Mathematical Model for Establishing the Time-Dependent Behavior of Rocks by the Gradient Method

Abstract

1. Introduction

- -

- The unsatisfactory state of the stability of the mining works at Suior is the result of the work profile’s shape not being correlated with the geomechanical and geomining conditions of their location;

- -

- The mining works with straight walls, vaulted ceiling and an unsupported floor were mostly made in rocks with pronounced tendencies towards an alteration and the swelling of the floors. This situation was often encountered at the 900 m, 850 m and 800 m horizons;

- -

- Profiles with straight walls, a vaulted ceiling and an unsupported floor located in Suior conditions are only applicable in directional galleries made on the vein and in areas where the vein has a high resistance;

- -

- In conditions where the rocks comprise kaolinized andesite intercalations and observations shows a tendency for the floors to swell, and circular and horseshoe-shaped profiles with a supported floor were required.

2. General Context of the Research

3. Deformation Characteristics in Time of Altered Andesite

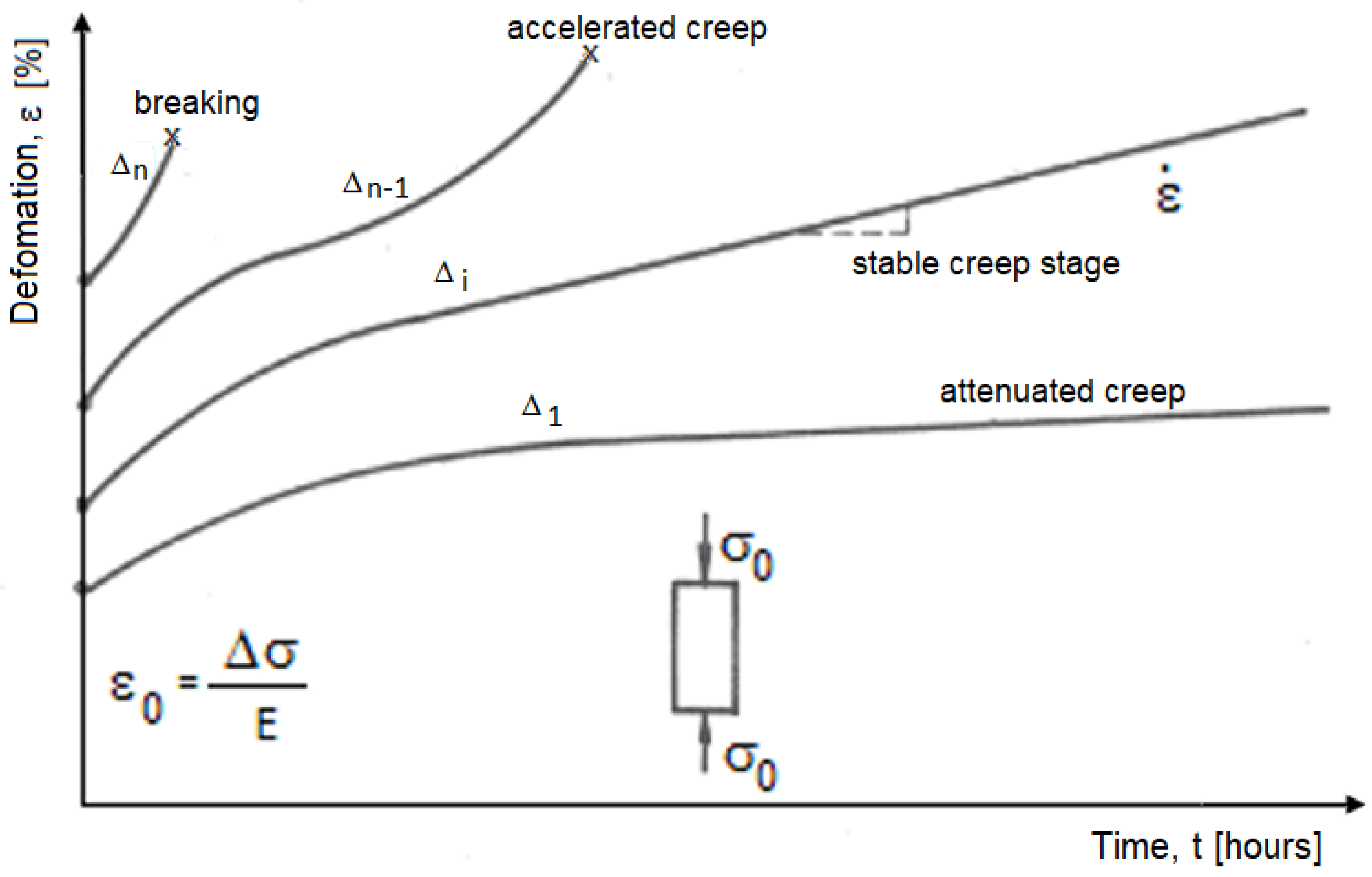

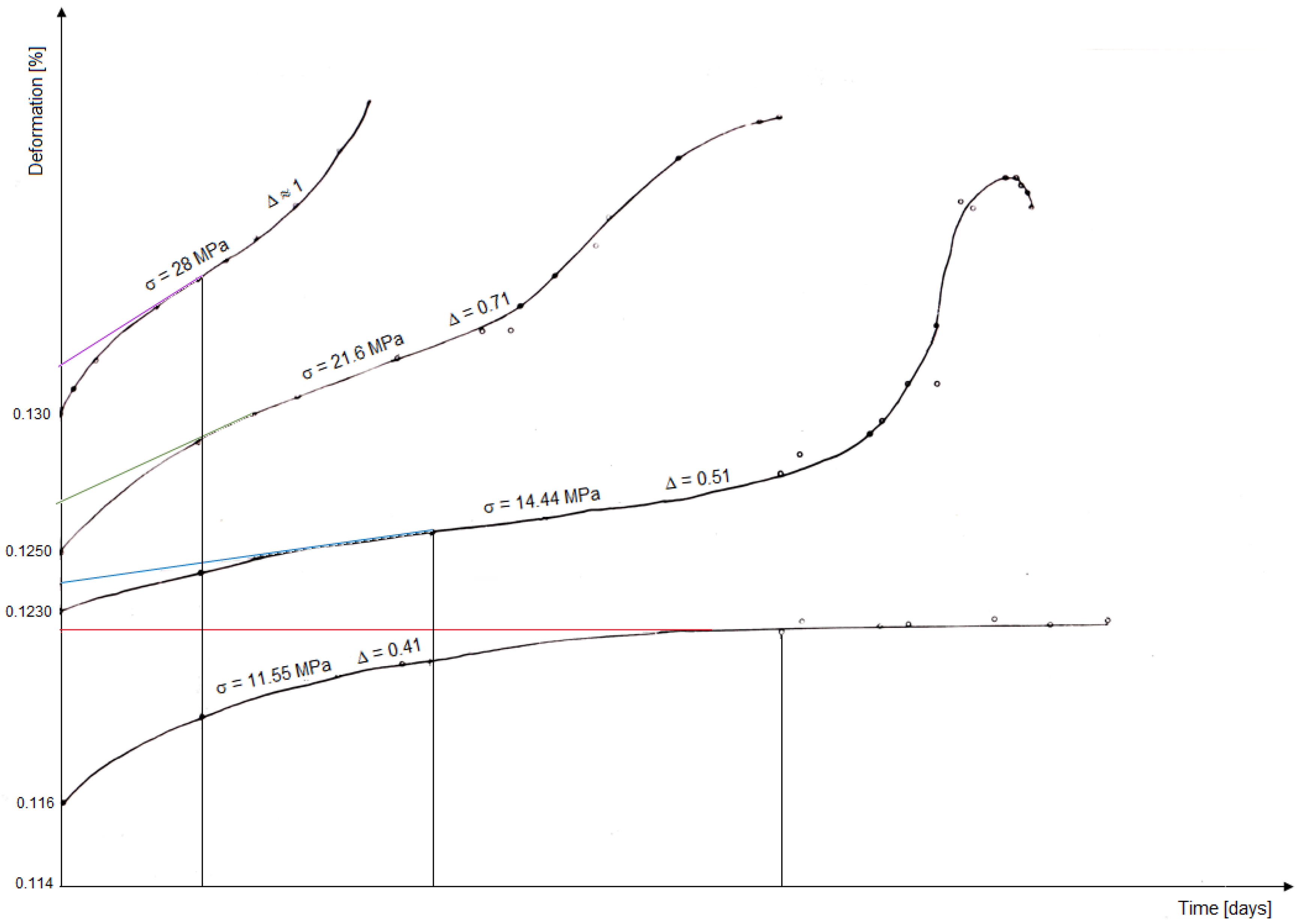

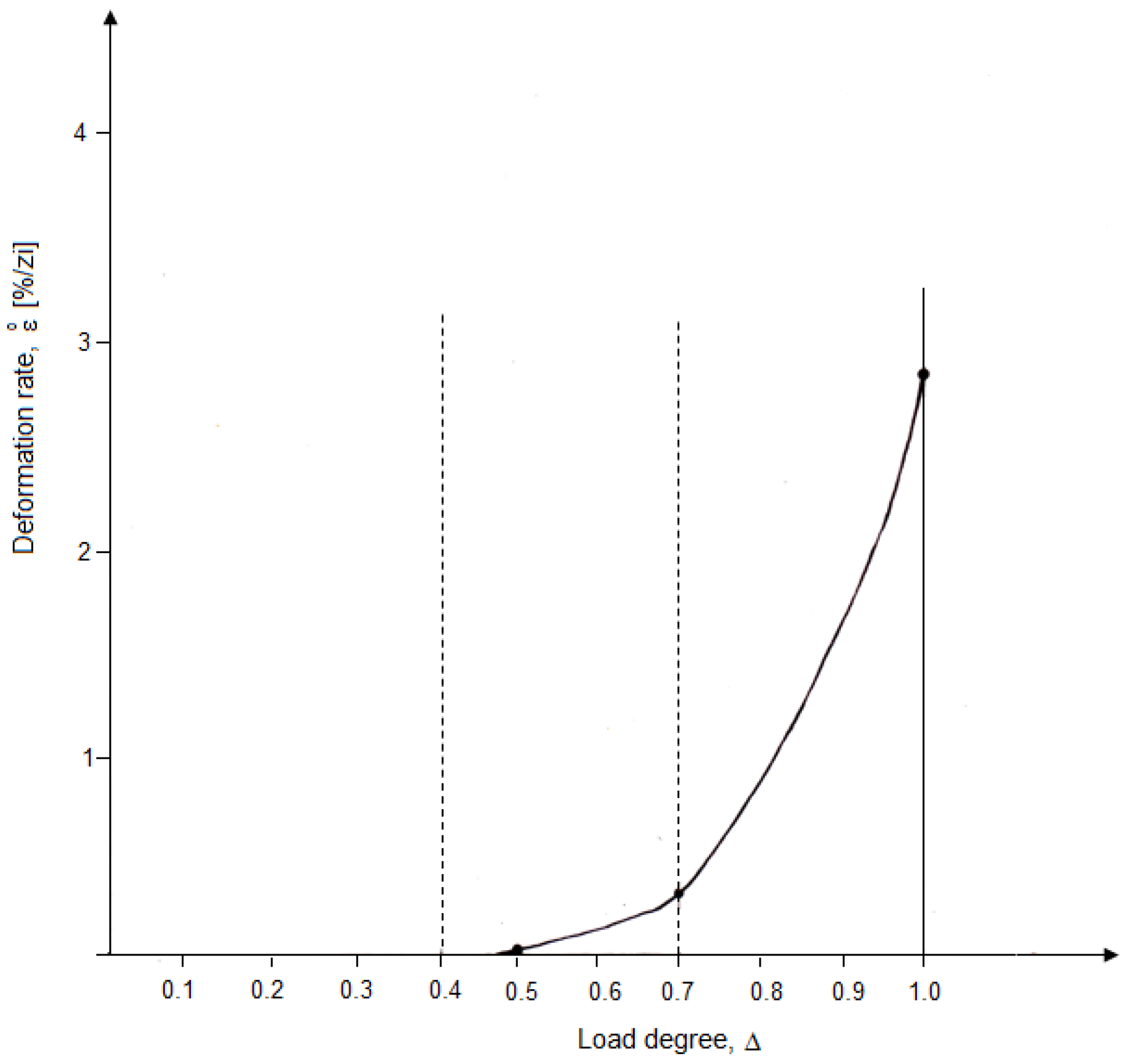

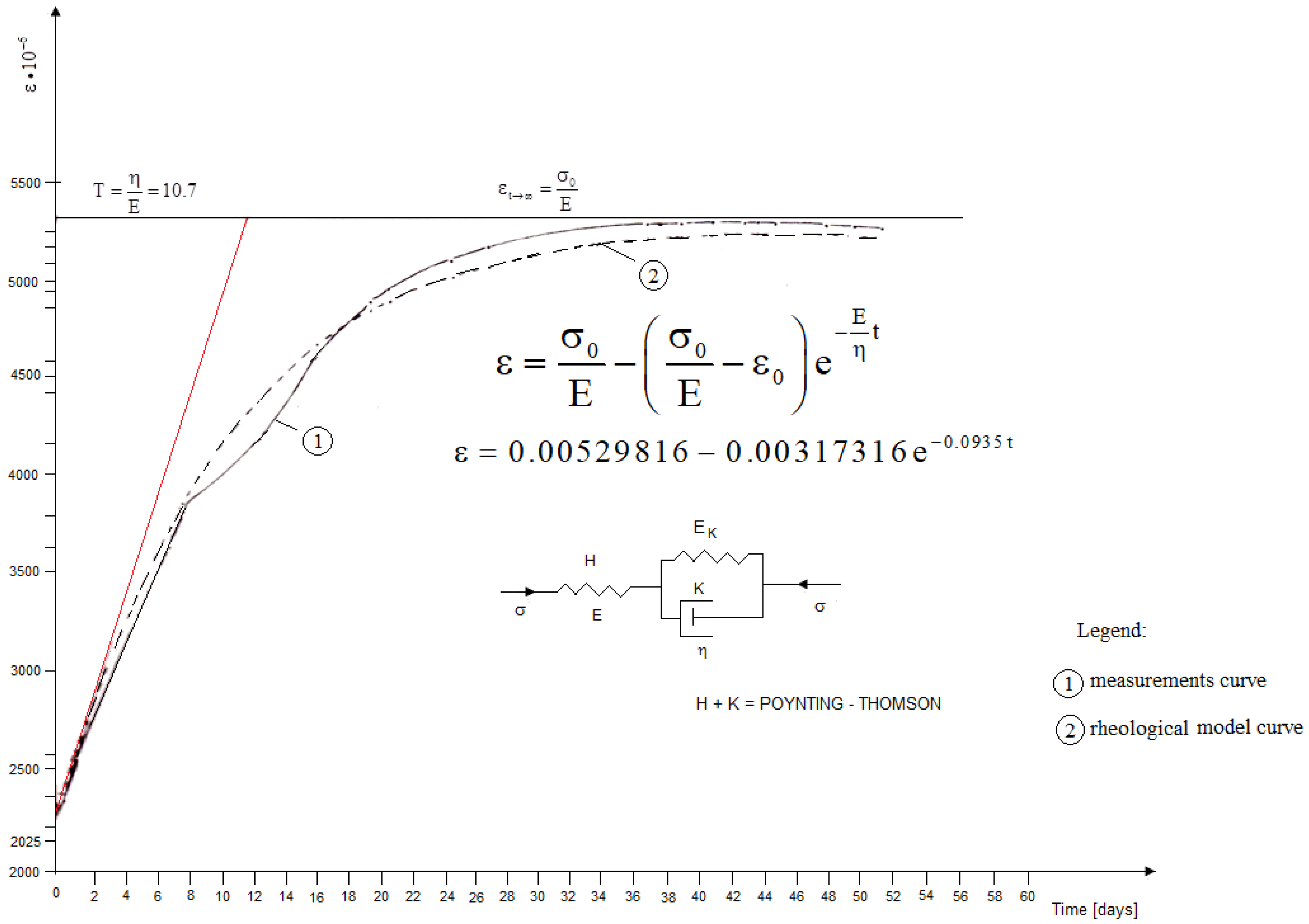

3.1. Deformation Characteristics in Time of Altered Andesite Established in Laboratory

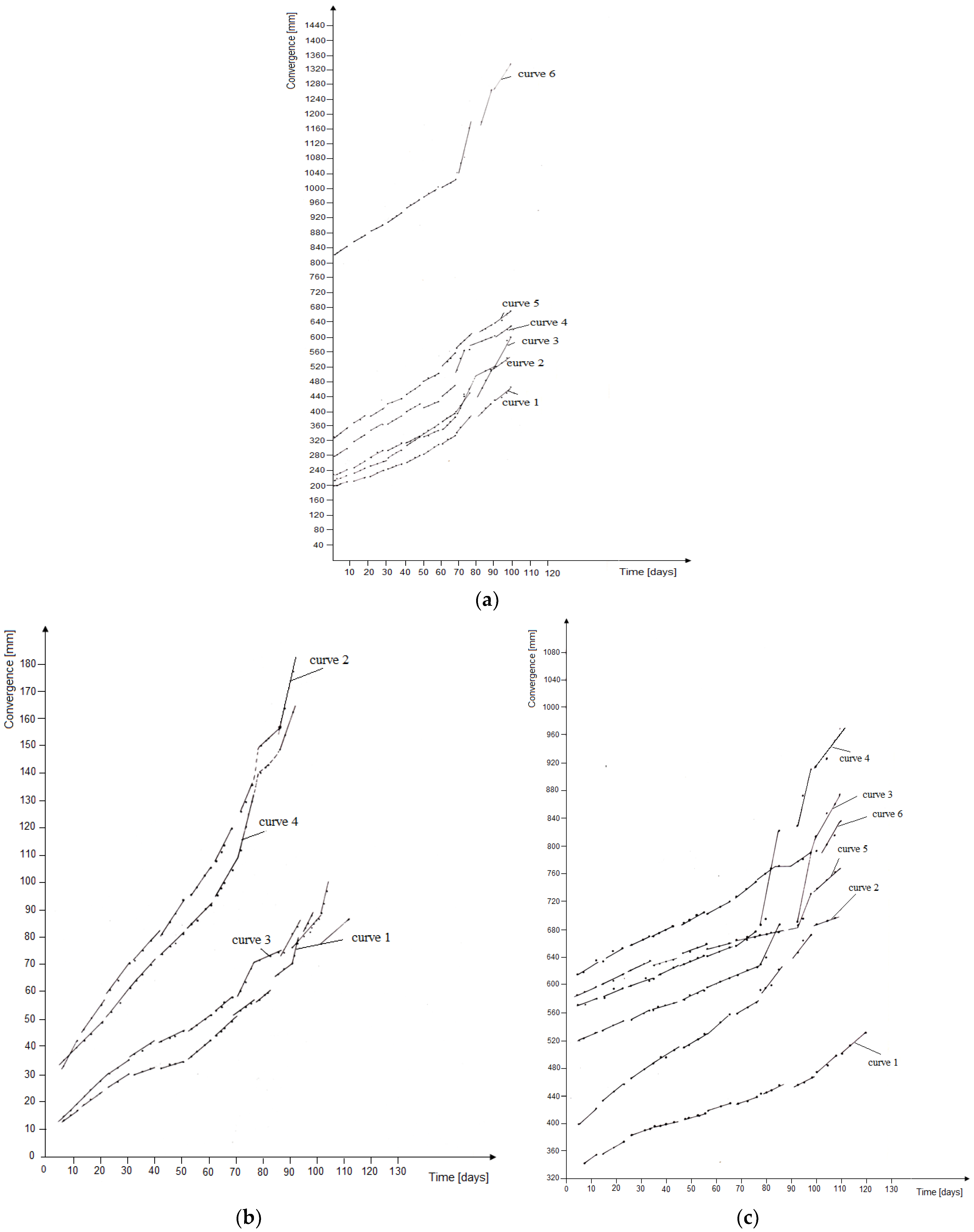

3.2. Deformation Characteristics in Time of Altered Andesite Established In Situ

3.2.1. Relaxation Law

3.2.2. Creep Law

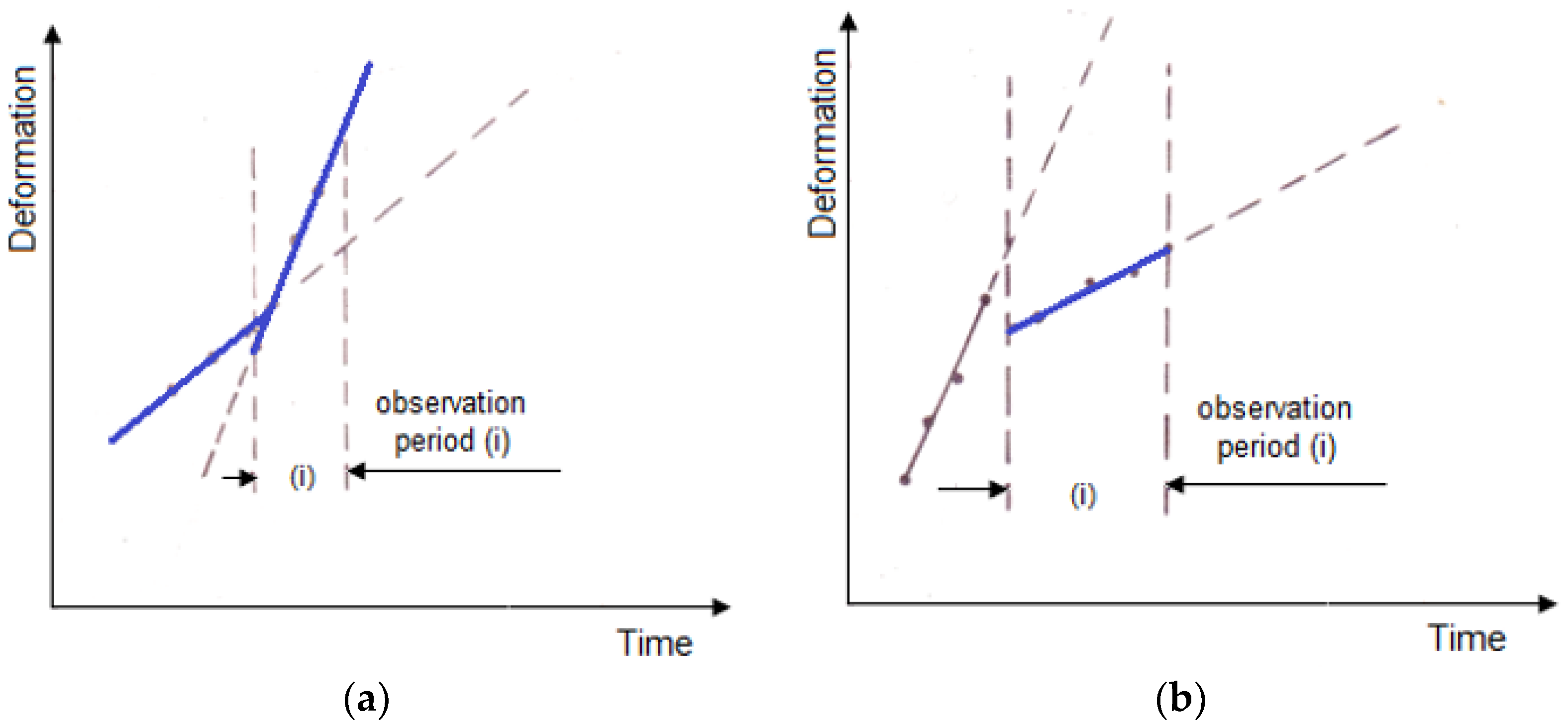

