Featured Application

Cement bound granular mixtures for base and sub-base layers of road pavements.

Abstract

Construction and demolition waste (CDW) and coconut husk are frequently discharged into landfills, creating an environmental problem. However, the CDW can be used to obtain good-quality recycled aggregates (RA), and the coconut husk can be processed into coconut fiber (CF). These materials can be used in the construction of cement bound granular mixtures (CBGM) to be applied as base and sub-base layers of road pavements. Such a large-scale application would bring value to these materials and reduce the extraction of non-renewable natural resources. In this work, the mechanical performance of CBGM with RA and CF reinforcement was evaluated and compared with a conventional CBGM with natural aggregate (NA). The mechanical performance was assessed through the immediate bearing index (IBI), unconfined compressive strength (UCS), indirect tensile strength (ITS), and flexural strength (FLS) tests. The results of the experimental program allow the conclusion that the CBGM with RA present similar performance to the CBGM with NA. Furthermore, the use of CF effectively reinforced the integrity of the CBGM specimens at post-test, indicating potential gains in durability after cracking occurrence.

1. Introduction

The construction of road pavement consumes a considerable amount of natural resources, particularly aggregates. The European Aggregates Association (UEPG) indicates an average annual demand of six tons per capita (in EU+EFTA space, 2018), which amounts to three billion tons per year, placing the aggregates sector as by far the largest consumer of natural resources among the non-energy extractive industries [1]. The UEPG estimates that 20% of the end use of aggregates is in transport infrastructure: roads, runways, railways, and waterways [1]. The majority of the aggregates used is obtained from crushing natural rocks. This permanent consumption of non-renewable resources is not sustainable. In addition, some regions already possess low reserves of quality aggregates [2,3,4,5,6].

Concomitantly, demolition and renovation actions produce significant waste, commonly designated as construction and demolition waste (CDW). Over the last years, a big portion of these materials was discharged into landfills [2]. As a result, the European Parliament and the European Council issued directives to promote the rational and efficient use of natural resources to tackle this environmental problem [7,8]. These directives are being transposed into national legislation. For example, in the case of Portugal, DL 102-D/2020 [9] recently increased the cost of CDW disposal into landfills from 11 to 22 EUR/ton and already predicts an increase to 35 EUR/ton in 2025. However, if properly processed, CDW can be used to obtain recycled aggregates (RA).

The use of RA, as the total or partial replacement of natural aggregates (NA), has already been validated for cement concrete [4,10,11,12,13,14] and unbound granular layers [15,16,17,18,19,20,21,22,23]. Compared to NA, in general, RA tend to present lower dry density, higher water absorption, and higher wear by abrasion. When crushed concrete materials mainly constitute the RA, these differences can be explained by the residual mortar adhered to the aggregates. Furthermore, when released and hydrated, this adhered mortar promotes self-cementing reactions that enhance the overall mechanical strength [15,18,24,25].

Regarding cement bound granular mixtures (CBGM), the use of RA has already been evaluated, generally presenting a lower maximum dry density and requiring a higher moisture content [3,26,27,28]. In addition, some authors evaluated the performance of CBGM in full-scale pavement test sections, and when testing with falling weight deflectometers, found the deflections of the sections with RA to be equal to or lower than those of the sections with NA [29,30,31]. Thus, the use of RA allowed a higher modulus in the pavement layer, which indicates enhanced mechanical behavior.

In bound materials, such as concrete and CBGM, the incorporation of fibers can cause a reinforcement effect. Regarding reinforcement, a material with the potential to be used in CBGM is coconut fiber (CF). CF, a natural fiber, is obtained from coconut husk. Coconut husk is a residue from the food sector, which extracts several products from the coconut. Currently, there is a lack of large-scale applications for this waste material, which is generally discharged into landfills, posing an environmental problem.

As natural materials, some variability in properties can occur. However, several authors have already highlighted the good mechanical properties of CF, such as tensile strength (90–286 MPa), tensile modulus (1.1–13 GPa), and a high maximum tensile strain (15–51%) [5]. CF also presents high durability due to its low cellulose and high lignin contents that retard its natural degradation [32].

