Enhancement of a Single-Axis Femtosecond Laser Scanning System by Using Two Galvanometers to Improve the Telecentricity and the Effective Scanning Length on Laser Process

Abstract

1. Introduction

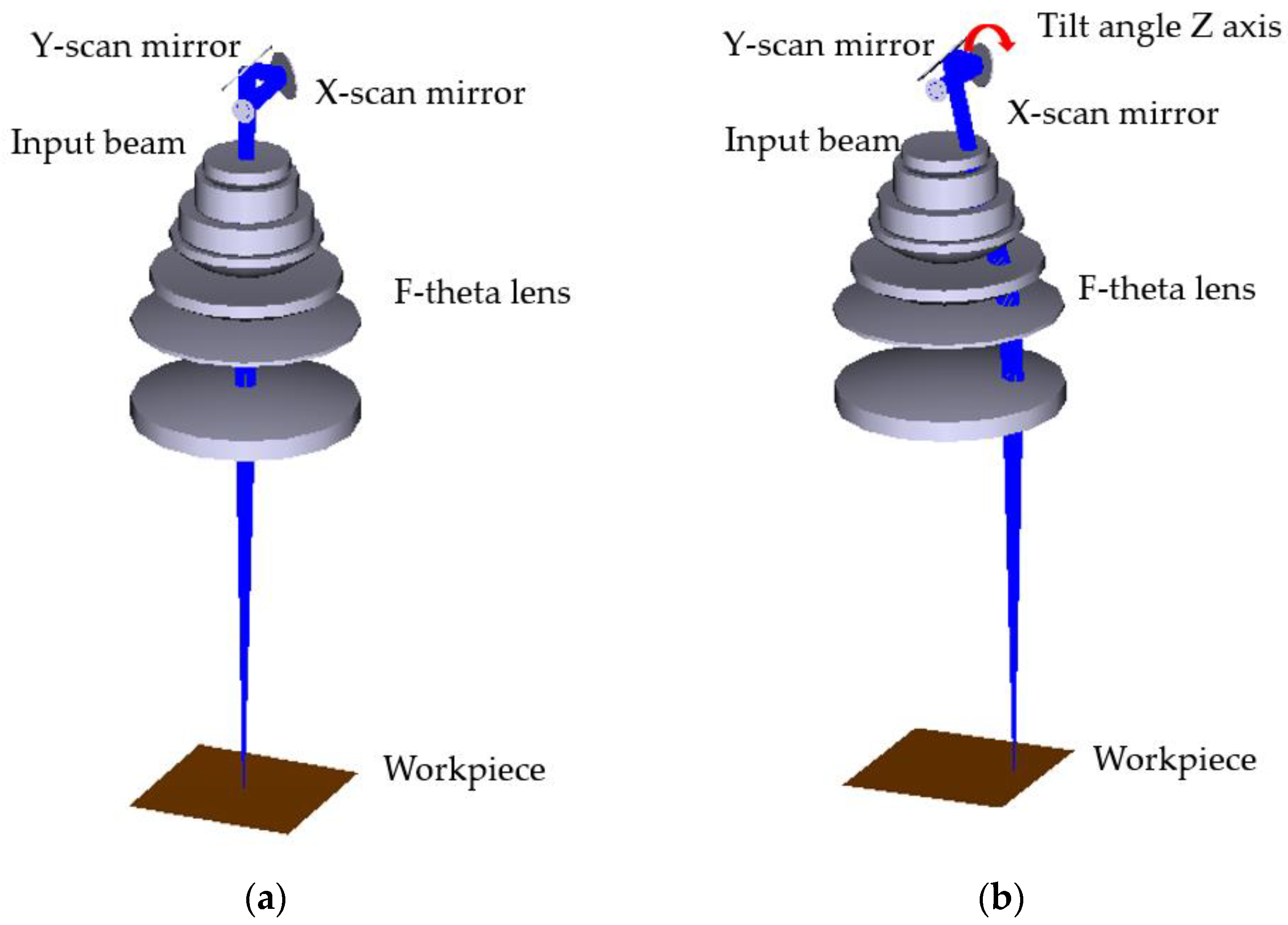

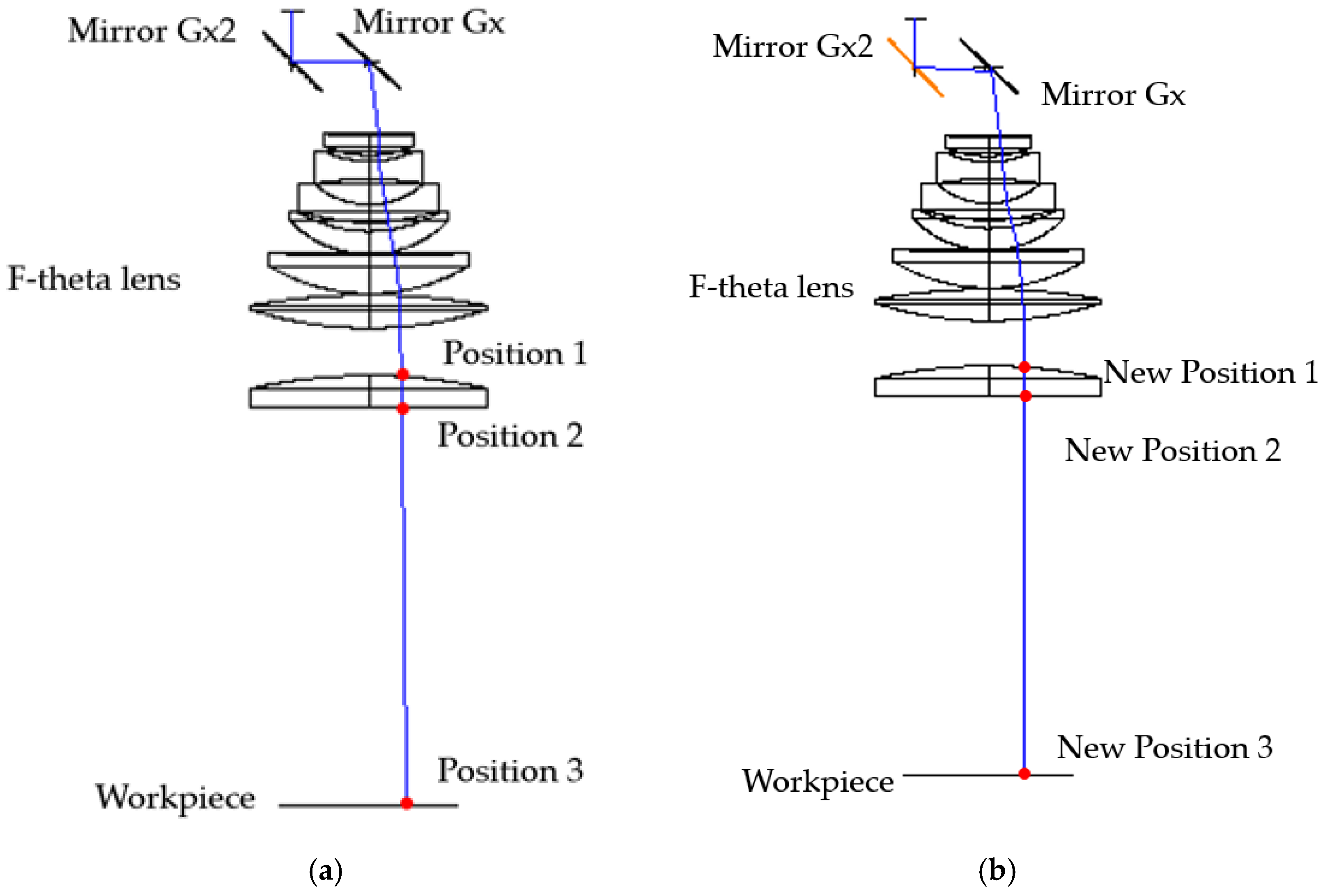

2. The Working Principle of the Single-Axis Scanning System with Two Galvanometers

