Geotechnical Behaviour of Fly Ash–Bentonite Used in Layers

Abstract

:1. Introduction

2. Materials Used

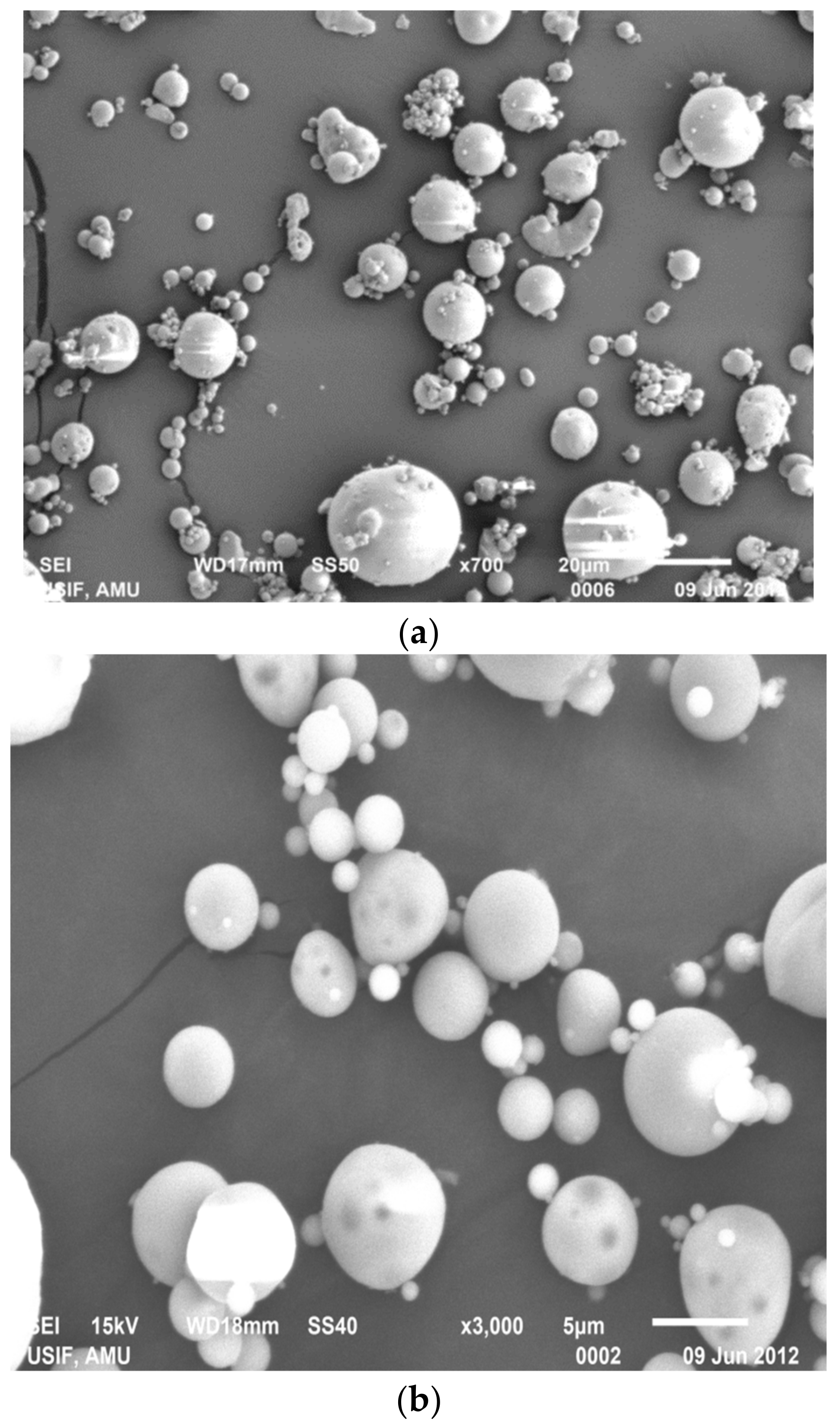

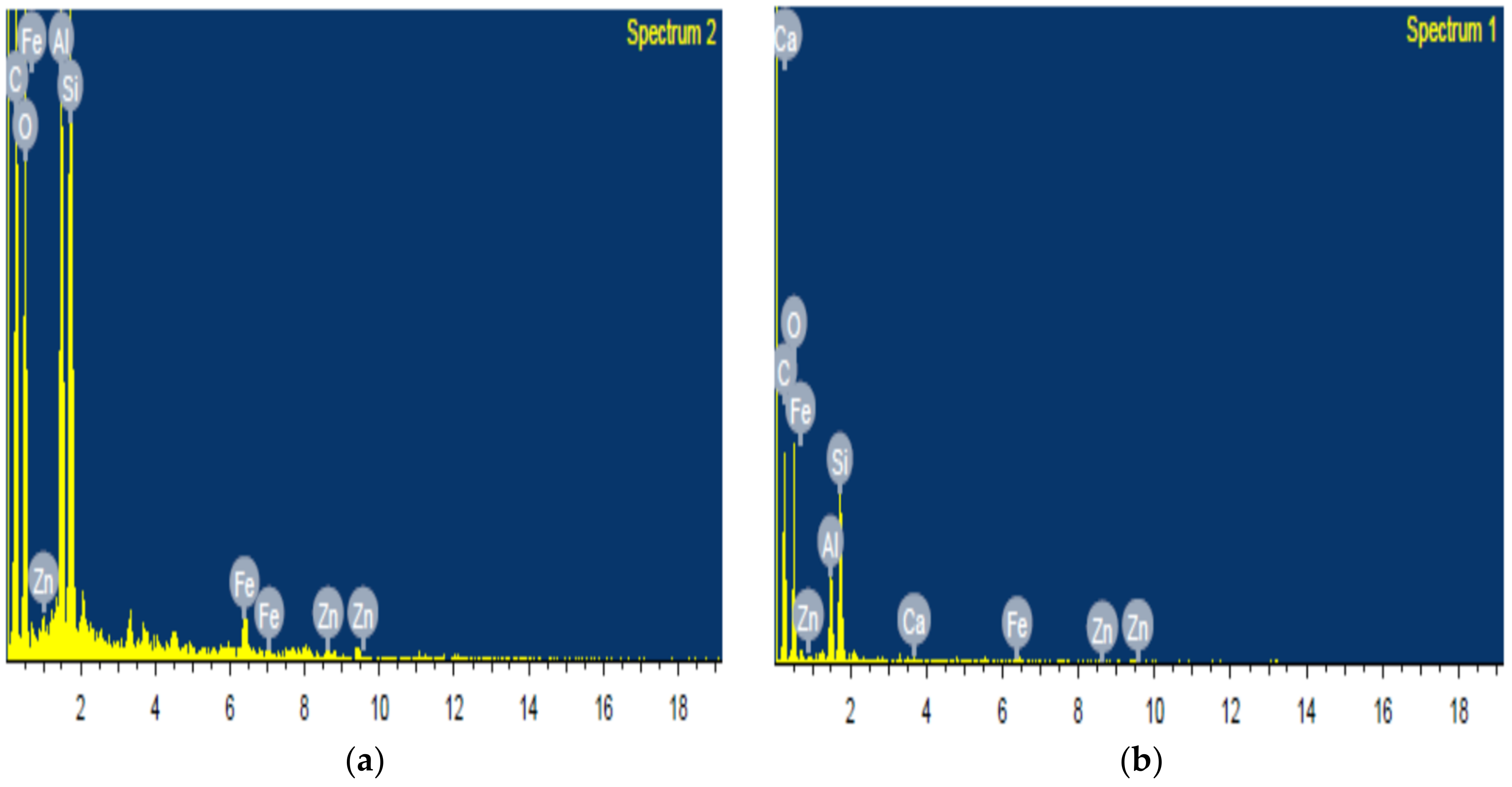

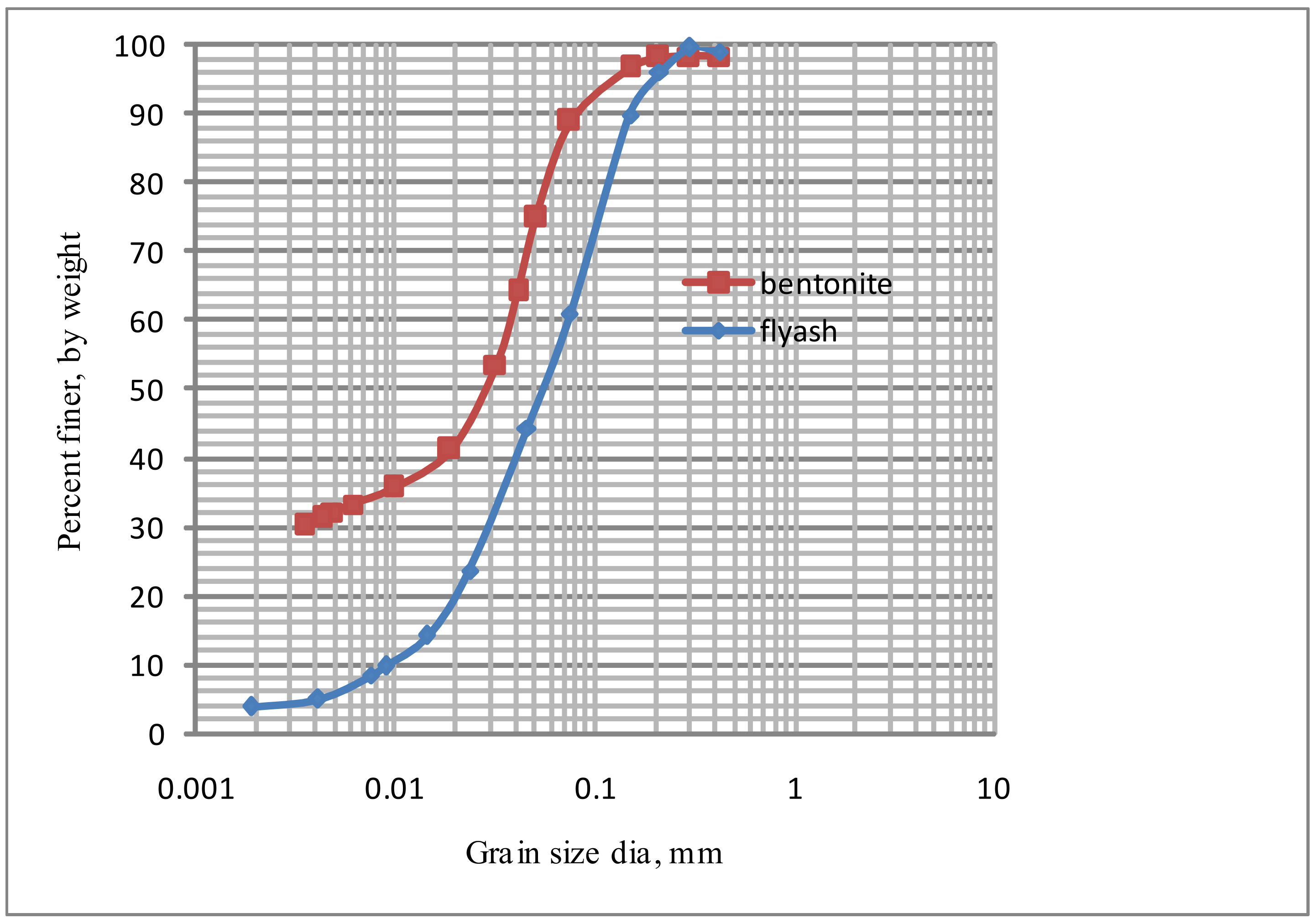

2.1. Fly Ash

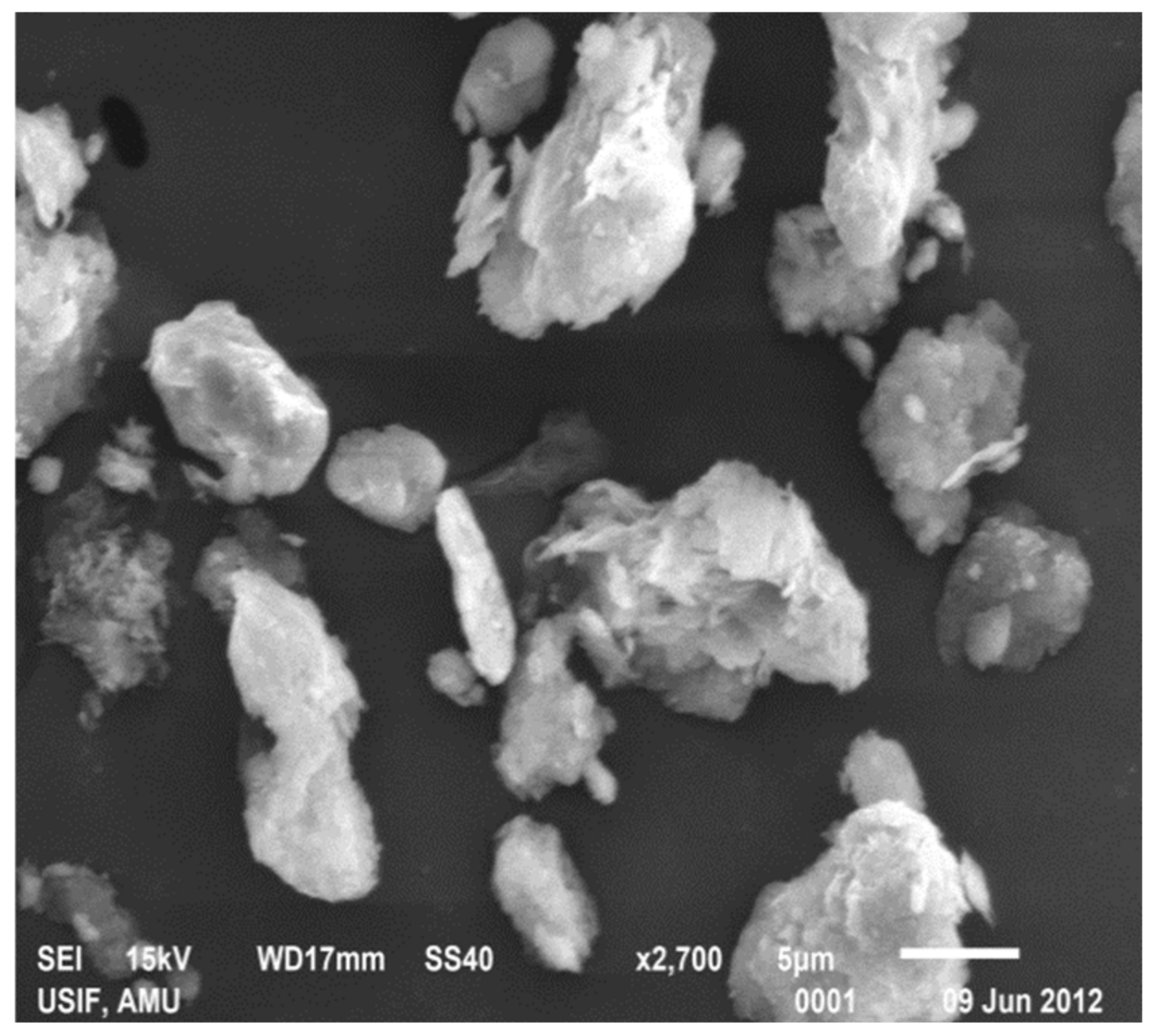

2.2. Bentonite

3. Experimental Programme

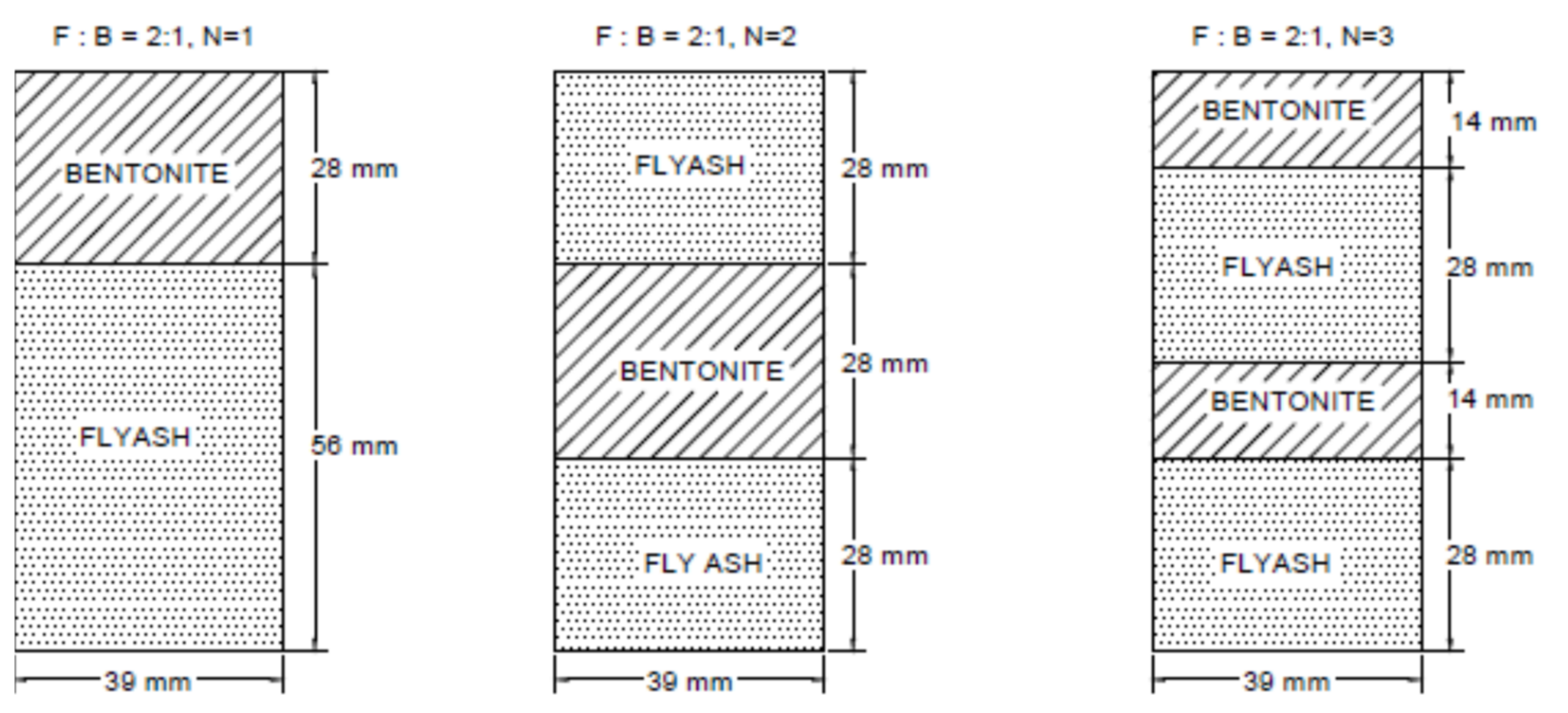

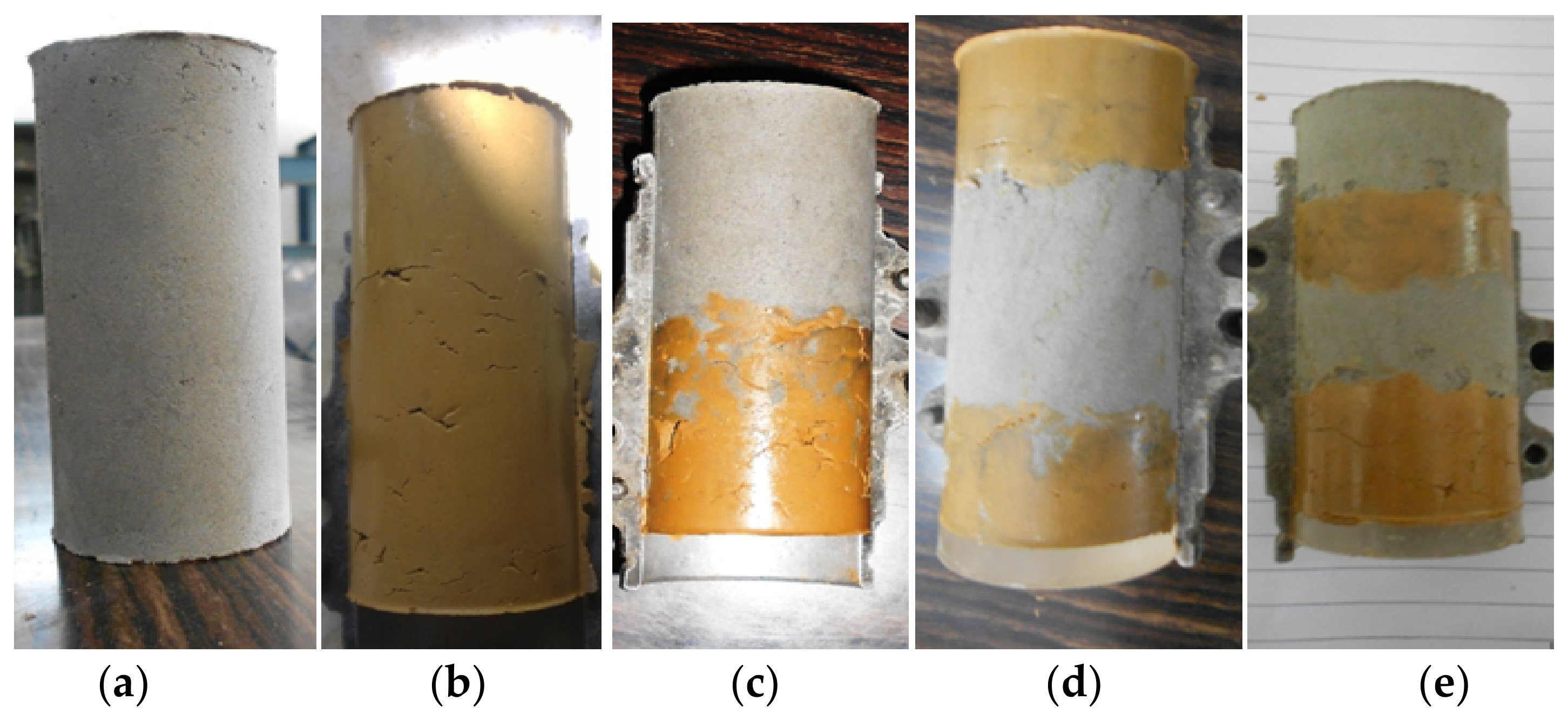

3.1. Sample Preparation

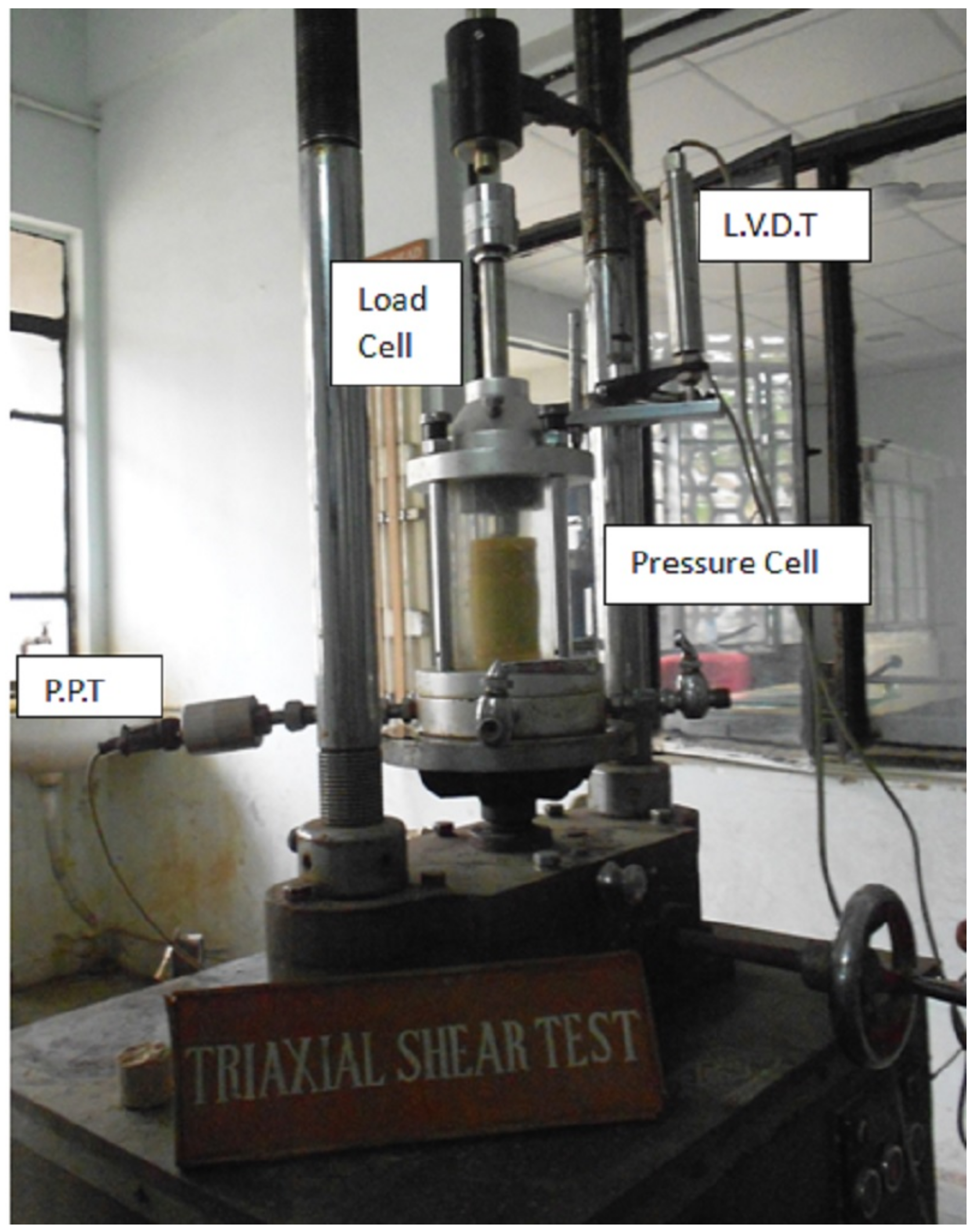

3.2. Test Procedure

4. Results and Discussion

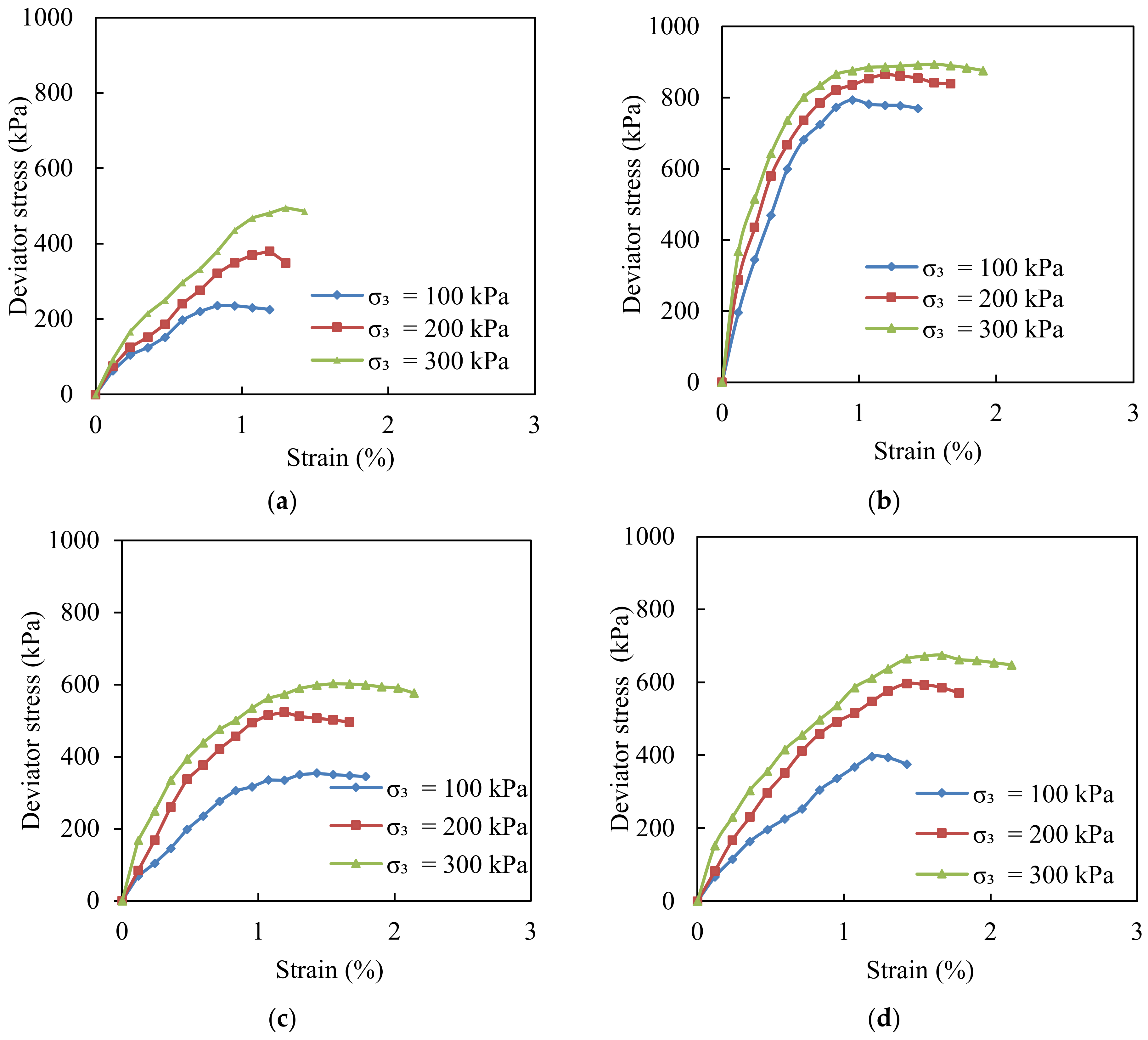

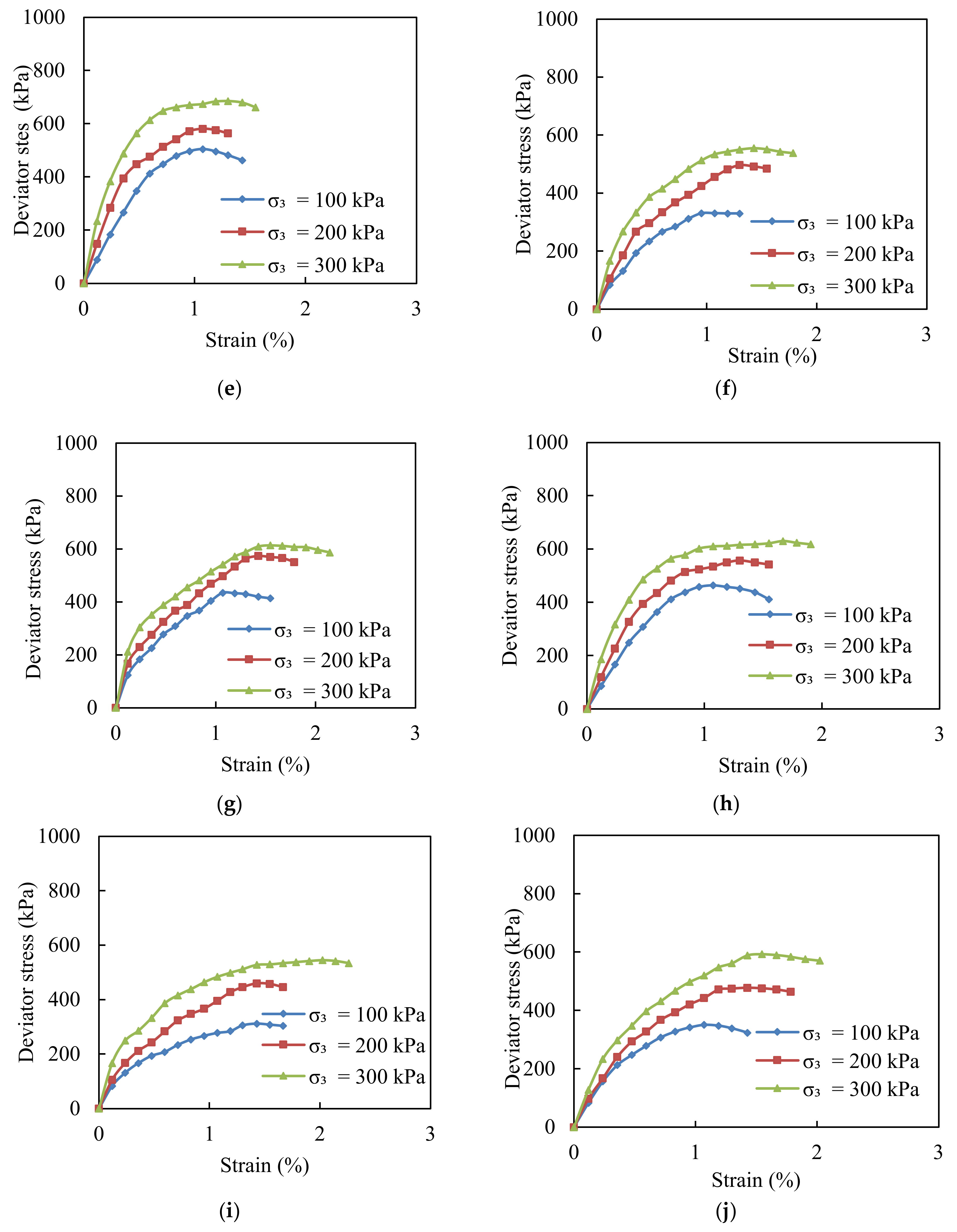

4.1. Stress-Strain Behaviour

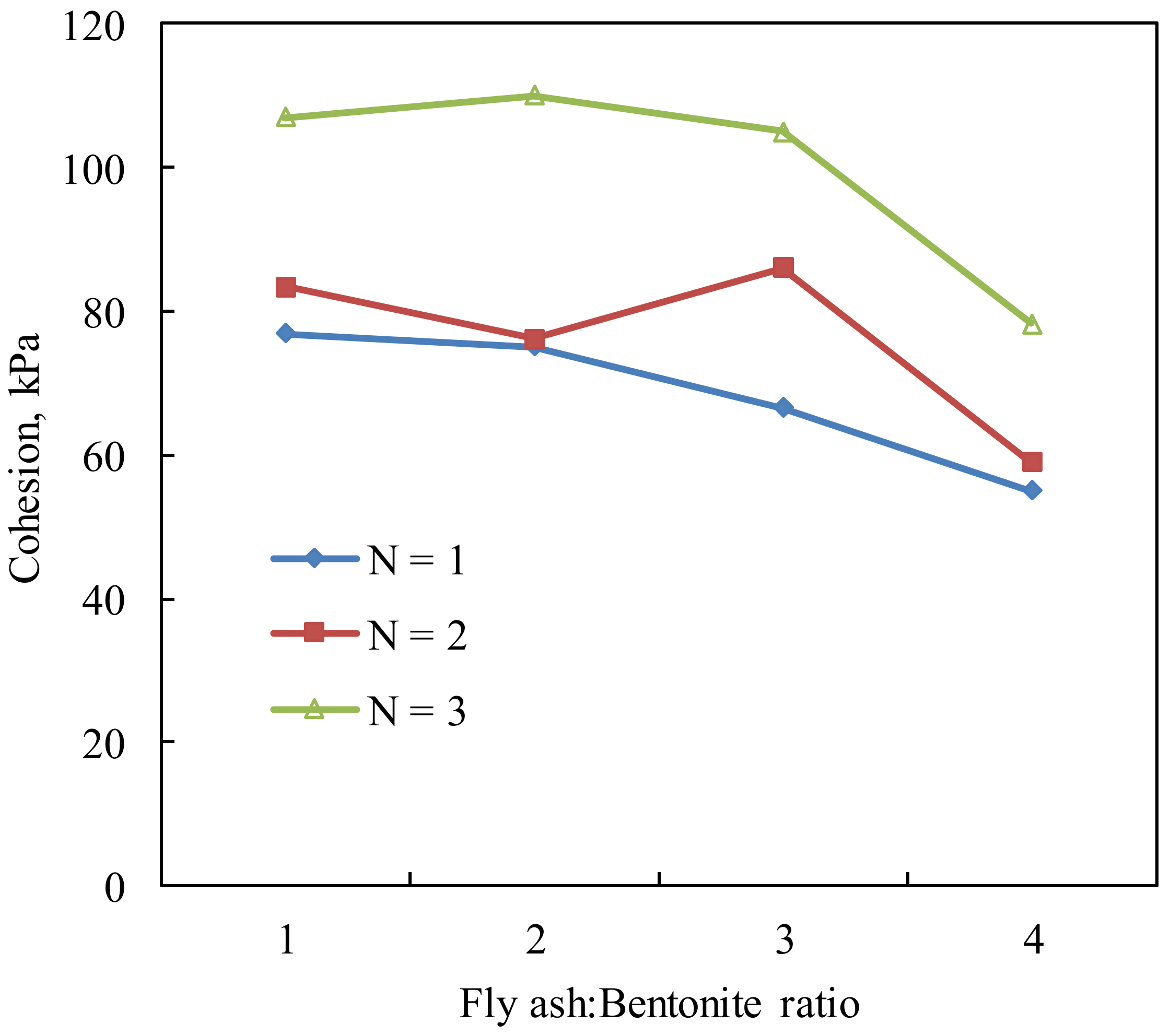

