Determination of the Filler Concentration of the Composite Tape

Abstract

1. Introduction

2. Materials and Methods

- is the filler concentration of the composite tape;

- is modulus of elasticity of the composite tape matrix;

- is the modulus of elasticity of the filler of the composite tape.

- is a matrix hardness;

- is the hardness of the filler.

- is the initial concentration of the filler of the composite tape;

- is the circumference of the CBRTB, which can be determined by the formula:

- is the diameter of the CBRTB;

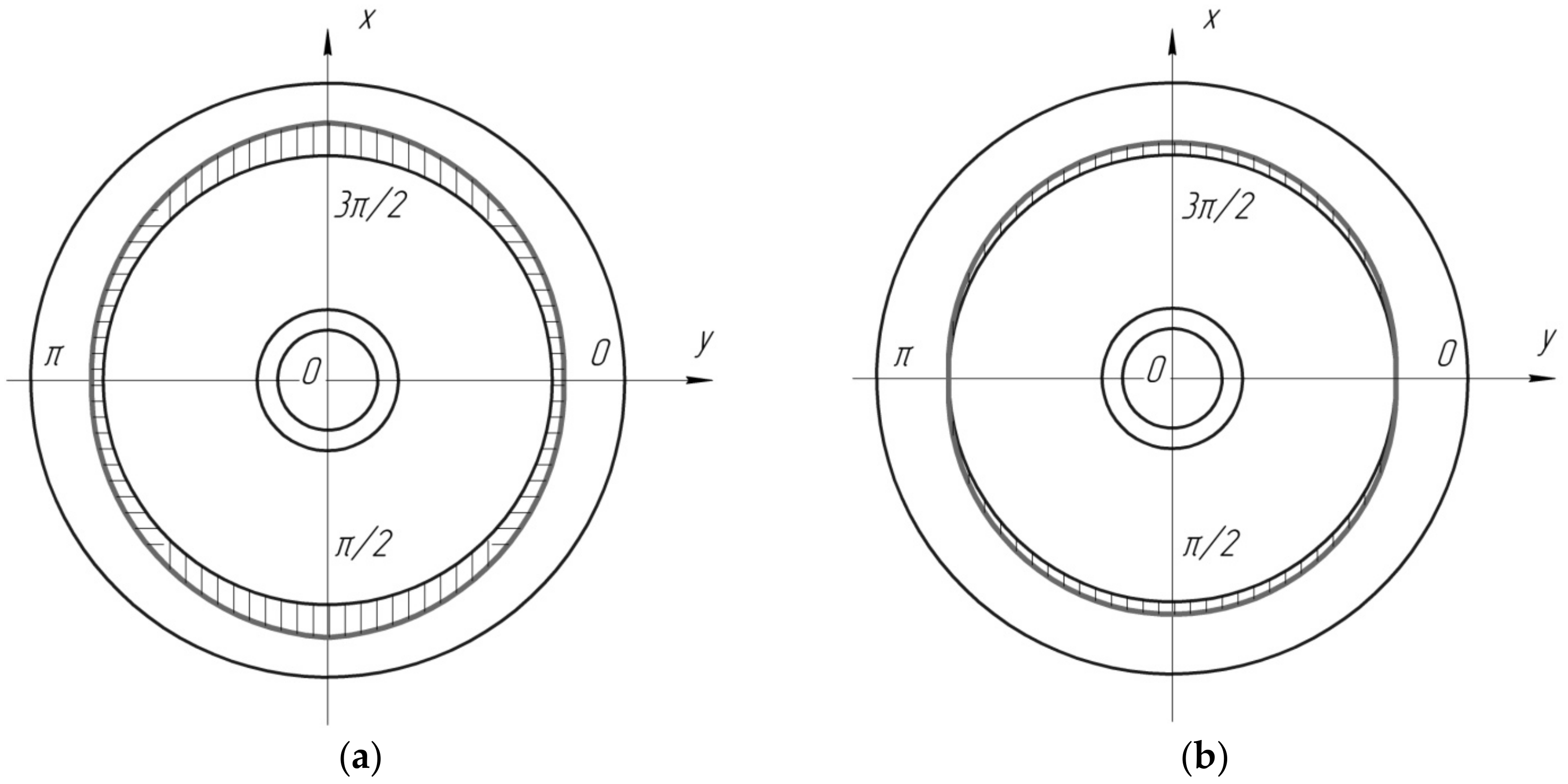

- is the angle for the corresponding point, which is shown in Figure 1.

