The Efficiency of Edge Banding Module in a Mass Customized Line for Wooden Doors Production

Abstract

1. Introduction

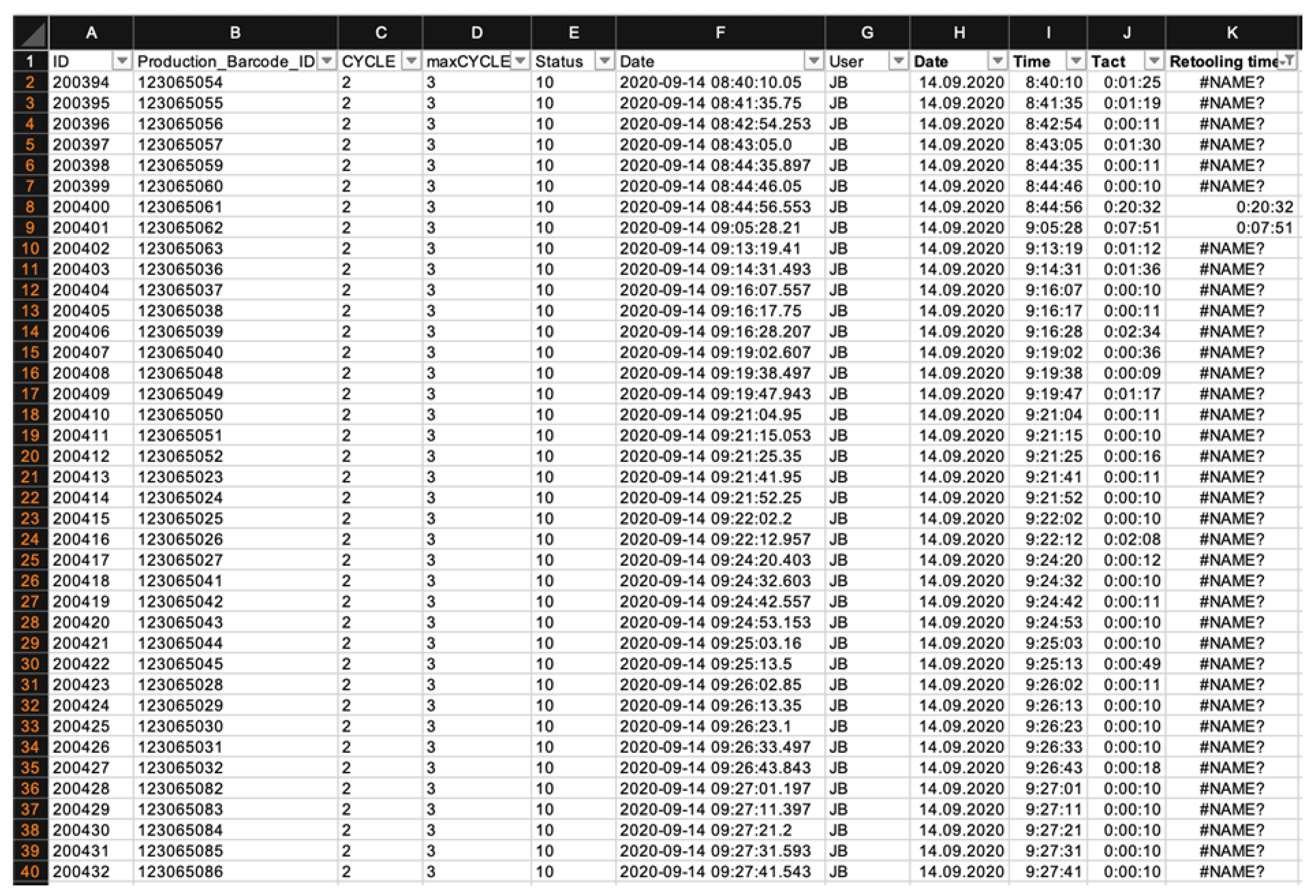

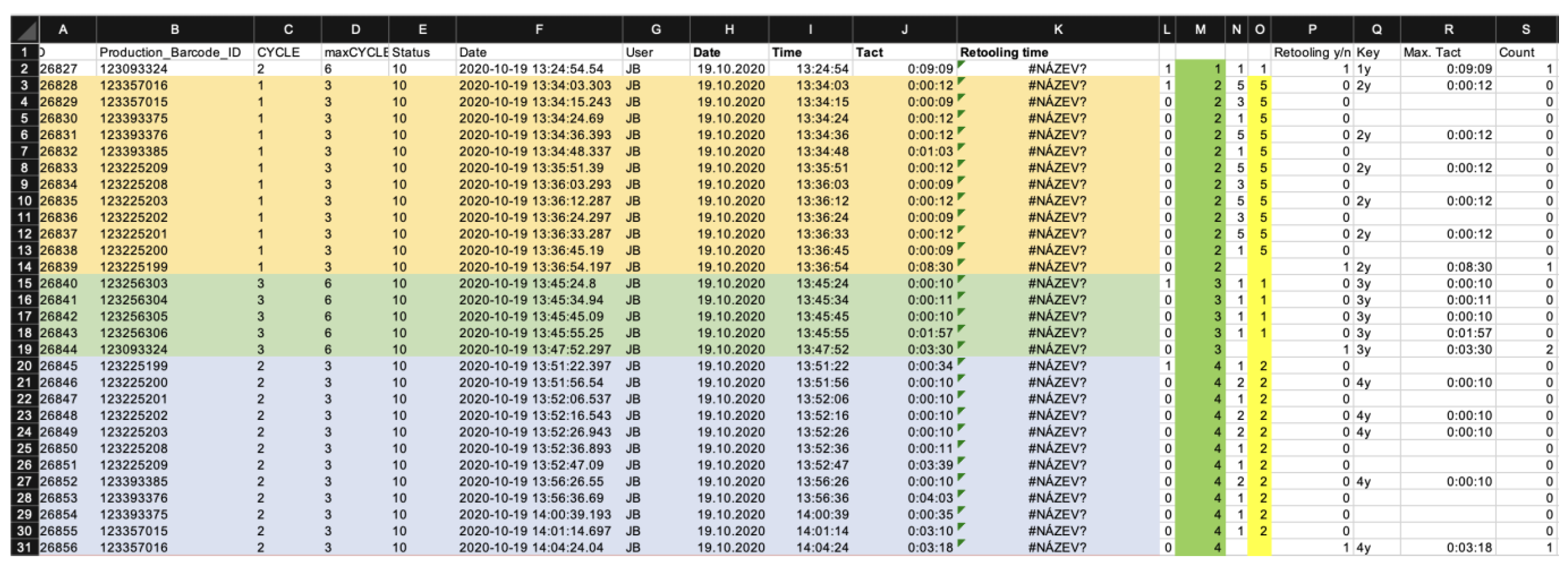

2. Materials and Methods

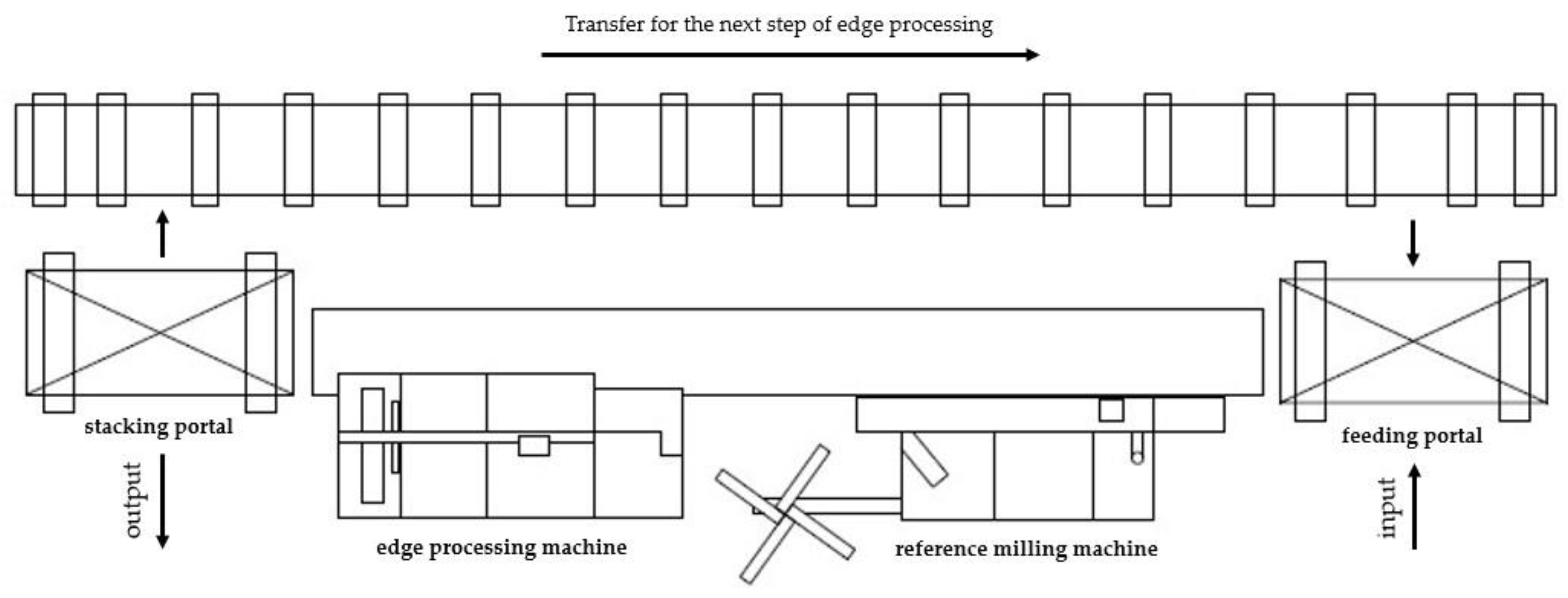

- Feeding door leaves for production (feeding portal);

- Reference edge milling (reference milling machine);

- Edge processing (the edge with a rebate processing machine);

- Stacking and transfer to the further processing of door leaves (two-way stacking portal).

