Laser-Induced Surface Modification on Wollastonite-Tricalcium Phosphate and Magnesium Oxide-Magnesium Stabilized Zirconia Eutectics for Bone Restoring Applications

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

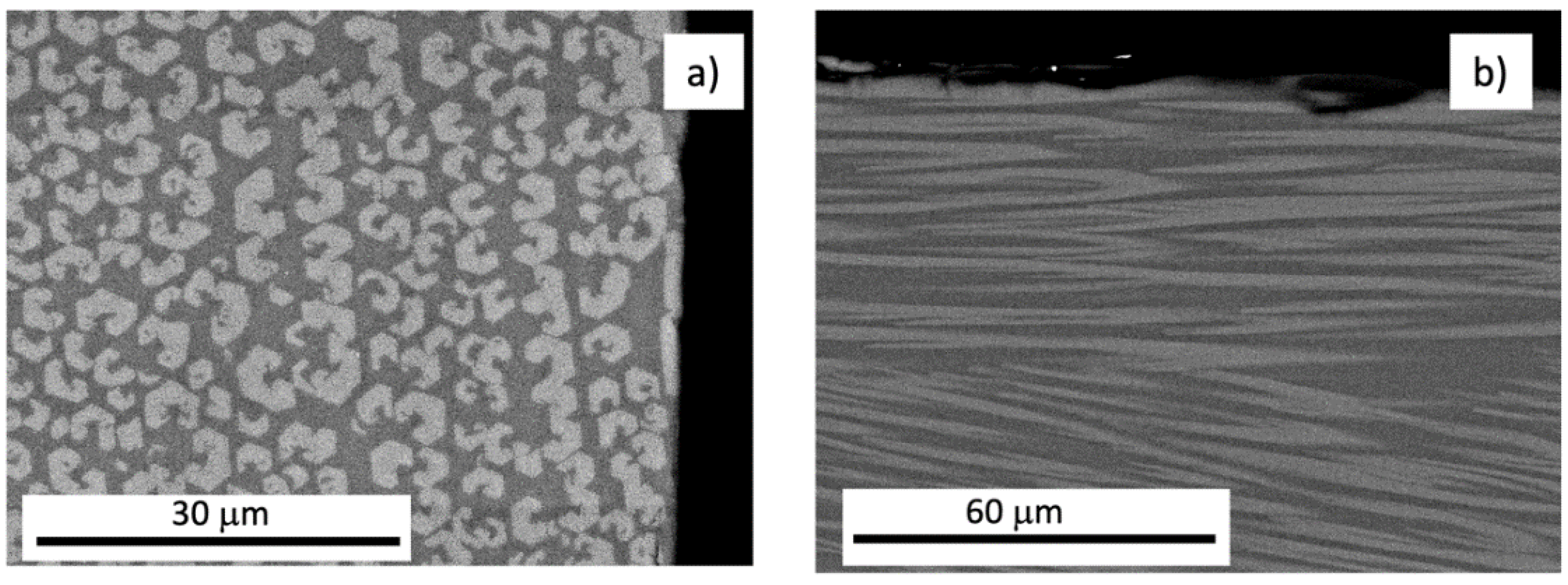

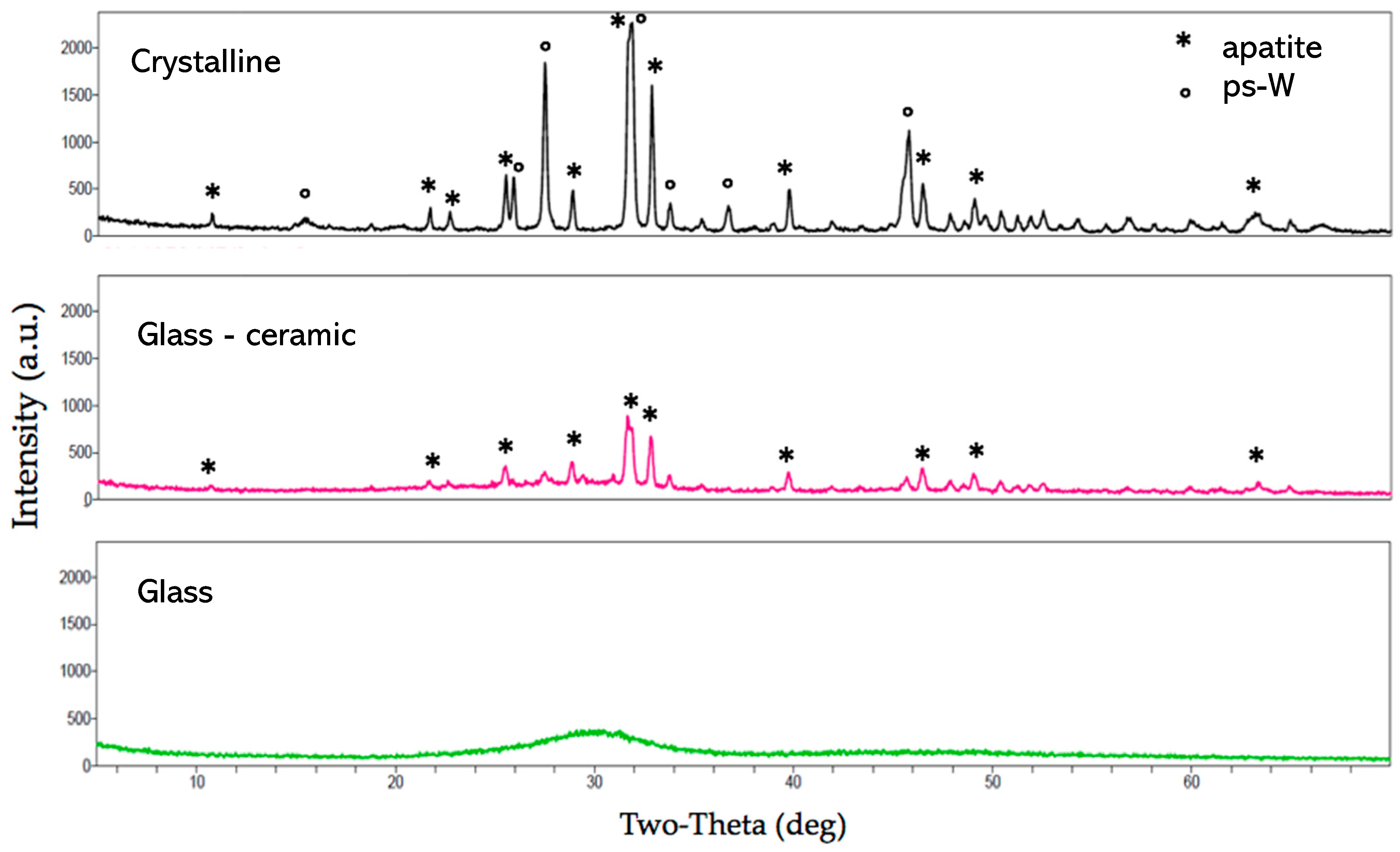

