Analytical Prediction of Molten Pool Dimensions in Powder Bed Fusion Considering Process Conditions-Dependent Laser Absorptivity

Abstract

1. Introduction

2. Analytical Modeling

3. Experimental Validation and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Saboori, A.; Iuliano, L.; Pavese, M. On the effect of rapid annealing on the microstructure and mechanical behavior of additively manufactured stainless steel by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2021, 828, 142109. [Google Scholar] [CrossRef]

- Caiazzo, F.; Campanelli, S.L.; Cardaropoli, F.; Contuzzi, N.; Sergi, V.; Ludovico, A.D. Manufacturing and characterization of similar to foam steel components processed through selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 92, 26–2130. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Posa, P.; Angelastro, A. Printability and microstructure of selective laser melting of WC/Co/Cr powder. Materials 2019, 12, 2397. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Posa, P.; Angelastro, A. Study of the aging treatment on selective laser melted maraging 300 steel. Mater. Res. Express 2019, 6, 066580. [Google Scholar] [CrossRef]

- Bayat, M.; Klingaa, C.G.; Mohanty, S.; De Baere, D.; Thorborg, J.; Tiedje, N.S.; Hattel, J.H. Part-scale thermo-mechanical modelling of distortions in Laser Powder Bed Fusion—Analysis of the sequential flash heating method with experimental validation. Addit. Manuf. 2020, 36, 101508. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2018, 25, 347–356. [Google Scholar] [CrossRef]

- Le, K.Q.; Tang, C.; Wong, C.H. On the study of keyhole-mode melting in selective laser melting process. Int. J. Therm. Sci. 2019, 145, 105992. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Patel, S.; Vlasea, M. Melting modes in laser powder bed fusion. Materialia 2020, 9, 100591. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Tenbrock, C.; Fischer, F.G.; Wissenbach, K.; Schleifenbaum, J.H.; Wagenblast, P.; Meiners, W.; Wagner, J. Influence of keyhole and conduction mode melting for top-hat shaped beam profiles in laser powder bed fusion. J. Mater. Process. Technol. 2020, 278, 116514. [Google Scholar] [CrossRef]

- Trapp, J.; Rubenchik, A.M.; Guss, G.; Matthews, M.J. In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl. Mater. Today 2017, 9, 341–349. [Google Scholar] [CrossRef]

- Solana, P.; Negro, G. A study of the effect of multiple reflections on the shape of the keyhole in the laser processing of materials. J. Phys. D Appl. Phys. 1997, 30, 3216. [Google Scholar] [CrossRef]

- Matthews, M.; Trapp, J.; Guss, G.; Rubenchik, A. Direct measurements of laser absorptivity during metal melt pool formation associated with powder bed fusion additive manufacturing processes. J. Laser Appl. 2018, 30, 032302. [Google Scholar] [CrossRef]

- Ettaieb, K.; Lavernhe, S.; Tournier, C. A flash-based thermal simulation of scanning paths in LPBF additive manufacturing. Rapid Prototyp. J. 2021, 27, 720–734. [Google Scholar] [CrossRef]

- Tran, H.C.; Lo, Y.L.; Le, T.N.; Lau, A.K.T.; Lin, H.Y. Multi-scale simulation approach for identifying optimal parameters for fabrication ofhigh-density Inconel 718 parts using selective laser melting. Rapid Prototyp. J. 2021, 28, 109–125. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; O’Neil, W.; Gibson, I.; Cordova, L.; Rolfe, B. Numerical and analytical investigation on meltpool temperature of laser-based powder bed fusion of IN718. Int. J. Heat Mass Transf. 2021, 177, 121477. [Google Scholar] [CrossRef]

- Ye, J.; Khairallah, S.A.; Rubenchik, A.M.; Crumb, M.F.; Guss, G.; Belak, J.; Matthews, M.J. Energy coupling mechanisms and scaling behavior associated with laser powder bed fusion additive manufacturing. Adv. Eng. Mater. 2019, 21, 1900185. [Google Scholar] [CrossRef]

