Development of a Multi-Sensor Concept for Real-Time Temperature Measurement at the Cutting Insert of a Single-Lip Deep Hole Drilling Tool

Abstract

:1. Introduction

2. Materials and Methods

2.1. Determination of Thermal Properties

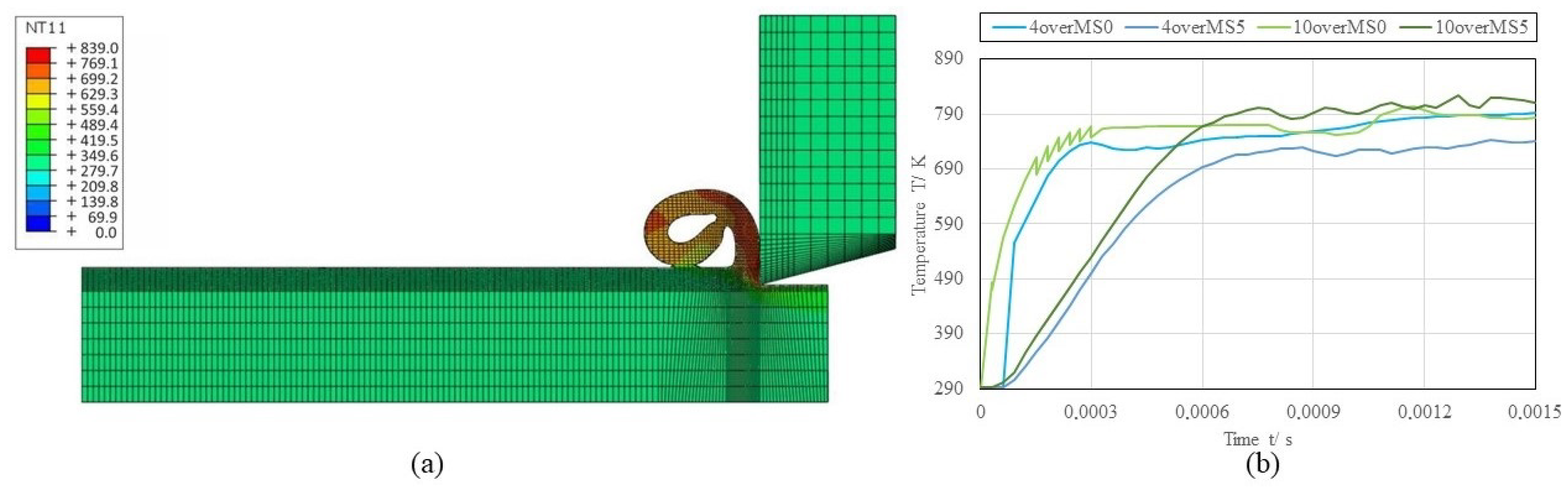

2.2. CEL Simulation of the SLD Process

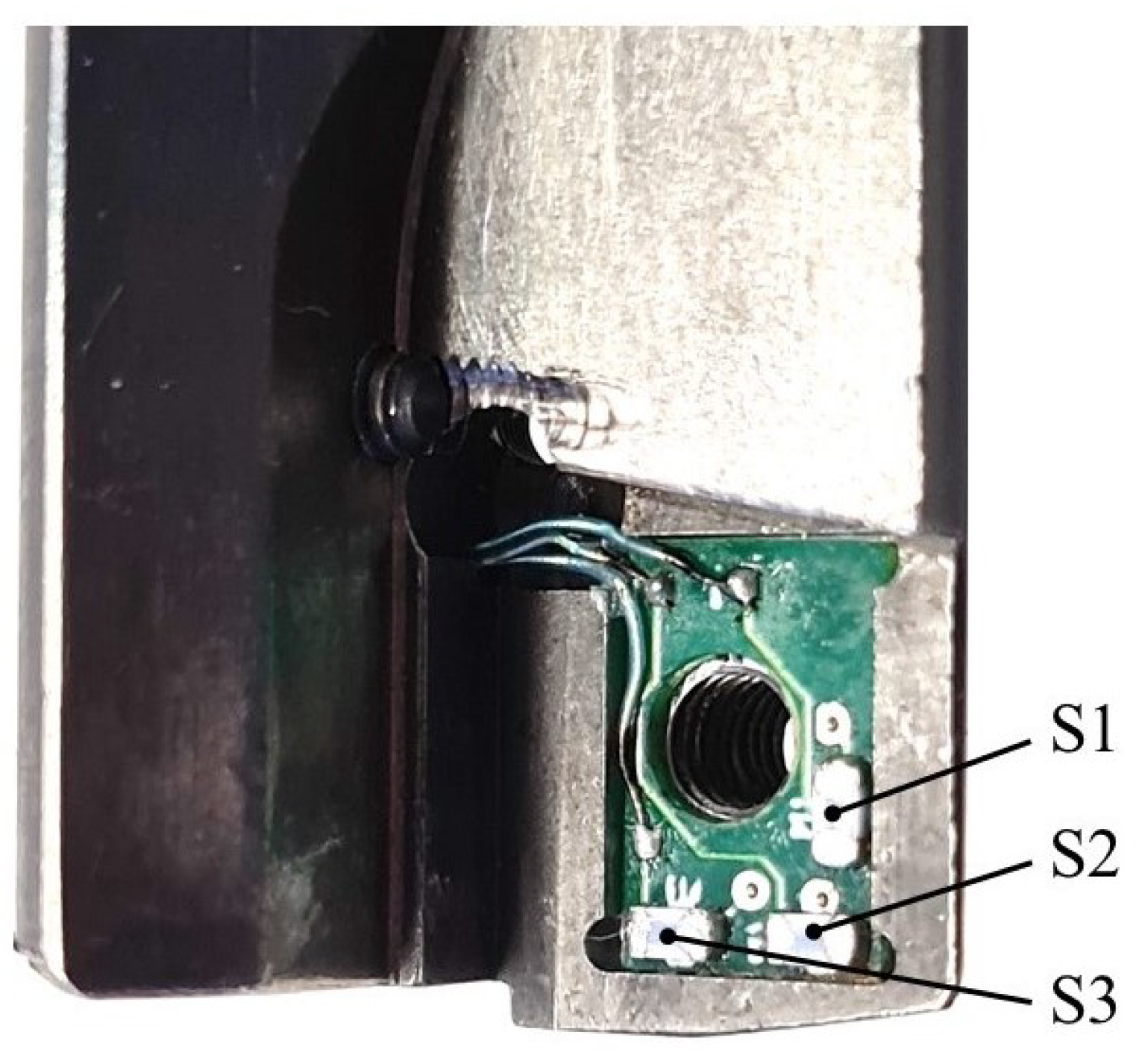

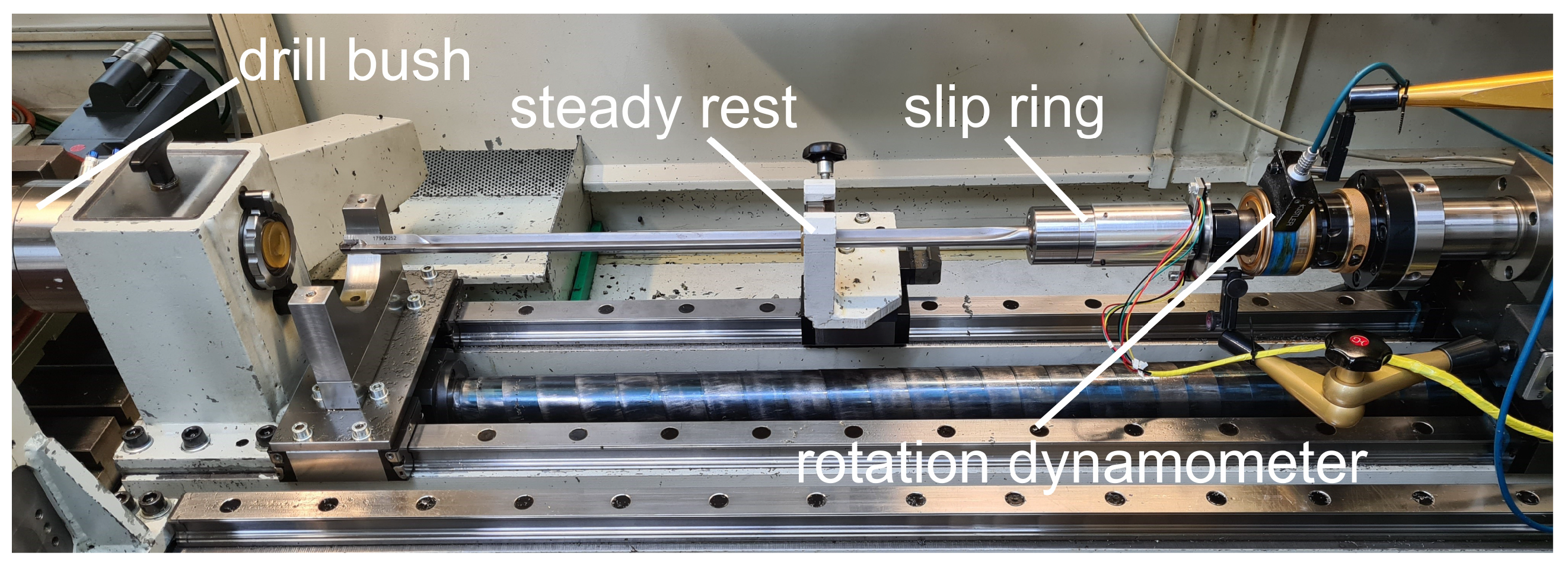

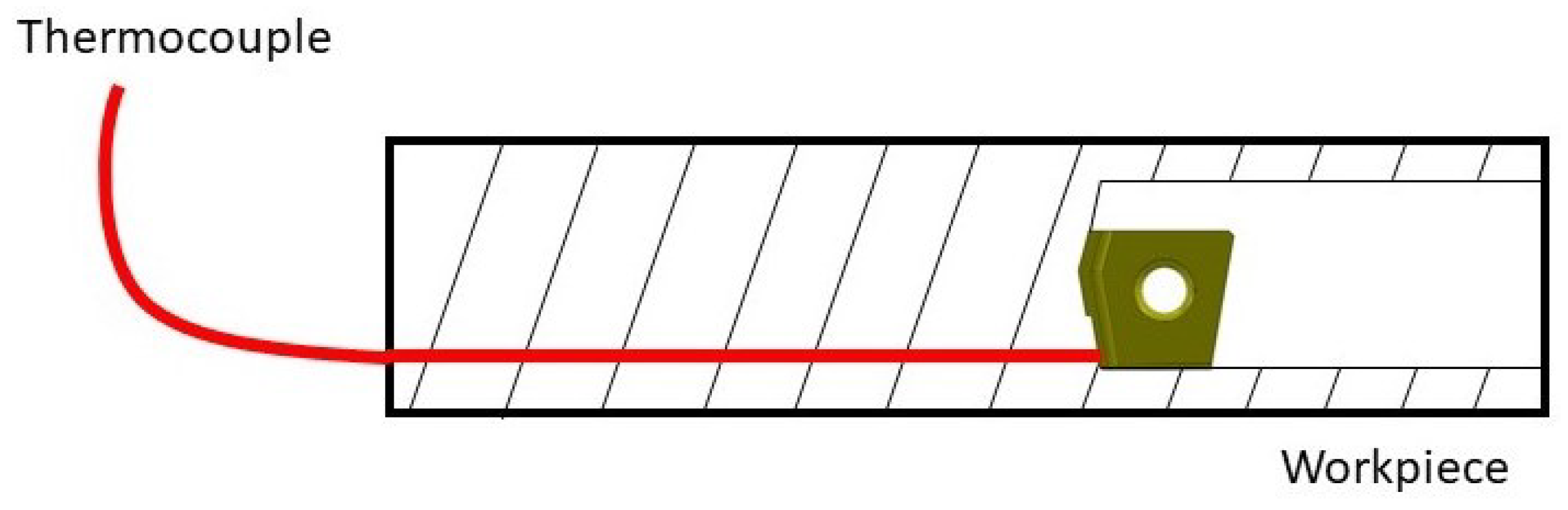

