Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network

Abstract

1. Introduction

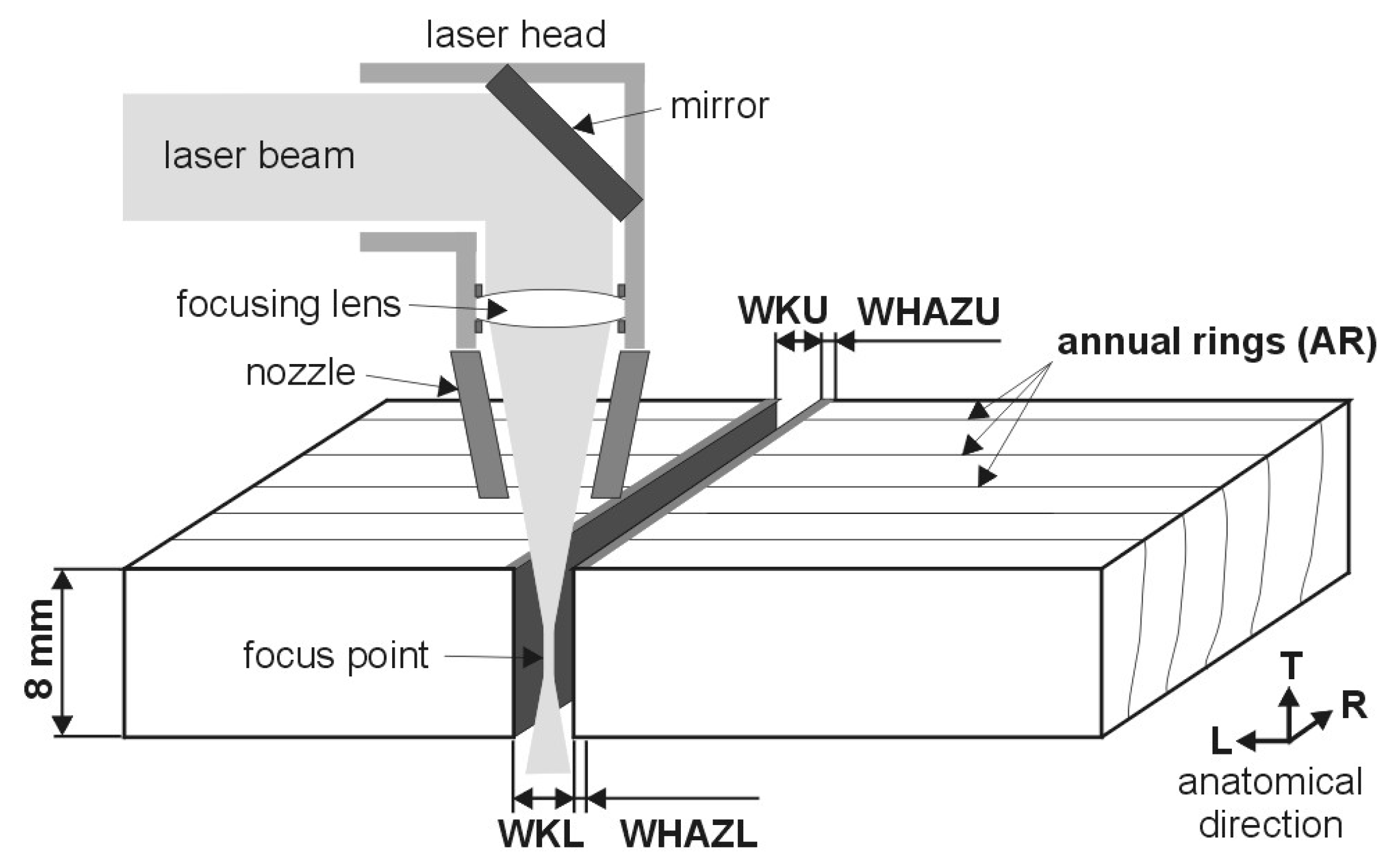

2. Materials and Methods

Basics of Artificial Neural Networks

- The neural network can learn

- The neural network can generalize

- Neural networks need more values of one or more parameters that change in every dataset as input compared with standard fitting procedures such as the-least squares method and many others.