3.1. W-TCP Eutectic

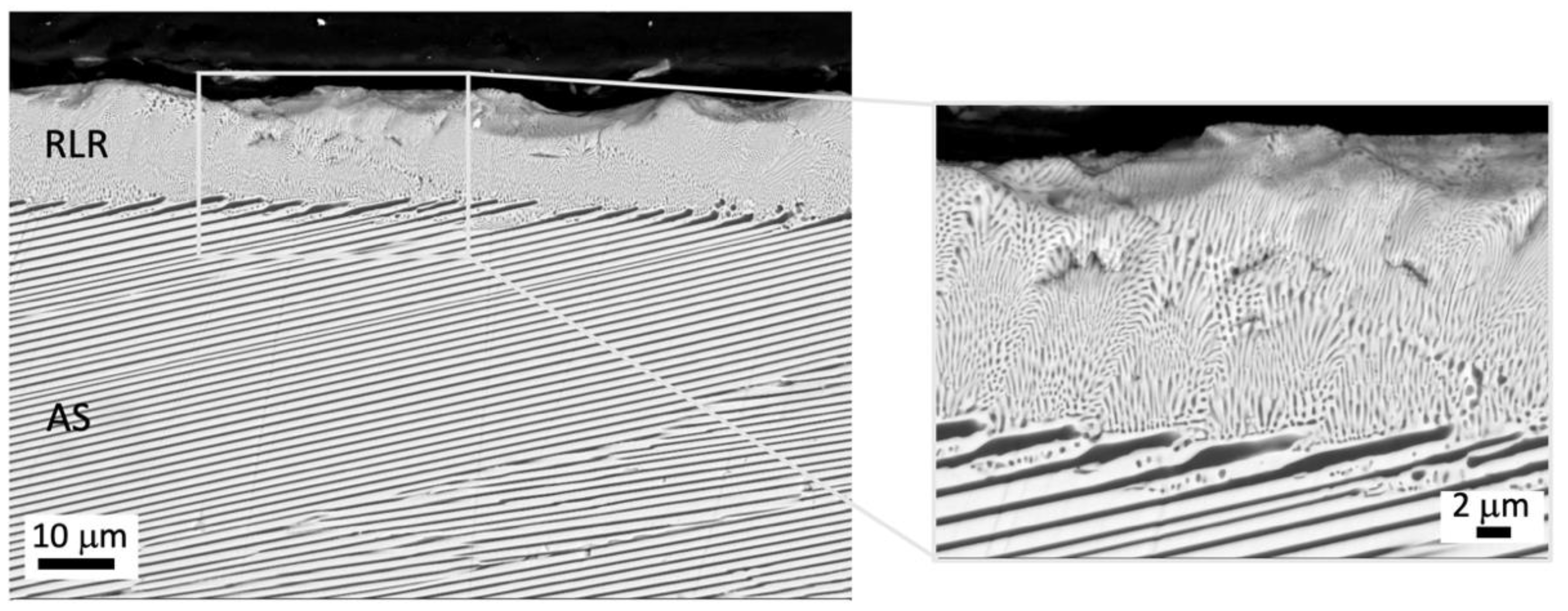

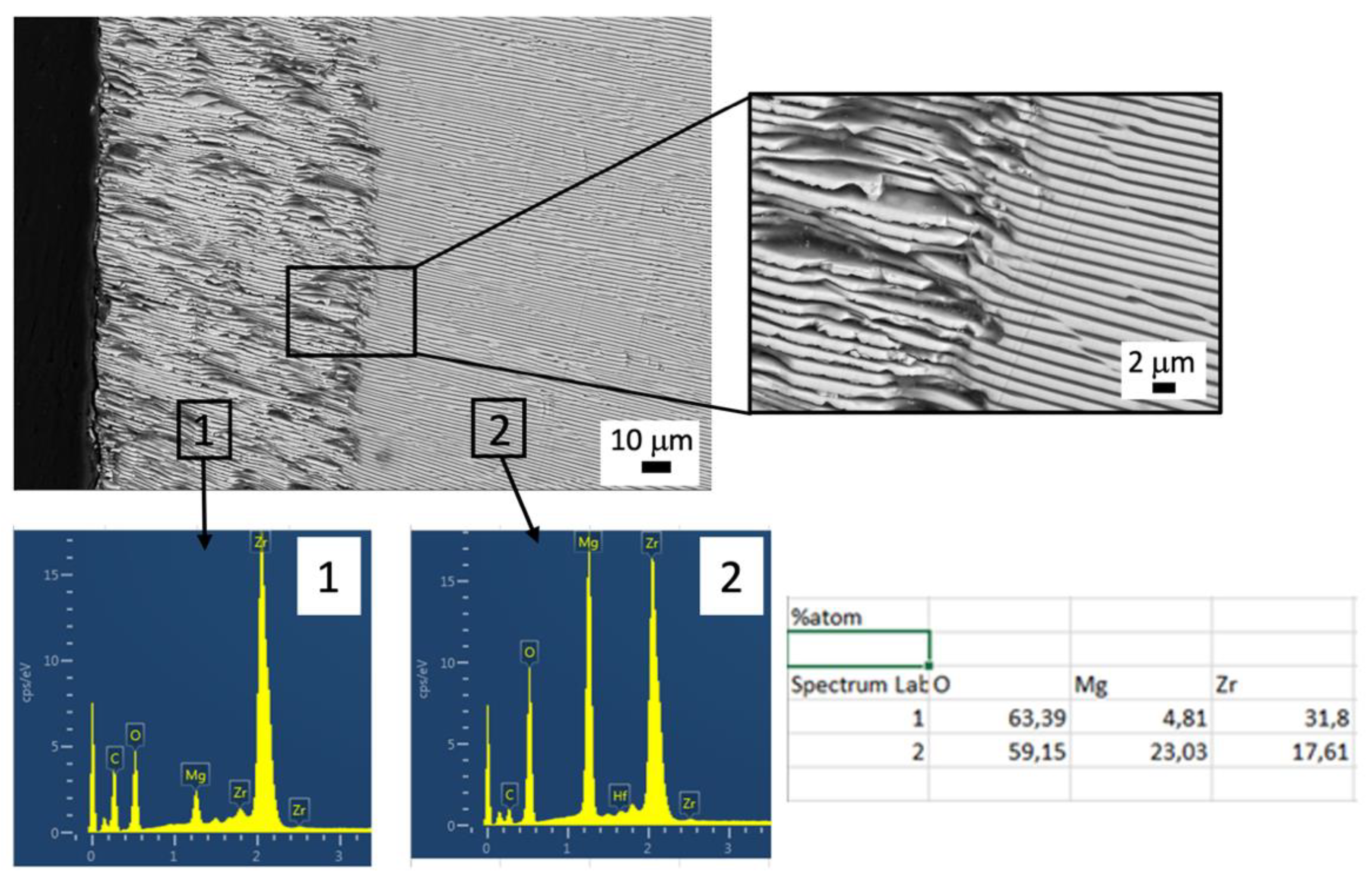

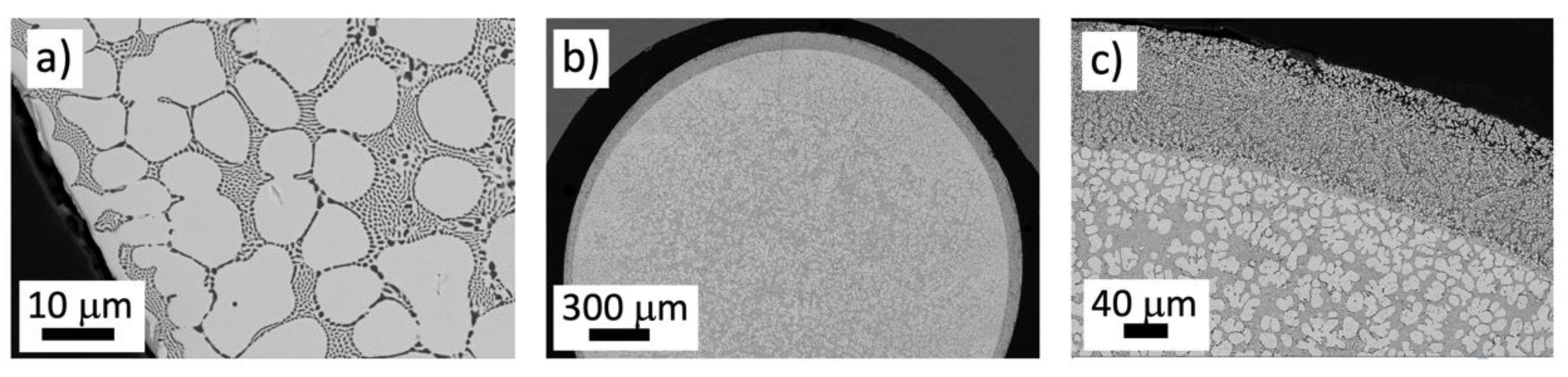

3.2. MgO-MgSZ Eutectic

3.3. Surface Structuring of MgO–MgSZ Eutectic by Laser Remelting and Phase Dissolution in SBF

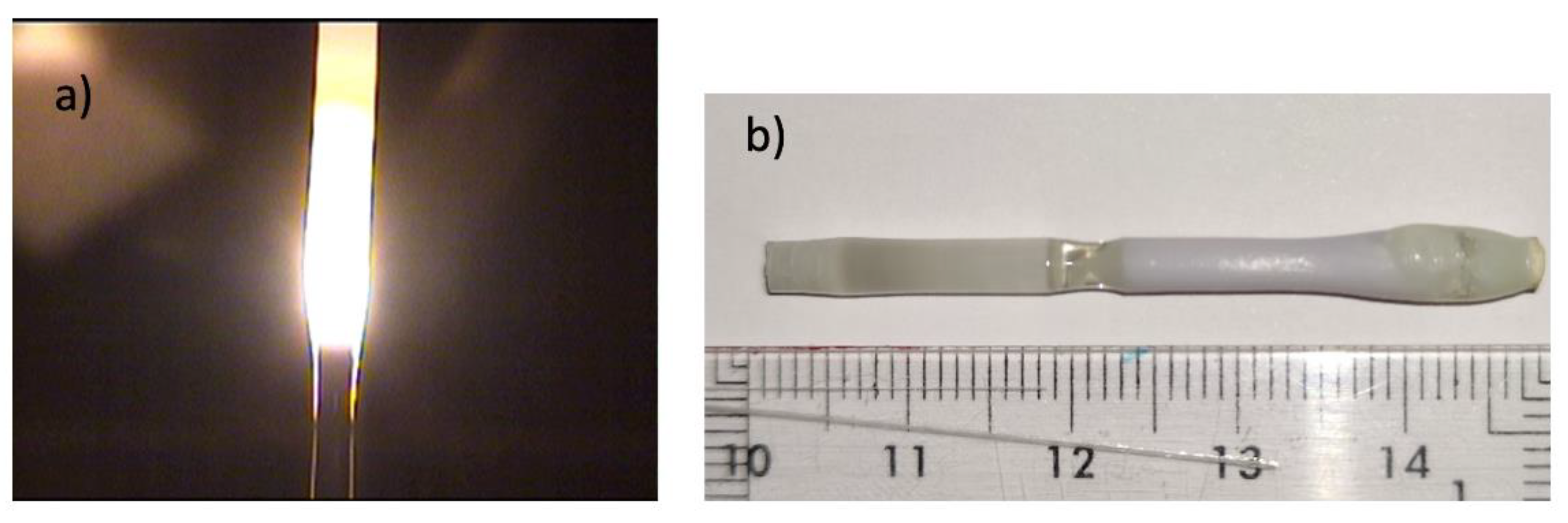

