Separation of Lignocellulose and Preparation of Xylose from Miscanthus lutarioriparius with a Formic Acid Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

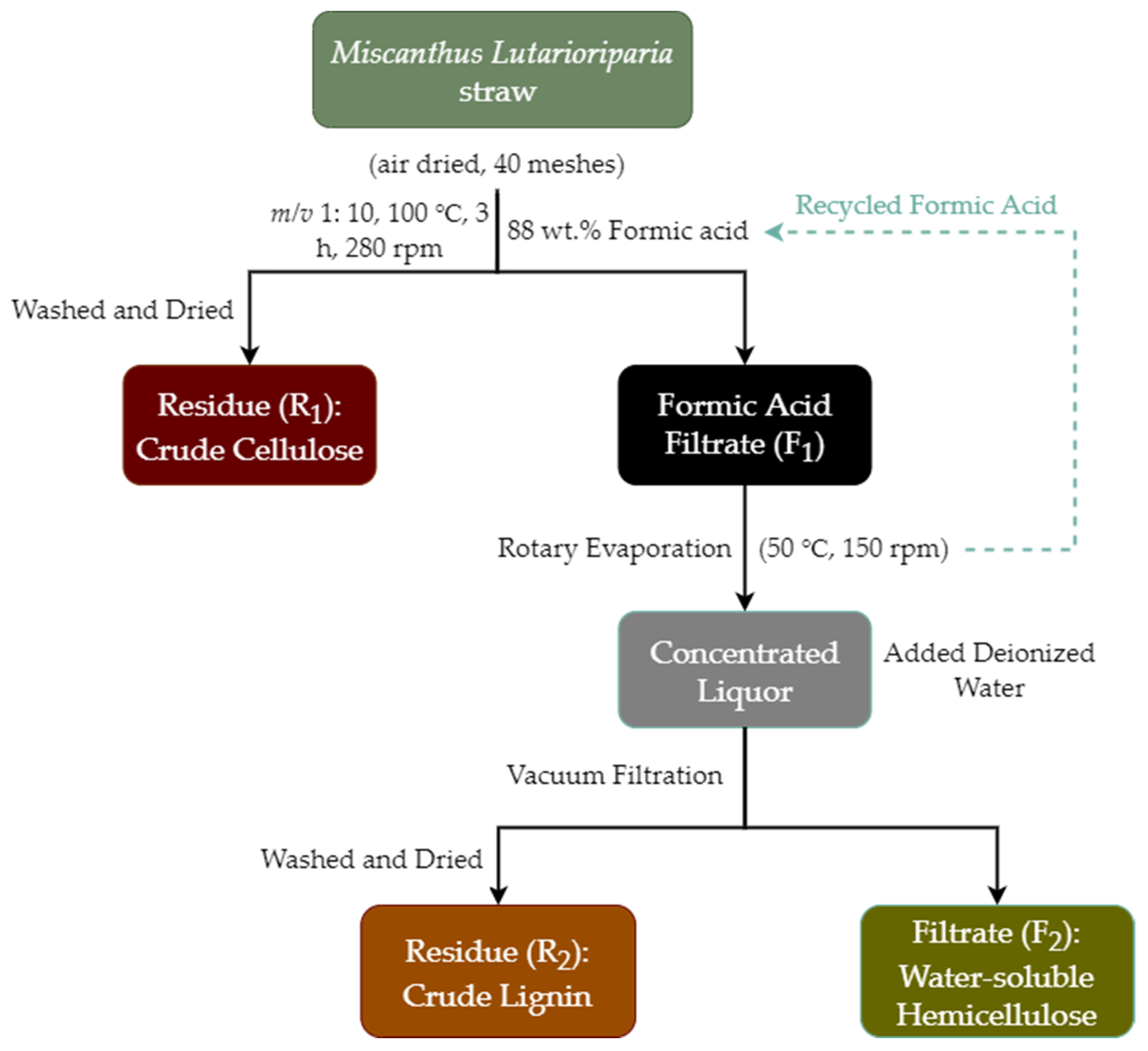

2.2. Formic Acid Pretreatment of Miscanthus lutarioriparius Straw

2.3. Composition Analysis of Crude Cellulose and Lignin

2.4. Structure Analysis of Crude Cellulose and Lignin

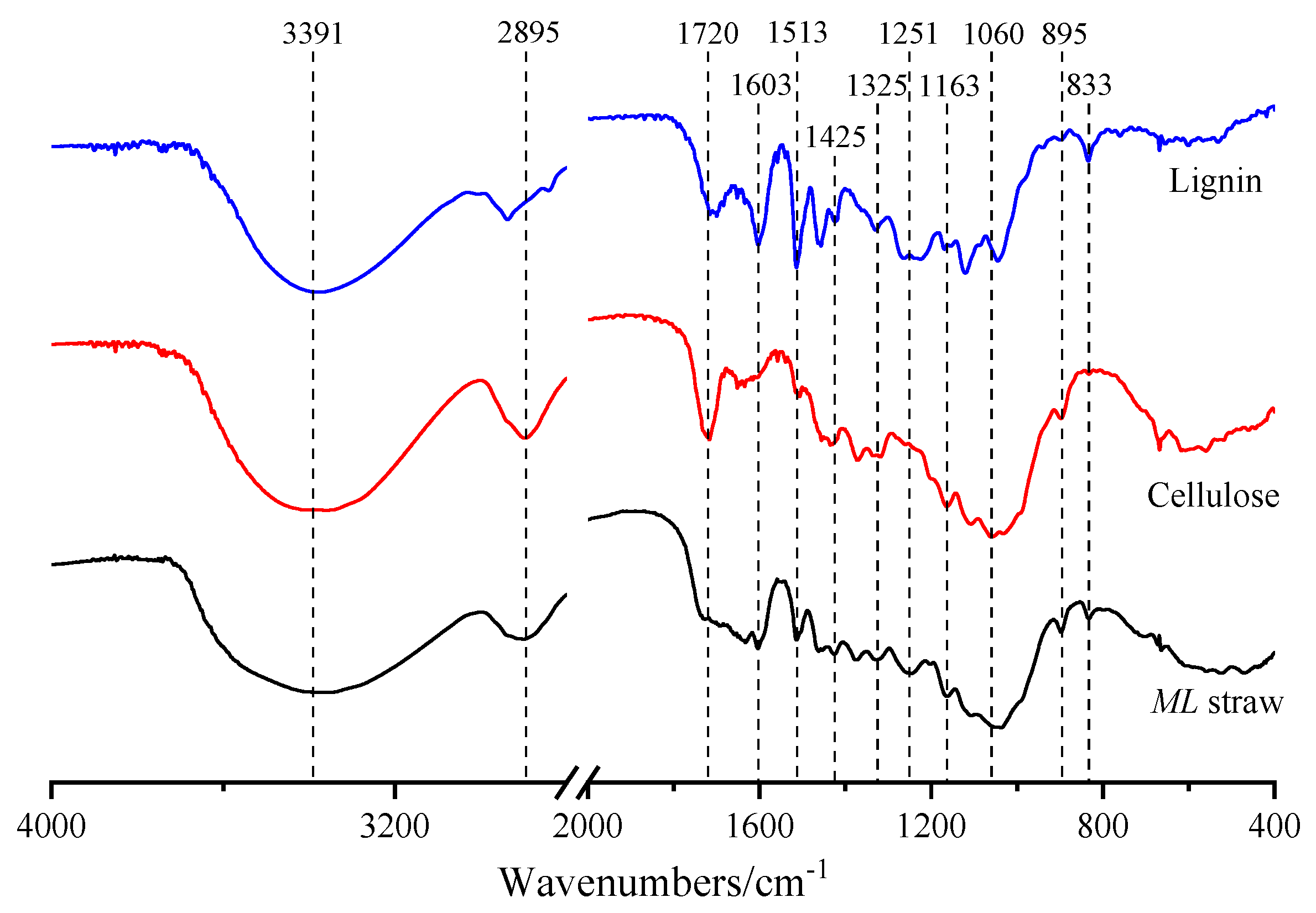

2.4.1. Fourier Transform Infrared Spectral (FT−IR) Analysis

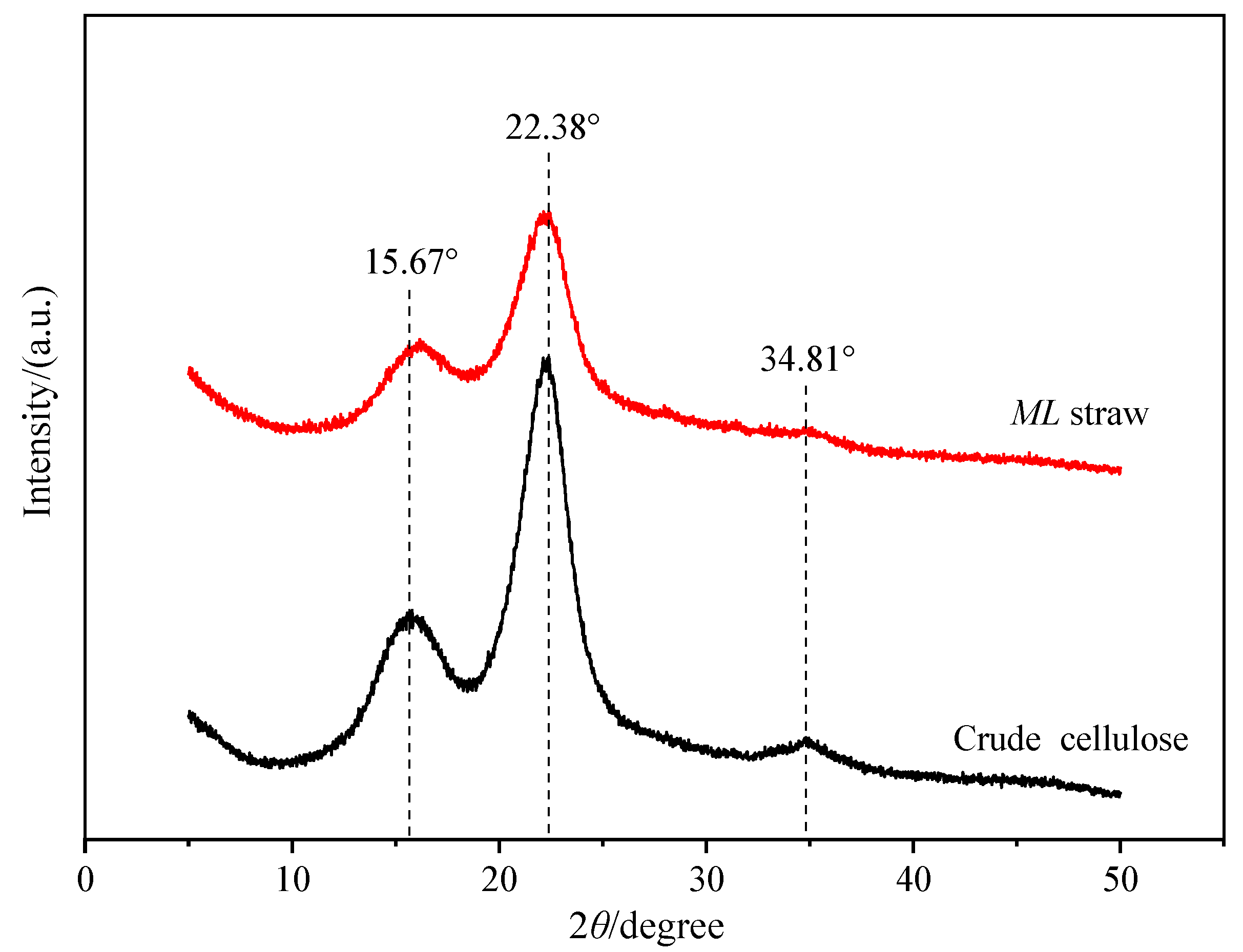

2.4.2. X-ray Diffraction (XRD) Analysis

