The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Potato Chip Preparation

2.3. Proximate Analysis

2.4. Sample Preparation for Total Phenolic Content and Anthocyanin Determination

Determination of Total Phenolic Content

2.5. Determination of Total Anthocyanins Content

2.6. Determination of Total Fat Content

2.7. Colour of Fresh Potato Tubers and Chips

2.8. The Texture of Potato Chips

2.9. Evaluation of Sensory Quality

2.10. Statistical Analysis

3. Results and Discussion

3.1. The Chemical and Physical Characteristics of Raw Potato Tubers

3.2. The Chemical Characteristics of Coloured-Flesh Potato Chips

3.3. The Physical Characteristics of Coloured-Flesh Potato Chips

3.4. Sensory Evaluation of Coloured-Flesh Potato Chips

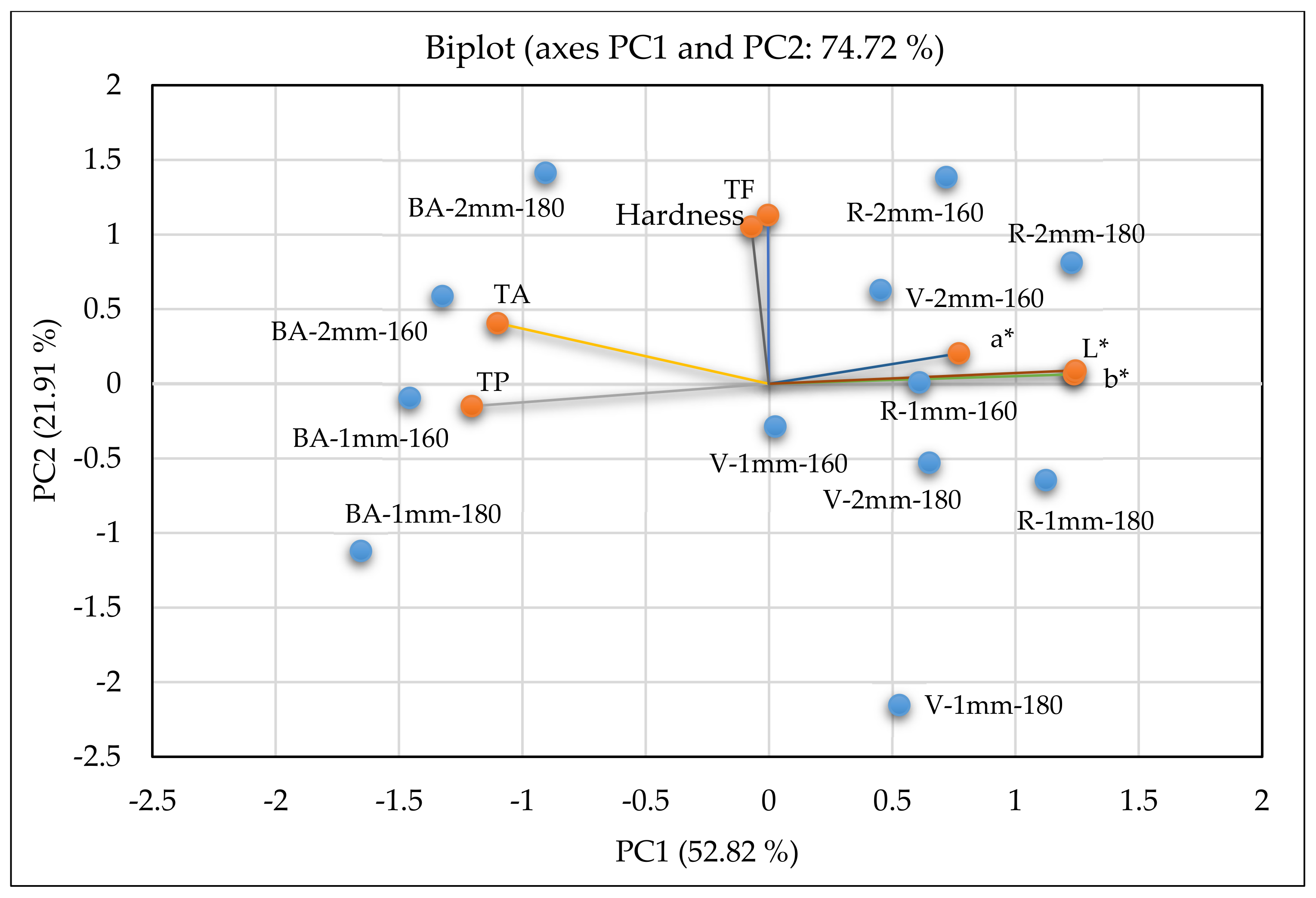

3.5. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Vaitkevičienė, N.; Kulaitienė, J.; Jarienė, E.; Levickienė, D.; Danilčenko, H.; Srednicka-Tober, D.; Rembiałkowska, E.; Hallmann, E. Characterization of bioactive compounds in Colored potato (Solanum Tuberosum L.) cultivars grown with conventional, organic, and biodynamic methods. Sustainability 2020, 12, 2701. [Google Scholar] [CrossRef]

- Vaitkevičienė, N. A comparative study on proximate and mineral composition of coloured potato peel and flesh. J. Sci. Food Agric. 2019, 99, 6227–6233. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.; Kumar, S. Study of biochemical changes in Solanum tuberosum due to infection and storage. J. Chem. Pharm. Res. 2012, 4, 2733–2739. [Google Scholar]

- Nayak, B.; Berrios, J.J.; Powers, J.R.; Tang, J.; JI, Y. Colored potatoes (Solanum tuberosum L.) dried for antioxidant-rich value-added foods. J. Food Process. Preserv. 2011, 35, 571–580. [Google Scholar] [CrossRef]

- Hamouz, K.; Lachman, J.; Pazderu, K.; Tomášek, J.; Hejtmánková, K.; Pivec, V. Differences in anthocyanin content and antioxidant activity of potato tubers with different flesh colour. Plant. Soil Environ. 2011, 57, 478–485. [Google Scholar] [CrossRef]

