A Novel Cementing Quality Evaluation Method Based on Convolutional Neural Network

Abstract

1. Introduction

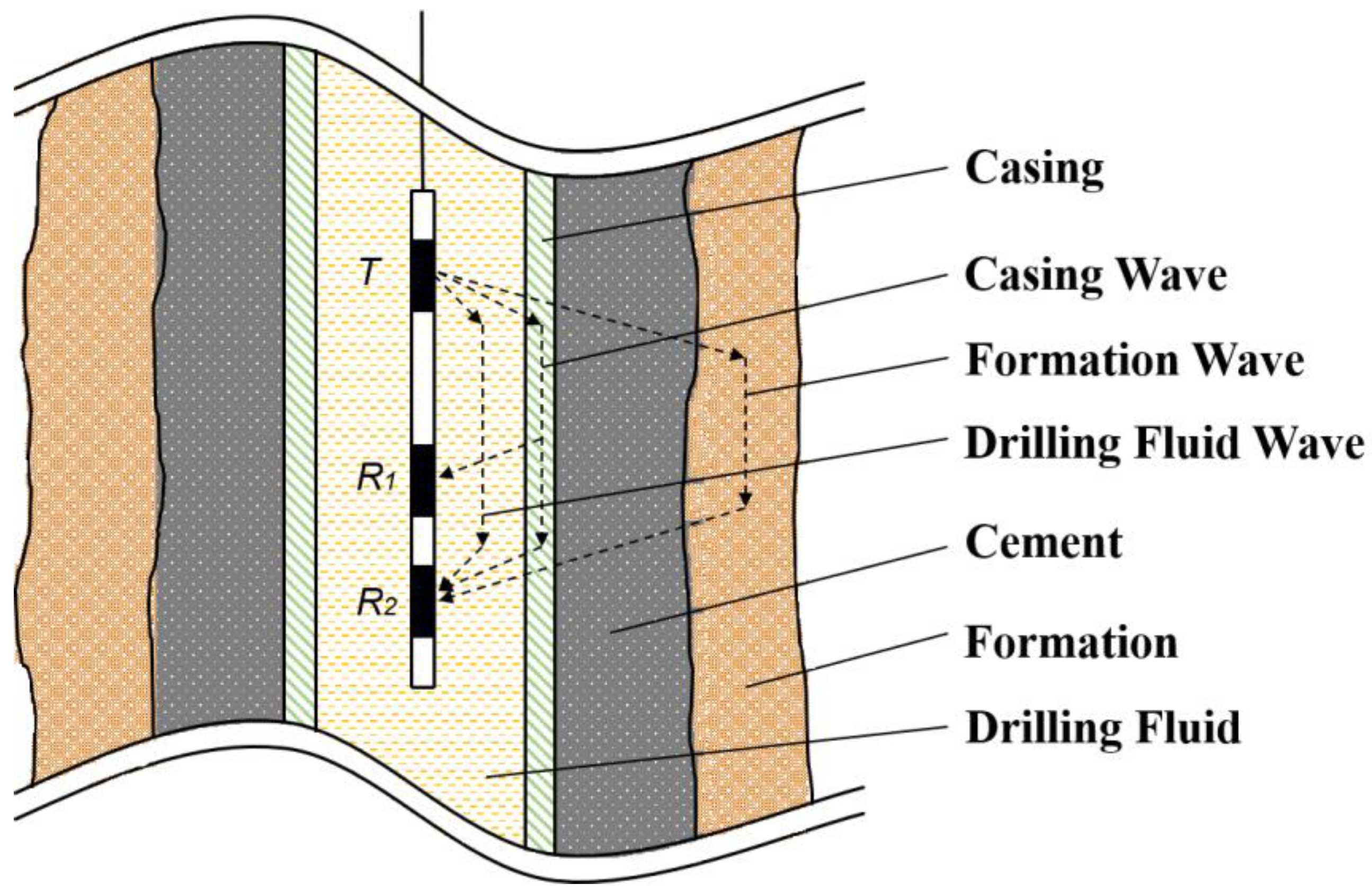

2. Background