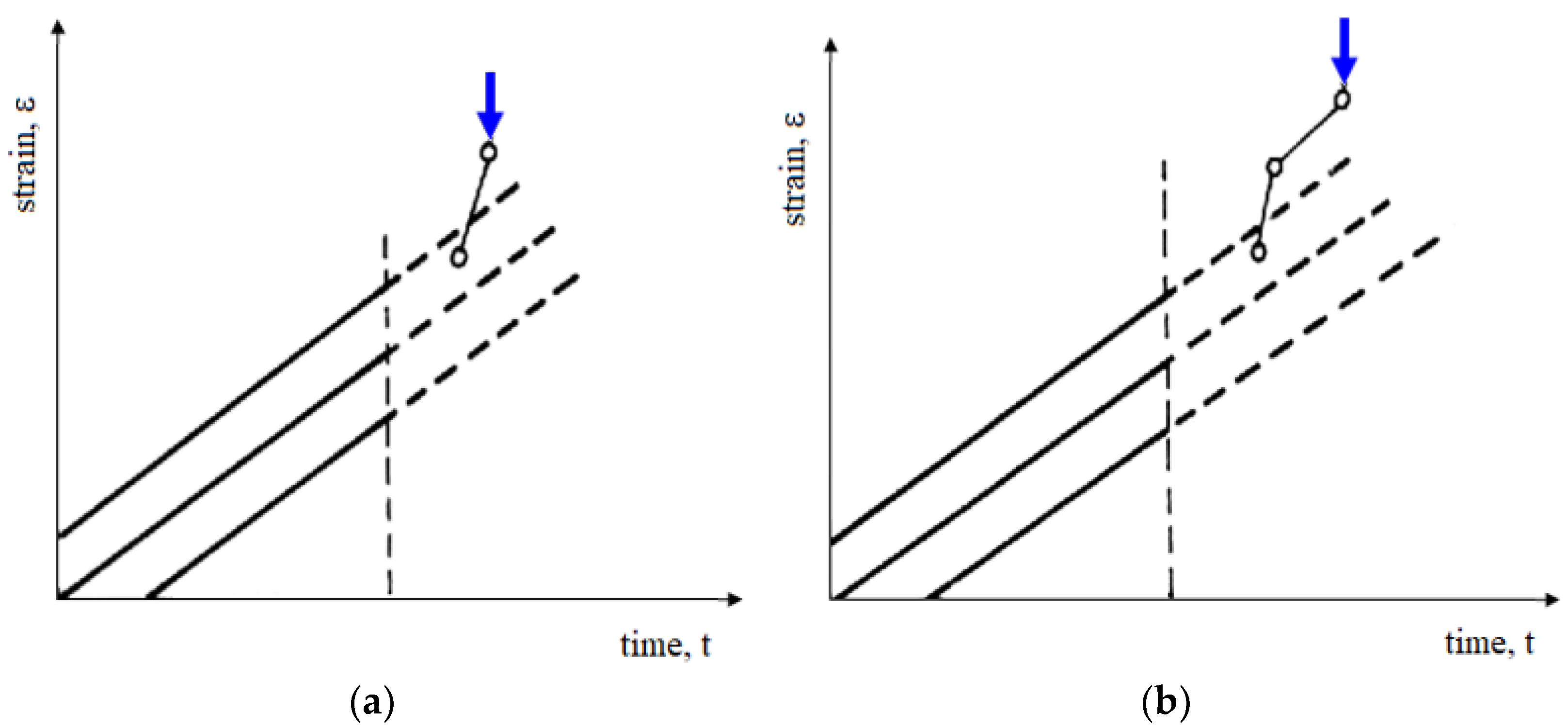

4. The Gradient Method

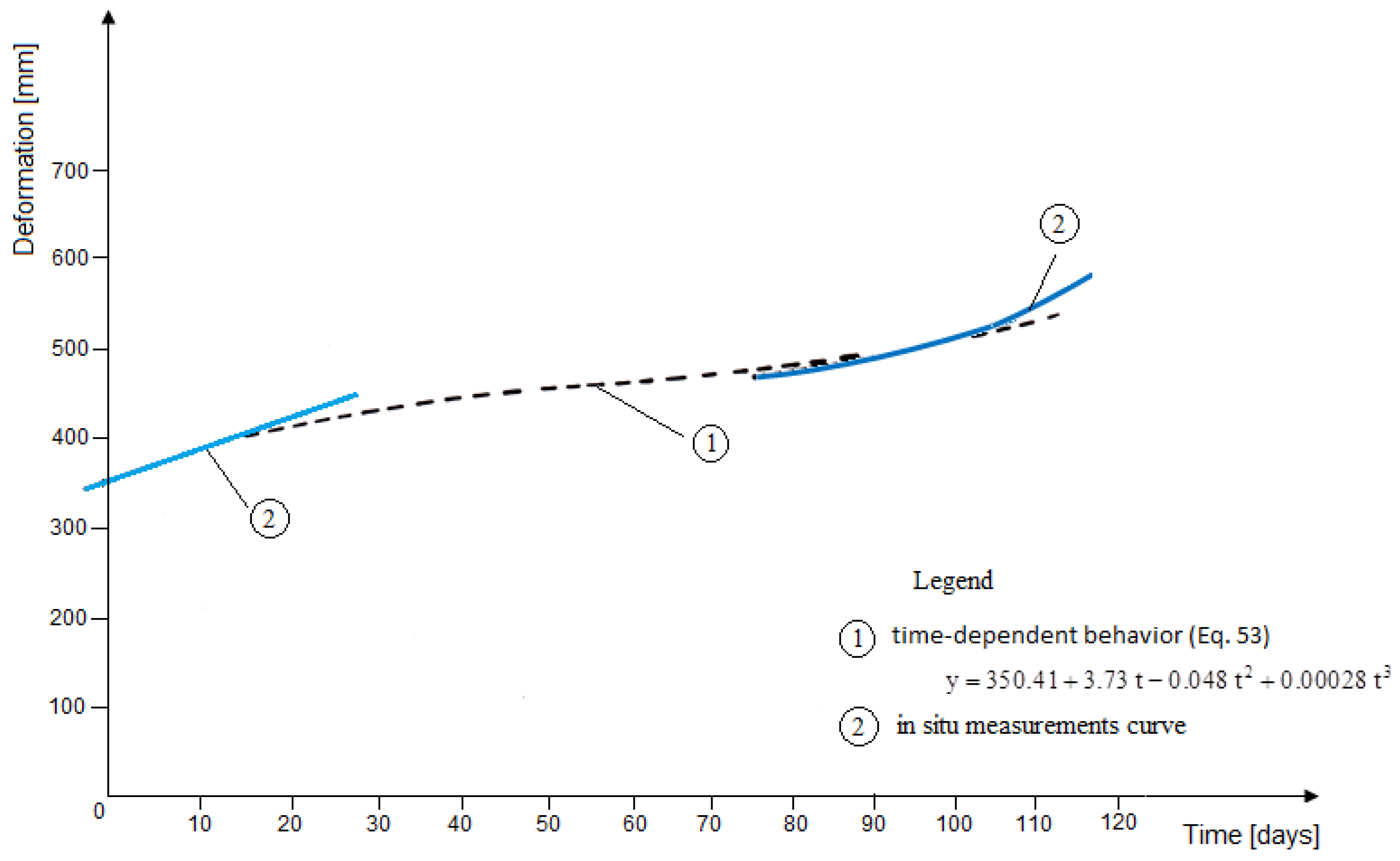

5. Results and Discussions

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

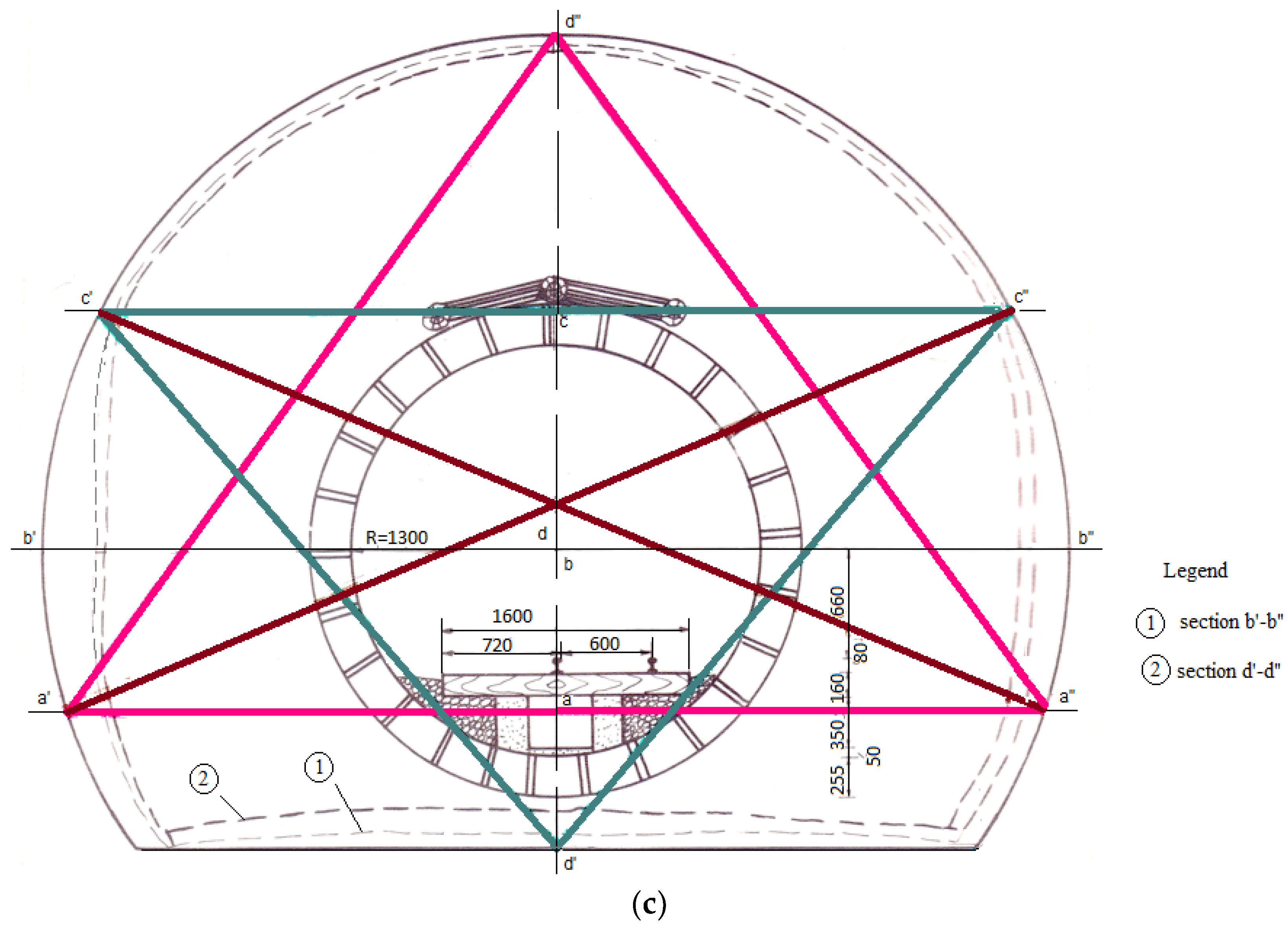

| Point Under Observation | Distance between Points (mm) | Value of Marks | Values of Measurements Made In Situ (Recorded with Deformation Measuring Devices) | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Date of Observation | |||||||||||||||||||||||||

| 10.03 | 12.03 | 14.03 | 17.03 | 24.03 | 26.03 | 29.03 | 31.03 | 04.04 | 07.04 | 09.04 | |||||||||||||||

| 1 | a’a | aa’’ | 1040 | 1020 | 1032 | 1017 | 1017 | 1015 | 1017 | 1015 | 1017 | 1015 | 1008 | 1011 | 1000 | 998 | 982 | 976 | 973 | 973 | 963 | 943 | 951 | 938 | |

| b’b | bb’’ | 1038 | 1080 | 1074 | 1069 | 1061 | 1064 | 1057 | 1059 | 1050 | 1051 | 1047 | 1043 | 1041 | 1035 | 1035 | 1033 | 1031 | 1030 | 1028 | 1021 | 1021 | 1003 | ||

| c’c | bb’’ | 975 | 974 | 968 | 970 | 964 | 961 | 943 | 950 | 930 | 943 | 925 | 936 | 921 | 918 | 918 | 924 | 907 | 905 | 901 | 900 | 898 | 893 | ||

| 1430 | d’d | dd’’ | 1070 | 1068 | 1069 | 1067 | 1067 | 1065 | 1065 | 1061 | 1065 | 1060 | 1065 | 1057 | 1064 | 1058 | 1058 | 1049 | 1051 | 1046 | 1051 | 1032 | 1051 | 1029 | |

| 2 | a’a | aa’’ | 1120 | 1080 | 1118 | 1074 | 1116 | 1070 | 1103 | 1000 | 1080 | 1051 | 1076 | 1051 | 1071 | 1050 | 1062 | 1046 | 940 | 1032 | 938 | 1030 | 926 | 1029 | |

| b’b | bb’’ | 1053 | 1051 | 1045 | 1032 | 1040 | 1010 | 1037 | 1000 | 1022 | 972 | 1020 | 970 | 1020 | 970 | 1020 | 963 | 1019 | 950 | 1015 | 940 | 1013 | 938 | ||