- Nawaz, A.; Danish, A.; Waseem, A.S.; Shahbaz, H.M.; Khalifa, I.; Ahmed, A.; Irshad, S.; Ahmad, S.; Ahmed, W. Evaluation and storage stability of potato chips made from different varieties of potatoes cultivated in Pakistan. J. Food Process. Preserv. 2021, 45, e15437. [Google Scholar] [CrossRef]

- Kita, A.; Bąkowska-Barczak, A.; Lisińska, G.; Hamouz, K.; Kułakowska, K. Antioxidant activity and quality of red and purple flesh potato chips. LWT Food Sci. Technol. 2015, 62, 525–531. [Google Scholar] [CrossRef]

- Lærke, P.E.; Christiansen, J. Variation in chemical composition of potato tubers and discolouration of crisps between and within years. Acta Hortic. 2005, 684, 109–117. [Google Scholar] [CrossRef]

- Bandana, S.V.; Kaushik, S.K.; Singh, B.; Raigond, P. Variation in biochemical parameters in different parts of potato tubers for processing purposes. J. Food. Sci. Technol. 2016, 53, 2040–2046. [Google Scholar] [CrossRef]

- Friedman, M.; Levin, C.E. Review of methods for the reduction of dietary content and toxicity of acrylamide. J. Agric. Food Chem. 2008, 56, 6113–6140. [Google Scholar] [CrossRef]

- Stadler, R.H.; Blank, I.; Varga, N.; Robert, F.; Hau, J.; Guy, P.A.; Robert, M.C.; Riediker, S. Acrylamide from Maillard reaction products. Nat. Cell Biol. 2002, 419, 449–450. [Google Scholar] [CrossRef] [PubMed]

- Mareček, J.; FrančákovA, H.; BojňanskA, T.; Fikselová, M.; Mendelova, A.; Ivanišova, E. Carbohydrates in varieties of stored potatoes and influence of storage on quality of fried products. J. Microbiol. Biotechnol. Food Sci. 2013, 2, 1744–1753. [Google Scholar]

- Mareček, J.; Fikselová, M.; Frančáková, H. Nutritional and technological value of selected edible potatoes during storage. In Zeszyty problemowe postepow nauk rolniczych. Warszawa Pol. Akad. Nauk. 2008, 530, 293–299. [Google Scholar]

- Freitas, S.T.; Pereira, E.I.P.; Gomez, A.C.S.; Brackmann, A.; Nicoloco, F.; Bisognin, D.A. Processing quality of potato tubers produced during autumn and spring and stored at different temperatures. Hortic. Bras. 2012, 30, 91–98. [Google Scholar] [CrossRef]

- Ezekiel, R.; Verma, S.C.; Sukumaran, N.P.; Shekhawat, G.S. A Guide to Potato Processor in India; (Technical Bulletin No. 48); Central Potato Research Institute: Shimla, India, 1999; pp. 14–39.