3. Results

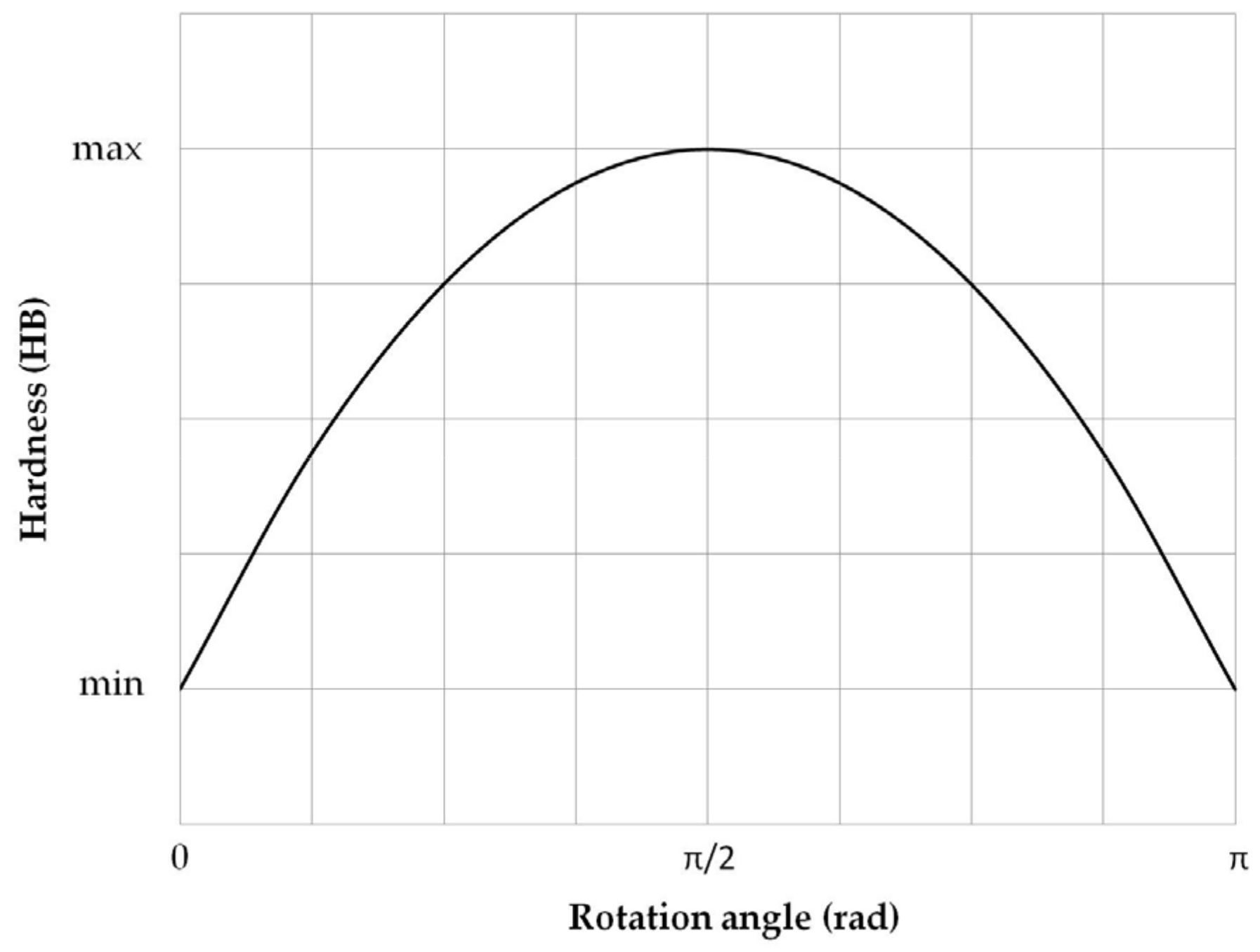

3.1. Composite Tape Hardness Test

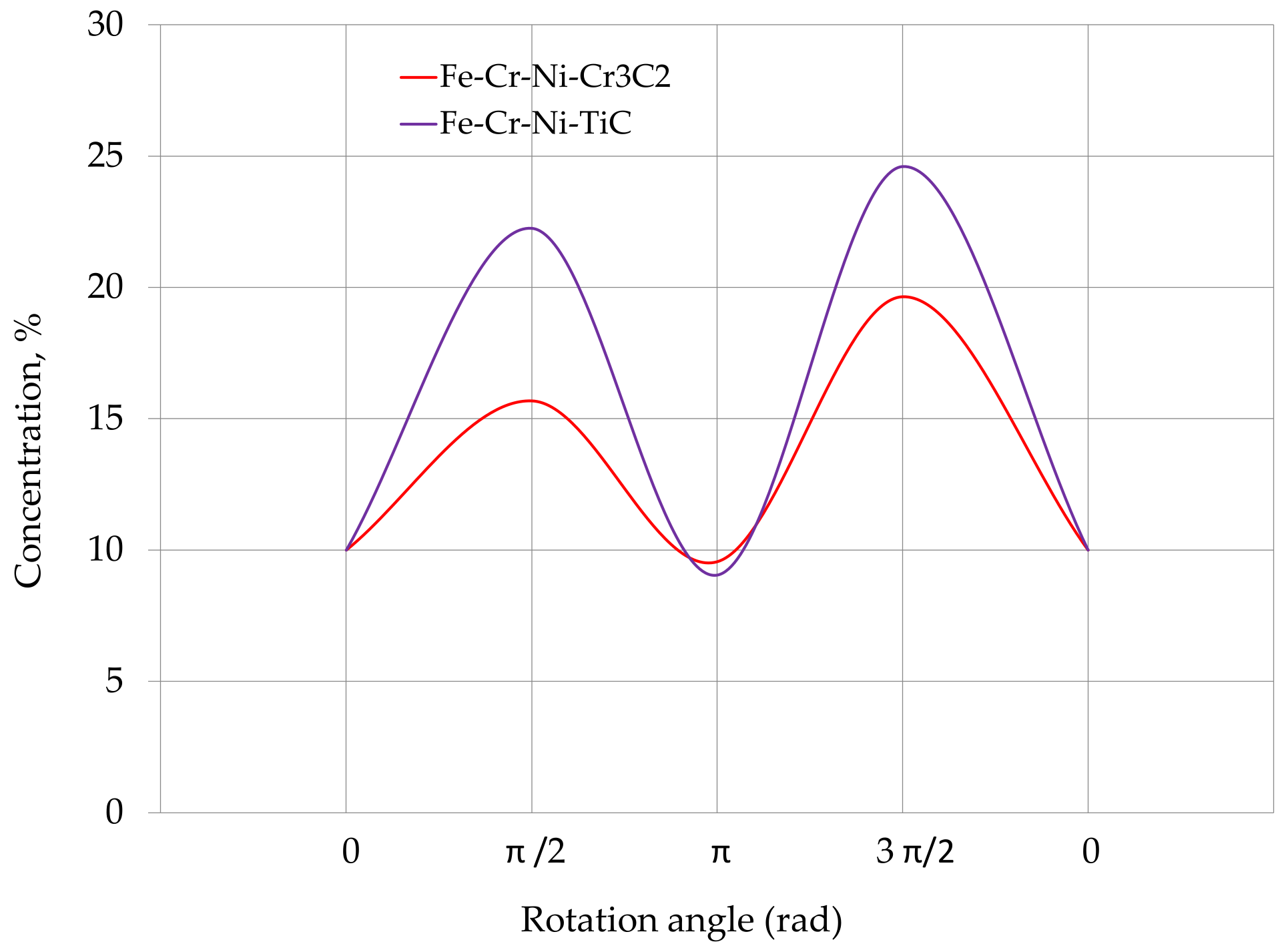

3.2. Theoretical Distribution of Filler in Composite Tape

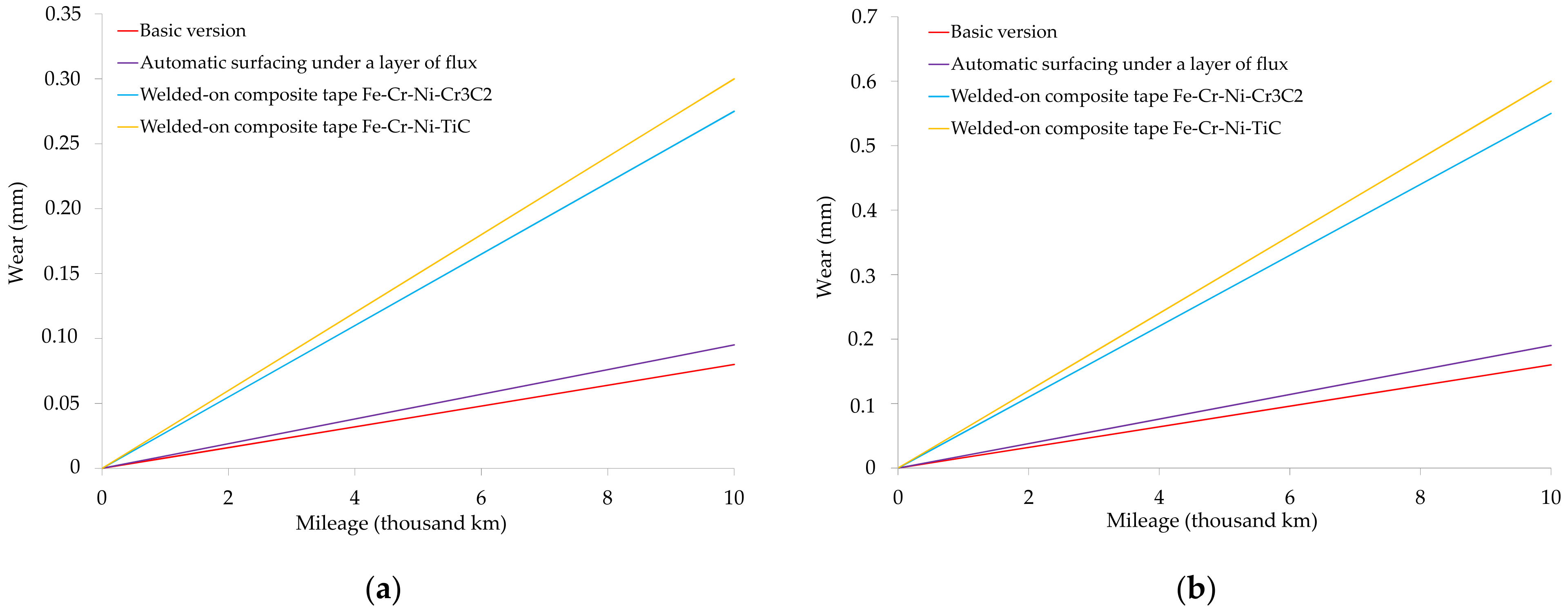

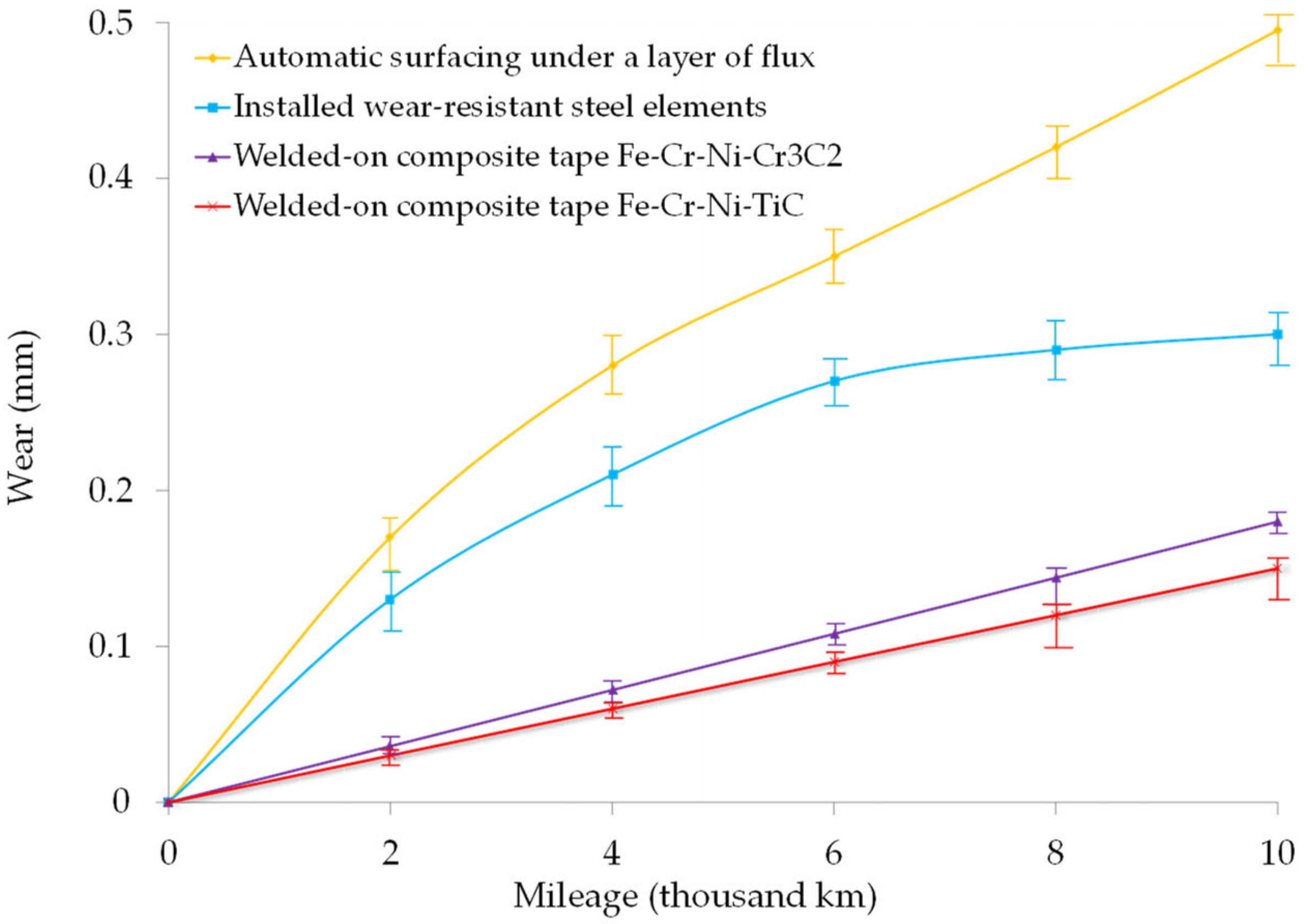

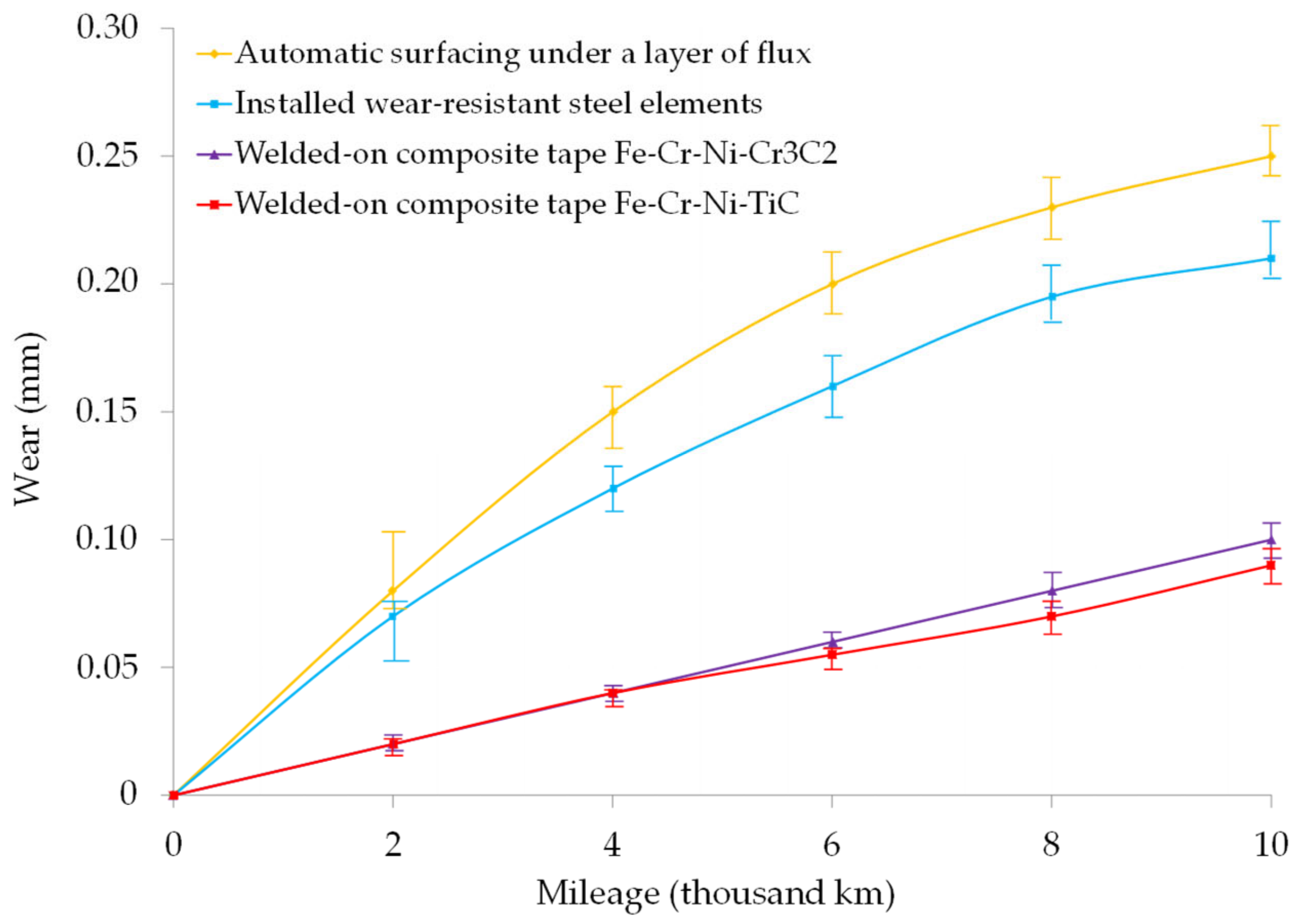

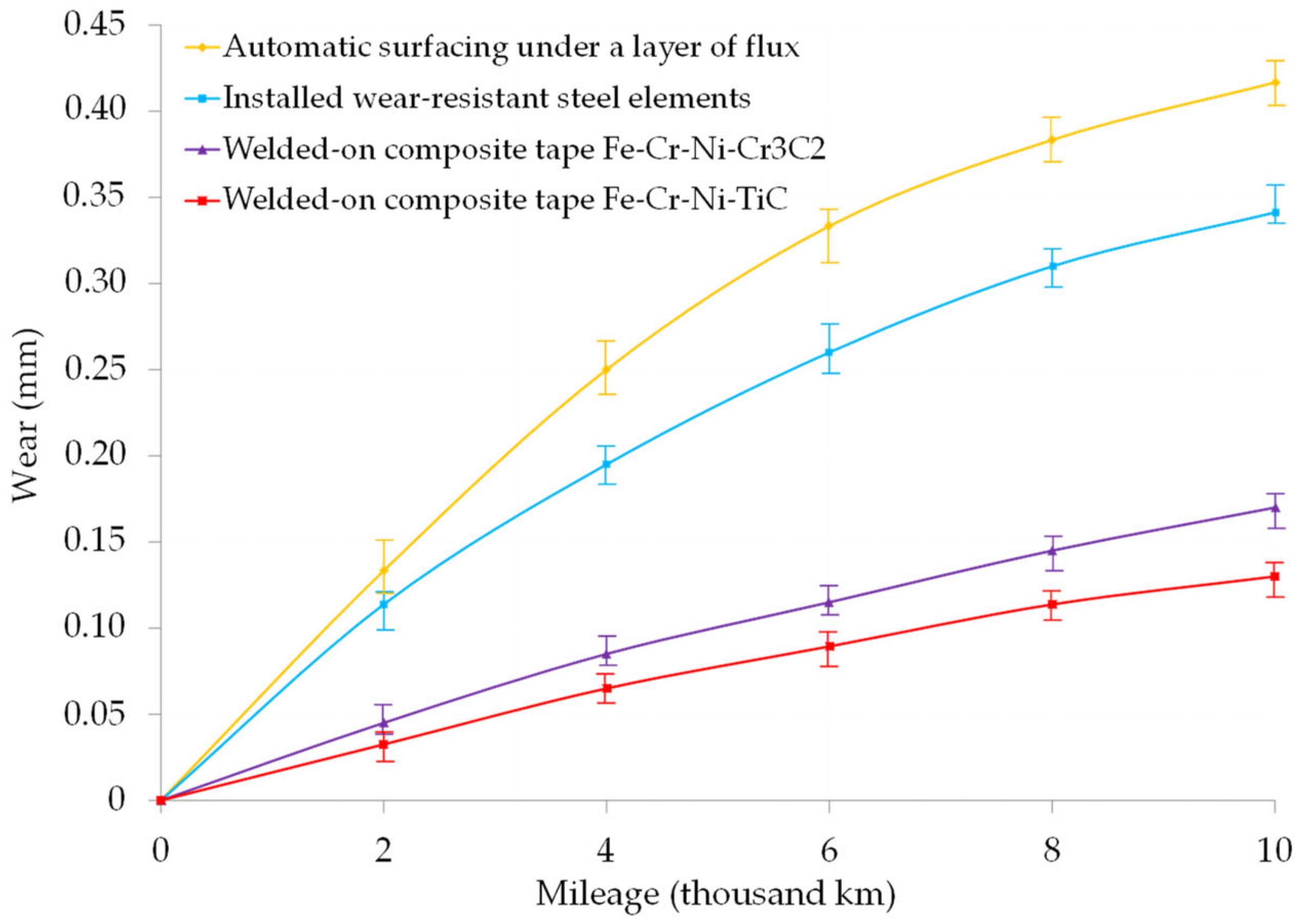

3.3. Theoretical Dependences of the Wear of a Composite Tape

3.4. Adhesion Strength of Composite Tapes

3.5. Experimental Studies of Wear of the CBRTB

- -

- With installed wear-resistant steel elements;

- -

- Restored cylindrical surfaces by automatic submerged arc surfacing.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, Z.; Lu, Y.; Miller, A.; Johnson, C.; Zhao, T. Risk Assessment of Railway Transportation Systems using Timed Fault Trees. Qual. Reliab. Eng. 2016, 32, 181–194. [Google Scholar] [CrossRef]