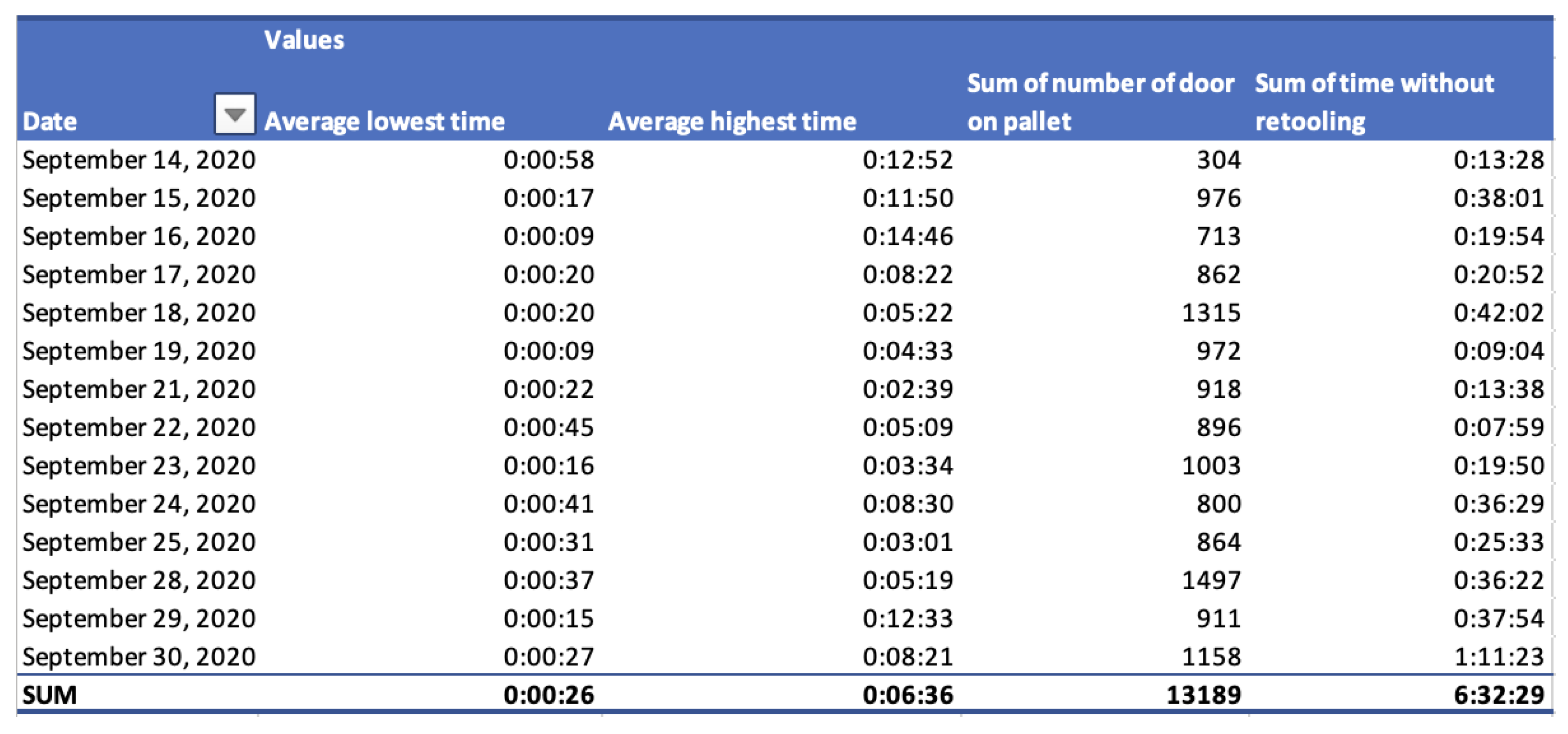

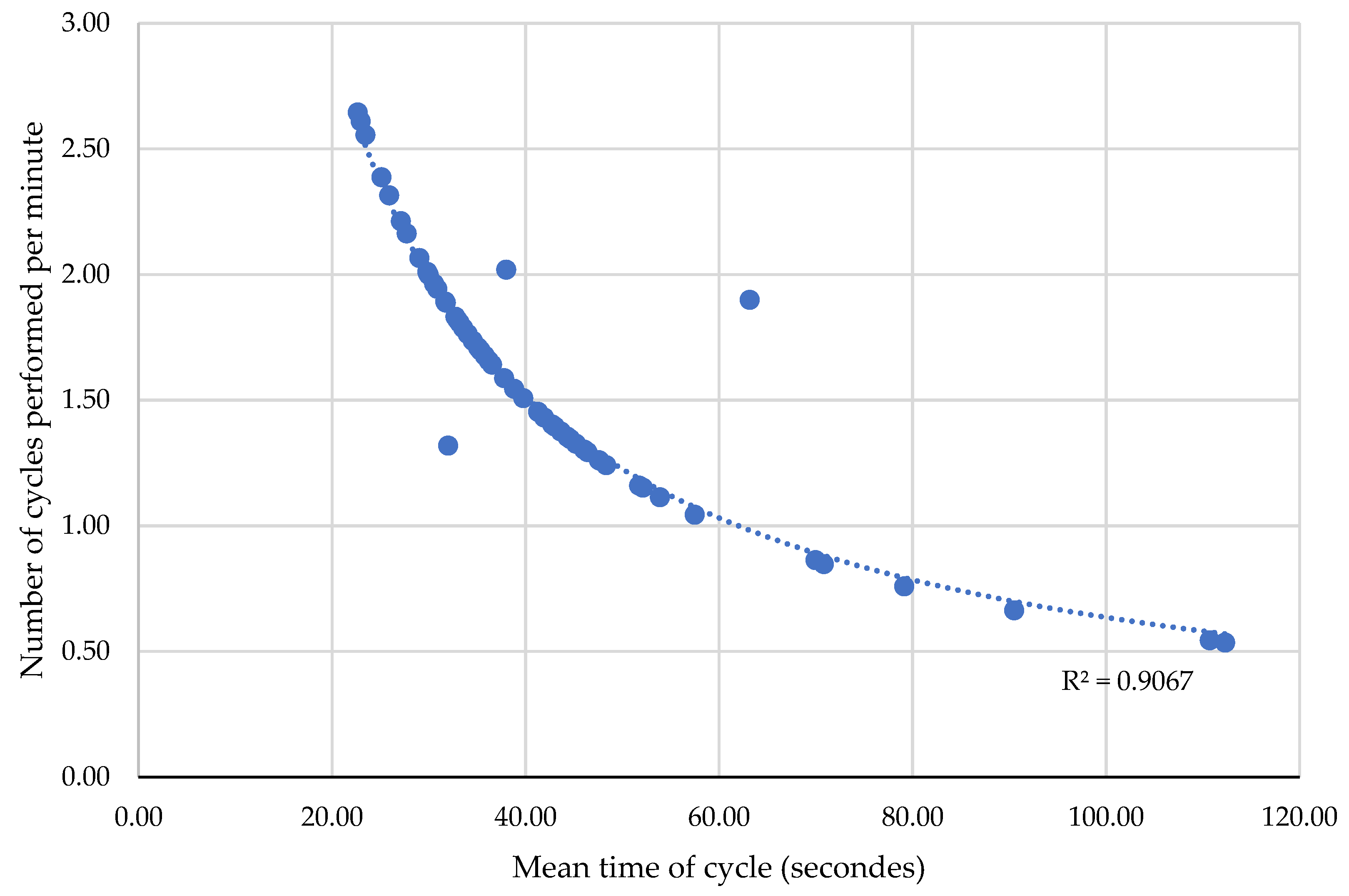

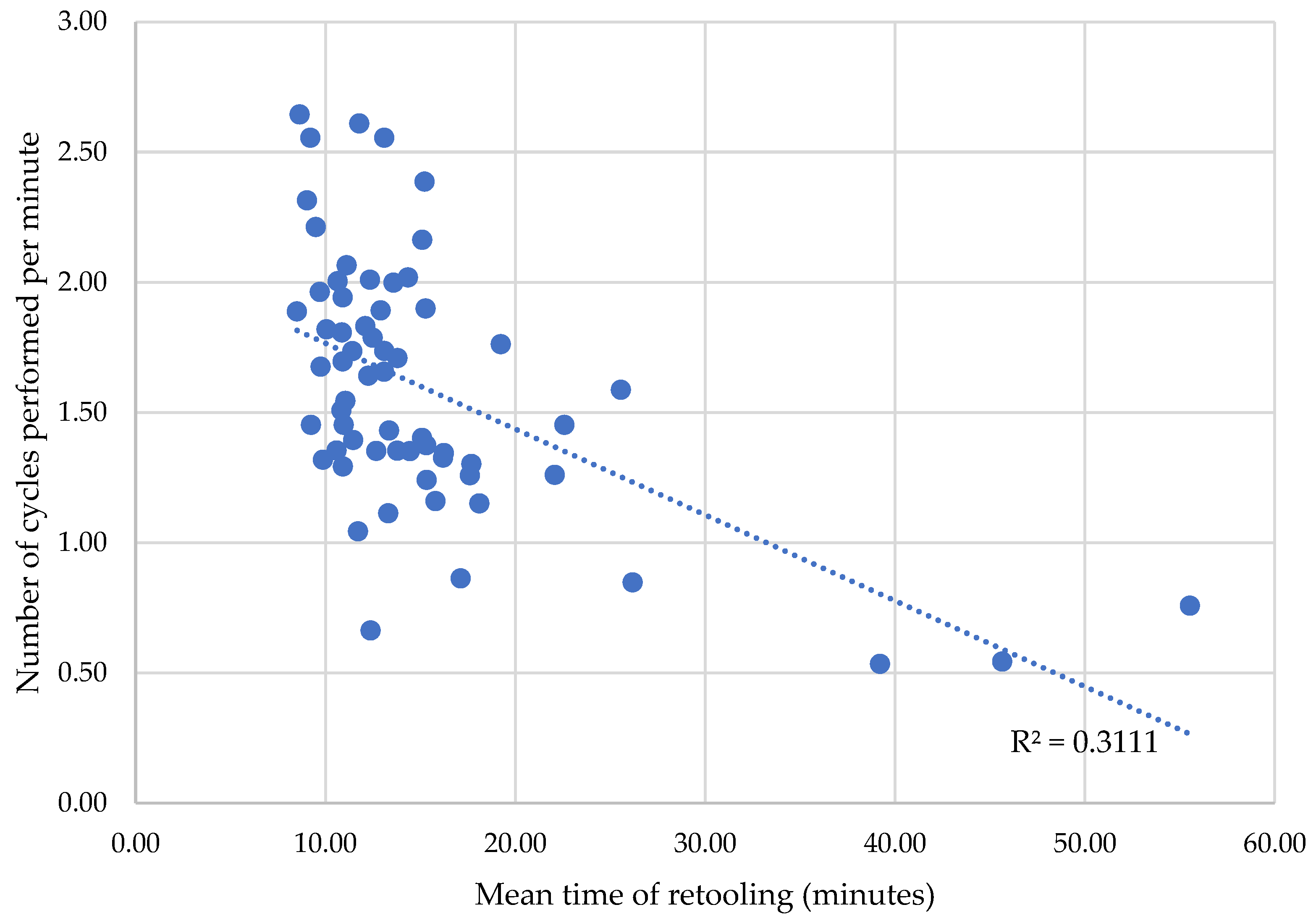

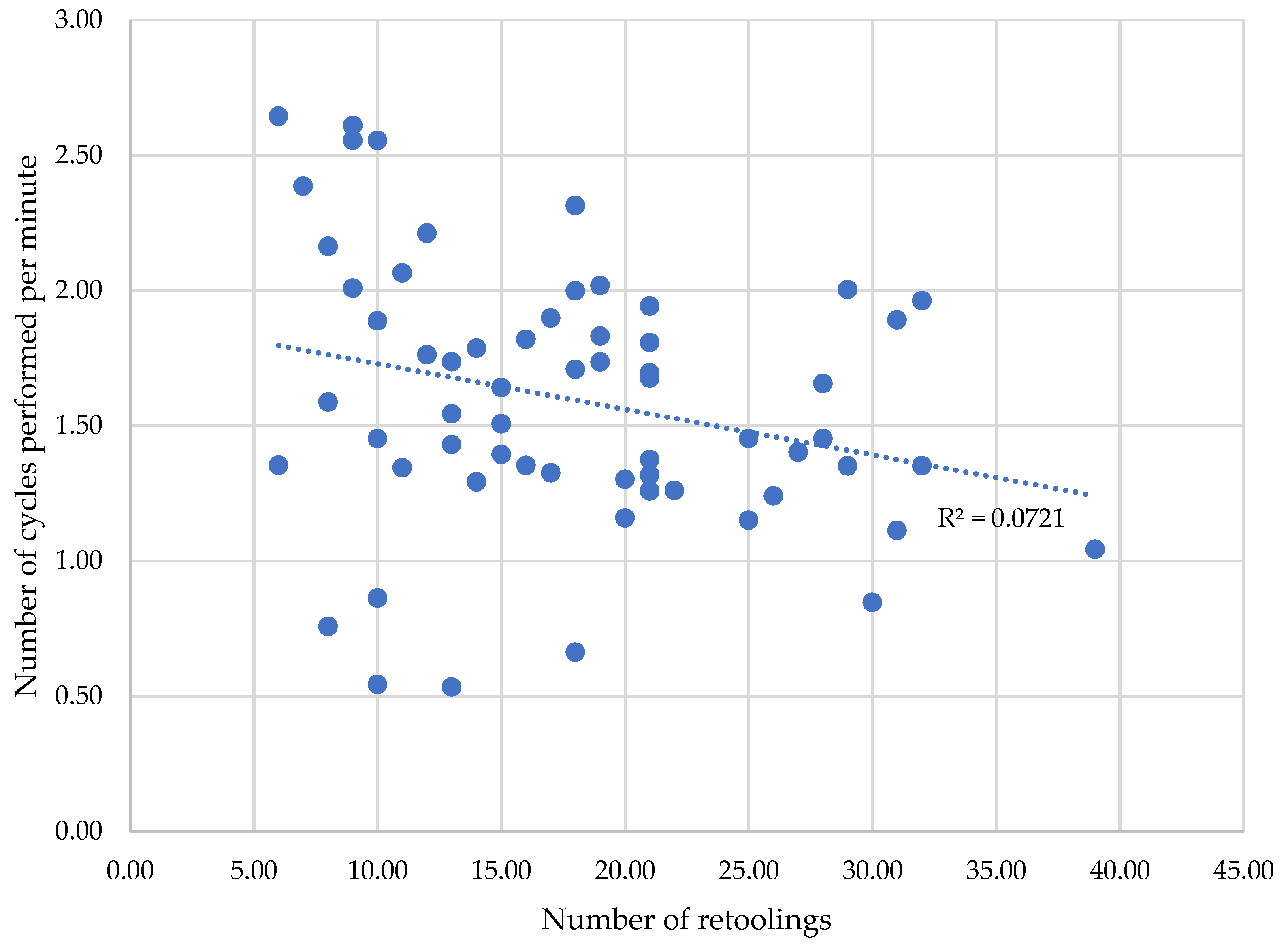

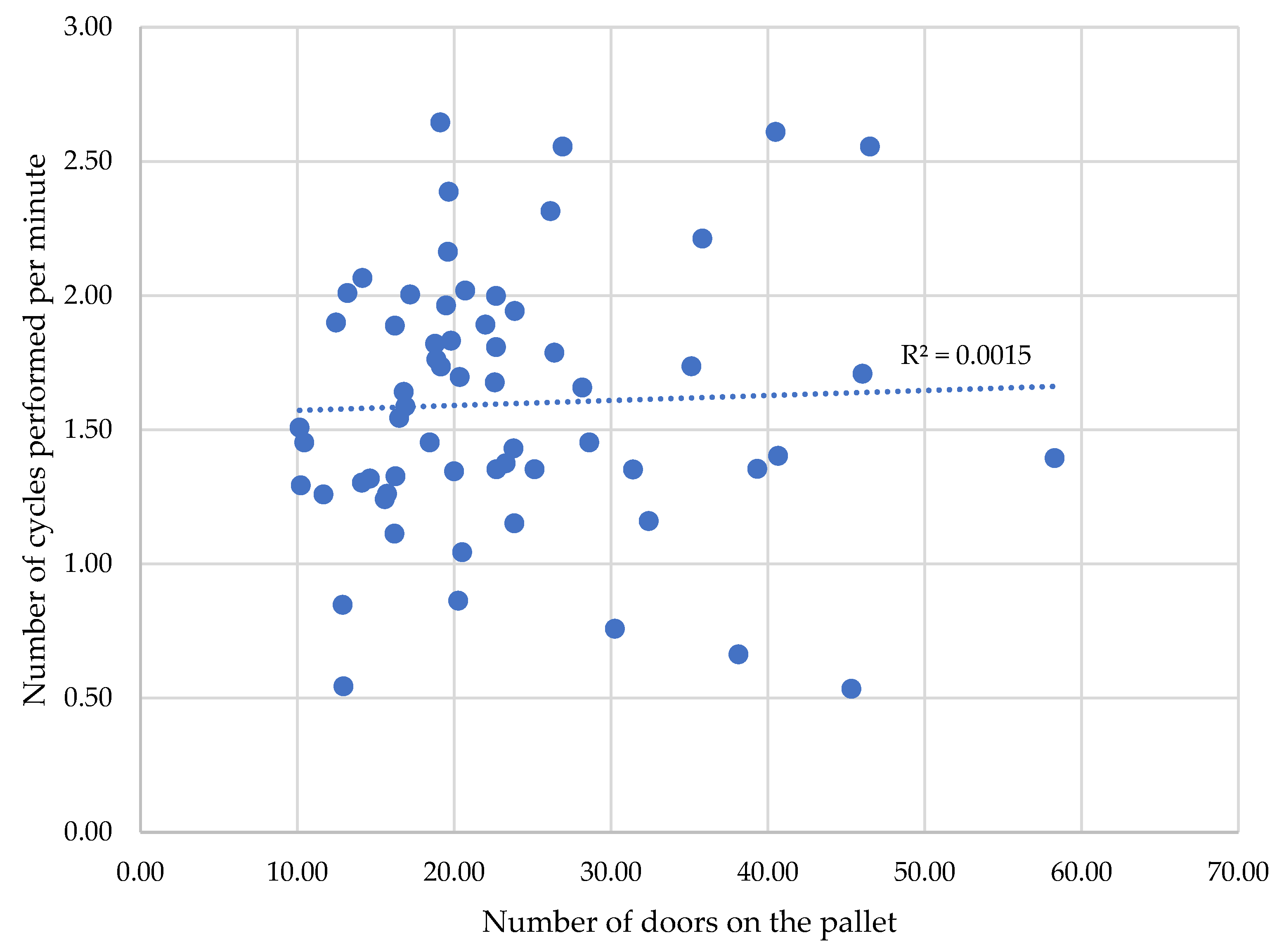

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davis, S.M. Future Perfect; Addison-Wesley Publishing: Reading, MA, USA, 1987. [Google Scholar]

- Sabioni, R.C.; Daaboul, J.; le Duigou, J. Joint Optimization of Product Configuration and Process Planning in Reconfigurable Manufacturing Systems. Int. J. Ind. Eng. Manag. 2022, 13, 58–75. [Google Scholar] [CrossRef]

- Piller, F.T. Mass Customization: Reflections on the State of the Concept. Int. J. Flex. Manuf. Syst. 2004, 16, 313–334. [Google Scholar] [CrossRef]

- Pędzik, M.; Bednarz, J.; Kwidziński, Z.; Rogoziński, T.; Smardzewski, J. The Idea of Mass Customization in the Door Industry Using the Example of the Company Porta KMI Poland. Sustainability 2020, 12, 3788. [Google Scholar] [CrossRef]