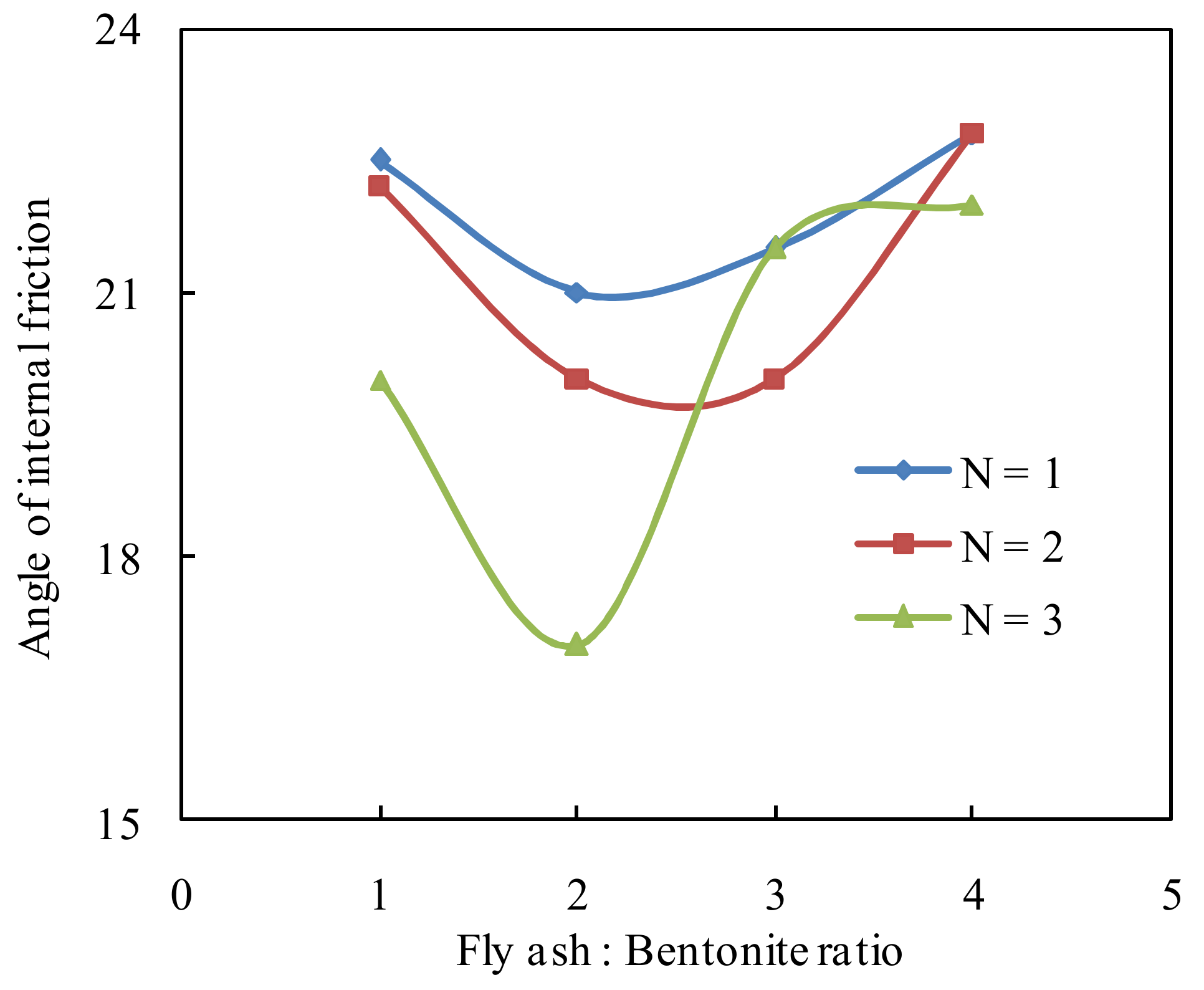

4.2. Shear Strength Parameters

5. Conclusions

- Fly ash is a nearly cohesionless substance that has a binding effect at the fly ash–bentonite layered system interfaces.

- For F:B = 1:1, 1:2, 1:3, and 1:4, the value of cohesion has been varied in the ranges of 76.8–107 kPa, 75–110 kPa, 66.6–105 kPa, and 55–78.2 kPa, respectively, for different layer arrangements. As the ratio of fly ash to bentonite is increased, the value of cohesion is decreased, while at the same ratio, the value of cohesion is increased by increasing the number of interfaces.