Several authors have previously explored the use of CF in bound materials (mostly cement concrete) and concluded that such an application was interesting [5]. The use of CF enhanced the mechanical performance of the bound material, producing gains in indirect tensile strength (ITS), flexural strength (FLS), toughness, impact resistance, and restraining crack development [33,34,35,36,37,38,39,40,41]. However, incorporating high dosages of CF can increase voids and decrease density, which may affect performance [36,37,42]. The use of CF, particularly at high dosages, affects workability, and in the case of cement concrete, decreases the slump value [42,43]. In the case of CBGM, the CF dosage should be optimized to ensure the integrity of the material, i.e., maximize durability. Currently, there is a gap in the knowledge regarding the mechanical performance of CBGM incorporating CF, as no literature was found on this matter.

Large amounts of CDW and coconut husk are produced, both of which lack significant large-scale applications. In this regard, the construction of road pavement is a possible application, as it is an activity that consumes large amounts of aggregate. In this study, to explore the use of fibers, these materials were included in bound layers, particularly sub-base and base layers. The consumption of RA and CF, which are obtained from waste materials, would enable savings in the consumption of natural resources and reduce the volumes of such materials in landfills.

This work promotes the use of recycled materials, RA and CF, in CBGM by presenting the results of an experimental program designed to understand their effects in the mechanical performance of CBGM. Following the materials characterization, the mechanical performance of the CBGM was assessed according to the current European specifications framework. The mechanical performance was evaluated in the laboratory through the immediate bearing index (IBI), unconfined compressive strength (UCS), ITS, and FLS tests.

2. Materials and Methods

2.1. Materials

The materials required for the production of conventional CBGM are aggregates, cement, and water. The variables under study were the type of aggregate and the incorporation of CF to promote a reinforcement effect. To isolate the effects of these variables, the same cement and water source (tap water) were used throughout the experimental program.

In total, six CBGM were studied, according to the compositions indicated in Table 1. In Table 1, the cement and the CF dosages are given as a percentage of dry aggregates mass and as a percentage of dry solids mass (cement and aggregate), respectively.

Table 1.

Designation and constituents of the six CBGM compositions studied.

Two types of aggregates were used: one NA and one RA. Table 2 presents the particle size distribution of the aggregates and the grading envelope indicated by the Portuguese infrastructure agency for the aggregate 0/31.5 to be used in CBGM [44]. The RA was obtained by processing CDW through a jaw crusher. Regarding lithology, the original aggregate of the RA was mainly derived from granodiorite.

Table 2.

Aggregate particle size distribution and specification limits used as reference.

The RA can be classified according to its constituents. According to EN 933-11 [45], which establishes a classification for the constituents of coarse RA (≥4 mm), the constitution of the RA was: 81.0% concrete, concrete products, and mortar; 18.3% unbound aggregate, natural stone, and hydraulically bound aggregate; 0.3% clay masonry, calcium silicate masonry, and aerated non-floating concrete; and 0.3% bituminous materials. For instance, under the AASHTO framework [46], this RA would classify as reclaimed concrete aggregate (RCA).

Table 3 presents the properties of the NA and RA. The Portuguese specifications [44] set a maximum of 30 and 40 for the flakiness index and Los Angeles coefficient, respectively. The specifications also indicate that when the percentage of fines is higher than 3%, the sand equivalent should be higher than 50. If the percentage of fines is higher than 3% and the sand equivalent is lower than 50, methylene blue must be lower than two. Finally, if the percentage of fines is lower than 3%, the characteristics of the fines are considered irrelevant to the general performance of the aggregate mixture. Thus, both aggregate types match the requirements of the specification. Regarding the RA, the higher Los Angeles abrasion and water absorption can be partially explained by the residual adhered mortar. Other authors also identified higher Los Angeles abrasion and water absorption of RA [10,17,20,47].

Table 3.

Properties of the natural and recycled aggregates.

In all mixtures, the cement used was Portland CEM II/A-L 42.5 R. This type of cement was selected because it is the one most used by the Portuguese industry. Aligned with the objective of reducing the consumption of natural resources, low cement dosages (2% or 3%) were used throughout the study. In addition, the use of a higher cement dosage can promote better mechanical strength, but it would also increase the possibility of shrinkage cracks.