2.3. Experimental Study

2.4. Analytical Model

3. Results

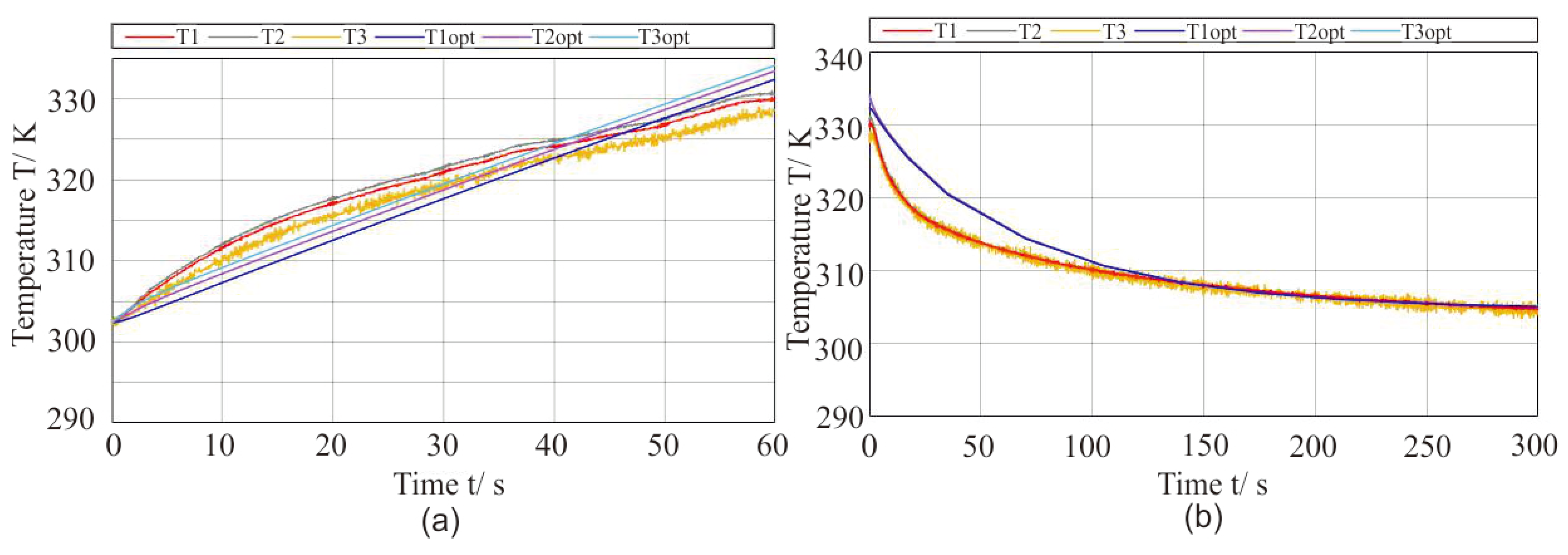

3.1. Thermal Parameters of the Sensor Integrated Tool

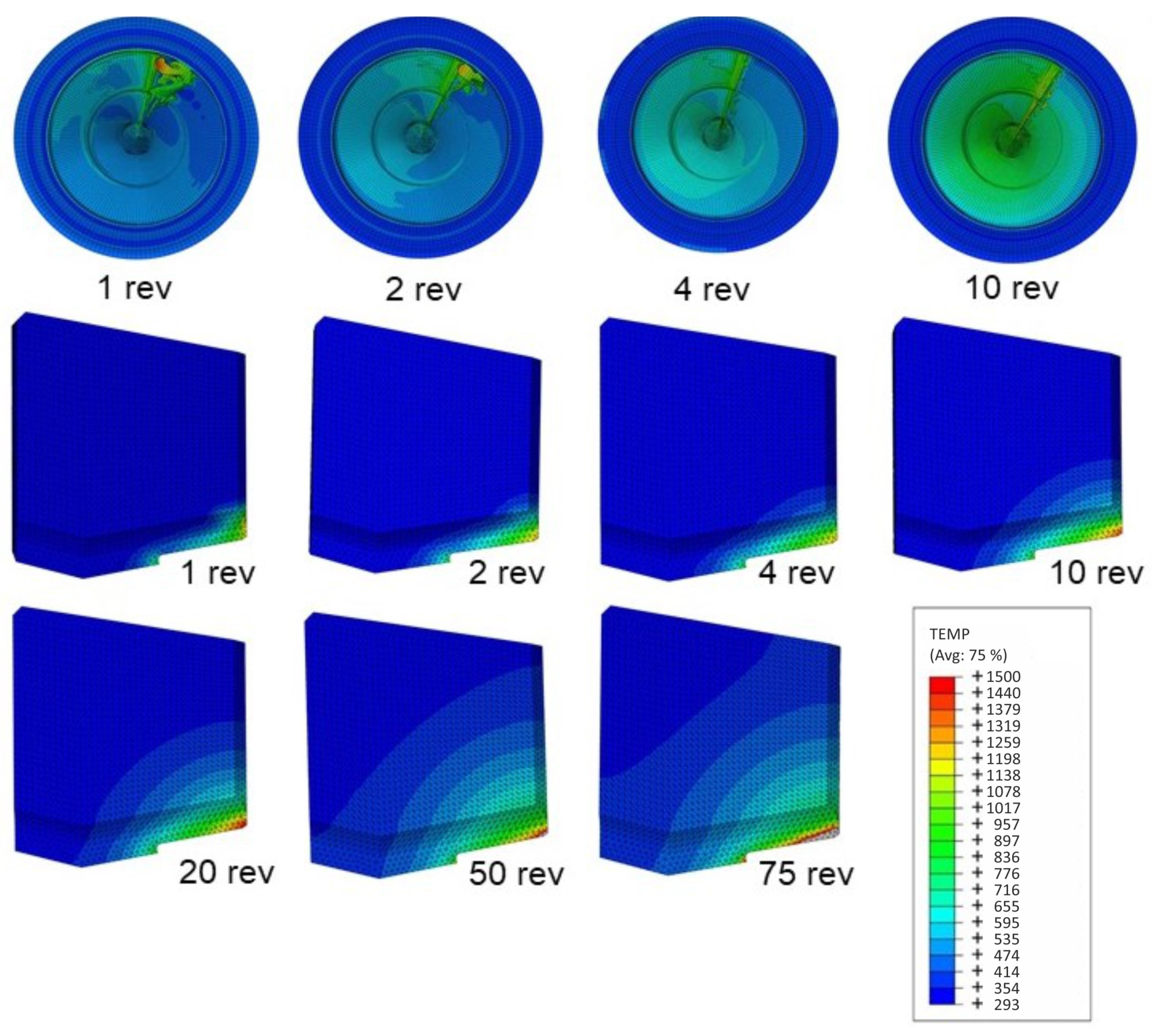

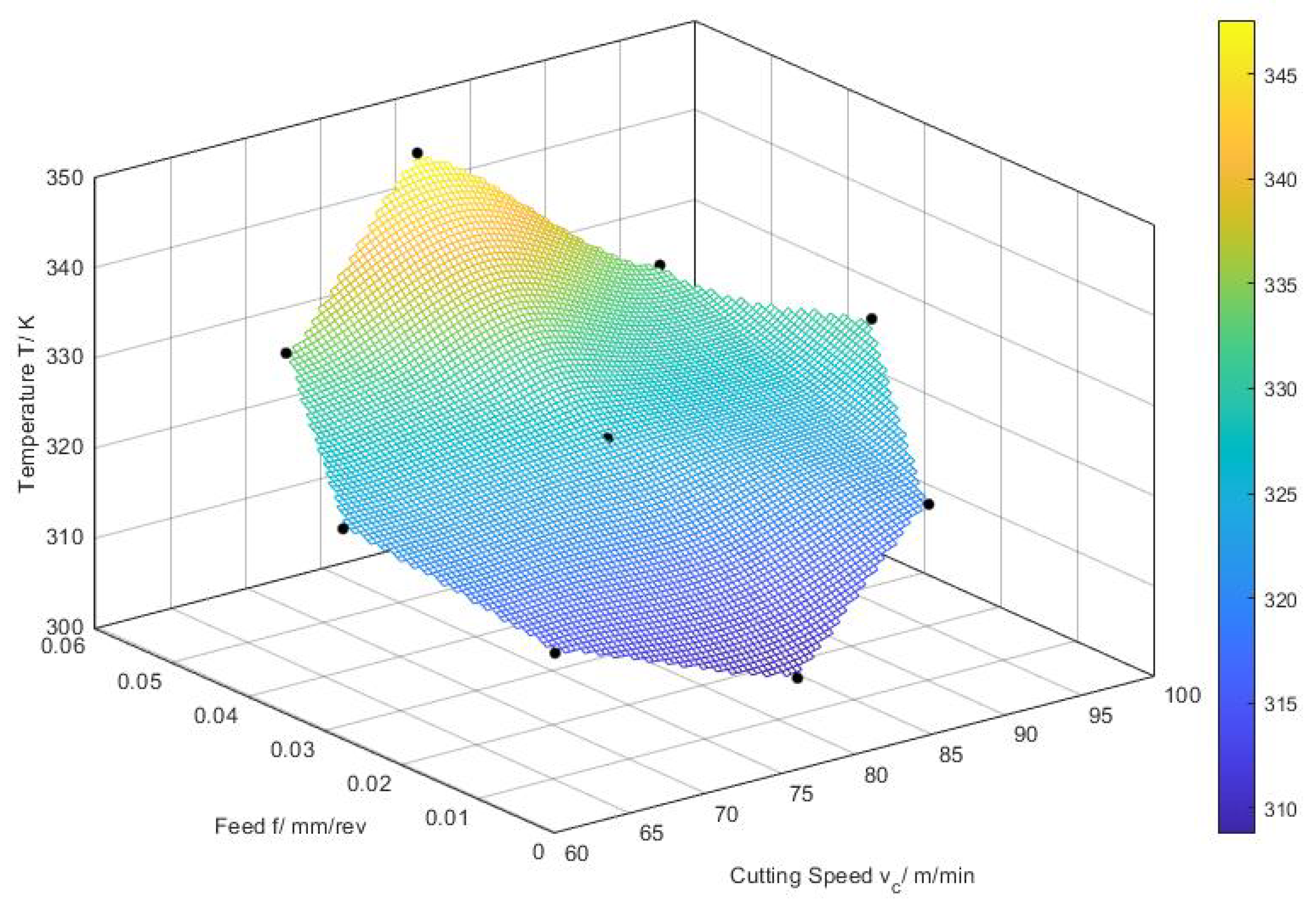

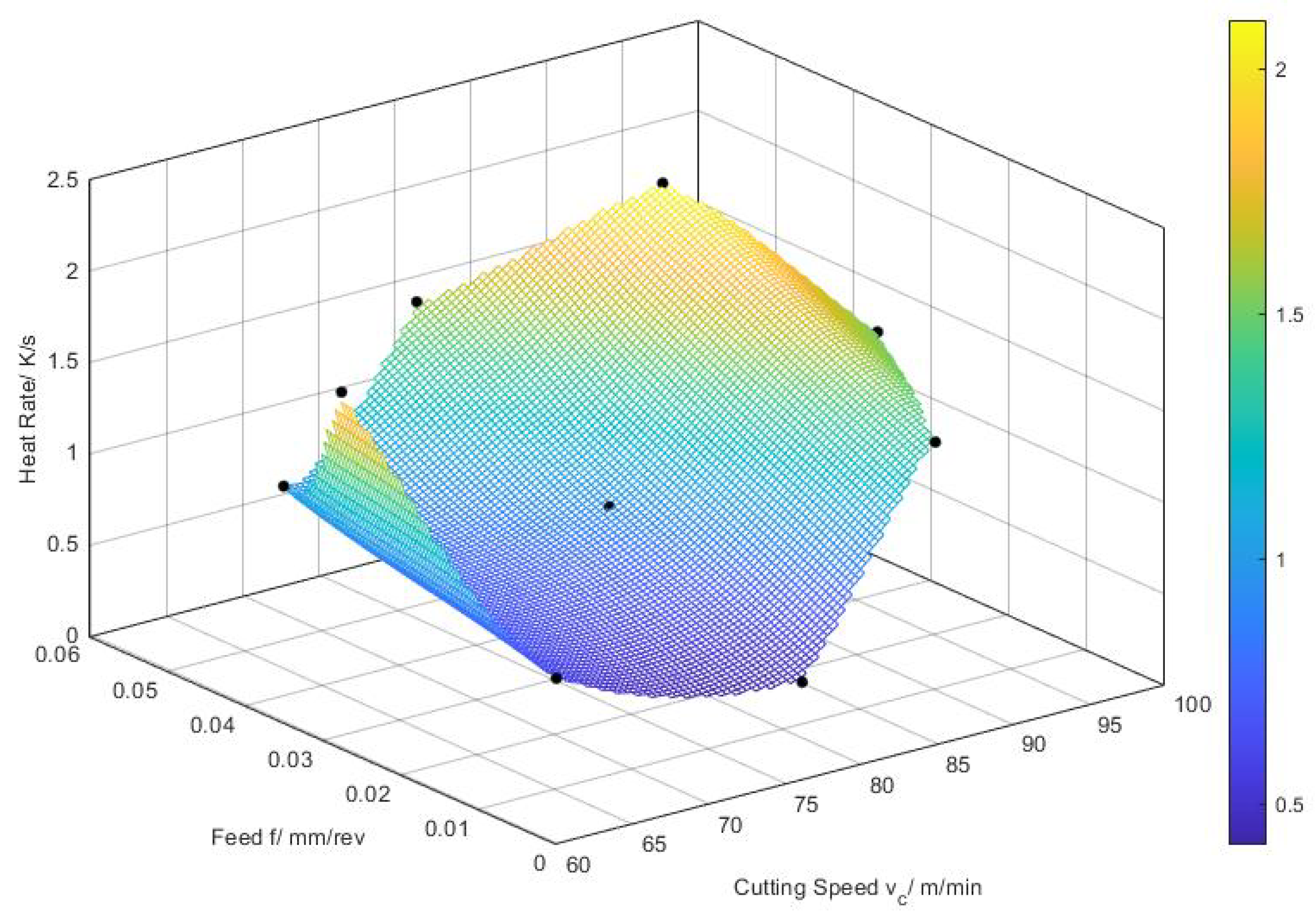

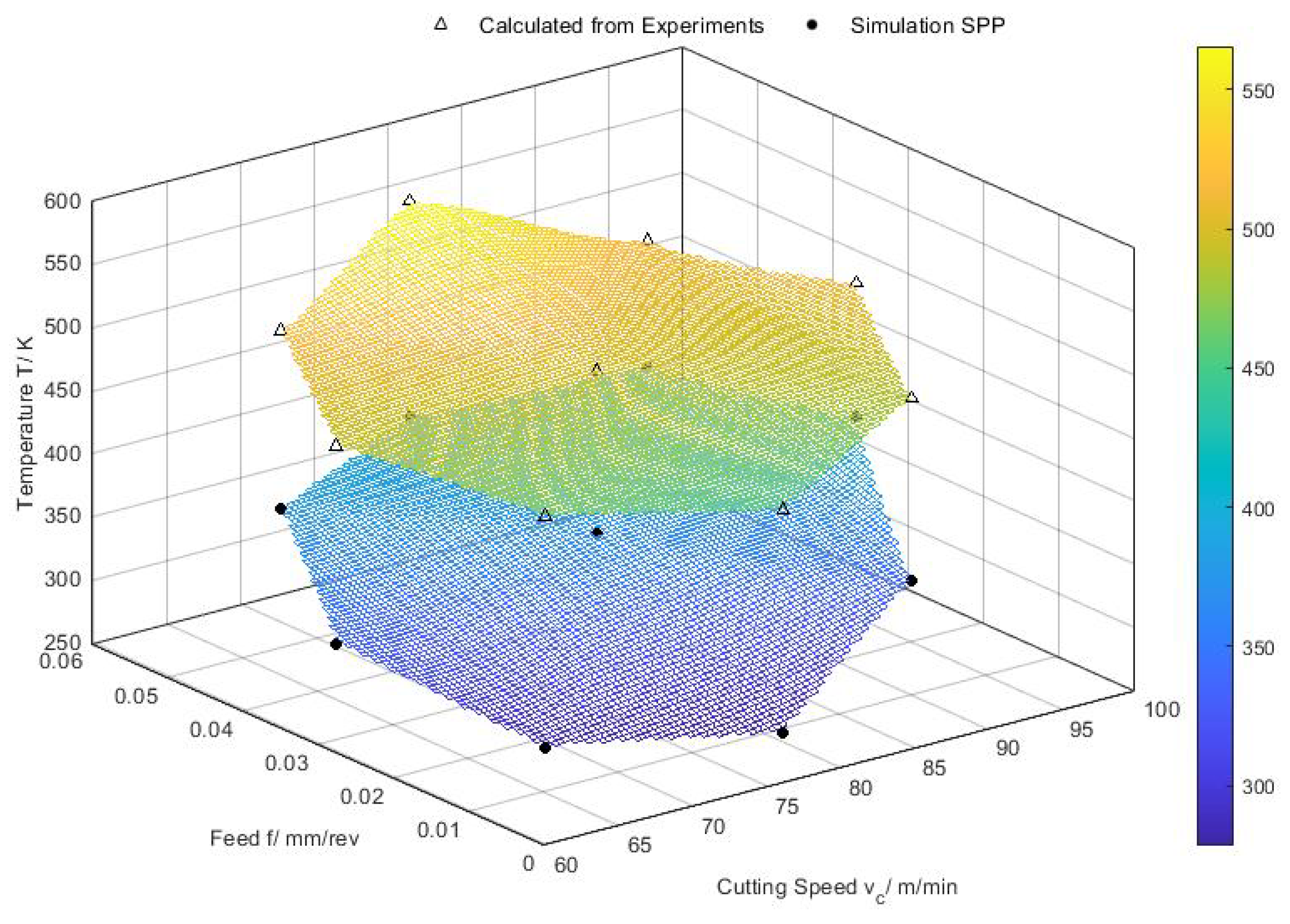

3.2. Temperature Distribution from CEL-Simulation

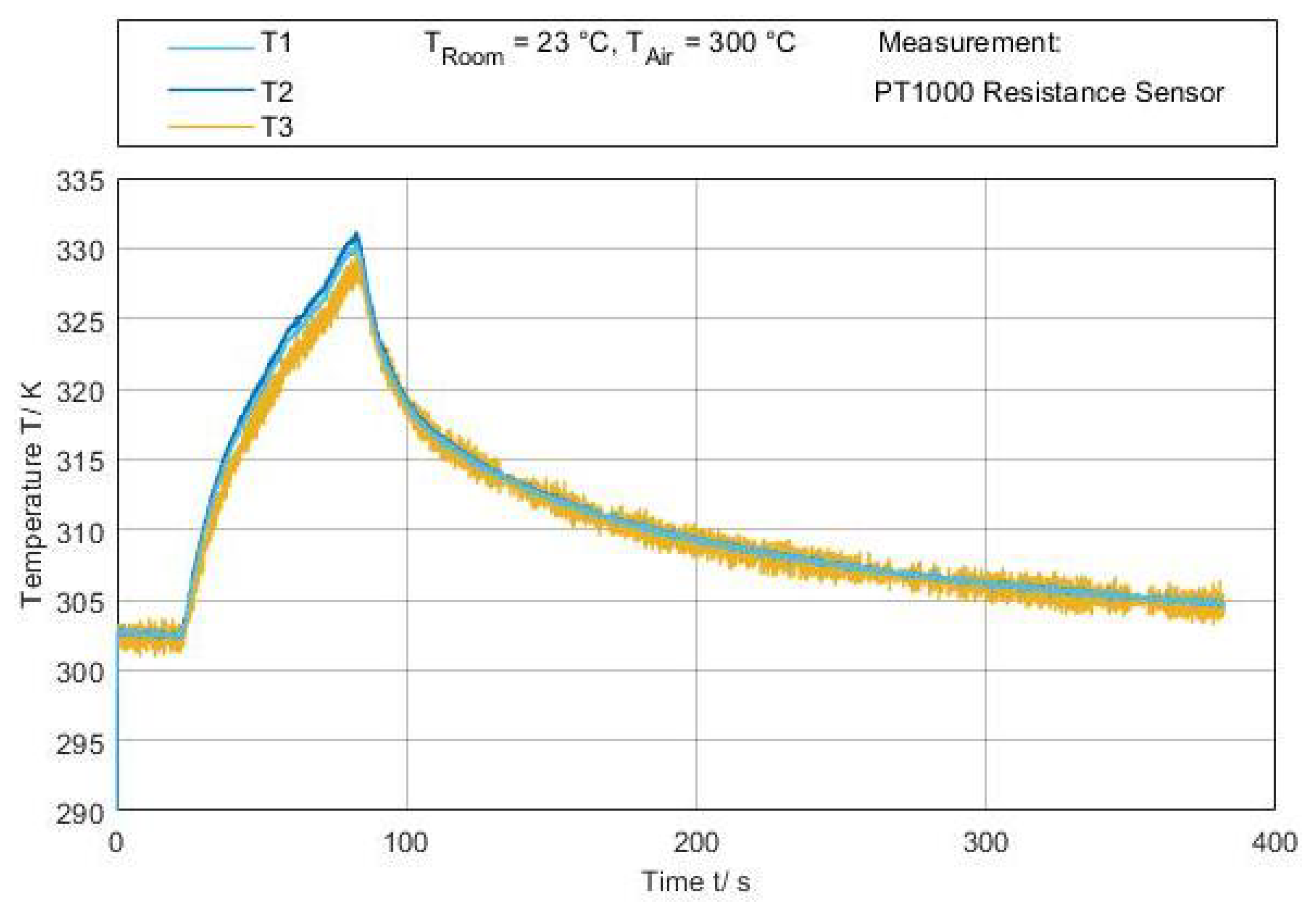

