Smoke Back-Layering Phenomenon under the Combined External Wind and Stack Effects in a Staircase

Abstract

:1. Introduction

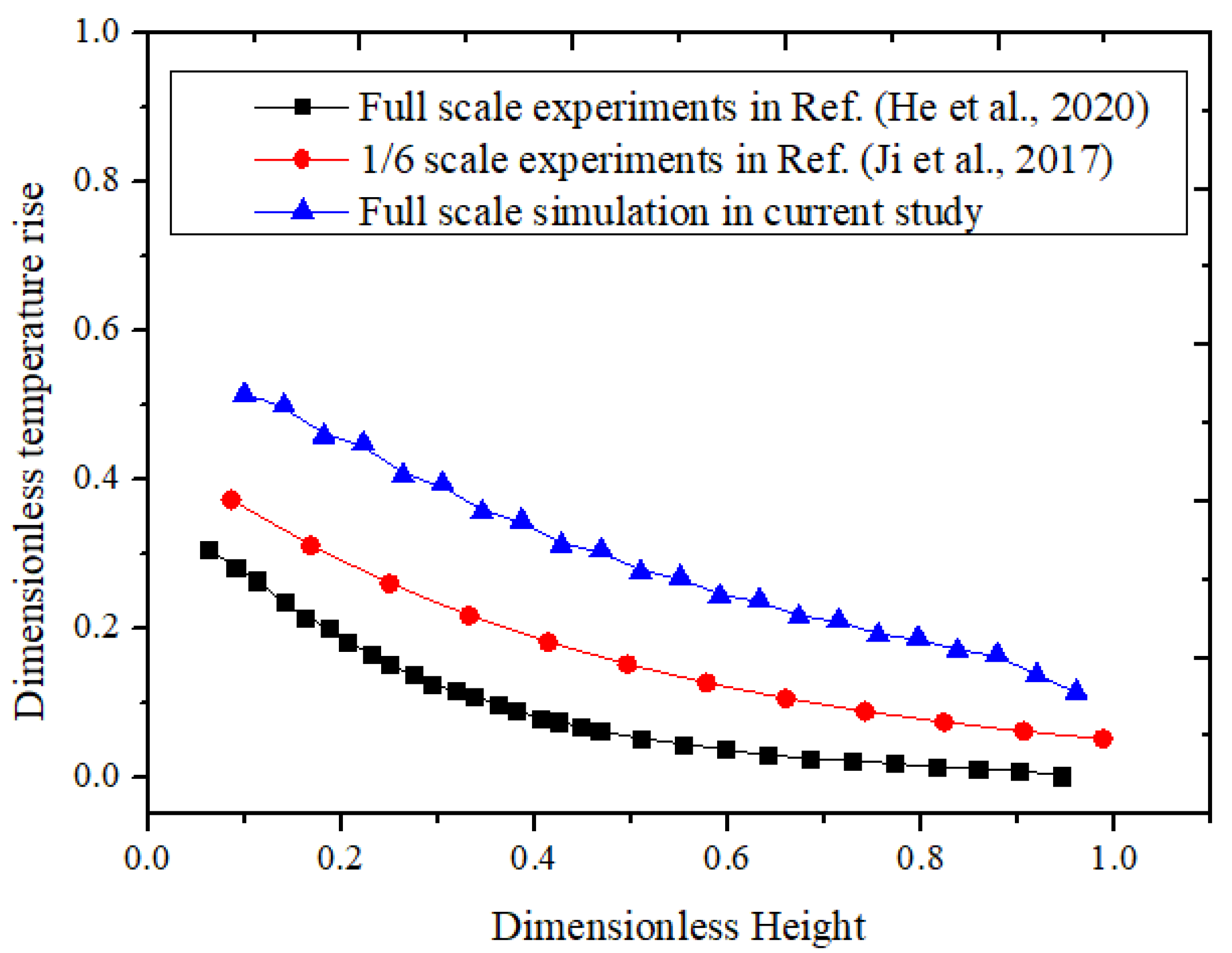

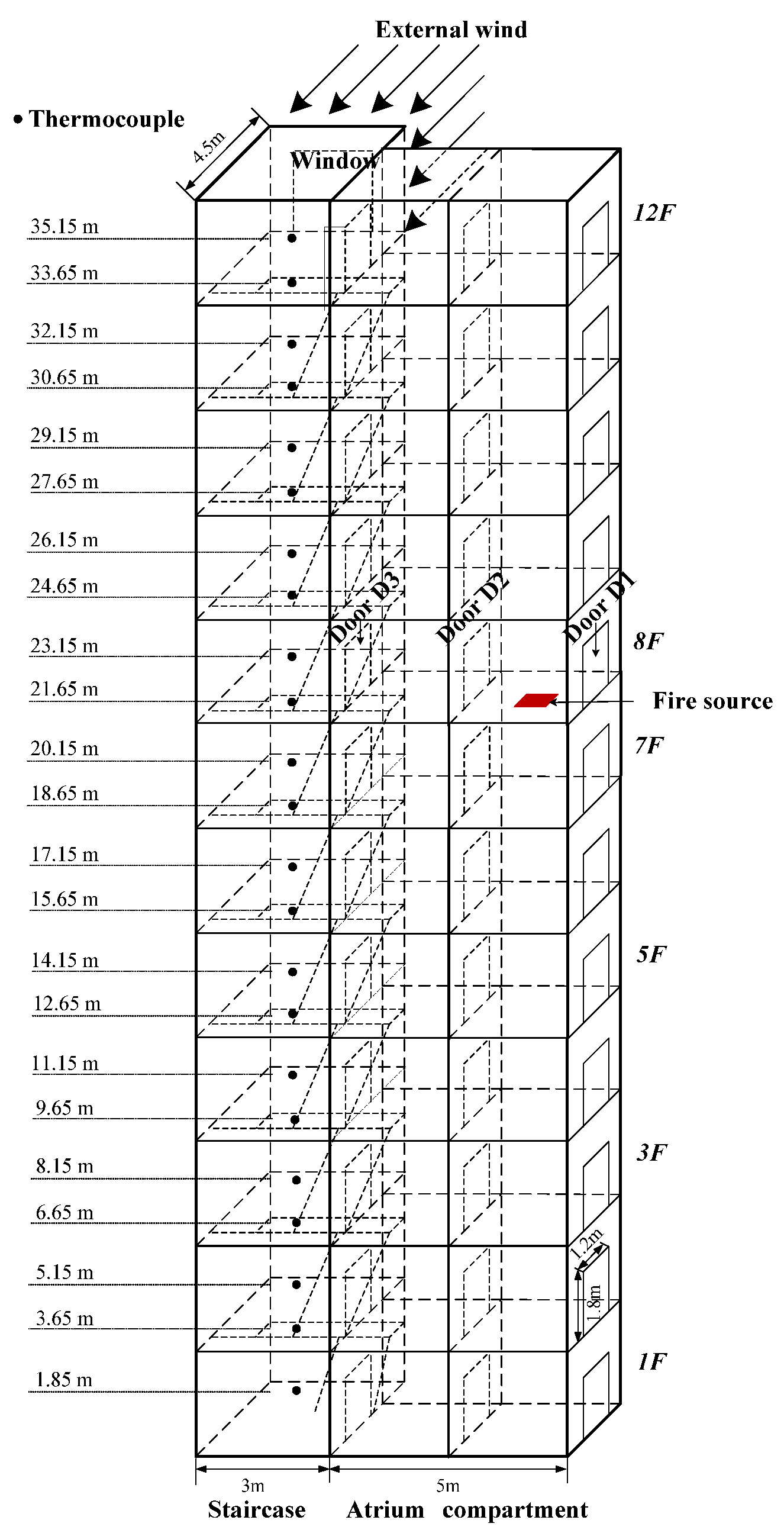

2. Numerical Modeling

3. Results and Discussion

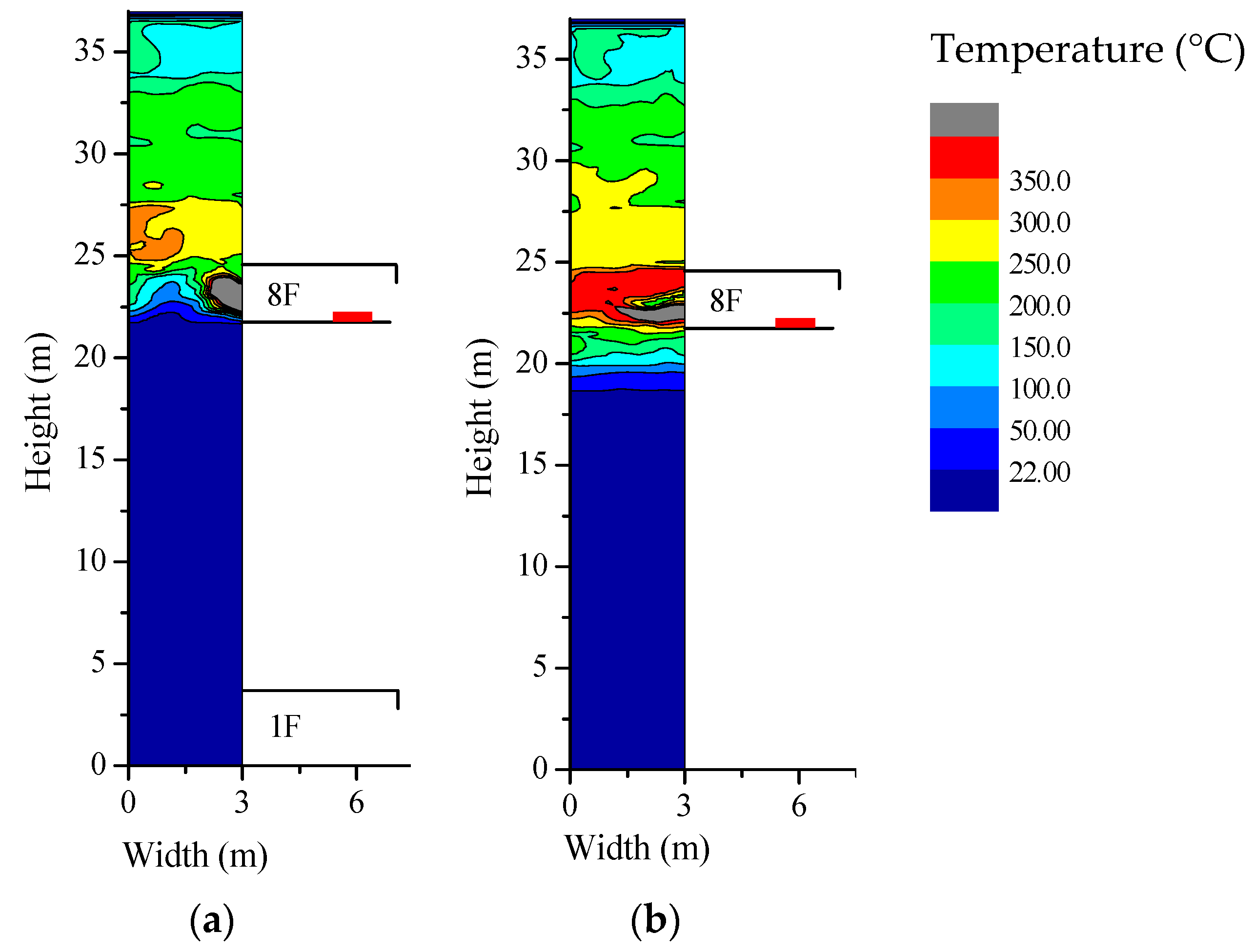

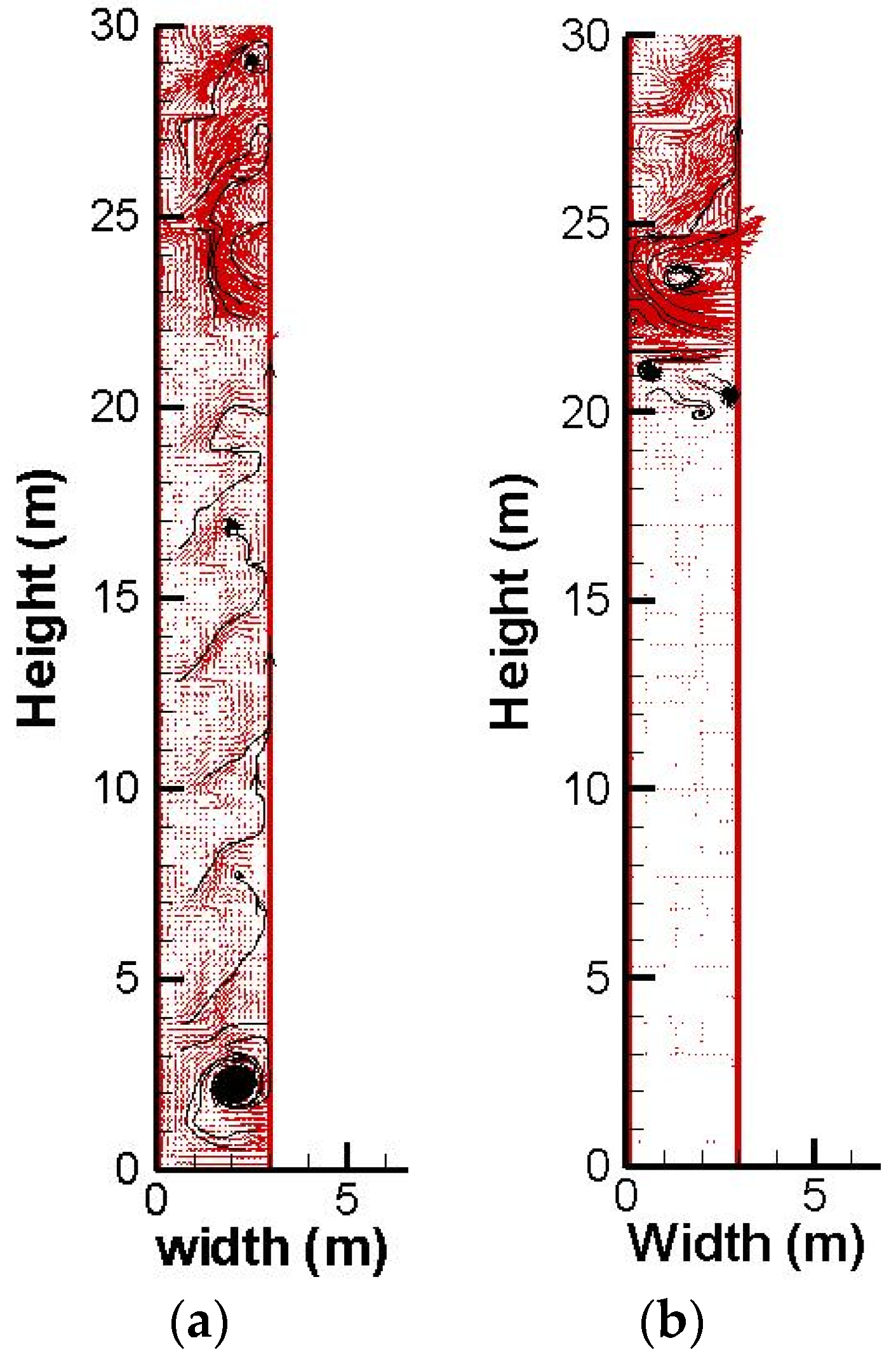

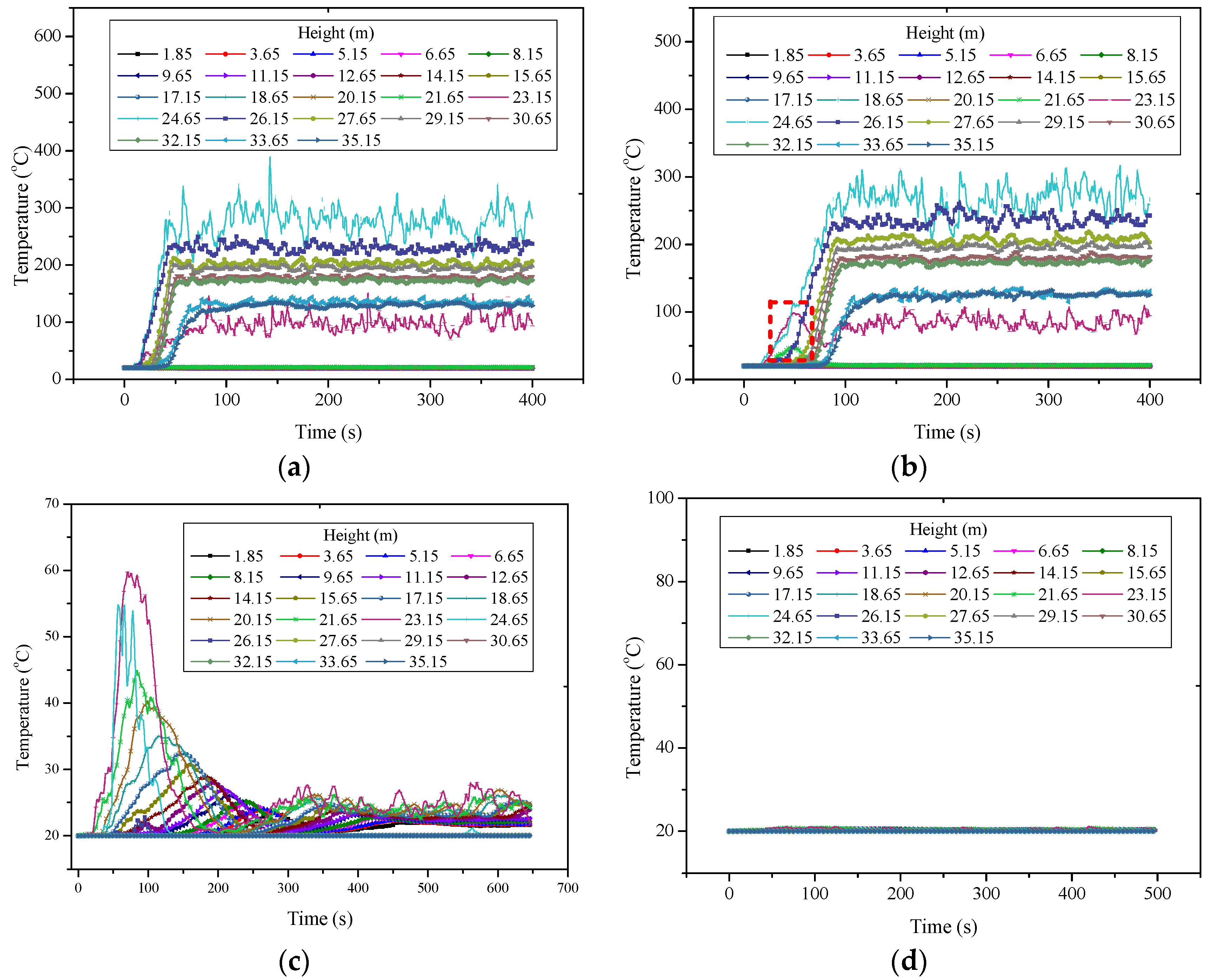

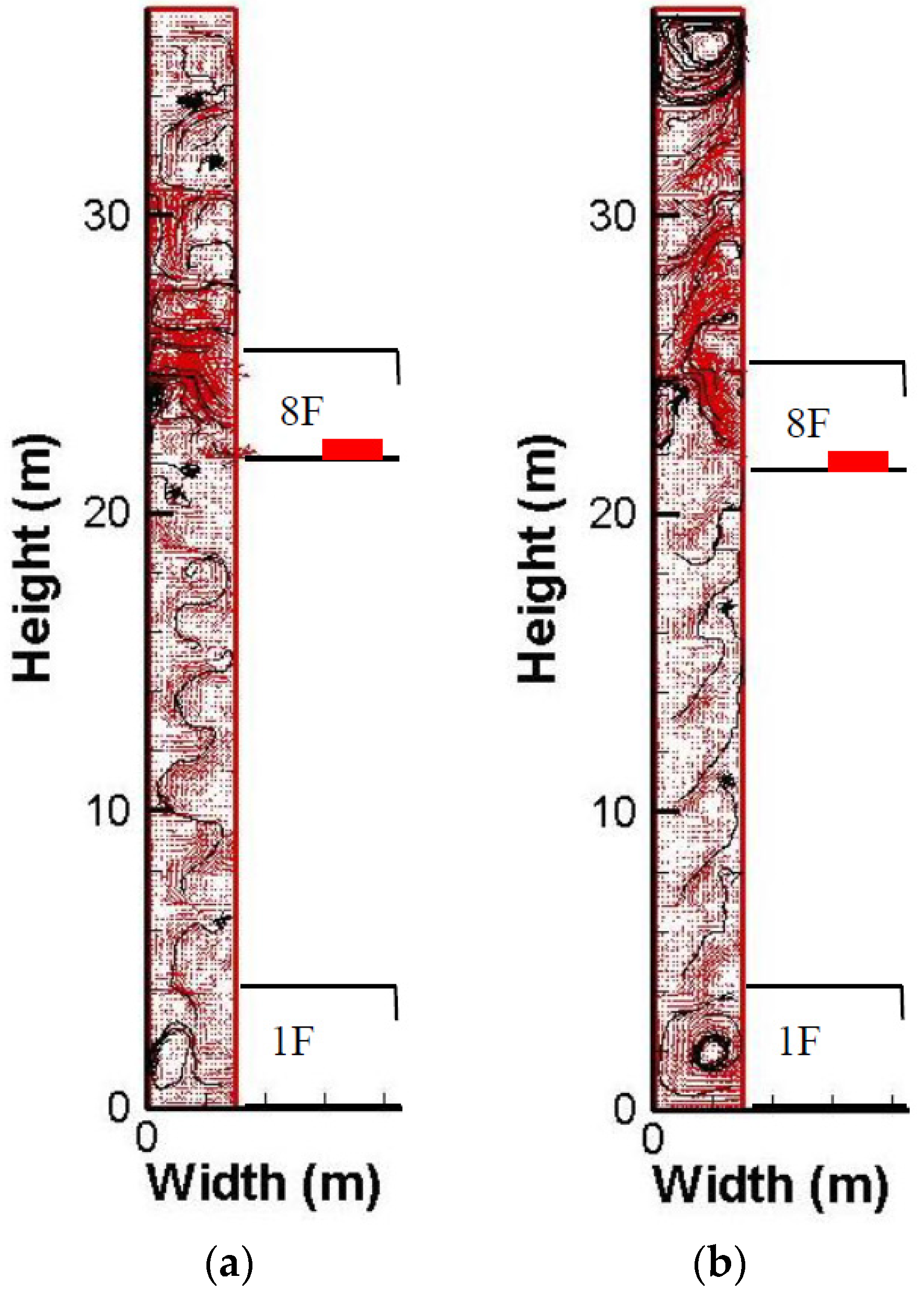

3.1. Effect of the Open Stair Door below the Fire Source on Smoke Movement Patterns

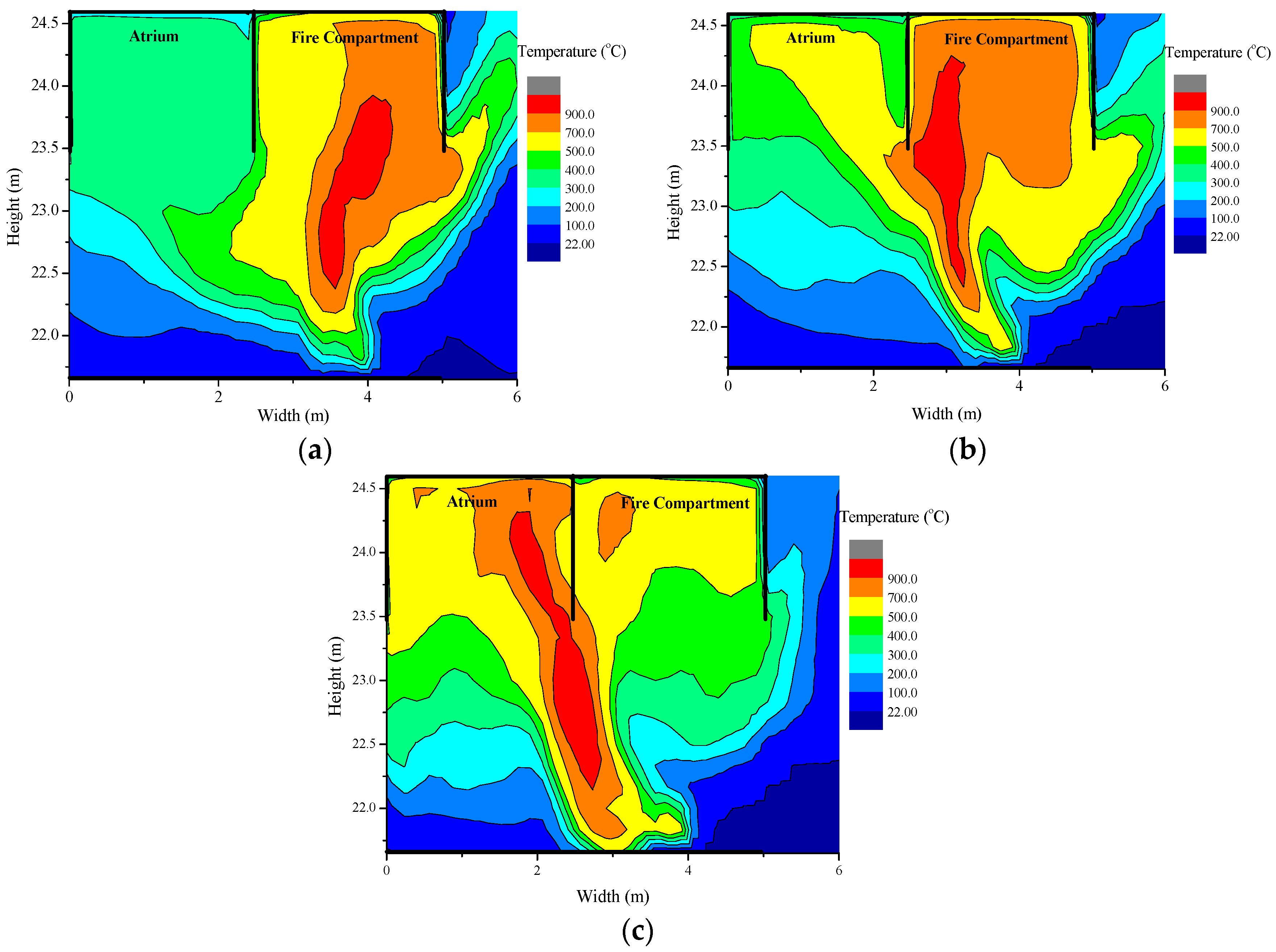

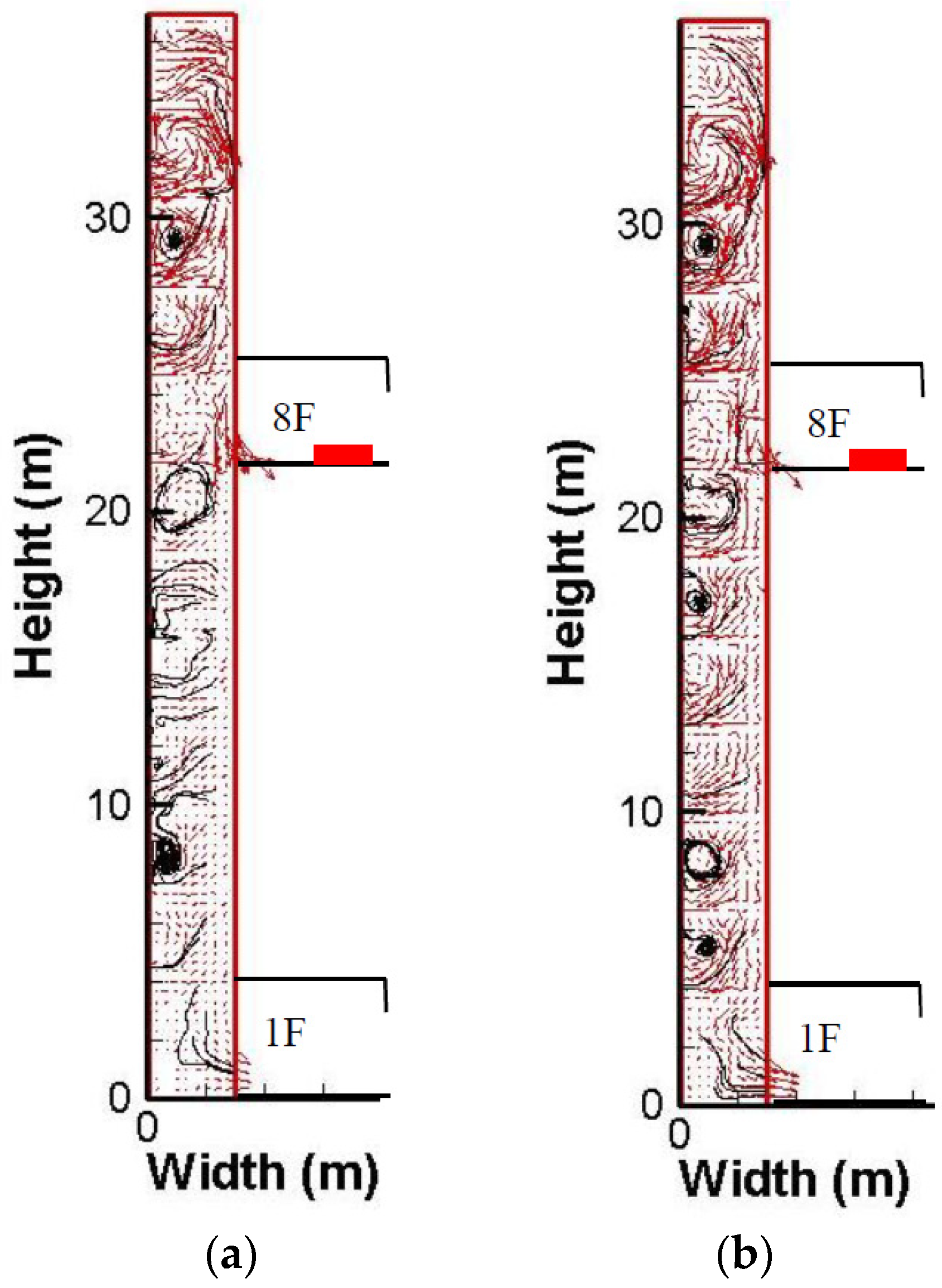