- Brar, A.; Bhatia, A.K.; Pandey, V.; Kumari, P. Biochemical and Phytochemical Properties of Potato: A Review. Chem. Sci. Rev. Lett. 2017, 6, 117–129. [Google Scholar]

- Sowokinos, J.R. Biochemical and molecular control of cold-induced sweetening in potatoes. Am. J. Potato Res. 2001, 3, 221–236. [Google Scholar] [CrossRef]

- Garayo, J.; Moreira, R. Vacuum frying of potato chips. J. Food Eng. 2002, 55, 181–191. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, N.; Ezekiel, R. Quality parameters of potato chips from different potato cultivars: Effect of prior storage and frying temperatures. Int. J. Food Prop. 2008, 11, 791–803. [Google Scholar] [CrossRef]

- Paunović, D.M.; Marković, J.M.; Stričević, L.P.; Vujasinović, V.B.; Stevanović, M.S.; Ćirković, A.L.; Rabrenović, B.B. The influence of cutting thickness, shape and moisture content on oil absorption during potato frying. J. Agric. Sci. 2021, 66, 67–74. [Google Scholar] [CrossRef]

- Abong, G.O.; Okoth, M.W.; Imungi, J.K.; Kabira, J.N. Effect of slice thickness and frying temperature on color, texture and sensory properties of crisps made from four kenyan potato cultivars. Am. J. Food Technol. 2011, 6, 753–762. [Google Scholar] [CrossRef][Green Version]

- Abong, G.O.; Okoth, M.W.; Imungi, J.K.; Kabira, J.N. Effects of cultivar, frying temperature and slice thickness on oil uptake and sensory quality of potato crisps processed from four Kenyan potato cultivars. J. Agric. Sci. Technol. 2011, 1, 753–762. [Google Scholar]

- Pedreschi, F.; Harnandez, P.; Figueroa, C. Modeling water loss during frying of potato slices. Int. J. Food Prop. 2005, 8, 289–299. [Google Scholar] [CrossRef]

- Polivanova, O.B.; Gins, E.M.; Moskalev, E.A.; Voinova, M.S.; Koroleva, A.K.; Semenov, A.Z.; Sivolapova, A.B.; Ivanova, A.S.; Kazakov, O.G.; Simakov, E.A.; et al. Quality evaluation, phytochemical characteristics and estimation of beta-carotene hydroxylase 2 (Chy2) alleles of interspecific potato hybrids. Agronomy 2021, 11, 1619. [Google Scholar] [CrossRef]

- Rodriguez-Saona, L.; Wrolstad, R. Influence of potato composition on chip color quality. Am. Potato J. 1997, 74, 87–106. [Google Scholar] [CrossRef]

- Pedreschi, F. Frying of potatoes: Physical, chemical, and microstructural changes. Dry. Technol. 2012, 30, 707–725. [Google Scholar] [CrossRef]

- Moyano, P.C.; Troncoso, E.; Pedreschi, F. Modeling texture kinetics during thermal processing of potato products. J. Food Sci. 2007, 72, 102–107. [Google Scholar] [CrossRef]

- Duckham, S.C.; Dodson, A.T.; Bakker, J.; Ames, J.M. Volatil flavor components of baked potato flesh: A comparison of eleven potato cvltivars. Food/Nahrung 2001, 45, 317–323. [Google Scholar] [CrossRef]

- Mamo, T. Nutritional and Sensory Property of Chips Made from Potato (S. T.). Adv. Res. 2018, 14, 1–8. [Google Scholar] [CrossRef]

- Lisinska, G.; Leszczynski, W. Potato Science and Technology; Elsevier Applied Science Publishers Ltd.: London, UK; New York, NY, USA, 1989; p. 391. [Google Scholar]

- LST ISO 751:2000; Fruit and Vegetable Products—Determination of Water–Insoluble Solids. Lithuanian Standards Board: Vilnius, Lithuania, 2000; p. 9.