| c’c | bb’’ | 995 | 993 | 990 | 991 | 980 | 987 | 969 | 981 | 964 | 972 | 964 | 962 | 962 | 961 | 934 | 952 | 920 | 938 | 920 | 938 | 918 | 938 | ||

| 2800 | d’d | dd’’ | 994 | 991 | 994 | 989 | 992 | 987 | 984 | 975 | 971 | 963 | 965 | 952 | 960 | 949 | 956 | 938 | 952 | 936 | 949 | 935 | 945 | 929 | |

| 3 | a’a | aa’’ | 1120 | 1090 | 1117 | 1078 | 1100 | 1070 | 1097 | 1065 | 1092 | 1061 | 1090 | 1038 | 1081 | 1027 | 1073 | 1020 | 1070 | 1014 | 1062 | 1009 | 1057 | 1003 | |

| b’b | bb’’ | 1036 | 1070 | 1031 | 1056 | 1028 | 1031 | 1018 | 1031 | 1005 | 1031 | 1003 | 1013 | 1000 | 920 | 997 | 984 | 992 | 975 | 938 | 970 | 987 | 960 | ||

| c’c | bb’’ | 990 | 1030 | 952 | 1023 | 875 | 1010 | 870 | 1010 | 870 | 1010 | 954 | 1010 | 848 | 1000 | 945 | 983 | 840 | 972 | 938 | 969 | 836 | 968 | ||

| 4700 | d’d | dd’’ | 956 | 953 | 956 | 951 | 954 | 951 | 954 | 949 | 953 | 941 | 941 | 945 | 920 | 930 | 916 | 927 | 905 | 922 | 905 | 911 | 905 | 905 | |

| 4 | a’a | aa’’ | 1025 | 1040 | 1022 | 1031 | 1019 | 1017 | 1015 | 1009 | 1007 | 1003 | 1005 | 1000 | 1001 | 1000 | 990 | 987 | 988 | 982 | 976 | 977 | 972 | 970 | |

| b’b | bb’’ | 995 | 993 | 982 | 974 | 975 | 960 | 963 | 959 | 942 | 954 | 947 | 951 | 945 | 949 | 945 | 943 | 940 | 941 | 936 | 936 | 927 | 936 | ||

| c’c | bb’’ | 785 | 893 | 781 | 856 | 780 | 851 | 777 | 835 | 772 | 820 | 762 | 805 | 758 | 792 | 752 | 778 | 952 | 769 | 950 | 965 | 746 | 750 | ||

| 5000 | d’d | dd’’ | 991 | 960 | 985 | 954 | 968 | 942 | 965 | 938 | 960 | 930 | 937 | 925 | 922 | 913 | 920 | 910 | 917 | 903 | 910 | 897 | 902 | 884 | |