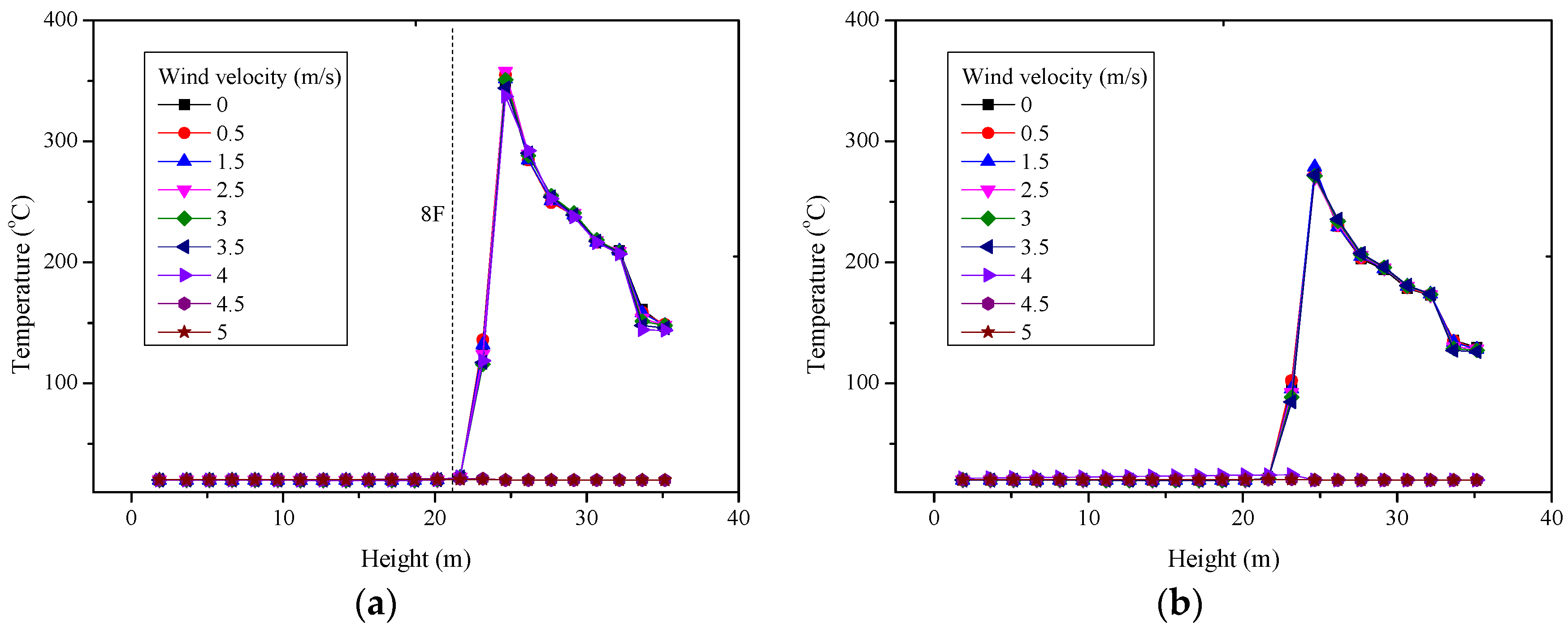

3.2. Wind Effect on the Smoke Movement with Open Stair Door below the Fire Source

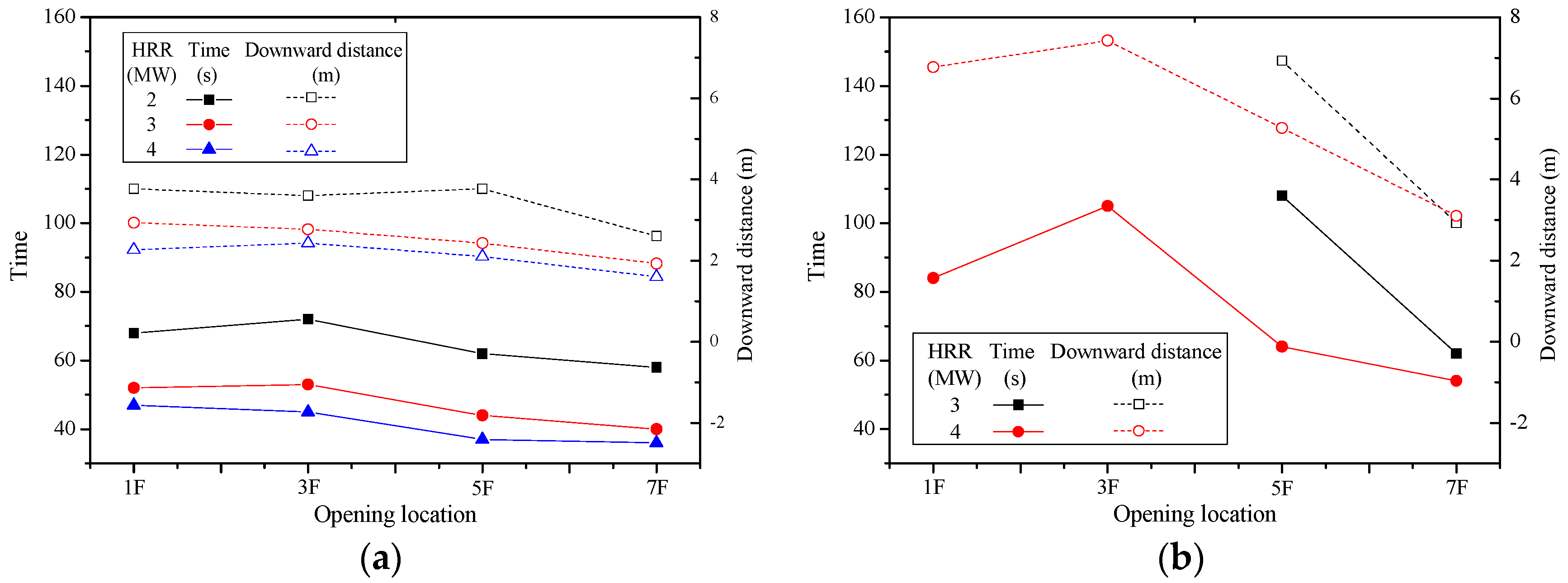

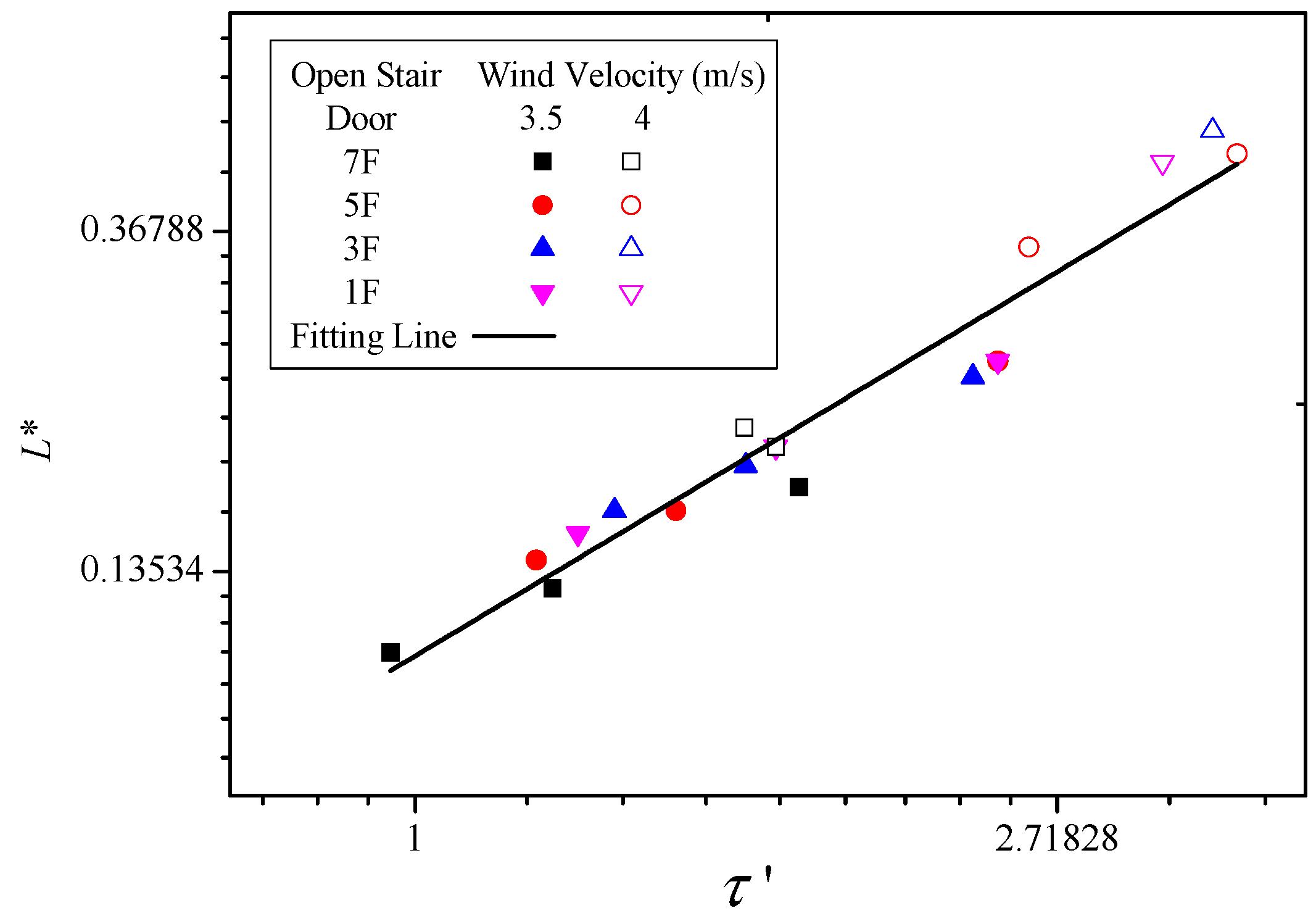

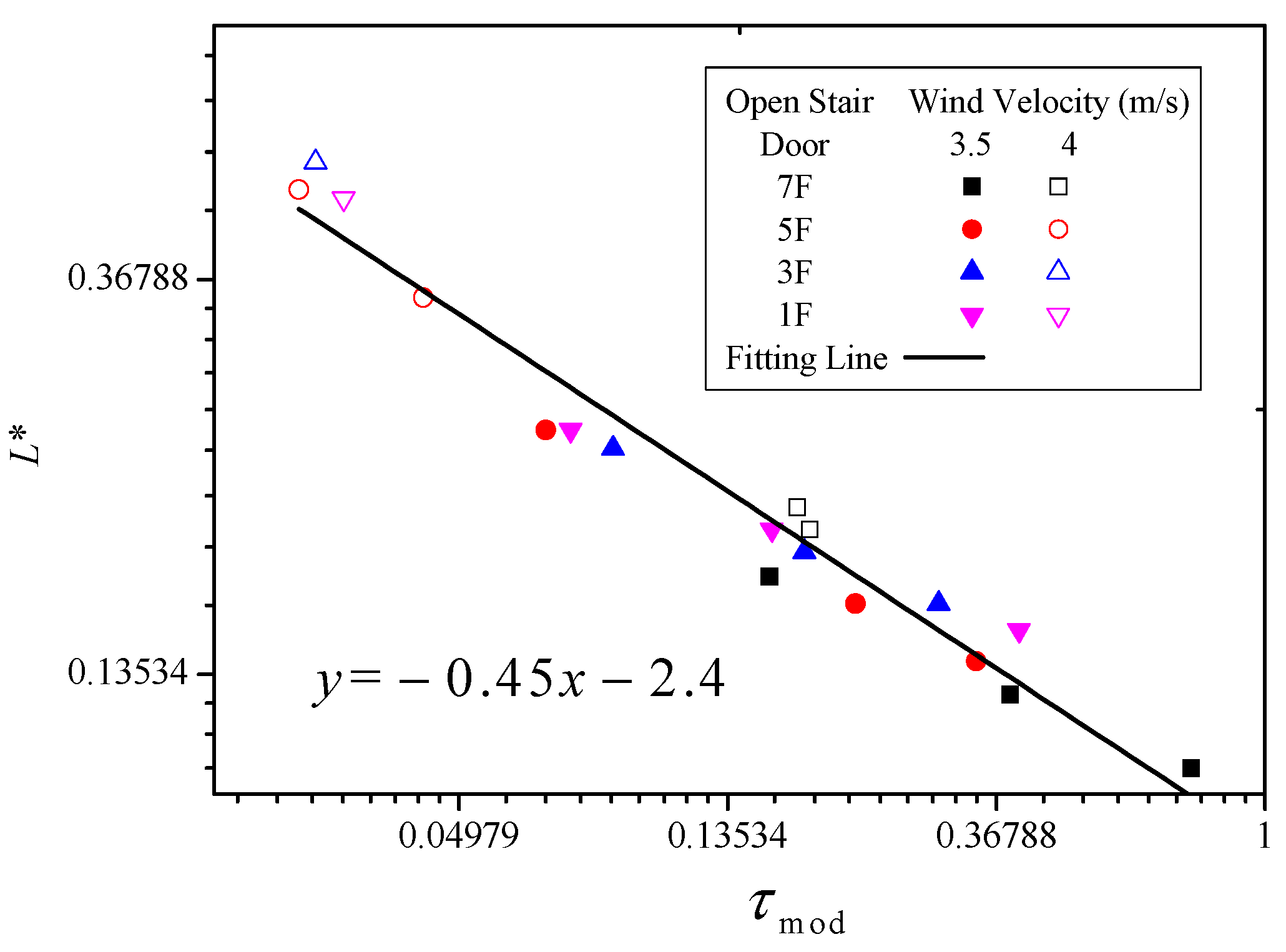

3.3. Smoke Back-Layering Distance under the External Wind

4. Conclusions

- (1)

- When the external wind is absent, downward moving smoke occurred, driven by pressure difference with closed stair doors below the fire floor.

- (2)

- When the stair doors open below the fire floor, four smoke behaviors are identified with the increasing wind