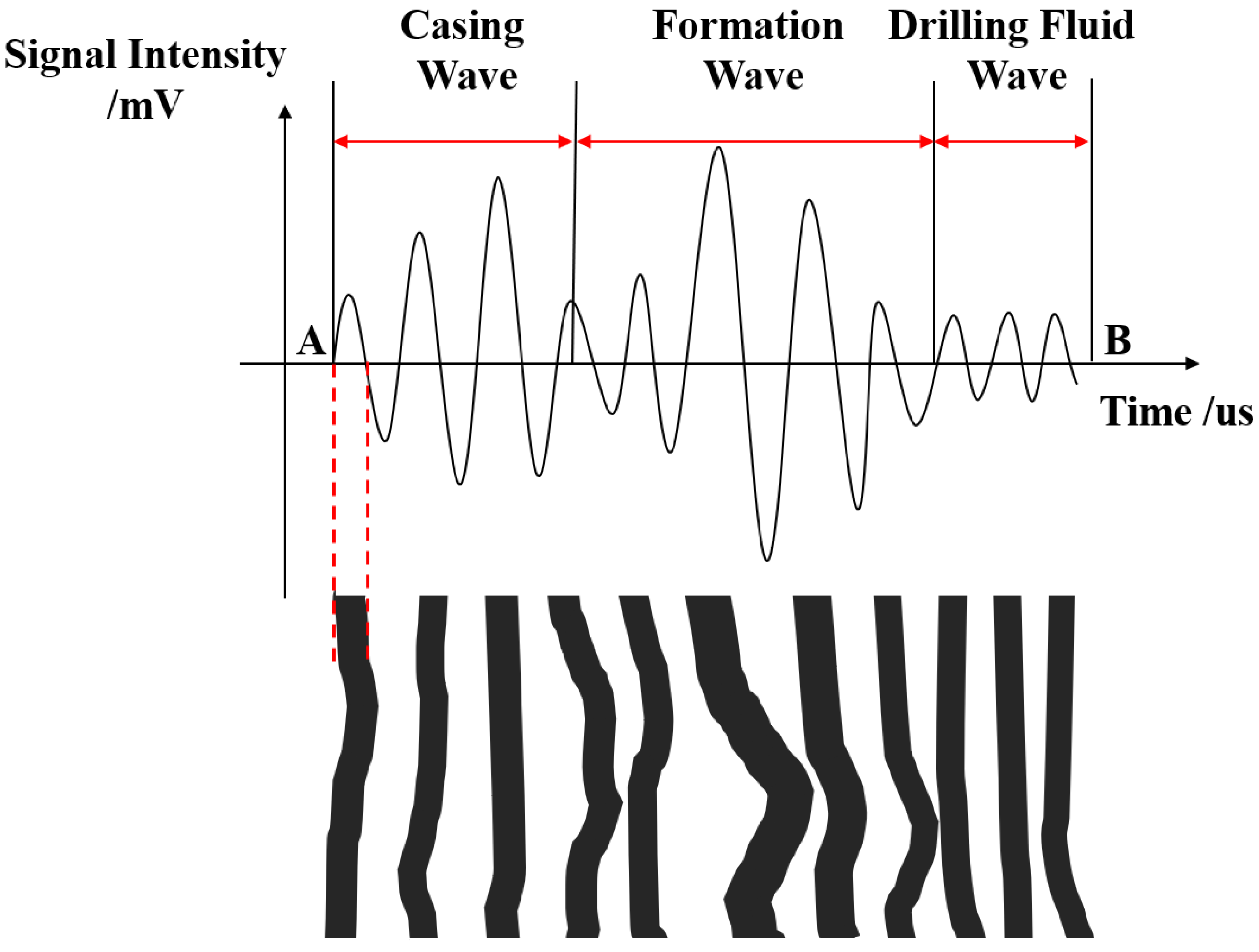

2.1. Logging Interpretation

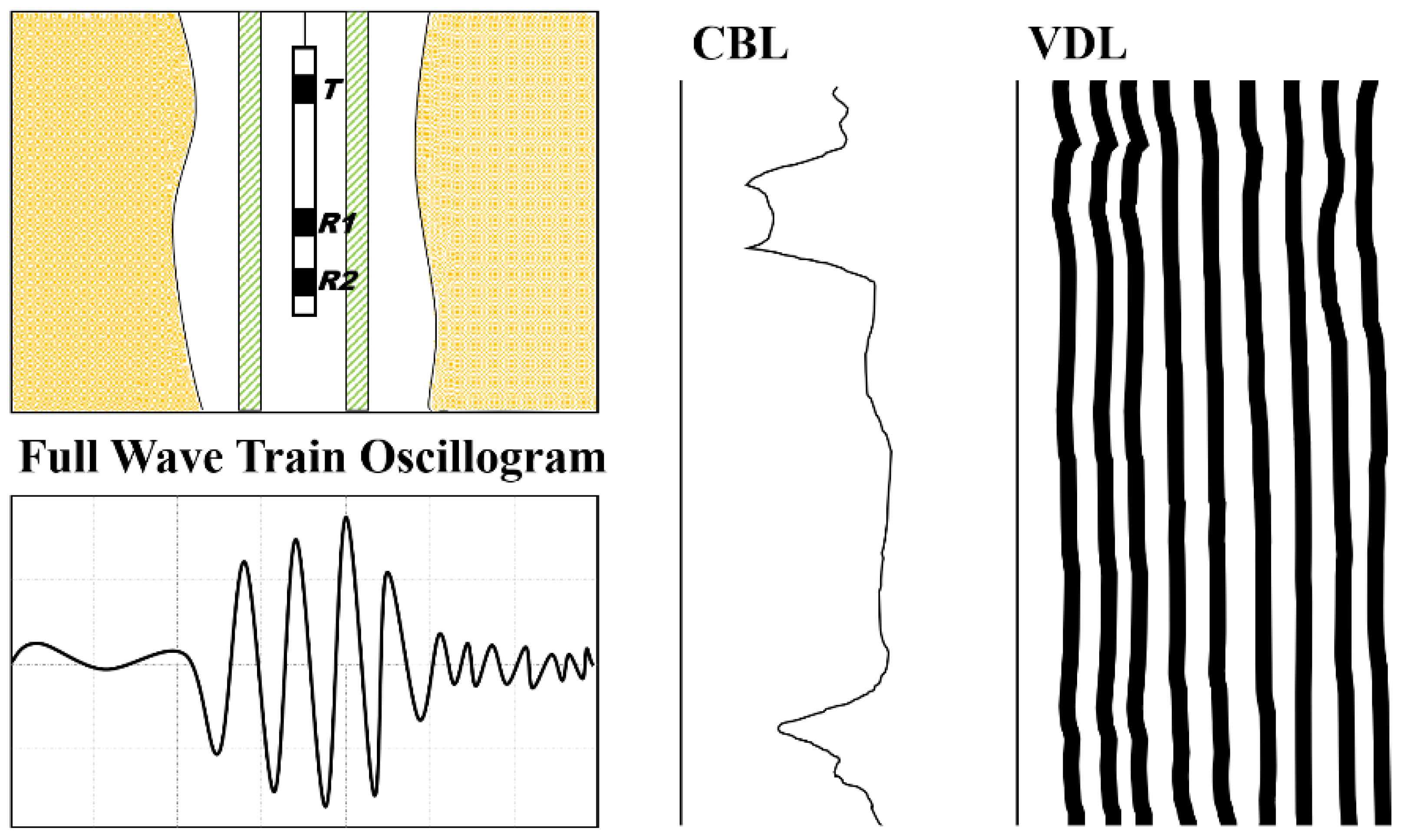

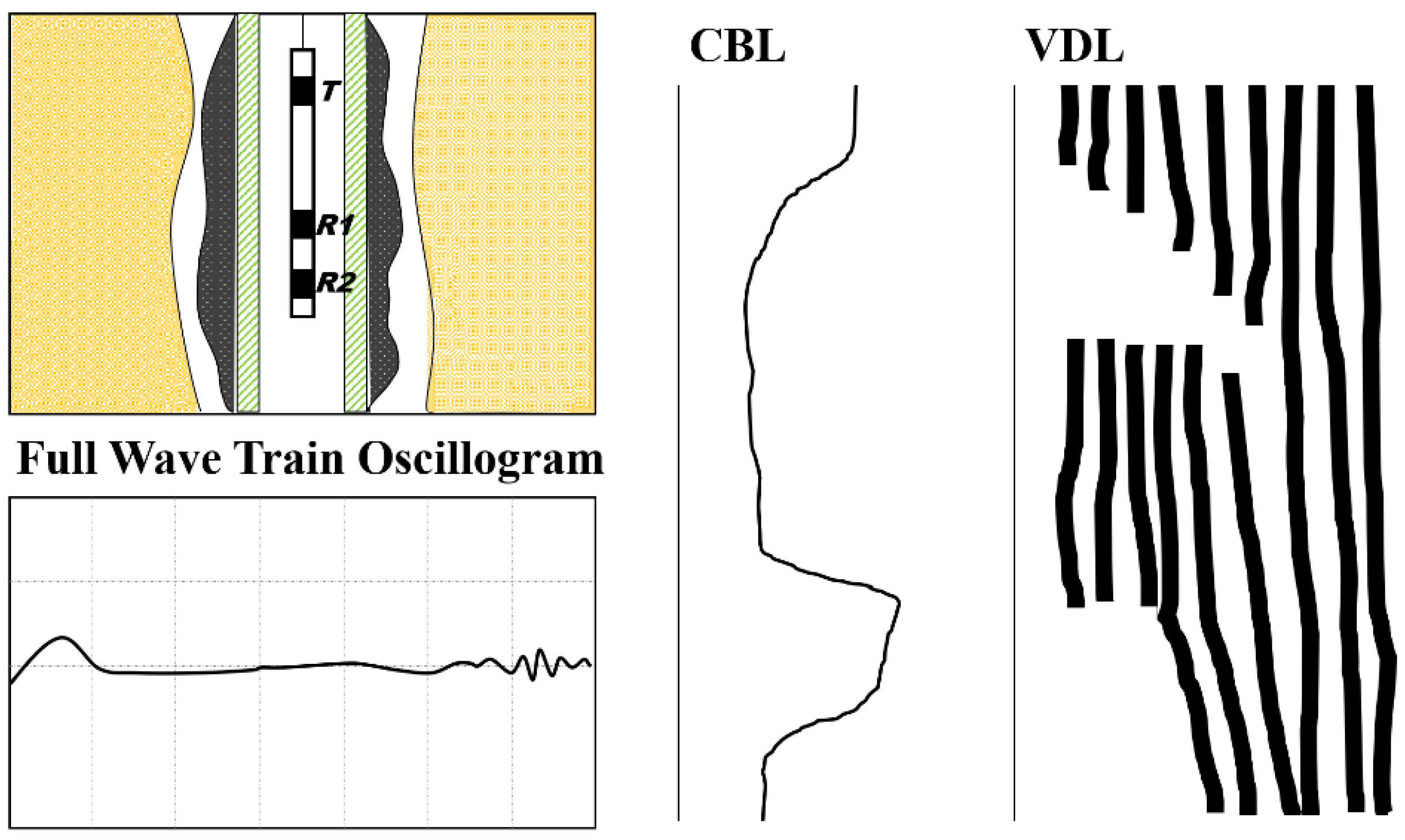

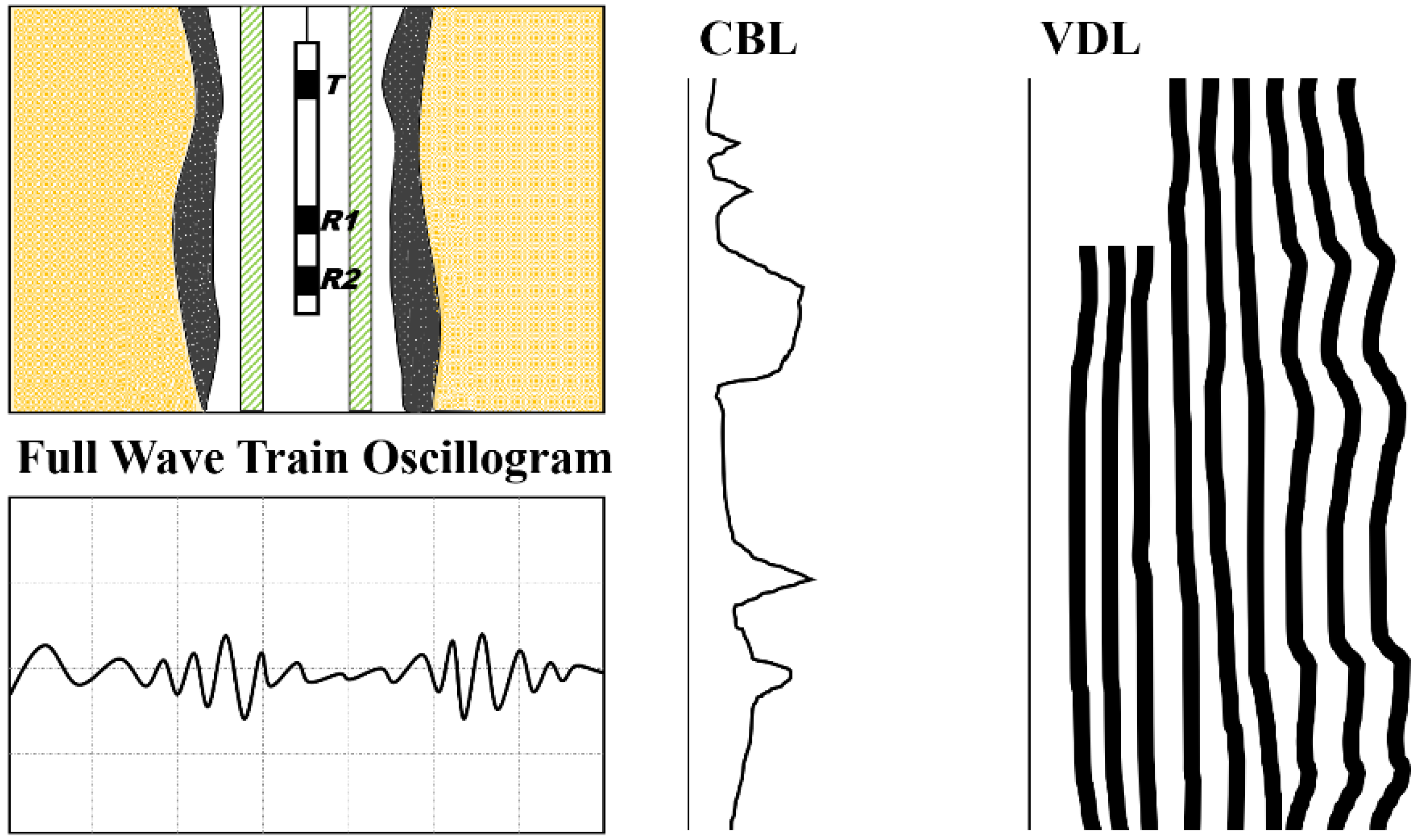

2.1.1. Interpretation of CBL-VDL

- (1)

- Free casing.

- (2)

- The first interface and the second interface are well cemented.

- (3)

- Good cementation at the first interface, poor cementation at the second interface.

- (4)

- Poor cementation at the first interface, good cementation at the second interface.

- (5)

- Poor cementation of the first and second interfaces.