- Babyak, M.; Keršys, R.; Neduzha, L. Improving the dependability evaluation technique of a transport vehicle. In Proceedings of the Transport Means 2020—24th International Conference, Kaunas, Lithuania, 30 September–2 October 2020; pp. 646–651. [Google Scholar]

- Pshinko, O.M.; Ursulyak, L.V.; Zhelieznov, K.I.; Shvets, A.O. To the problem of train running safety. IOP Conf. Ser. Mater. Sci. Eng. 2020, 985, 012014. [Google Scholar] [CrossRef]

- Lingaitis, L.P.; Mjamlin, S.; Baranovsky, D.; Jastremskas, V. Experimental Investigations on Operational Reliability of Diesel Locomotyves Engines. Eksploatacja Niezawodnosc—Maint. Reliab. 2012, 14, 5–10. [Google Scholar]

- Baranovskyi, D.; Myamlin, S.; Kebal, I. Increasing the Carrying Capacity of the Solid-Body Rail Freight Car. Adv. Sci. Technol. Res. J. 2022, 16, 219–225. [Google Scholar] [CrossRef]

- Baranovskyi, D.; Muradian, L.; Bulakh, M. The Method of Assessing Traffic Safety in Railway Transport. IOP Conf. Ser. Mater. Sci. Eng. 2021, 666, 042075. [Google Scholar] [CrossRef]

- Lingaitis, L.P.; Mjamlin, S.; Baranovsky, D.; Jastremskas, V. Prediction methodology of durability of locomotives diesel engines. Eksploatacja Niezawodnosc—Maint. Reliab. 2012, 14, 154–159. [Google Scholar]

- Bulakh, M.; Okorokov, A.; Baranovskyi, D. Risk System and Railway Safety. IOP Conf. Ser. Mater. Sci. Eng. 2021, 666, 042074. [Google Scholar] [CrossRef]

