure 9.

Number of articles in each layer from 2010 to 2021.

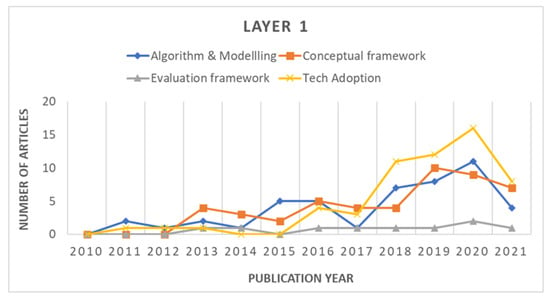

Regarding Layer 1, “AR Concept and Theory”, the publications can be categorized into four subjects (see Table 9 and Figure 10). This layer is dedicated to the concept of how AR adoption benefits in solving problems in one specific field of manufacturing: the new theories and fundamentals to build and utilize AR for manufacturing contexts. The algorithm is a crucial element in developing an AR system. It consists of studies relevant to Artificial Intelligent methodology, establishing the base for AR to grow into intelligent systems [191]. A conceptual framework provides a general view of what the AR systems are and how they can be implemented. It may be relevant to the systems’ capabilities, the system functions of the AR user interface, the system data flow or system management [190]. The evaluation framework forms the fundamental of heuristic guidelines either for the evaluating and selecting of AR elements for implementation or for analyzing and evaluating the usability of AR solutions in the context of manufacturing. For example, Quality function deployment mixed with an Analytic hierarchy process (QFD-AHP) methodology was applied for the selection of the appropriate AR visual technology in creating an implementation for the aviation industry in [123] or to support the decision-makers with quantitative information for a more efficient selection of single AR devices (or combinations) in manufacturing [87]. Technology transfer and adoption in the industry is relevant to articles that provide a holistic view about the current challenges, limitations and potential improvements that could support the adoption of AR technology in an industry context while satisfying the business requirements of companies. Literature review articles about AR in manufacturing usually contribute to the Technology Adoption category [77,190,235].

Table 9.

Articles on Layer 1 Concept and Theory Layer.

Figure 10.

Number of articles in each category of layer 1 from 2010 to 2021.

After analyzing the data, it showed that there is a nearly balanced investigation into “Conceptual Framework” (48 articles, or 24% of the total) and “Algorithm and Modelling” (47 articles, or 23.5% of the total). Only 9 articles, or 4.5% of the total, contribute to the “Evaluation framework”, while there is a high interest at the moment in “Technology transfer/adoption”, with 57 articles, or 28.5% of the total. Considering this, all selected AR literature review articles can be considered to reuse for AR technology transfer and adoption in the long-term in a manufacturing context.

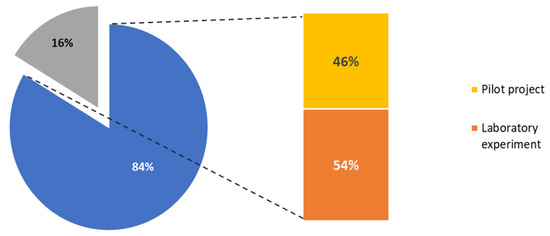

In layer 4, the relevant articles are analyzed and divided into two categories based on their industry adoption stages: “tested in the industry” and “novel stage.” When an application has been tested in a real manufacturing context or field experiments are carried out, it is characterized as “tested in the industry.” The “novel stage” is more relevant to applications or implementations that focus on solving specific issues of AR technology, such as tracking, calibration, etc., and is only tested in the laboratory environment. Besides that, pilot projects are relevant to those that implemented AR in an industrial environment but with no comprehensive tests carried out. Those proposing and developing a comprehensive AR-based solution that has high potential to integrate further in a real manufacturing context are also considered as pilot projects. The results reveal that 84% of applications are still in the novel stage, while the remaining 16% are tested in the industry and can be improved further for industry adoption (see Figure 11).

Figure 11.

Industry adoption distribution of AR solutions 2010–2021.

Although the novel stage projects achieve potential results, user acceptance, human-centric issues, seamless user interaction and user interface are still challenges that need investigating for long-term industry adoption in manufacturing [2]. Because AR is a technology enhancing human perspectives by virtual and real context fusion, a universal human-centered model for AR-based solutions development can help in closing the gap between academia and industry implementations [236,237]. Following the international human-centered design standards ISO 9241-210, 2019 [188,195], a human-centered model can be developed by combining a simplified AR pipeline [17] and AR system elements [238] with a value-sensitive design approach for smart 4.0 operators [239]. All the AR-based implementations and their industry adoption status are shown in Table 10.