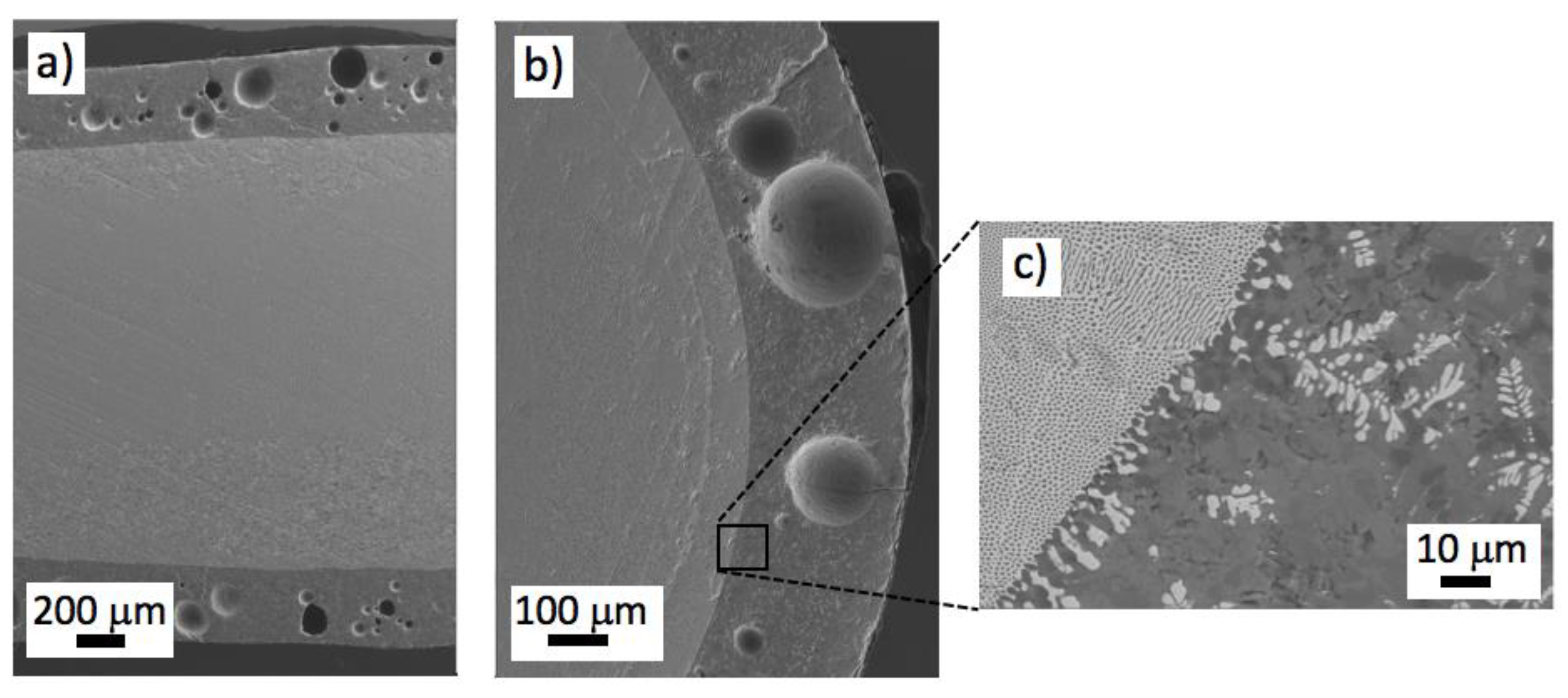

3.4. W-TCP Coatings on MgO-MgSZ Rods

4. Conclusions

- Directionally solidified eutectics in the W–TCP and MgO–MSZ systems with good comprehensive properties and controlled microstructure have been grown by the LFZ technique. Microstructure characteristics at different solidification rate were investigated.

- W–TCP eutectic composition. Microstructure was strongly dependent on processing rate, obtaining crystalline eutectics, glass–ceramics, or glasses when increased the growth rate. At slow rate of 20 mm/h phases of apatite and pseudo-wollastonite were observed. At moderate rates of 100 mm/h crystalline phases of apatite in a glass matrix of calcium silicate were formed. At rates above 200 mm/h the eutectic rods grew amorphous. Crystalline cylinders were subjected to a superficial laser melting process, generating a glassy layer that improved their flexural strength, from 73.8 MPa to 129 MPa.

