Investigation on Deformation Behavior of the Crossing Section of Two Municipal Road Tunnels during Construction

Abstract

1. Introduction

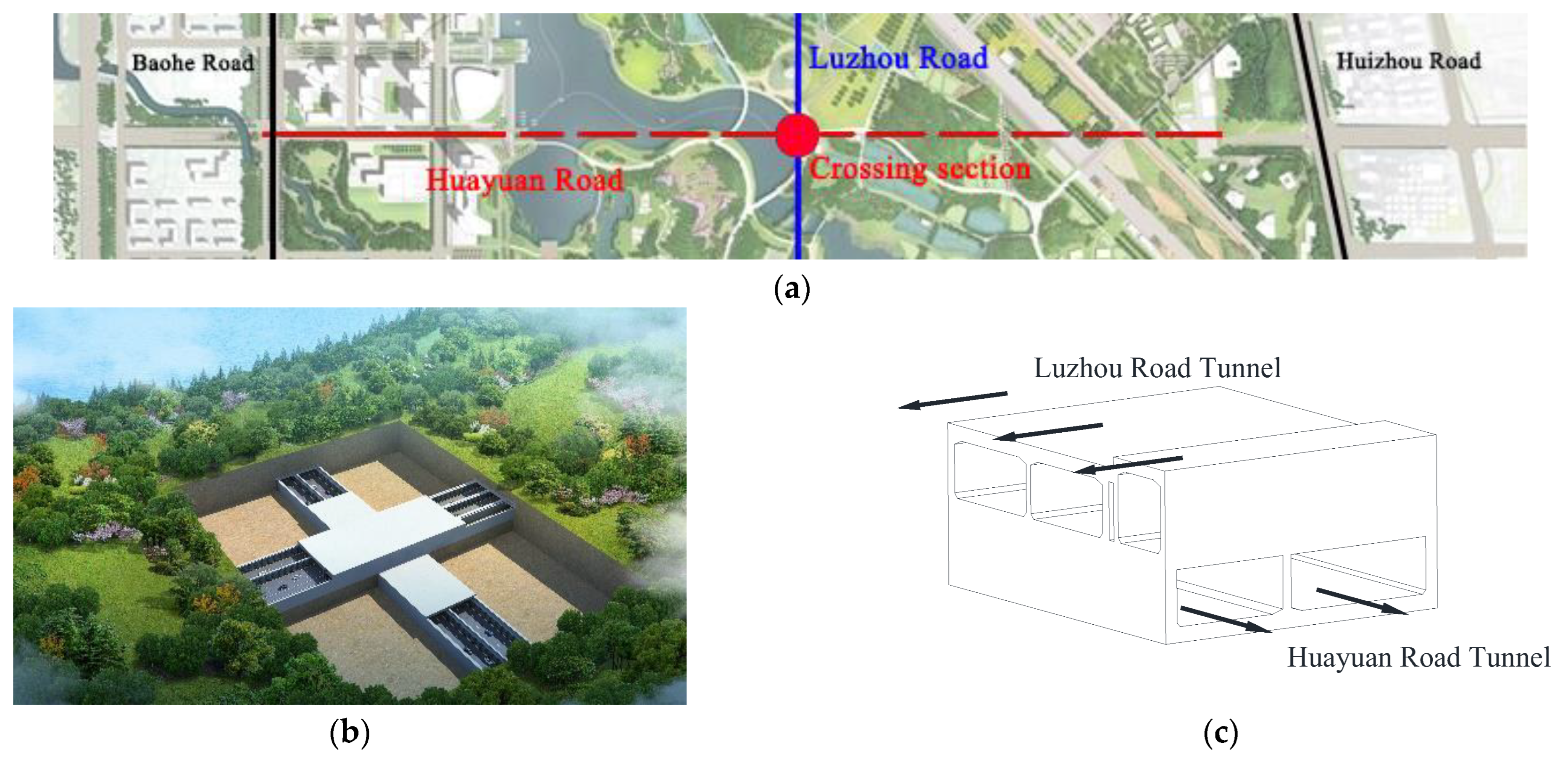

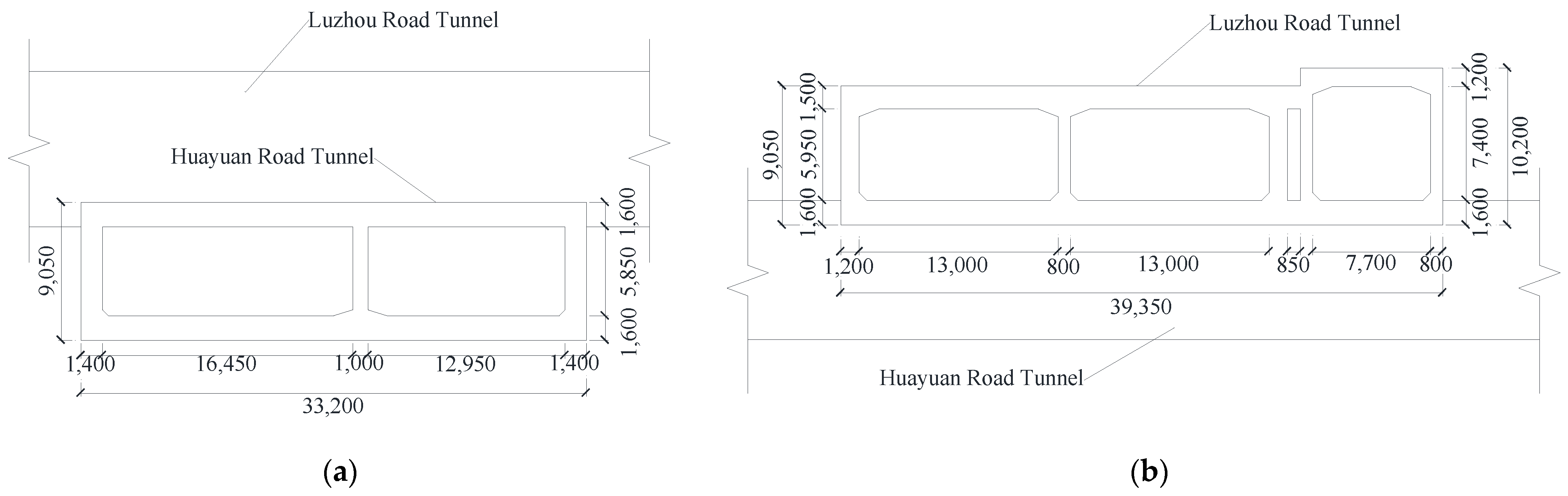

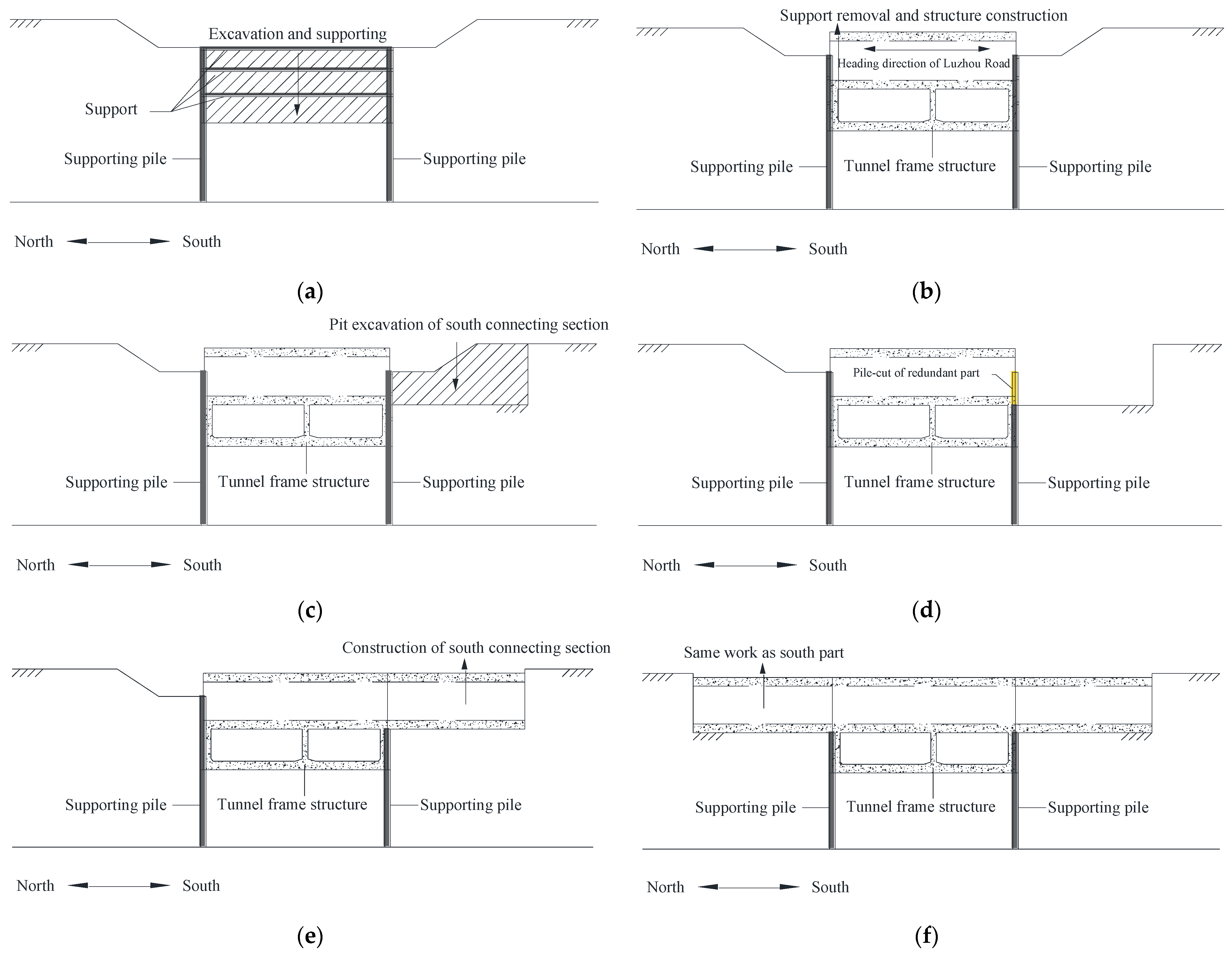

2. Background

3. Numerical Model and Analysis Method

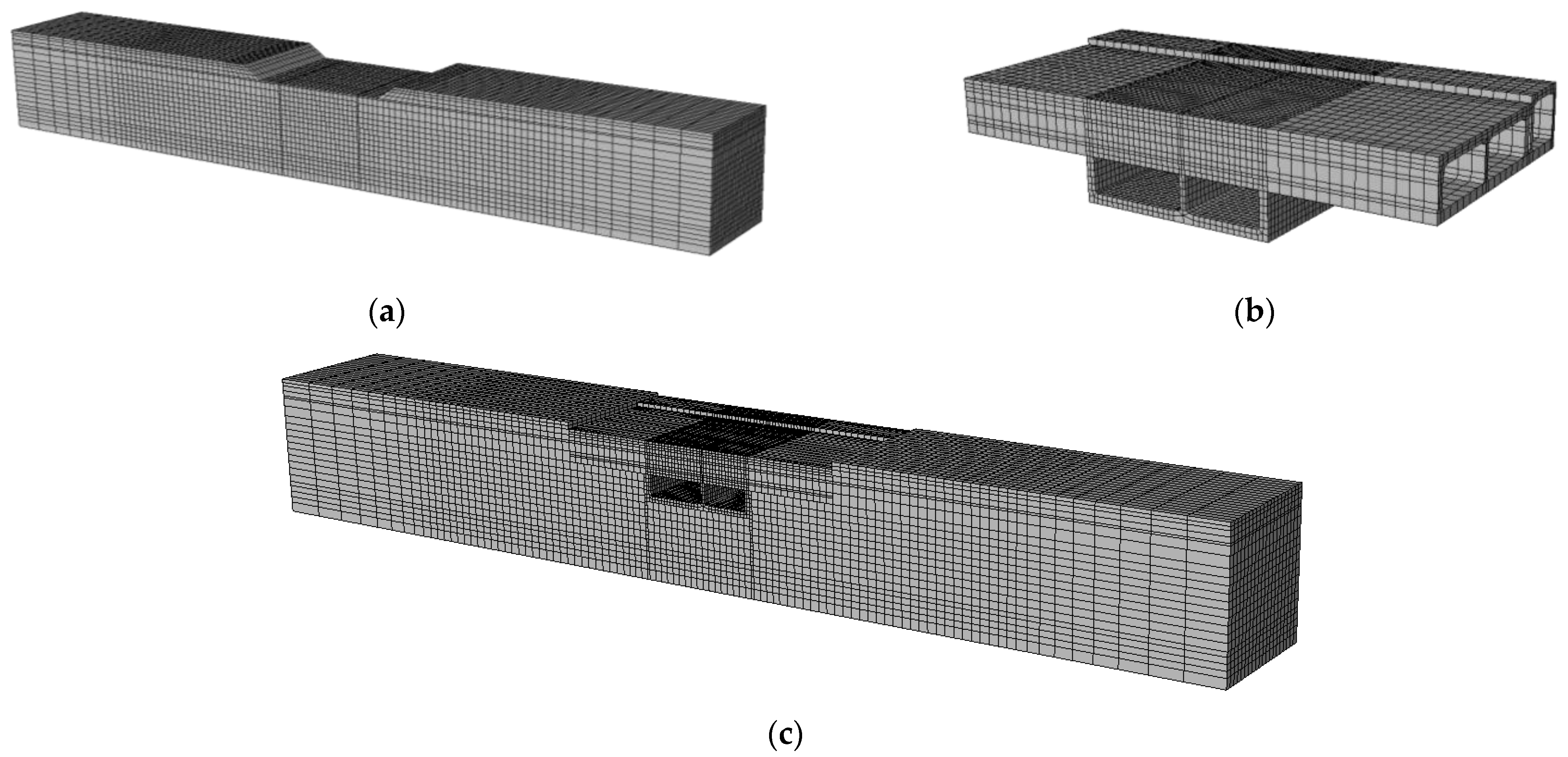

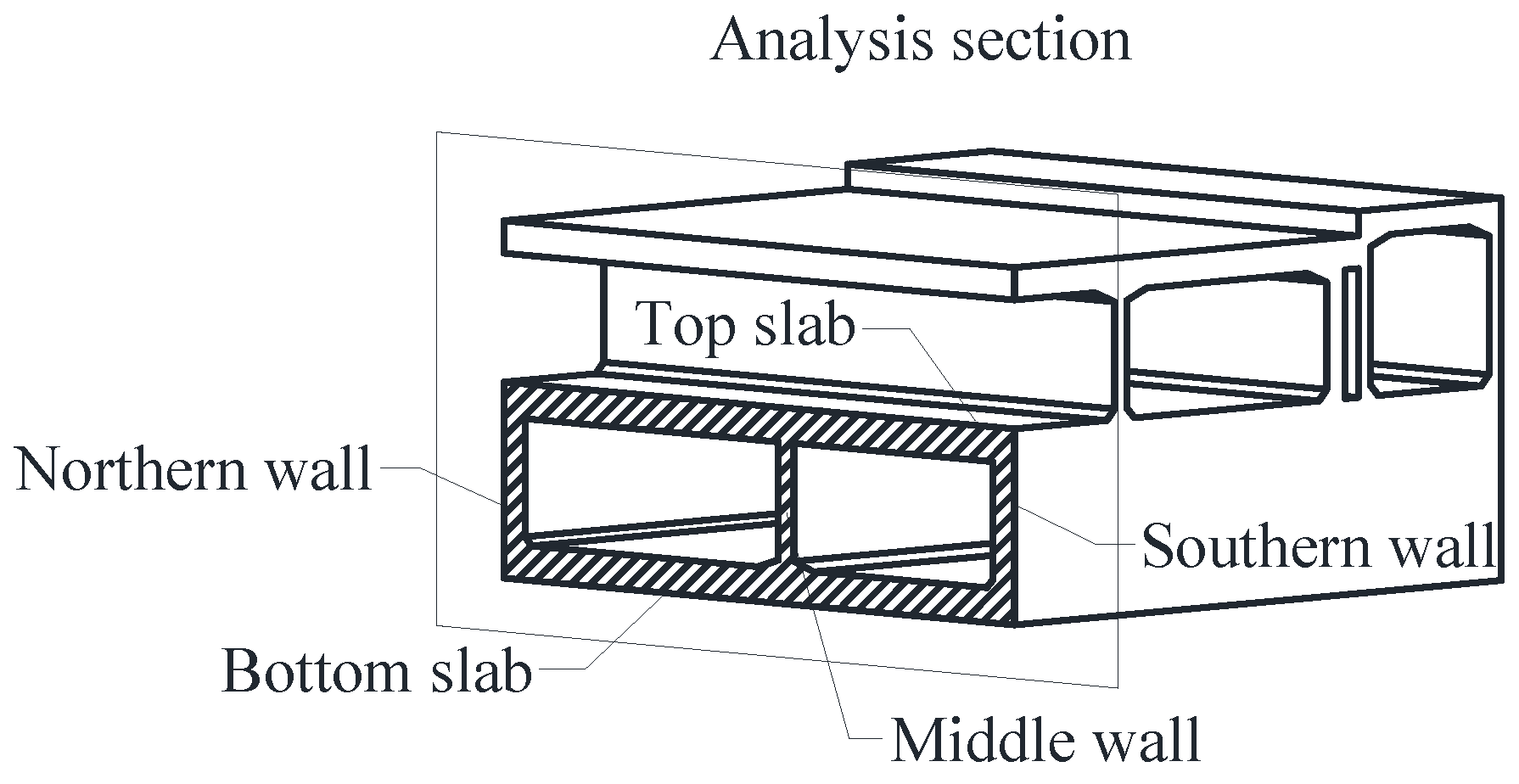

3.1. Numerical Model

3.2. Constitutive Model and Parameters

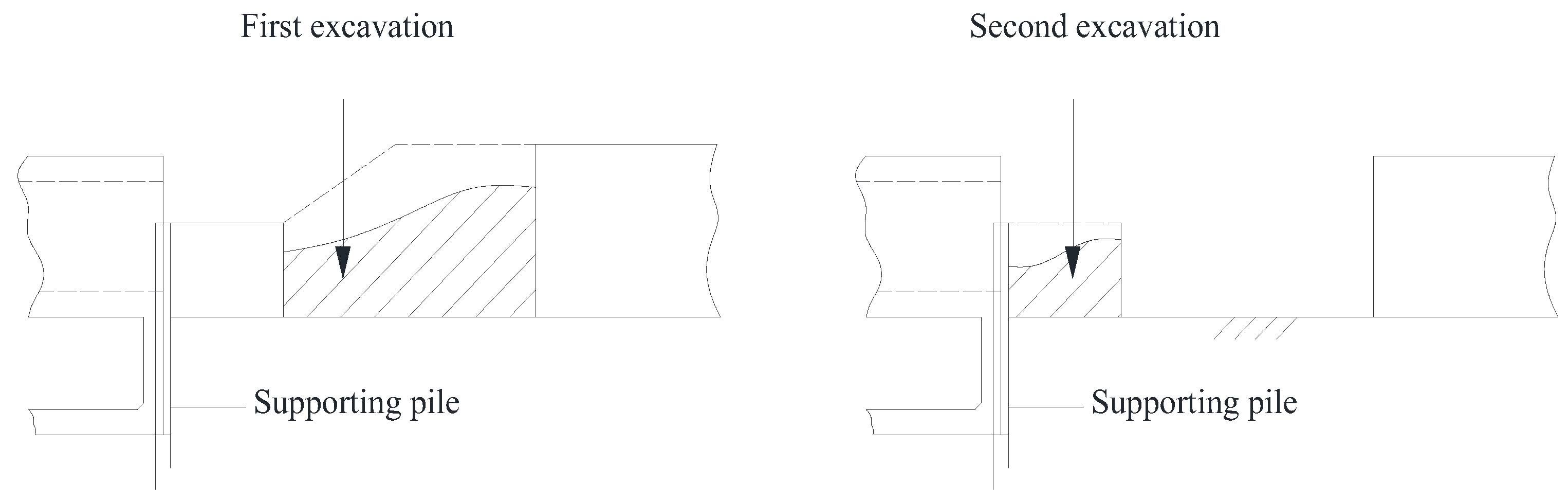

3.3. Construction Procedure in Numerical Analysis

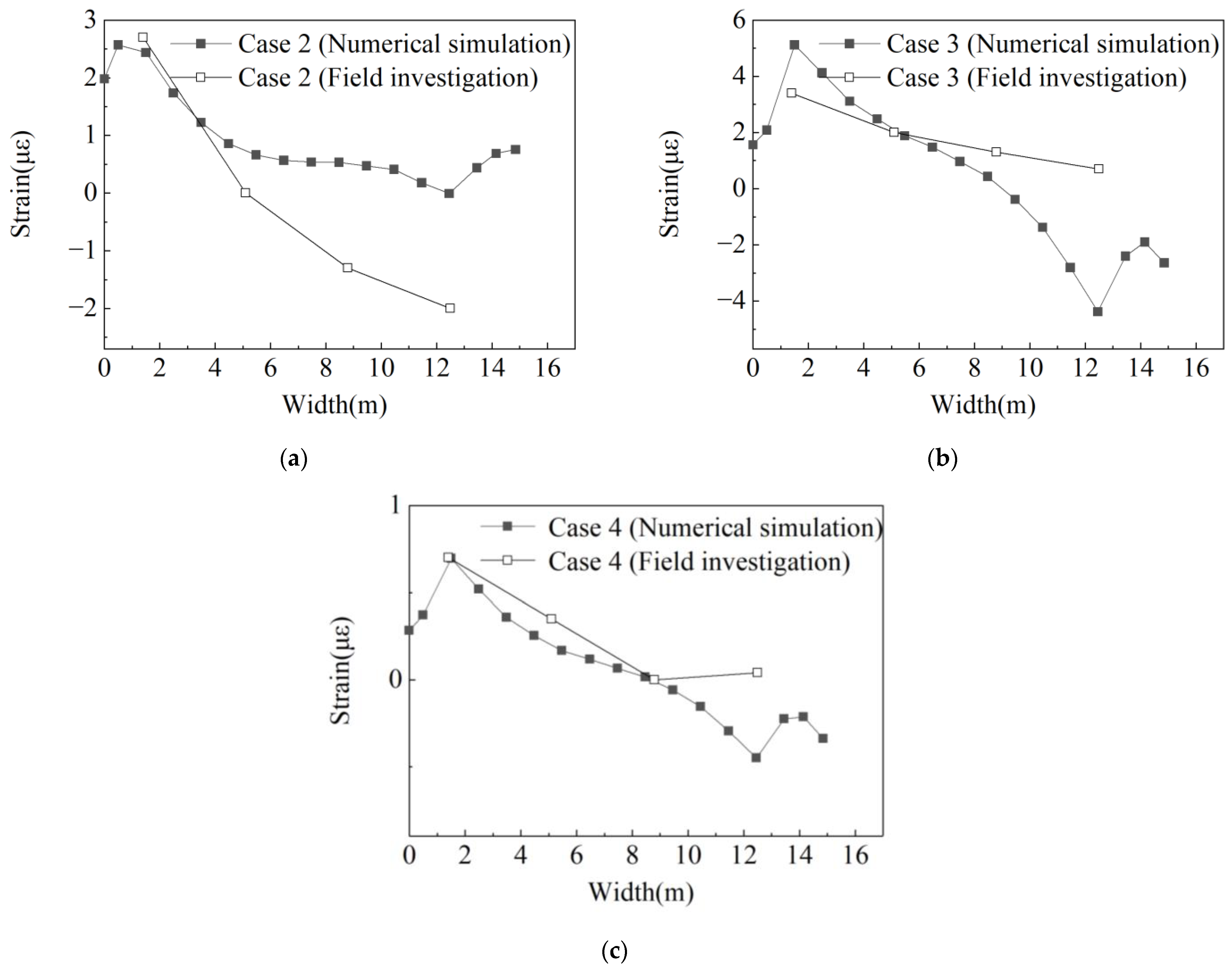

3.4. Valuation of Numerical Model

4. Results and Analysis

4.1. Results of Asymmetrical Construction