- LT EN ISO 10520:2000; Native Starch—Determination of Starch Content—Ewers Polarimetric Method. Lithuanian Standards Board: Vilnius, Lithuania, 2000; p. 3.

- Al-Mhanna, N.M.; Huebner, H.; Buchholz, R. Analysis of the sugar content in food products by using gas chromatography mass spectrometry and enzymatic methods. Foods 2018, 7, 185. [Google Scholar] [CrossRef]

- Tamilselvi, N.; Krishnamoorthy, P.; Dhamotharan, R.; Arumugam, P.; Sagadevan, E. Analysis of total phenols, total tannins and screening of phytocomponents in Indigofera aspalathoides (Shivanar Vembu) Vahl EX DC. J. Chem. Pharm. Res. 2012, 4, 3259–3262. [Google Scholar]

- Naumann, C.; Bassler, R. Methodenbuch (1983–1999) Band III. Die Chemische Untersuchung von Futtermitteln; VDLUFA-Verlag: Darmstadt, Germany, 1997. [Google Scholar]

- CIE L*a*b* color scale. Applications Note. Insight on Color. In HunterLab Technical Manual; Hunter Lab: Reston, VA, USA, 2008; Volume 8, pp. 1–4.

- Salvador, A.; Varela, P.; Sanz, T.; Fiszman, S.M. Understanding potato chips crispy texture by simultaneous fracture and acoustic measurements, and sensory analysis. LWT Food Sci. Technol. 2009, 42, 763–767. [Google Scholar] [CrossRef]

- Kaaber, L.; Bråthen, E.; Martinsen, B.K.; Shomer, I. The effect of storage conditions on chemical content of raw potatoes and texture of cooked potatoes. Potato Res. 2001, 44, 153–163. [Google Scholar] [CrossRef]

- Sogut, T.; Ozturk, F. Effects of harvesting time on some yield and quality traits of different maturing potato cultivars. Afr. J. Biotechnol. 2011, 10, 7349–7355. [Google Scholar]

- Rymuza, K.; Radzka, E.; Lenartowicz, T. The impact of environmental conditions on the content of starch in tubers of medium early potato cultivars (in Polish). Acta Agroph. 2015, 22, 279–289. [Google Scholar]

- Leonel, M.; Carmo, E.L.; Fernandes, A.M.; Franco, C.M.L.; Soratto, R.P. Physicochemical properties of starches isolated from potato cultivars grown in soils with different phosphorus availability. J. Sci. Food Agric. 2016, 96, 1900–1905. [Google Scholar] [CrossRef]

- Braun, H.; Fontes, P.C.R.; Finger, F.L.; Busato, C.; Cecon, P.R. Carbohydrates and dry matter in tubers of potato cultivars as affected by nitrogen doses. Cienc. Agrotecn. 2010, 34, 285–293. [Google Scholar] [CrossRef]

- Das, S.; Mitra, B.; Saha, A.; Mandal, S.; Paul, P.K.; El-Sharnouby, M.; Hassan, M.M.; Maitra, S.; Hossain, A. Evaluation of quality parameters of seven processing type potato (Solanum tuberosum L.) cultivars in the Eastern Sub-Himalayan plains. Foods 2021, 10, 1138. [Google Scholar] [CrossRef]

- Wayumba, B.O.; Choi, H.S.; Seok, L.Y. Selection and evaluation of 21 potato (Solanum Tuberosum) breeding clones for cold chip processing. Foods 2019, 8, 98. [Google Scholar] [CrossRef]

- Hamouz, K.; Lachman, J.; Hejtmánková, K.; Pazderů, K.; Čížek, M.; Dvořák, P. Effect of natural and growing conditions on the content of phenolics in potatoes with different flesh colour. Plant Soil Environ. 2010, 56, 368–374. [Google Scholar] [CrossRef]

- Carrera, C.; Aliaño-González, M.J.; Valaityte, M.; Ferreiro-González, M.; Barbero, G.F.; Palma, M.A. Novel Ultrasound-assisted extraction method for the analysis of anthocyanins in potatoes (Solanum tuberosum L.). Antioxidants 2021, 10, 1375. [Google Scholar] [CrossRef]

