Abstract

Limestone calcined clay cement (LC3) has considerable potential for large-scale implementation. We investigated three selected kaolinitic clays at different locations in South Africa. LC3 mortars were compared to Portland cement mortar as control, particularly the hydration phase mineralogy/content, microstructure, compressive strength, and 3D void structure. The investigation indicated that similar pozzolanic oxide (SiO2 + Al2O3) could be obtained from calcined clay of varied kaolinite content. While kaolinite content improves the pozzolanic activity, consistency, and compressive strength of the mortar, the void refinement at the microscale depends on the degree of limestone filling/hydration. The hydration phase contents, microstructure, mineralogy, and porosity of the processed kaolinitic clays were determined to be adequate. However, it is noted that the intrinsic content of limestone (and gypsum) in commercially available Portland cement should be considered for equivalent clinker, limestone, and gypsum contents of 50%, 15%, and 5%, respectively.

1. Introduction

Limestone calcined clay cement (LC3) is a relatively new, environmentally friendly, sustainable cement that has been identified to have potential to reduce the construction industry’s carbon footprint. The limestone and calcined clay partly replace the clinker content for cement production. Lately, research efforts have multiplied to advance the understanding of LC3 as a binder in many countries and regions, moving towards its commercial production [1,2]. However, there is a dearth of research on the development of LC3 in South Africa.

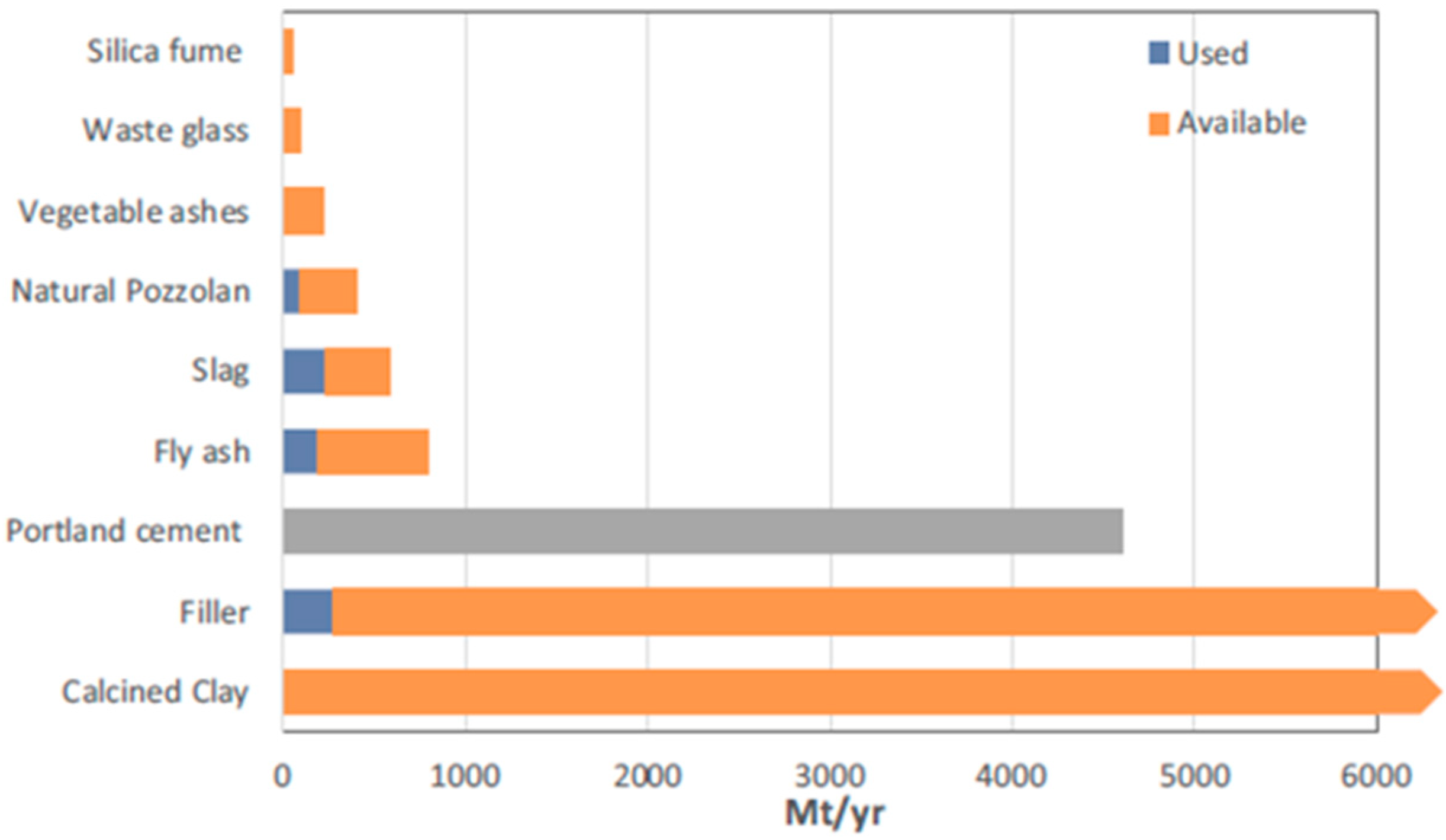

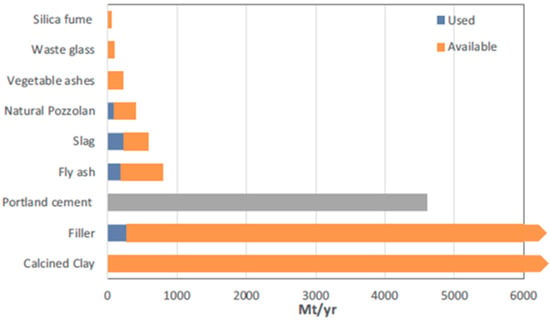

Before the advent of LC3, other supplementary cementitious materials (SCMs) from natural materials, agricultural wastes, and industrial wastes such as fly ash, granulated blast furnace slag, and silica fume were investigated [3,4]. The main shortcoming of these SCMs is their uneven global distribution and limited availability, whereas limestone (as filler) and clay are more naturally distributed around the globe. The estimated availability of several viable SCMs in relation to the amount of cement produced is shown in Figure 1, where the grey colour represents Portland cement. In South Africa, fly ash is produced in significant quantities as a by-product of coal combustion for power generation. However, because coal combustion is a major source of CO2 emissions, the supply of fly ash in the long term is in doubt [5]. LC3 primarily consists of two alternative materials: calcined kaolinitic clay and limestone [3,6]. Therefore, studying the suitability of South African clay for LC3 production is important. Calcined clays, particularly when combined with limestone, have promising potential for expanding the use of SCMs in cement and concrete as a partial substitute for clinker [7].

Figure 1.

Estimated availability of possible SCMs vs. cement production [8].

The use of industrial waste, such as fly ash and granulated blast furnace slag, is commonplace in cement production but is generally limited in replacing clinker in Portland cement (PC). LC3 has been shown to reduce clinker up to 50% (50% ground Portland clinker, 30% ground calcined clay, 15% ground limestone, and 5% ground gypsum) [7]. Other component proportions are also possible, but cement prepared according to the above composition achieves mechanical properties similar to ordinary Portland cement (OPC) at 28 days of curing at most, provided that the clay contains at least 40% kaolin [7,9]. The kaolinite content of calcinated clay is directly proportional to the performance of the LC3 [6,10], including better pore refinement, hydration, strength, and durability.