3. Results and Discussion

3.1. Measured Values

3.2. ANN Prediction

- The coefficient of determination R2 for all the output parameters dependent on the input parameters is at least 0.933.

- The slope which should be close to 1 is for all the studied parameters higher than 0.94, which is a very good result.

- The maximum value of Rel_RMSE which in percentage is equal to 3.5% is highly under the measuring accuracy from which we can conclude that ANN can predict with accuracy all the studied cutting results’ parameters.

- ANN can teach and predict with very high accuracy all the studied parameters.

- In the next three chapters we will deal with prediction of (WKU, WHAZU), (WKL, WHAZL) and WKR vs. P and AR and discuss the effects of P and AR on all the predicted parameters.

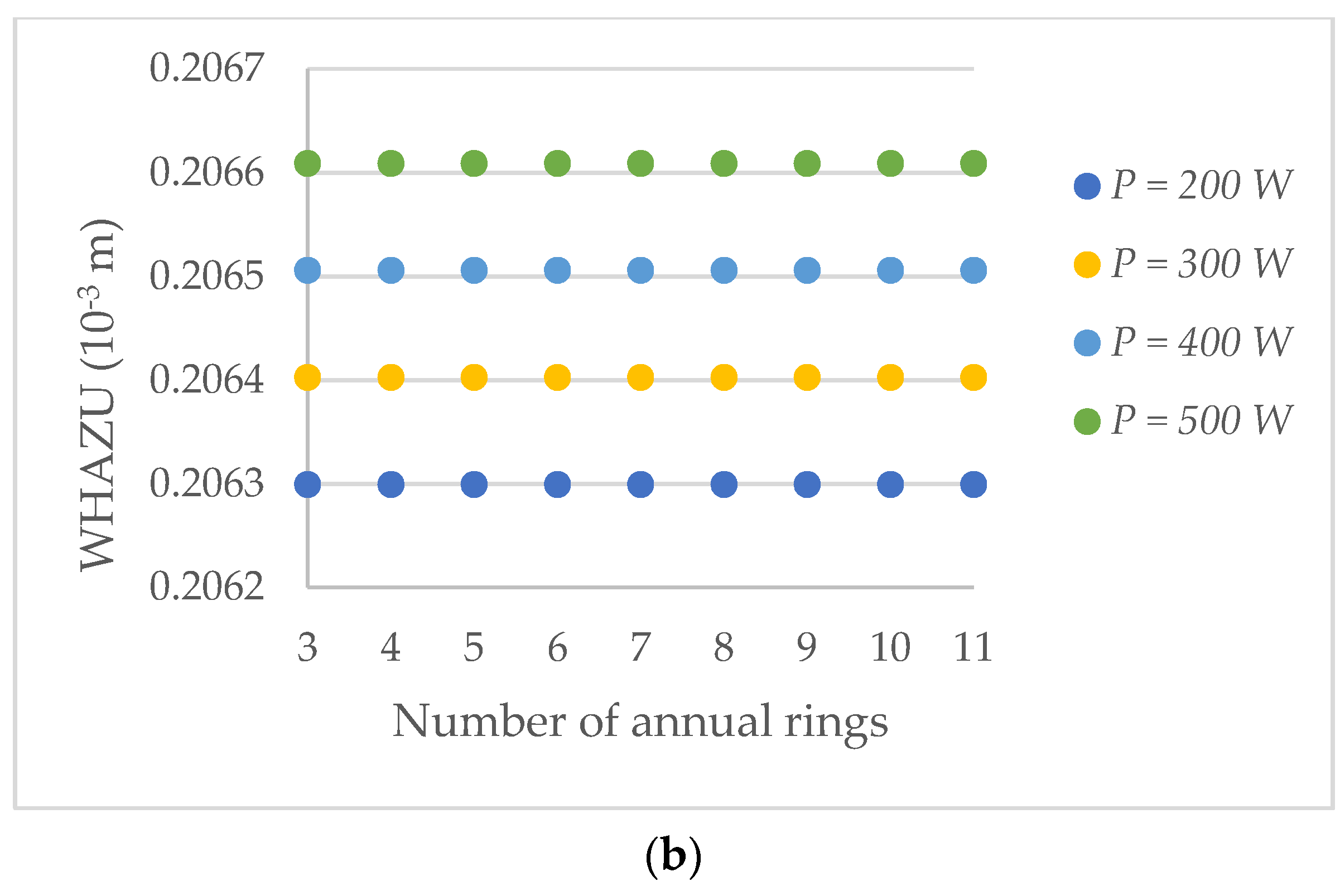

3.3. Prediction of WKU, WHAZU versus AR and P

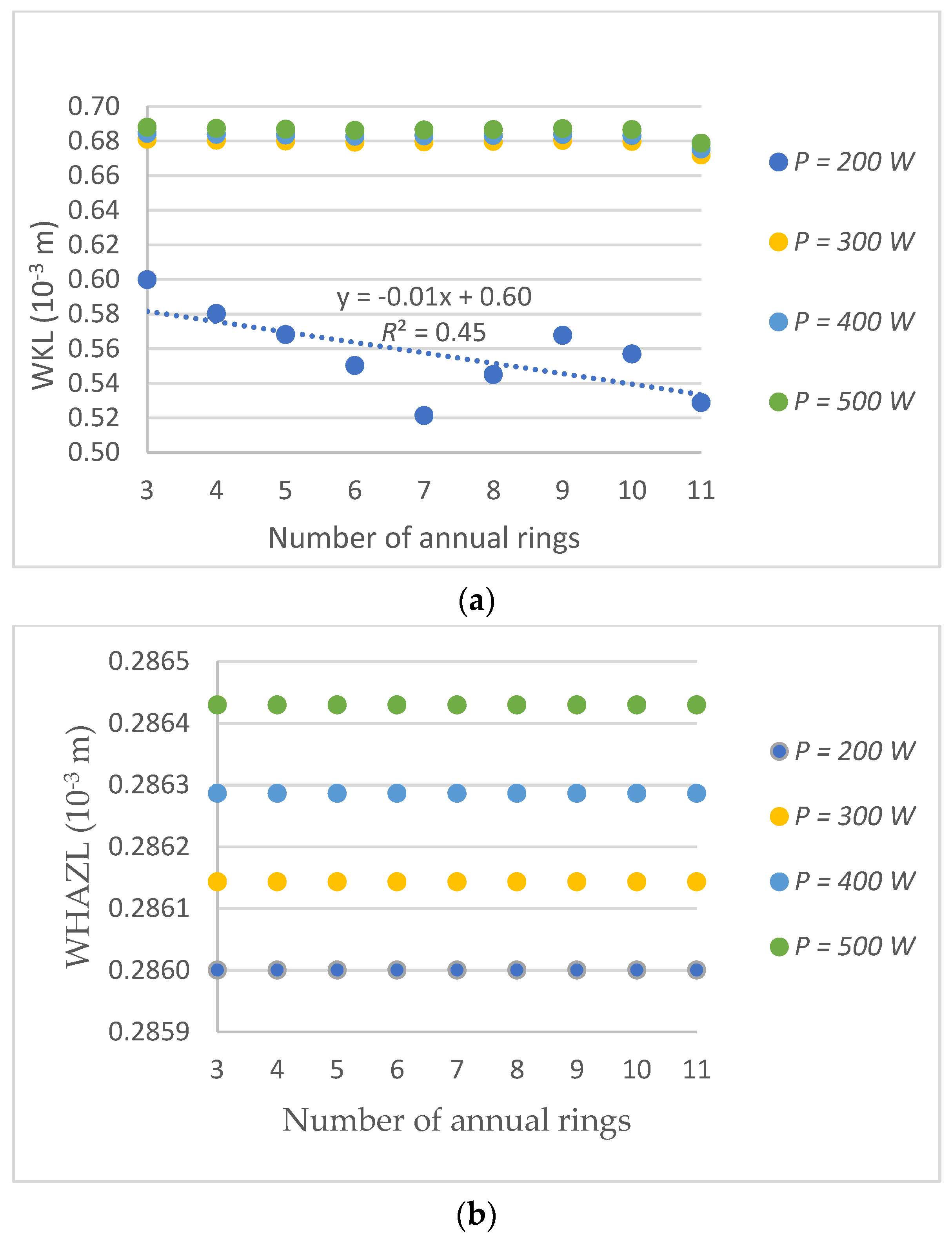

3.4. Prediction of WKL, WHAZL versus AR, P

3.5. Comparison of P and AR Effect on Cutting Kerf Width and Width of the Heat Affected Zone for the Upper Board and Lower Board

- For all values of P, AR value of WKU is statistically significantly higher than for WKL which is caused by the fact that at lower board heat transfer, it plays a more significant role in the kerf region.

- For all values of P, AR value of WHAZU is statistically significantly lower than for WHAZL which is caused by the fact that at lower board heat transfer, it plays a more significant role in the heat affected zone region.

- The smallest difference between the values of WKU and WKL is at a minimal power of 200 W.

- AR and P do not play a significant role in both WHAZU and WHAZL.

- WHAZU is significantly lower than WHAZL because of heat transfer from the upper board to the lower board in the HAZ region.