velocity: upward moving smoke, first downward then upward moving smoke, downward moving smoke, and no smoke inside the staircase.

- (3)

- Smoke behaviors are directly related to the flame tilt direction. Smoke moves upward when the flame tilts to the staircase and moves downward when the flame tilts to the opposite direction.

- (4)

- The back-layering distance with the first downward then upward moving smoke increases with the increasing open stair door location and wind velocity. A modified correlation is established to predict the smoke back-layering distance and time.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, L.; Milke, J.A.; Merci, B. Special issue on fire safety of high-rise buildings. Fire Technol. 2017, 53, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Gao, Z.; Ji, J.; Li, K. Modeling of positive pressure ventilation to prevent smoke spreading in sprinklered high-rise buildings. Fire Saf. J. 2018, 95, 87–100. [Google Scholar] [CrossRef]

- Klote, J.H. A General Routine for Analysis of Stack Effect; National Institute of Standards and Technology, Building and Fire Research Laboratory: Gaithersburg, MD, USA, 1991. [Google Scholar]

- Harmathy, T.Z. Simplified model of smoke dispersion in buildings by stack effect. Fire Technol. 1998, 34, 6–17. [Google Scholar] [CrossRef]

- Qi, D.; Wang, L.; Zmeureanu, R. An analytical model of heat and mass transfer through non-adiabatic high-rise shafts during fires. Int. J. Heat Mass Transf. 2014, 72, 585–594. [Google Scholar] [CrossRef]

- Tanaka, T.; Fujita, T.; Yamaguchi, J. Investigation into rise time of buoyant fire plume fronts. Int. J. Eng. Perform. -Based Fire Codes 2000, 2, 14–25. [Google Scholar]