- Cavusoglu, H.; Cavusoglu, H.; Raghunathan, S. Selecting a Customization Strategy Under Competition: Mass Customization, Targeted Mass Customization, and Product Proliferation. IEEE Trans. Eng. Manag. 2007, 54, 12–28. [Google Scholar] [CrossRef]

- Du, X.; Jiao, J.; Tseng, M.M. Understanding Customer Satisfaction in Product Customization. Int. J. Adv. Manuf. Technol. 2006, 31, 396–406. [Google Scholar] [CrossRef]

- Bardakci, A.; Whitelock, J. Mass-customisation in Marketing: The Consumer Perspective. J. Consum. Mark. 2003, 20, 463–479. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Lin, L.; Shafiee, S. An Online Community-Based Dynamic Customisation Model: The Trade-off between Customer Satisfaction and Enterprise Profit. Int. J. Prod. Res. 2021, 59, 1–29. [Google Scholar] [CrossRef]

- Bonenberg, A.; Branowski, B.; Kurczewski, P.; Lewandowska, A.; Sydor, M.; Torzyński, D.; Zabłocki, M. Designing for Human Use: Examples of Kitchen Interiors for Persons with Disability and Elderly People. Hum. Factors Ergon. Manuf. Serv. Ind. 2019, 29, 177–186. [Google Scholar] [CrossRef]

- Gejdoš, M.; Hitka, M. The Impact of the Secular Trend of the Slovak Population on the Production of Wooden Beds and Seating Furniture. Forests 2022, 13, 1599. [Google Scholar] [CrossRef]

- Bumgardner, M.S.; Nicholls, D.L. Sustainable Practices in Furniture Design: A Literature Study on Customization, Biomimicry, Competitiveness, and Product Communication. Forests 2020, 11, 1277. [Google Scholar] [CrossRef]

- Langová, N.; Réh, R.; Igaz, R.; Krišťák, Ľ.; Hitka, M.; Joščák, P. Construction of Wood-Based Lamella for Increased Load on Seating Furniture. Forests 2019, 10, 525. [Google Scholar] [CrossRef]

- Blecker, T.; Friedrich, G. Mass Customization: Challenges and Solutions; Springer: Boston, MA, USA, 2006; Volume 87, ISBN 978-0-387-32222-3. [Google Scholar]

- Sydor, M.; Pinkowski, G.; Kučerka, M.; Kminiak, R.; Antov, P.; Rogoziński, T. Indentation Hardness and Elastic Recovery of Some Hardwood Species. Appl. Sci. 2022, 12, 5049. [Google Scholar] [CrossRef]

- Sydor, M.; Rogoziński, T.; Stuper-Szablewska, K.; Starczewski, K. The Accuracy of Holes Drilled in the Side Surface of Plywood. Bioresources 2019, 15, 117–129. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, G.; Zhuang, Q.; Tian, G. Multi-Objective Low-Carbon Disassembly Line Balancing for Agricultural Machinery Using MDFOA and Fuzzy AHP. J. Clean. Prod. 2019, 233, 1465–1474. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, H.; Zhang, H.; Mendis, G.; Sutherland, J.W. Value Recovery Options Portfolio Optimization for Remanufacturing End of Life Product. J. Clean. Prod. 2019, 210, 419–431. [Google Scholar] [CrossRef]