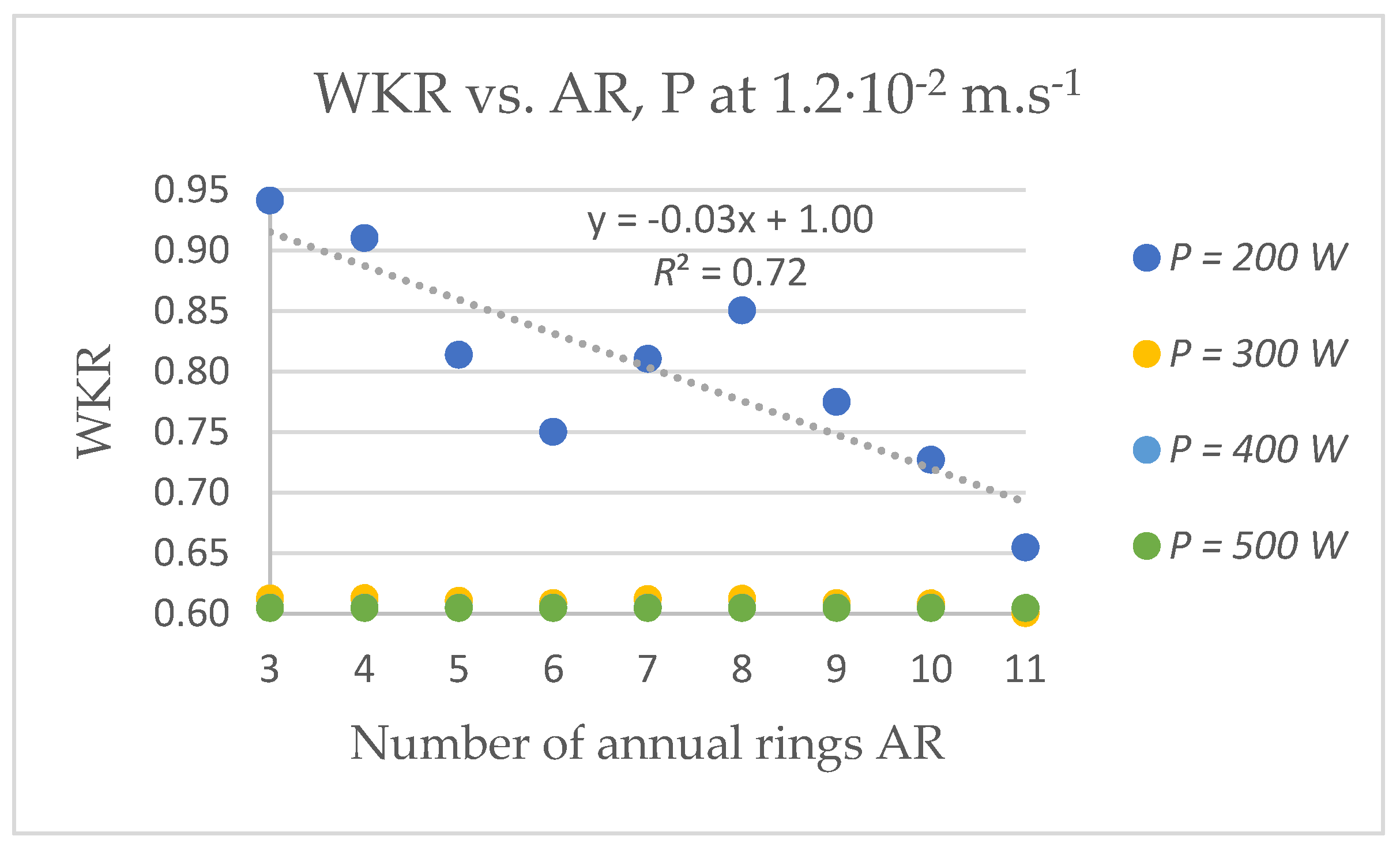

3.6. Prediction of WKR versus Number of Annual Rings AR and Laser Power P

4. Conclusions

- The width of a kerf at the upper surface (WKU) and the width of a kerf at the lower surface (WKL) do not increase with a P higher than 300 W.

- Both AR and P do not have a significant effect on WHAZU and WHAZL.

- AR changes WKR only when P is lower than 300 W, thus AR has an effect on WKR only for low CO2 laser powers.

- The values of WKU for all the studied parameters of P and AR are statistically significantly higher than for WKL which is in contrast with the increased value of WHAZL vs. WHAZU at cca. 40% level.

- The values of WKR at a P higher than 200 W are cca. equal to 0.7 which is a very low value therefore higher powers lead to worse cutting quality so we can conclude that they are not appropriate for a cutting speed of 1.2·10−2 m·s−1.

- Generally, the value of P = 200 W improves the cutting quality in the terms of WKR values and therefore they are optimal for wood cutting at 1.2·10−2 m·s−1. The values of WKR at P = 200 W are higher than the values of this parameter at 100 and 150 W even if the cutting speed at optimization (1.2.10−2 m·s−1) is higher than at the measured dataset (max 0.9. 10−2 m·s−1).

- Prediction of the cutting conditions of spruce wood machined by CO2 laser effects on cut characteristics, obtained by artificial neural network MLP 3-3-5, can be used for qualitative characterization of the cutting conditions in wooden technological processes.

- In our article, we predicted the effect of P and AR by constant value of v on the cut characteristics and therefore we used regression modelling using ANN in Statistica software. According to abovementioned parameters this showed a very good correlation, and a low sum of squares error, which for characterization of wood materials cutting is highly under the error level at which these properties are measured, which is in good agreement with other authors’ results.

- In the next stage of research, we will focus on studying the cutting speed v, the number of annual circles (AR) and the laser power P effect on all above-mentioned parameters, as it is very useful to compare the results with other approaches, which should be deep learning approaches, non-linear parametric fitting procedures and many others to optimize the accuracy of the prediction of cut characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abidou, D.; Yusoff, N.; Nazri, N.; Awang, M.A.O.; Hassan, M.A.; Sarhan, A.A.D. Numerical simulation of metal removal in laser drilling using radial point interpolation method. Eng. Anal. Bound. Elem. 2017, 77, 89–96. [Google Scholar] [CrossRef]

- Mukherjee, K.T.; Grendzwell, P.A.A.; McMillin, C.W. Gas-flow parameters in laser cutting of wood-nozzle design. For. Prod. J. 1990, 40, 39–42. Available online: https://www.fs.usda.gov/research/treesearch/8245 (accessed on 11 September 2022).