- Ji, J.; Li, L.J.; Shi, W.X.; Fan, C.G.; Sun, J.H. Experimental investigation on the rising characteristics of the fire-induced buoyant plume in stairwells. Int. J. Heat Mass Transf. 2013, 64, 193–201. [Google Scholar] [CrossRef]

- Li, L.J.; Ji, J.; Fan, C.G.; Sun, J.H.; Yuan, X.Y.; Shi, W.X. Experimental investigation on the characteristics of buoyant plume movement in a stairwell with multiple openings. Energy Build. 2014, 68, 108–120. [Google Scholar] [CrossRef]

- Ji, J.; Li, M.; Shi, W.; Gao, Z.; Sun, J.; Lo, S. Deflection characteristic of flame with the airflow induced by stack effect. Int. J. Therm. Sci. 2017, 115, 160–168. [Google Scholar] [CrossRef]

- Madrzykowski, D.; Kerber, S.I. Fire Fighting Tactics under Wind Driven Conditions: Laboratory Experiments; Fire Protection Research Foundation: Gaithersburg, MD, USA, 2009. [Google Scholar]

- Gao, W.; Liu, N.; Delichatsios, M.; Yuan, X.; Bai, Y.; Chen, H.; Zhang, L. Fire spill plume from a compartment with dual symmetric openings under cross wind. Combust. Flame 2016, 167, 409–421. [Google Scholar] [CrossRef]

- Li, M.; Gao, Z.; Ji, J.; Li, K.; Sun, J. Wind effects on flame projection probability from a compartment with opposing openings. Fire Saf. J. 2017, 91, 414–421. [Google Scholar] [CrossRef]