Deposits of kaolinitic clay in South Africa are abundant, as shown in Table 1. With these deposits, an LC3 project can potentially lead to a standard and mainstream general-use cement in South Africa for better environmental sustainability and cost-efficiency. CO2 emission can be potentially reduced by 40%/tonne, cost reduced by 33%/tonne, and embodied energy reduced by 22%, implying cleaner production and sustainability if a production plant is situated close to huge clay deposits [11,12,13].

Table 1.

Selected kaolinite clay deposits in South Africa [5].

The pozzolanic mineral of interest in clay is the kaolinite content, but it also contains other passive phase crystals such as quartz, carbonates, and metal oxides. Generally, the structural composition of kaolinite is one tetrahedral layer of (Si2O5)2− and one octahedral layer of (Al2(OH)4)2+, with each layer forming each face of the sheet. During calcination, the mineral loses its crystallinity and reduces to active silica and alumina (metakaolin), known for their reactivity as SCM. The metakaolin is formed during the calcination of raw clay as a transition phase that retains the lamellar structure of kaolinite while reducing the sheet and tubular dimensions [4]. Due to varying geological and weathering conditions in different regions of the world, clay soil can have varying crystallinity, resulting in various mineral structures. The kaolinite content varies based on the mode of formation of the kaolin, the source rocks, and the climatic conditions prevailing during its formation, ranging from 17% to 95% [4]. Based on geological formation, the potential of South African clays for LC3 is evaluated.

One method to determine the kaolinitic content of clay is thermogravimetric analysis (TGA). From the TGA, the mass loss between room temperature and 200 °C is neglectable due to dehydration. An endothermic peak from 400 °C to 600 °C shows the dehydroxylation of kaolinite and the formation of metakaolin [5,14]. The proportion of kaolinite may be calculated using the mass change throughout this temperature range and the known molecular weights of kaolinite and water. This principle was used to determine the kaolinite content of the clay samples for this study.

The main pozzolanic reaction from calcined clay can be summarised in Equation (1), and the presence of limestone and gypsum extends this reaction to Equations (2) and (3).

where = aluminates, = alumina (), = quicklime (CaO), = , = portlandite [], = water (), = silica (), and = sulphate ().

Calcium aluminium silica hydrate (CASH), ettringite (Aft phase—), and mono-sulfo-aluminate (AFm phase, ) phases are formed when metakaolin ( reacts as a pozzolanic material with calcium hydroxide (CH), water (H), and sulphate () [4,6,14]. Calcite (CaCO3 from limestone) reacts with tricalcium aluminate/aluminium calcium oxide (C3A/Al2Ca3O6) from clinker to form hemi- and mono-carbo-aluminate phases (, respectively). Aluminates from metakaolin also react with calcite in LC3, enhancing carbo-aluminate phase formation [6] and inhibiting the further formation of AFm [1]. The contents of these phases in LC3 composites indicate the extent of pozzolanic reactions [15] and were investigated in this study by X-ray diffraction (XRD) analysis. The pozzolanic activity and filling effect of calcined clay and limestone can efficiently reduce porosity and improve cement-based materials’ microstructure densification and mechanical characteristics [13,16].

In this study, we investigated the performance of three South African clay samples for the production of LC3. The kaolinite content of each clay sample was determined since this is significant to the suitability of the clay samples for LC3. The limestone, PC, and three clay samples were characterised to understand their properties’ influence on the LC3 binder and mortar. The hydrate phase contents of the mortar were determined to examine the extent of pozzolanic activity and to understand the microstructure and strength properties obtained from the mortar samples. The study’s findings provide information to the South African cement industry that could encourage embracing LC3 as a viable, sustainable alternative cement. It also adds to the pool of knowledge on clays from other geological origins, as there has been increased study on the efficacy of clays having various geologic characteristics [7,13].