2.1.2. Subjectivity of Manual Interpretation

2.2. Automatic Interpretation Based on Neural Network

3. Data and Methods

3.1. Datasets

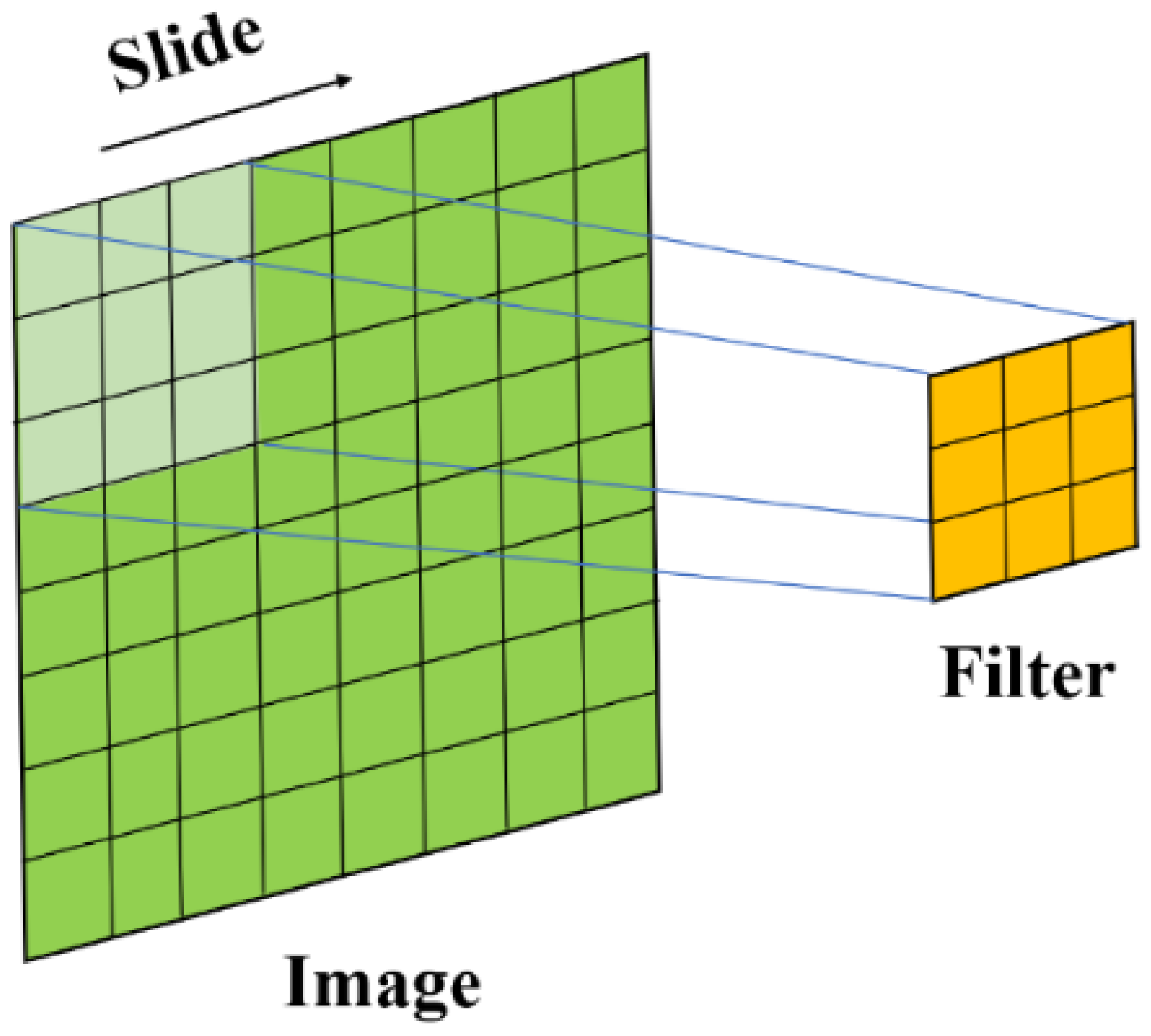

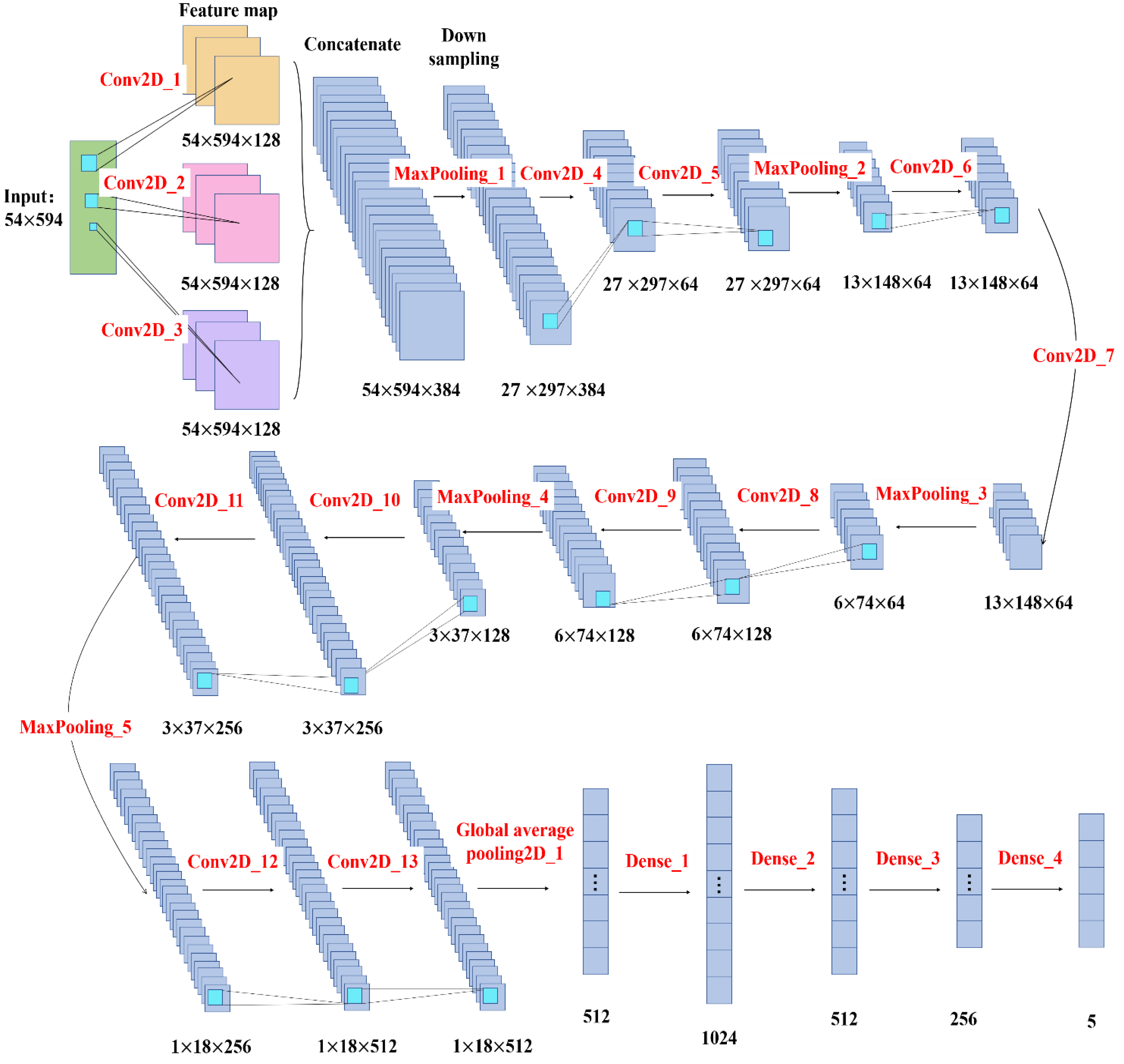

3.2. Neural Network Setting

3.3. Accuracy and Measurement Standards

4. Results and Discussion

4.1. Impact of Network Structure on Results

- Time complexity

- 2.