- Shibo, W.; Yong, M.; Bing, T.; Li, P. Modeling and simulating of center plate of the body torsion behavior during bogie curve and turnout negotiation. J. Mech. Sci. Technol. 2014, 28, 2723–2732. [Google Scholar] [CrossRef]

- Olshevskiy, A.; Kim, C.W.; Yang, H.I.; Olshevskiy, A. Wear simulation for the centre plate arrangement of a freight car. Veh. Syst. Dyn. 2015, 53, 856–876. [Google Scholar] [CrossRef]

- Romero Navarrete, J.A.; Otremba, F. A variable friction centre plate. In IFToMM World Congress on Mechanism and Machine Science; Springer: Cham, Switzerland, 2019; pp. 3611–3620. [Google Scholar] [CrossRef]

- Poveda-Reyes, S.; Rizzetto, L.; Triti, C.; Shi, D.; Garcia-Jimenez, E.; Molero, G.D.; Santarremigia, F.E. Risk evaluation of failures of the running gear with effects on rail infrastructure. Eng. Fail. Anal. 2021, 128, 105613. [Google Scholar] [CrossRef]

- Gorbunov, M.; Kara, S.; Nozhenko, O.; Fomin, O.; Vaiciūnas, G.; Petrenko, V. Creation of the image of the new generation freight car bogie. In Proceedings of the Transport Means 2018—22nd International Scientific Conference, Trakai, Lithuania, 3–5 October 2018; pp. 1277–1283. [Google Scholar]

- Martynov, I.; Trufanova, A.; Shovkun, V. Construction of the simulation model “car railway track” for modeling the dynamic loading process of the boot node. MATEC Web Conf. 2018, 230, 101–115. [Google Scholar] [CrossRef][Green Version]

- Anthony, L. US 20190106131 A1. Railway Truck Bolster Center Bowl Liner. Publication Apr 11, 2019. B61F 5/04 (20060101). Swoboda; Anthony, L. (Villa Ridge, MO). Available online: https://www.freepatentsonline.com/y2019/0106131.html (accessed on 11 October 2022).