2. Materials and Methods

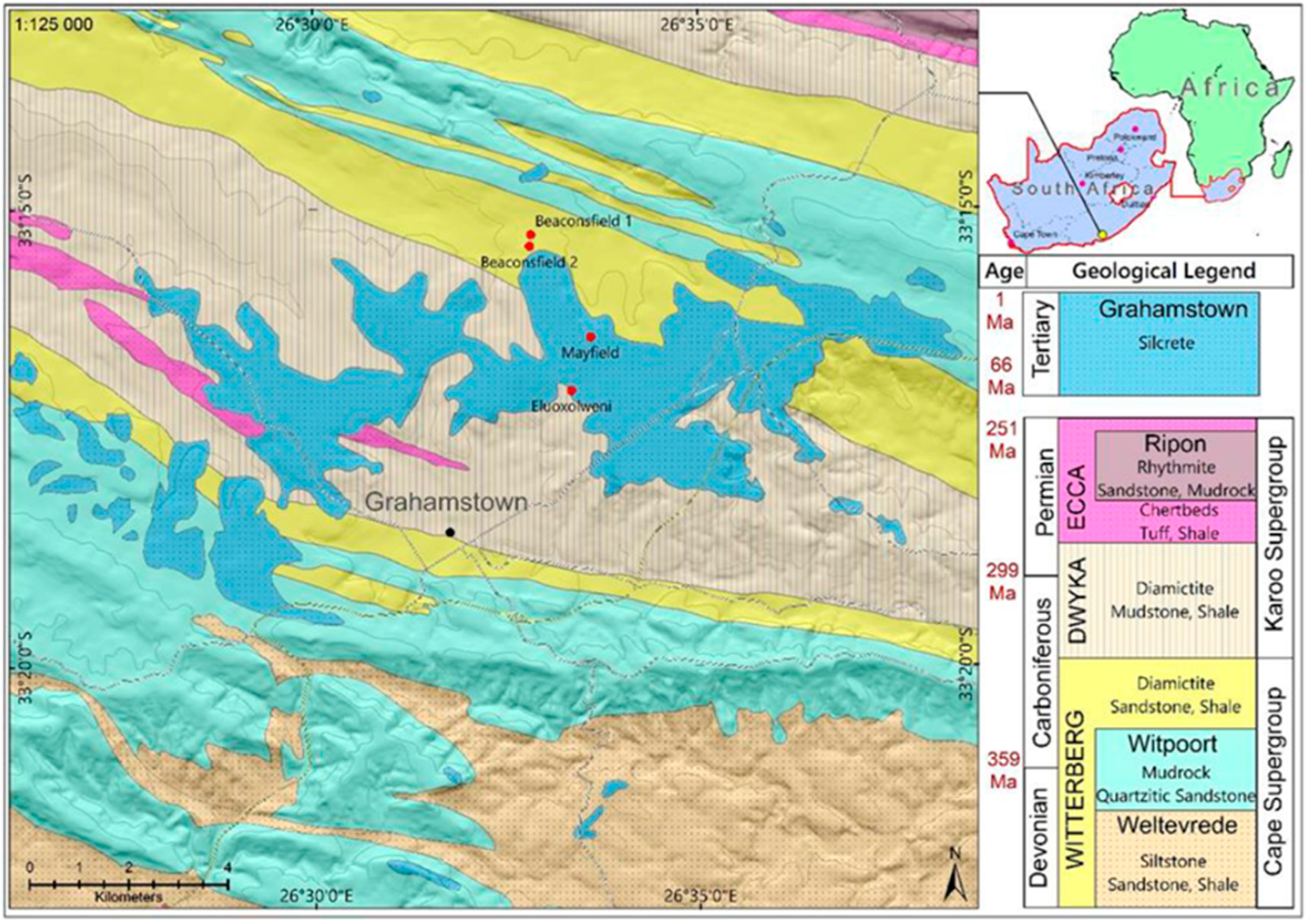

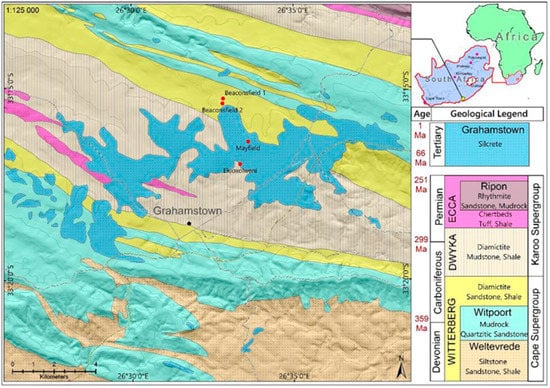

Three composite clay samples were selected from Grahamstown, South Africa, for investigation. The geologic map of Grahamstown can be seen in Figure 2. The red dots on the map indicate the three locations where the clays were obtained. The first location is Eluoxolweni (EXW), which falls within the Dwyka Group of the Karoo Supergroup, though currently covered by the Tertiary Silcrete. The second location is Mayfield North (MFN), and the last location is Beaconsfield, with Beaconsfield 1 North (BFN) and Beaconsfield 2 South (BFS). Both the Mayfield and Beaconsfield deposits fall within the Witterberg Group of the Cape Supergroup. However, the sample from BFS was left out of this study, as it is similar to BFN. Therefore, the three clay samples are labelled EXW, MFN, and BFN.

Figure 2.

Geological map of Grahamstown.

The collected clay samples were processed by grinding and oven-drying at 100 °C for 24 h, then sieving to achieve a maximum grain size of 60 µm. This processing was carried out to guarantee similar fineness to the PC to maximise the physico-chemical interaction of the clay as pozzolans. Finally, the materials were calcined at 650 °C for 1.5 h and cooled at room temperature. At this temperature (see TGA results in Section 3.1.2), the mass loss rate becomes constant, signifying significant dehydroxylation for the formation of active silica and alumina.

Usually, LC3 could be LC3-50 or LC3-65, with the number 50 or 65 indicating the content of cement clinker. The limestone and clay will then usually be in a ratio of 1:2. Typically, LC3-50 will consist of 50% ground Portland clinker, 30% ground calcined clay, 15% ground limestone, and 5% ground gypsum. However, some studies have investigated other combinations of LC3, such as ratios of 1:1.25, 1:2, and 1:3.5, and limestone contents ranging from 10% to 20% [17]. In some countries, including South Africa, CEM I 52.5 N (ground cement clinker and about 5% gypsum) is no longer commercially produced. Thus, for this study, Portland–limestone cement, Suretech CEM II/A-L 52.5 N supplied by Pretoria Portland cement (PPC), South Africa, was used. This choice was geared towards an on-site implementation of LC3 where commercially available PC in South Africa can be readily deployed for use rather than Portland clinker. In the same vein, commercially available Idwala Kulubrite 5 limestone from Idwala Industrial Holdings (Pty) Ltd. (Port Shepstone, South Africa) and gypsum (CaSO4.2H2O) from Associated Chemical Enterprises (ACE) (Johannesburg, South Africa) were used. The LC3 was mixed with locally sourced sand (Malmesbury sand) to make mortar samples and cast into moulds. A polycarboxylate ester base superplasticiser (CHRYSO Premia 310) was used to achieve the desired workability of the mortar mixture.

2.1. Material Characterisation

The characterisation of materials was carried out in two phases: one was on the powders (three processed clay samples—EXW, MFN, and BFN; limestone, cement), and the second phase included characterising the four mortar samples made from PC and LC3 (EXW, MFN, BFN). The mortar samples’ characterisation was carried out after 28 days.

For the powders, particle size distribution (PSD) of the calcined clays, limestone, and PC were determined. The chemical oxide composition of the calcined clays and limestone was determined by X-ray fluorescence (XRF) analysis, while the kaolinite contents of clays were determined by thermogravimetric analysis (TGA). Furthermore, the clays and limestone morphology were investigated by scanning electron microscopy and energy-dispersive spectroscopy (SEM-EDS). For the mortar, qualitative and quantitative X-ray diffraction (XRD) analyses were performed to determine the hydration phases. The microstructure of the hardened mortar of the cement and clays was investigated using SEM-EDS.

2.1.1. Particle Size Distribution (PSD)

The PSD, determined by static laser light scattering (Saturn DigiSizer 5200), uses a laser in conjunction with a charge-coupled device (CCD) containing over one million detector elements to measure particle size [18]. These detectors are placed to measure the intensity of light scattered by the particles at various angles. Light is scattered by particles in a pattern dependent on their size, shape, refractive index, and wavelength of incident light. Based on the Mie theory, the PSD is calculated from the angle distribution of the scattered light intensity collected by the detectors [18].

2.1.2. Chemical Composition

The chemical oxide composition was determined by XRF using a PANalytical Axious Wavelength Dispersive spectrometer. To facilitate the XRF test, the clay and limestone samples were milled in a tungsten carbide Zibb mill before preparing a fused disc for major trace element analysis. The mill was cleaned with clean, uncontaminated quartz after each sample to avoid cross-contamination. Glass disks were prepared for XRF analysis using 7 g of high-purity trace element and rare earth element-free flux (LiBO2 = 32.83%, Li2B4O7 = 66.67%, LiI = 0.50%) mixed with 0.7 g of each powder sample. The mixtures of each sample and flux were fused in platinum crucibles with a Claisse M4 gas fluxer at a temperature between 1100 and 1200 °C. Major elements were analysed on a fused glass disk using a 2.4 kW Rhodium tube. Matrix effects in the samples were corrected by applying theoretical alpha factors and measured line overlap factors to the raw intensities measured with the SuperQ PANalytical software.

2.1.3. Kaolinite Content in Clay

Kaolinite content in clay was determined by TGA using a Malvern PANalytical Aeris diffractometer. The specimens were heated from ambient temperature to 750 °C in a nitrogen atmosphere at a rate of 10 °C/min, and the mass loss was recorded. The content was determined as a percentage of the raw clay. As noted earlier, mass loss up to 200 °C is due to dehydration, and an endothermic peak between 400 and 600 °C is due to kaolinite dehydroxylation. These can be used to determine the kaolinite content (KC) [15]:

where is the percentage of kaolinite content, is the percentage mass loss of the clay at 600 °C relative to 200 °C, is the molecular mass of kaolinite (258.071 g/mol), and is the molecular mass of water (18.015 g/mol).

2.1.4. SCMs Morphology and Mortar Microstructure

The morphology of the SCMs (limestone powder and EXW, BFN, and MFN clay samples) was determined by SEM (+EDS to examine the elemental composition of the particles) analysis. The microstructure of the PC and LC3 mortar samples after 28 days (sliced into 15 × 15 × 7 mm specimens) was also investigated by SEM + EDS for 2D microstructure analyses. All the samples were impregnated with epoxy resins and left to polymerise for 24 h. The powder samples were gently grounded by hand with silicon carbide paper to improve flatness, and the mortar samples were mechanically grounded with SiC 500 and 100 grids for 5 min each at 350 rpm. All the samples were then polished at 150 rpm. The specimens were further treated through drying, vacuum pumping, and carbon coating [19]. The SEM was carried out using Zeiss MERLIN SEM Gemini 2 and the EDS (Inca EDS X-Sight system, Oxford Instruments, Abingdon, UK) with a 20 keV electron beam voltage to obtain further information on their chemical composition as needed [20].