- For F:B = 1:1, 1:2, 1:3, and 1:4, the value of angle of shearing resistance has been varied in the range of 17–22.8° for different layer arrangements. The value of the angle of shearing resistance has been found to decreases with the increase in the number of interfaces for a specified ratio of fly ash to bentonite.

- The stress–strain behaviour of the fly ash–bentonite layered system is initially elastic at low stress levels and becomes non-linear at higher stress levels.

- As the number of interfaces and confining pressures grow, the shear strength and net safe bearing capacity of the fly ash–bentonite layered system increases.

- Based on laboratory model tests, it has been suggested that the embankment may provide greater stability if it is constructed for a fly ash to bentonite ratio of 3:1 (75% of fly ash and 25% of bentonite in layers) by keeping the number of interfaces as N = 3.

- It has been found that a 3:1 ratio of fly ash to bentonite with three interfaces can be successfully used for filling low-lying areas and in many other engineering constructions, while also providing a means of using the material without negatively impacting the environment. However, the authors recommend that large-scale studies be conducted in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhatt, A.; Priyadarshinia, S.; Mohanakrishnana, A.C.; Abria, A.; Sattlera, M.; Techapaphawitc, S. Physical, Chemical, and Geotechnical Properties of Coal Fly Ash: A Global Review. Case Stud. Constr. Mater. 2019, 11, e00486. [Google Scholar] [CrossRef]