- Ghayebloo, S.; Tarokh, M.J.; Venkatadri, U.; Diallo, C. Developing a Bi-Objective Model of the Closed-Loop Supply Chain Network with Green Supplier Selection and Disassembly of Products: The Impact of Parts Reliability and Product Greenness on the Recovery Network. J. Manuf. Syst. 2015, 36, 76–86. [Google Scholar] [CrossRef]

- Pędzik, M.; Tomczak, K.; Janiszewska-Latterini, D.; Tomczak, A.; Rogoziński, T. Management of Forest Residues as a Raw Material for the Production of Particleboards. Forests 2022, 13, 1933. [Google Scholar] [CrossRef]

- Pędzik, M.; Kwidziński, Z.; Rogoziński, T. Particles from Residue Wood-Based Materials from Door Production as an Alternative Raw Material for Production of Particleboard. Drv. Ind. 2022, 73, 351–357. [Google Scholar] [CrossRef]

- Bhamu, J.; Singh Sangwan, K. Lean Manufacturing: Literature Review and Research Issues. Int. J. Oper. Prod. Manag. 2014, 34, 876–940. [Google Scholar] [CrossRef]

- Gupta, S.; Jain, S.K. A Literature Review of Lean Manufacturing. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 241–249. [Google Scholar] [CrossRef]

- Antosz, K.; Ciecińska, B. Podstawy Zarządzania Parkiem Maszyn w Przedsiębiorstwie; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 2011; ISBN 978-83-7199-688-7. [Google Scholar]

- Furman, J.; Orszag, P.R. Slower Productivity and Higher Inequality: Are They Related? SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Kwidziński, Z.; Drewczyński, M.; Rogoziński, T.; Pędzik, M. Energy Efficiency in Mass Customized Production of Wooden Doors. In Proceedings of the Chip and Chipless Woodworking Processes, Zvolen, Slovakia, 15–17 September 2022; Volume 13. [Google Scholar]

- Kwidziński, Z.; Bednarz, J.; Sankiewicz, Ł.; Pędzik, M.; Rogoziński, T. TechnoPORTA Intelligent, Customized Technological Line for the Automated Production of Technical Doors—Selected Technical and Economic Indicators. Ann. WULS For. Wood Technol. 2021, 114, 96–100. [Google Scholar] [CrossRef]

- Kwidziński, Z.; Bednarz, J.; Pędzik, M.; Sankiewicz, Ł.; Szarowski, P.; Knitowski, B.; Rogoziński, T. Innovative Line for Door Production Technoporta—Technological and Economic Aspects of Application of Wood-Based Materials. Appl. Sci. 2021, 11, 4502. [Google Scholar] [CrossRef]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004; ISBN 978-0-07-139231-0. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking, 1st ed.; Lean Enterprise Institute; Taylor & Francis: Abingdon, UK, 1996; ISBN 978-0-684-81035-5. [Google Scholar]

- Malms, M.; Ostasz, M.; Gilliot, M.; Bernier-Bruna, P.; Cargemel, L.; Suarez, E.; Cornelius, H.; Duranton, M.; Koren, B.; Rosse-Laurent, P.; et al. ETP4HPC’s Strategic Research Agenda for High-Performance Computing in Europe 4. 2020. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiUvLiBzeb7AhXWUGwGHQsJAyoQFnoECAwQAQ&url=https%3A%2F%2Fhal.inria.fr%2Fhal-03354396%2Ffile%2FETP4HPC_SRA4_2020_web_20200331.pdf&usg=AOvVaw1qFzhCZq0jSEhLZkZEAPGD (accessed on 15 November 2022). [CrossRef]

- Skotnicka-Zasadzień, B. Analiza Efektywności Zastosowania Metody FMEA w Małym Przedsiębiorstwie Przemysłowym. Syst. Support. Prod. Eng. 2012, 2, 142–153. [Google Scholar]

- Permana, A.; Purba, H.H.; Rizkiyah, N.D. A Systematic Literature Review of Total Quality Management (TQM) Implementation in the Organization. Int. J. Prod. Manag. Eng. 2021, 9, 25. [Google Scholar] [CrossRef]

- Lasrado, F.; Nyadzayo, M. Improving Service Quality. Int. J. Qual. Reliab. Manag. 2020, 37, 393–410. [Google Scholar] [CrossRef]

- Tasleem, M.; Khan, N.; Masood, S.A. Impact of TQM and Technology Management on Organizational Performance. Mehran Univ. Res. J. Eng. Technol. 2016, 35, 585–598. [Google Scholar] [CrossRef][Green Version]

- Garcia-Buendia, N.; Moyano-Fuentes, J.; Maqueira-Marín, J.M.; Cobo, M.J. 22 Years of Lean Supply Chain Management: A Science Mapping-Based Bibliometric Analysis. Int. J. Prod. Res. 2021, 59, 1901–1921. [Google Scholar] [CrossRef]

- Uriona Maldonado, M.; Leusin, M.E.; de Albuquerque Bernardes, T.C.; Vaz, C.R. Similarities and Differences between Business Process Management and Lean Management. Bus. Process Manag. J. 2020, 26, 1807–1831. [Google Scholar] [CrossRef]