- Azizah, A.H.; Wee, K.C.; Azizah, O.; Azizah, M. Effect of boiling and stir frying on total phenolics, carotenoids and radical scavenging activity of pumpkin (Cucurbita moschato). Int. Food Res. J. 2009, 16, 45–51. [Google Scholar]

- Silveira, A.C.; Falagán, N.; Aguayo, V.F.; Escalona, V.H. Compositional changes on colored and light-yellow-fleshed potatoes subjected to two cooking processes. CyTA–J. Food. 2017, 15, 241–248. [Google Scholar] [CrossRef]

- Kita, A.; Bakowska-Barczak, A.; Hamouz, K.; Kułakowska, K.; Lisinska, G. The effect of frying on anthocyanin stability and antioxidant activity of crisps from red- and purple-fleshed potatoes (Solanum tuberosum L.). J. Food Compos. Anal. 2013, 32, 169–175. [Google Scholar] [CrossRef]

- Jarienė, E.; Vaitkevičienė, N.; Danilčenko, H.; Tajner-Czopek, A.; Rytel, E.; Kucharska, A.; Sokół-Łętowska, A.; Gertchen, M.; Jeznach, M. Effect of biodynamic preparations on the phenolic antioxidants in potatoes with coloured-flesh. Biol. Agric. Hortic. 2017, 33, 172–182. [Google Scholar] [CrossRef]

- Lachman, J.; Hamouz, K.; Šulc, M.; Orsák, M.; Pivec, V.; Hejtmánková, A.; Dvořák, P.; Čepl, J. Cultivar differences of total anthocyanins and anthocyanidins in red and purple-fleshed potatoes and their relation to antioxidant activity. Food Chem. 2009, 114, 836–843. [Google Scholar] [CrossRef]

- Brown, C.R.; Durst, R.; Wrolstad, R.; Jong, W. Variability of phytonutrient content of potato in relation to growing location and cooking method. Potato Res. 2008, 51, 259–270. [Google Scholar] [CrossRef]

- Krokida, M.K.; Oreopolou, V.; Maroulis, Z.B.; Marinos-Kouris, D. Deep fat frying of potato strips quality issues. Drying Technol. 2001, 19, 879–935. [Google Scholar] [CrossRef]

- Yadav, D.V.; Shukla, R.; Kaushik, U.; Priyadarshini, D. Effect of frying time and temperature on the oil uptake characterstics of pre-treated potato (Solanum Tuberosum) chips. IJREAT 2014, 2, 1–10. [Google Scholar]

- Moyano, P.C.; Pedreschi, F. Kinetics of oil uptake during frying of potato slices: Effect of pre-treatments. LWT Food Sci. Technol. 2006, 39, 285–291. [Google Scholar] [CrossRef]

- Kita, A.; Lisińska, G.; Gołubowska, G. The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chem. 2007, 102, 1–5. [Google Scholar] [CrossRef]

| Years | Months | |||||

|---|---|---|---|---|---|---|

| April | May | June | July | August | September | |

| Air temperature (°C) | ||||||

| 2018 | 10.3 | 17.0 | 17.3 | 19.5 | 19.1 | 14.6 |

| The standard rate of climate (SRC) * | 7.0 | 12.8 | 15.7 | 18.0 | 17.1 | 12.0 |

| Rainfall (mm) | ||||||

| 2018 | 42.5 | 27.3 | 16.0 | 107.7 | 65.4 | 57.0 |

| The standard rate of climate (SRC) * | 43 | 57 | 73 | 89 | 75 | 66 |

| Quality Parameters | Potato Cultivar | p-Value | ||

|---|---|---|---|---|

| Blaue Anneliese | Valfi | Rosemarie | ||

| Flesh Colour | ||||

| Dark Purple | Light Purple | Light Red | ||

| Dry matter (g 100 g−1) | 21.44 a | 19.59 b | 18.00 c | 0.013 |

| Starch (g 100 g−1 DM) | 89.56 a | 71.03 b | 76.05 b | <0.001 |

| Reducing sugars (g 100 g−1 DM) | 0.54 b | 0.88 a | 0.59 b | 0.004 |

| Total phenolic content (mg g−1 DM) | 19.11 a | 17.40 b | 14.18 c | <0.001 |

| Total anthocyanins content (mg g−1 DM) | 5.70 a | 2.74 b | 2.66 b | <0.001 |

| Colour parameters | ||||

| L* | 29.78 c | 48.83 b | 56.81 a | <0.001 |

| a* | 15.48 a | 11.30 b | 15.42 a | 0.002 |

| b* | −8.16 c | −5.53 b | 12.39 a | <0.001 |

| Potato Cultivar | Slice Thickness (mm) | Frying Temperature (°C) | Total Phenolic Content (mg g−1 DM) | Loss of Phenolic (%) | Total Anthocyanins Content (mg g−1 DM) | Loss of Anthocyanins (%) | Total Fat Content (g 100 g−1 DM) |