| 5 | a’a | aa’’ | 967 | 979 | 960 | 972 | 951 | 970 | 948 | 963 | 943 | 953 | 943 | 953 | 940 | 950 | 938 | 948 | 921 | 934 | 918 | 928 | 916 | 922 | |

| b’b | bb’’ | 965 | 964 | 961 | 955 | 957 | 950 | 951 | 943 | 950 | 930 | 946 | 930 | 942 | 925 | 940 | 920 | 936 | 917 | 928 | 907 | 923 | 904 | ||

| c’c | bb’’ | 795 | 890 | 790 | 874 | 787 | 861 | 783 | 859 | 775 | 857 | 769 | 846 | 762 | 742 | 758 | 732 | 752 | 810 | 942 | 807 | 734 | 803 | ||

| 5000 | d’d | dd’’ | 915 | 911 | 913 | 908 | 907 | 905 | 903 | 905 | 900 | 900 | 898 | 899 | 891 | 897 | 887 | 898 | 871 | 863 | 869 | 852 | 866 | 842 | |

| 6 | a’a | aa’’ | 826 | 830 | 825 | 830 | 820 | 830 | 813 | 827 | 810 | 800 | 803 | 794 | 800 | 790 | 800 | 776 | 794 | 756 | 768 | 730 | 760 | 708 | |

| b’b | bb’’ | 883 | 881 | 871 | 876 | 854 | 868 | 843 | 863 | 832 | 860 | 830 | 860 | 828 | 860 | 789 | 845 | 777 | 836 | 740 | 821 | 730 | 810 | ||

| c’c | bb’’ | 800 | 827 | 774 | 823 | 770 | 820 | 769 | 758 | 765 | 778 | 693 | 775 | 680 | 773 | 678 | 769 | 673 | 760 | 654 | 758 | 645 | 742 | ||

| 4800 | d’d | dd’’ | 998 | 897 | 991 | 895 | 988 | 782 | 986 | 773 | 984 | 768 | 951 | 759 | 920 | 751 | 919 | 748 | 912 | 743 | 898 | 732 | 891 | 722 | |

| 7 | a’a | aa’’ | 980 | 981 | 979 | 981 | 977 | 979 | 971 | 977 | 965 | 977 | 957 | 977 | 950 | 975 | 947 | 973 | 943 | 970 | 935 | 952 | 931 | 943 | |

| b’b | bb’’ | 997 | 994 | 990 | 984 | 988 | 973 | 950 | 932 | 895 | 893 | 884 | 887 | 872 | 880 | 892 | 872 | 870 | 840 | 864 | 840 | 852 | 840 | ||

| c’c | bb’’ | 680 | 720 | 680 | 711 | 680 | 685 | 680 | 683 | 680 | 683 | 680 | 683 | 679 | 680 | 671 | 678 | 662 | 663 | 660 | 658 | 657 | 646 | ||