- Space complexity

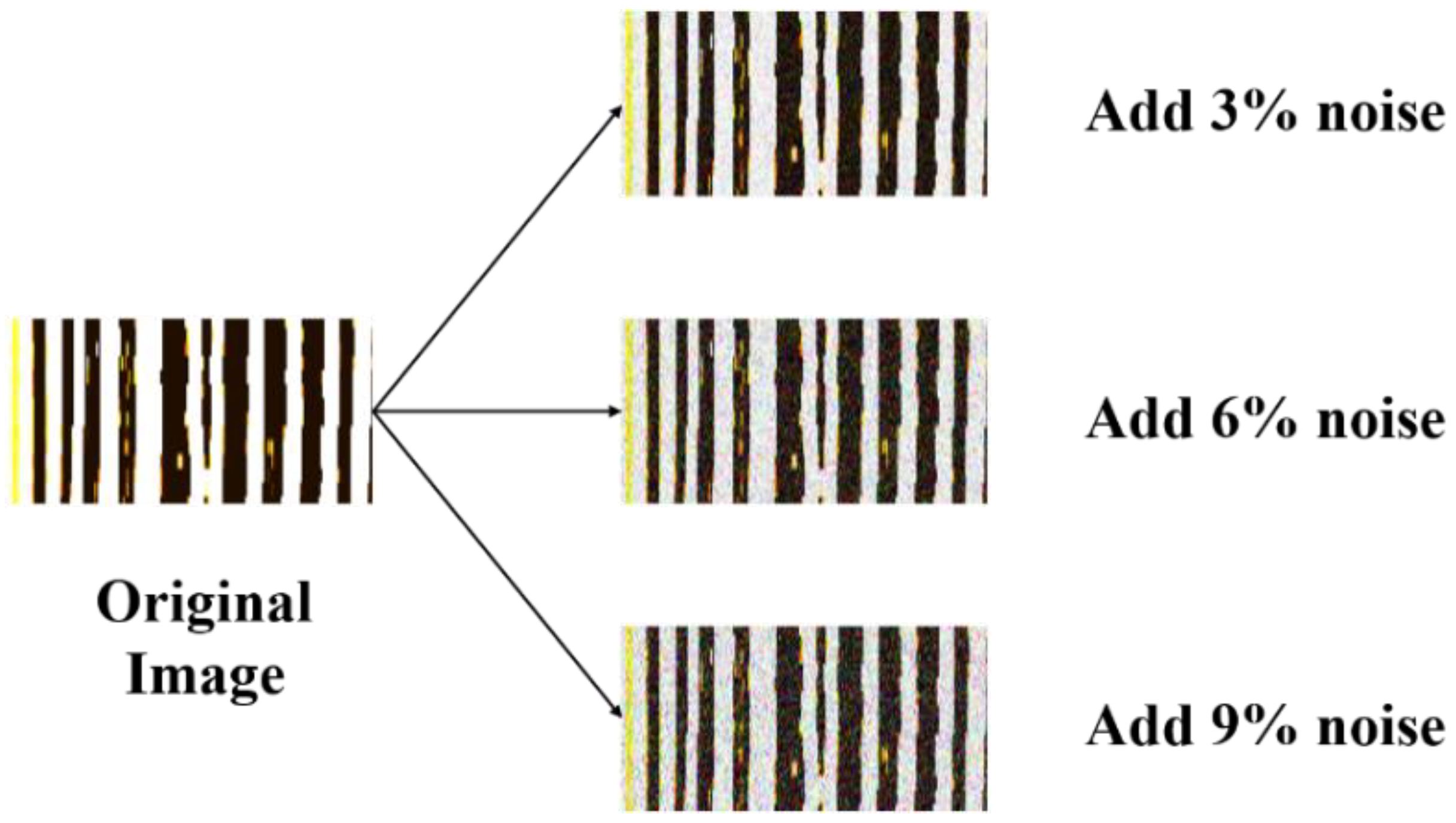

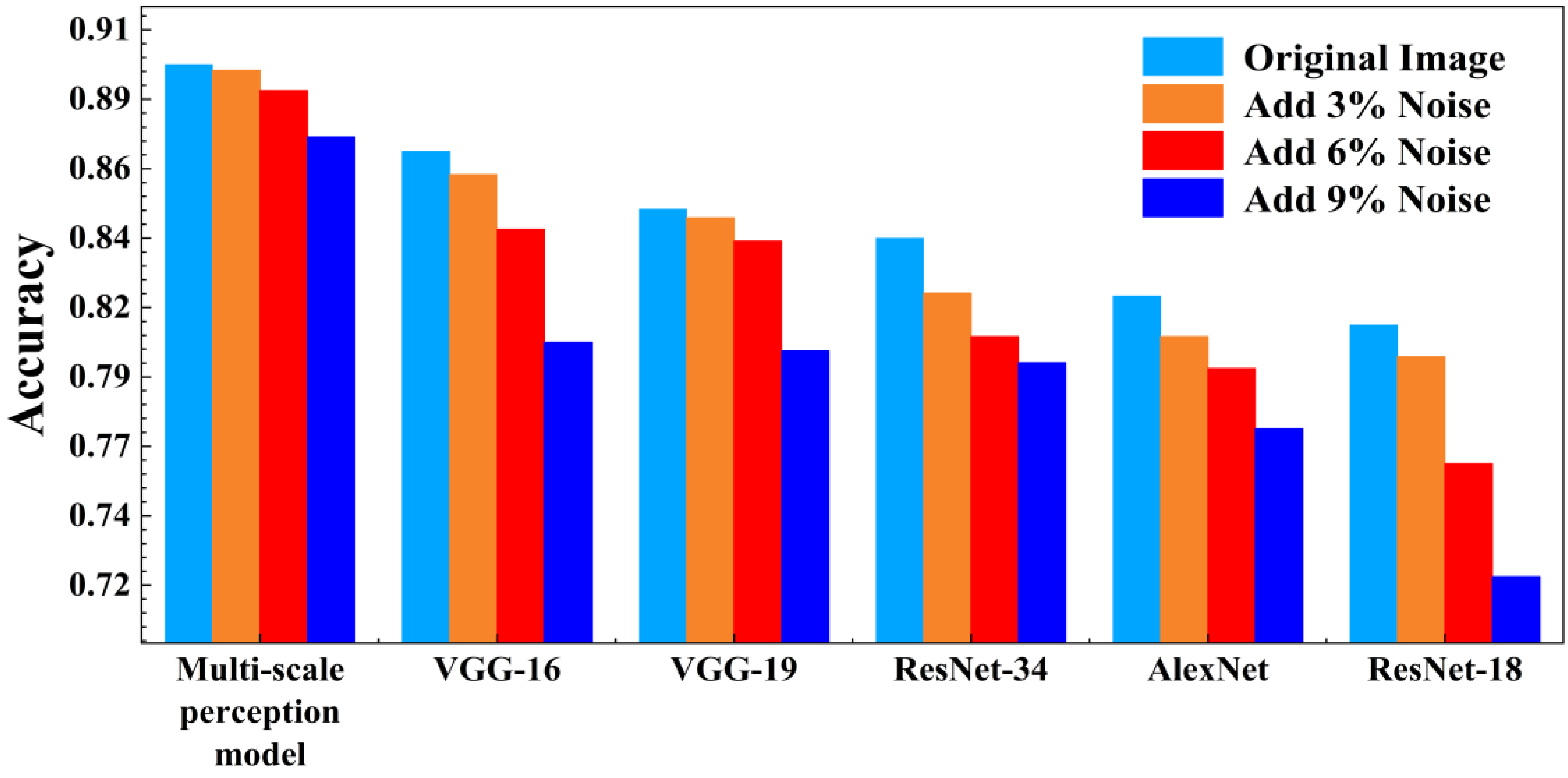

4.2. Model Stability Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al Farsi, G. Casing Failures Correlated with Cementing Quality in Steam Injection Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27 October 2014. [Google Scholar] [CrossRef]

- Ravi, K.; Weber, L. Drill-Cutting Removal in a Horizontal Wellbore for Cementing. In Proceedings of the Society of Petroleum Engineers SPE/IADC Drilling Conference, New Orleans, LA, USA, 3 December 1996. [Google Scholar] [CrossRef]

- Time, E.; Viggen, E.M.; Mishra, S.; Berg, E. Assisted Cement Log Interpretation. In Proceedings of the SPE Norway Subsurface Conference, Bergen, Norway, 22 April 2022. [Google Scholar] [CrossRef]

- Viggen, E.M.; Merciu, I.A.; Løvstakken, L.; Måsøy, S.-E. Automatic interpretation of cement evaluation logs from cased boreholes using supervised deep neural networks. J. Pet. Sci. Eng. 2020, 195, 107539. [Google Scholar] [CrossRef]

- Benge, G. Cement Evaluation—A Risky Business. Spe Drill. Completion 2016, 30, 322–326. [Google Scholar] [CrossRef]

- Hanif, R.; Ashour, S.H.; Yee, S.; Hay, M.A. Understanding Cement Quality in Intermediate Casing Against Aquifers Using Cement Bond Logs: A Case Study of Cementing Against Aquifers in UAE. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 29 January 2018. [Google Scholar] [CrossRef]

- Belozerov, B.; Bukhanov, N.; Egorov, D. Automatic Well Log Analysis Across Priobskoe Field Using Machine Learning Methods. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 15 October 2018. [Google Scholar] [CrossRef]

- Xiangjun, C.; Weiyan, L.; Shunhui, Y. New problems and ideas in cementing quality evaluation. Logging Technol. 2015, 39, 1–5. [Google Scholar] [CrossRef]