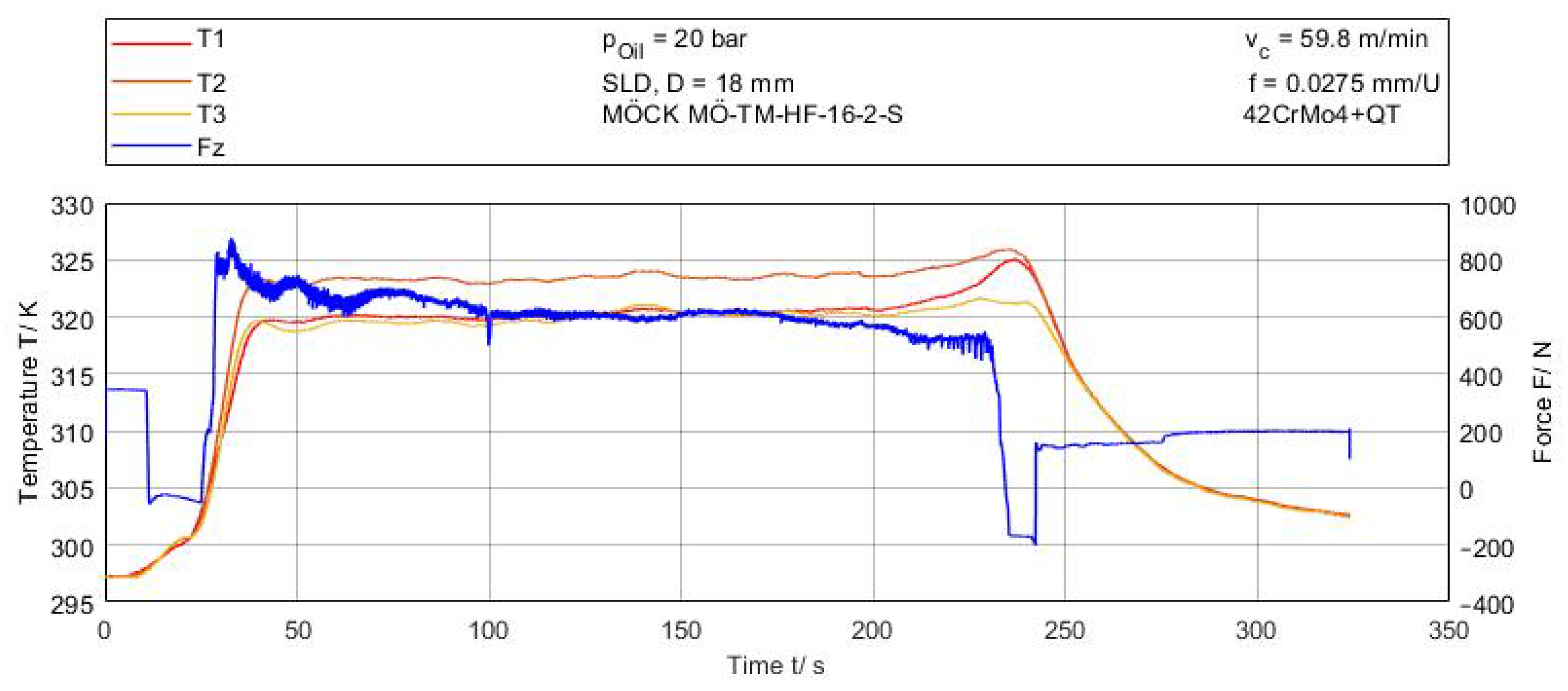

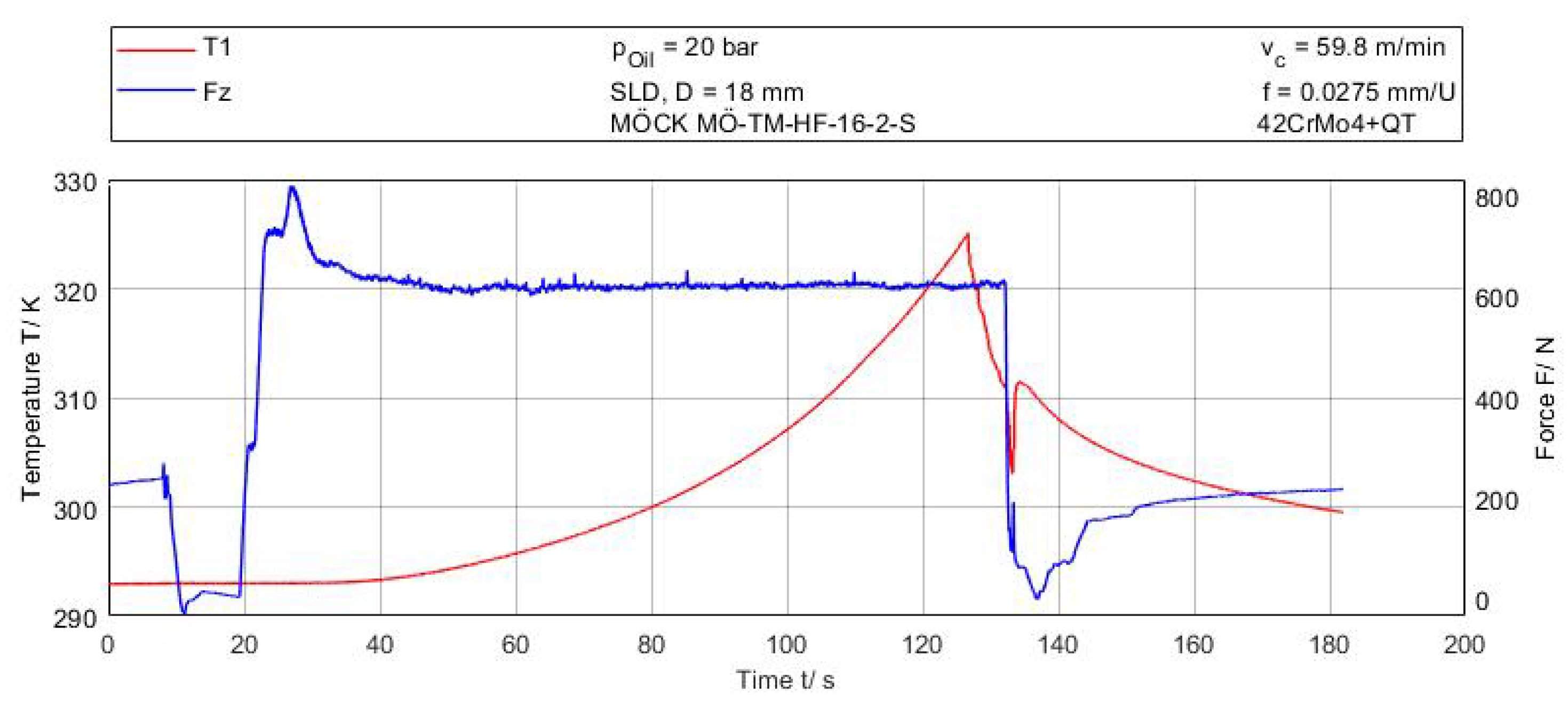

3.3. Experimental Temperature Measurement

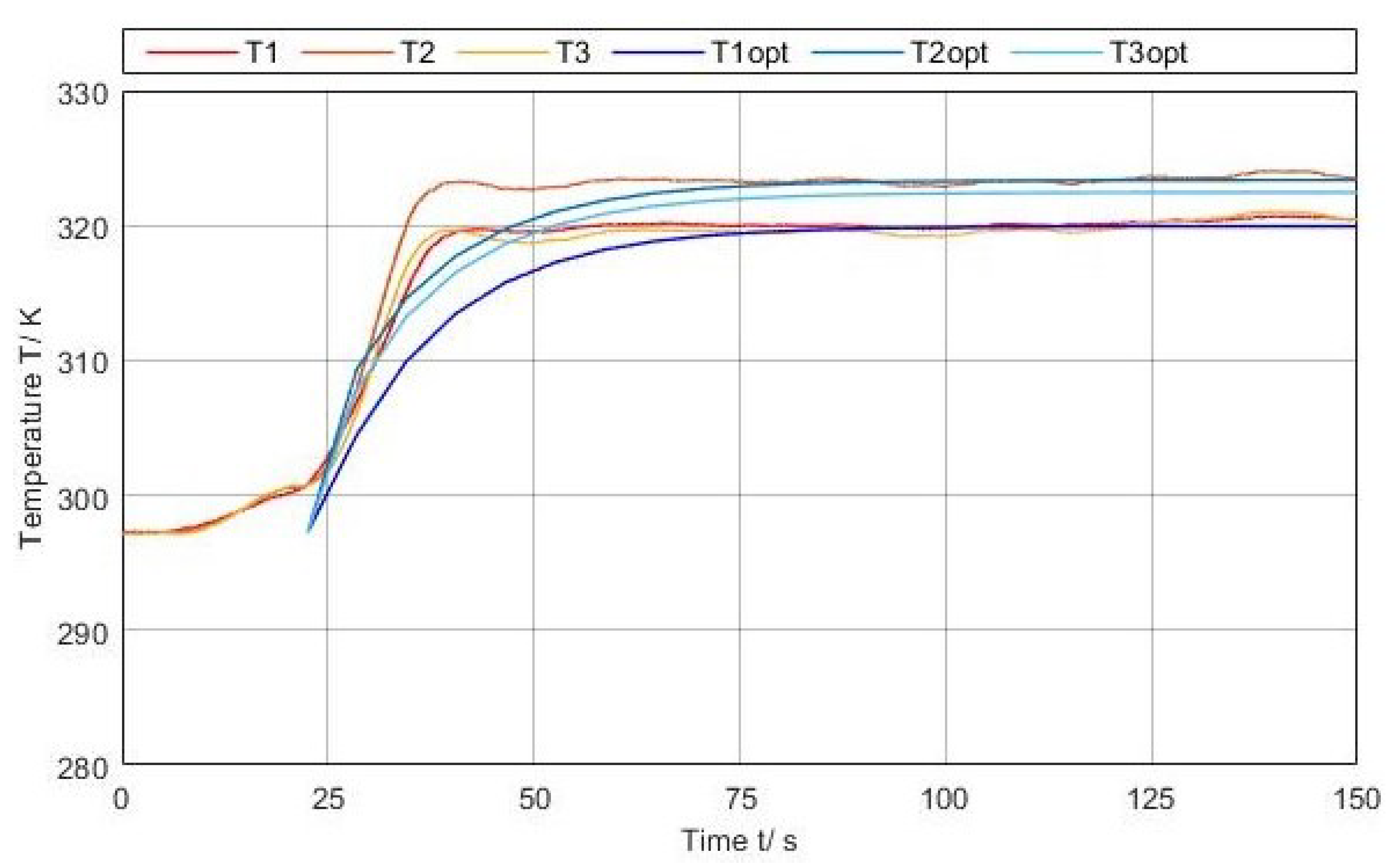

3.4. Calculation of Actual Tool Temperatures

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CEL | Coupled Eulerian–Lagrangian |

| DFG | Deutsche Forschungsgesellschaft |

| JC | Johnson–Cook |

| MQL | Minimum Quantity Lubrication |