2.1.5. Mortar Hydration and Binder Phases

The mineralogical contents of the uncalcined clay, calcined clay, Portland cement, and mortar were determined by X-ray diffractometry (XRD) analysis using a Malvern PANalytical Aeris diffractometer with PIXcel detector and fixed slits with Fe-filtered Co-Kα radiation. The mortar hydration phases were determined after 28 days. The mortar samples were milled similarly and scanned using the backloading preparation method. Additionally, the material was scanned after adding 20% silicon (Si) for the quantitative determination of amorphous content and homogenised using an agate mortar pestle. The phases were identified using X’Pert HighScore Plus analytical software. The relative phase amounts (weight %) were estimated using the Rietveld method [21].

2.2. Mortar Mixture and Strength

The constituent of the mortar mixture is shown in Table 2. PC serves as the control for comparison with the LC3. The compositions were formulated for the PC mortar for a target strength of 40 MPa and a mini-slump of 180–200 mm. To make the mortar, the dry materials (sand, cement, calcined clay, limestone, and gypsum) were mixed in a Hobart mixer for two minutes before adding the measured water and remixing for another five minutes. The superplasticiser was added thereafter, and the mixture was mixed further for five minutes, for a total of twelve minutes. The slump of the mortar was evaluated immediately using a mini-slump cone test. The mortar mixture was cast into 50 × 50 × 50 mm moulds and vibrated for one minute, placed in a climate-controlled room of 24 °C and 65% relative humidity for 24 h. After that, the mortar cubes were demoulded and cured in water until the testing age. The compressive strengths of the samples were tested at 3, 7, and 28 days following SANS 5863 [22].

Table 2.

Mix constituents of the mortar.

2.3. Porosity

The 3D void microstructure of the PC and LC3 mortars was investigated using X-ray computed tomography (XCT) using a General Electric V|TomeX L240 device (Boston, MA, USA) with 220 kV and 200 A and copper beam filtration of 1.5 mm and an 80 μm voxel size. Mortar with dimensions of 50 × 50 × 50 mm from the clay samples (EXW, MFN, BFN) and PC were scanned. Images were captured in 2000 rotation steps during a complete 360° rotation of the sample, which took 500 milliseconds per picture. The first image was discarded at each phase position, and the following three images were combined to provide high image consistency [23,24]. The automated scan optimiser was used to remove artefacts caused by possible sample movement or X-ray spot drift. Datos reconstruction software was used to complete the reconstruction. Volume Graphics Studio (VGS) Max 3.5 was used to visualise and analyse the data [23,24].