- Simanova, Ľ.; Gejdoš, P. Implementation of the Six Sigma Methodology in Increasing the Capability of Processes in the Company of the Furniture Industry of the Slovak Republic. Manag. Syst. Prod. Eng. 2021, 29, 54–58. [Google Scholar] [CrossRef]

- Raval, S.J.; Kant, R.; Shankar, R. Analyzing the Lean Six Sigma Enabled Organizational Performance to Enhance Operational Efficiency. Benchmarking Int. J. 2020, 27, 2401–2434. [Google Scholar] [CrossRef]

- Sfreddo, L.S.; Vieira, G.B.B.; Vidor, G.; Santos, C.H.S. ISO 9001 Based Quality Management Systems and Organisational Performance: A Systematic Literature Review. Total Qual. Manag. Bus. Excell. 2021, 32, 389–409. [Google Scholar] [CrossRef]

- Pacana, A.; Ulewicz, R. Analysis of Causes and Effects of Implementation of the Quality Management System Compliant with ISO 9001. Pol. J. Manag. Stud. 2020, 21, 283–296. [Google Scholar] [CrossRef]

- Bessant, J.; Lamming, R.; Noke, H.; Phillips, W. Managing Innovation beyond the Steady State. Technovation 2005, 25, 1366–1376. [Google Scholar] [CrossRef]

- Yen-Tsang, C.; Csillag, J.M.; Siegler, J. Theory of Reasoned Action for Continuous Improvement Capabilities: A Behavioral Approach. Rev. Adm. Empres. 2012, 52, 546–564. [Google Scholar] [CrossRef][Green Version]

- Corredera, A.; Macia, A.; Sanz, R.; Hernandez, J.L. An Automated Monitoring System for Surveillance and KPI Calculation. In Proceedings of the 2016 IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems (EESMS), Bari, Italy, 13–14 June 2016; pp. 1–6. [Google Scholar]

- Borsos, G.; Iacob, C.C.; Calefariu, G. The Use KPI’s to Determine the Waste in Production Process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012102. [Google Scholar] [CrossRef]

- Tzeng, G.-H.; Cheng, H.-J.; Huang, T.D. Multi-Objective Optimal Planning for Designing Relief Delivery Systems. Transp. Res. E Logist. Transp. Rev. 2007, 43, 673–686. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, H.; Xue, D. A Multi-Population Co-Evolutionary Genetic Programming Approach for Optimal Mass Customisation Production. Int. J. Prod. Res. 2017, 55, 621–641. [Google Scholar] [CrossRef]

- Zipkin, P. The Limits of Mass Customization. Sloan Manag. Rev 2001, 42, 81–87. [Google Scholar]

- Korčok, M.; Koleda, P.; Barcík, Š.; Očkajová, A.; Kučerka, M. Effect of Technological and Material Parameters on Final Surface Quality of Machining When Milling Thermally Treated Spruce Wood. Martin 2019, 14, 10004–10013. [Google Scholar]

- Kminiak, R.; Siklienka, M.; Igaz, R.; Krišťák, Ľ.; Gergeľ, T.; Němec, M.; Réh, R.; Očkajová, A.; Kučerka, M. Effect of Cutting Conditions on Quality of Milled Surface of Medium-Density Fibreboards. Bioresources 2019, 15, 746–766. [Google Scholar] [CrossRef]

- Grasselli, M.R.; Nguyen-Huu, A. Inventory Growth Cycles with Debt-Financed Investment. Struct. Chang. Econ. Dyn. 2018, 44, 1–13. [Google Scholar] [CrossRef]

- Mendelson, H.; Parlaktürk, A.K. Competitive Customization. Manuf. Serv. Oper. Manag. 2008, 10, 377–390. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z. Batch Size Optimization of Multi-Stage Flow Lines in Terms of Mass Customization. Int. J. Simul. Model. 2020, 19, 219–230. [Google Scholar] [CrossRef]

- Hou, S.; Gao, J.; Wang, C. Design for Mass Customisation, Design for Manufacturing, and Design for Supply Chain: A Review of the Literature. IET Collab. Intell. Manuf. 2022, 4, 1–16. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwidziński, Z.; Hanincová, L.; Tyma, E.; Bednarz, J.; Sankiewicz, Ł.; Knitowski, B.; Pędzik, M.; Procházka, J.; Rogoziński, T. The Efficiency of Edge Banding Module in a Mass Customized Line for Wooden Doors Production. Appl. Sci. 2022, 12, 12510. https://doi.org/10.3390/app122412510

Kwidziński Z, Hanincová L, Tyma E, Bednarz J, Sankiewicz Ł, Knitowski B, Pędzik M, Procházka J, Rogoziński T. The Efficiency of Edge Banding Module in a Mass Customized Line for Wooden Doors Production. Applied Sciences. 2022; 12(24):12510. https://doi.org/10.3390/app122412510

Chicago/Turabian StyleKwidziński, Zdzisław, Luďka Hanincová, Eryka Tyma, Joanna Bednarz, Łukasz Sankiewicz, Bartłomiej Knitowski, Marta Pędzik, Jiří Procházka, and Tomasz Rogoziński. 2022. "The Efficiency of Edge Banding Module in a Mass Customized Line for Wooden Doors Production" Applied Sciences 12, no. 24: 12510. https://doi.org/10.3390/app122412510

APA StyleKwidziński, Z., Hanincová, L., Tyma, E., Bednarz, J., Sankiewicz, Ł., Knitowski, B., Pędzik, M., Procházka, J., & Rogoziński, T. (2022). The Efficiency of Edge Banding Module in a Mass Customized Line for Wooden Doors Production. Applied Sciences, 12(24), 12510. https://doi.org/10.3390/app122412510