The CF was obtained by processing waste from coconut husk. A sample of CF used for the CBGM production is presented in Figure 1. The properties of the CF are presented in Table 4. The CF dosage in the CBGM (0.1%) was selected according to the literature [5]. In the CBGM with CF, the fibers were added last, after mixing aggregates, cement, and water. Moreover, as CF presents high water absorption, it was soaked in water prior to mixing.

Figure 1.

Sample of coconut fiber.

Table 4.

Properties of the CF.

2.2. Specimens Preparation and Test Methods

A 180 L drum mixer was used to produce the specimens in the laboratory. For the IBI, UCS, and ITS tests, the cylindrical specimens (approximately 150 mm in diameter and 150 mm in height) were compacted using a vibrating hammer following EN 13286-51 [48]. For the FLS tests, the specimens (approximately 400 × 100 × 100 mm) were compacted in rectangular molds, simulating the compaction conditions adopted for the cylindrical specimens. The target maximum dry density (MDD) and optimum water content (OWC) were previously determined according to EN 13286-1 [49], using the vibrating hammer compaction in EN 13286-4 [50]. As a result, an MDD of 2.19 and 1.96 Mg/m3 and an OWC of 4.1% and 9.2% were obtained for the mixtures with NA and RA, respectively. Following compaction, the specimens were conditioned in a curing chamber at 20 °C and 95% relative humidity for the curing age indicated in Table 5.

Table 5.

Type of test and curing age adopted in the experimental program.

Table 5.

Type of test and curing age adopted in the experimental program.

| Type of Test | Test Standard | Reference | Curing Age |

|---|---|---|---|

| IBI | EN 13286-47 | [51] | n.a. |

| UCS | EN 13286-41 | [52] | 7 days |

| ITS | EN 13286-42 | [53] | 7 and 28 days |

| FLS | EN 12390-5 | [54] | 28 days |

n.a.—not applicable.

The mechanical performance of the CBGM was assessed through a laboratory experimental program involving the tests presented in Table 5. IBI was evaluated through the immediate California bearing ratio (CBR) test. In this case, the CBR test was carried out 60 to 90 min after the preparation of the CBGM specimens, and no surcharge was applied. The UCS tests were conducted under constant load, ensuring that rupture of the specimen occurred within 30 to 60 s, as indicated by the respective test standard. The ITS tests were conducted under constant displacement (50 mm/min), ensuring that the stress increase was no greater than 0.2 MPa/s, as indicated by the respective test standard. In the case of FLS, we followed the test standard for hardened concrete, as no dedicated test standard is available for CBGM. The center-point loading method was used and loading was applied under constant displacement (1.27 mm/min), ensuring that the loading rate of 0.05 MPa/s was not exceeded.

3. Results and Discussion

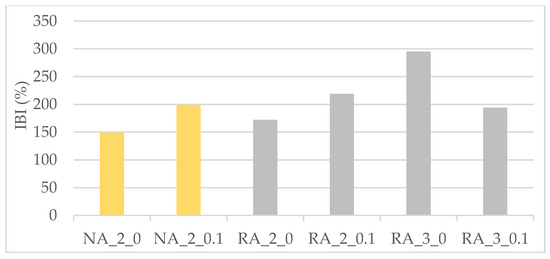

3.1. Immediate Bearing Index

The results of the IBI are presented in Figure 2. As the IBI was performed within 60 to 90 min after the specimen preparation, the strength gain due to cement hydration should be negligible. Thus, as expected, the cement dosage had no clear effect on IBI. Additionally, the use of CF had no clear effect on IBI. However, the 2% cement CBGM with NA and RA presented an increase in IBI with the use of CF. Conversely, the CBGM with RA and 3% cement showed lower IBI when the CF was added.

Figure 2.

Immediate bearing index of the CBGM.

The CBGM constituents can explain the high values of the IBI. The good-quality aggregates and controlled particle size distribution, within the limits of the specification, can explain the IBI values. Possibly, the differences in the IBI among the studied mixtures can be explained by a better (or worse) aggregate interlocking being achieved in some of the specimens.