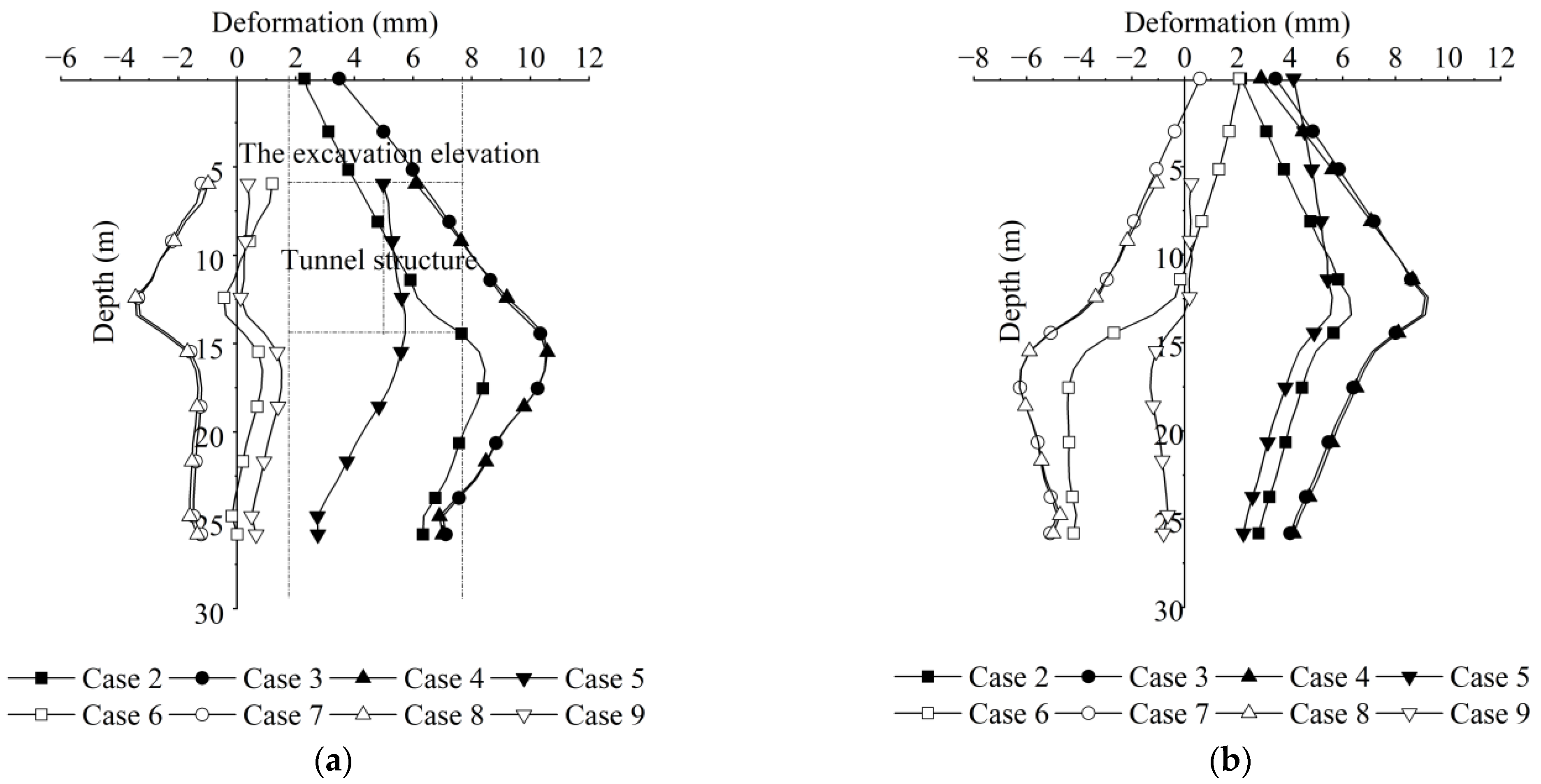

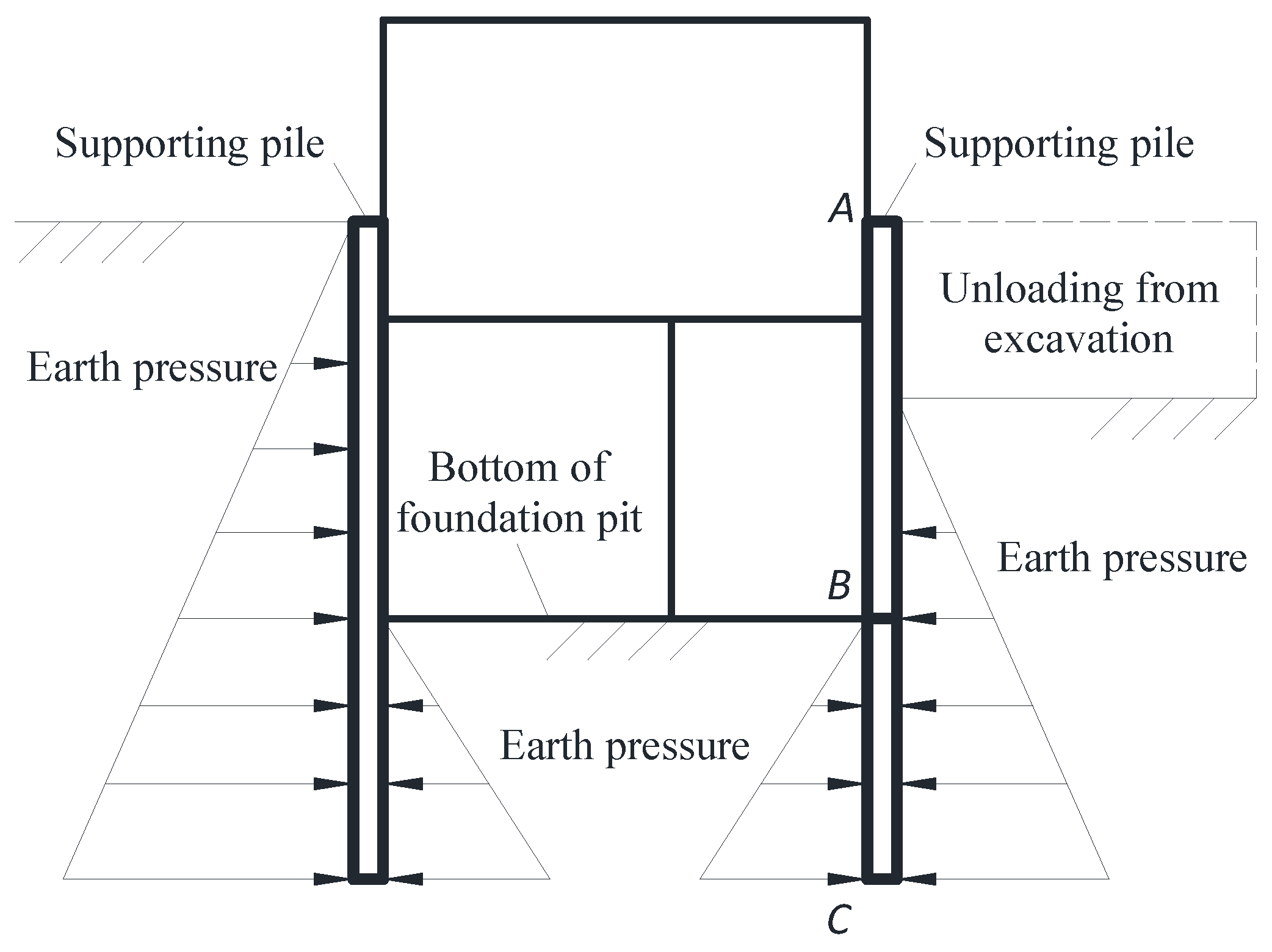

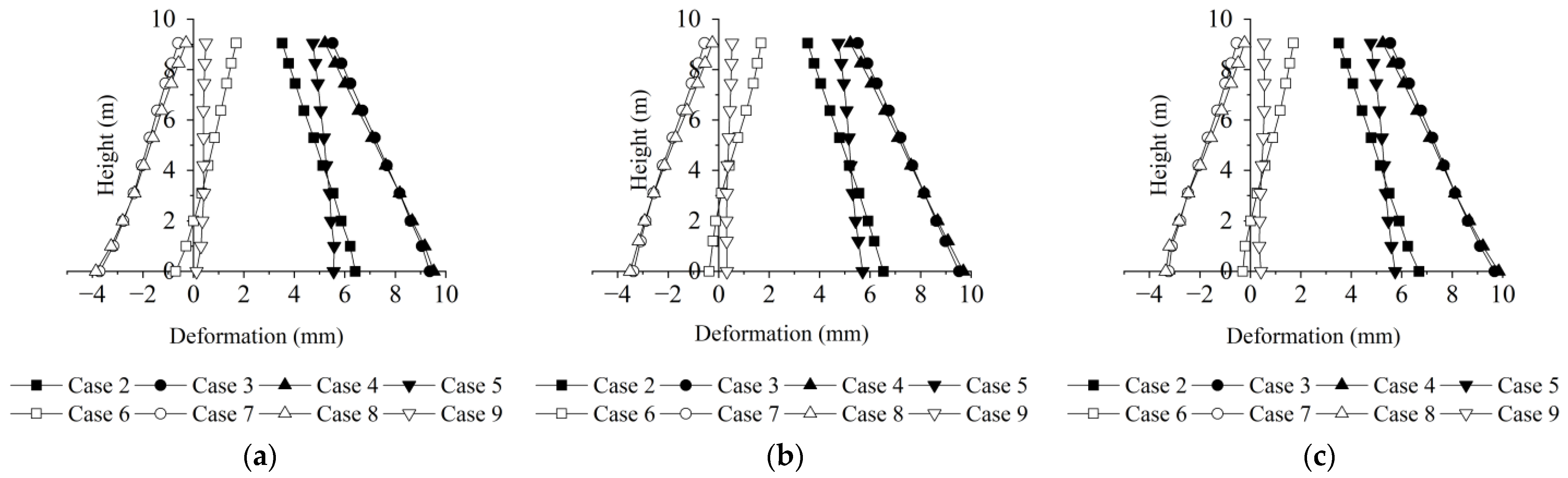

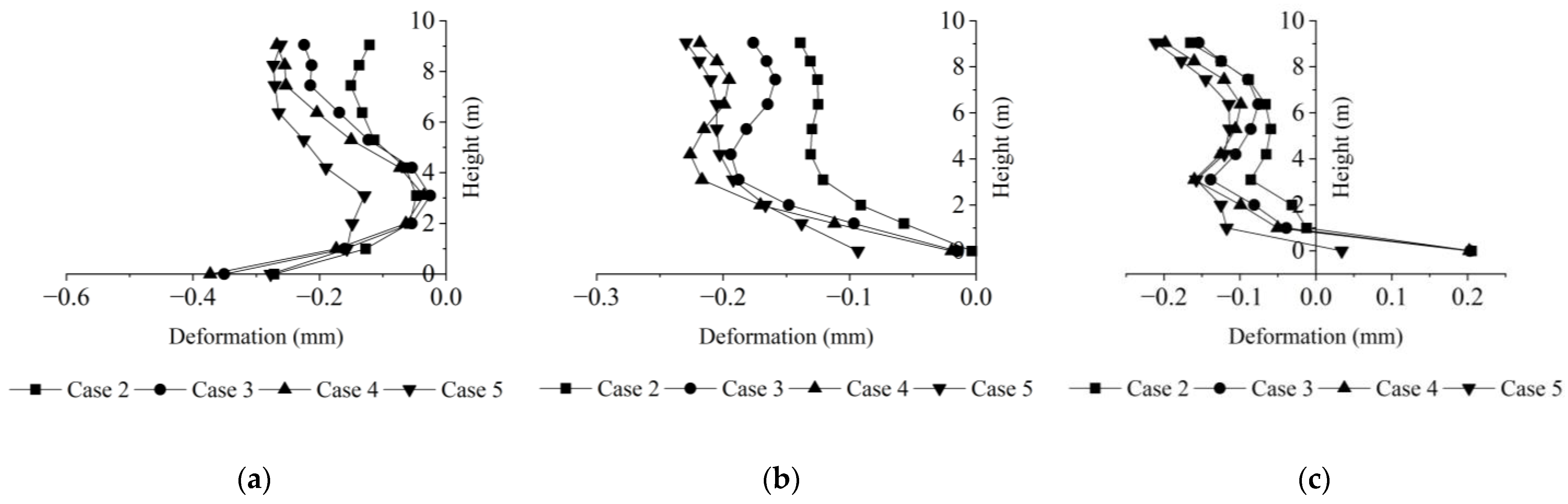

4.1.1. Lateral Displacement of Supporting Pile

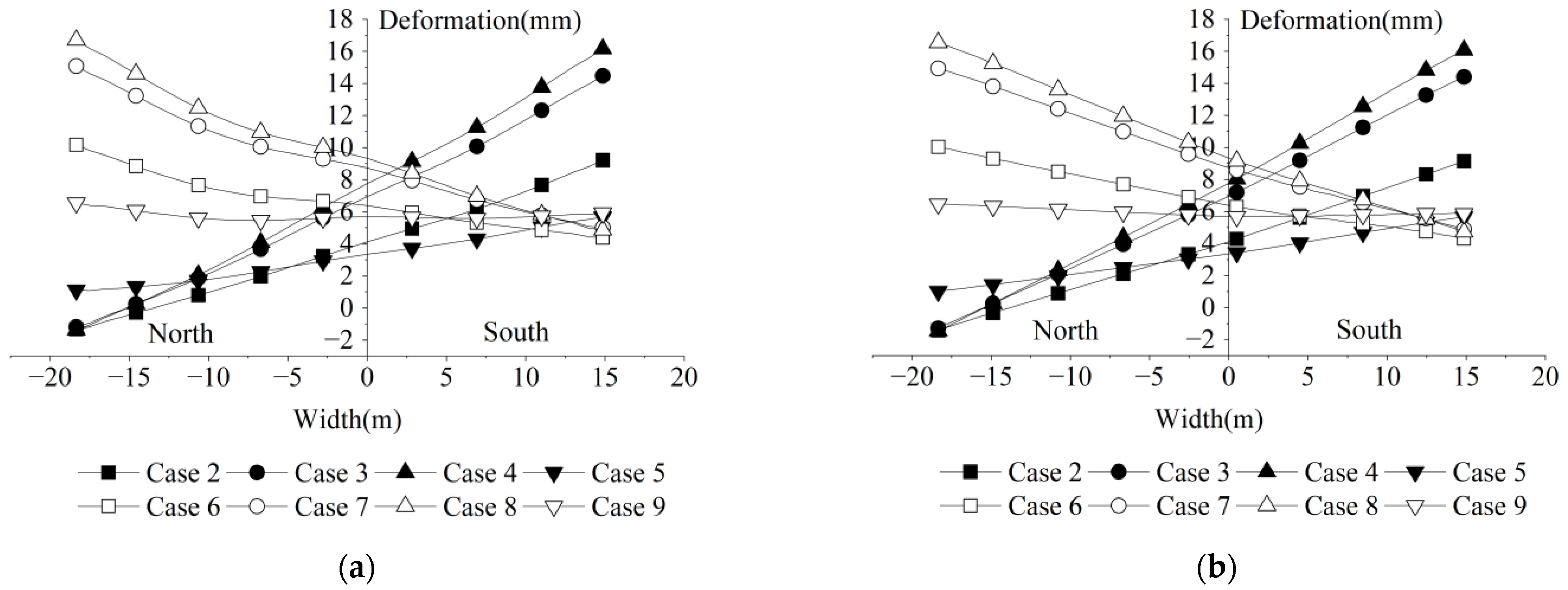

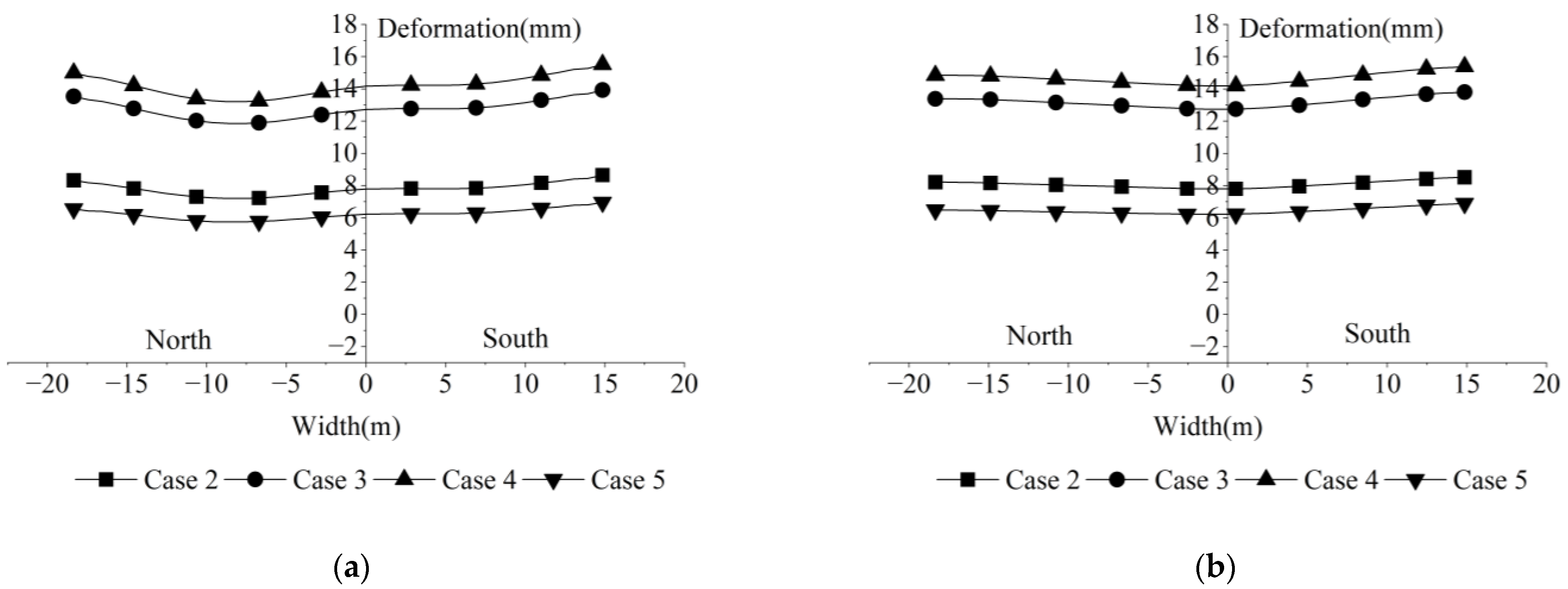

4.1.2. Deformation of Tunnel Frame Structure

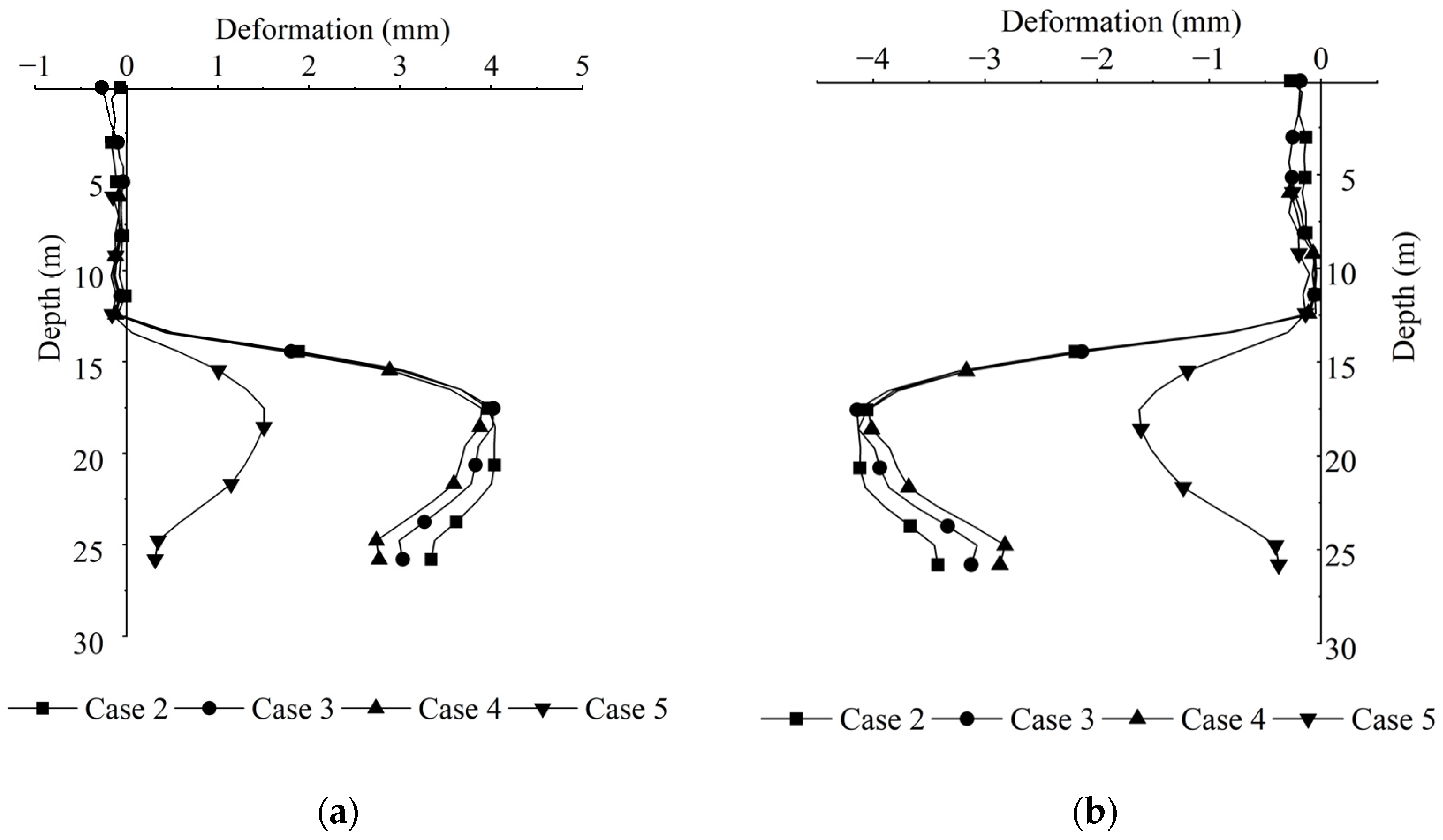

4.2. Results of Asymmetrical Construction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klar, A.; Vorster, T.E.B.; Soga, K.; Mair, R.J. Soil—Pipe Interaction Due to Tunnelling: Comparison between Winkler and Elastic Continuum Solutions. Géotechnique 2005, 55, 461–466. [Google Scholar] [CrossRef]