- Voleti, D.K.; Reddicharla, N.; Guntupalli, S. Smart Way for Consistent Cement Bond Evaluation and Reducing Human Bias Using Machine Learning. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11 September 2020. [Google Scholar] [CrossRef]

- Santos, L.; Taleghani, A.D. Machine learning framework to generate synthetic cement evaluation logs for wellbore integrity analysis. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Virtual, 18 June 2021. [Google Scholar]

- Pardue, G.H.; Morris, R.L. Cement Bond Log-A Study of Cement and Casing Variables. J. Pet. Technol. 1963, 15, 545–555. [Google Scholar] [CrossRef]

- Fan, H.; Yu, J. Cementing and Completion Operations; Petroleum Industry Press: Beijing, China, 2007; pp. 110–111. [Google Scholar]

- Popović, Z.B.; Thomas, J.D. A user’s guide. Cardiovascular Diagnosis and Therapy. Assess. Obs. Var. 2017, 7, 317–324. [Google Scholar] [CrossRef]

- Onalo, D.; Adedigba, S.; Khan, F.; James, L.A.; Butt, S. Data driven model for sonic well log prediction. J. Pet. Sci. Eng. 2018, 170, 1022–1037. [Google Scholar] [CrossRef]

- Gkortsas, V.-M.; Bose, S.; Zeroug, S. Machine learning for the automated detection of diagnosis-revealing features on leaky flexural wave imager data. In Proceedings of the 45th Annual Review of Progress in Quantitative Nondestructive Evaluation, Burlington, VT, USA, 15 July 2018. [Google Scholar] [CrossRef]

- He, H.; Xu, H.; Zhang, Y.; Gao, K.; Li, H.; Ma, L.; Li, J. Mask R-CNN based automated identification and extraction of oil well sites. Int. J. Appl. Earth Obs. Geoinf. 2022, 112, 102875. [Google Scholar] [CrossRef]

- Shelhamer, E.; Long, J.; Darrell, T. Fully Convolutional Networks for Semantic Segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 640–651. [Google Scholar] [CrossRef] [PubMed]