For the CBGM supporting immediate trafficking, the European specification for CBGM, EN 14227-1 [55], recommends a minimum IBI of 40%. However, all the studied CBGM presented an IBI equal to or higher than 150%, indicating no problems regarding immediate trafficking.

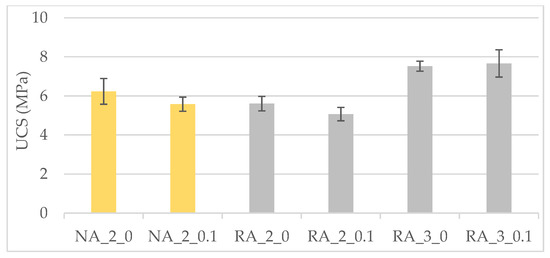

3.2. Unconfined Compressive Strength

The results of the 7 days UCS are presented in Figure 3. For each CBGM, the average values and standard deviations shown in Figure 3 were determined from three tested specimens. All CBGM presented good UCS results, with average values higher than 5 MPa. Such strength levels allow them to easily comply with the UCS requirements set by most infrastructure agencies. The values largely exceed the minimum UCS set by the Portuguese infrastructure agency [44], a 28 days UCS higher than 1 MPa, and the minimum UCS indicated by the Australian Guide to Pavement Technology [56], a 28 days UCS higher than 2 MPa. Regarding UCS, some of the more demanding specifications are the Spanish PG-3 [57] that requires a 7 days UCS higher than 4.5 MPa and the South African Pavement Engineering Manual, SAPEM [58], which indicates a minimum 7 days UCS of 4 MPa and 6 MPa for the CSM-C2 and CSM-C1 classes, respectively.

Figure 3.

Unconfined compressive strength of the CBGM at 7 days of curing.

In the case of the CBGM with 2% cement, the use of CF caused a slight decrease in the UCS, 11% and 10% for the CBGM with NA and RA, respectively. On the other hand, in the CBGM with RA and 3% cement, the use of CF increased the UCS by 2%. These variations indicate that the CF reinforcement did not contribute to increasing the UCS. However, on a smaller scale, this was to be expected, as some studies about the use of CF in cement concrete noted that the presence of the CF could promote an increase in voids with a respective decrease in density, which in turn affects UCS.

For the CBGM using RA, the increase in cement dosage from 2% to 3% increased UCS by 34% and 51% for the CBGM without CF and using CF, respectively.

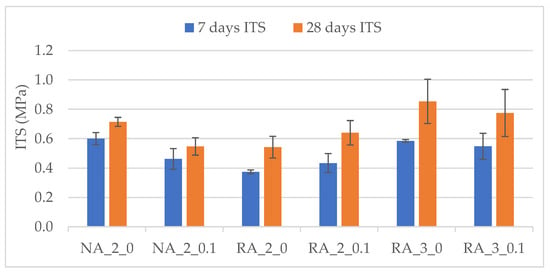

3.3. Indirect Tensile Strength

The ITS test results at 7 and 28 days of curing are presented in Figure 4, where the bars represent the average results, and the error marks represent the standard deviation. For each CBGM and curing age, three specimens were tested. The lowest ITS values were obtained with the RA_2_0 mixture, with 0.374 and 0.542 MPa at 7 and 28 days of curing, respectively. Thus, all CBGM exceed the minimum ITS indicated by several references such as a former Portuguese specification by Junta Autonoma de Estradas (JAE) [59] and SAPEM [58]. SAPEM indicates a minimum ITS at 7 days of 0.20 and 0.25 MPa for the CSM-C4 and CSM-C3 classes, respectively (for CSM-C2 and CSM-C1, the minimum ITS is not set). JAE indicates a minimum ITS of 0.20 and 0.30 MPa at 7 and 28 days, respectively.

Figure 4.

Indirect tensile strength of the CBGM at 7 and 28 days of curing.

The use of RA, as a substitution of the NA, did not compromise the ITS. In the case of the CBGM with 2% cement, if compared with the CBGM with NA, the CBGM with RA presented a variation in ITS of −38% and −24% without CF and −6% and +17% with CF at 7 and 28 days, respectively. For the CBGM with RA, at 7 days, the increase in the cement dosage from 2% to 3% increased ITS by 56% and 26% for the CBGM without CF and with CF, respectively. For the CBGM with RA, at 28 days of curing, the increase in the cement dosage from 2% to 3% increased ITS by 58% and 21% for the CBGM without CF and with CF, respectively.