- Vorster, T.E.; Klar, A.; Soga, K.; Mair, R.J. Estimating the Effects of Tunneling on Existing Pipelines. J. Geotech. Geoenvironmental Eng. 2005, 131, 1399–1410. [Google Scholar] [CrossRef]

- Zhang, J.-F.; Chen, J.-J.; Wang, J.-H.; Zhu, Y.-F. Prediction of Tunnel Displacement Induced by Adjacent Excavation in Soft Soil. Tunn. Undergr. Space Technol. 2013, 36, 24–33. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M.; Wang, W. Evaluation of Deformation Response for Adjacent Tunnels Due to Soil Unloading in Excavation Engineering. Tunn. Undergr. Space Technol. 2013, 38, 244–253. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, M.; Zhao, Q. A Simplified Analysis for Deformation Behavior of Buried Pipelines Considering Disturbance Effects of Underground Excavation in Soft Clays. Arab. J. Geosci. 2015, 8, 7771–7785. [Google Scholar] [CrossRef]

- Liang, R.; Xia, T.; Huang, M.; Lin, C. Simplified Analytical Method for Evaluating the Effects of Adjacent Excavation on Shield Tunnel Considering the Shearing Effect. Comput. Geotech. 2017, 81, 167–187. [Google Scholar] [CrossRef]

- Liang, R.; Wu, W.; Yu, F.; Jiang, G.; Liu, J. Simplified Method for Evaluating Shield Tunnel Deformation Due to Adjacent Excavation. Tunn. Undergr. Space Technol. 2018, 71, 94–105. [Google Scholar] [CrossRef]

- Han, J.; Zhao, W.; Jia, P.; Guan, Y.; Chen, Y.; Jiang, B. Risk Analysis of the Opening of Shield-Tunnel Circumferential Joints Induced by Adjacent Deep Excavation. J. Perform. Constr. Facil. 