- Rubenchik, A.; Wu, S.; Mitchell, S.; Golosker, I.; LeBlanc, M.; Peterson, N. Direct measurements of temperature-dependent laser absorptivity of metal powders. Appl. Opt. 2015, 54, 7230–7233. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Zhang, S.; Teng, C.; Zeng, K.; Robinson, C.; Pal, D.; Stucker, B. Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog. Addit. Manuf. 2017, 2, 157–167. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; De Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Boley, C.D.; Khairallah, S.A.; Rubenchik, A.M. Calculation of laser absorption by metal powders in additive manufacturing. Appl. Opt. 2015, 54, 2477–2482. [Google Scholar] [CrossRef]

- Karayagiz, K.; Elwany, A.; Tapia, G.; Franco, B.; Johnson, L.; Ma, J.; Karaman, I.; Arróyave, R. Numerical and experimental analysis of heat distribution in the laser powder bed fusion of Ti-6Al-4V. IISE Trans. 2019, 51, 136–152. [Google Scholar] [CrossRef]

- Vastola, G.; Pei, Q.X.; Zhang, Y.W. Predictive model for porosity in powder-bed fusion additive manufacturing at high beam energy regime. Addit. Manuf. 2018, 22, 817–822. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Martin, A.A.; Lee, J.R.I.; Guss, G.; Calta, N.P.; Hammons, J.A.; Nielsen, M.H.; Chaput, K.; Schwalbach, E.; Shah, M.N.; et al. Controlling interdependent meso-nanosecond dynamics and defect generation in metal 3D printing. Science 2020, 368, 660–665. [Google Scholar] [CrossRef]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S.I. Finite element simulation of selective laser melting process considering optical penetration depth of laser in powder bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Lee, K.H.; Yun, G.J. A Novel Heat Source Model for Analysis of Melt Pool Evolution in Selective Laser Melting Process. Addit. Manuf. 2020, 36, 101497. [Google Scholar] [CrossRef]

- Fergani, O.; Berto, F.; Welo, T.; Liang, S.Y. Analytical modelling of residual stress in additive manufacturing. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 971–978. [Google Scholar] [CrossRef]

- Ji, X.; Mirkoohi, E.; Ning, J.; Liang, S.Y. Analytical modeling of post-printing grain size in metal additive manufacturing. Opt. Lasers Eng. 2020, 124, 105805. [Google Scholar] [CrossRef]

- Ning, J.; Wang, W.; Zamorano, B.; Liang, S.Y. Analytical modeling of lack-of-fusion porosity in metal additive manufacturing. Appl. Phys. A 2019, 125, 797. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of in-process temperature in powder feed metal additive manufacturing considering heat transfer boundary condition. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 7, 585–593. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C.; Beuth, J.L. Prediction of lack-of-fusion porosity for powder bed fusion. Addit. Manuf. 2017, 14, 39–48. [Google Scholar] [CrossRef]

- Seidel, C.; Zaeh, M.F. Multi-scale modelling approach for contributing to reduced distortion in parts made by laser-based powder bed fusion. Procedia CIRP 2018, 67, 197–202. [Google Scholar] [CrossRef]

- Promoppatum, P.; Yao, S.C.; Pistorius, P.C.; Rollett, A.D. A comprehensive comparison of the analytical and numerical prediction of the thermal history and solidification microstructure of Inconel 718 products made by laser powder-bed fusion. Engineering 2017, 3, 685–694. [Google Scholar] [CrossRef]

- Wang, W.; Garmestani, H.; Liang, S.Y. Prediction of molten pool size and vapor depression depth in keyhole melting mode of laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2022, 119, 6215–6223. [Google Scholar] [CrossRef]

- Wang, W.; Ning, J.; Liang, S.Y. Analytical Prediction of Balling, Lack-of-Fusion and Keyholing Thresholds in Powder Bed Fusion. Appl. Sci. 2021, 11, 12053. [Google Scholar] [CrossRef]