Table 10.

Layer 4 AR solutions and their industry adoption status 2010–2021.

Layer 5 provides an overview of the emerging trend in integrating AR with AI, industrial IoT, Digital twin and other comprehensive industry 4.0 technologies that result in the development of layer 5 Intelligent AR (IAR) solutions. This layer provides the holistic approach for implementing intelligent industry 4.0 elements with AR to enhance the robust and smart features of AR systems/solutions for long-term adoption in industry. This layer considers all studies that propose or involve interesting, significant concepts, algorithms and implementations that show high potential in the further development of the IAR system in the future (see Table 11).

Table 11.

Layer 5 Intelligent AR relevant articles 2010–2021.

Artificial Neural Networks (ANN) and Convolutional Neural Networks (CNN) are recently applied or proposed for further improvement of the registration methods by enhancing the CV-based tracking algorithms [74,191], while Industrial IoTs and Digital Twin are frequently considered in recent studies [37,190] to utilize Big data information and the advantages of AR in visualization, fusing digital data with a real working context.

3.2. Answering RQ3 to RQ5

This section considers all selected articles to establish a broad view about current AR development tools in manufacturing, thus making conclusions about how those tools could be utilized for developing AR solutions for the quality sector.

RQ3: What are available tools to develop AR-based applications for quality sector?

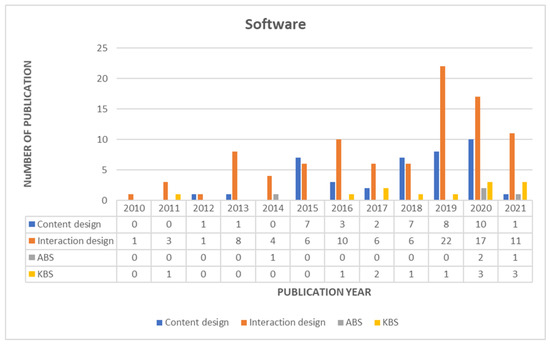

- Software design

Regarding Layer 2 Implementation, the number of articles dealing with the software side (150 articles, 75%) and hardware side is nearly balanced (148 articles, 74%). These numbers once more emphasize that AR technology has reached its mature point, where the improvement in either the AR software side or the AR hardware side would boost the technology adoption speed for AR solutions in manufacturing. There are a dominant number of Interaction design articles dealing with high functional user interfaces (95 articles, or 47.5% of the total), which is understandable due to high demands in interactive activities on the shop-floor level in manufacturing. Content design, with 40 articles, or 20% of the total, is the second dominant interest when considering software design. There are 4 articles, or 2% of the total, and 12 articles, or 6% of the total, dedicated to Agent-based AR and Knowledge-based AR systems, respectively. Although these two percentages of Agent-based AR and Knowledge-based AR are not significant, they are essential for the further integration of AI elements into AR systems supporting manufacturing in long term. The articles of each category relating to this sublayer Software design are listed in Table 12 and the number of articles of each category over the period 2010–2021 is depicted in Figure 12.

Table 12.

Articles on Layer 2 Implementation-sublayer Software from 2010–2021.

Figure 12.

Number of articles about AR software design in manufacturing over years 2010–2021.

There has been a steady interest in Interaction design for AR-based in a manufacturing context over the years, which reached its peak in 2019. This is a positive trend for the long-term adoption of AR solutions in manufacturing be-cause manufacturing at the shop-floor level consists of lots of interactive activities between operators, especially interaction of operators with working spaces as well as and operators that need essential manufacturing information/data in the right manner of time [8,63,195].

Content design is the second dominant category in software design for AR solutions in manufacturing. In 2018–2020, AR content design especially focusing on visual elements and the conversion of manufacturing actions into standard symbols for AR content are key points [104,112,129,186].

Knowledge-based AR applications are designed to incorporate the domain knowledge of experts during the authoring phase to create a knowledge-based system (KBS) built on technical documents, manuals and other relevant documentation of the authoring domain (assembly, maintenance, quality control, etc.) [30,138,191].

Agent-based AR utilizes the available entities of a system and their attributes to integrate into the AR solutions, supporting autonomy decision making [102,190].