- De Luca, A.; Caputo, F. A review on analytical failure criteria for composite materials. AIMS Mater. Sci. 2017, 4, 1165–1185. [Google Scholar] [CrossRef]

- Todor, M.P.; Bulei, C.; Kiss, I. An overview on fiber-reinforced composites used in the automotive industry. ANNALS Fac. Eng. Hunedoara—Int. J. Eng. 2017, 15, 181–188. [Google Scholar]

- Benzait, Z.; Trabzon, L. A Review of Recent Research on Materials Used in Polymer–Matrix Composites for Body Armor Application. J. Compos. Mater 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Narayana, K.J.; Burela, R.G. A review of recent research on multifunctional composite materials and structures with their applications. Mater. Today Proc. 2018, 5, 5580–5590. [Google Scholar] [CrossRef]

- Gan, Y.X. A review of electrohydrodynamic casting energy conversion polymer composites. AIMS Mater. Sci. 2018, 5, 206–225. [Google Scholar] [CrossRef]

- Al-Mezrakchi, R.; Al-Ramthan, A.; Alam, S. Designing and modeling new generation of advanced hybrid composite sandwich structure armors for ballistic threats in defense applications. AIMS Mater. Sci. 2020, 7, 608–631. [Google Scholar] [CrossRef]

- Czech, K.; Oliwa, R.; Krajewski, D.; Bulanda, K.; Oleksy, M.; Budzik, G.; Mazurkow, A. Hybrid Polymer Composites Used in the Arms Industry: A Review. Materials 2021, 4, 3047. [Google Scholar] [CrossRef]

- Sharma, V.K.; Kumar, V.; Joshi, R.S.; Jain, S.; Kumar, P. A Review of Recent Research on Rare Earth Particulate Composite Materials and Structures with Their Applications. Trans. Indian Inst. Met. 2021, 74, 2569–2581. [Google Scholar] [CrossRef]

- Ghalandari, M.; Toozandehjani, H.; Mahariq, I.; Abeljawad, T. Determination of Composite Properties in the Presence of Fiber Deboning and Matrix Damage by Using the Method of Cell. Preprints 2020, 6, 2020090143. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Z.M. Stress concentration factor in matrix of a composite reinforced with transversely isotropic fibers. J. Compos. Mater. 2013, 48, 81–98. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y.; Jin, Q. A novel synergistic multi-scale modeling framework to predict micro- and meso-scale damage behaviors of 2D triaxially braided composite. Int. J. Damage Mech. 2021, 31, 108–141. [Google Scholar] [CrossRef]

- Huang, Z.-M. Constitutive Relation, Deformation, Failure and Strength of Composites Reinforced with Continuous/Short Fibers or Particles. Compos. Struct. 2020, 262, 113279. [Google Scholar] [CrossRef]

- Kanaoun, S.K. Effective Properties of Matrix Composite Materials with High Volume Concentrations of Inclusions (Effective Field Approach). In Continuum Models and Discrete Systems; Bergman, D.J., Inan, E., Eds.; NATO Science Series; Springer: Dordrecht, The Netherlands, 2004; Volume 158, p. 537. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Liu, L. Assessment of composite failure and ultimate strength without experiment on composite. Acta Mech. Sin. 2014, 30, 569–588. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Xin, L.M. Stress Concentration Factor in Matrix of a Composite Subjected to Transverse Compression. Int. J. Appl. Mech. 2016, 8, 1650034. [Google Scholar] [CrossRef]

- Lapčík, L.; Maňas, D.; Lapčíková, B.; Vašina, M.; Staněk, M.; Čépe KVlček, J.; Waters, K.E.; Greenwood, R.W.; Rowson, N.A. Effect of filler particle shape on plastic-elastic mechanical behavior of high density poly(ethylene)/mica and poly(ethylene)/wollastonite composites. Compos. B Eng. 2018, 141, 92–99. [Google Scholar] [CrossRef]

- Leon, A.; Perez, M.; Barasinski, A.; Abisset-Chavanne, E.; Defoort, B.; Chinesta, F. Multi-Scale Modeling and Simulation of Thermoplastic Automated Tape Placement: Effects of Metallic Particles Reinforcement on Part Consolidation. Nanomaterials 2019, 9, 695. [Google Scholar] [CrossRef]

- Marghalani, H.Y. Effect of filler particles on surface roughness of experimental composite series. J. Appl. Oral Sci. Rev. FOB 2010, 18, 59–67. [Google Scholar] [CrossRef]

- Gao, Y.; Picot, O.T.; Bilotti, E.; Peijs, T. Influence of Filler Size on the Properties of Poly(lactic acid) (PLA)/Graphene Nanoplatelet (GNP) Nanocomposites. Eur. Polym. J. 2016, 86, 117–131. [Google Scholar] [CrossRef]