2.4.3. Scanning Electron Microscope (SEM) Analysis

2.4.4. Thermogravimetry (TG) and Differential Thermogravimetry (DTG) Analysis

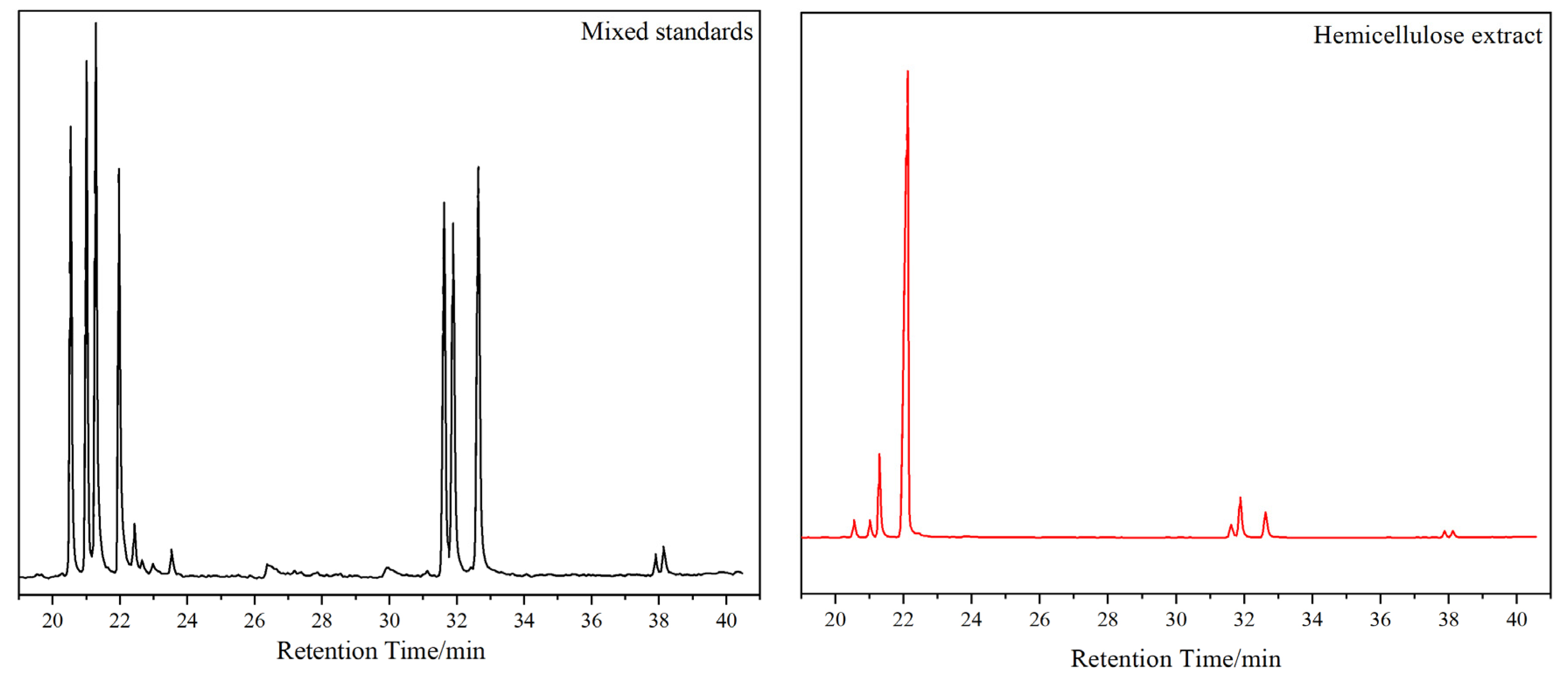

2.5. Determination of Monosaccharide Compositions in Hemicellulose Extract

2.6. Decolorization of Crude Xylose Extract

2.7. Purification of Crude Xylose Extract

2.7.1. Effect of Resin Static Adsorption on Main Compositions of Xylose

2.7.2. Separation Effect of Dowex 50wx4 Resin on Xylose and Arabinose

2.8. Statistical Analysis

3. Results

