Investigation of the Behaviors of Methanol Spray Impingement and Wall Wetting

Abstract

:1. Introduction

2. Experimental Setup and Methodology

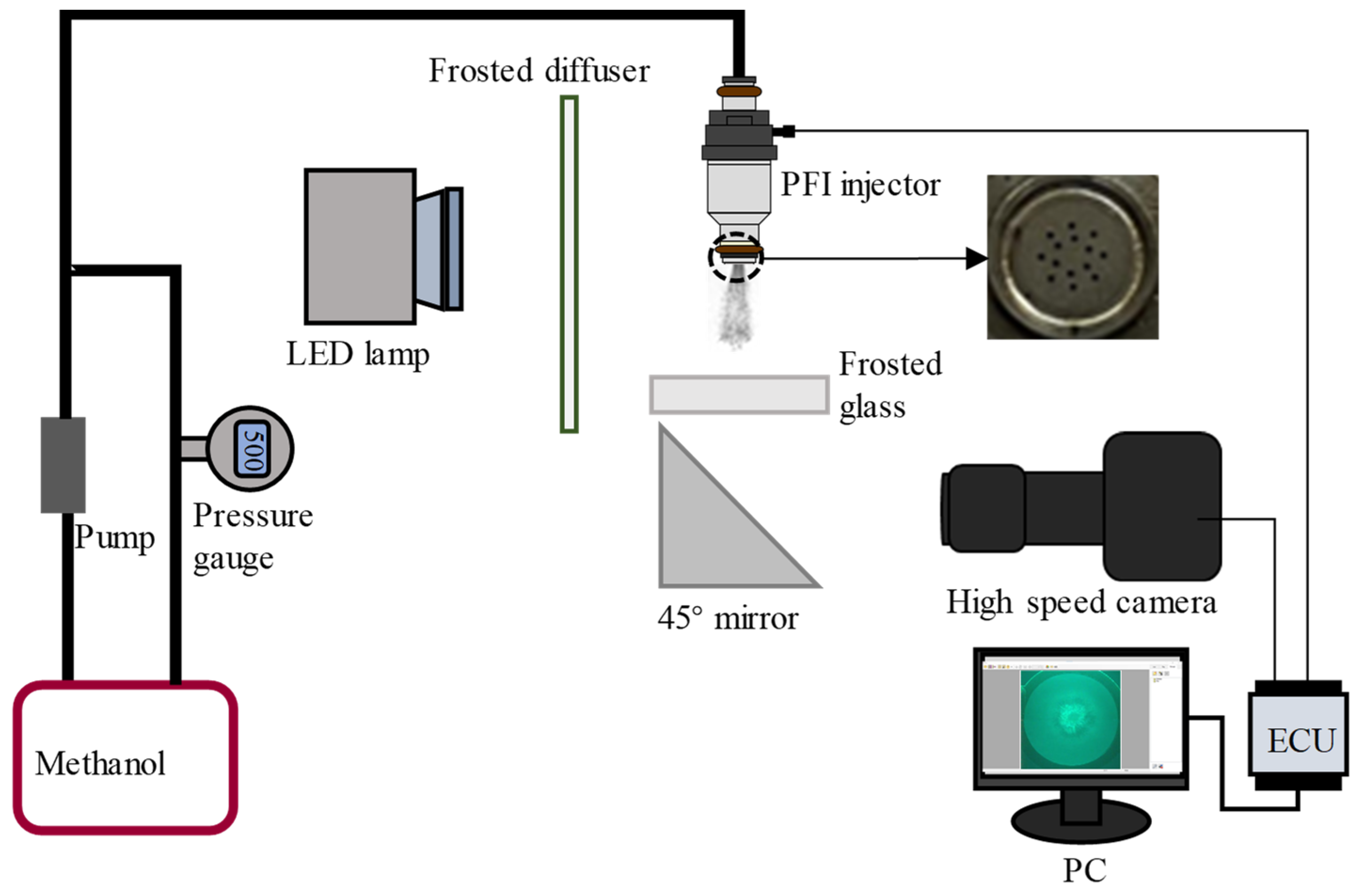

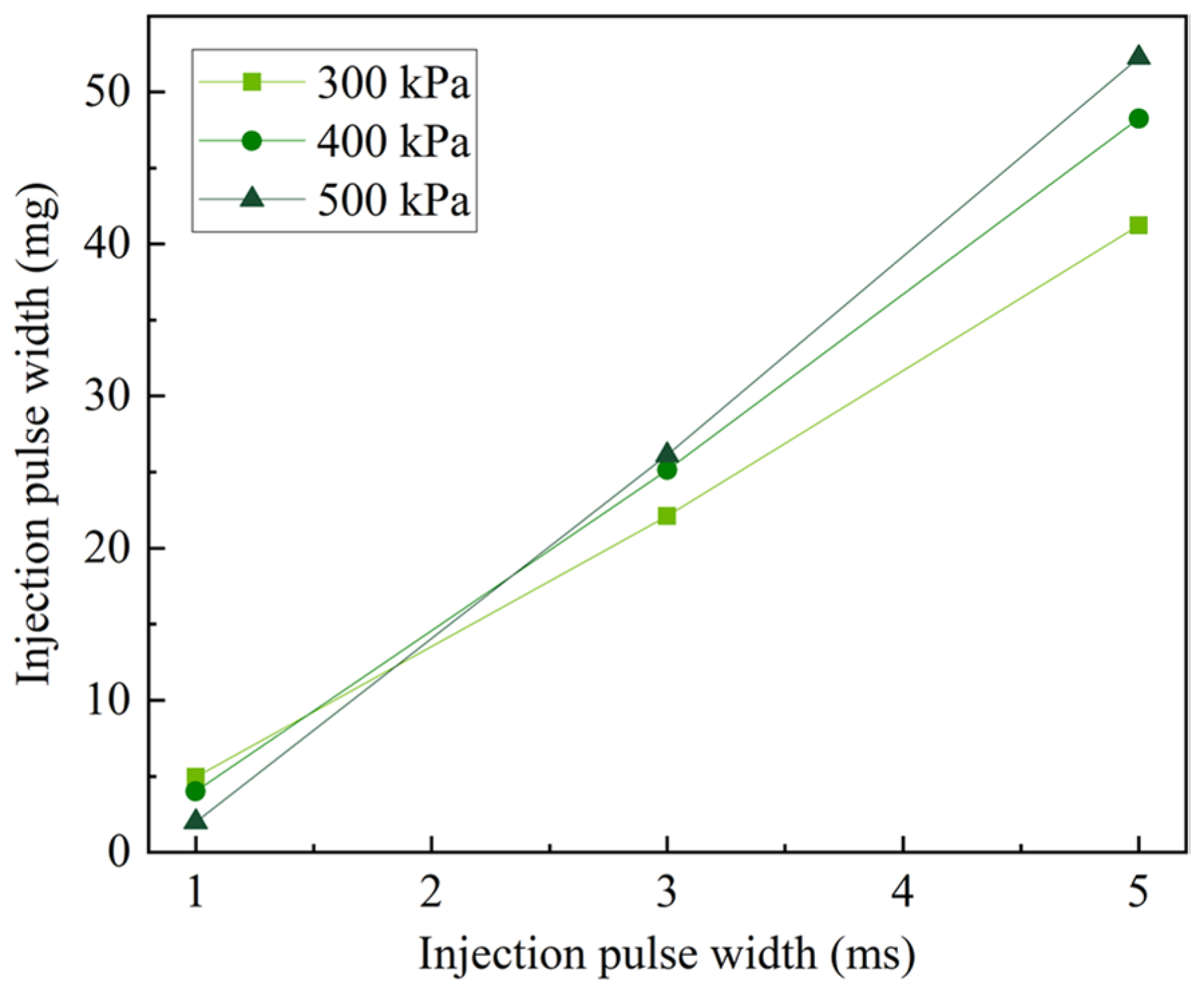

2.1. Experimental Apparatus

2.2. Methanol Characteristics and Initial Conditions

2.3. Spray Image Processing

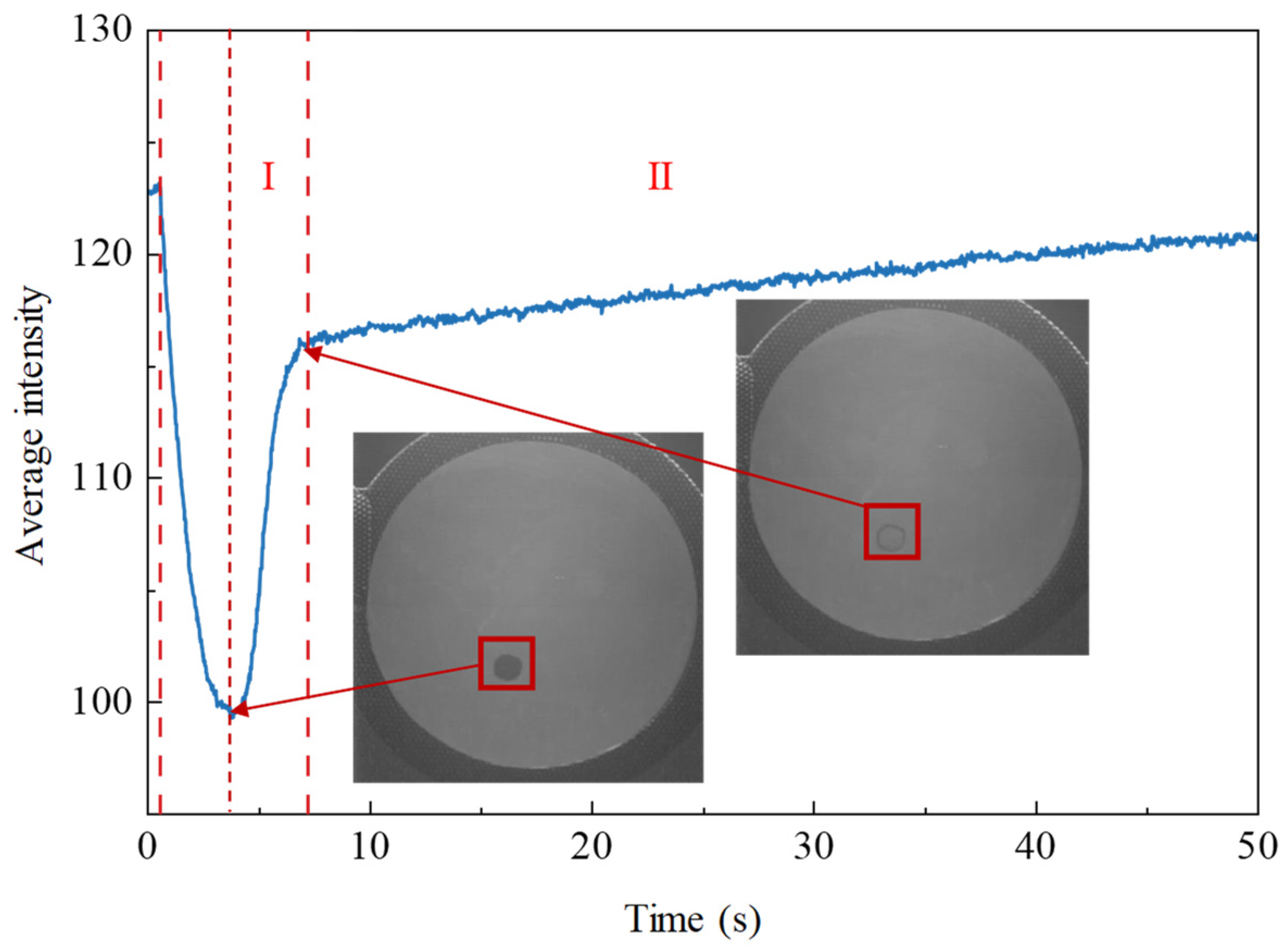

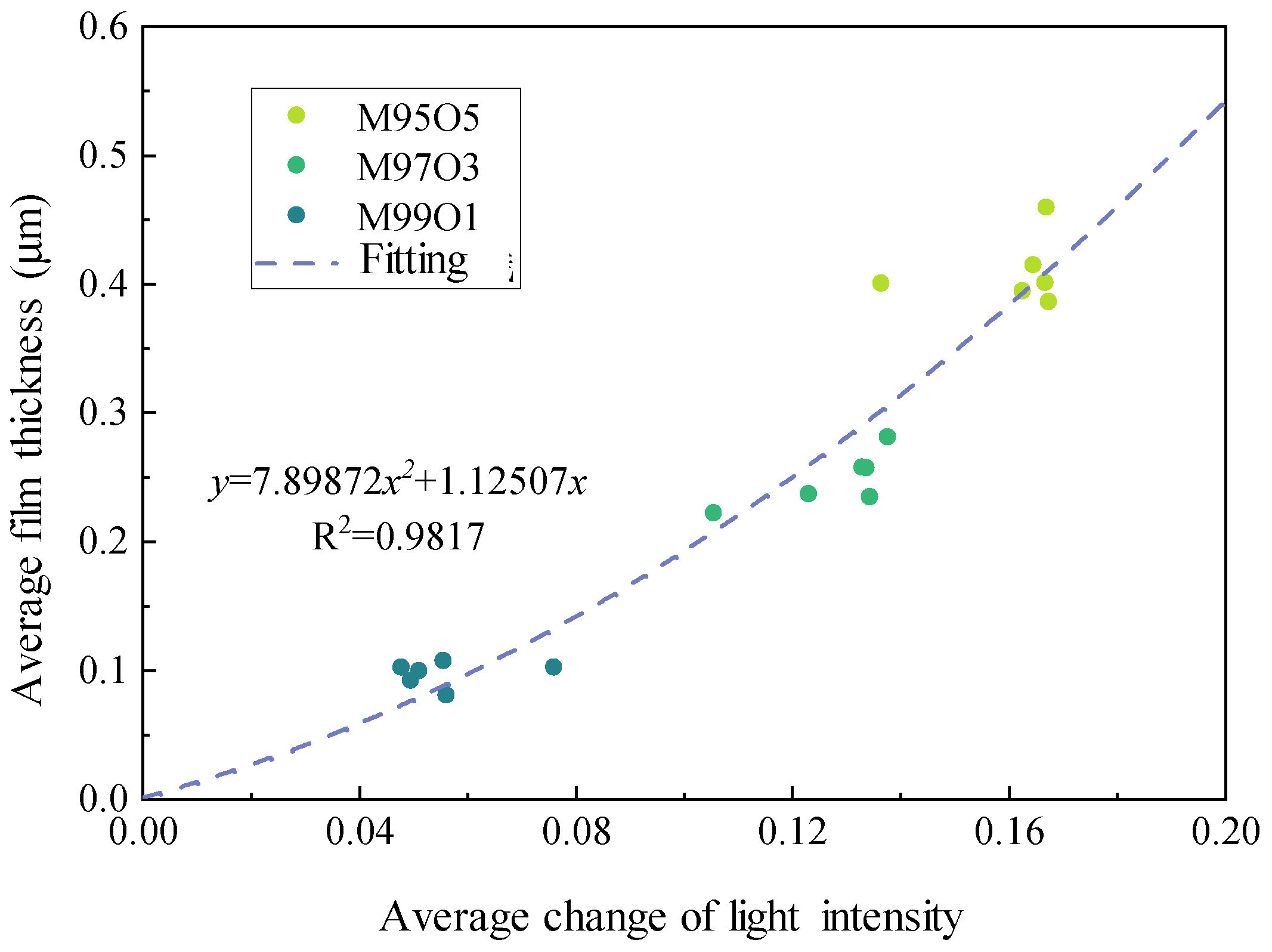

2.4. RIM Calibration

3. Results and Discussion

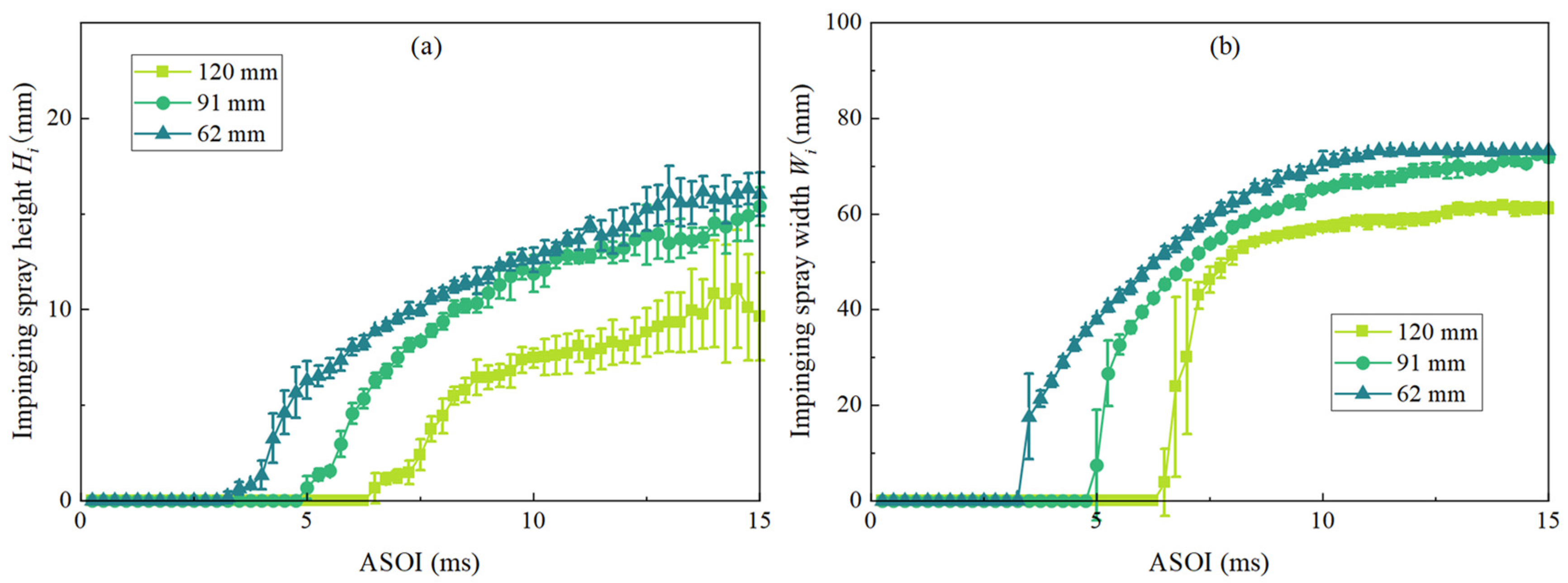

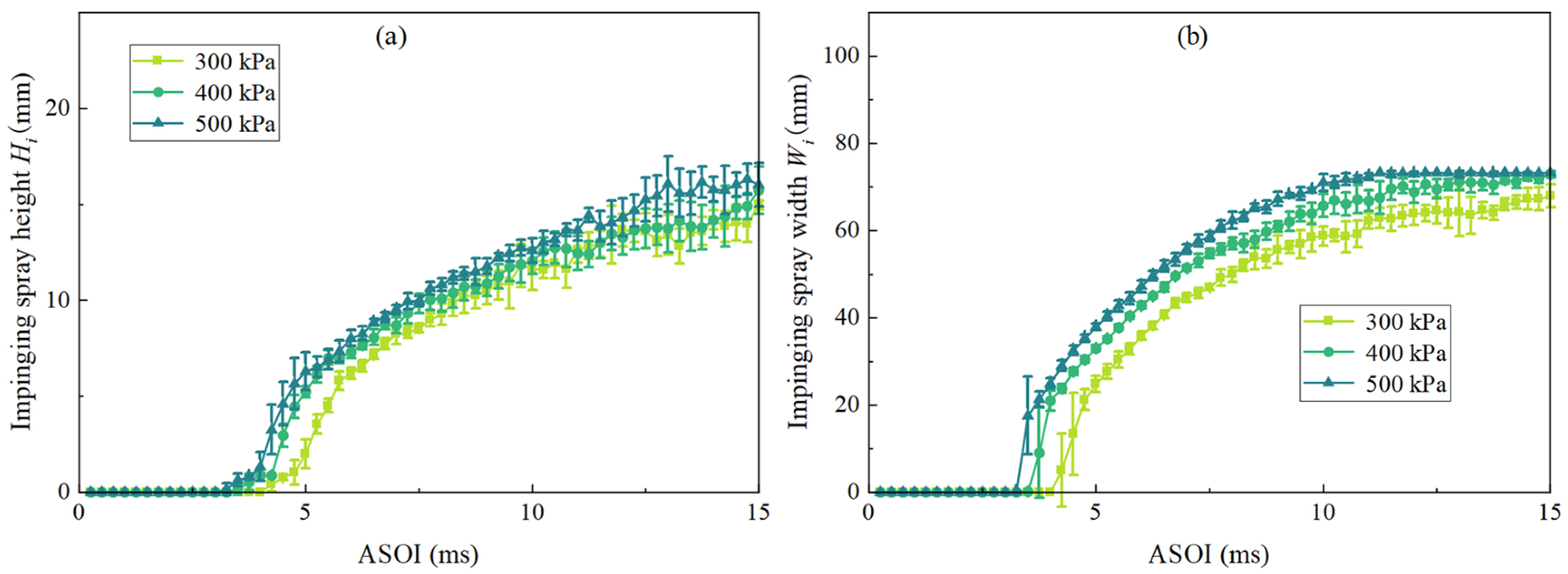

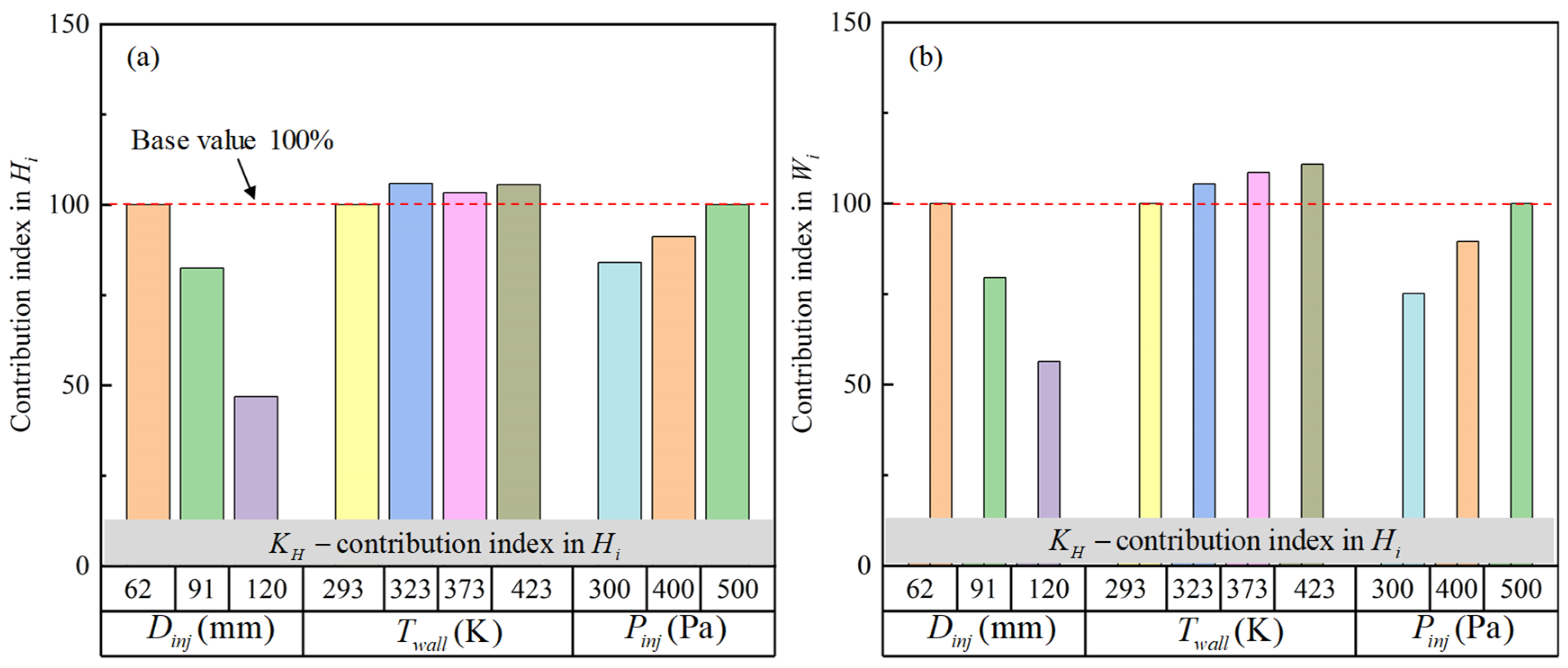

3.1. Macroscopic Behaviors of Spray Impingement

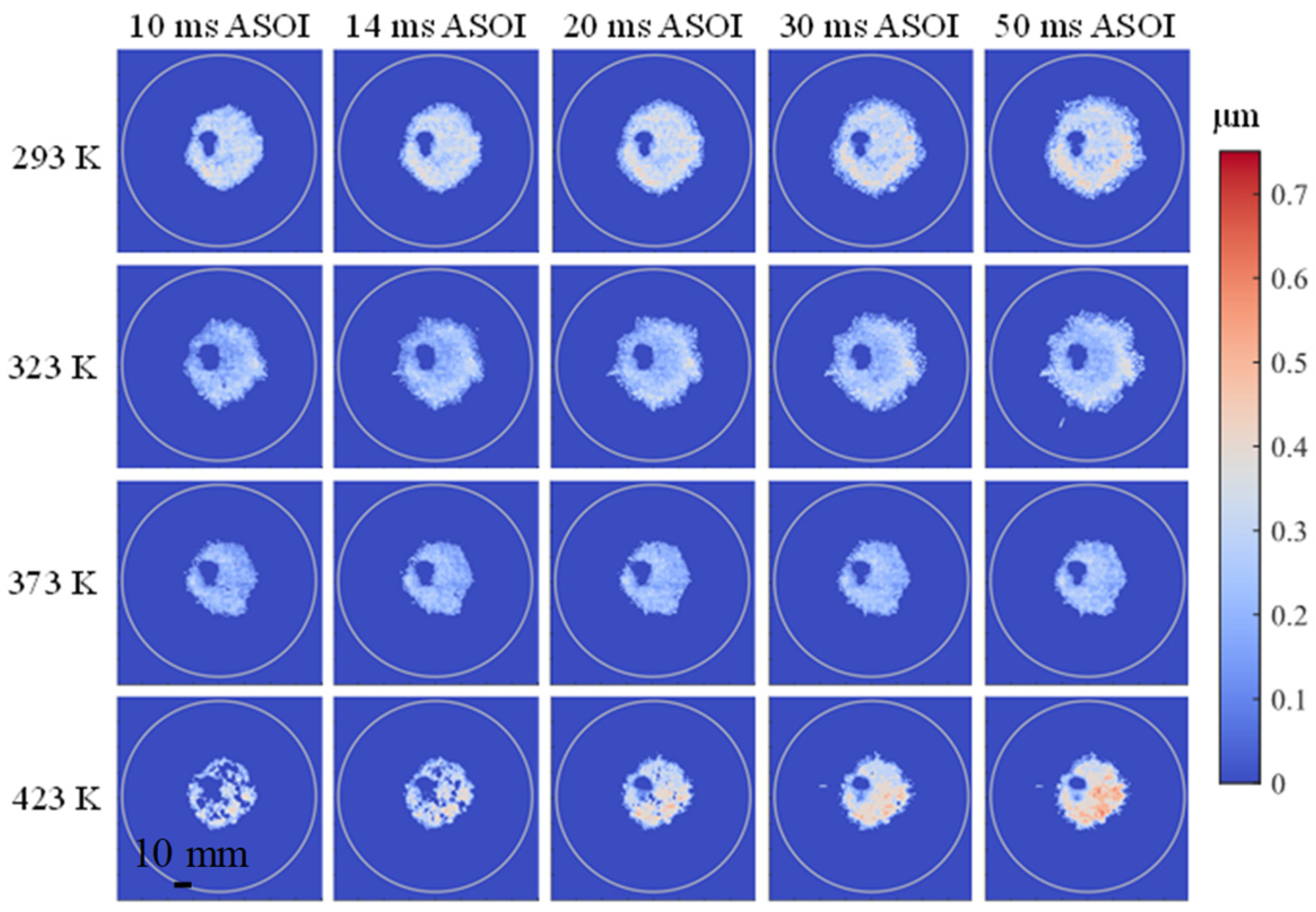

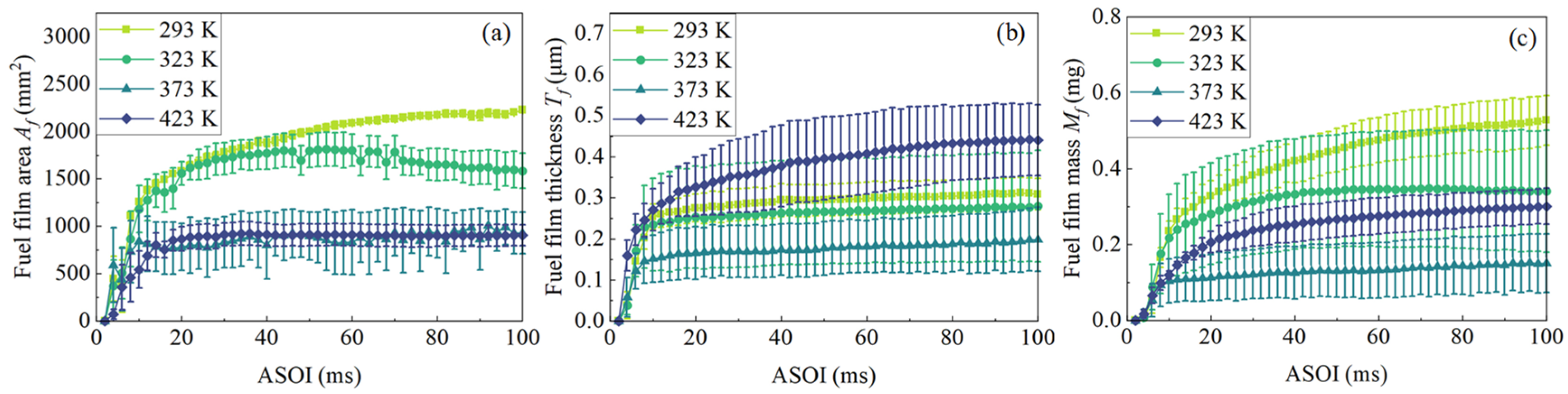