- Sinn, G.; Chuchala, D.; Orlowski, K.; Tauble, P. Cutting model parameters from frame sawing of natural and impregnated Scots Pine (Pinus sylvestris L.). Eur. J. Wood Wood Prod. 2020, 78, 777–784. [Google Scholar] [CrossRef]

- Martinez-Conde, A.; Krenke, T.; Frybort, S.; Muller, U. Review: Comparative analysis of CO2 laser and conventional sawing for cutting of lumber and wood-based materials. Wood Sci. Technol. 2017, 51, 943–966. [Google Scholar] [CrossRef]

- Ready, J.F.; Farson, D.F.; Feeley, T. LIA Handbook of Laser Materials Processing; Laser Institute of America, Magnolia Publishing: Orlando, FL, USA; Springer Nature: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Asibu, E.K. Principles of Laser Materials Processing; John Wiley and Sons: New York, NY, USA, 2009. [Google Scholar]

- Kubovský, I.; Krišťák, Ľ.; Suja, J.; Gajtanska, M.; Igaz, R.; Ružiak, I.; Réh, R. Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser. Appl. Sci. 2020, 10, 8113. [Google Scholar] [CrossRef]

- Nukman, Y.; Saiful, R.I.; Azuddin, M.; Aznijar, A.Y. Selected Malaysian Wood CO2 Laser Cutting Parameters and Cut Quality. Am. J. Appl. Sci. 2008, 5, 990–996. [Google Scholar] [CrossRef]

- Barcikowski, S.; Koch, G.; Odermatt, J. Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites. Holz Roh Werkst. 2006, 64, 94–103. [Google Scholar] [CrossRef]

- Lum, K.C.P.; Hg, S.L.; Black, I. CO2 laser cutting of MDF: Determination of process parameter settings. J. Opt. Laser Technol. 2000, 32, 67–76. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Olabi, A.G.; Benyounis, K.Y. Investigating the CO2 laser cutting parameters of MDF wood composite material. Opt. Laser Technol. 2011, 43, 648–659. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Rossini, N.S.; Dassisti, M.; Alrashed, K.; Aldaham, T.A.; Benyounis, K.Y.; Olabi, A.G. Evaluation and optimization of laser cutting parameters for plywood materials. Opt. Lasers Eng. 2013, 51, 1029–1043. [Google Scholar] [CrossRef]

- Barnekov, V.G.; McMillin, C.W.; Huber, H.A. Factors influencing laser cutting of wood. For. Prod. J. 1986, 36, 55–58. [Google Scholar]

- Barnekov, V.G.; Huber, H.A.; McMillin, C.W. Laser machining wood composites. For. Prod. J. 1989, 39, 76–78. [Google Scholar] [CrossRef]

- Ng, S.L.; Lum KC, P.; Black, I. CO2 laser cutting of MDF:2. Estimation of power distribution. J. Opt. Laser Technol. 2000, 32, 77–87. [Google Scholar] [CrossRef]

- Hernandez-Castaneda, C.J.; Sezer, K.H.; Li, L. The effect of moisture content in fibre laser cutting of pine wood. Opt. Lasers Eng. 2011, 49, 1139–1152. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Boutinguiza, M.; del Val., J.; Comesana, R.; Lusquinos, F.; Pou, J. Laser Cutting: A Review on the Influence of Assist Gas. Materials 2019, 12, 157. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, C.; Xue, B.; Miao, Q.; Liu, J. Processing Technology and Experimental Analysis of Gas-assisted Laser Cut Micro Thin Wood. BioResources 2020, 15, 5366–5378. [Google Scholar] [CrossRef]

- Dhanachandra, N.; Manglem, K.; Chanu, Y.J. Image Segmentation Using K-means Clustering Algorithm and Subtractive Clustering Algorithm. Procedia Comput. Sci. 2015, 54, 764–771. [Google Scholar] [CrossRef]