- MgO–MgSZ eutectic composition. The microstructure changed from fibrillar/lamellar to colonies and cells with increasing growth rate in the range from 50 to 750 mm/h. Correspondingly, the phase spacing decreased gradually. The relationship between eutectic phase spacing with solidification rate can be summarized as λ = 8.24V−1/2. Hardness and the fracture toughness of 11 GPa and 1.5 MPam1/2, respectively, were obtained for rods grown at 750 mm/h. Flexural strength of 900 MPa was obtained.

- A simple and useful strategy to prepare rapidly solidified MgO–MgSZ nanoeutectic ceramic rods by laser surface remelting is proposed. After laser remelting, the lamellar spacing was refined sharply, without the need of high temperature preheating to avoid crack generation.

- After soaking in SBF, the MgO phase of the eutectic dissolves, leaving a zirconia skeleton on the surface in contact with the liquid. Pores of around 0.2 μm with approximately the same size as the structural elements (zirconia phase) are homogeneously distributed on the ceramic surface.

- The limited bioactivity of the MgO–MgSZ eutectic can be improved by the use of W–TCP eutectic as a bioactive cladding. The combination of dip coating and laser surface melting was able to meet the requirements in terms of coating thickness, homogeneity, and adhesion to the substrate. No coating spallation from the substrate was observed that could result in adverse clinical response.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Najafinezhad, A.; Abdellahi, M.; Ghayour, H.; Soheily, A.; Chami, A.; Khandan, A. A comparative study on the synthesis mechanism, bioactivity and mechanical properties of three silicate bioceramics. Mater. Sci. Eng. C 2017, 72, 259–267. [Google Scholar] [CrossRef] [PubMed]

- De Aza, P.N.; Guitian, F.; De Aza, S. A new bioactive material which transforms in situ into hydroxyapatite. Acta Mater. 1998, 46, 2541–2549. [Google Scholar] [CrossRef]

- De Aza, A.H.; Velasquez, P.; Alemany, M.I.; Pena, P.; De Aza, P.N. In-situ bone-like apatite formation from a Bioeutectic ceramic in SBF dynamic flow. J. Am. Ceram. Soc. 2007, 90, 1200–1207. [Google Scholar] [CrossRef]

- Pietak, A.M.; Reid, J.W.; Stott, M.J.; Sayer, M. Silicon substitution in the calcium phosphate bioceramics. Biomaterials. 2007, 28, 4023–4032. [Google Scholar] [CrossRef] [PubMed]

- Fan, G.; Su, H.; Zhang, J.; Guo, M.; Yang, H.; Liu, H.; Wang, E.; Liu, L.; Fu, H. Microstructure and cytotoxicity of Al2O3-ZrO2 eutectic bioceramics with high mechanical properties prepared by laser floating zone melting. Ceram. Int. 2018, 44, 17978–17985. [Google Scholar] [CrossRef]

- Amat, N.F.; Muchtar, A.; Yahaya, N.; Ghazali, M.J. A Review of Zirconia as a Dental Restorative Material. Aust. J. Basic Appl. Sci. 2012, 6, 9–13. [Google Scholar]

- Jing, Q.; Bao, J.; Ruan, F.; Song, X.; An, S.; Zhang, Y.; Tian, Z.; Lv, H.; Gao, J.; Xie, M. High-fracture toughness and aging-resistance of 3Y-TZP ceramics with a low Al2O3 content for dental applications. Ceram. Int. 2019, 45, 6066–6073. [Google Scholar] [CrossRef]

- Marcelli, E.; Costantino, M.L.; Villa, T.; Bagnoli, P.; Zannoli, R.; Corazza, I.; Cercenelli, L. Effect of intermediate ZrO2-CaO coatings deposited by cold thermal spraying on the titanium-porcelain bond in dental restorations. J. Prosthet. Dent. 2014, 112, 1201–1211. [Google Scholar] [CrossRef] [PubMed]

- Grima, L.; Díaz-Pérez, M.; Gil, J.; Sola, D.; Peña, J.I. Generation of a Porous Scaffold with a Starting Composition in the CaO–SiO2–MgO–P2O5 System in a Simulated Physiological Environment. Appl. Sci. 2020, 10, 312. [Google Scholar] [CrossRef]