| MS | Mass Scaling |

| PTC | Positive Temperature Coefficient |

| RTD | Resistance Temperature Detector |

| SLD | Single-Lip Deep Hole Drilling |

| A | Area |

| Heat transfer coefficient | |

| Acoustic Wave Speed | |

| Specific Heat | |

| l | Length |

| D | Diameter |

| E | Young’s Modulus |

| f | Feed |

| k | Conductivity |

| L | Element Length |

| Poisson’s Ratio | |

| Volumetric Flow Rate | |

| Density | |

| s | Distance |

| t | Time |

| T | Temperature |

| Diffusion Angle | |

| v | Speed |

| Cutting Speed | |

| Flow Rate | |

| Thermal Expansion |

References

- Biermann, D.; Bleicher, F.; Heisel, U.; Klocke, F.; Möhring, H.C.; Shih, A. Deep hole drilling. CIRP Ann. 2018, 67, 673–694. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 3208: Tiefbohren mit Einlippenbohrern; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2014. [Google Scholar]

- Wittkop, S. Einlippentiefbohren Nichtrostender Stähle; Schriftenreihe des ISF; Vulkan-Verl.: Essen, Germany, 2007; Volume 40. [Google Scholar]

- Oezkaya, E.; Baumann, A.; Michel, S.; Schnabel, D.; Eberhard, P.; Biermann, D. Cutting fluid behavior under consideration of chip formation during micro single-lip deep hole drilling of Inconel 718. Int. J. Model. Simul. 2022, 1–15. [Google Scholar] [CrossRef]

- Davies, M.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A. On The Measurement of Temperature in Material Removal Processes. CIRP Ann. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Wegert, R.; Alhamede, M.A.; Guski, V.; Schmauder, S.; Möhring, H.C. Sensor-Integrated Tool for Self-Optimizing Single-Lip Deep Hole Drilling. Int. J. Autom. Technol. 2022, 16, 126–137. [Google Scholar] [CrossRef]