| 4700 | d’d | dd’’ | 869 | 865 | 832 | 834 | 800 | 810 | 783 | 790 | 760 | 767 | 753 | 746 | 732 | 730 | 728 | 728 | 725 | 722 | 720 | 712 | 715 | 702 | |

| 8 | a’a | aa’’ | 876 | 877 | 871 | 863 | 862 | 850 | 854 | 847 | 850 | 841 | 849 | 823 | 846 | 819 | 641 | 813 | 835 | 805 | 828 | 790 | 810 | 782 | |

| b’b | bb’’ | 875 | 871 | 872 | 865 | 870 | 859 | 868 | 843 | 865 | 836 | 863 | 824 | 860 | 861 | 654 | 659 | 847 | 859 | 640 | 834 | 932 | 823 | ||

| c’c | bb’’ | 740 | 743 | 740 | 739 | 738 | 735 | 735 | 712 | 730 | 704 | 727 | 700 | 719 | 692 | 709 | 685 | 700 | 675 | 698 | 663 | 691 | 654 | ||

| 2600 | d’d | dd’’ | 976 | 971 | 965 | 952 | 950 | 914 | 923 | 914 | 915 | 912 | 903 | 869 | 900 | 891 | 900 | 884 | 891 | 875 | 884 | 862 | 871 | 852 | |

| 9 | a’a | aa’’ | 755 | 760 | 753 | 758 | 749 | 745 | 745 | 732 | 740 | 729 | 731 | 729 | 720 | 728 | 720 | 718 | 719 | 710 | 709 | 699 | 704 | 693 | |

| b’b | bb’’ | 730 | 780 | 721 | 776 | 719 | 760 | 709 | 743 | 700 | 700 | 703 | 699 | 705 | 699 | 700 | 699 | 698 | 698 | 675 | 678 | 661 | 665 | ||

| c’c | bb’’ | 575 | 748 | 570 | 739 | 565 | 730 | 551 | 720 | 550 | 714 | 550 | 709 | 545 | 704 | 532 | 680 | 528 | 640 | 521 | 638 | 516 | 635 | ||

| 2500 | d’d | dd’’ | 960 | 967 | 954 | 887 | 940 | 800 | 928 | 792 | 900 | 785 | 884 | 778 | 829 | 774 | 883 | 762 | 871 | 753 | 869 | 732 | 864 | 728 | |

| 10 | a’a | aa’’ | 770 | 762 | 750 | 782 | 710 | 661 | 682 | 659 | 650 | 652 | 643 | 641 | 641 | 638 | 639 | 625 | 636 | 600 | 627 | 598 | 613 | 591 | |

| b’b | bb’’ | 710 | 747 | 700 | 731 | 692 | 724 | 634 | 702 | 625 | 685 | 621 | 675 | 621 | 614 | 617 | 613 | 602 | 613 | 594 | 607 | 585 | 600 | ||

| c’c | bb’’ | 610 | 607 | 599 | 606 | 593 | 600 | 581 | 600 | 560 | 593 | 558 | 587 | 550 | 579 | 542 | 561 | 534 | 550 | 530 | 546 | 525 | 531 | ||

| d’d | dd’’ | 858 | 781 | 531 | 764 | 798 | 750 | 790 | 742 | 788 | 730 | 768 | 730 | 753 | 728 | 743 | 719 | 740 | 711 | 732 | 703 | 730 | 692 | ||

Appendix B

| Measuring Range (Days) | Measured Values, (mm) | Slope | Evolution of Deformations | Slopes Comparison | Dispersion | Ordinates Comparison |