3.1. Analysis of Compositions of Crude Cellulose and Lignin

3.2. FT−IR Analysis of Crude Cellulose and Lignin

3.3. XRD Analysis of Crude Cellulose

3.4. SEM Analysis of Crude Cellulose

3.5. TGA Analysis of Crude Lignin

3.6. Composition Analysis of Hemicellulose Extract

3.7. Decolorization on Crude Xylose Extract with Activated Carbon

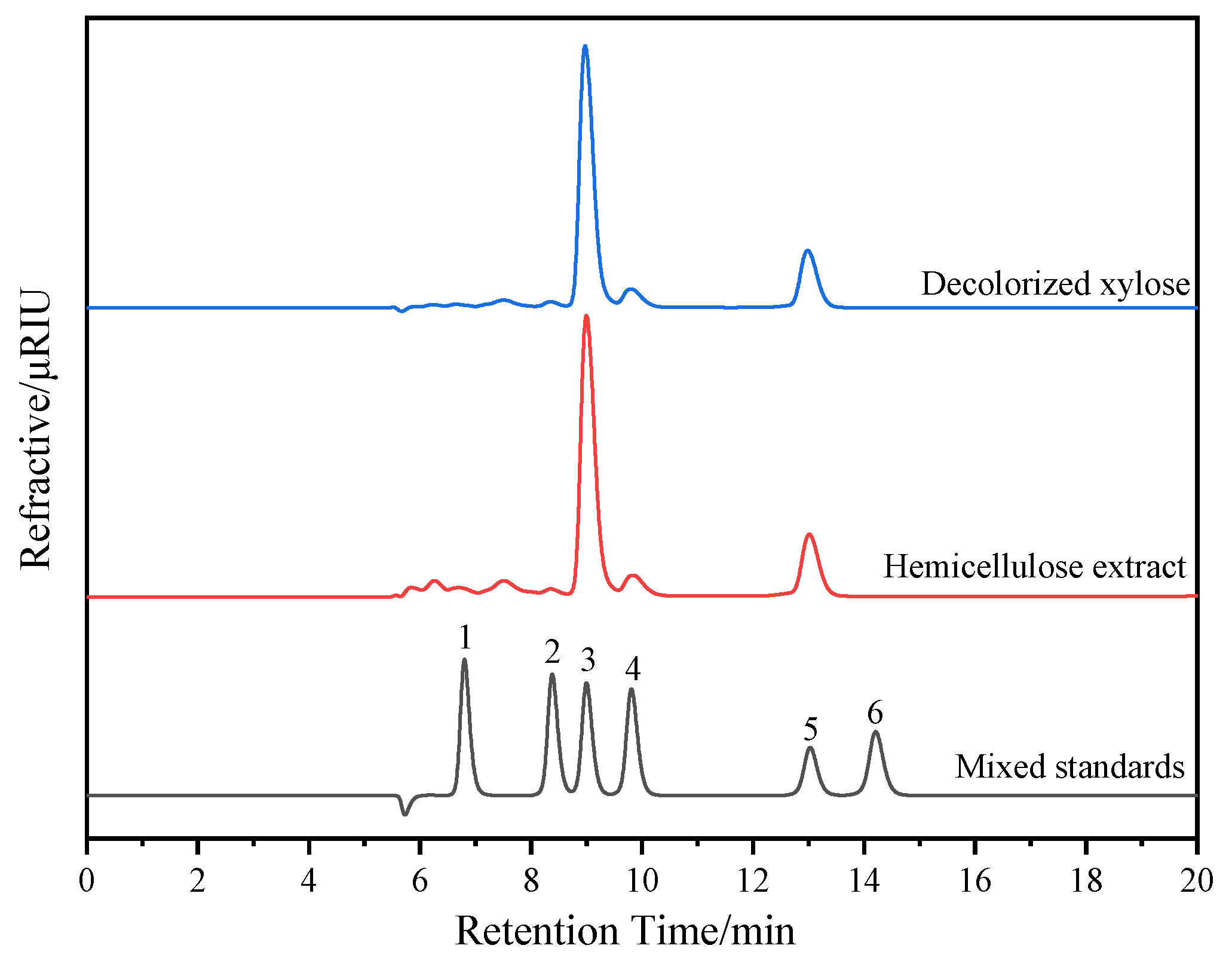

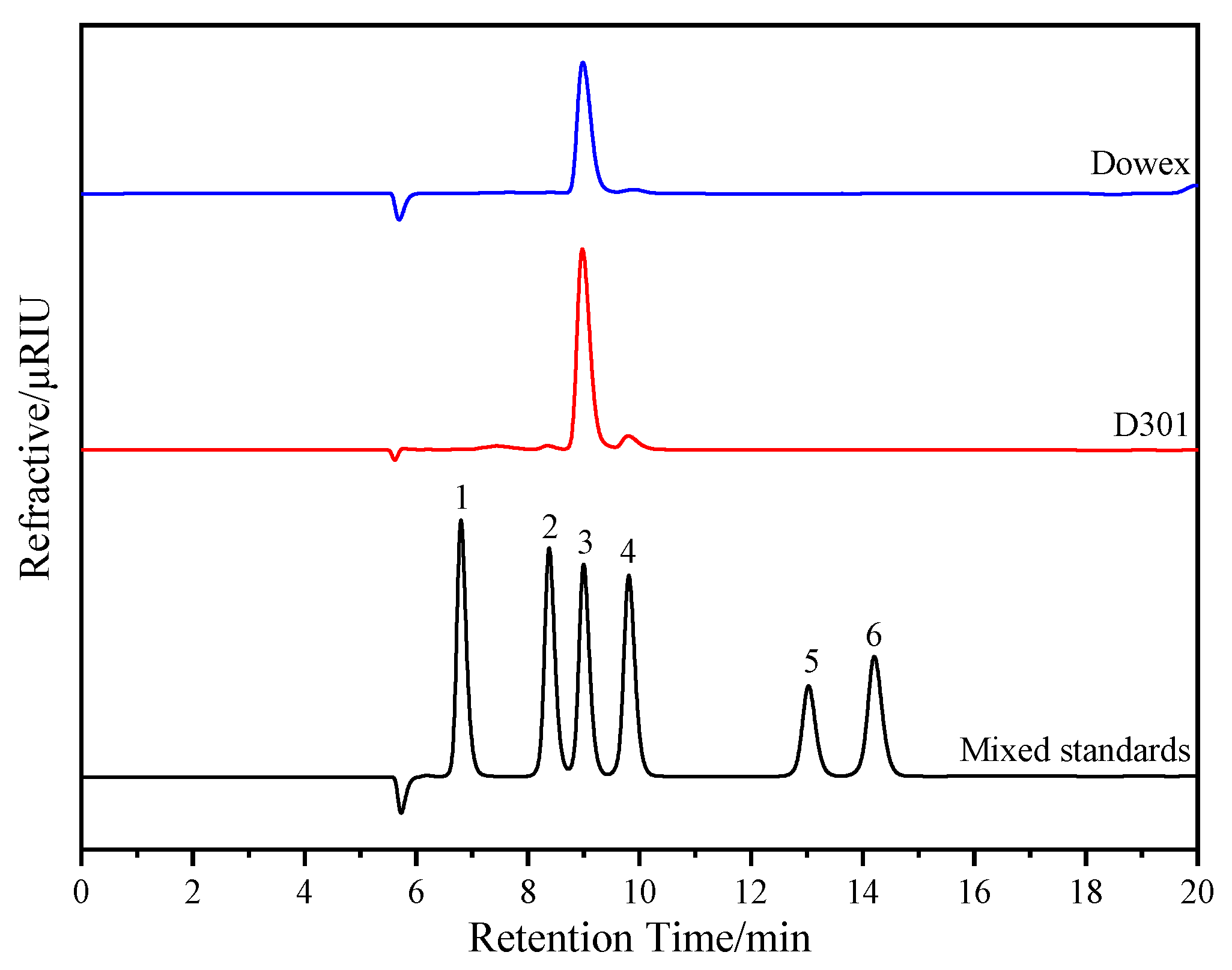

3.8. Purification of Crude Xylose Extract

3.8.1. Screening Results of Static Adsorption of Resins

3.8.2. Analysis Results of Xylose Purity before and after Resin Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, D.; Hu, J.G.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C.H. Lignin valorization: Lignin nanoparticles as high-value bio-additive for multifunctional nanocomposites. Biotechnol. Biofuels 2017, 10, 192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Walter, D.; Sharma, V.K.; Mengshan, L.; Govind, N.; Varma, R.S. Lignocellulosic Biomass Transformations via Greener Oxidative Pretreatment Processes: Access to Energy and Value-Added Chemicals. Front. Chem. 2018, 6, 141. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.F.; Du, X.H.; Jin, M.T.; Wu, S.; Wang, L.; Qiao, N.; Yu, D.Y. A two-step process for pre-hydrolysis of hemicellulose in pulp-impregnated effluent with high alkali concentration to improve xylose production. J. Hazard. Mater. 2021, 402, 123573. [Google Scholar] [CrossRef] [PubMed]

- Arora, S.; Gupta, N.; Singh, V. pH-Controlled Efficient Conversion of Hemicellulose to Furfural Using Choline-Based Deep Eutectic Solvents as Catalysts. ChemSusChem 2021, 14, 3953–3958. [Google Scholar] [CrossRef] [PubMed]