- Ren, F.; Hu, L.; Zhang, X.; Sun, X.; Fang, X. Temperature evolution from stratified-to well-mixed condition inside a fire compartment with an opening subjected to external wind. Proc. Combust. Inst. 2020, 38, 4495–4503. [Google Scholar] [CrossRef]

- Ji, J.; Yuan, X.; Li, K.; Sun, J. Influence of the external wind on flame shapes of n-heptane pool fires in long passage connected to a shaft. Combust. Flame 2015, 162, 2098–2107. [Google Scholar] [CrossRef]

- Ji, J.; Zhu, L.; Ding, L.; Yu, L.; Wan, H. Numerical investigation of external wind effect on smoke characteristics in a stairwell. Fire Technol. 2020, 56, 1681–1702. [Google Scholar] [CrossRef]

- Wang, Y.F.; Yan, P.N.; Zhang, B.; Jiang, J.C. Thermal buoyant smoke back-layering length in a naturally ventilated tunnel with vertical shafts. Appl. Therm. Eng. 2016, 93, 947–957. [Google Scholar] [CrossRef]

- Hostikka, S.; Janardhan, R.K.; Riaz, U.; Sikanen, T. Fire-induced pressure and smoke spreading in mechanically ventilated buildings with air-tight envelopes. Fire Saf. J. 2017, 91, 380–388. [Google Scholar] [CrossRef] [Green Version]

- Zhao, G.; Beji, T.; Merci, B. Study of FDS simulations of buoyant fire-induced smoke movement in a high-rise building stairwell. Fire Saf. J. 2017, 91, 276–283. [Google Scholar] [CrossRef]

- Ahn, C.S.; Kim, D.Y.; Park, C.; Kim, M.W.; Kim, T.; Bang, B.H.; An, S.; Yarin, A.L.; Yoon, S.S. Experimental and numerical study of smoke behavior in high-rise stairwells with open and closed windows. Int. J. Therm. Sci. 2020, 157, 106500. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; Floyd, J.; McDermott, R.; Weinschenk, C.; Overholt, K. Fire Dynamics Simulator (Version 6), Users’ Guide; National Institute of Standards and Technology Report; NIST Special Publication: Gaithersburg, MD, USA, 2013. [Google Scholar]

- Guo, F.; Gao, Z.; Wan, H.; Ji, J.; Yu, L.; Ding, L. Influence of ambient pressure on critical ventilation velocity and back-layering distance of thermal driven smoke in tunnels with longitudinal ventilation. Int. J. Therm. Sci. 2019, 145, 105989. [Google Scholar] [CrossRef]

- Yan, G.; Wang, M.; Yu, L.; Duan, R.; Xia, P. Effects of ambient pressure on smoke movement patterns in vertical shafts in tunnel fires with natural ventilation systems. Build. Simul. 2020, 13, 931–941. [Google Scholar] [CrossRef]

- He, J.; Huang, X.; Ning, X.; Zhou, T.; Wang, J.; Yuen, R. Stairwell smoke transport in a full-scale high-rise building: Influence of opening location. Fire Saf. J. 2020, 117, 103151. [Google Scholar] [CrossRef]

- Qi, D.; Wang, L.; Zhao, G. Froude-Stanton modeling of heat and mass transfer in large vertical spaces of high-rise buildings. Int. J. Heat Mass Transf. 2017, 115, 706–716. [Google Scholar] [CrossRef]

- Weng, M.C.; Lu, X.L.; Liu, F.; Du, C.X. Study on the critical velocity in a sloping tunnel fire under longitudinal ventilation. Appl. Therm. Eng. 2016, 94, 422–434. [Google Scholar] [CrossRef]

- Fan, C.G.; Yang, J. Experimental study on thermal smoke back-layering length with an impinging flame under the tunnel ceiling. Exp. Therm. Fluid Sci. 2017, 82, 262–268. [Google Scholar] [CrossRef]

- Wan, H.; Gao, Z.; Han, J.; Ji, J.; Ye, M.; Zhang, Y. A numerical study on smoke back-layering length and inlet air velocity of fires in an inclined tunnel under natural ventilation with a vertical shaft. Int. J. Therm. Sci. 2019, 138, 293–303. [Google Scholar] [CrossRef]

| Fire Floor | HRR/MW | Open Stair Doors (D1–D3) | Wind Velocity (m/s) |

|---|---|---|---|

| 8th | 4 | 7th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5, 5.5 |

| 5th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 3rd | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 1st | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| None | 0 | ||

| 3 | 7th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5, 5.5 | |

| 5th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 3rd | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 1st | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 2 | 7th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | |

| 5th | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 3rd | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 | ||

| 1st | 0, 0.5, 1.5, 2.0 2.5, 3, 3.5, 4, 4.5, 5 |

| Wind Velocity (m/s) | 0, 0.5, 1.5, 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | |

|---|---|---|---|---|---|---|---|---|

| Opening Location | HRR(MW) | |||||||

| 1F | 2 |  | T |   |  | N | N | - |

| 3 |  | T |   |  | N | N | - | |

| 4 |  | T |   |   |  | N | - | |

| 3F | 2 |  | T |   |  | N | N | - |

| 3 |  | T |   |  |  | N | - | |

| 4 |  | T |   |   |  | N | - | |

| 5F | 2 |  | T |   |  |  | N | - |

| 3 |  | T |   |   |  | N | - | |

| 4 |  | T |   |   |  | N | - | |

| 7F | 2 |  | T |   |  |  | N | - |

| 3 |  | T |   |   |  |  | N | |

| 4 |  | T |   |   |  |  | N | |

upward moving smoke,

upward moving smoke,  downward moving smoke,

downward moving smoke,

first downward then upward moving smoke. T, critical transition condition of the upward moving smoke; N, no smoke inside the staircase.

first downward then upward moving smoke. T, critical transition condition of the upward moving smoke; N, no smoke inside the staircase.Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, L.; Chen, J.; Mu, Z.; Liu, S. Smoke Back-Layering Phenomenon under the Combined External Wind and Stack Effects in a Staircase. Appl. Sci. 2022, 12, 1469. https://doi.org/10.3390/app12031469

Li M, Wang L, Chen J, Mu Z, Liu S. Smoke Back-Layering Phenomenon under the Combined External Wind and Stack Effects in a Staircase. Applied Sciences. 2022; 12(3):1469. https://doi.org/10.3390/app12031469

Chicago/Turabian StyleLi, Man, Lingling Wang, Junya Chen, Zhenrong Mu, and Suqi Liu. 2022. "Smoke Back-Layering Phenomenon under the Combined External Wind and Stack Effects in a Staircase" Applied Sciences 12, no. 3: 1469. https://doi.org/10.3390/app12031469

APA StyleLi, M., Wang, L., Chen, J., Mu, Z., & Liu, S. (2022). Smoke Back-Layering Phenomenon under the Combined External Wind and Stack Effects in a Staircase. Applied Sciences, 12(3), 1469. https://doi.org/10.3390/app12031469