|---|---|---|---|---|---|---|

| STATION 1—vertical | ||||||

| 1–10 (May) | 376 383 394 | 0.67 | - | - | - | - |

| 10–20 (May) | 396 405 414 | 0.55 |  |  | = |  |

| 20–30 (May) | 422 430 432 435 | 0.34 | = |  | = | = |

| 1–10 (June) | 437 439 442 | 0.25 | = | = | = | = |

| 10–20 (June) | 446 448 452 454 | 0.25 | = | = | = | = |

| 20–30 (June) | 458 465 470 | 0.32 | = | = | = | = |

| 1–10 (July) | 469 472 478 | 0.32 | = | = | = | = |

| 10–20 (July) | 482 484 486 494 | 0.44 | = | = | = | = |

| 20–30 (July) | 495 498 504 | 0.44 | = | = | = | = |

| 1–10 (August) | 513 523 537 | 0.84 |  |  |  |  |

| 10–20 (August) | 540 551 571 | 0.84 | = | = | = | = |

| STATION 2—vertical | ||||||

| 1–10 (May) | 439 446 462 | 0.84 | - | - | - | - |

| 10–20 (May) | 473 486 496 | 0.78 |  |  | - |  |

| 20–30 (May) | 504 518 524 | 0.60 | = | = | = | = |

| 1–10 (June) | 527 536 536 545 | 0.60 | = | = | = | = |

| 10–20 (June) | 550 554 560 569 | 0.58 | = | = | = | = |

| 20–30 (June) | 570 586 598 | 0.84 | = | = | = | = |

| 1–10 (July) | 598 607 614 | 0.58 | = | = | = | = |

| 10–20 (July) | 632 635 638 661 | 1.28 |  |  | = |  |

| 20–30 (July) | 686 703 711 | 1.28 | = | = | = | |

| 1–10 (August) | 726 732 736 746 | 0.38 | = |  | = |  |

| STATION 3—vertical | ||||||

| 1–10 (May) | 625 630 638 | 0.42 | - | - | - | - |

| 10–20 (May) | 641 646 654 | 0.42 |  |  | = |  |

| 20–30 (May) | 660 670 674 | 0.42 | = | = | = | = |

| 1–10 (June) | 668 670 674 676 | 0.29 | = |  | = |  |

| 10–20 (June) | 686 687 693 697 | 0.36 | = | = | = | = |

| 20–30 (June) | 690 695 699 | 0.21 | = | = | = | = |

| 1–10 (July) | 704 704 709 | 0.21 | = | = | = | = |

| 10–20 (July) | 711 713 715 716 | 0.21 |  | = | = | = |

| 20–30 (July) | 726 734 770 | 2.25 | = |  | = |  |

| 1–10 (August) | 777 790 801 807 | 0.90 | = |  | = |  |

| STATION 4—vertical | ||||||

| 1–10 (May) | 560 562 570 | 0.36 | - | - | - | - |

| 10–20 (May) | 573 583 588 | 0.40 |  | = | = |  |

| 20–30 (May) | 589 599 604 | 0.36 | = | = | = | = |

| 1–10 (June) | 603 608 610 614 | 0.36 | = | = | = | = |

| 10–20 (June) | 619 624 628 632 | 0.36 | = | = | = | = |

| 20–30 (June) | 636 644 649 | 0.36 | = | = | = | = |

| 1–10 (July) | 654 660 666 | 0.36 | = | = | = | = |

| 10–20 (July) | 669 670 727 | 1.96 |  |  | = |  |

| 20–30 (July) | 730 798 825 | 5.67 | = |  | = |  |

| 1–10 (August) | 832 841 854 875 | 1.60 | = |  | = |  |

| STATION 5—vertical | ||||||

| 1–10 (May) | 655 658 674 | 0.53 | - | - | - | - |

| 10–20 (May) | 674 688 692 | 0.53 |  | = | = | = |

| 20–30 (May) | 697 705 709 | 0.42 | = | = | = | = |

| 1–10 (June) | 709 714 718 725 | 0.51 | = | = | = | = |

| 10–20 (June) | 729 733 740 743 | 0.51 | = | = | = | = |

| 20–30 (June) | 742 752 759 | 0.47 | = | = | = | = |

| 1–10 (July) | 767 778 788 | 0.78 | = |  | = |  |

| 10–20 (July) | 794 800 808 809 | 0.78 | = | = | = | = |

| 20–30 (July) | 817 820 829 | 0.78 | = | = | = | = |

| 1–10 (August) | 852 886 898 912 | 1.73 | = |  | = |  |

| STATION 6—vertical | ||||||

| 1–10 (May) | 610 612 620 | 0.36 | - | - | - | - |

| 10–20 (May) | 622 633 635 | 0.36 |  | = | = | = |

| 20–30 (May) | 638 648 646 | 0.36 | = | = | = | = |

| 1–10 (June) | 648 655 663 664 | 0.36 | = | = | = | = |

| 10–20 (June) | 670 674 678 682 | 0.36 | = | = | = | = |

| 20–30 (June) | 680 688 694 | 5.23 | = |  | = |  |

| 1–10 (July) | 696 708 716 | 0.73 | = | = | = | = |

| 10–20 (July) | 725 734 850 861 | 5.67 | = |  | = |  |

| 20–30 (July) | 968 910 949 | 3.73 | = |  | = |  |

| 1–10 (August) | 954 965 990 1000.7 | 1.38 | = |  | = |  |

| STATION 1—horizontally | ||||||

| 1–10 (May) | 200 200 204 210 | 0.38 | - | - | - | - |

| 10–20 (May) | 212 218 221 | 0.42 |  | = | = | = |

| 20–30 (May) | 225 234 240 | 0.60 | = | = | = | = |

| 1–10 (June) | 244 249 253 256 | 0.49 | = | = | = | = |

| 10–20 (June) | 262 267 275 280 | 0.49 | = | = | = | = |

| 20–30 (June) | 284 297 304 310 | 0.81 | = |  | = |  |

| 1–10 (July) | 312 325 327 335 | 0.73 | = | = | = | = |

| 10–20 (July) | 342 356 376 384 | 1.38 | = |  | = |  |

| 20–30 (July) | 398 410 421 | 1.19 | = | = | = | |

| 1–10 (August) | 432 439 451 466 | 0.96 | = |  | = |  |

| STATION 2—horizontally | ||||||

| 1–10 (May) | 230 230 234 242 | 0.49 | - | - | - | - |

| 10–20 (May) | 248 258 265 | 0.62 |  |  | = |  |

| 20–30 (May) | 274 288 294 | 0.62 | = | = | = | = |

| 1–10 (June) | 294 301 305 315 | 0.62 | = | = | = | = |

| 10–20 (June) | 316 320 327 332 | 0.62 | = | = | = | = |

| 20–30 (June) | 340 348 357 366 | 0.49 | = |  | = |  |

| 1–10 (July) | 374 382 387 395 | 1.28 | = |  | = |  |

| 10–20 (July) | 398 416 430 451 | 2.47 | = |  | = |  |

| 20–30 (July) | 464 484 510 | 0.62 | - |  | - |  |

| 1–10 (August) | 517 531 546 549 | 0.96 | = | = | = | = |

| STATION 3—horizontally | ||||||

| 1–10 (May) | 214 220 220 226 | 0.44 | -- | - | - | - |

| 10–20 (May) | 234 240 246 | 0.53 |  |  | = |  |

| 20–30 (May) | 252 258 264 | 0.42 | = |  | = |  |

| 1–10 (June) | 275 282 288 294 | 0.75 | = |  | = |  |

| 10–20 (June) | 308 314 322 330 | 0.84 | = | = | = | = |

| 20–30 (June) | 348 340 357 366 | 0.84 | = | = | = | = |

| 1–10 (July) | 374 382 387 395 | 0.84 | = | = | = | = |

| 10–20 (July) | 398 416 440 451 | 1.73 | = |  | = |  |

| 20–30 (July) | 464 484 510 | 2.47 | = |  | = |  |

| 1–10 (August) | 519 583 603 | 2.47 | = | = | = | = |

| STATION 4—horizontally | ||||||

| 1–10 (May) | 330 334 341 354 | 0.75 | - | - | - | - |

| 10–20 (May) | 370 378 388 | 0.75 |  | = | = | = |

| 20–30 (May) | 388 398 407 | 0.75 | = | = | = | = |

| 1–10 (June) | 421 426 434 | 0.75 | = | = | = | = |

| 10–20 (June) | 446 454 461 471 | 0.62 | = | = | = | = |

| 20–30 (June) | 482 490 496 504 | 0.49 | = | = | = | = |

| 1–10 (July) | 524 536 544 559 | 1.03 | = |  | = |  |

| 10–20 (July) | 571 584 594 606 | 3.27 | = |  | = |  |

| 20–30 (July) | 620 624 634 | 0.49 | = |  | = | = |

| 1–10 (August) | 640 647 665 673 | 0.87 | = | = | = | = |

| STATION 5—horizontally | ||||||

| 1–10 (May) | 278 282 288 298 | 0.93 | - | - | - | - |

| 10–20 (May) | 318 330 336 | 0.73 | = |  | = |  |

| 20–30 (May) | 349 357 365 | 0.75 | = | = | = | = |

| 1–10 (June) | 367 374 380 388 | 0.49 | = | = | = | = |

Appendix C

| Computing Relations for N = 9 | u | |||||

|---|---|---|---|---|---|---|

| 0 | 0 | −20 | 0 | 18 | 0 | |

| 1 | 1 | −17 | −9 | 9 | 9 | |

| 2 | 2 | −8 | −13 | −11 | 4 | |

| 3 | 3 | 7 | −7 | −21 | −11 | |

| 4 | 4 | 28 | 14 | 14 | 4 | |

| γ | 60 | 924 | 1188 | 3432 | 3120 | |

| H | 60 | 308 | 20,800 | |||

| Computing Relations for N = 11 | u | |||||

| 0 | 0 | −10 | 0 | 6 | 0 | |

| 1 | −9 | −14 | −31 | 4 | 4 | |

| 2 | 2 | −6 | −23 | −1 | 4 | |

| 3 | 3 | −1 | −22 | −6 | −1 | |

| 4 | 4 | 6 | −6 | −6 | −6 | |

| 5 | 5 | 15 | 30 | 6 | 3 | |

| γ | 110 | 858 | 5148 | 3420 | 6240 | |

| H | 110 | 41,148 | 249,600 | |||

| 10 | ||||||

| Computing Relations for N = 12 | u | |||||

| 1/2 | 1 | −35 | −7 | 28 | 20 | |

| 3/2 | 3 | −29 | −19 | 12 | 44 | |

| 5/2 | 5 | −17− | −25 | −13 | 29 | |

| 7/2 | 7 | 1 | −21 | −33 | −21 | |

| 9/2 | 9 | 25 | −3 | −27 | −57 | |

| 11/2 | 11 | 55 | 33 | 33 | 33 | |

| γ | 286 | 4004 | 7722 | 27,456 | 106,080 | |

| H | 143 | 11,583 | 707,200 | |||

Appendix D

References

- Dubuskin, K.I. Ispâtanie Porod na Polzucesti; Nauka: Novosibirsk, Russia, 1972. [Google Scholar]

- Kidibinski, A. Rheological models of Upper Sillesian Carboniferous Rock. Int. J. Rock Mech. Min. Sci. 1966, 3, 279–306. [Google Scholar] [CrossRef]

- Reiner, M. Rheology Handbuch der Physik; Spring: Berlin/Heidelberg, Germany, 1958. [Google Scholar]

- Reiner, M. Deformation, Strain and Flow, 2nd ed.; K.H. Levis and Coltd: London, UK, 1960. [Google Scholar]

- Reiner, M. Reologia; Nauka: Novosibirsk, Russia, 1965. [Google Scholar]

- Rozovski, M.I. Izucenie napriajenogo sostoiania vokrug gorizontalnoi vârabotki s ucetom posledeistva v gornâh porodah. Izv. AN URSS OTN 1958, 2, 11–18. [Google Scholar]

- Rozovski, M.I. Obrabotka krivâh polzucesti na osnove integralnâh upravenii. Izv. Vuzov Maşinstroenie 1960, 3, 25–44. [Google Scholar]

- Rozovski, M.I. Polzucesti i dlitelnoe razruşenie materialov. J. Tehn. Fiz. 1961, 11, 41–48. [Google Scholar]

- Aydan, O.; Kawamoto, T. The stability assessment of a large underground opening at great depth. In Proceedings of the 17th International Mining Congress and Exhibition of Turkey (IMCET 2001), Ankara, Turkey, 19–22 June 2001; Volume 1, pp. 277–288. [Google Scholar]

- Toderaş, M. Rocks Rheology in the Stability of Underground Mining Works. Study Case: Sedimentary Rocks from Jiu Valley, Romania; Scholars’ Press International Publishing House, Lambert Academic Publishing: Saarbrücken, Germany, 2015; p. 549. ISBN 978-3-639-76796-4. [Google Scholar]

- Todorescu, A. Study of Stress-Deformation State around the Mining Works Depending on the Rheological Behavior of the Rock Massif; Section “Mathematical Modeling in Earth SCIENCE”; Mining institute: Petroşani, Romania, 1980. [Google Scholar]

- Berest, P. Viscoplasticity in Rock Mechanics, Geomaterials, Constitutiv Equations and Modeling; Elsevier Applied Science: Amsterdam, The Netherlands, 1989; pp. 239–262. [Google Scholar]

- Bruckl, E. The Rheology of Specially Continous Mass Creep in Rock. Rock Mech. 1972, 4, 237–250. [Google Scholar] [CrossRef]

- Hoek, E. Practical Rock Engineering; RocScience: Toronto, ON, Canada, 2007. [Google Scholar]

- Jagger, J.C. Rock Mechanics and Engineering; Cambridge at the University Press: Cambridge, UK, 1972. [Google Scholar]

- Jagger, J.C. Elasticity, Fracture and Flow; Methuen: London, UK, 1962. [Google Scholar]

- Liu, R. Significance of a Basic Rheological Model in Geology and Its Application. Earth Sci. Front. 2007, 4, 61–65. [Google Scholar]

- Liu, R.; Zhang, B.; Zhang, C. The Kelvin Model Describing Rock Materials with Behaviour of a Viscoelastic Solid. Earth Sci. Front. 2008, 3, 221–225. [Google Scholar]

- Navroski, P.A.; Mroz, Z. Constitutive model for rocks accouting for vâscoplastic deformation and damage. In Proceedings of the 33rd U.S. Symposium on Rock Mechanics, Santa Fe, New Mexico, Mexico, 3–6 June 1992; Balkema: Rotterdam, The Netherlands, 1992. [Google Scholar]

- Reiner, M. Outline of a Systematic of Rheological Theories; Selected Papers on Rheology; Elsevier Scient Publishing Company: Amsterdam, The Netherlands, 1975. [Google Scholar]

- Stolle, D.F.E. Viscoelasticity and Plasticity Numerical Stability Revisited. In Proceedings of the 3rd International Symposium. On Numerical Models in Geomechanics, Niagara Falls, ON, Canada, 8–11 May 1989; Elserer Applied Science: London, UK, 1989. [Google Scholar]

- Zhong, T. Overview of the rheological models for rocks. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 032020. [Google Scholar] [CrossRef]

- Toderaş, M. Rheological model for analyzing of the underground excavations stability based on the principle of interaction. Min. Rev. 2008, 5–6, 20–22. (In Romanian) [Google Scholar]

- Li, Z.; Li, Z.; Liu, J.; Xu, R.; Xu, R.; Shi, W. Study of grouting effectiveness based on shear strength evaluation with experimental and numerical approaches. Acta Geotech. 2021, 16, 3991–4005. [Google Scholar] [CrossRef]

- Xu, R.; Xu, R.; Zhang, S.; Li, Z.; Li, Z.; Yan, X. Experimental investigation of the strain rate effect on crack initiation and crack damage thresholds of hard rock under quasi-static compression. Acta Geotech. 2022. [Google Scholar] [CrossRef]

- Wang, M.; Chen, B.; Zhao, H. Data-driven rock strength parameters identification using artificial bee colony. Buildings 2022, 12, 725. [Google Scholar] [CrossRef]

- Liu, F.Z. Study of the Stability of Surrounding Rock Deep Roadway; Shandong University of Science and Technology: Qingdao, China, 2005. [Google Scholar]

- Xu, X.; He, M.; Gao, Y. Study on Mining Pressure Law and Pressure Relief Control under Influence of Key Layer. Min. Metall. Explor. 2021, 38, 1985–1996. [Google Scholar] [CrossRef]

- Toderas, M.; Moraru, R. The Effect of Increasing the Water Content on Rocks Characteristics from Suior, Romania. Min. Miner. Depos. J. Min. Miner. Depos. 2017, 11, 1–14. [Google Scholar] [CrossRef]

- Hirian, C. Rock Mechanics; Didactic and Pedagogical Publishing House: Bucharest, Romania, 1981. (In Romanian) [Google Scholar]

- Nasonov, L.N. Mehanika gornâh porod i kreplenie gornâh vârabotok; Nedra: Moskva, Russia, 1969. [Google Scholar]

- Todorescu, A.; Hirian, C.; Gaiducov, V.; Arad, V.; Toderaş, M. Theoretical—Experimental Research Regarding the Assesment an Approach Method of Geomechanical Characteristics of Rocks Reinforced by Injection of Cement; Research Project with MCT; Ministry of Research: Bucharest, Romania, 1994–1997; Nr.369B/B/. (In Romanian) [Google Scholar]