|---|---|---|---|---|---|---|---|

| Blaue Anneliese | 1 | 160 | 10.86 a | 43.17 | 1.95 a | 65.79 | 38.60 cd |

| 1 | 180 | 10.34 b | 45.89 | 1.66 b | 70.87 | 36.49 e | |

| 2 | 160 | 8.86 c | 53.64 | 1.91 a | 66.49 | 39.45 b | |

| 2 | 180 | 6.98 e | 63.47 | 1.62 b | 71.58 | 40.52 a | |

| Valfi | 1 | 160 | 7.46 d | 57.13 | 0.72 fg | 73.72 | 39.54 b |

| 1 | 180 | 4.77 f | 72.59 | 0.50 gh | 81.75 | 35.84 e | |

| 2 | 160 | 4.59 f | 73.62 | 0.70 g | 74.45 | 39.25 bc | |

| 2 | 180 | 3.85 g | 77.87 | 0.44 h | 83.94 | 37.74 d | |

| Rosemarie | 1 | 160 | 6.94 e | 51.06 | 1.14 c | 57.14 | 39.50 b |

| 1 | 180 | 3.81 g | 73.13 | 0.89 e | 66.54 | 38.26 cd | |

| 2 | 160 | 3.66 g | 74.19 | 1.09 d | 59.02 | 39.05 bc | |

| 2 | 180 | 3.68 g | 74.05 | 0.84 ef | 68.42 | 39.04 bc | |

| p-value | Cultivars | <0.0001 | <0.0001 | 0.0080 | |||

| Slice thickness | <0.0001 | 0.083 | <0.0001 | ||||

| Frying temperature | <0.0001 | <0.0001 | <0.0001 | ||||

| Cultivars-slice thickness | 0.0014 | 0.2216 | 0.0008 | ||||

| Cultivars-frying temperature | 0.0650 | 0.3590 | 0.0009 | ||||

| Slice thickness-frying temperature | <0.0001 | 0.7761 | <0.0001 | ||||

| Cultivars-slice thickness-frying temperature | <0.0001 | 0.2802 | 0.2123 | ||||

| Potato Cultivar | Slice Thickness | Frying Temperature | Colour | Hardness (N) | ||