- Möhring, H.C.; Kushner, V.; Storchak, M.; Stehle, T. Temperature calculation in cutting zones. CIRP Ann. 2018, 67, 61–64. [Google Scholar] [CrossRef]

- Menze, C.; Wegert, R.; Reeber, T.; Erhardt, F.; Moehring, H.C.; Stegmann, J. Numerical methods for the simulation of segmented chips and experimental validation in machining of Ti-6al-4v. MM Sci. J. 2021, 2021, 5052–5060. [Google Scholar] [CrossRef]

- Wegert, R.; Guski, V.; Möhring, H.C.; Schmauder, S. Determination of thermo-mechanical quantities with a sensor-integrated tool for single lip deep hole drilling. Procedia Manuf. 2020, 52, 73–78. [Google Scholar] [CrossRef]

- Fandiño, D.; Guski, V.; Wegert, R.; Möhring, H.C.; Schmauder, S. Simulation Study on Single-Lip Deep Hole Drilling Using Design of Experiments. J. Manuf. Mater. Process. 2021, 5, 44. [Google Scholar] [CrossRef]

- Guski, V.; Wegert, R.; Schmauder, S.; Möhring, H.C. Correlation between subsurface properties, the thermo-mechanical process conditions and machining parameters using the CEL simulation method. Procedia CIRP 2022, 108, 100–105. [Google Scholar] [CrossRef]

- Nickel, J.; Baak, N.; Volke, P.; Walther, F.; Biermann, D. Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components. J. Manuf. Mater. Process. 2021, 5, 120. [Google Scholar] [CrossRef]

- Nickel, J.; Baak, N.; Walther, F.; Biermann, D. Investigation of the thermomechanical loads on the bore surface during single-lip deep hole drilling of steel components. Procedia CIRP 2022, 108, 805–810. [Google Scholar] [CrossRef]

- Schermann, T.; Marsolek, J.; Schmidt, C.; Fleischer, J. Aspects of the simulation of a cutting process with ABAQUS/Explicit including the interaction between the cutting process and the dynamic behavior of the dynamic behavior of the machine tool. In Proceedings of the 9th CIRP International Workshop on Modeling of Machining Operations, Bled, Slovenia, 11–12 May 2006. [Google Scholar]

- Hammelmüller, F.; Zehetner, C. Increasing numerical efficiency in coupled Eulerian-Lagrangian metal forming simulations. In Proceedings of the XIII International Conference on Computational Plasticity. Fundamentals and Applications, COMPLAS XIII, Barcelona, Spain, 1–3 September 2015. [Google Scholar]

- Kurgin, S.; Dasch, J.; Simon, D.; Barber, G.; Zou, Q. Evaluation of the convective heat transfer coefficient for minimum quantity lubrication (MQL). Ind. Lubr. Tribol. 2012, 64, 376–386. [Google Scholar] [CrossRef]

- Nadolny, Z.; Dombek, G. Thermal properties of mixtures of mineral oil and natural ester in terms of their application in the transformer. E3S Web Conf. 2017, 19, 01040. [Google Scholar] [CrossRef] [Green Version]

| Density / kg/m | Young’s Modulus E/ MPa | Poissonsratio / - | Thermal Expansion / m/mK | Conductivity k/ W/mK | Specific Heat / J/kgK |

|---|---|---|---|---|---|

| 15,700 | 524,000 | 0.23 | 6.3 | 82.24 | 579.45 |

| Young’s Modulus E/ MPa | Thermal Expansion / m/mK | Conductivity k/ W/mK | Specific Heat / J/kgK | Temperature T/ K |

|---|---|---|---|---|

| 217,000 | 10.8 | - | 291.24 | 173 |

| 213,000 | 11.7 | - | 354.03 | 273 |

| 212,000 | 11.9 | 41.7 | 361.89 | 293 |

| 207,000 | 12.5 | 43.4 | 389.36 | 373 |

| 199,000 | 13.0 | 43.2 | 418.41 | 473 |

| 192,000 | 13.6 | 41.4 | 445.88 | 573 |

| 184,000 | 14.1 | 39.1 | 479.64 | 673 |

| 175,000 | 14.5 | 36.7 | 531.45 | 773 |

| 164,000 | 14.9 | 34.1 | 610.73 | 873 |

| 69,000 | 14.9 | 34.1 | 610.73 | 1773 |

| A/MPa | B/MPa | C/ - | n/- | m/- | T/K | T/K |

|---|---|---|---|---|---|---|

| 595 | 580 | 0.023 | 0.133 | 1.03 | 1793 | 300 |

| /- | /- | /- | /- | /- | /K | /K | /1/s |

|---|---|---|---|---|---|---|---|

| 011 | 0.04 | −0.02 | 1 | 0.12 | 1793 | 300 | 1 |

| Nr. | Cutting Speed /m/min | Feed f/mm/rev |

|---|---|---|

| 1 | 59.82 | 0.02750 |

| 2 | 77.50 | 0.02750 |

| 3 | 90.00 | 0.04500 |

| 4 | 77.50 | 0.00275 |

| 5 | 95.18 | 0.02750 |

| 6 | 65.00 | 0.01000 |

| 7 | 65.00 | 0.04500 |

| 8 | 90.00 | 0.01000 |

| 9 | 77.50 | 0.05225 |

| Specific Heat /J/kgK | Conductivity k/W/mK | Heat Transfer Coefficient /W/mm K |

|---|---|---|

| 436 | 106.1 | 313.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramme, J.; Wegert, R.; Guski, V.; Schmauder, S.; Moehring, H.-C. Development of a Multi-Sensor Concept for Real-Time Temperature Measurement at the Cutting Insert of a Single-Lip Deep Hole Drilling Tool. Appl. Sci. 2022, 12, 7095. https://doi.org/10.3390/app12147095

Ramme J, Wegert R, Guski V, Schmauder S, Moehring H-C. Development of a Multi-Sensor Concept for Real-Time Temperature Measurement at the Cutting Insert of a Single-Lip Deep Hole Drilling Tool. Applied Sciences. 2022; 12(14):7095. https://doi.org/10.3390/app12147095

Chicago/Turabian StyleRamme, Johannes, Robert Wegert, Vinzenz Guski, Siegfried Schmauder, and Hans-Christian Moehring. 2022. "Development of a Multi-Sensor Concept for Real-Time Temperature Measurement at the Cutting Insert of a Single-Lip Deep Hole Drilling Tool" Applied Sciences 12, no. 14: 7095. https://doi.org/10.3390/app12147095

APA StyleRamme, J., Wegert, R., Guski, V., Schmauder, S., & Moehring, H.-C. (2022). Development of a Multi-Sensor Concept for Real-Time Temperature Measurement at the Cutting Insert of a Single-Lip Deep Hole Drilling Tool. Applied Sciences, 12(14), 7095. https://doi.org/10.3390/app12147095