3. Results and Discussion

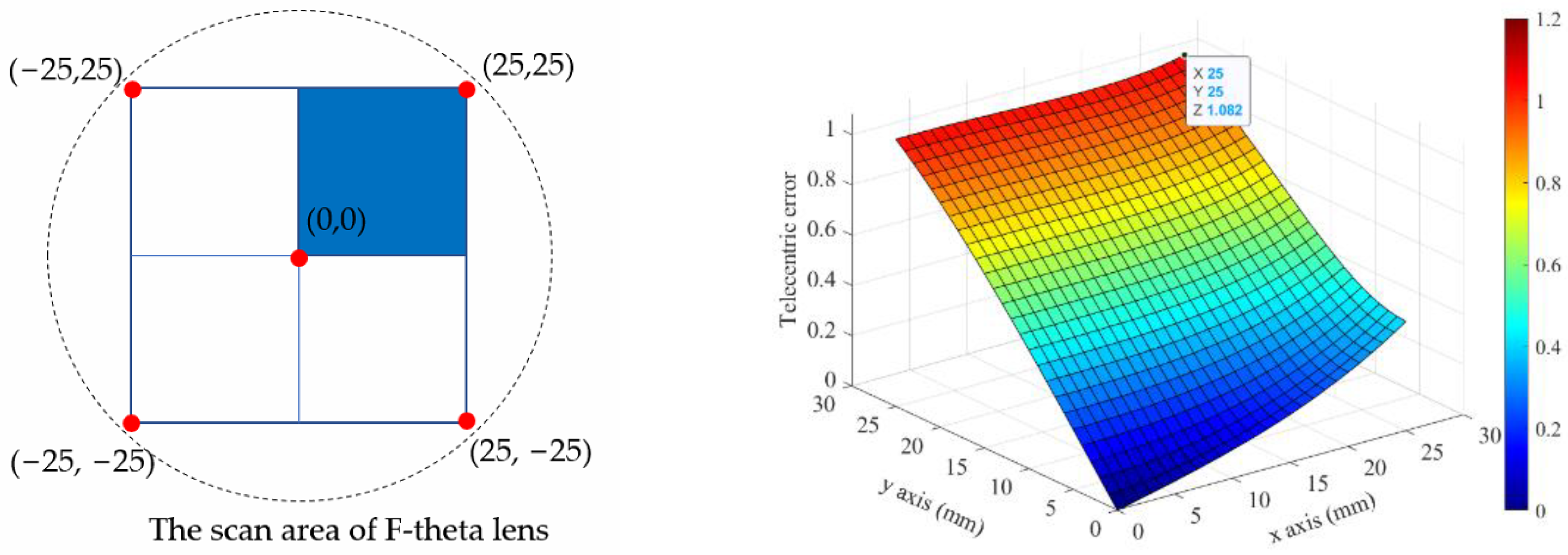

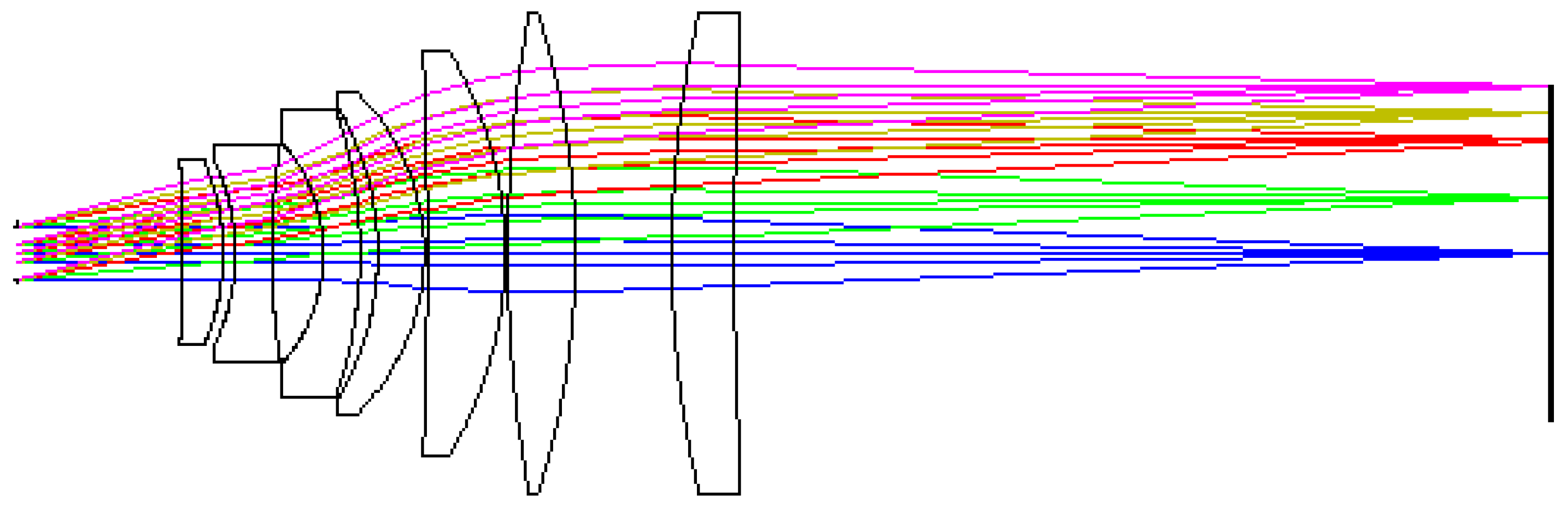

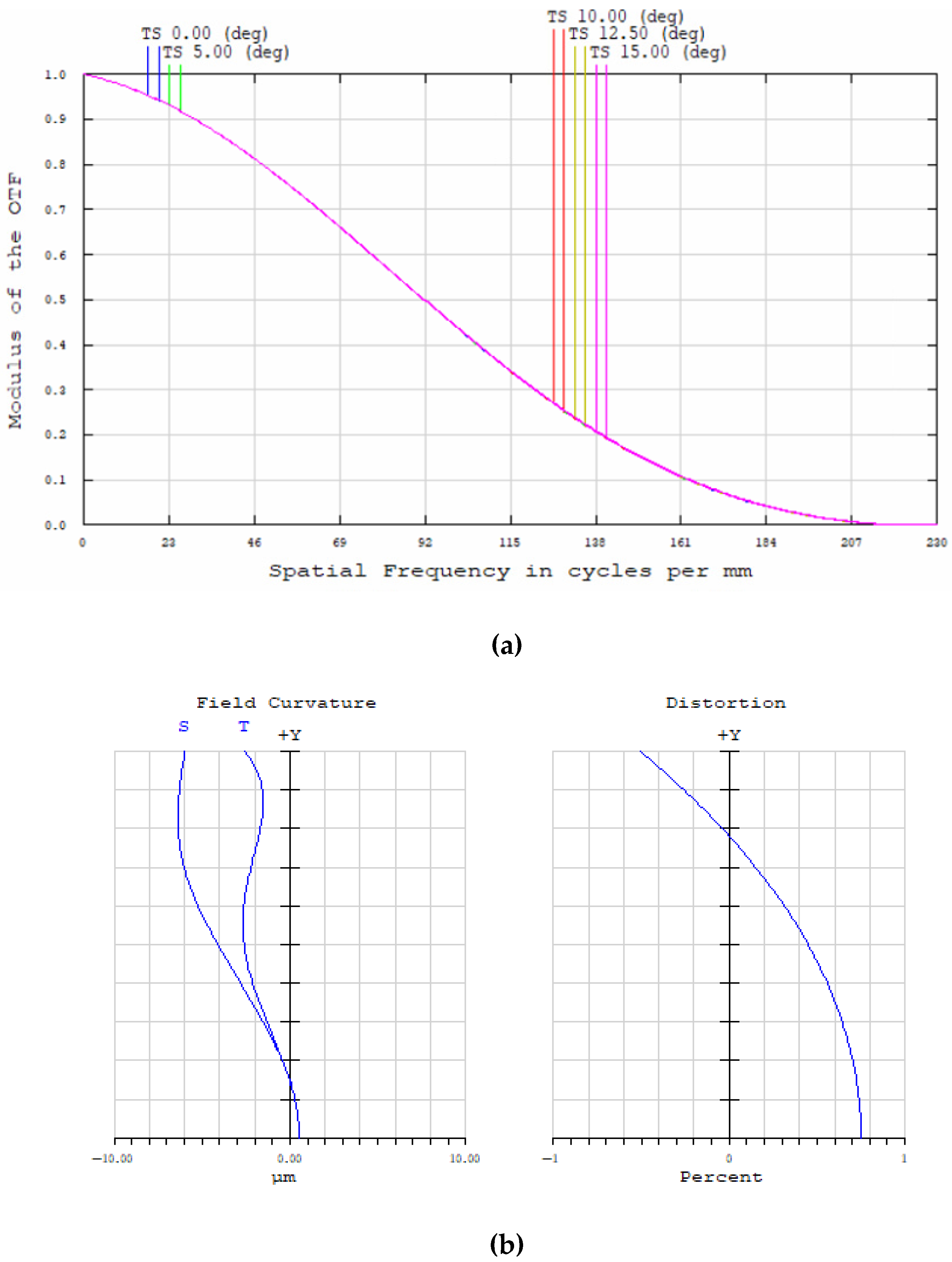

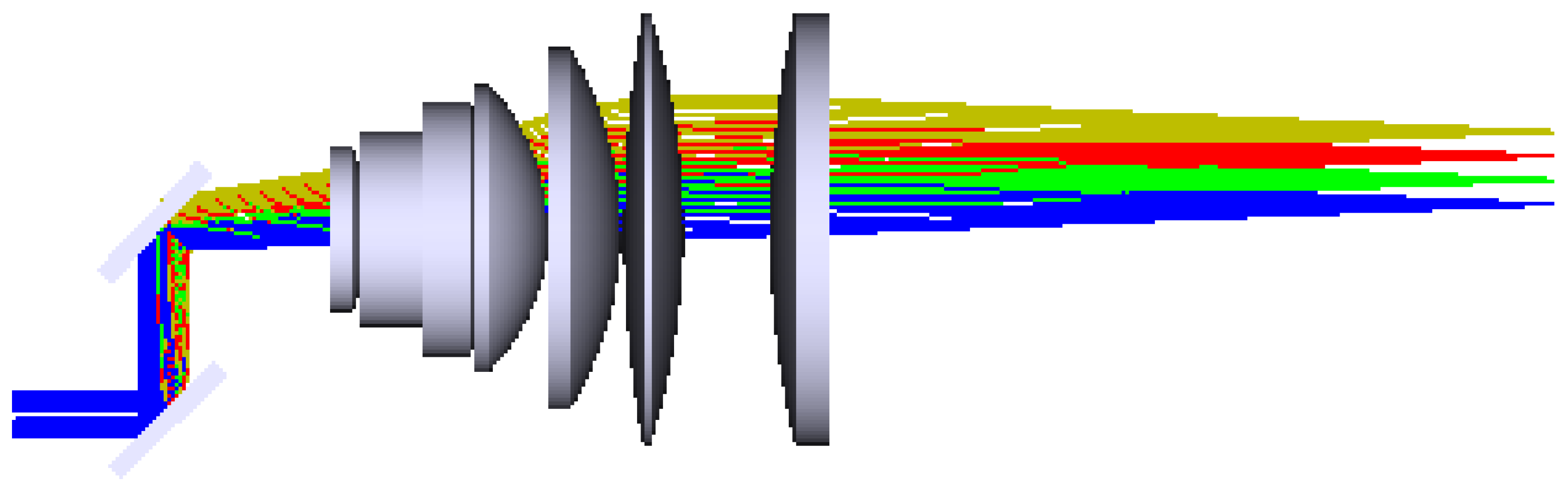

3.1. F-Theta Lens Design

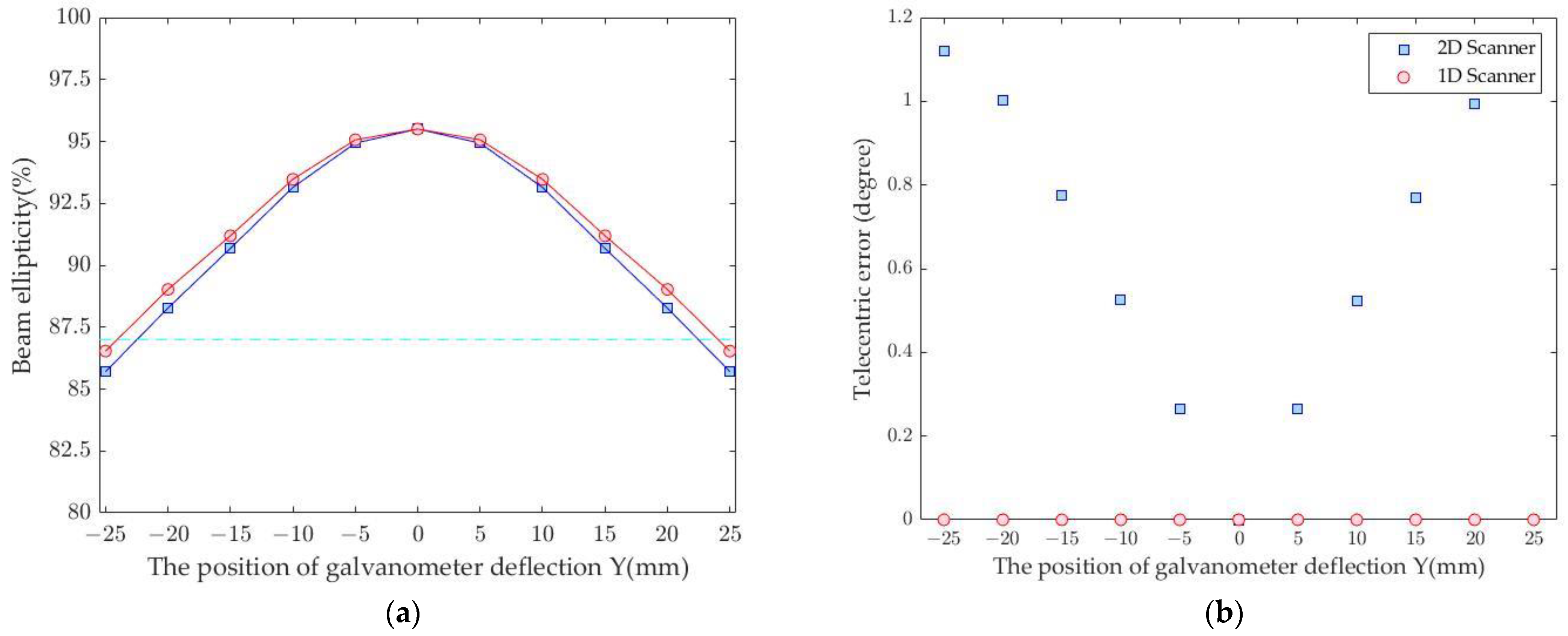

3.2. Single Galvanometer Scanner Model

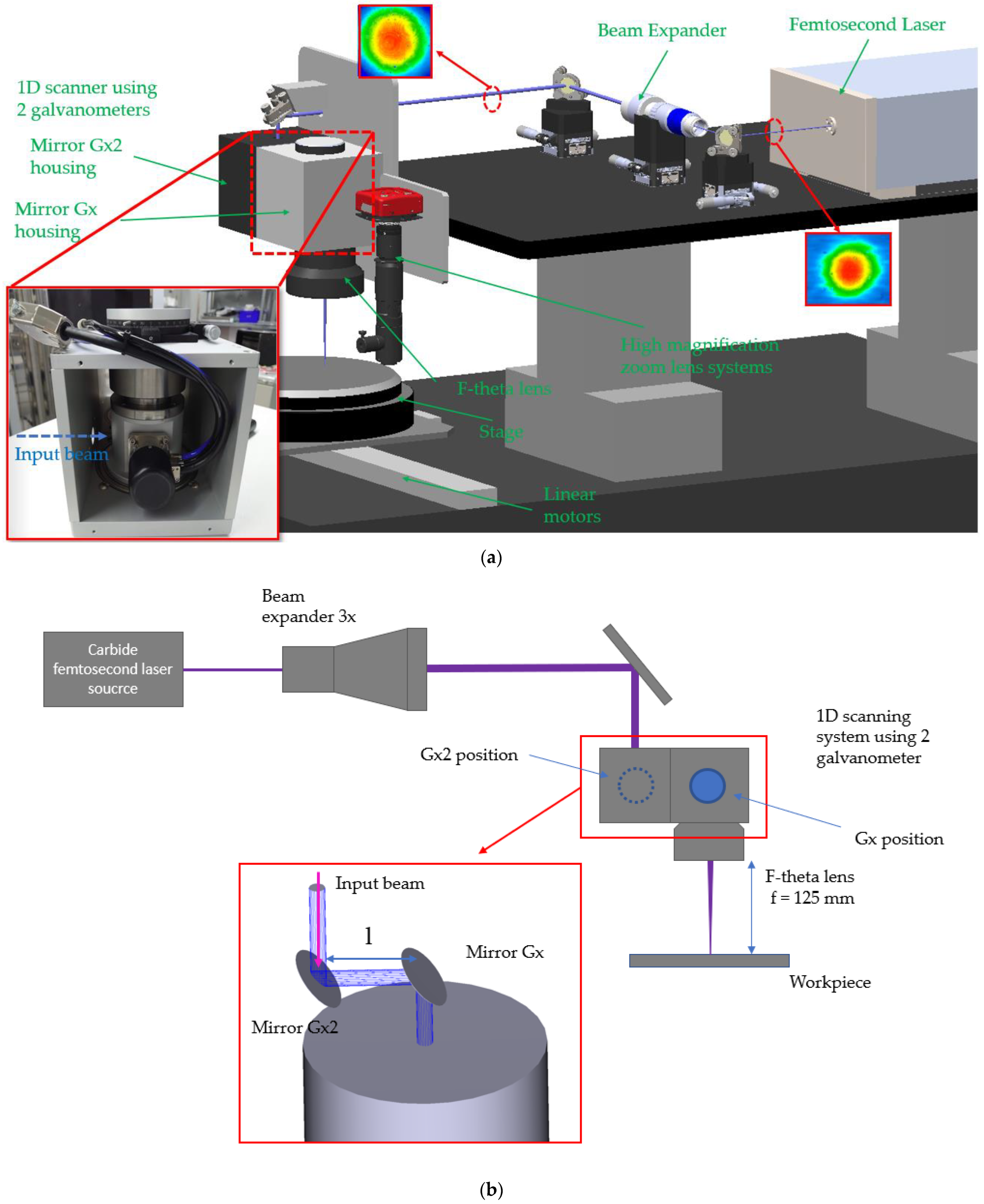

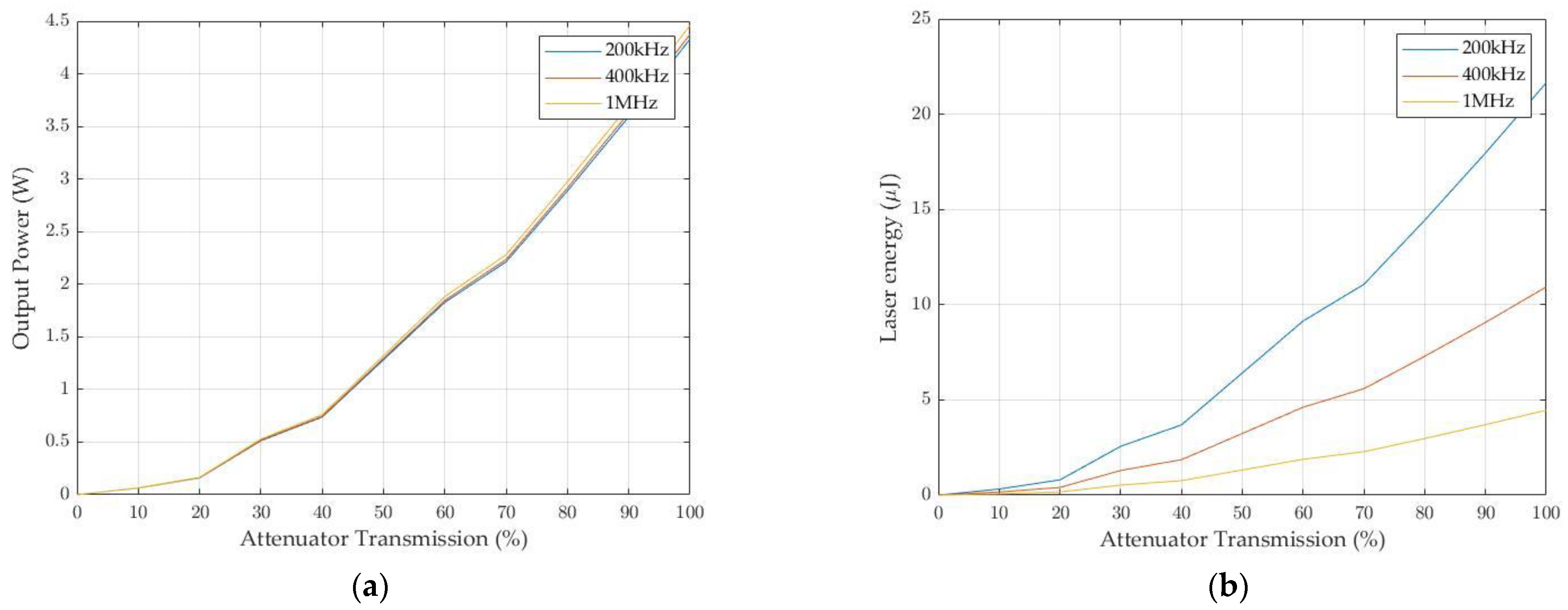