- Verdini, F.; Gaudino, E.C.; Grillo, G.; Tabasso, S.; Cravotto, G. Cellulose Recovery from Agri-Food Residues by Effective Cavitational Treatments. Appl. Sci. 2021, 11, 4693. [Google Scholar] [CrossRef]

- Prasad, R.K.; Chatterjee, S.; Mazumder, P.B.; Gupta, S.K.; Sharma, S.; Vairale, M.G.; Datta, S.; Dwivedi, S.K.; Gupta, D.K. Bioethanol production from waste lignocelluloses: A review on microbial degradation potential. Chemosphere 2019, 231, 88–606. [Google Scholar] [CrossRef]

- Huang, J.W.; Zhu, Y.K.; Liu, T.Y.; Sun, S.L.; Ren, J.L.; Wu, A.M.; Li, H.L. A novel wet-mechanochemical pretreatment for the efficient enzymatic saccharification of lignocelluloses: Small dosage dilute alkali assisted ball milling. Energy Convers. Manag. 2019, 194, 46–54. [Google Scholar] [CrossRef]

- Gschwend, F.J.V.; Chambon, C.L.; Biedka, M.; Brandt-Talbot, A.; Fennell, P.S.; Hallett, J.P. Quantitative glucose release from softwood after pretreatment with low-cost ionic liquids. Green Chem. 2019, 21, 692–703. [Google Scholar] [CrossRef]

- Sahoo, D.; Ummalyma, S.B.; Okram, A.K.; Pandey, A.; Sankar, M.; Sukumaran, R.K. Effect of dilute acid pretreatment of wild rice grass (Zizania latifolia) from Loktak Lake for enzymatic hydrolysis. Bioresour. Technol. 2018, 253, 252–255. [Google Scholar] [CrossRef]

- Hammerer, F.; Loots, L.; Do, J.L.; Therien, J.P.D.; Nickels, C.W.; Friščić, T.; Auclair, K. Solvent-Free Enzyme Activity: Quick, High-Yielding Mechanoenzymatic Hydrolysis of Cellulose into Glucose. Angew. Chem. Int. Ed. Engl. 2018, 130, 2651–2654. [Google Scholar] [CrossRef]

- Su, X.J.; Zhang, C.Y.; Li, W.J.; Wang, F.; Wang, K.Q.; Liu, Y.; Li, Q.M. Radiation-Induced Structural Changes of Miscanthus Biomass. Appl. Sci. 2020, 10, 1130. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.B.; Liu, D.H. Multi-products co-production improves the economic feasibility of cellulosic ethanol: A case of Formiline pretreatment-based biorefining. Appl. Energy 2019, 250, 229–244. [Google Scholar] [CrossRef]

- Zhang, M.J.; Qi, W.; Liu, R.; Su, R.X.; Wu, S.M.; He, Z.M. Fractionating lignocellulose by formic acid: Characterization of major components. Biomass Bioenergy 2010, 34, 525–532. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Xu, H.H.; Yu, H.F.; Hu, L.H.; Liu, Y. Formic acid fractination towards highly efficient cellulose-derived PdAg bimetallic catalyst for H2 evolution. Green Energy Environ. 2020, 7, 172–183. [Google Scholar] [CrossRef]

- Jing, W.X.; Zhe, W. A Study on Catalytic Hydrolysis of Corncob by Formic Acid. Adv. Mater. Res. 2012, 560–561, 321–324. [Google Scholar] [CrossRef]

- Jin, C.D.; Yang, M.; Shuang, E.; Liu, J.L.; Zhang, S.L.; Sheng, K.C.; Zhang, X.M. Corn stover valorization by one-step formic acid fractionation and formylation for 5-hydroxymethylfurfural and high guaiacyl lignin production. Bioresour. Technol. 2020, 299, 122586. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.H.; Yuan, R.; Zhang, B.S.; Wang, B.; Chu, Y.Q.; Wang, Z.J. Full fractionation of cellulose, hemicellulose, and lignin in pith-leaf containing corn stover by one-step treatment using aqueous formic acid. Ind. Crop. Prod. 2021, 172, 113962. [Google Scholar] [CrossRef]

- Tian, G.Y.; Xu, J.Y.; Fu, Y.J.; Guo, Y.Z.; Wang, Z.J.; Li, Q. High β-O-4 polymeric lignin and oligomeric phenols from flow-through fractionation of wheat straw using recyclable aqueous formic acid. Ind. Crop. Prod. 2019, 131, 142–150. [Google Scholar] [CrossRef]

- Zhu, S.W.; Zhan, W.; Yu, H.F.; Liu, Y. Fractionation of lignin and cellulose from Pterocarpus macarocarpus Kurz using formic acid. J. Beijing Univ. Chem. Technol. 2019, 46, 57–63. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Xu, W.Y.; Wang, X.J.; Ni, S.Z.; Rosqvist, E.; Smatt, J.H.; Peltonen, J.; Hou, Q.X.; Qin, M.H.; Willfor, S.; et al. From Biomass to Nanomaterials: A Green Procedure for Preparation of Holistic Bamboo Multifunctional Nanocomposites Based On Formic Acid Rapid Fractionation. ACS Sustain. Chem. Eng. 2019, 7, 6592–6600. [Google Scholar] [CrossRef] [Green Version]