Regarding the use of CF, the effects in the ITS of the CBGM were not obvious. In the CBGM with NA, the use of CF led to a reduction in ITS of 23% at both the 7th and 28th days. The use of CF in the CBGM with RA caused variations in ITS of +16% and +18% in the mixture with 2% cement and −6% and −9% in the mixture with 3% cement at 7 and 28 days, respectively.

However, the effects on strength were not clear. The use of CF highly enhanced the integrity of the CBGM specimens post-test. Figure 5 presents an example of CBGM with RA at post-test, without CF (left) and with CF (right). While the specimens without CF tended to split into two halves and presented some disaggregation, the specimens with CF maintained their integrity, and the loss of particles was minimal. Such an effect is visually more impactful on the ITS and FLS tests than on the others analyzed. However, a similar effect occurred with the UCS post-test.

Figure 5.

Example of CBGM specimens, without CF (left) and with CF (right), after the indirect tensile strength test.

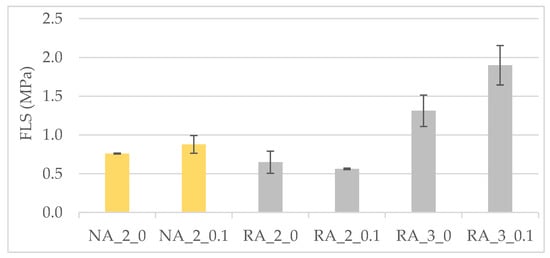

3.4. Flexural Strength

The results of the FLS test are presented in Figure 6. In Figure 6, the bars represent averages and the error marks represent standard deviation. For each CBGM, two specimens were tested. Generally, due to the much lower cement dosage, the CBGM presented an FLS that is much lower than a conventional cement concrete. Thus, the FLS tests were conducted only at 28 days of curing and not earlier.

Figure 6.

Flexural strength of the CBGM at 28 days of curing.

In the CBGM with 2% cement, all FLS values ranged from 0.5 to 1.0 MPa. Accordingly, the CBGM with RA and 3% cement presented a higher FLS. For the CBGM with RA, the increase in the cement dosage from 2% to 3% increased FLS by 102% and 237% for the CBGM without CF and with CF, respectively. Such an increase was expected, as a 2% cement content is a particularly low dosage.

The use of CF caused a variation in FLS of +16%, −13%, and +45% for the CBGM with NA and 2% cement, the CBGM with RA and 2% cement, and the CBGM with RA and 3% cement, respectively. Thus, in the case of FLS, the use of CF seems to be more effective if the original FLS (without CF) is higher, as in the cases of the CBGM with RA and 3% cement and the CBGM with NA and 2% cement. In addition, a visual effect of the use of CF in the CBGM was that the specimens did not break, splitting into two halves, after reaching the peak load (Figure 7).

Figure 7.

Example of CBGM specimens, without CF (top) and with CF (bottom), after the flexural strength test.

4. Conclusions

The construction of pavement layers demands a significant amount of materials, particularly aggregates and, generally, natural aggregates (NA) are used. In this work, we evaluated the feasibility, in terms of mechanical performance, of using recycled aggregates (RA), mostly crushed concrete, derived from construction and demolition waste (CDW) and coconut fiber (CF) obtained from discarded coconut husk in the construction of cement bound granular mixture (CBGM). Such CBGM are commonly used in sub-base and base layers of road pavement. The use of RA and CF, obtained from actual waste materials, would enable savings in the consumption of non-renewable natural resources.

An experimental program was developed in the laboratory to evaluate the mechanical performance of CBGM incorporating the abovementioned materials. The studied CBGM were tested for immediate bearing index (IBI), unconfined compressive strength (UCS), indirect tensile strength (ITS), and flexural strength (FLS). The obtained results highlight the suitability of RA for CBGM application and the potential of CF to provide a fiber reinforcement effect. Furthermore, the experimental results allowed the following conclusions:

- Regarding immediate trafficking, the IBI results indicate good performance for all CBGM, underlining the suitability of RA to replace NA.