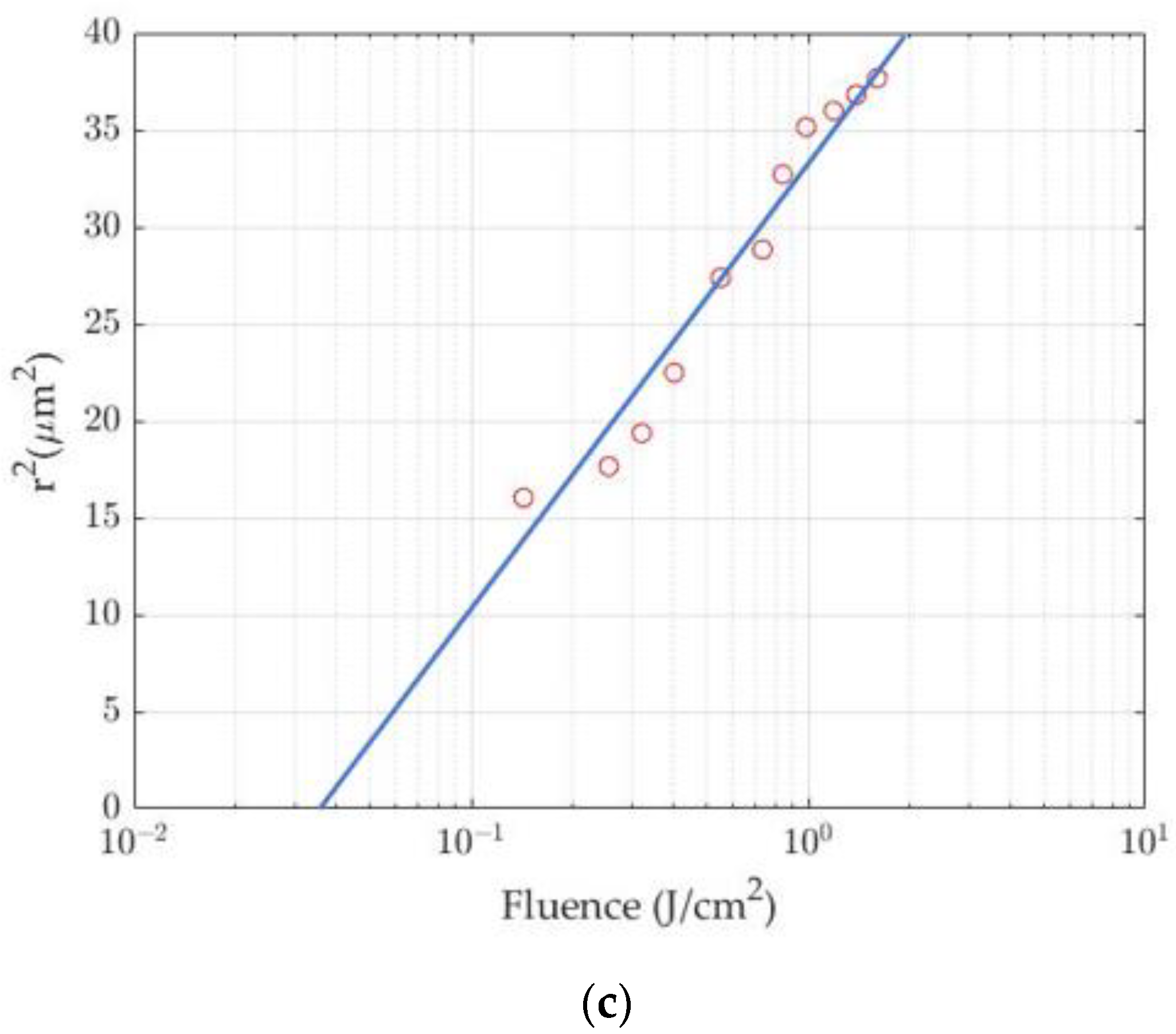

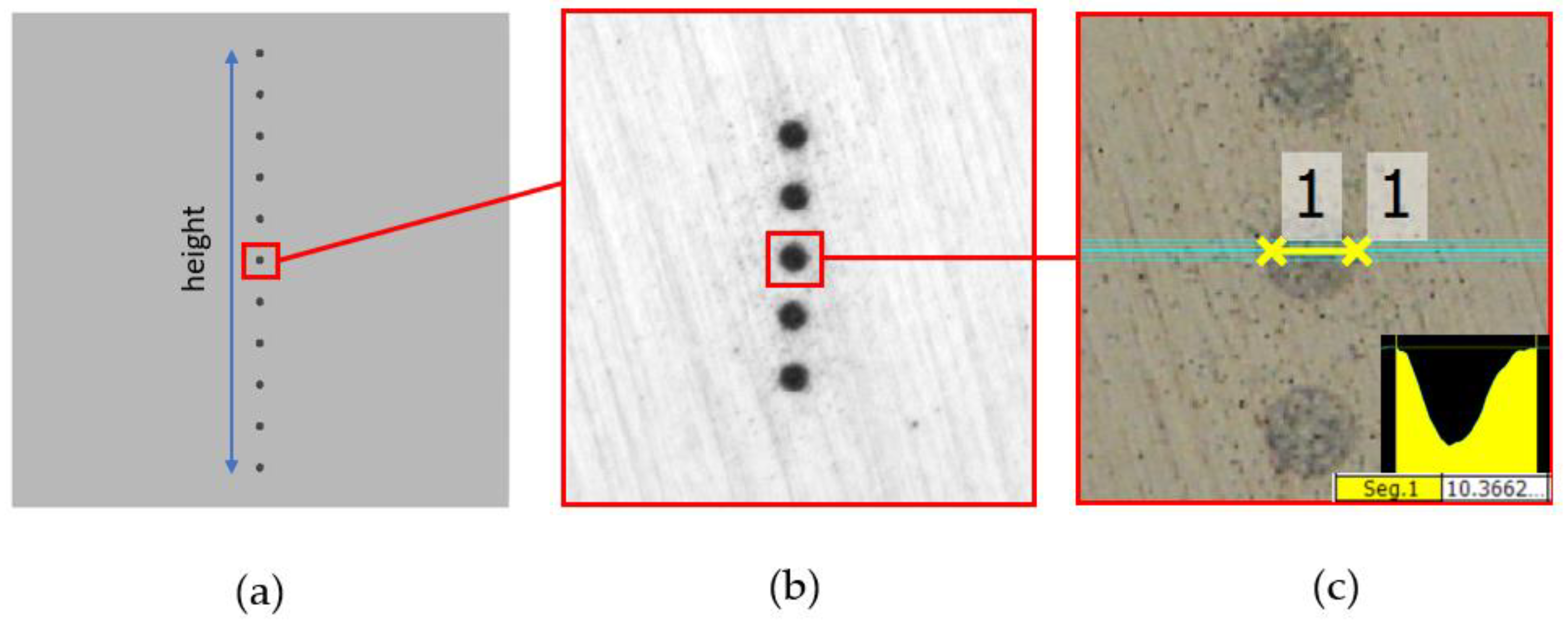

3.3. Optical Experimental Setup and Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lopez, J.; Mishchik, K.; Mincuzzi, G.; Audouard, E.; Mottay, E.; Kling, R. Efficient metal processing using high average power ultrafast laser. J. Laser Micro/Nanoeng. 2017, 12, 296–303. [Google Scholar]

- Loeschner, U.; Schille, J.; Streek, A.; Knebel, T.; Hartwig, L.; Hillmann, R.; Endisch, C. High-Rate Laser Microprocessing Using a Polygon Scanner System. J. Laser Appl. 2015, 27, S29303. [Google Scholar] [CrossRef]

- Römer, G.R.B.E.; Bechtold, P. Electro-Optic and Acousto-Optic Laser Beam Scanners. Phys. Proc. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Marshall, G.F.; Stutz, G.E. Handbook of Optical and Laser Scanning, 2nd ed.; CRC Press: New York, NY, USA, 2004; pp. 394–439. Available online: https://library.oapen.org/handle/20.500.12657/41669 (accessed on 10 September 2022).

- Montagu, J.; Hoffman, C.; Driggers, R. Scanners—Galvanometric and resonant. In Encyclopedia of Optical Engineering, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 2460–2489. [Google Scholar]

- Büsing, L. Optische Systeme Für Die Hochpräzise, Scanner Basierte Multistrahlbearbeitung Mit Ultrakurzen Laserpulsen. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2016. Available online: https://publications.rwth-aachen.de/record/572320 (accessed on 31 May 2022).