- Rajak, T.K.; Yadu, L.; Chouksey, S.K. Effect of fly ash on geotechnical properties and stability of coal mine overburden dump: An overview. Appl. Sci. 2020, 2, 973. [Google Scholar] [CrossRef]

- Lauzurique, Y.; Montalvo, S.; Salazar, R.; García, V.; Huiliñir, C. Fly ash from coal combustion as improver of anaerobic digestion: A review. J. Environ. Chem. Eng. 2021, 9, 106422. [Google Scholar] [CrossRef]

- Mathur, N. Report on Fly Ash Generation at Coal/Lignite Based Thermal Power Stations and its Utilization in the Country for the Year; Ministry of Power, Government of India: New Delhi, India, 2020; p. 110016. [Google Scholar]

- Vittal, G. Bulk utilization of fly ash in construction of road embankments in India. Coal Ash India 2001, 2, 6–7. [Google Scholar]

- Indraratna, B.; Nutalaya, P.; Kuganenthira, N. Stabilization of a dispersive soil by blending with fly ash. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 275–290. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Prashant, J.P.; Sridharan, A. Effect of fly ash on the index properties of BC soil. Soils Found. 1996, 36, 97–103. [Google Scholar] [CrossRef] [Green Version]

- Kaniraj, S.R.; Havanagi, V.G. Behavior of cement-stabilized fiber-reinforced fly ash–soil mixtures. J. Geotech. Geoenviron. Eng. ASCE 2001, 127, 574–584. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Strength Characteristics of Class F Fly ash Modified with Lime and Gypsum. J. Geotech. Geoenvironmental. Eng. 2007, 133, 7. [Google Scholar] [CrossRef]

- Senol, A. Effect of fly ash and polypropylene fibres content on the soft soils. Bull. Eng. Geol. Environ. 2012, 71, 379–387. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Sridharan, A.; Stalin, V.K. Hydraulic conductivity of bentonite-sand mixtures. Can. Geotechn. J. 2000, 37, 406–413. [Google Scholar] [CrossRef]

- Pandian, N.S.; Nagaraj, T.S.; Raju, P.N. Permeability and compressibility behavior of bentonite-sand/soil mixes. Geotechnical. Test. J. 1995, 18, 86–93. [Google Scholar]