- The mechanical performance tests—UCS, ITS, and FLS—revealed that the CBGM with RA presented a reasonably similar performance to the CBGM with high-quality NA, clearly indicating that the use of RA does not compromise the overall performance of the CBGM. Furthermore, notwithstanding the low cement dosages considered, 2% and 3%, all CBGM exceeded the usual minimum strength requirements set by the specifications of infrastructure administrations.

- The use of CF promoted the effect of fiber reinforcement. However, in the cases of UCS and ITS, it did not have clear effects in the peak resistance of the CBGM. On the other hand, it effectively enhanced FLS at a higher cement dosage (3%). Generally, in all the tests, the use of CF maintained the integrity of the specimens at post-test. Furthermore, if compared to the CBGM without CF, the specimens of CBGM with CF presented minimal loss of particles and splitting during test loading and at post-test. Such an effect highlights the potential of CF to enhance the durability of the CBGM and its response under damaged (post-cracking) conditions.

More studies are needed to quantify the effects on durability. For example, further studies will be conducted to evaluate durability following the mass loss due to brushing methods as indicated by AASHTO T 135 [60] and AASHTO T136 [61]. In addition, to better understand construction feasibility and in-service performance, the construction of a full-scale test section is ongoing. This test section will have different pavement stretches, using CBGM with NA and RA and without CF and with CF. Following construction, the bearing capacity will be periodically evaluated using falling weight deflectometer equipment.

Author Contributions

Conceptualization, J.C., L.P.-S. and J.N.; methodology, J.C., L.P.-S. and J.N.; validation, L.P.-S. and J.N.; investigation, J.C. and L.P.-S.; data curation, J.C.; writing—original draft preparation, J.C.; writing—review and editing, J.C., L.P.-S. and J.N.; project administration, L.P.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Portuguese national funding agency for science, research, and technology (Fundação para a Ciência e a Tecnologia (FCT), I.P.), under the Research Project PTDC/ECI-TRA/32244/2017.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to acknowledge Laboratory of Transport Infrastructures of Instituto Superior Técnico (LVCT-IST), Laboratory of Geotechnics of Instituto Superior Técnico (LG-IST), Industria de Betão, S.A. (IBERA), and Laboratory of Soils and Pavements, Repartição de Engenharia de Aeródromos da Direção de Infraestruturas, Portuguese Air Force (LSP-FAP) for their support of the experimental program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- UEPG. European Agregates Association, Annual Review 2019–2020; UEPG: Brussels, Belgium, 2021. [Google Scholar]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Cannone Falchetto, A.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Pasetto, M. The re-utilisation of discarded building materials in cement-stabilised layers of road and airfield pavements. Waste Manag. Ser. 2000, 1, 548–566. [Google Scholar]

- Tavakoli, D.; Hashempour, M.; Heidari, A. Use of waste materials in concrete: A review. Pertanika J. Sci. Technol. 2018, 26, 499–522. [Google Scholar]

- Crucho, J.; Picado-Santos, L.; Neves, J. Cement-treated pavement layers incorporating construction and demolition waste and coconut fibres: A review. Int. J. Pavement Eng. 2021. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Silva, F. Cement-treated volcanic scoria for low-traffic road pavements in the Azores archipelago. Materials 2021, 14, 6080. [Google Scholar] [CrossRef]

- UE Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018, amending Directive 1999/31/EC on the landfill of waste. Off. J. Eur. Union 2018, L150, 100–108.

- UE Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018, amending Directive 2008/98/EC on waste. Off. J. Eur. Union 2018, L150, 109–140.