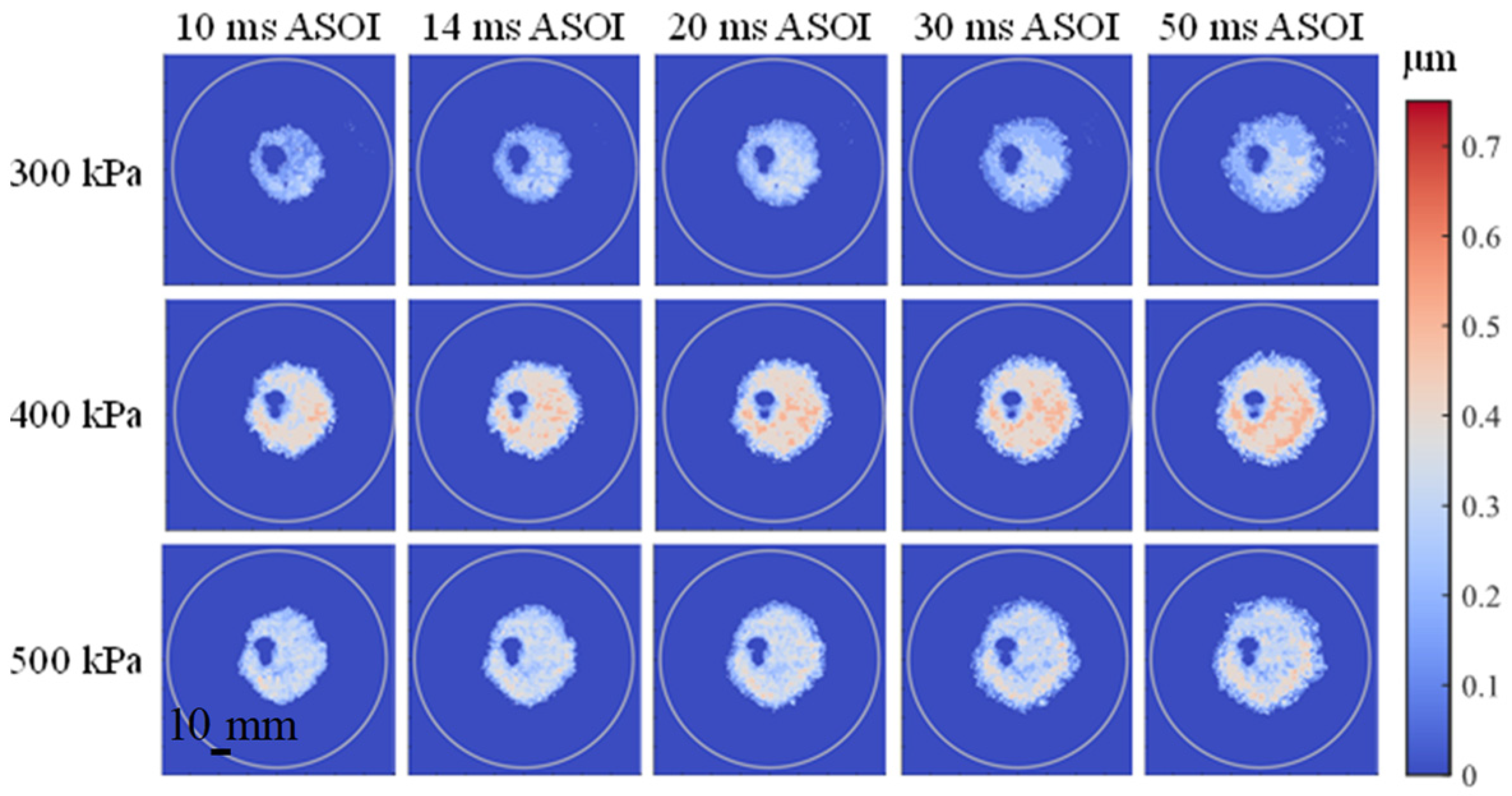

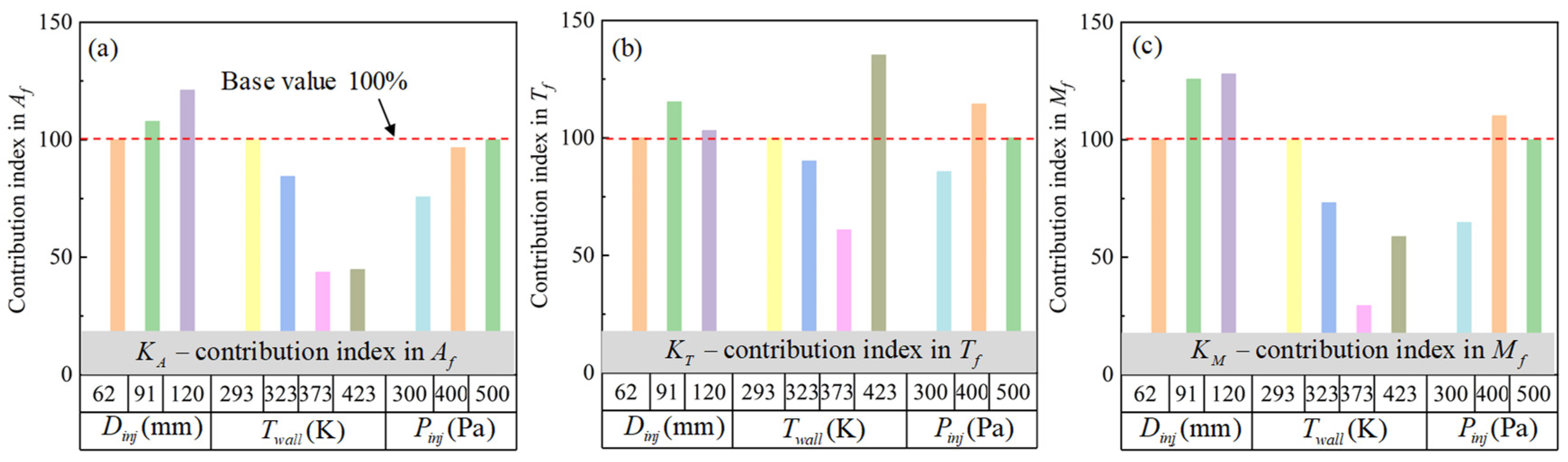

3.2. Fuel Adhesion Formation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ASOI | after the start of the injection |

| the light intensity of the point | |

| the adhesive fuel film thickness of the point | |

| RIM | Refractive index matching |

| GDI | Gasoline direct injection |

| PFI | Port fuel injection |

| Contribution index | |

| Impinging spray height | |

| Impinging spray width | |

| Injection pressure | |

| Injection pulse width | |

| Wall temperature | |

| Impingement distance | |

| Average fuel film thickness | |

| Fuel film mass | |

| Fuel film area | |

| Adhesive fuel film |