- Kashir, M.; Yanful, E.K. Hydraulic conductivity of bentonite permeated with acid mine drainage. Can. Geotech. J. 2001, 38, 1034–1048. [Google Scholar] [CrossRef]

- Sivapullaiah, P.V.; Lakshmikantha, H. Properties of Fly ash as Hydraulic Barrier. Soil Sediment. Contam. 2004, 13, 489–504. [Google Scholar] [CrossRef]

- Younus, M.M.; Sreedeep, S. Evaluation of Bentonite-Fly ash Mix for Its Application in Landfill Liners. J. Test. Eval. 2012, 40, 40–49. [Google Scholar] [CrossRef]

- Mollamahmutoglu, M.; Yilmaz, Y. Potential Use of Fly ash and Bentonite Mixture as Liner or Cover at Waste Disposal Areas. Environ. Geol. 2001, 40, 1316–1324. [Google Scholar] [CrossRef]

- Garg, A.; Reddy, N.G.; Huang, H. Modelling contaminant transport in fly ash–bentonite composite landfill liner: Mechanism of different types of ions. Sci. Rep. 2020, 10, 11330. [Google Scholar] [CrossRef] [PubMed]

- Wasil, M. Effect of Bentonite Addition on the Properties of Fly Ash as a Material for Landfill Sealing Layers. Appl. Sci. 2020, 10, 1488. [Google Scholar] [CrossRef] [Green Version]

- ASTM C 618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: Philadelphia, PA, USA, 2019.

- Zabielska-Adamska, K. Characteristics of Compacted Fly Ash as a Transitional Soil. Materials 2020, 13, 1387. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IS: 2720-Part 3; Methods of Test for Soils: Determination of Specific Gravity, Section 1 Fine Grained Soils. Indian Standards Institution: New Delhi, India, 1980.

- IS: 2720-Part 4; Methods of Test for Soils: Grain Size Analysis. Indian Standards Institution: New Delhi, India, 1985.

- IS: 2720-Part 5; Code of Practice for Determination of Liquid Limit and Plastic Limit. Indian Standards Institution: New Delhi, India, 1985.

- IS: 2720-Part 10; Methods of Test for Soils: Determination of Unconfined Compressive Strength. Indian Standards Institution: New Delhi, India, 1991.

| Composition | Percentage |

|---|---|

| Silicon dioxide (SiO2) | 59.00 |

| Alumina (Al2O3) | 29.00 |

| Iron oxide (Fe2O3) | 6.50 |

| Calcium oxide (CaO) | 1.80 |

| Magnesium oxide (MgO) | 1.44 |

| Sodium oxide (Na2O) | 0.80 |

| Sulphur trioxide (SO3) | 0.28 |

| Properties | Fly Ash | Bentonite |

|---|---|---|

| Specific gravity | 2.19 | 2.73 |

| Optimum moisture content (OMC), % | 22 | 28 |

| Unit weight, kN/m3 | 14.39 | 21.5 |

| Maximum dry density (MDD), kN/m3 | 11.8 | 16.8 |

| Liquid limit (WL), % | 24 | 261 |

| Plastic limit (WP), % | Non plastic | 38 |

| Plasticity index (P.I), % | 24 | 223 |

| Coefficient of permeability, (10−10 m/sec) | 551 | 8.52 |

| Unconfined compression strength, kN/m2 | 34 | 176 |

| Classification | Class F | CH |

| Test Description | No. of Interfaces (N) | Confining Pressure (kPa) | Total No. of Tests | ||

|---|---|---|---|---|---|

| 100 | 200 | 300 | |||

| Fly Ash Sample | - | ✓ | ✓ | ✓ | 6 |

| Bentonite Sample | - | ✓ | ✓ | ✓ | 6 |

| F:B = 1:1 | 1 | ✓ | ✓ | ✓ | 6 |

| 2 | ✓ | ✓ | ✓ | 6 | |

| 3 | ✓ | ✓ | ✓ | 6 | |

| F:B = 2:1 | 1 | ✓ | ✓ | ✓ | 6 |

| 2 | ✓ | ✓ | ✓ | 6 | |

| 3 | ✓ | ✓ | ✓ | 6 | |

| F:B = 3:1 | 1 | ✓ | ✓ | ✓ | 6 |

| 2 | ✓ | ✓ | ✓ | 6 | |

| 3 | ✓ | ✓ | ✓ | 6 | |

| F:B = 4:1 | 1 | ✓ | ✓ | ✓ | 6 |

| 2 | ✓ | ✓ | ✓ | 6 | |

| 3 | ✓ | ✓ | ✓ | 6 | |

| F:B | Cohesion (c), kPa | Angle of Internal Friction (ϕ), ° | ||||

|---|---|---|---|---|---|---|

| N = 1 | N = 2 | N = 3 | N = 1 | N = 2 | N = 3 | |

| 1:1 | 76.8 | 83.4 | 107 | 22.5 | 22.2 | 20 |

| 2:1 | 75 | 76.1 | 110 | 21 | 20 | 17 |

| 3:1 | 66.6 | 86 | 105 | 21.5 | 20 | 21.5 |

| 4:1 | 55 | 59 | 78.2 | 22.8 | 22.8 | 22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, M.; Khan, M.A.; Alsabhan, A.H.; Almajid, A.A.; Alam, S.; Khan, M.A.; Biswas, T.; Pu, J. Geotechnical Behaviour of Fly Ash–Bentonite Used in Layers. Appl. Sci. 2022, 12, 1421. https://doi.org/10.3390/app12031421

Hasan M, Khan MA, Alsabhan AH, Almajid AA, Alam S, Khan MA, Biswas T, Pu J. Geotechnical Behaviour of Fly Ash–Bentonite Used in Layers. Applied Sciences. 2022; 12(3):1421. https://doi.org/10.3390/app12031421

Chicago/Turabian StyleHasan, Murtaza, Mehboob Anwer Khan, Abdullah H. Alsabhan, Abdullah A. Almajid, Shamshad Alam, Mohammad Amir Khan, Tinku Biswas, and Jaan Pu. 2022. "Geotechnical Behaviour of Fly Ash–Bentonite Used in Layers" Applied Sciences 12, no. 3: 1421. https://doi.org/10.3390/app12031421

APA StyleHasan, M., Khan, M. A., Alsabhan, A. H., Almajid, A. A., Alam, S., Khan, M. A., Biswas, T., & Pu, J. (2022). Geotechnical Behaviour of Fly Ash–Bentonite Used in Layers. Applied Sciences, 12(3), 1421. https://doi.org/10.3390/app12031421