- Periyasamy, K.G.K.; Zuo, H.; He, S. Flexible Printed Circuit Board Magnetic Micromirror for Laser Marking/Engraving. J. Micromech. Microeng. 2019, 29, 085001. [Google Scholar] [CrossRef]

- Zheng, L.J.; Wang, C.Y.; Song, Y.X.; Yang, L.P.; Qu, Y.P.; Ma, P.; Fu, L.Y. A Review on Drilling Printed Circuit Boards. Adv. Mater. Res. 2011, 188, 441–449. [Google Scholar] [CrossRef]

- Franz, D.; Häfner, T.; Kunz, T.; Roth, G.-L.; Rung, S.; Esen, C.; Hellmann, R. Ultrashort Pulsed Laser Drilling of Printed Circuit Board Materials. Materials 2022, 15, 3932. [Google Scholar] [CrossRef]

- van Breemen, A.J.J.M.; Ollearo, R.; Shanmugam, S.; Peeters, B.; Peters, L.C.J.M.; van de Ketterij, R.L.; Katsouras, I.; Akkerman, H.B.; Frijters, C.H.; Giacomo, F.D.; et al. A Thin and Flexible Scanner for Fingerprints and Documents Based on Metal Halide Perovskites. Nat. Electron. 2021, 4, 818–826. [Google Scholar] [CrossRef]

- Takamatsu, T.; Fujita, S. Microscopic Tomography by Laser Scanning Microscopy and Its Three-dimensional Reconstruction. J. Microsc. 1988, 149, 167–174. [Google Scholar] [CrossRef]

- Webb, R.H. Confocal Optical Microscopy. Rep. Prog. Phys. 1996, 59, 427. [Google Scholar] [CrossRef]

- Mertz, J. Nonlinear Microscopy: New Techniques and Applications. Curr. Opin. Neurobiol. 2004, 14, 610–616. [Google Scholar] [CrossRef]

- Choi, W.; Fang-Yen, C.; Oh, S.; Lue, N.; Dasari, R.R.; Feld, M.S.; Badizadegan, K. Tomographic Phase Microscopy. Imaging Microsc. 2008, 10, 48–50. [Google Scholar] [CrossRef]

- Gafner, M.; Remund, S.M.; Chaja, M.W.; Neuenschwander, B. High-Rate Laser Processing with Ultrashort Laser Pulses by Combination of Diffractive Elements with Synchronized Galvo Scanning. Adv. Opt. Technol. 2021, 10, 333–352. [Google Scholar] [CrossRef]

- Finger, J.; Hesker, M. High Power Ultrashort Pulse Laser Processing Using a Flexible Multibeam Approach. J. Phys. Photonics 2021, 3, 021004. [Google Scholar] [CrossRef]

- Cui, M.; Lu, L.; Zhang, Z.; Guan, Y. A Laser Scanner–Stage Synchronized System Supporting the Large-Area Precision Polishing of Additive-Manufactured Metallic Surfaces. Engineering 2021, 7, 1732–1740. [Google Scholar] [CrossRef]

- Belosludtsev, A.; Buinovskis, D. Significant Increase of U.V. Reflectivity of SiC Galvanometer Mirror Scanners for the High-Power Laser Applications. Opt. Laser Technol. 2021, 140, 107027. [Google Scholar] [CrossRef]

- 2-Axis Galvo Scanner Hardware Manual, Aerotech; 2015–2021. Available online: https://www.aerotech.com/resources-manuals-help-files/ (accessed on 29 July 2022).

- Ozga, C. Unseen Possibilities of F-Theta Lenses. Opt. Photonik 2018, 13, 48–51. [Google Scholar] [CrossRef]

- Meng, X.; Cao, G.; Li, X.; Lv, Q. 2-D Scanning Galvanometer Error Analysis and Its Correction. J. Phys. Conf. Ser. 2019, 1345, 022068. [Google Scholar] [CrossRef]

- Qi, B.-L.; Wang, C.-H.; Guo, D.-B.; Zhang, B. A Scanning Distortion Correction Method Based on X–Y Galvanometer Lidar System. Chin. Phys. B 2021, 30, 044206. [Google Scholar] [CrossRef]

- Li, Y.; Cui, T.; Li, Q.; Zhang, B.; Bai, Y.; Wang, C. A Study of Correction Method to the Pincushion Distortion Based on Dual Galvanometer LiDAR Scanning System. Optik 2019, 181, 555–561. [Google Scholar] [CrossRef]

- Franz, D.; Häfner, T.; Kunz, T.; Roth, G.-L.; Rung, S.; Esen, C.; Hellmann, R. Characterization of a Hybrid Scanning System Comprising Acousto-Optical Deflectors and Galvanometer Scanners. Appl. Phys. B 2022, 128, 55. [Google Scholar] [CrossRef]

- Delgado, M.A.O.; Lasagni, A.F. Reducing Field Distortion for Galvanometer Scanning System Using a Vision System. Opt. Laser Eng. 2016, 86, 106–114. [Google Scholar] [CrossRef]

- Zhong, Y.; Tang, Z.; Gross, H. Correction of 2D-Telecentric Scan Systems with Freeform Surfaces. Opt. Express 2020, 28, 3041. [Google Scholar] [CrossRef] [PubMed]

- Pisanello, M.; Zheng, D.; Balena, A.; Pisano, F.; Vittorio, M.D.; Pisanello, F. An Open Source Three-Mirror Laser Scanning Holographic Two-Photon Lithography System. PLoS ONE 2022, 17, e0265678. [Google Scholar] [CrossRef] [PubMed]

- Sofroniew, N.J.; Flickinger, D.; King, J.; Svoboda, K. A Large Field of View Two-Photon Mesoscope with Subcellular Resolution for in Vivo Imaging. Elife 2016, 5, e14472. [Google Scholar] [CrossRef] [PubMed]

- Single Pivot Point Laser Scan Heads Product Manual, Aerotech; 2019–2021. Z.E.M.A.X. Development Corporation. Available online: https://www.aerotech.com/product/laser-scan-heads/agv-spo-high-performance-single-pivot-point-laser-scan-heads/ (accessed on 28 September 2022).

- ISO 11145:2018; Optics and Photonics—Lasers and Laser-Related Equipment—Vocabulary and Symbols. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/72944.html (accessed on 13 January 2022).