3. Test Results and Discussion

3.1. Binder Properties

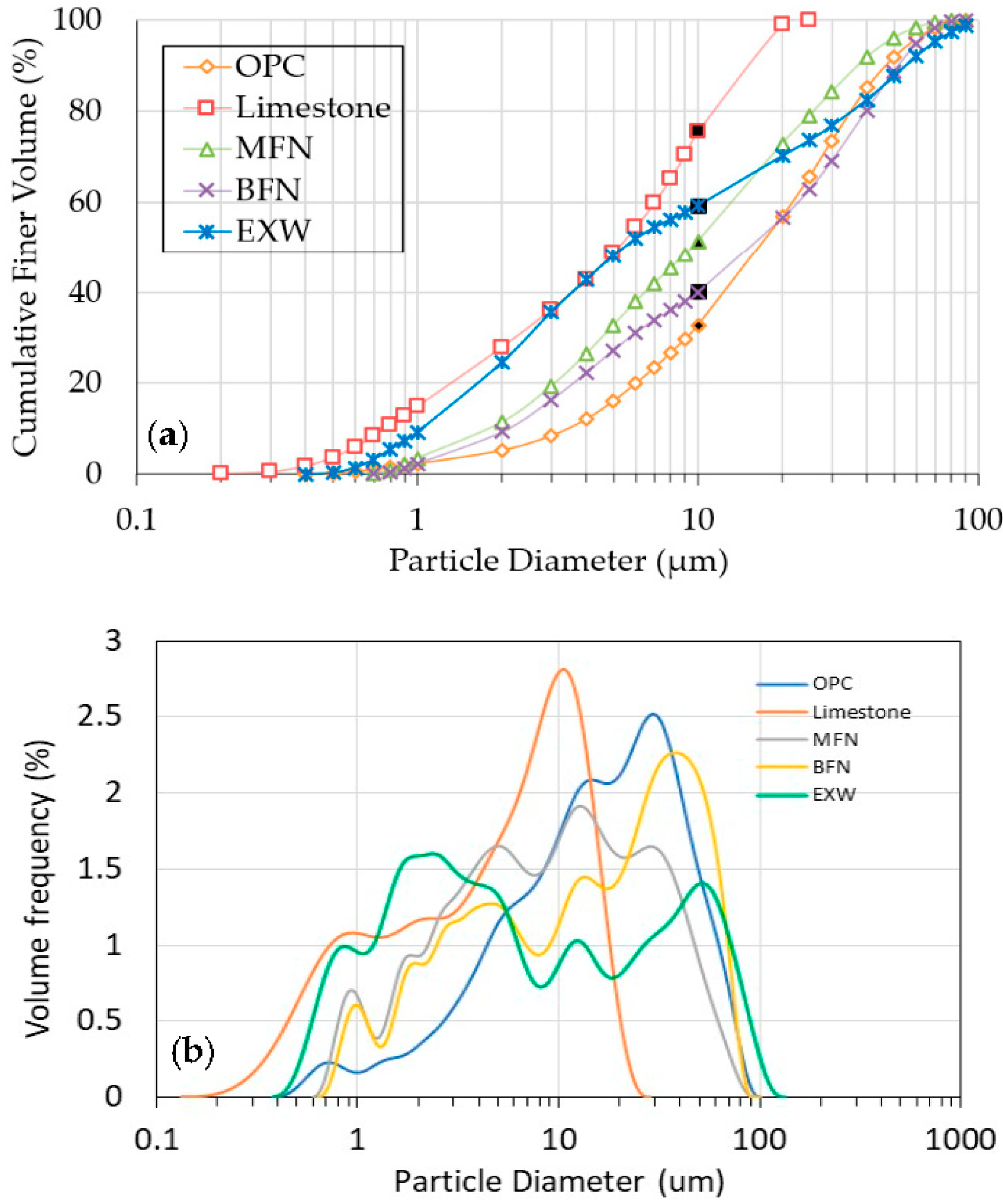

3.1.1. Particle Size Distribution

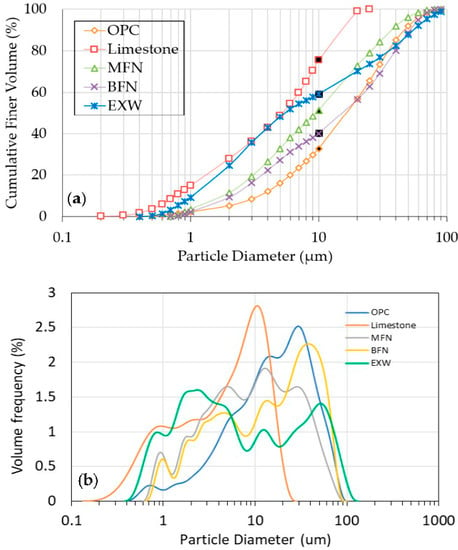

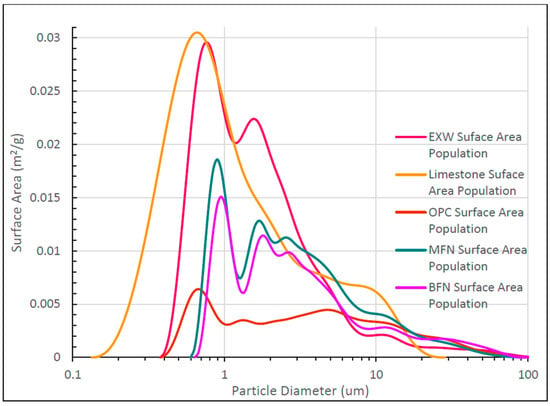

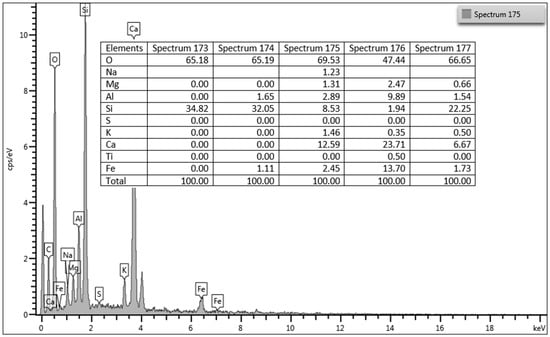

The particle size distribution (PSD) of the three calcined clay samples, limestone, and cement are presented in Figure 3a,b. D10, D50, and D90 are defined as sizes in the PSD where 10%, 50%, and 90% of the total volume of material in the sample are accumulated, respectively [25]. D50 is the median size of the distribution of each material. All four powders have finer particles than the PC, ensuring sufficient physico-chemical interaction as a composite binder. The EXW is the finest of the three clay samples and is closer to that of the limestone. EXW has an average particle size of 5.45 µm, while the limestone has 5.2 µm. the specific surface area distribution of the binders can be found in the Appendix A (Figure A1) EXW particle sizes seem to be widely spread across 1.1–54.9 µm, while the MFN, BFN, and limestone particles seem to contain greater size ranges (37.1, 51.8, 54.9, 13.7, respectively).

Figure 3.

Particle size distribution of the binders: (a) cumulative finer volume, (b) percentage distribution of the sizes.

Generally, the finer the SCMs, the better their reactivity [26]. Therefore, the clay samples finer than the PC are expected to show efficient reactivity with the hydration by-products (Ca(OH)2). In addition, the limestone, being the finest of the lot, is expected to have adequate filler/hydrating effects, improving the density of the matrix [15,27], which can imply fewer air voids and better durability. These will enhance the physico-chemical interaction of the limestone and calcined clay with the PC.