References

- Moreira, A.; Moita, A.; Panão, M. Advances and challenges in explaining fuel spray impingement: How much of single droplet impact research is useful? Prog. Energy Combust. Sci. 2010, 36, 554–580. [Google Scholar] [CrossRef]

- Katsura, N.; Saito, M.; Senda, J.; Fujimoto, H. Characteristics of a Diesel Spray Impinging on a Flat Wall. SAE Trans. 1989, 98, 252–268. [Google Scholar] [CrossRef]

- Arcoumanis, C.; Chang, J.-C. Flow and Heat Transfer Characteristics of Impinging Transient Diesel Sprays. SAE Trans. 1994, 103, 1092–1116. [Google Scholar] [CrossRef]

- Stratmann, J.; Martin, D.; Unterlechner, P.; Kneer, R. Near-Wall Characteristics of an Impinging Gasoline Spray at Increased Ambient Pressure and Wall Temperature. At. Sprays 2009, 19, 997–1012. [Google Scholar] [CrossRef]

- Mathews, W.S.; Lee, C.F.; Peters, J.E. Experimental Investigations of Spray/Wall Impingement. At. Sprays 2003, 13, 20. [Google Scholar] [CrossRef]

- Park, J.; Xie, X.; Kim, H.; Lai, M.-C. Visualization and measurement of a narrow-cone DI gasoline spray for the impingement analysis. Int. J. Automot. Technol. 2004, 5, 221–238. [Google Scholar] [CrossRef]

- Montanaro, A.; Allocca, L.; Lazzaro, M.; Meccariello, G. Impinging Jets of Fuel on a Heated Surface: Effects of Wall Temperature and Injection Conditions; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Montanaro, A.; Allocca, L.; Meccariello, G.; Lazzaro, M. Schlieren