- Li, M.F.; Yu, P.; Li, S.X.; Wu, X.F.; Xiao, X.; Bian, J. Sequential two-step fractionation of lignocellulose with formic acid organosolv followed by alkaline hydrogen peroxide under mild conditions to prepare easily saccharified cellulose and value-added lignin. Energy Convers. Manag. 2017, 148, 1426–1437. [Google Scholar] [CrossRef]

- Xu, Y.Z.; Fu, G.Y.; Tang, N.; He, Z.H.; Jian, L.C.; Zhao, Y.Y. Distribution of Triarrhena lutarioriparia and its reserve characteristics of nitrogen and phosphorus in Dongting Lake. E3S Web Conf. 2021, 237, 01004. [Google Scholar] [CrossRef]

- Tao, X.; Li, J.; Zhang, P.Y.; Nabi, M.; Jin, S.G.; Li, F.; Wang, S.Q.; Ye, J.P. Reinforced acid-pretreatment of Triarrhena lutarioriparia to accelerate its enzymatic hydrolysis. Int. J. Hydrogen Energy 2017, 42, 18301–18308. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process Samples. Available online: https://www.nrel.gov/docs/gen/fy08/42623.pdf (accessed on 2 September 2021).

- Segal, L.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Li, P.; Cai, D.; Luo, Z.F.; Qin, P.Y.; Chen, C.J.; Wang, Y.; Zhang, C.W.; Wang, Z.; Tan, T.W. Effect of acid pretreatment on different parts of corn stalk for second generation ethanol production. Bioresour. Technol. 2016, 206, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.F.; Chen, L.; Chen, J.P.; Su, X.J.; Liu, Y.; Wang, K.Q.; Qin, W.S.; Qi, H.; Deng, M. The Effect of 60Co γ-Irradiation on the Structure and Thermostability of Alkaline Lignin and Its Irradiation Derived Degradation Products. Waste Biomass Valorization 2018, 10, 3025–3035. [Google Scholar] [CrossRef]

- Vârban, R.; Crișan, I.; Vârban, D.; Ona, A.; Olar, L.; Stoie, A.; Ștefan, R. Comparative FT-IR Prospecting for Cellulose in Stems of Some Fiber Plants: Flax, Velvet Leaf, Hemp and Jute. Appl. Sci. 2021, 11, 8570. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Sankhla, S.; Sardar, H.H.; Neogi, S. Greener extraction of highly crystalline and thermally stable cellulose micro-fibers from sugarcane bagasse for cellulose nano-fibrils preparation. Carbohydr. Polym. 2021, 251, 117030. [Google Scholar] [CrossRef]

- Domínguez, E.; del Río, P.G.; Romaní, A.; Garrote, G.; Gullón, P.; de Vega, A. Formosolv Pretreatment to Fractionate Paulownia Wood Following a Biorefinery Approach: Isolation and Characterization of the Lignin Fraction. Agronomy 2020, 10, 1205. [Google Scholar] [CrossRef]

- Wu, X.F.; Chen, L.; He, W.Q.; Qi, H.; Zhang, Y.; Zhou, Y.J.; Su, X.J.; Deng, M.; Wang, K.Q. Characterize the physicochemical structure and enzymatic efficiency of agricultural residues exposed to γ-irradiation pretreatment. Ind. Crop. Prod. 2020, 150, 112228. [Google Scholar] [CrossRef]

- Fortunati, E.; Benincasa, P.; Balestra, G.M.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crop. Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Vazquez, M.J.; Garrote, G.; Alonso, J.L.; Dominguez, H.; Parajo, J.C. Refining of autohydrolysis liquors for manufacturing xylooligosaccharides: Evaluation of operational strategies. Bioresour. Technol. 2005, 96, 889–896. [Google Scholar] [CrossRef]

- Zdarta, J.; Thygesen, A.; Holm, M.S.; Meyer, A.S.; Pinelo, M. Direct separation of acetate and furfural from xylose by nanofiltration of birch pretreated liquor: Effect of process conditions and separation mechanism. Sep. Purif. Technol. 2020, 239, 116546. [Google Scholar] [CrossRef]

- Chen, K.F.; Luo, G.; Lei, Z.F.; Zhang, Z.Y.; Zhang, S.C.; Chen, J.M. Chromatographic separation of glucose, xylose and arabinose from lignocellulosic hydrolysates using cation exchange resin. Sep. Purif. Technol. 2018, 195, 288–294. [Google Scholar] [CrossRef]

| Samples | Contents (%) | |||

|---|---|---|---|---|

| Cellulose | Hemicellulose | ASL | AIL | |

| ML straw | 41.89 ± 0.73 b | 18.21 ± 0.42 a | 2.53 ± 0.04 a | 16.77 ± 0.18 b |

| Crude cellulose | 83.60 ± 0.15 a | 5.15 ± 0.05 b | 0.50 ± 0.02 c | 6.35 ± 0.27 c |

| Crude lignin | 2.20 ± 0.26 c | 3.86 ± 0.11 c | 1.40 ± 0.01 b | 85.40 ± 0.68 a |