- Carslaw, H.; Jaeger, J. Conduction of Heat in Solids; Chapter 10; Oxford Science Publication: Oxford, UK, 1990. [Google Scholar]

- Wang, W.; Ning, J.; Liang, S.Y. Prediction of lack-of-fusion porosity in laser powder-bed fusion considering boundary conditions and sensitivity to laser power absorption. Int. J. Adv. Manuf. Technol. 2021, 112, 61–70. [Google Scholar] [CrossRef]

- Ye, J.; Rubenchik, A.M.; Crumb, M.F.; Guss, G.; Matthews, M.J. Laser absorption and scaling behavior in powder bed fusion additive manufacturing of metals. In Proceedings of the CLEO: Science and Innovations (pp. JW2A-117), San Jose, CA, USA, 13–18 May 2018; Optical Society of America: Rochester, NY, USA, 2018. [Google Scholar]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Rai, R.; Elmer, J.W.; Palmer, T.A.; DebRoy, T. Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4V, 304L stainless steel and vanadium. J. Phys. D Appl. Phys. 2007, 40, 5753. [Google Scholar] [CrossRef]

- Rubenchik, A.M.; King, W.E.; Wu, S.S. Scaling laws for the additive manufacturing. J. Mater. Process. Technol. 2018, 257, 234–243. [Google Scholar] [CrossRef]