and Mie Scattering Imaging System to Evaluate Liquid and Vapor Contours of a Gasoline Spray Impacting on a Heated Wall; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Catapano, F.; Costa, M.; Marseglia, G.; Sementa, P.; Sorge, U.; Vaglieco, B.M. An Experimental and Numerical Investigation of GDI Spray Impact over Walls at Different Temperatures; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Ogata, Y. Fuel adhesion characteristics under non-evaporation and evaporation conditions: Part 2—Effect of ambient pressure. Fuel 2019, 251, 98–105. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Ogata, Y.; Zhang, W.; Fujikawa, T. Fuel adhesion characteristics under non-evaporation and evaporation conditions: Part 1—Effect of injection pressure. Fuel 2019, 240, 317–325. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Uchitomi, S.; Ogata, Y.; Zhang, W.; Fujikawa, T. Effect of temperature on fuel adhesion under spray-wall impingement condition. Fuel 2018, 234, 56–65. [Google Scholar] [CrossRef]

- Yu, H.; Liang, X.; Shu, G.; Wang, Y.; Zhang, H. Experimental investigation on spray-wall impingement characteristics of n-butanol/diesel blended fuels. Fuel 2016, 182, 248–258. [Google Scholar] [CrossRef]

- Li, Y.; Huang, Y.; Yang, S.; Luo, K.; Chen, R.; Tang, C. A comprehensive experimental investigation on the PFI spray impingement: Effect of impingement geometry, cross-flow and wall temperature. Appl. Therm. Eng. 2019, 159, 113848. [Google Scholar] [CrossRef]

- Akop, M.Z.; Zama, Y.; Furuhata, T.; Arai, M. Experimental Investigations on Adhered Fuel and Impinging Diesel Spray Normal to a Wall. At. Sprays 2013, 23, 211–231. [Google Scholar] [CrossRef]

- Akop, M.Z.; Zama, Y.; Furuhata, T.; Arai, M. Characteristics of Adhesion of Diesel Fuel on Impingement Disk Wall. Part 1: Effect of Impingement Area and Inclination Angle of Disk. At. Sprays 2013, 23, 725–744. [Google Scholar] [CrossRef]

- Akop, M.Z.; Zama, Y.; Furuhata, T.; Arai, M. Characteristics of Adhesion Diesel Fuel on an Impingement Disk Wall Part 2: Droplet Weber Number and Adhered Fuel Mass. At. Sprays 2014, 24, 651–671. [Google Scholar] [CrossRef]