- Toderaş, M. Rock Mechanics, Soil and Underground Constructions; Universitas Publishing House: Petroşani, Romania, 2014; Volume II, p. 1167, ISBN 978-973-741-381-9, p. 516, ISBN 978-973-741-383-3. (In Romanian) [Google Scholar]

- Toderaş, M.; Danciu, C. Stability Analysis Methods of Underground Mining Works; Lambert Academic Publishing: Toronto, ON, Canada, 2017; p. 380. ISBN 978-620-2-19847-9. [Google Scholar]

- Griggs, D.T. Creep of Rocks. J. Geol. 1939, 47, 225–251. [Google Scholar] [CrossRef]

- Goodman, R.E. Introduction to Rock Mechanics; John Wiley: Hoboken, NJ, USA, 1981. [Google Scholar]

- Mohammad, R.Z.; Ahmad, F. Analytical solutions for the stresses and deformations of deep tunnels in an elastic-brittle-plastic rock mass considering the damaged zone. Tunn. Undergr. Space Technol. 2016, 58, 186–196. [Google Scholar]

- Stagg, K.G.; Zienkievici, O.C. Rock Mechanics in Engineering Practice; John Wiley: Hoboken, NJ, USA, 1968. [Google Scholar]

- Wardle, L.J. The equivalent anisotropic properties of layered rock and soil masses. Rock Mech. 1972, 4, 155–175. [Google Scholar] [CrossRef]

- Toderaş, M. Guide to the Design of Underground Mining Works; Universitas Publishing House: Petroşani, Romania, 2015; p. 214. ISBN 978-973-741-432-8. (In Romanian) [Google Scholar]

- Erjanov, J.S. Teoria Polzucesti Gornâh Porod i ee Prilojenia; Nauka: Alma, Kazakhstan, 1964. [Google Scholar]

- Hoek, E. Reliability of Hoek-Brown estimates of rock mass properties and their impact on design. Int. J. Rock Mech. Min. Sci. 1998, 35, 63–68. [Google Scholar] [CrossRef]

- Park, K.; Kim, Y. Analytical solution for a circular opening in an elastic-brittle-plastic rock. Int. J. Rock Mech. Min. Sci. 2006, 43, 616–622. [Google Scholar] [CrossRef]

- Sharan, S.K. Elastic-brittle-plastic analysis of circular openings in Hoek-Brown media. Int. J. Rock Mech. Min. Sci. 2003, 40, 817–824. [Google Scholar] [CrossRef]

- Sharan, S.K. Analytical solutions for stresses and displacements around a circular opening in a generalized Hoek-Brown rock. Int. J. Rock Mech. Min. Sci. 2008, 45, 78–85. [Google Scholar] [CrossRef]

- Kubetsky, V.L. Investigation of Stresses in Pressure Tunnel Linings with regard to creep of concrete and surrounding rock mass. In Proceedings of the 2nd Congress of the International Society of Rock Mechanics, Belgrade, Serbia, 21–26 September 1970; pp. 4–9. [Google Scholar]

- Fine, J.; Tincelin, E. Determination de la stabilité des edifices souterraines galeries, tunnels, pilliers, grandes cavités. Rev. L’Ind. Miner. 1971, 2, 117–122. [Google Scholar]

- Zeng, C.; Zhou, Y.; Zhang, L.; Mao, D.; Bai, K. Study on overburden failure law and surrounding rock deformation control technology of mining through fault. PLoS ONE 2022, 17, e0262243. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Jiang, C.; Zheng, P.; Li, N.; Zhan, Y. Deformation and failure mechanism of surrounding rocks in crossed-roadway and its support strategy. Eng. Fail. Anal. 2020, 116, 104743. [Google Scholar] [CrossRef]

- Xu, Q.; Li, Y.; Lu, J.; Zhang, L. The use of surrounding rock loosening circle theory combined with elastic-plastic mechanics calculation method and depth learning in roadway support. PLoS ONE 2020, 15, e0234071. [Google Scholar] [CrossRef]

| Rock Type | Samples Dimensions (mm) | Load Stress, σ0, (MPa) | Tests Duration, t | Mean Breaking Stress, σmed, (MPa) | Load Degree, σ0/σmed | ||

|---|---|---|---|---|---|---|---|

| d | h | Hours | Days | ||||

| Altered pyroxene andesite 1 | 42 | 42 | 11.55 | 1198 | 50 | 28.00 | 0.41 |

| 14.44 | 1198 | 50 | 0.51 | ||||

| 21.60 | 168 | 7 | 0.70 | ||||

| 28.00 | 12 | 0,5 | 1.00 | ||||

| Rock Type | Load Stress, σ0, (MPa) | Stabilization Time, t (Hours) | Stable Area, σ0/σcritic | Relative Stability Area, σ0/σcritic | Unstable Area, σ0/σcritic |

|---|---|---|---|---|---|

| Altered pyroxene andesite 1 | 11.55 | 165 | 0.41 | 0.41–0.71 | 0.71 |

| 14.44 | |||||

| 21.60 | |||||

| 28.00 |

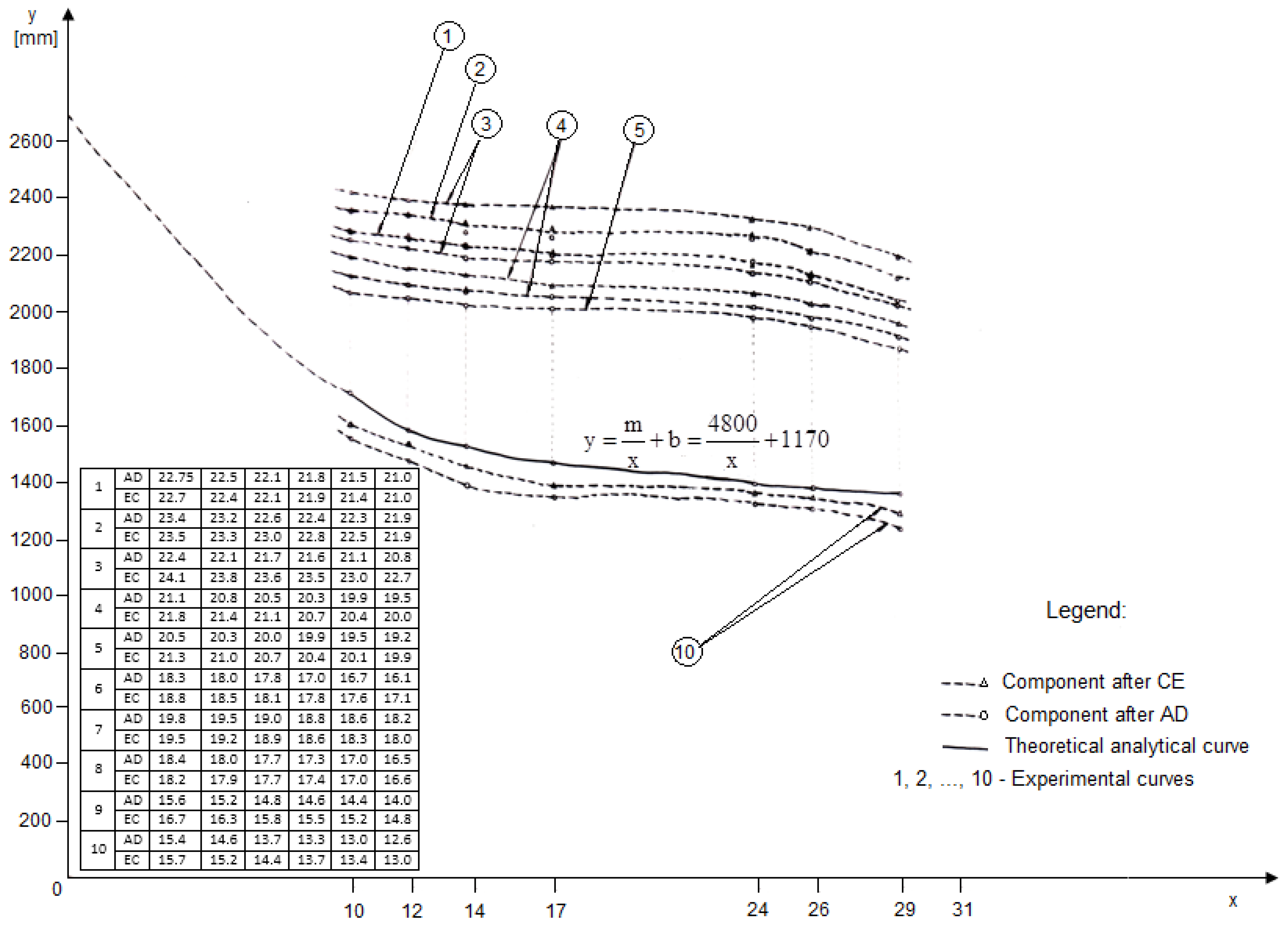

| Function Type | Coefficients | Coefficients Values 1 |

|---|---|---|

| m | 4800 | |

| b | 1170 |

| Computing Relations for N = 10 = H0 1 | u | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | −4 | −12 | 18 | 6 | |

| 1 | 3 | −3 | −31 | 3 | 11 | |

| 2 | 5 | −1 | −35 | −17 | 1 | |

| 3 | 7 | 2 | −14 | −22 | −14 | |

| 4 | 9 | 6 | 42 | 18 | 6 | |

| γ | 165 | 264 | 5.148 | 6.864 | 7.800 | |

| H | 528 | 78.000 | ||||

| x | yk 1 | Values of yk | Size of (y+i − y−i) | Value | Size of (y+i + y−i) | Value |