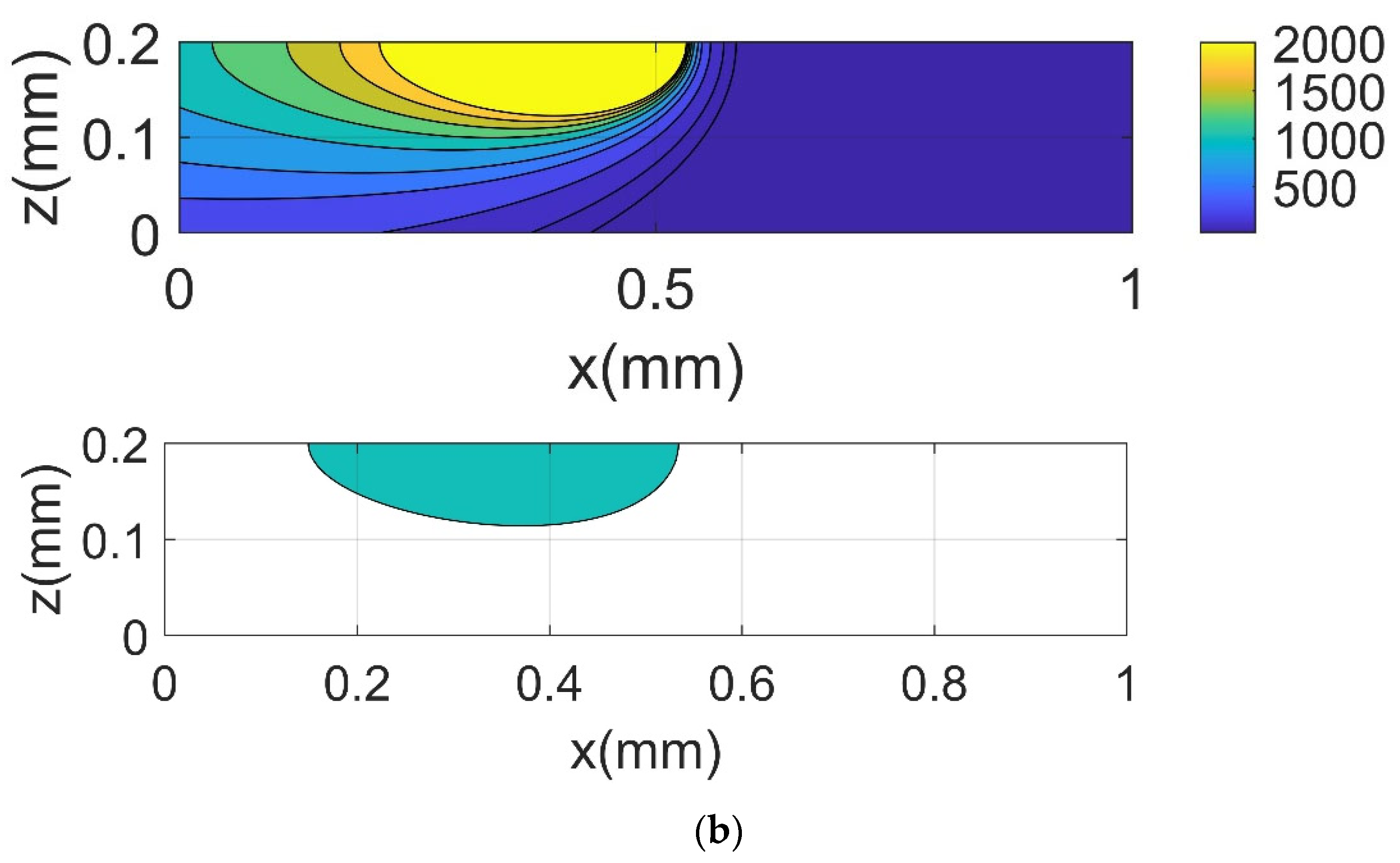

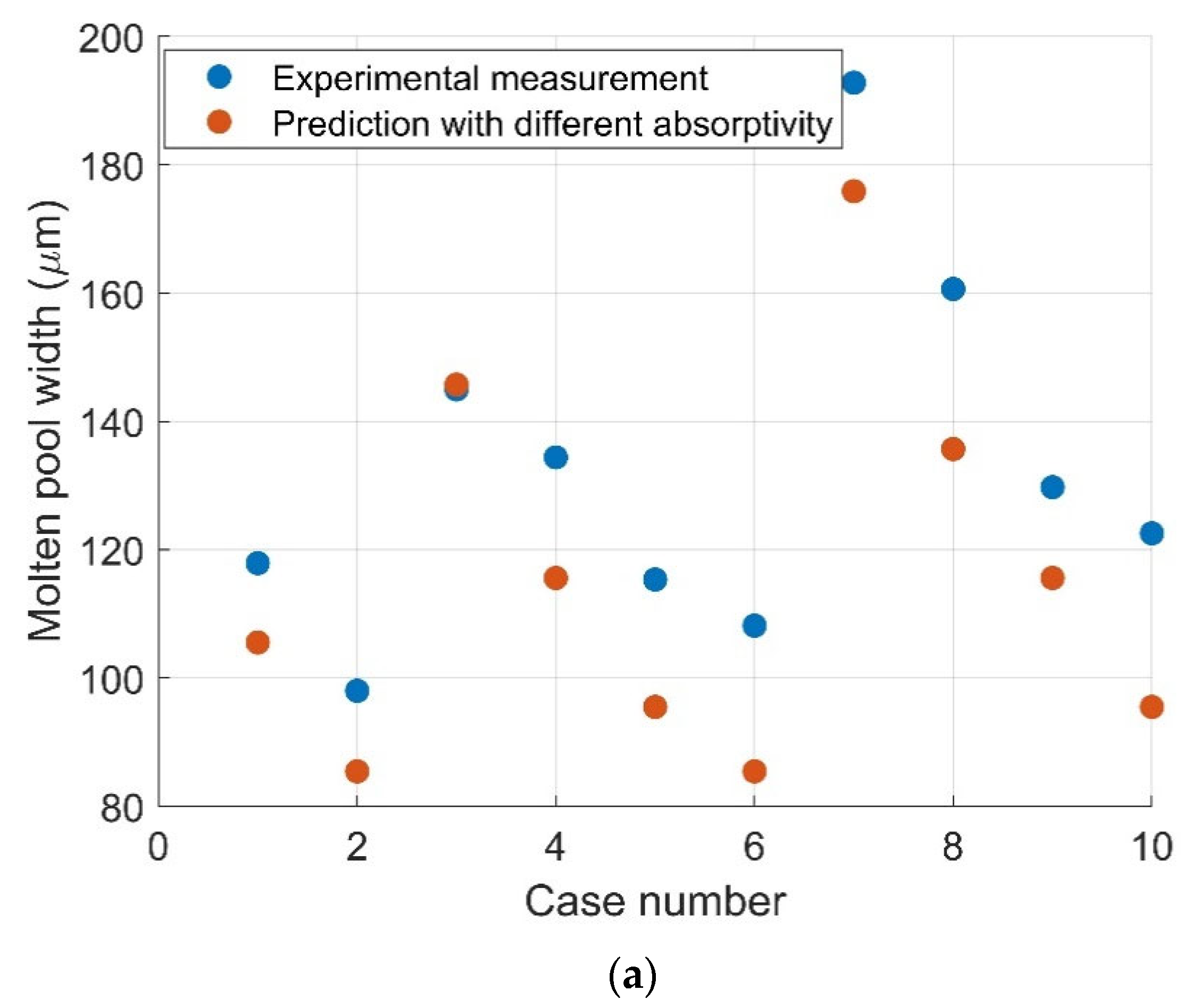

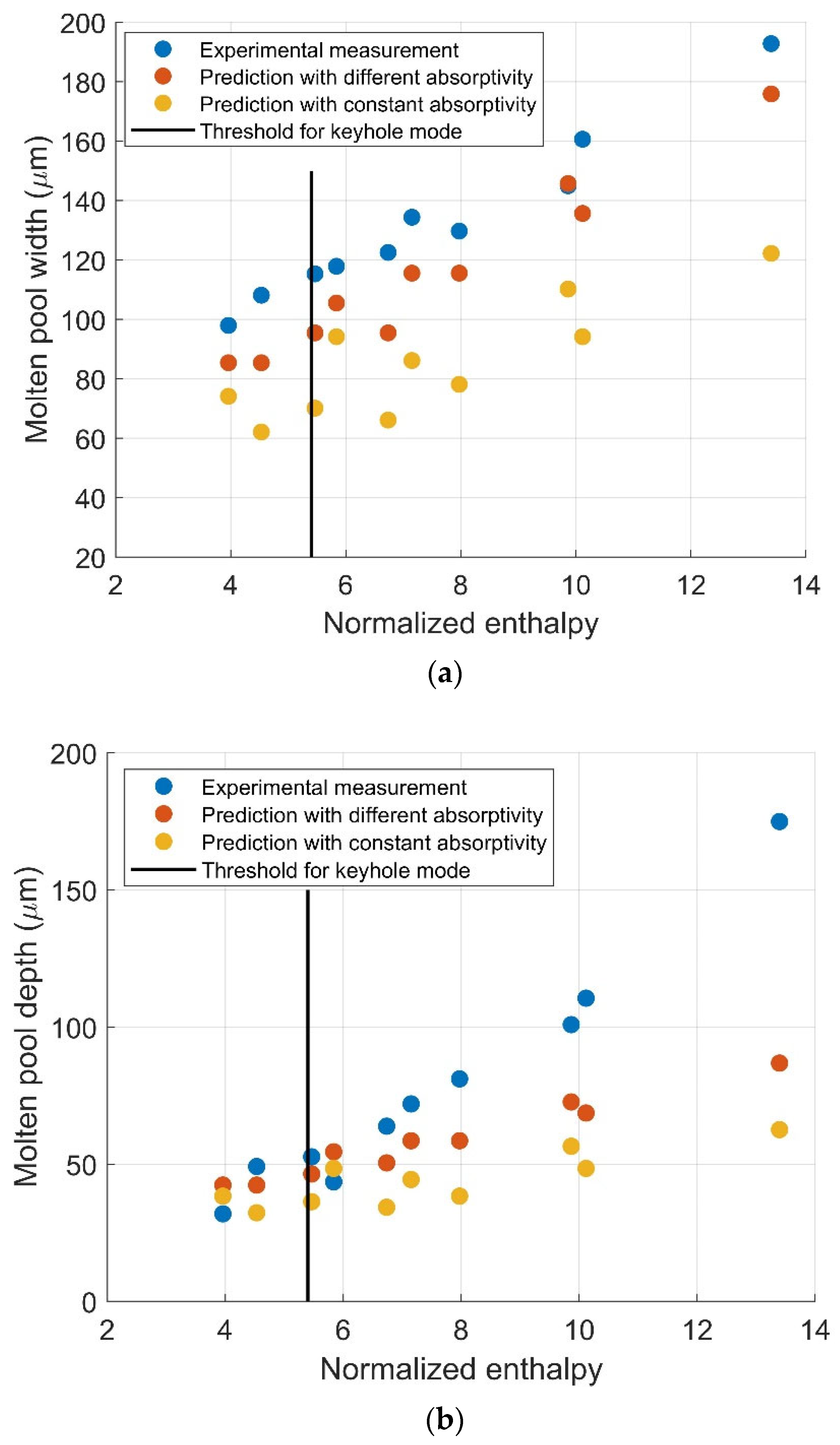

| Case Number | Power (W) | Scanning Speed (mm/s) | Normalized Enthalpy | Calculated Absorptivity | Measured Results | Predicted Results | |||

|---|---|---|---|---|---|---|---|---|---|

| Depth (µm) | Width (µm) | Depth (µm) | Width (µm) | Length (µm) | |||||

| 1 | 100 | 500 | 4.6 | 0.57 | 43.6 | 117.9 | 54.5 | 105.5 | 180.9 |

| 2 | 100 | 750 | 3.7 | 0.48 | 31.9 | 98.0 | 42.4 | 85.4 | 145.7 |

| 3 | 150 | 500 | 6.9 | 0.65 | 100.9 | 145.0 | 72.7 | 145.7 | 291.5 |

| 4 | 150 | 750 | 5.6 | 0.57 | 72.0 | 134.4 | 58.6 | 115.6 | 251.3 |

| 5 | 150 | 1000 | 4.9 | 0.51 | 52.7 | 115.3 | 46.5 | 95.5 | 216.1 |