- Kim, K.-R.; Cho, J.-H.; Lee, N.-Y.; Kim, H.-J.; Cho, S.-H.; Park, H.-J.; Choi, B. High-Precision and Ultrafast UV Laser System for next-Generation Flexible P.C.B. Drilling. J. Manuf. Syst. 2016, 38, 107–113. [Google Scholar] [CrossRef]

- Zemax. Optical Design Program User’s Guide; Zemax: Kirkland, WA, USA, 2014. [Google Scholar]

- Hofmann, O.; Stollenwerk, J.; Loosen, P. Design of Multi-Beam Optics for High Throughput Parallel Processing. J Laser Appl 2020, 32, 012005. [Google Scholar] [CrossRef]

- Ehrmann, J.S. Optics for vector scanning. Proc. SPIE 1991, 1454, 245–256. [Google Scholar]

- Verboven, P.E. Distortion Correction Formulas for Pre-Objective Dual Galvanometer Laser Scanning. Appl. Opt. 1988, 27, 4172. [Google Scholar] [CrossRef]

- Fused Silica Optics F-Theta lens S4LFT4125/075, Datasheet, Sill Optics. 2022. Available online: https://www.silloptics.de/service/downloads (accessed on 29 July 2022).

- Fischer, R.E.; Galeb, B.T.; Yoder, P.R. Optical System Design, 2nd ed.; SPIE Press: New York, NY, USA, 2008; pp. 199–212. Available online: https://www.accessengineeringlibrary.com/content/book/9780071472487 (accessed on 31 May 2022).

- Carbide Femtosecond Laser, Datasheet, Light Conversion. 2022. Available online: https://lightcon.com/product/carbide-femtosecond-lasers/#downloads (accessed on 1 August 2022).

- Profile-Analyzing Laser Microscope VKX-200, Manual, Keyence. 2022. Available online: https://www.keyence.com.tw/products/microscope/laser-microscope/vk-x100_x200/index_pr.jsp (accessed on 1 August 2022).

- Poder, K.; Cole, J.M.; Wood, J.C.; Lopes, N.C.; Alatabi, S.; Foster, P.S.; Kamperidis, C.; Kononenko, O.; Palmer, C.A.; Rusby, D.; et al. Measurements of Self-Guiding of Ultrashort Laser Pulses over Long Distances. Plasma Phys. Control. Fusion 2017, 60, 014022. [Google Scholar] [CrossRef]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

| Surface | Type | Radius (mm) | Thickness (mm) | Glass | Semi-Diameter (mm) |

|---|---|---|---|---|---|

| Object | Standard | Infinity | 0 | 0 | |

| 1 | Standard | Infinity | 20 | 0 | |

| Stop | Standard | Infinity | 20 | 1.0 | |

| 3 | Coordinate break | 0 | 0 | ||

| 4 | Coordinate break | 0 | 0 | ||

| 5 | Standard | Infinity | 0 | Mirror | 7.087 |

| 6 | Coordinate break | 0 | 0 | ||

| 7 | Coordinate break | 0 | 0 | ||

| 8 | Standard | Infinity | −40 | 5.00994 | |

| 9 | Coordinate break | 0 | 0 | ||

| 10 | Coordinate break | 0 | 0 | ||

| 11 | Standard | Infinity | 0 | Mirror | 7.105 |

| 12 | Coordinate break | 0 | 0 | ||

| 13 | Coordinate break | 0 | 0 | ||

| 14 | Standard | Infinity | 28.8 | 5.306 | |

| 15 | Standard | −568.068 | 8.0 | C79-80 | 16.8 |

| 16 | Standard | −44.924 | 2.342 | 17.8 | |

| 17 | Standard | −41.135 | 7.0 | Silica | 18 |

| 18 | Standard | 129.864 | 9.991 | 21 | |

| 19 | Standard | −32.099 | 9.0 | C79-80 | 21.2 |

| 20 | Standard | −84.939 | 3.375 | 27.5 | |

| 21 | Standard | −55.865 | 9.0 | Silica | 28 |

| 22 | Standard | −43.469 | 0.543 | 31 | |

| 23 | Standard | −981.242 | 15.0 | C79-80 | 37 |

| 24 | Standard | −75.330 | 0.502 | 39 | |

| 25 | Standard | 265.039 | 13.0 | Silica | 46.5 |

| 26 | Standard | −153.780 | 18.545 | 46.5 | |

| 27 | Standard | 208.267 | 12.0 | C79-80 | 46.5 |

| 28 | Standard | 714.772 | 156.905 | 46.5 | |

| Image | Standard | Infinity | - |

| Experimental Setup | Aerotech, 2019–2021 | Pisanello, 2022 | Franz, 2022 | Group of Authors |

|---|---|---|---|---|

| Methods | 2D scanner using three galvanometers | 2D scanner using three galvanometers | AOD + 2D scanner | 1D scanner using two galvanometers |

| F-theta lens scan area [mm2] | 170 × 170 | 10 × 10 | 35 × 35 | 53 × 53 |

| Telecentricity error [°] | 12.7 | 11.5 | 1.5 | 1.1 |

| Wavelength [nm] | 355 | 450–1100 | 532 | 355 |

| Extended working length | 63 mm | 200 µm | unspecified | 3.6 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, X.-H.; Chen, C.-M.; Le, H.-T.; Lee, H.-Y. Enhancement of a Single-Axis Femtosecond Laser Scanning System by Using Two Galvanometers to Improve the Telecentricity and the Effective Scanning Length on Laser Process. Appl. Sci. 2022, 12, 12434. https://doi.org/10.3390/app122312434

Nguyen X-H, Chen C-M, Le H-T, Lee H-Y. Enhancement of a Single-Axis Femtosecond Laser Scanning System by Using Two Galvanometers to Improve the Telecentricity and the Effective Scanning Length on Laser Process. Applied Sciences. 2022; 12(23):12434. https://doi.org/10.3390/app122312434

Chicago/Turabian StyleNguyen, Xuan-Huy, Chao-Ming Chen, Hien-Thanh Le, and Hsiao-Yi Lee. 2022. "Enhancement of a Single-Axis Femtosecond Laser Scanning System by Using Two Galvanometers to Improve the Telecentricity and the Effective Scanning Length on Laser Process" Applied Sciences 12, no. 23: 12434. https://doi.org/10.3390/app122312434

APA StyleNguyen, X.-H., Chen, C.-M., Le, H.-T., & Lee, H.-Y. (2022). Enhancement of a Single-Axis Femtosecond Laser Scanning System by Using Two Galvanometers to Improve the Telecentricity and the Effective Scanning Length on Laser Process. Applied Sciences, 12(23), 12434. https://doi.org/10.3390/app122312434