- Fukuta, S.; Nomura, M.; Ikeda, T.; Yoshizawa, M.; Yamasaki, M.; Sasaki, Y. UV laser machining of wood. Eur. J. Wood Wood Prod. 2016, 74, 261–267. [Google Scholar] [CrossRef]

- Fukuta, S.; Nomura, M.; Ikeda, T.; Yoshizawa, M.; Yamasaki, M.; Sasaki, Y. Wavelength dependence of machining performance in UV-, VIS- and NIR-laser cutting of wood. J. Wood Sci. 2016, 62, 316–323. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Surface properties of beech wood after CO2 laser engraving. Coatings 2020, 10, 77. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Impact of different radiation forms on beech wood discolouration. Wood Res. 2018, 63, 923–934. Available online: http://www.woodresearch.sk/wr/201806/01.pdf (accessed on 30 August 2022).

- Kubovský, I.; Kačík, F.; Veľková, V. The effects of CO2 laser irradiation on color and major chemical component changes in hardwoods. BioResources 2018, 13, 2515–2529. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačík, F.; Reinprecht, L. The impact of UV radiation on the change of colour and composition of the surface of lime wood treated with CO2 laser. J. Photochem. Photobiol. A Chem. 2016, 322, 60–66. [Google Scholar] [CrossRef]

- Avramidis, S.; Liadis, L. Predicting wood thermal conductivity using artificial neural networks. Wood Fiber. Sci. 2005, 37, 682–690. Available online: https://wfs.swst.org/index.php/wfs/article/view/260/260 (accessed on 15 August 2022).

- Tiryaki, S.; Malkocoglu, A.; Ozsahin, S. Using artificial neural networks for modeling surface roughness of wood in machining process. Constr. Build. Mater. 2014, 66, 329–335. [Google Scholar] [CrossRef]

- Tiriyaki, S.; Ozsahin, S.; Aydin, A. Employing artificial neural networks for minimizing surface roughness and power consumption in abrasive machining of wood. Eur. J. Wood Wood Prod. 2017, 75, 347–358. [Google Scholar] [CrossRef]

- Tiryaki, S.; Malkocoglu, A.; Ozsahin, S. Artificial neural network modelling to predict optimum power consumption in wood machining. Drewno 2016, 59, 109–125. [Google Scholar] [CrossRef]

- Akyuz, I.; Ozsahin, S.; Tiryaki, S.; Aydin, A. An application of artificial neural networks for modelling formaldehyde emission based on process parameters in particleboard manufacturing process. Clean Technol. Environ. Pol. 2017, 19, 1449–1458. [Google Scholar] [CrossRef]

- Tiryaki, S.; Aras, U.; Kalaycioglu, H.; Erisir, E.; Aydin, A. Predictive Models for Modulus of Rupture and Modulus of Elasticity of Particleboard Manufactured in Different Pressing Conditions. High Temp. Mat. Proc. 2017, 36, 623–634. [Google Scholar] [CrossRef]

- Bardak, S.; Tiryaki, S.; Bardak, T.; Aydin, A. Predictive Performance of Artificial Neural Network and Multiple Linear Regression Models in Predicting Adhesive Bonding Strength of Wood. Strength Mater. 2016, 48, 811–824. [Google Scholar] [CrossRef]

- Akyuz, I.; Ersen, N.; Tiryaki, S.; Bayram, B.C.; Akyuz, K.C.; Peker, H. Modelling and comparison of bonding strength of impregnated wood material by using different methods: Artificial neural network and multiple linear regression. Wood Res. 2019, 64, 483–497. Available online: http://www.woodresearch.sk/.../10.pdf (accessed on 29 September 2022).