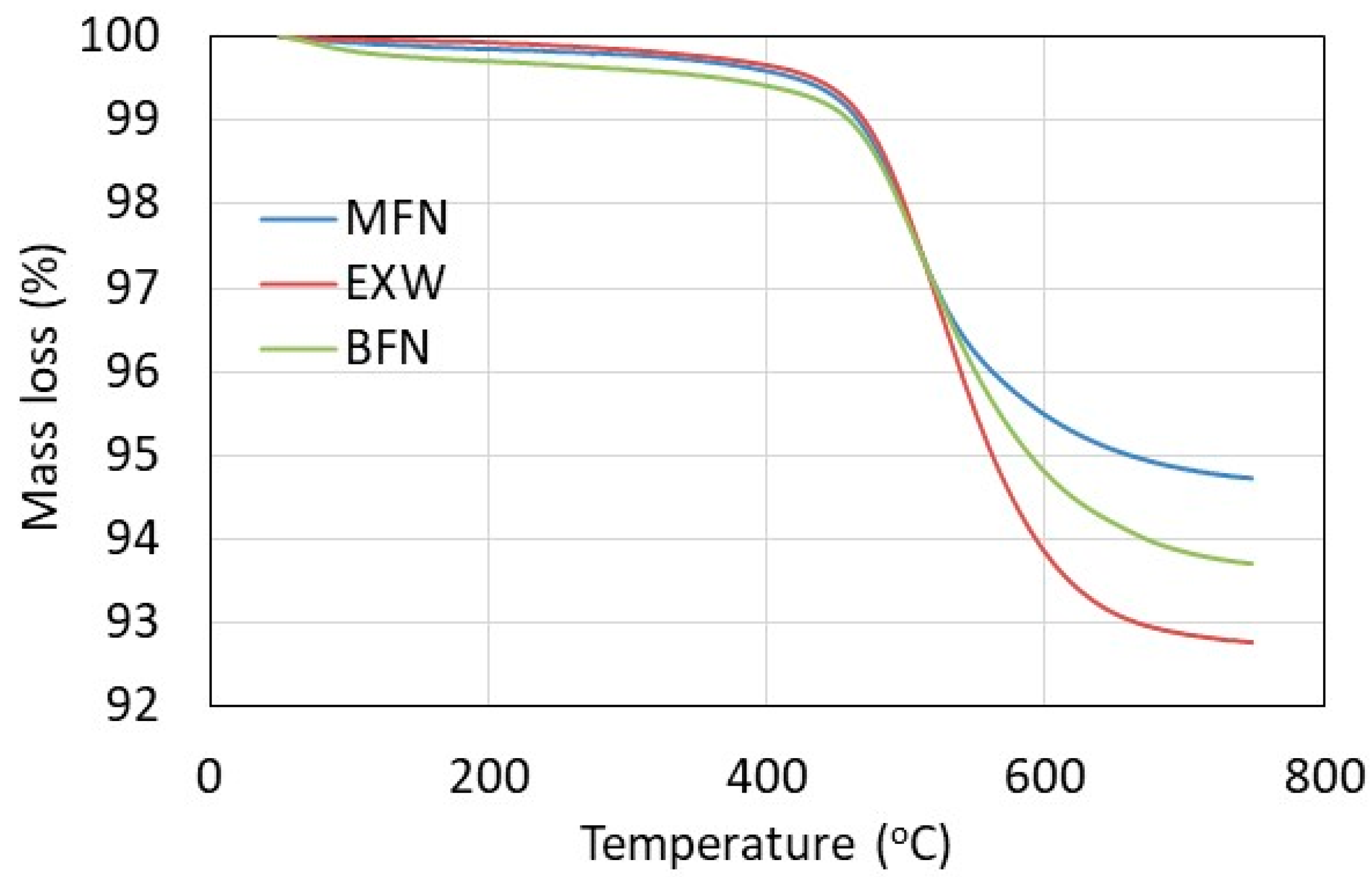

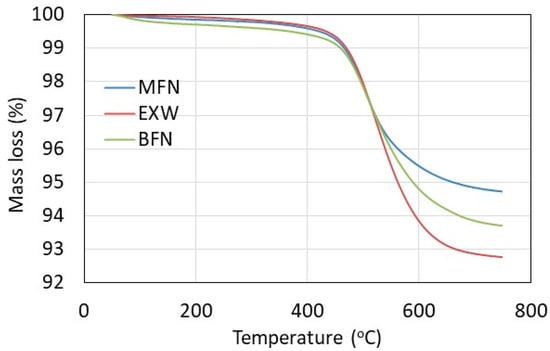

3.1.2. Kaolinite Content

The TGA result used to determine the kaolinite content of the raw clay samples, as illustrated in Section 2.1.3, is shown in Figure 4. The TGA results are the average of two repeated tests with a coefficient of variance of about 5–10%. The estimated percentage of kaolinitic content of the three raw clay samples is shown in Table 3. As noted earlier, the higher the kaolinitic content, the higher the performance expected from the LC3 binders [6,10]. A kaolinite content of at least 40% is expected to yield strengths similar to the reference OPC at 40–50% substitution. EXW seems to be the only clay sample to satisfy this requirement, though their pozzolanic oxide compositions (discussed later) appear similar, with relatively higher SiO2 and lower Al2O3. This implies that varied kaolinite content of raw clay can yield similar pozzolanic oxide content; the hydrates and strength properties are discussed later.

Figure 4.

TGA results of the raw clay samples.

Table 3.

Determined kaolinitic content of the raw clay samples.

3.1.3. Chemical Composition

Determining the chemical composition allows for estimating the pozzolanic oxide content (silicon dioxide (SiO2), aluminium oxide (Al2O3), and iron (III) oxide (Fe2O3)) known to be responsible for the pozzolanic activity that yields hydrates responsible for strength [26]. According to ASTM C618 [28], their cumulative value should be more than 70%. It should be noted that the amorphous portion of this content (Section 3.1.4) is responsible for pozzolanicity. Table 4 shows the oxide composition of the clay samples and limestone. The pozzolanic oxide contents are 94.87%, 95.46%, and 94.7% for MFN, EXW, and BFN, respectively, indicating that the requirement is satisfied. In this case, Fe2O3 contributes less than 1%. This high content confirms that calcining the clay yielded a sufficient amount of target metakaolin (Al2O7Si2). As noted earlier, the calcination of the kaolinite in the raw clay converts it to metakaolin. The loss on ignition (LOI) also satisfies the less than 10% requirement of ASTM C618 [28].

Table 4.

Oxide compositions of the calcined clay samples and limestone.

Comparing these values to those observed in the literature [3,6,27], these clay samples obtained in South Africa seem to be relatively higher in SiO2 content, at ≥70% compared to an average of about 50% (clay samples from India, North/South America, South Asia) reported in the literature. Conversely, the Al2O3 content seems lower, at about 17–23% compared to the 40% reported in the literature. This implies that the clay contains some 2:1 clay minerals and not just 1:1 structures (such as kaolin); that is, an octahedral alumina sheet is sandwiched between two tetrahedral silica sheets, contributing to more silica content. The mineral composition detailed in the next section confirms this. As noted earlier, due to varying geological settings and weathering conditions from one country or region to another, clay soil has varying mineral chemical signatures, and Al2O3 is key to the hydrates and strength of LC3 composites; it is suspected that the use of South African clay for cementitious composites may be lagging in performance. By implication, it can be said that the structural composition of the selected South African clay has more SiO2 components than Al2O3.

3.1.4. Binder Mineralogy

The mineral composition of the raw clay, calcined clay, and Portland cement are shown in Table 5 and Table 6, respectively. As noted earlier, a 2:1 mineral may be responsible for a large amount of silica obtained for the XRF results. Muscovite obtained from the XRD results in Table 5 is a mica family of clay minerals with a 2:1 structure. The results also show that the calcination of the raw clay yielded about 29–33% of amorphous content. It is noted that the kaolinite content from the XRD is less than that of the TGA and may be associated with the quartz in the XRD result being part of the crystalline silica from the kaolinite and muscovite. The mineral composition of the CEM II in Table 6 shows that about 16% of limestone is present with little or no gypsum. This implies that the limestone content of the LC3 should consider that precluded in CEM II.

Table 5.

Mineral compositions of the clay samples.

Table 6.

Mineral composition of the Portland cement.