- Kennard, F.L.; Bradt, R.C.; Stubican, V.S. Directional Solidification of the ZrO2-MgO Eutectic. J. Am. Ceram. Soc. 1974, 57, 428–431. [Google Scholar] [CrossRef]

- De Aza, P.N.; Guitian, F.; De Aza, S. Phase diagram of wollastonite–tricalcium phosphate. J. Am. Ceram. Soc. 1995, 78, 1653–1656. [Google Scholar] [CrossRef]

- Sola, D.; Ester, F.J.; Oliete, P.B.; Peña, J.I. Study of the stability of the molten zone and the stresses induced during the growth of Al2O3-Y3Al5O12 eutectic composite by the laser floating zone technique. J. Eur. Ceram. Soc. 2011, 31, 1211–1218. [Google Scholar] [CrossRef]

- Magallanes-Perdomo, M.; Pena, P.; De Aza, P.N.; Carrodeguas, R.G.; Rodríguez, M.A.; Turrillas, X.; De Aza, S.; De Aza, A.H. Devitrification studies of wollastonite–tricalcium phosphate eutectic glass. Acta Biomater. 2009, 5, 3057–3066. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.P.; Liu, C.T. A new approach to understanding and measuring glass formation in bulk amorphous materials. Intermetallics 2004, 12, 1035–1043. [Google Scholar] [CrossRef]

- Pardo, J.A.; Peña, J.I.; Merino, R.I.; Cases, R.; Larrea, A.; Orera, V.M. Spectroscopic properties of Er3+ and Nd3+ doped glasses with 0.8CaSiO3–0.2Ca3(PO4)2 eutectic composition. J. Non-Cryst. Solids 2002, 298, 23–31. [Google Scholar] [CrossRef]

- Cabral, A.A., Jr.; Fredericci, C.; Zanotto, E.D. A test of the Hrub parameter to estimate glass-forming ability. J. Non-Cryst. Solids 1997, 219, 182–186. [Google Scholar] [CrossRef]

- Hill, R.G.; Brauer, D.S. Predicting the bioactivity of glasses using the network connectivity or split network models. J. Non-Cryst. Solids 2011, 357, 3884–3887. [Google Scholar] [CrossRef]

- Trapp, H.J.L.; Stevels, J.M. Physical Properties of Invert Glasses. In Proceedings of the Glasstechn. Ber., 32K V. International Glass Congress, München, Germany, 29 June 1959; pp. VI/31–52. [Google Scholar]

- Lebecq, I.; Désanglois, F.; Leriche, A.; Follet-Houttemane, C. Compositional dependence on the in vitro bioactivity of invert or conventional bioglasses in the Si-Ca-Na-P system. J. Biomed. Mater. Res. Part. A. 2007, 83, 156–168. [Google Scholar] [CrossRef]

- Magallanes-Perdomo, M.; Luklinska, Z.B.; De Aza, A.H.; Carrodeguas, R.G.; De Aza, S.; Pena, P. Bone-like forming ability of apatite–wollastonite glass ceramic. J. Eur. Ceram. Soc. 2011, 31, 1549–1561. [Google Scholar] [CrossRef]

- Ibáñez, A.; Sandoval, F. La Wollastonita: Propiedades, síntesis y aplicaciones cerámicas. Bol. Soc. Esp. Ceram. Vidr. 1993, 32, 349–361. [Google Scholar]

- Ruseska, G.; Fidancevska, E.; Bossert, J. Mechanical and Thermal-Expansion Characteristics of Ca10(PO4)6(OH)2-Ca3(PO4)2 Composites. Sci. Sinter. 2006, 38, 245–253. [Google Scholar] [CrossRef]

- Sola, D.; Oliete, P.B.; Merino, R.I.; Peña, J.I. Directionally solidified Ni doped MgO-MgSZ eutectic composites for thermophotovoltaic devices. J. Eur. Ceram. Soc. 2019, 39, 1206–1213. [Google Scholar] [CrossRef]

- Rahmati, M.; Mozafari, M. A critical review on the cellular and molecular interactions at the interface of zirconia-based biomaterials. Ceram. Int. 2018, 44, 16137–16149. [Google Scholar] [CrossRef]

- Hao, L.; Lawrence, J. The adsorption of human serum albumin (HSA) on CO2 laser modified magnesia partially stabilised zirconia (MgO-PSZ). Colloids Surf. B Biointerfaces 2004, 34, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Yilbas, B.S. Laser treatment of zirconia surface for improved surface hydrophobicity. J. Alloys Compd. 2015, 625, 208–215. [Google Scholar] [CrossRef]

- De Zanet, A.; Casalegno, V.; Salvo, M. Laser surface texturing of ceramics and ceramic composite materials—A review. Ceram. Int. 2021, 47, 7307–7320. [Google Scholar] [CrossRef]