| 6 | 150 | 1200 | 4.4 | 0.46 | 49.2 | 108.1 | 42.4 | 85.4 | 201.0 |

| 7 | 195 | 500 | 8.9 | 0.68 | 174.9 | 192.8 | 86.9 | 175.9 | 386.9 |

| 8 | 195 | 750 | 7.3 | 0.62 | 110.5 | 160.6 | 68.7 | 135.7 | 351.8 |

| 9 | 195 | 1000 | 6.3 | 0.57 | 81.1 | 129.7 | 58.6 | 115.6 | 316.6 |

| 10 | 195 | 1200 | 5.8 | 0.53 | 63.9 | 122.5 | 50.5 | 95.5 | 286.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Ning, J.; Garmestani, H.; Liang, S.Y. Analytical Prediction of Molten Pool Dimensions in Powder Bed Fusion Considering Process Conditions-Dependent Laser Absorptivity. Appl. Sci. 2022, 12, 11926. https://doi.org/10.3390/app122311926

Wang W, Ning J, Garmestani H, Liang SY. Analytical Prediction of Molten Pool Dimensions in Powder Bed Fusion Considering Process Conditions-Dependent Laser Absorptivity. Applied Sciences. 2022; 12(23):11926. https://doi.org/10.3390/app122311926

Chicago/Turabian StyleWang, Wenjia, Jinqiang Ning, Hamid Garmestani, and Steven Y. Liang. 2022. "Analytical Prediction of Molten Pool Dimensions in Powder Bed Fusion Considering Process Conditions-Dependent Laser Absorptivity" Applied Sciences 12, no. 23: 11926. https://doi.org/10.3390/app122311926

APA StyleWang, W., Ning, J., Garmestani, H., & Liang, S. Y. (2022). Analytical Prediction of Molten Pool Dimensions in Powder Bed Fusion Considering Process Conditions-Dependent Laser Absorptivity. Applied Sciences, 12(23), 11926. https://doi.org/10.3390/app122311926