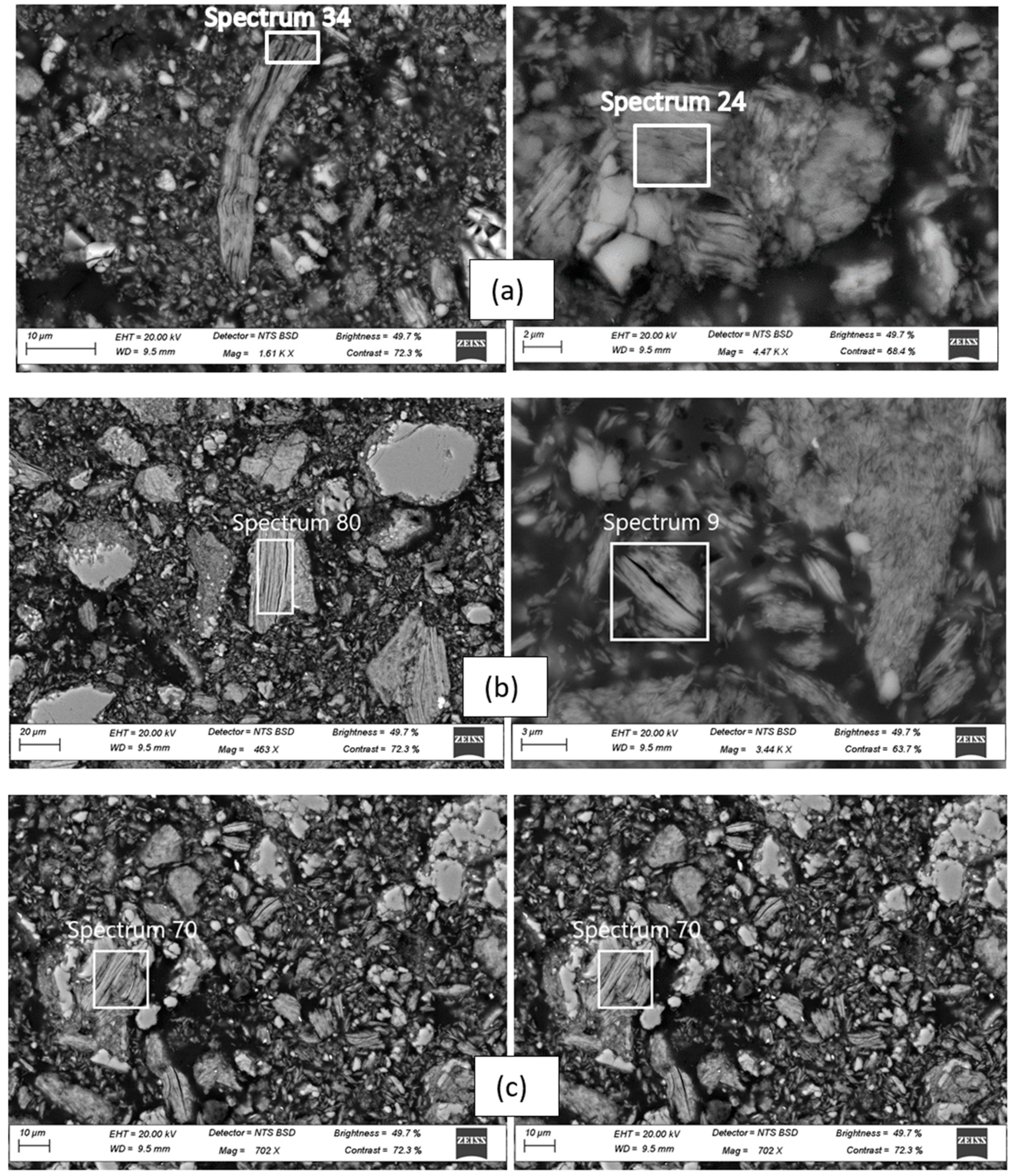

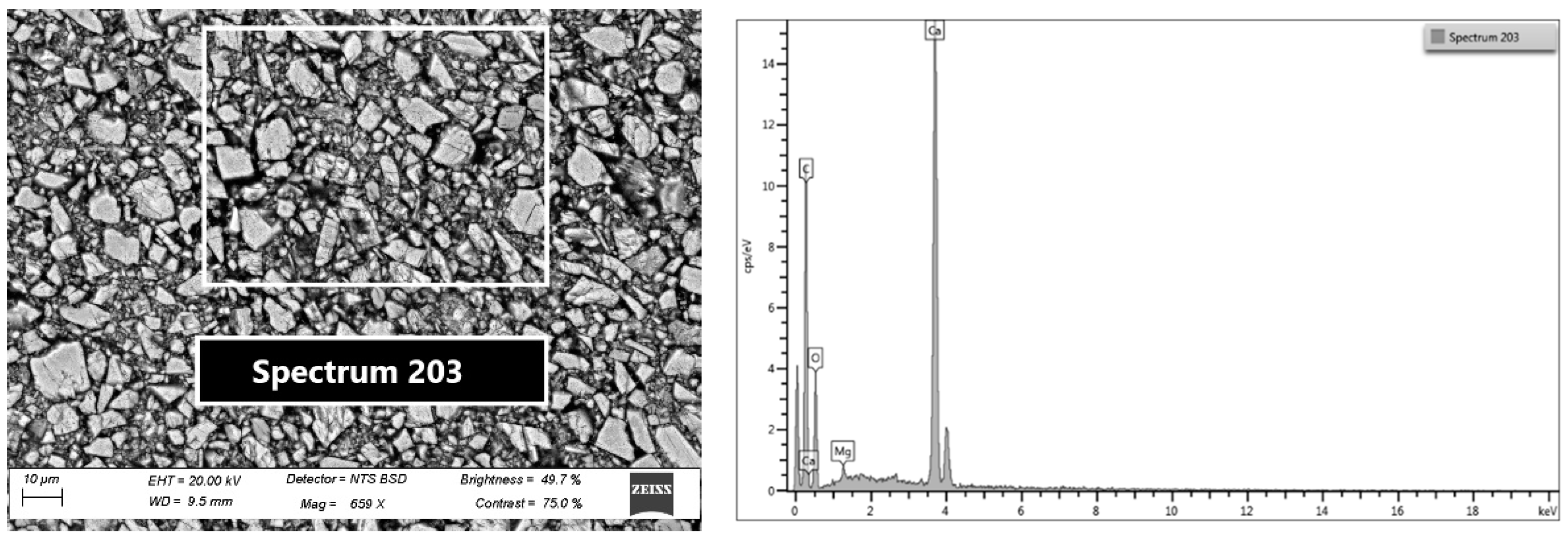

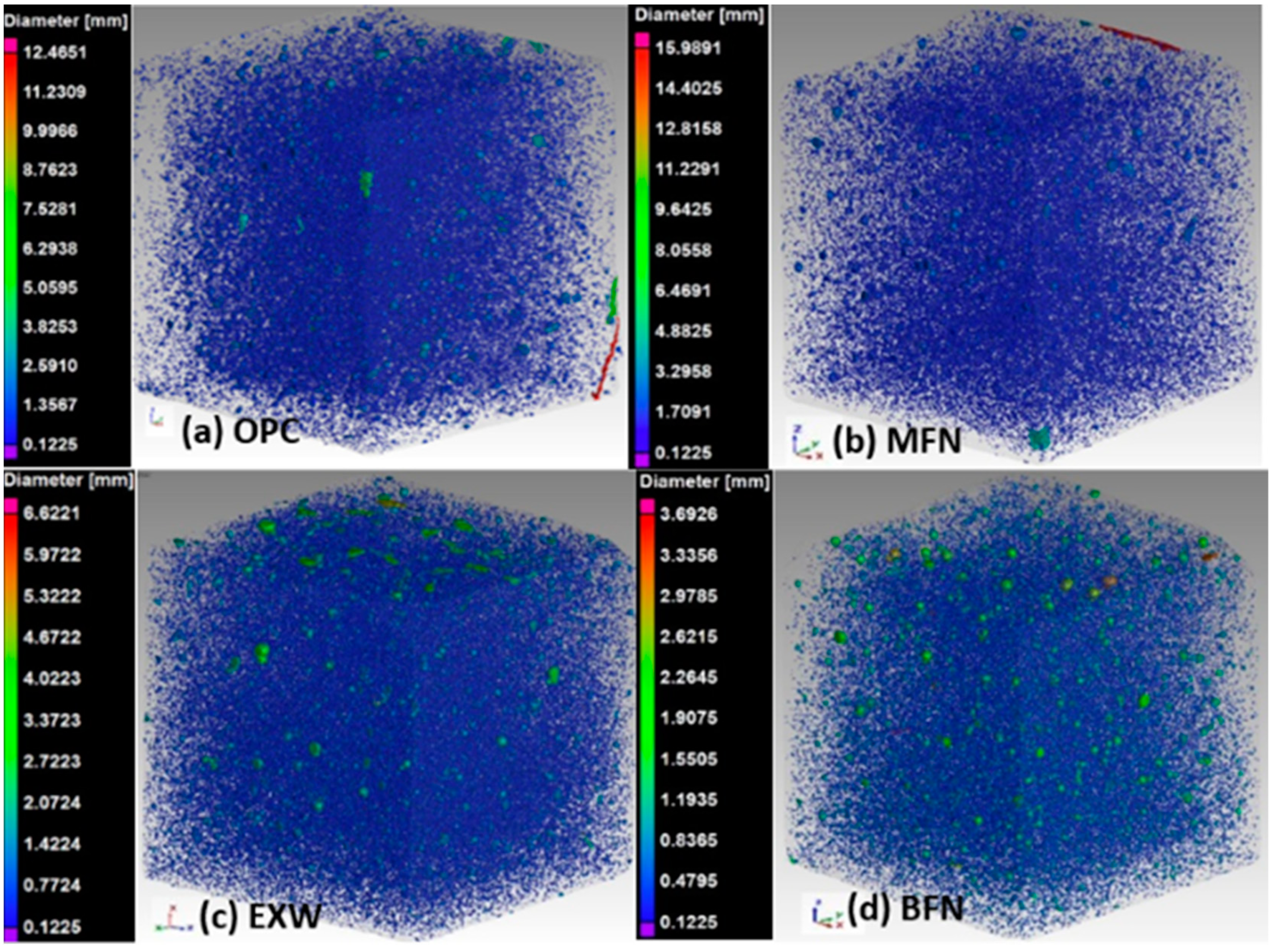

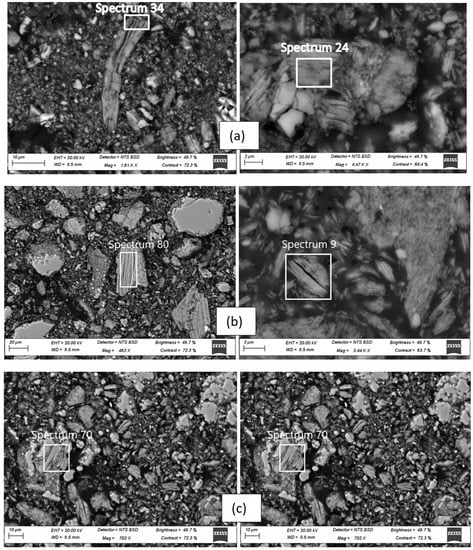

3.1.5. Calcined Clay and Limestone Morphology

The morphology of the calcined clay samples (EXW, BFN, MFN) and limestone investigated by SEM is detailed in this section. After calcination, amorphous metakaolin (MK) products (Al2O7Si4) are formed, and the major elements to identify are aluminium, silicon, and oxygen, confirmed by EDS by taking spectra of particles from the SEM micrographs. Investigating the morphology of the samples helps to elucidate the physical shapes, texture, and clustering of the particles as they relate to the PSD in Section 2.1.4 [13].

Figure 5a–c shows the particle morphology of the EXW, BFN, and MFN clay samples, respectively. The EDS analysis of the selected particles’ area spectra (average of about 28 spectra) is shown in Table 7. Figure 5 shows that the clay particles are generally flat and irregular with kaolinite booklets; EXW, in particular, tends to be elongated. The