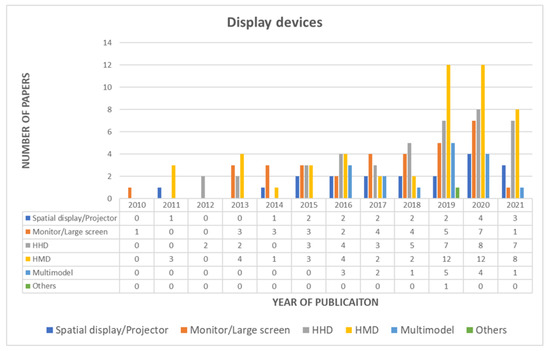

- Display devices

This subsection presents an overview of the most popular display devices used in the development of AR solutions in manufacturing, which provide good references for the development of AR-assisted quality activities later. Table 8 and Figure 13 depict in detail the main display devices mentioned and applied in the selected and analyzed articles for this SLR. The implementation of one device rather than another depends on the purpose justification of the AR application. The evolution of display technology is also considered for the analysis of display devices.

Figure 13.

Number of articles about AR display devices in manufacturing over years 2010–2021.

Starting from the most dominant display device, HMD is mentioned in 50 articles, which is 25% of the selected articles, all of which comprehensively included HMD into their content. This is thanks to the advantages of HMD, which are portability, hands-free interaction and user experience enhancement through direct overlaying of computer-generated information onto users’ views. The HMDs mentioned in the selected articles are usually commercial devices that are available on the market. Hololens is the one that is utilized the most among commercial optical see-through HMDs (OST-HMD) [8,52,53,220]. According to [240,241], another type of HMD is video see-through HMD (VST-HMD). In this category of HMD, Samsung Gear VR or Oculus are remarkable candidates. A customized VST-HMD based on the use of Z800 3D visor by Emagin combined with a USB camera—Microsoft LifeCam VX6000—was made to create an interactive AR implementation for virtual assembly in [167]. In terms of technology, the current HMD devices’ ergonomics (weight, resolution, field of view (FOV)) have improved compared to the past, and have moved closer to the industrial requirements for long-term implementation. The technology of OST-HMD allows users to observe the real context through a transparent panel while at the same time seeing the computer-generated information projected onto it. The VST-HMD has cameras affixed to the front of the HMD which captures the real-world images, superimposes the digital information onto those images and then displays AR content through a small display area in front of the user’s eyes [242]. Due to the amount of information that needs processing, VST-HMDs usually have higher latency (the time gap between the real world’s occurring events and the ones perceived by users’ eyes). The current challenges of both types of HMD technology are system latency, FoV, costs, ergonomics and view distortion [2].

The second dominant display device is HHD, with 42 articles, or 21% of selected articles for this SLR. HHDs utilized in the articles are mainly commercial devices such as tablets and mobiles. The greatest advantage of using these HHDs is that the users are more familiar with the technology because mobiles and tablets are also used in daily activities such as work, entertainment, etc. In addition, their portability, cross-platform development, cost and capabilities also make them promising alternatives to HMDs [77,195]. However, in tasks or activities requiring both free hands and intensive manual interaction on the shopfloor, such as assembly [160], quality control [30,194], etc., HHDs were not an appropriate selection in some cases.

The third and fourth trending display devices providing in-situ, hands-free AR displaying content are Monitors/large screens (34 articles, or 7% of the total) and Project for spatial display (19 articles, or 9.5% of the total). Monitors and large screens are also commonly selected for developing a human-centered smart system to support assembly tasks or quality assurance activities [30,147,164], provide assembly training assistance tools [166] or real-time data for cyber-physical machine tools monitoring [200], etc. Monitors and large screens are popular devices that are available in any manufacturing or shop-floor context. By utilizing them for developing AR solutions, the cost aspect can be satisfied. However, these systems usually require an external camera system or webcam for capturing real-world images to support the tracking and registration modules of AR applications. Nevertheless, portability is a limitation of using these display devices. Regarding Spatial AR (SAR) display with a projector, this is a favorite display method applied in spot-welding by utilizing the advantages of direct display digital information onto the work piece to enhance workers’ concentration, thus reducing the process errors [201]. The system is considered as SAR when the projection is directly displayed onto the physical object. In another scenario of spot-welding inspection, SAR was applied to directly indicate the welding spots for the operators to check during the quality control process of the welding spots, which helped in reducing the inspection process time [209]. For these applications that support spot-welding relevant processes, one important note is the correct rendering for the readability of the indicator text. Besides that, text legibility is also essential, which was comprehensively investigated in a study to enhance the quality and effectiveness of applying SAR in industrial applications [75]. The projector is also popularly used in assisting the assembly process. A projection-based AR system was proposed to monitor and provide instruction for the operator during the assembly process in [161], or to provide the picking information together with assembly data for the operation as in [185]. Then, in a higher-level conceptual system, real-time instructions for assembly using SAR were comprehensively studied and demonstrated in [63]. Finally, during implementation at a real working environment in a factory, projected AR was utilized together with data digitalization to support the setting up of a die cutters process, which resulted in effective cost saving and processing error reduction [198].