- DRE. Decreto-Lei n.o 102-D/2020. In Diário da República, 1a Série, N.o 239—10 de Dezembro de 2020; Assembleia da República: Lisboa, Portugal, 2020; pp. 2–269. [Google Scholar]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Sadati, S.; Khayat, K.H. Field performance of concrete pavement incorporating recycled concrete aggregate. Constr. Build. Mater. 2016, 126, 691–700. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. Effect of recycled concrete aggregate properties on mixture proportions of structural concrete. Transp. Res. Rec. 2012, 2290, 105–114. [Google Scholar] [CrossRef]

- Gonzalez-Burón, J.; Nougués, A. Study of granular base course with incorporation of recycled concrete aggregates—Argentinas’ experience. In Proceedings of the PIARC—26th World Road Congress, Abu Dhabi, United Arab Emirates, 6–10 October 2019. [Google Scholar]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Chai, L.; Monismith, C.L.; Harvey, J. Re-Cementation of Crushed Material in Pavement Bases; Pavement Research Center, University of California: Berkeley and Davis, CA, USA, 2009. [Google Scholar]

- Freire, A.C.; Neves, J.; Roque, A.; Martins, I.; Antunes, M.L.; Faria, G. Use of construction and demolition recycled materials (C&DRM) in road pavements validated on experimental test sections. In Proceedings of the WASTES 2013: Solutions, Treatments and Opportunities 2nd International Conference, Braga, Portugal, 11–13 September 2013; pp. 91–96. [Google Scholar]

- Freire, A.C.; das Neves, J.M.C.; Roque, A.J.; Martins, I.M.; de Lurdes Antunes, M. Feasibility study of milled and crushed reclaimed asphalt pavement for application in unbound granular layers. Road Mater. Pavement Des. 2019, 629, 1500–1520. [Google Scholar] [CrossRef]

- Courard, L.; Rondeux, M.; Zhao, Z.; Michel, F. Use of recycled fine aggregates from C&DW for unbound road sub-base. Materials 2020, 13, 2994. [Google Scholar]

- Ciampa, D.; Cioffi, R.; Colangelo, F.; Diomedi, M.; Farina, I.; Olita, S. Use of unbound materials for sustainable road infrastructures. Appl. Sci. 2020, 10, 3465. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Arm, M. Self-cementing properties of crushed demolishing concrete in unbound layers results from triaxial tests and field tests. Waste Manag. Ser. 2000, 1, 579–587. [Google Scholar]

- Jitsangiam, P.; Boonserm, K.; Phenrat, T.; Chummuneerat, S. Recycled Concrete Aggregates in Roadways: A Laboratory Examination of Self-Cementing Characteristics. J. Mater. Civ. Eng. 2015, 27, 04014270. [Google Scholar] [CrossRef]

- Behiry, A.E.A.E.M. Utilization of cement treated recycled concrete aggregates as base or subbase layer in Egypt. Ain Shams Eng. J. 2013, 4, 661–673. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Recycling of waste aggregate in cement bound mixtures for road pavement bases and sub-bases. Constr. Build. Mater. 2016, 108, 112–118. [Google Scholar] [CrossRef]

- Stehlik, D.; Dasek, O.; Hyzl, P.; Coufalik, P.; Krcmova, I.; Varaus, M. Pavement construction using road waste building—From a model to reality. Road Mater. Pavement Des. 2015, 16, 314–329. [Google Scholar] [CrossRef]

- Qamhia, I.I.A.; Tutumluer, E.; Ozer, H.; Shoup, H.; Beshears, S.; Trepanier, J. Evaluation of Chemically Stabilized Quarry Byproduct Applications in Base and Subbase Layers through Accelerated Pavement Testing. Transp. Res. Rec. 2019, 2673, 259–270. [Google Scholar] [CrossRef]

- Agrela, F.; Barbudo, A.; Ramírez, A.; Ayuso, J.; Carvajal, M.D.; Jiménez, J.R. Construction of road sections using mixed recycled aggregates treated with cement in Malaga, Spain. Resour. Conserv. Recycl. 2012, 58, 98–106. [Google Scholar] [CrossRef]

- Pérez, P.; Agrela, F.; Herrador, R.; Ordoñez, J. Application of cement-treated recycled materials in the construction of a section of road in Malaga, Spain. Constr. Build. Mater. 2013, 44, 593–599. [Google Scholar] [CrossRef]

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of coconut fiber in coconut shell concrete and its mechanical and bond properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and durability of coconut-fiber-reinforced concrete in aggressive environments. Constr. Build. Mater. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Ali, M.; Chouw, N. Experimental investigations on coconut-fibre rope tensile strength and pullout from coconut fibre reinforced concrete. Constr. Build. Mater. 2013, 41, 681–690. [Google Scholar] [CrossRef]