| Monosaccharides | Rha | Fuc | Ara | Xyl | Man | Glc | Gal | GlcA | GalA |

|---|---|---|---|---|---|---|---|---|---|

| Retention Time (min) | 20.57 | 21.04 | 21.32 | 22.00 | 31.64 | 31.91 | 32.65 | 37.91 | 38.13 |

| Content (%) | 1.99 | 1.88 | 8.64 | 74.89 | 1.82 | 5.42 | 3.73 | 0.84 | 0.79 |

| Treatment | Content (%) | Retention Rate of Xylose (%) | Decolorization Rate of Xylose (%) | |||

|---|---|---|---|---|---|---|

| Xylose | Arabinose | Glucose | Formic Acid | |||

| Formic acid | 55.00 | 5.14 | 0.80 | 39.06 | 89.80 | — |

| Decolorization | 54.22 | 5.18 | 0.86 | 39.76 | 88.58 | 93.66 |

| Resin Type | Content (mg/g) | |||

|---|---|---|---|---|

| Glu | Ara | Xyl | Formic Acid | |

| D201 | 0.13 ± 0.00 b,c | 0.68 ± 0.07 a | 8.13 ± 0.06 a | 36.80 ± 0.63 c |

| D301 | 0.28 ± 0.09 a | 0.59 ± 0.00 b | 7.68 ± 0.34 b | 62.77 ± 0.92 b |

| D311 | 0.30 ± 0.08 a | 0.52 ± 0.03 c,d | 7.43 ± 0.08 b | 67.43 ± 0.20 a |

| 717 | 0.05 ± 0.00 c | 0.50 ± 0.02 c,d | 6.49 ± 0.08 d | 36.76 ± 0.11 c |

| D113 | 0.15 ± 0.00 b,c | 0.56 ± 0.02 b,c | 5.43 ± 0.08 e | 4.63 ± 0.09 e |

| 732 | 0.21 ± 0.00 a,b | 0.46 ± 0.04 d | 3.86 ± 0.13 f | 6.17 ± 0.14 d |

| 734 | 0.22 ± 0.09 a,b | 0.51 ± 0.01 c,d | 6.86 ± 0.23 c | 6.34 ± 0.04 d |

| Resin Type | Resolving Rate (%) | |||

|---|---|---|---|---|

| Glu | Ara | Xyl | Formic Acid | |

| D201 | 47.25 ± 0.69 b | 73.88 ± 0.24 e | 77.12 ± 1.58 d | 10.91 ± 0.65 d |

| D301 | 20.19 ± 0.64 d | 96.89 ± 0.70 a | 91.35 ± 1.17 a | 0.71 ± 0.03 f |

| D311 | 22.45 ± 0.50 c | 93.68 ± 0.46 b | 81.21 ± 1.60 c | 0.57 ± 0.00 f |

| 717 | 83.19 ± 1.54 a | 74.15 ± 0.92 e | 73.53 ± 0.45 e | 6.42 ± 0.24 e |

| D113 | 19.40 ± 0.96 d | 45.63 ± 1.35 f | 59.71 ± 1.93 f | 50.15 ± 1.12 c |

| 732 | 6.30 ± 0.06 e | 78.58 ± 0.76 d | 88.65 ± 1.16 b | 70.40 ± 0.28 b |

| 734 | 19.19 ± 0.14 d | 84.15 ± 0.32 c | 89.53 ± 1.45 a,b | 74.42 ± 0.24 a |

| Resin Treatment | Content (%) | Recovery Rate of Xylose (%) | ||||

|---|---|---|---|---|---|---|

| Xylose | Arabinose | Glucose | Formic Acid | Others | ||

| D301 | 86.34 | 7.77 | 1.90 | 0.11 | 3.88 | 96.80 |

| Dowex 50wx4 | 95.01 | 1.70 | 0.41 | 0.08 | 0.88 | 84.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, J.; He, W.-Q.; Li, Q.-M.; Chen, L.; Wu, X.-F.; Su, X.-J. Separation of Lignocellulose and Preparation of Xylose from Miscanthus lutarioriparius with a Formic Acid Method. Appl. Sci. 2022, 12, 1432. https://doi.org/10.3390/app12031432

Ouyang J, He W-Q, Li Q-M, Chen L, Wu X-F, Su X-J. Separation of Lignocellulose and Preparation of Xylose from Miscanthus lutarioriparius with a Formic Acid Method. Applied Sciences. 2022; 12(3):1432. https://doi.org/10.3390/app12031432

Chicago/Turabian StyleOuyang, Jia, Wen-Qiang He, Qing-Ming Li, Liang Chen, Xiao-Fen Wu, and Xiao-Jun Su. 2022. "Separation of Lignocellulose and Preparation of Xylose from Miscanthus lutarioriparius with a Formic Acid Method" Applied Sciences 12, no. 3: 1432. https://doi.org/10.3390/app12031432

APA StyleOuyang, J., He, W.-Q., Li, Q.-M., Chen, L., Wu, X.-F., & Su, X.-J. (2022). Separation of Lignocellulose and Preparation of Xylose from Miscanthus lutarioriparius with a Formic Acid Method. Applied Sciences, 12(3), 1432. https://doi.org/10.3390/app12031432