- Chollet, F. Deep Learning with Python; Manning Publications, Co.: Shelter Island, NY, USA, 2018; pp. 213–220. [Google Scholar]

- Khan, A.; Sohail, A.; Zahoora, U.; Qureshi, A.S. A survey of the recent architectures of deep convolutional neural networks. Artif. Intell. Rev. 2020, 53, 5455–5516. [Google Scholar] [CrossRef]

- Crow, W.; Carey, J.W.; Gasda, S.; Williams, D.B.; Celia, M. Wellbore integrity analysis of a natural CO2 producer. Int. J. Greenh. Gas Control. 2010, 4, 186–197. [Google Scholar] [CrossRef]

- Zhongyuan, W.; Zhang, X.; Zhang, C.; Wang, H. Lithology identification method based on LSTM recurrent neural network. Lithol. Reserv. 2021, 33, 120–128. [Google Scholar] [CrossRef]

- Smirnov, E.A.; Timoshenko, D.M.; Andrianov, S.N. Comparison of Regularization Methods for ImageNet Classification with Deep Convolutional Neural Networks. Aasri Procedia 2014, 6, 89–94. [Google Scholar] [CrossRef]

- Nazaré, T.S.; da Costa, G.B.P.; Contato, W.A.; Ponti, M. Deep Convolutional Neural Networks and Noisy Images. Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications. In Proceedings of the 22nd Iberoamerican Congress, CIARP 2017, Valparaíso, Chile, 7–10 November 2017; pp. 416–424. [Google Scholar] [CrossRef]

| CBL Characteristics | VDL Characteristic | Cementing Quality Results |

|---|---|---|

| Maximum | Obvious casing wave band and blank formation wave | Free casing |

| Minimum | The casing wave is dark and the formation wave is obvious | Good |

| Low | Both casing wave and formation wave are dark | Better |

| Medium | Obvious casing wave and dark formation wave | Fair |

| High, but not maximum | The casing wave band is obvious, the formation wave stripe is dark | Weak |

| Layers | Parameters | Activation |

|---|---|---|

| Conv2D_1 | Filters: 128, Kernel size: 5 5, Strides (1, 1) | ReLu |

| Conv2D_2 | Filters: 128, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_3 | Filters: 128, Kernel size: 1 1, Strides (1, 1) | ReLu |

| MaxPooling_1 | Pool size: 3 3, Strides (2, 2) | None |

| Conv2D_4 | Filters: 64, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_5 | Filters: 64, Kernel size: 3 3, Strides (1, 1) | ReLu |

| MaxPooling_2 | Pool size: 2 2, Strides (2, 2) | None |

| Conv2D_6 | Filters: 64, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_7 | Filters: 64, Kernel size: 3 3, Strides (1, 1) | ReLu |

| MaxPooling_3 | Pool size: 2 2, Strides (2, 2) | None |

| Conv2D_8 | Filters: 128, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_9 | Filters: 128, Kernel size: 3 3, Strides (1, 1) | ReLu |

| MaxPooling_4 | Pool size: 2 2, Strides (2, 2) | None |

| Conv2D_10 | Filters: 256, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_11 | Filters: 256, Kernel size: 3 3, Strides (1, 1) | ReLu |

| MaxPooling_5 | Pool size: 2 2, Strides (2, 2) | None |

| Conv2D_12 | Filters: 512, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Conv2D_13 | Filters: 512, Kernel size: 3 3, Strides (1, 1) | ReLu |

| Global average Pooling2D_1 | - | - |

| Dense_1 | Number of neurons: 1024, Dropout: 0.5 | ReLu |

| Dense_2 | Number of neurons: 512, Dropout: 0.5 | ReLu |

| Dense_3 | Number of neurons: 256, Dropout: 0.5 | ReLu |

| Dense_4 | Number of neurons: 5 | Softmax |

| Model | Accuracy | Cross-Entropy | Time Complexity (1,000,000) | Space Complexity (1,000,000) |

|---|---|---|---|---|

| Multi-scale perception model | 0.90 | 0.2481 | 8436 | 7 |

| VGG-16 | 0.87 | 0.2913 | 23,499 | 66 |

| VGG-19 | 0.85 | 0.3412 | 28,389 | 71 |

| ResNet-34 | 0.84 | 0.3684 | 13,026 | 25 |

| AlexNet | 0.82 | 0.5377 | 11,821 | 111 |

| ResNet-18 | 0.81 | 0.5687 | 9894 | 13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, C.; Wang, Z.; Song, X.; Zhu, Z.; Yang, D.; Liu, M. A Novel Cementing Quality Evaluation Method Based on Convolutional Neural Network. Appl. Sci. 2022, 12, 10997. https://doi.org/10.3390/app122110997

Fang C, Wang Z, Song X, Zhu Z, Yang D, Liu M. A Novel Cementing Quality Evaluation Method Based on Convolutional Neural Network. Applied Sciences. 2022; 12(21):10997. https://doi.org/10.3390/app122110997

Chicago/Turabian StyleFang, Chunfei, Zheng Wang, Xianzhi Song, Zhaopeng Zhu, Donghan Yang, and Muchen Liu. 2022. "A Novel Cementing Quality Evaluation Method Based on Convolutional Neural Network" Applied Sciences 12, no. 21: 10997. https://doi.org/10.3390/app122110997

APA StyleFang, C., Wang, Z., Song, X., Zhu, Z., Yang, D., & Liu, M. (2022). A Novel Cementing Quality Evaluation Method Based on Convolutional Neural Network. Applied Sciences, 12(21), 10997. https://doi.org/10.3390/app122110997