2018, 32, 04017123. [Google Scholar] [CrossRef]

- Sun, H.; Chen, Y.; Zhang, J.; Kuang, T. Analytical Investigation of Tunnel Deformation Caused by Circular Foundation Pit Excavation. Comput. Geotech. 2019, 106, 193–198. [Google Scholar] [CrossRef]

- Xu, R.; Shen, S.; Dong, M.; Cheng, K. A Simplified Calculation Method for Vertical Displacement of Shield Tunnel Caused by Adjacent Excavation. Geotech. Geol. Eng. 2021, 39, 2269–2286. [Google Scholar] [CrossRef]

- Lin, Y.L.; Cheng, X.M.; Yang, G.L.; Li, Y. Seismic response of a sheet-pile wall with anchoring frame beam by numerical simulation and shaking table test. Soil Dyn. Earthq. Eng. 2018, 115, 352–364. [Google Scholar] [CrossRef]

- Lin, Y.L.; Cheng, X.M.; Yang, G.L. Shaking table test and numerical simulation on a combined retaining structure response to earthquake loading. Soil Dyn. Earthq. Eng. 2018, 108, 29–45. [Google Scholar] [CrossRef]

- Lin, Y.L.; Yang, G.L.; Yang, X.; Zhao, L.H.; Shen, Q.; Qiu, M.M. Response of gravity retaining wall with anchoring frame beam supporting a steep rock slope subjected to earthquake loading. Soil Dyn. Earthq. Eng. 2017, 92, 633–649. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Shi, M.J.; Mašín, M.D.; Sun, M.H.; Lei, G.H. Influence of Sand Density and Retaining Wall Stiffness on the Three-Dimensional Responses of a Tunnel to Basement Excavation. Can. Geotech. J. 2015, 52, 1811–1829. [Google Scholar] [CrossRef]

- Huang, X.; Huang, H.; Zhang, D. Centrifuge Modelling of Deep Excavation over Existing Tunnels. Proc. Inst. Civ. Eng. Geotech. Eng. 2014, 167, 3–18. [Google Scholar] [CrossRef]

- Liu, G.B.; Huang, P.; Shi, J.W.; Ng, C.W.W. Performance of a Deep Excavation and Its Effect on Adjacent Tunnels in Shanghai Soft Clay. J. Perform. Constr. Facil. 2016, 30, 04016041. [Google Scholar] [CrossRef]

- Chang, C.-T.; Sun, C.-W.; Duann, S.W.; Hwang, R.N. Response of a Taipei Rapid Transit System ŽTRTS/Tunnel to Adjacent Excavation; Elsevier: Oxfprd, UK, 2001; Volume 16, pp. 151–158. [Google Scholar]