|---|---|---|---|---|---|---|

| 10 | y−5 | y+5 − y−5 | - | - | ||

| 20 | y−4 | y+4 − y−4 | - | - | ||

| 30 | y−3 | y+3 − y−3 | - | - | ||

| 40 | y−2 | y+2 − y−2 | - | - | ||

| 50 | y−1 | y+1 − y−1 | - | - | ||

| 60 | y0 | - | - | - | - | |

| 70 | y+1 | - | - | y+1 + y−1 | ||

| 80 | y+2 | - | - | y+2 + y−2 | ||

| 90 | y+3 | - | - | y+3 + y−3 | ||

| 100 | y+4 | - | - | y+4 + y−4 | ||

| 110 | y+5 | - | - | y+5 + y−5 |

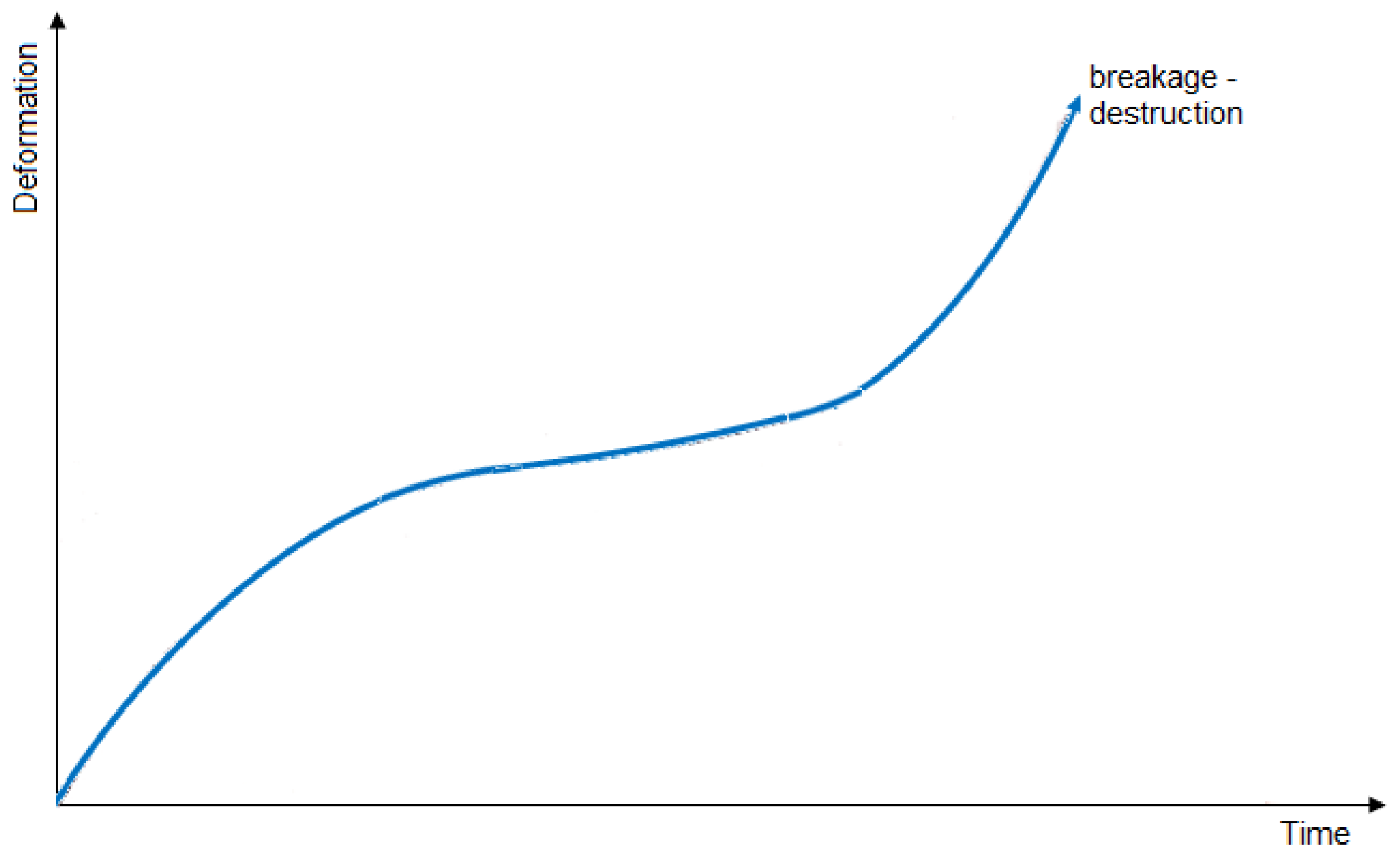

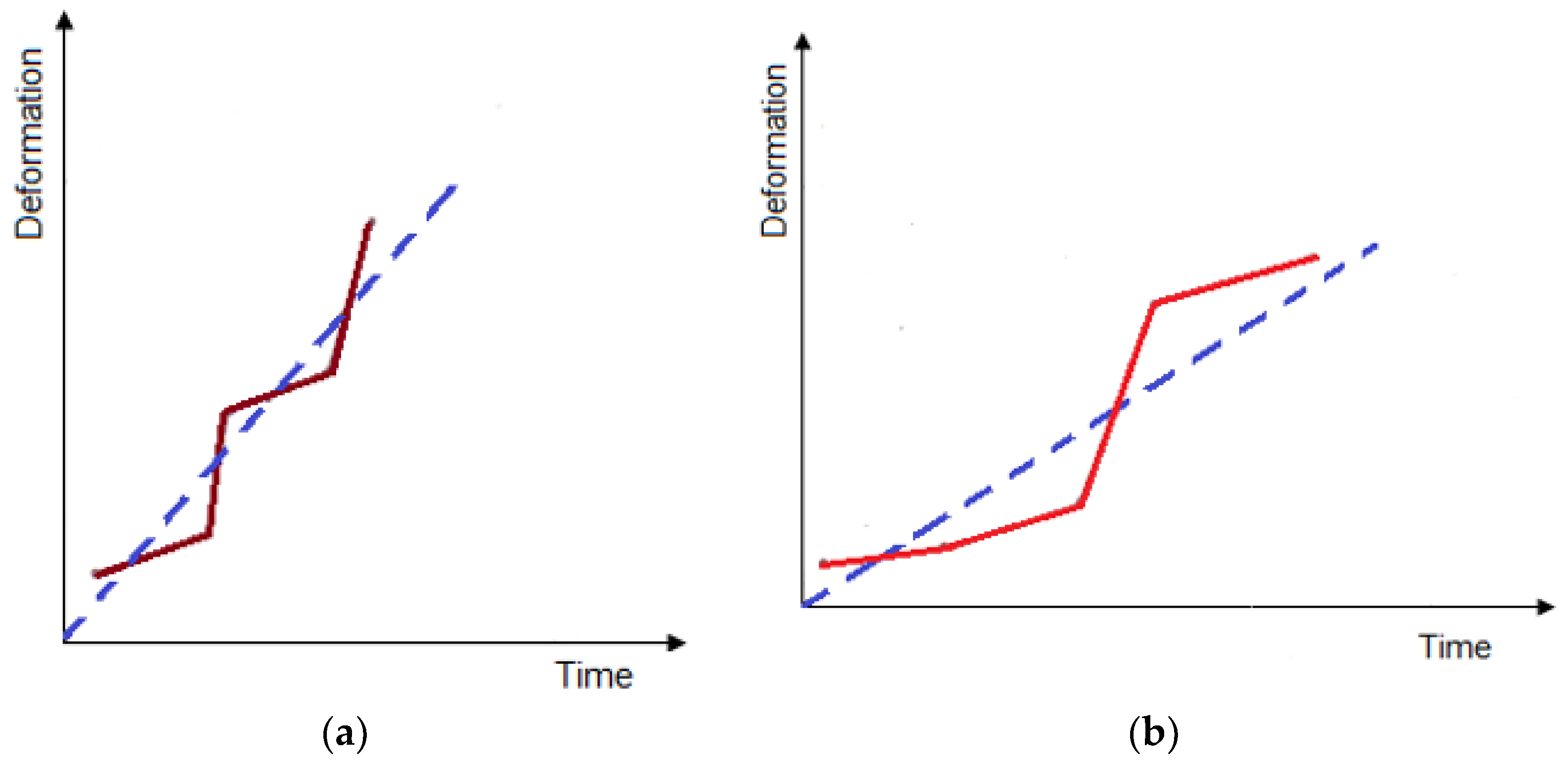

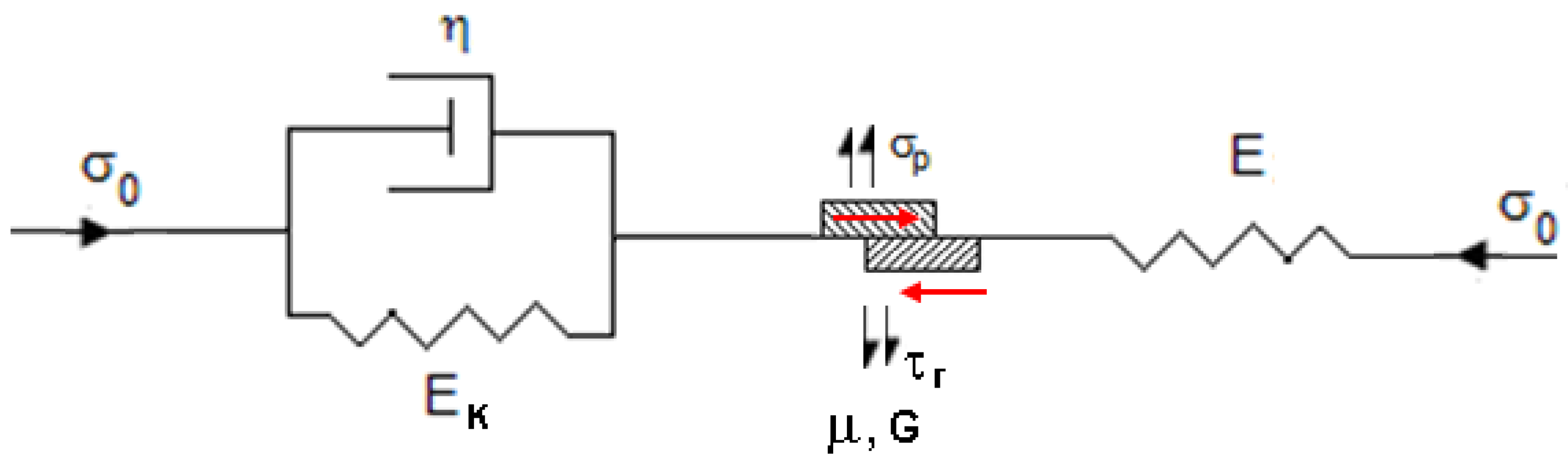

| Stage | State | Behavior 1 | Flow Criterion | Effects that Appear |

|---|---|---|---|---|

| 1 | Initial state | Elastic to elastic–viscous (Poynting–Thomson model) | - | No change in volume |

| 2 | Weathering state | Elastic–plastic | Volume increase | |

| 3 | Breaking | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toderas, M. Mathematical Model for Establishing the Time-Dependent Behavior of Rocks by the Gradient Method. Appl. Sci. 2022, 12, 11877. https://doi.org/10.3390/app122311877

Toderas M. Mathematical Model for Establishing the Time-Dependent Behavior of Rocks by the Gradient Method. Applied Sciences. 2022; 12(23):11877. https://doi.org/10.3390/app122311877

Chicago/Turabian StyleToderas, Mihaela. 2022. "Mathematical Model for Establishing the Time-Dependent Behavior of Rocks by the Gradient Method" Applied Sciences 12, no. 23: 11877. https://doi.org/10.3390/app122311877

APA StyleToderas, M. (2022). Mathematical Model for Establishing the Time-Dependent Behavior of Rocks by the Gradient Method. Applied Sciences, 12(23), 11877. https://doi.org/10.3390/app122311877