It is crucial to note that the capabilities of the above display hardware are changing rapidly, but they both have their advantages and drawbacks, which are detailed in Table 13.

There is a small percentage of articles—16 articles, or 8% of the total—applying the multimodal displaying technique, and only 1 article, or 0.5% of the total, completely used another technique, which was haptic AR to support assembly process [11]. Multimodal display provides the immersive experience for more than one human sense, which can be mixed between visual displaying and audio to enrich the capabilities of AR applications in industry 4.0 [122] or effectively support and attract the awareness of the worker during the mechanical assembly process [164]. A combination of haptic feedback and visual information is commonly utilized in self-aware worker-centered intelligent manufacturing systems [166] or in applications that require lots of bare-hand interactions with physical objects such as assembly or maintenance [90,127,171].

By having a general view about how displaying devices are utilized in manufacturing through the above analysis, a conclusion regarding display device selection for AR assisting in the quality field can be made. By considering the specific working conditions/requirements such as human working environment, movements, flexibility, etc., as well as the advantages/disadvantages of each display technology, the appropriate display devices can be evaluated and selected for each specific AR-assisted quality application. The QFD-AHP methodology mentioned in Layer 1 could be utilized to systematically evaluate all these elements.

Table 13.

Articles on Layer 2 Implementation-sublayer Hardware from 2010–2021.

Table 13.

Articles on Layer 2 Implementation-sublayer Hardware from 2010–2021.

| Display Devices | Representative Works | Advantages | Disadvantages |

|---|---|---|---|

| HMD | [8,52,53,55,56,64,72,79,88,97,102] [104,108,113,125,129,130,131,143,145] [146,149,150,151,155,156,157,158,160] [163,165,167,173,174,175] [178,189,190,191,192,196,203] [204,211,212,219,220,221,222,225] | Portability Hands-free | Ergonomics FoV Resolution |

| HHD | [7,51,52,65,67,73,77,84,86] [100,131,132,138,139,141,144] [153,157,159,162,169,177,181] [182,187,188,189,192,195,199] [202,204,205,206,207,208,209] [214,217,220,221,225,235] | Portability Mobile | Hand-occupied FoV Resolution |

| Projector/ SAR | [60,63,75,92,105,113,116] [131,142,161,163,170,176] [184,185,198,201,209,224] | Hands-free Directly project onto the object User tracking is not essential User movements do not affect the visualization | Low light-intensity Objects displaying in mid-air |

| Monitor/ Large screen | [30,57,59,61,62,66,68,71,81] [93,94,98,99,109,112,119,121,144,147] [148,150,154,159,172,180,186] [193,199,200,210,213,215,216,218] | Hands-free Low-cost Common devices in working environment | Portability |

| Multimodal | [58,90,103,122,126,127,140,152] [164,166,168,171,179,183,194,223] | Enriching immersive information Compensating the issues of each displaying techniques | User distraction could be a problem if information in different senses is provided at the same time |

| Others | [11] | Low-cost | Not intuitive Limitation in transmitted information |

- Tracking methods

By having a general view about how displaying devices are utilized in manufacturing through the above analysis, a conclusion of display devices selection for AR assisting in the quality field can be made. By considering the specific working conditions/requirements such as human working environment, movements, flexibility, etc., as well as the advantages/disadvantages of each display technology, the appropriate display devices can be evaluated and selected for each specific AR-assisted quality application. The QFD-AHP methodology mentioned in Layer 1 could be utilized to systematically evaluate all these elements.