- Fitriani, P.; Kwon, H.; Zhou, X.; Yoon, D.H. Joining of SiCf/SiC using a layered Ti3SiC2-SiCw and TiC gradient filler. J. Eur. Ceram. Soc. 2020, 40, 1043–1051. [Google Scholar] [CrossRef]

- Xiao, Z.; Ouyang, S.; Zhu, X.; Xu, W.; Wang, Z.; Shao, C. Investigation of Ti3AlC2 formation mechanism through diffusional reaction between carbon and Mo-modified Ti6Al4V. J. Eur. Ceram. Soc. 2020, 40, 1125–1131. [Google Scholar] [CrossRef]

- Guan, P.; Lei, J.; Zou, Y.; Zhang, Y. Improved Thermo-Mechanical Properties and Reduced Hydrogen Permeation of Short Side-Chain Perfluorosulfonic Acid Membranes Doped with Ti3C2Tx. Materials 2021, 14, 7875. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Fornes, T.D.; Paul, D.R. Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 2003, 44, 4993–5013. [Google Scholar] [CrossRef]

- Ciselli, P. The Potential of Carbon Nanotubes in Polymer Composites. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherland, 2007. [Google Scholar]

- Eriksson, M.; Goossens, H.; Peijs, T. Influence of the Solidification Process on the Mechanical Properties of Solid-State Drawn PCL/Sepiolite Nanocomposite Tapes. Fibers 2020, 8, 70. [Google Scholar] [CrossRef]

- Ostash, O.P.; Zhmur-Klimenko, V.T.; Yarema, S.Y.; Yushchenko, K.A.; Strok, L.P.; Belotserkovets, V.I. Low-temperature cyclic crack resistance of weld joints of Fe-Cr-Ni and Fe-Cr-Mn steels. Sov. Mater. Sci. 1983, 19, 205–209. [Google Scholar] [CrossRef]

- Starikov, S.A.; Kuznetsov, A.R.; Sagaradze, V.V.; Gornostyrev, Y.N.; Pechenkin, V.A.; Stepanov, I.A. Formation of grain boundary segregations in alloy Fe-Cr-Ni during strong deformation and under radiation. Phys. Met. Metallogr. 2012, 113, 241–245. [Google Scholar] [CrossRef]

- Andreev, A.O.; Galkin, M.P.; Libman, M.A.; Mironov, V.D.; Petrovskii, V.N.; Estrin, E.I. Use of Laser Heat Treatment for Creating Gradient Materials Based on the Fe–Cr–Ni System. Met. Sci. Heat Treat. 2014, 56, 53–56. [Google Scholar] [CrossRef]

- McCafferty, E. A Recent Model of Passivity for Fe-Cr and Fe-Cr-Ni Alloys. In Surface Chemistry of Aqueous Corrosion Processes; SpringerBriefs in Materials; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Zhang, J.; Young, D.J. Water Vapor Effects on Corrosion of Fe–Cr and Fe–Cr–Ni Alloys Containing Silicon in CO2 Gas at 818 °C. Oxid. Met. 2015, 83, 575–594. [Google Scholar] [CrossRef]

| Composite Tape | Average Hardness, HB | |||||

|---|---|---|---|---|---|---|

| Filler Concentration, % | ||||||

| 10 | 15 | 20 | 25 | 30 | 35 | |

| Fe-Cr-Ni-Cr3C2 | 335 | 344 | 372 | 395 | 390 | 382 |

| Fe-Cr-Ni-TiC | 359 | 374 | 397 | 387 | 378 | 366 |

| Composite Tape | Adhesion Strength, MPa | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pin No. | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Mean | |

| Fe-Cr-Ni-TiC | 287 ± 2 | 290 ± 2 | 297 ± 3 | 305 ± 2 | 295 ± 1 | 308 ± 2 | 307 ± 2 | 301 ± 1 | 303 ± 1 | 298 ± 2 | 299.2 ± 1.8 |

| Fe-Cr-Ni-Cr3C2 | 308 ± 1 | 309 ± 2 | 329 ± 3 | 315 ± 1 | 322 ± 3 | 328 ± 3 | 320 ± 2 | 308 ± 1 | 306 ± 1 | 312 ± 2 | 315.7 ± 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baranovskyi, D.; Myamlin, S.; Bulakh, M.; Podosonov, D.; Muradian, L. Determination of the Filler Concentration of the Composite Tape. Appl. Sci. 2022, 12, 11044. https://doi.org/10.3390/app122111044

Baranovskyi D, Myamlin S, Bulakh M, Podosonov D, Muradian L. Determination of the Filler Concentration of the Composite Tape. Applied Sciences. 2022; 12(21):11044. https://doi.org/10.3390/app122111044

Chicago/Turabian StyleBaranovskyi, Denys, Sergey Myamlin, Maryna Bulakh, Dmytro Podosonov, and Leonty Muradian. 2022. "Determination of the Filler Concentration of the Composite Tape" Applied Sciences 12, no. 21: 11044. https://doi.org/10.3390/app122111044

APA StyleBaranovskyi, D., Myamlin, S., Bulakh, M., Podosonov, D., & Muradian, L. (2022). Determination of the Filler Concentration of the Composite Tape. Applied Sciences, 12(21), 11044. https://doi.org/10.3390/app122111044