- Fiocco, L.; Li, S.; Stevens, M.M.; Bernardo, E.; Jones, J.R. Biocompatibility and bioactivity of porous polymer-derived Ca-Mg silicate ceramics. Acta Biomater. 2017, 50, 56–67. [Google Scholar] [CrossRef]

- Edrees, S.J.; Shukur, M.M.; Obeid, M.M. First-principle analysis of the structural, mechanical, optical and electronic properties of wollastonite monoclinic polymorph. Comput. Condens. Matter. 2018, 14, 20–26. [Google Scholar] [CrossRef]

- Kumar, R.R.; Wang, M. Modulus and hardness evaluations of sintered bioceramic powders and functionally graded bioactive composites by nano-indentation technique. Mater. Sci. Eng. A. 2002, 338, 230–236. [Google Scholar] [CrossRef]

- Díaz-Pérez, M.; Grima, L.; Moshtaghioun, B.M.; Peña, J.I. CaO–MgO–SiO2–P2O5- based multiphase bio-ceramics fabricated by directional solidification: Microstructure features and in vitro bioactivity studies. Ceram. Int. 2021, 47, 17041–17048. [Google Scholar] [CrossRef]

- Albert, D.L.; Katzenberger, M.J.; Agnew, A.M.; Kemper, A.R. A comparation of rib cortical bone compressive and tensile material properties: Trends with age, sex, and loading rate. J. Mech. Behav. Biomed. Mater. 2021, 122, 104668. [Google Scholar] [CrossRef]

- Bose, S.; Fielding, G.; Tarafder, S.; Bandyopadhyay, A. Understanding of dopant-induced osteogenesis and angiogenesis in calcium phosphate ceramics. Trends Biotechnol. 2013, 31, 594–605. [Google Scholar] [CrossRef] [PubMed]

- Mansoorianfar, M.; Shokrgozar, M.A.; Mehrjoo, M.; Tamjid, E.; Simchi, A. Nanodiamonds for surface engineering of orthopedic implants: Enhanced biocompatibility in human osteosarcoma cell culture. Diam. Relat. Mater. 2013, 40, 107–114. [Google Scholar] [CrossRef]

- Velásquez, P.; de la Casa-Lillo, M.A.; Peña, J.I.; de Aza, P.N. Influencia de la microestructura en la bioactividad de materiales bioeutécticos. In Proceedings of the X Congreso Nacional de Materiales, San Sebastián, Spain, 18–20 June 2008; Mondragon Unibertsitateko: San Sebastián, Spain, 2008; pp. 579–582. [Google Scholar]

- Jones, J.R. Review of bioactive glass: From Hench to hybrids. Acta Biomater. 2013, 9, 4457–4486. [Google Scholar] [CrossRef] [PubMed]

| Material | HV (GPa) | Toughness (MPa m1/2) | Flexural Strength (MPa) |

|---|---|---|---|

| Crystalline | 4.6 ± 0.45 | 1.39 ± 0.3 | 73.8 |

| Glass ceramic | 5.1 ± 0.78 | 0.99 ± 0.28 | 82.3 |

| Glass | 4.9 ± 0.18 | 1.08 ± 0.12 | 310 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Sola, D.; Peña, J.I. Laser-Induced Surface Modification on Wollastonite-Tricalcium Phosphate and Magnesium Oxide-Magnesium Stabilized Zirconia Eutectics for Bone Restoring Applications. Appl. Sci. 2022, 12, 12188. https://doi.org/10.3390/app122312188

Wang S, Sola D, Peña JI. Laser-Induced Surface Modification on Wollastonite-Tricalcium Phosphate and Magnesium Oxide-Magnesium Stabilized Zirconia Eutectics for Bone Restoring Applications. Applied Sciences. 2022; 12(23):12188. https://doi.org/10.3390/app122312188

Chicago/Turabian StyleWang, Shunheng, Daniel Sola, and Jose I. Peña. 2022. "Laser-Induced Surface Modification on Wollastonite-Tricalcium Phosphate and Magnesium Oxide-Magnesium Stabilized Zirconia Eutectics for Bone Restoring Applications" Applied Sciences 12, no. 23: 12188. https://doi.org/10.3390/app122312188

APA StyleWang, S., Sola, D., & Peña, J. I. (2022). Laser-Induced Surface Modification on Wollastonite-Tricalcium Phosphate and Magnesium Oxide-Magnesium Stabilized Zirconia Eutectics for Bone Restoring Applications. Applied Sciences, 12(23), 12188. https://doi.org/10.3390/app122312188