- Sharma, J.S.; Hefny, A.M.; Zhao, J.; Chan, C.W. Effect of Large Excavation on Deformation of Adjacent MRT Tunnels. Tunn. Undergr. Space Technol. 2001, 16, 93–98. [Google Scholar] [CrossRef]

- Chen, R.; Meng, F.; Li, Z.; Ye, Y.; Ye, J. Investigation of Response of Metro Tunnels Due to Adjacent Large Excavation and Protective Measures in Soft Soils. Tunn. Undergr. Space Technol. 2016, 58, 224–235. [Google Scholar] [CrossRef]

- Meng, F.; Chen, R.; Xu, Y.; Wu, H.; Li, Z. Centrifuge Modeling of Effectiveness of Protective Measures on Existing Tunnel Subjected to Nearby Excavation. Tunn. Undergr. Space Technol. 2021, 112, 103880. [Google Scholar] [CrossRef]

- Chen, S.; Cui, J.; Liang, F. Centrifuge Model Investigation of Interaction between Successively Constructed Foundation Pits. Appl. Sci. 2022, 12, 7975. [Google Scholar] [CrossRef]

- Lin, Y.L.; Li, Y.X.; Zhao, L.H.; Yang, T.Y. Investigation on the seismic response of a three-stage soil slope supported by the anchor frame structure. J. Cent. South Univ. 2020, 27, 1290–1305. [Google Scholar] [CrossRef]

- Lin, Y.L.; Lu, L.; Yang, G.L. Seismic behavior of a single-form lattice anchoring structure and a combined retaining structure supporting soil slope: A comparison. Environ. Earth Sci. 2020, 79, 78. [Google Scholar] [CrossRef]

- Lin, Y.L.; Zhao, L.H.; Yang, T.Y.; Yang, G.L.; Chen, X.B. Investigation on seismic behavior of combined retaining structure with different rock shapes. Struct. Eng. Mech. 2020, 73, 599–612. [Google Scholar]

- Zhang, J.; Xie, R. Effect of Foundation Pit With Different Support and Excavation Methods on Adjacent Buried Hydrogen Pipe. J. Press. Vessel Technol. 2021, 143, 054502. [Google Scholar] [CrossRef]

- Zhou, F.; Zhou, P.; Li, J.; Lin, J.; Ge, T.; Deng, S.; Ren, R.; Wang, Z. Deformation Characteristics and Failure Evolution Process of the Existing Metro Station under Unilateral Deep Excavation. Eng. Fail. Anal. 2022, 131, 105870. [Google Scholar] [CrossRef]

- Wang, C.; Sun, H.; Zhang, J.; Lu, Y. Influence of Foundation Pit Excavation on Tunnels at Different Locations. Shock. Vib. 2022, 2022, 4282253. [Google Scholar] [CrossRef]

- Yang, Q.-R.; Li, M.-G.; Chen, J.-J. Influence of a Flexible Retaining Wall on Performance of an Adjacent Deep Excavation. KSCE J. Civ. Eng. 2022, 26, 661–672. [Google Scholar] [CrossRef]

- Liu, B.; Lin, H.; Chen, Y.; Liu, J.; Guo, C. Deformation Stability Response of Adjacent Subway Tunnels Considering Excavation and Support of Foundation Pit. Lithosphere 2022, 2022, 7227330. [Google Scholar] [CrossRef]

- Chen, T.; Zhou, K.; Wei, J.; Liu, X.C.; Lin, Y.L.; Zhang, J.; Shen, Q. Analysis on the excavation influence of triangular-distribution tunnels for the wind pavilion group of a metro station. J. Cent. South Univ. 2020, 27, 3852–3874. [Google Scholar] [CrossRef]

- Liao, S.-M.; Wei, S.-F.; Shen, S.-L. Structural Responses of Existing Metro Stations to Adjacent Deep Excavations in Suzhou, China. J. Perform. Constr. Facil. 2016, 30, 04015089. [Google Scholar] [CrossRef]

- Li, M.-G.; Wang, J.-H.; Chen, J.-J.; Zhang, Z.-J. Responses of a Newly Built Metro Line Connected to Deep Excavations in Soft Clay. J. Perform. Constr. Facil. 2017, 31, 04017096. [Google Scholar] [CrossRef]

| Layer ID | Soil Layer | Unit Weight/γ (kN·m−3) | Elastic Modulus/E (MPa) | Poisson Ratio/ν | Internal Friction Angle/ϕ (°) | Cohesive (kPa) |

|---|---|---|---|---|---|---|

| ① | Miscellaneous fill | 18.5 | 21 | 0.3 | 10.0 | 5.0 |

| ② | Clay | 19.2 | 33 | 0.3 | 15.0 | 81.2 |

| ③ | Clay | 19.2 | 42 | 0.28 | 15.6 | 88.9 |

| ④ | Silty clay | 19.1 | 36 | 0.27 | 18.0 | 26.7 |

| ⑤ | Clay | 19.3 | 48 | 0.28 | 15.8 | 97.0 |

| ⑥ | Silty clay with silt | 20.0 | 36 | 0.3 | 25.0 | 20.0 |

| ⑦ | Argillaceous sandstone strongly weathered | 20.5 | 48 | 0.3 | 30.0 | 28.0 |

| Unit Weight/γ (kN·m−3) | Elastic Modulus/E (MPa) | Poisson Ratio/ν |

|---|---|---|

| 26.0 | 3.15 × 104 | 0.2 |

| Asymmetrical Construction | Symmetrical Construction | ||

|---|---|---|---|

| Cases | Procedure | Cases | Procedure |

| 1 | Construction of crossing point | 1 | Construction of crossing point |

| 2 | First soil excavation behind southern piles | 2 | First soil excavation behind pile on both sides |

| 3 | Second soil excavation behind southern piles | 3 | Second soil excavation behind pile on both sides |

| 4 | Southern pile cut | 4 | Pile cut |

| 5 | Construction of southern connecting section | 5 | Construction of northern connecting section |

| 6 | First soil excavation behind northern piles | ||

| 7 | Second soil excavation behind northern piles | ||

| 8 | Northern pile cut | ||

| 9 | Construction of northern connecting section | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.-Y.; Yue, R.-H.; Lin, Y.-L.; Huang, C.-J.; Jiang, X. Investigation on Deformation Behavior of the Crossing Section of Two Municipal Road Tunnels during Construction. Appl. Sci. 2022, 12, 12274. https://doi.org/10.3390/app122312274

Zhao C-Y, Yue R-H, Lin Y-L, Huang C-J, Jiang X. Investigation on Deformation Behavior of the Crossing Section of Two Municipal Road Tunnels during Construction. Applied Sciences. 2022; 12(23):12274. https://doi.org/10.3390/app122312274

Chicago/Turabian StyleZhao, Chen-Yu, Ren-Hui Yue, Yu-Liang Lin, Cong-Jun Huang, and Xu Jiang. 2022. "Investigation on Deformation Behavior of the Crossing Section of Two Municipal Road Tunnels during Construction" Applied Sciences 12, no. 23: 12274. https://doi.org/10.3390/app122312274

APA StyleZhao, C.-Y., Yue, R.-H., Lin, Y.-L., Huang, C.-J., & Jiang, X. (2022). Investigation on Deformation Behavior of the Crossing Section of Two Municipal Road Tunnels during Construction. Applied Sciences, 12(23), 12274. https://doi.org/10.3390/app122312274