- Chen, J.; Chouw, N. Flexural behaviour of flax FRP double tube confined coconut fibre reinforced concrete beams with interlocking interface. Compos. Struct. 2018, 192, 217–224. [Google Scholar] [CrossRef]

- Chen, J.; Chouw, N. Nonlinear flexural behaviour of flax FRP double tube confined coconut fibre reinforced concrete. Mater. Des. 2016, 93, 247–254. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effect of super plasticizer on the properties of medium strength concrete prepared with coconut fiber. Constr. Build. Mater. 2018, 182, 703–715. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Gonçalves, S.A. Use of Coconut Fiber in Concrete (in Portuguese). Master’s Thesis, Instituto Superior de Engenharia do Porto, Porto, Portugal, 2016. [Google Scholar]

- Walter Otunyo, A.; Dan Nyechieo, N. Mechanical Properties and Fracture Behaviour of Coconut Fibre Reinforced Concrete (CFRC). Am. J. Civ. Eng. Archit. 2017, 5, 208–216. [Google Scholar] [CrossRef][Green Version]

- IP. Specifications; Portuguese Infrastructure Agency: Almada, Portugal, 2014.

- CEN. EN 933-11:2009; Tests for Geometrical Properties of Aggregates—Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate. European Committee for Standardization: Brussels, Belgium, 2009.

- AASHTO. M 319-02 (2015); Standard Specification for Reclaimed Concrete Aggregate for Unbound Soil-Aggregate Base Course. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility assessment of the use of recycled aggregates for asphalt mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- CEN. EN 13286-51:2004; Unbound and Hydraulically Bound Mixtures—Part 51: Method for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Vibrating Hammer Compaction. European Committee for Standardization: Brussels, Belgium, 2004.

- CEN. EN 13286-1:2003; Unbound and Hydraulically Bound Mixtures—Part 1: Test Methods for Laboratory Reference Density and Water Content—Introduction, General Requirements and Sampling. European Committee for Standardization: Brussels, Belgium, 2003.

- CEN. EN 13286-4:2003; Unbound and Hydraulically Bound Mixtures—Part 4: Test Methods for Laboratory Reference Density and Water Content—Vibrating Hammer. European Committee for Standardization: Brussels, Belgium, 2003.

- CEN. EN 13286-47:2012; Unbound and Hydraulically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. European Committee for Standardization: Brussels, Belgium, 2012.

- CEN. EN 13286-41:2003; Unbound and Hydraulically Bound Mixtures—Part 41: Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures. European Committee for Standardization: Brussels, Belgium, 2003.

- CEN. EN 13286-42:2003; Unbound and Hydraulically Bound Mixtures—Part 42: Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures. European Committee for Standardization: Brussels, Belgium, 2003.

- CEN. EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- CEN. EN 14227-1:2013; Hydraulically Bound Mixtures—Specifications—Part 1: Cement Bound Granular Mixtures. European Committee for Standardization: Brussels, Belgium, 2013.

- Austroads. Guide to Pavement Technology Part 4D—Stabilised Materials, 2nd ed.; Austroads: Sydney, Australia, 2019; ISBN 978-1-925854-12-1. [Google Scholar]

- Ministerio de Fomento. FOM/2523/2014, Pliego de Prescripciones Técnicas Generales para Obras de Carreteras y Puentes (PG-3); Gobierno de España: Madrid, Spain, 2015.

- SANRAL. Standards. In South African Pavement Engineering Manual; South African National Roads Agency: Pretoria, South Africa, 2014. [Google Scholar]

- Branco, F.; Pereira, P.; Picado-Santos, L. Highway Pavements; Almedina: Coimbra, Portugal, 2016. (In Portuguese) [Google Scholar]

- AASHTO. T 135-13 (2013); Standard Method of Test for Wetting-and-Drying Test of Compacted Soil-Cement Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- AASHTO. T 136-13 (2013); Standard Method of Test for Freezing-and-Thawing Tests of Compacted Soil-Cement Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).