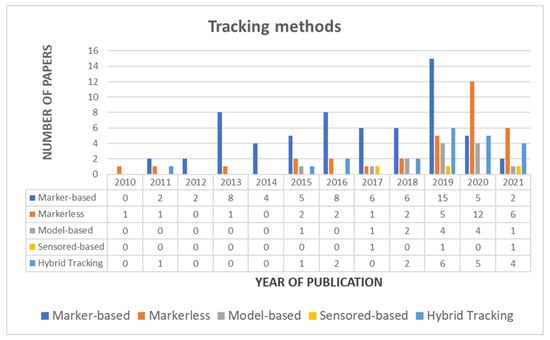

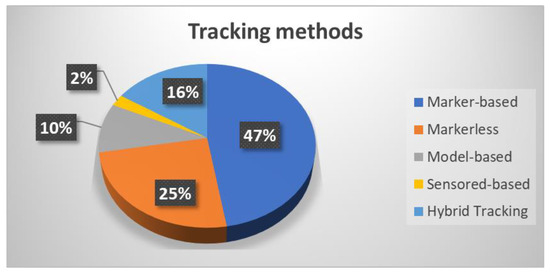

This subsection provides an insight into the current tracking methods utilized in developing AR solutions in manufacturing, thus giving useful references for working on AR assistance in the quality field in the future. Table 14 and Table 15 list in detail the tracking methods used in articles on this SLR. In Table 14, besides Global Percentage, which is calculated for 200 selected articles, Relative Percentage demonstrates the composition of each tracking method that contributes to 133 tracking relevant articles. Then, Figure 14 and Figure 15 illustrate the holistic view of the distribution and evolution of tracking methods over the period from 2010 to 2021.

Table 14.

Number of articles classified by tracking methods.

Figure 14.

Number of articles about AR tracking methods in manufacturing over years 2010–2021.

Figure 15.

Distribution of tracking methods in terms of tracking methods from 2010–2021.

Tracking plays an important role in the real-time AR assisting in manufacturing application. It calculates the pose and position of the physical components as well as the relative pose of the camera to those components in real-time. The orientation (6DoF) and the position of an object form a pose. High accuracy in tracking this provides the users’ location and their movements in reference to the surrounding environments, which is an important requirement for AR-based manufacturing applications [243], except in some applications using SAR. Tracking technology is one of the main challenges affecting AR application in support of intelligent manufacturing [2]. Robustness and low latency at an acceptable computation cost also need considering in terms of AR tracking. It is essential to distinguish between recognition and tracking. Recognition seeks to estimate the camera posture without relying on any previous information provided by the camera. When the AR system is initialized or at any time when there is a tracking failure, recognition is made. In contrast, tracking aims to analyze the camera pose based on the camera’s previous frame [244].

Currently, there are three main categories of tracking techniques, known as computer vision-based (CV-based), sensor-based and hybrid-tracking, the latter of which utilizes both CV-based and sensor-based tracking techniques at the same time [188]. CV-based tracking techniques are usually utilized for indoor environments and can be classified into three categories in terms of “a priori” methods, which are: marker-based tracking, markerless tracking (feature-based or natural feature tracking NFT) and model-based tracking. “A priori” is predefined knowledge about the object, which would be tracked. It could be a marker, a feature map or a model regarding marker-based, markerless and model-based tracking techniques, respectively. In order to initialize “a-priori” knowledge to support the CV-based tracking methods, “ad-hoc” methods can be applied to create the information that establishes “a priori” knowledge. In addition, “ad-hoc” could provide marker tracking methods or feature tracking methods based on Optical flow, Parallel Tracking and Mapping (PTAM) and Simultaneous Localization and Mapping (SLAM) [34]. A sensor-based method tracks the location of the sensor, which could be Radio Frequency Identification (RFID), a magnetic sensor, an ultrasonic sensor, a depth camera, an inertial sensor, infra-red (IR), GPS, etc.

Table 15.

Articles on Tracking methods from 2010–2021.

Table 15.

Articles on Tracking methods from 2010–2021.

| Classification Criteria | References | ||

|---|---|---|---|

| Tracking method | CV-based tracking | Marker-based tracking | [7,55,64,77,79,81,84,88,93,94,97,98,99,100] [103,104,109,112,121,122,125,130,132] [142,143,144,145,147,148,149,152,155,157,158,160] [164,165,168,169,171,174,177,178] [180,181,182,183,184,186,193,198,199,202,205] [206,209,211,212,214,215,218,221,223] |

| Markerless tracking | [30,51,54,57,61,62,65,66,69,72,74] [119,138,150,156,159,162] [172,175,187,189,192,197] [201,203,204,210,211] [216,217,219,220,225] | ||

| Model based tracking | [8,67,68,73,86,139,141,153] [154,191,194,222,235] | ||

| Sensor-based tracking | [11,161,200] | ||

| Hybrid tracking | [52,53,56,58,59,71,90,102,127] [140,163,166,167,173,179,188,190] [195,196,208,213] | ||