- Bardak, S.; Tiryaki, S.; Nemli, G.; Aydin, A. Investigation and neural network prediction of wood bonding quality based on pressing conditions. Int. J. Adh. Adh. 2016, 68, 115–123. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.H.V.; Ji, X.; Yuan, B.; Trinh, H.M.; Do, K.T.L.; Guo, M. Prediction of the color change of heat-treated wood during artificial weathering by artificial neural network. Eur. J. Wood Wood Prod. 2019, 77, 1107–1116. [Google Scholar] [CrossRef]

- Nguyen, T.H.V.; Nguyen, T.T.; Ji, X.; Guo, M. Predicting color change in Wood During Heat Treatment using an artificial neural network model. BioResources 2018, 13, 6250–6264. [Google Scholar] [CrossRef]

- Demir, A.; Cakiroglu, E.O.; Aydin, I. Determination of CNC processing parameters for the best wood surface quality via artificial neural network. Wood Mater. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Demir, A.; Birinci, A.U.; Ozturk, H. Determination of the surface characteristics of medium density fibreboard processed with CNC machine and optimisation of CNC process parameters by using artificial neural networks. J. Manuf. Sci. Technol. 2021, 35, 929–942. [Google Scholar] [CrossRef]

- Dou, Z.; Sun, Y.; Zhang, Y.; Wang, T.; Wu, C.; Fan, S. Regional Manufacturing Industry Demand Forecasting: A Deep Learning Approach. Appl. Sci. 2021, 11, 6199. [Google Scholar] [CrossRef]

| Value at P | WKU (10−3 m) | WKL (10−3 m) | WKR (-) | WHAZU (10−3 m) | WHAZL (10−3 m) |

|---|---|---|---|---|---|

| 100 | |||||

| 150 |

| Value at v | WKU (10−3 m) | WKL (10−3 m) | WKR (-) | WHAZU (10−3 m) | WHAZL (10−3 m) |

|---|---|---|---|---|---|

| 3 | |||||

| 6 | |||||

| 9 |

| Value at AR | WKU (10−3 m) | WKL (10−3 m) | WKR (-) | WHAZU (10−3 m) | WHAZL (10−3 m) |

|---|---|---|---|---|---|

| 3 | |||||

| 4 | |||||

| 5 | |||||

| 6 | |||||

| 7 | |||||

| 8 | |||||

| 9 | |||||

| 10 | |||||

| 11 |

| Net | Training Error (-) | Testing Error (-) | Validation Error (-) |

|---|---|---|---|

| MLP 3-7-5 | 0.019 | 0.023 | 0.022 |

| MLP 3-3-5 | 0.010 | 0.013 | 0.011 |

| MLP 3-10-5 | 0.018 | 0.022 | 0.022 |

| MLP 3-6-5 | 0.004 | 0.014 | 0.011 |

| MLP 3-10-5 | 0.030 | 0.030 | 0.036 |

| Statistical Parameter of | WKU (10−3 m) | WKL (10−3 m) | WKR (-) | WHAZU (10−3 m) | WHAZL (10−3 m) |

|---|---|---|---|---|---|

| Slope (-) | 0.970 | 0.960 | 0.940 | 0.960 | 0.970 |

| R2 (-) | 0.950 | 0.980 | 0.933 | 0.960 | 0.970 |

| RMSE (parameter units) | 0.010 | 0.004 | 0.012 | 0.001 | 0.002 |

| Rel_RMSE (-) | 0.018 | 0.012 | 0.035 | 0.009 | 0.013 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ružiak, I.; Igaz, R.; Kubovský, I.; Gajtanska, M.; Jankech, A. Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network. Appl. Sci. 2022, 12, 11355. https://doi.org/10.3390/app122211355

Ružiak I, Igaz R, Kubovský I, Gajtanska M, Jankech A. Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network. Applied Sciences. 2022; 12(22):11355. https://doi.org/10.3390/app122211355

Chicago/Turabian StyleRužiak, Ivan, Rastislav Igaz, Ivan Kubovský, Milada Gajtanska, and Andrej Jankech. 2022. "Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network" Applied Sciences 12, no. 22: 11355. https://doi.org/10.3390/app122211355

APA StyleRužiak, I., Igaz, R., Kubovský, I., Gajtanska, M., & Jankech, A. (2022). Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network. Applied Sciences, 12(22), 11355. https://doi.org/10.3390/app122211355