- Akop, M.Z.; Zama, Y.; Furuhata, T.; Arai, M. Characteristics of Adhesion Diesel Fuel on an Impingement Disk Wall. Part 3: Ambient Pressure Effect. At. Sprays 2014, 24, 625–650. [Google Scholar] [CrossRef]

- Yu, H.; Liang, X.; Shu, G.; Sun, X.; Zhang, H. Experimental investigation on wall film ratio of diesel, butanol/diesel, DME/diesel and gasoline/diesel blended fuels during the spray wall impingement process. Fuel Process. Technol. 2017, 156, 9–18. [Google Scholar] [CrossRef]

- Drake, M.C.; Fansler, T.D.; Solomon, A.S.; Szekely, G.A. Piston Fuel Films as a Source of Smoke and Hydrocarbon Emissions from a Wall-Controlled Spark-Ignited Direct-Injection Engine. SAE Trans. 2003, 112, 762–783. [Google Scholar] [CrossRef]

- Yang, B.; Ghandhi, J. Measurement of Diesel Spray Impingement and Fuel Film Characteristics Using Refractive Index Matching Method; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Ding, C.-P.; Sjöberg, M.; Vuilleumier, D.; Reuss, D.L.; He, X.; Böhm, B. Fuel film thickness measurements using refractive index matching in a stratified-charge SI engine operated on E30 and alkylate fuels. Exp. Fluids 2018, 59, 59. [Google Scholar] [CrossRef]

- Ding, C.-P.; Vuilleumier, D.; Kim, N.; Reuss, D.L.; Sjöberg, M.; Boehm, B. Effect of engine conditions and injection timing on piston-top fuel films for stratified direct-injection spark-ignition operation using E30. Int. J. Engine Res. 2020, 21, 302–318. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Duan, H.; Cai, C.; Jia, M.; Zhang, Y. Experimental study on the boiling criterion of the fuel film formed from spray/wall impingement. Exp. Fluids 2019, 60, 179. [Google Scholar] [CrossRef]

- He, X.; Li, Y.; Liu, C.; Sjöberg, M.; Vuilleumier, D.; Liu, F.; Yang, Q. Characteristics of spray and wall wetting under flash-boiling and non-flashing conditions at varying ambient pressures. Fuel 2020, 264, 116683. [Google Scholar] [CrossRef]

- Fansler, T.D.; Parrish, S.E. Spray measurement technology: A review. Meas. Sci. Technol. 2014, 26, 012002. [Google Scholar] [CrossRef]

- Mulero, M.; Zapata, J.; Vilar, R.; Martínez, V.; Gadow, R. Automated image inspection system to quantify thermal spray splat morphology. Surf. Coat. Technol. 2015, 278, 1–11. [Google Scholar] [CrossRef]

- Sezgin, M.; Sankur, B. Survey over image thresholding techniques and quantitative performance evaluation. J Electron Imaging 2004, 13, 146–168. [Google Scholar] [CrossRef]

- Gong, C.; Luo, H.; Wu, X.; Nishida, K. Experimental Analysis in Dynamics Characteristics of Impinging Spray By a PFI Injector: From Spray Atomization to Fuel Adhesion Formation. At. Sprays 2021, 31, 77–96. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Uchitomi, S.; Ogata, Y.; Zhang, W.; Fujikawa, T. Effect of spray impingement distance on piston top fuel adhesion in direct injection gasoline engines. Int. J. Engine Res. 2020, 21, 742–754. [Google Scholar] [CrossRef]

- Maligne, D.; Bruneaux, G. Time-Resolved Fuel Film Thickness Measurement for Direct Injection SI Engines Using Refractive Index Matching; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Bai, C.X.; Rusche, H.; Gosman, A.D. Modeling of Gasoline Spray Impingement. At. Sprays 2002, 12, 1–27. [Google Scholar] [CrossRef] [Green Version]

| Fuel | Methanol (M100) |

|---|---|

| Density @ 293 K (g/mL) | 0.79 |

| Viscosity @ 293 K (mPa·s) | 0.55 |

| Surface tension @ 293 K (mN/m) | 18.8 |

| Boiling point (K) | 337.95 |

| Heat of vaporization @ 293 K (kJ/mol) | 35.295 |

| Refractive index @ 293 K (N/D) | 1.3284 |

| Parameters/Units | Value |

|---|---|

| )/mm | 120, 91, 62 |

| )/K | 293, 323, 373, 423 |

| )/kPa | 300, 400, 500 |

| )/ms | 3 |

| Ambient temperature/°C | 20 |

| Ambient pressure/kPa | 94.7 |

| Mixed Solution | Proportion of Methanol/%vol | Proportion of n-Octanol/%vol | Deposited Volume/μL |

|---|---|---|---|

| M95O5 | 95 | 5 | 0.5, 0.6, 0.7, 0.8, 0.9, 1.0 |

| M97O3 | 97 | 3 | 0.5, 0.6, 0.7, 0.8, 0.9, 1.0 |

| M99O1 | 99 | 1 | 0.5, 0.6, 0.7, 0.8, 0.9, 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-J.; Wei, Y.-J.; Jamil, H.; Liu, S.-H. Investigation of the Behaviors of Methanol Spray Impingement and Wall Wetting. Appl. Sci. 2022, 12, 12263. https://doi.org/10.3390/app122312263

Zhang Y-J, Wei Y-J, Jamil H, Liu S-H. Investigation of the Behaviors of Methanol Spray Impingement and Wall Wetting. Applied Sciences. 2022; 12(23):12263. https://doi.org/10.3390/app122312263

Chicago/Turabian StyleZhang, Ya-Jie, Yan-Ju Wei, Huzaifa Jamil, and Sheng-Hua Liu. 2022. "Investigation of the Behaviors of Methanol Spray Impingement and Wall Wetting" Applied Sciences 12, no. 23: 12263. https://doi.org/10.3390/app122312263

APA StyleZhang, Y.-J., Wei, Y.-J., Jamil, H., & Liu, S.-H. (2022). Investigation of the Behaviors of Methanol Spray Impingement and Wall Wetting. Applied Sciences, 12(23), 12263. https://doi.org/10.3390/app122312263