|---|---|---|---|---|---|---|

| L* | a* | b* | ||||

| Blaue Anneliese | 1 mm | 160 °C | 33.16 c | 3.57 def | −5.76 ef | 4.91 c |

| 1 mm | 180 °C | 22.47 d | 4.74 cde | −6.94 f | 4.99 c | |

| 2 mm | 160 °C | 29.15 c | 4.07 cde | −3.96 e | 5.84 c | |

| 2 mm | 180 °C | 32.17 c | 5.77 c | −5.88 ef | 7.15 b | |

| Valfi | 1 mm | 160 °C | 39.48 b | 2.04 f | 8.72 c | 3.91 d |

| 1 mm | 180 °C | 40.63 b | 4.76 cde | 8.27 c | 2.83 e | |

| 2 mm | 160 °C | 40.42 b | 2.85 ef | 12.02 b | 7.16 b | |

| 2 mm | 180 °C | 43.76 b | 4.91 cd | 5.20 d | 5.60 c | |

| Rosemarie | 1 mm | 160 °C | 43.60 b | 13.33 ab | 13.46 b | 3.28 de |

| 1 mm | 180 °C | 44.06 ab | 15.01 a | 13.84 b | 2.75 e | |

| 2 mm | 160 °C | 40.16 b | 11.04 b | 14.12 b | 8.77 a | |

| 2 mm | 180 °C | 48.09 a | 11.00 b | 17.51 a | 6.94 b | |

| p-value | Cultivars | <0.0001 | <0.0001 | <0.0001 | 0.0089 | |

| Slice thickness | 0.3855 | 0.0010 | 0.0482 | 0.0069 | ||

| Frying temperatures | 0.0988 | 0.1029 | 0.0296 | <0.0001 | ||

| Cultivars-slice thickness | 0.0135 | 0.2388 | 0.0032 | 0.0013 | ||

| Cultivars-frying temperatures | 0.5588 | 0.0012 | 0.2896 | <0.0001 | ||

| Slice thickness-frying temperatures | 0.0016 | 0.4087 | 0.1858 | 0.6200 | ||

| Cultivars-slice thickness-frying temperatures | 0.0890 | 0.4628 | 0.0104 | 0.0464 | ||

| Potato Cultivar | Slice Thickness | Frying Temperature | Flavour | Aroma | Texture | Colour | Total Score |

|---|---|---|---|---|---|---|---|

| Blaue Anneliese | 1 mm | 160°C | 3.94 ab | 3.83 abc | 3.54 cd | 4.54 a | 3.96 abcd |

| 1 mm | 180°C | 4.13 a | 4.21 a | 4.54 ab | 4.61 a | 4.37 a | |

| 2 mm | 160°C | 4.04 a | 3.89 abc | 4.82 a | 4.54 a | 4.32 ab | |

| 2 mm | 180°C | 3.93 ab | 4.04 abc | 4.54 ab | 4.34 ab | 4.21 abc | |

| Valfi | 1 mm | 160°C | 3.48 b | 3.78 abc | 3.19 d | 4.36 ab | 3.71 d |

| 1 mm | 180°C | 4.06 a | 3.56 c | 4.43 ab | 3.92 b | 3.99 abcd | |

| 2 mm | 160°C | 3.76 ab | 3.76 abc | 3.57 c | 4.39 ab | 3.87 cd | |

| 2 mm | 180°C | 3.77 ab | 3.96 abc | 3.98 bc | 3.87 b | 3.89 bcd | |

| Rosemarie | 1 mm | 160°C | 4.03 a | 3.60 bc | 4.44 ab | 4.32 ab | 4.10 abc |

| 1 mm | 180°C | 3.92 ab | 4.00 abc | 4.45 ab | 4.13 b | 4.12 abc | |

| 2 mm | 160°C | 3.53 b | 3.54 c | 3.84 c | 4.54 a | 3.86 cd | |

| 2 mm | 180°C | 3.90 ab | 4.09 ab | 4.44 ab | 4.43 ab | 4.21 abc | |

| p-value | Cultivars | 0.0598 | 0.1623 | 0.0020 | 0.0442 | 0.0105 | |

| Slice thickness | 0.4326 | 0.6127 | 0.3449 | 0.7286 | 0.7162 | ||

| Frying temperatures | 0.0565 | 0.0256 | 0.0005 | 0.0514 | 0.0515 | ||

| Cultivars-slice thickness | 0.3055 | 0.5815 | 0.0093 | 0.3498 | 0.6613 | ||

| Cultivars-frying temperatures | 0.2842 | 0.1589 | 0.1473 | 0.2869 | 0.9840 | ||

| Slice thickness-frying temperatures | 0.2970 | 0.5781 | 0.0340 | 0.6840 | 0.3093 | ||

| Cultivars x slice thickness-frying temperatures | 0.0537 | 0.4141 | 0.0093 | 0.8013 | 0.1223 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaitkevičienė, N.; Jarienė, E.; Kulaitienė, J.; Levickienė, D. The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature. Appl. Sci. 2022, 12, 1211. https://doi.org/10.3390/app12031211

Vaitkevičienė N, Jarienė E, Kulaitienė J, Levickienė D. The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature. Applied Sciences. 2022; 12(3):1211. https://doi.org/10.3390/app12031211

Chicago/Turabian StyleVaitkevičienė, Nijolė, Elvyra Jarienė, Jurgita Kulaitienė, and Dovilė Levickienė. 2022. "The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature" Applied Sciences 12, no. 3: 1211. https://doi.org/10.3390/app12031211

APA StyleVaitkevičienė, N., Jarienė, E., Kulaitienė, J., & Levickienė, D. (2022). The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature. Applied Sciences, 12(3), 1211. https://doi.org/10.3390/app12031211