texture of the particles also tends to be fibrous. These shapes and textures are expected to reduce their workability in the mortar mixture [29]. The morphology of the limestone particles is shown in Figure 6, and the particles tend to be flat and prismatic. With the fineness of limestone obtained in Section 3.1.1 and morphology obtained here, it is expected that the particles should be able to serve as fillers for improving the strength of the mortar samples. Table 7 shows that the main elements are aluminium, silicon, and oxygen, supporting the earlier XRF results (Table 4).

Figure 5.

SEM images of clay samples at two levels of magnification: (a) EXW, (b) BFN, (c) MFN.

Table 7.

EDS average elemental results from 28 spectra each.

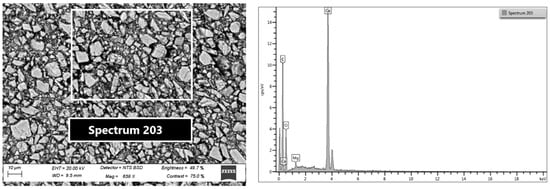

Figure 6.

SEM images of limestone powder and the EDS analysis from the spectrum (the insert table is the average of 12 other spectra).

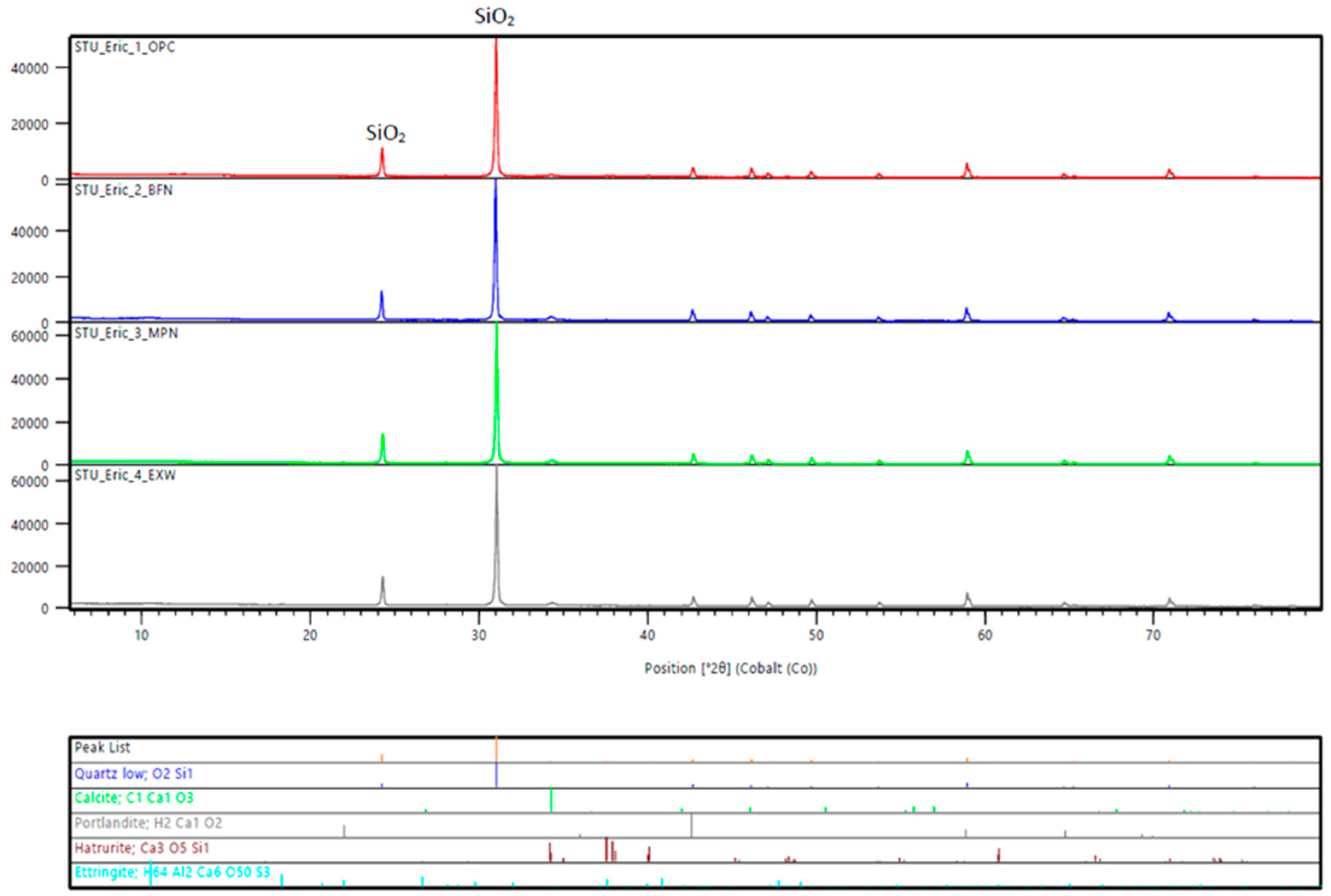

3.1.6. Mortar Hydrate Mineralogy and Content

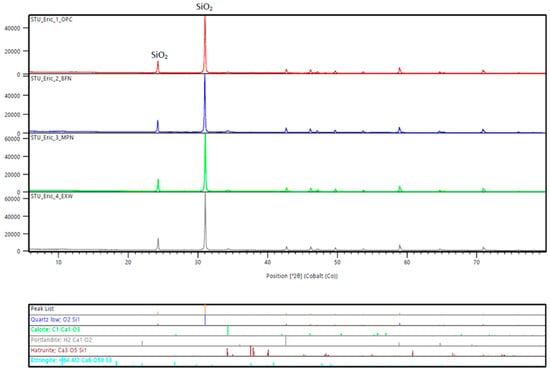

Results of the XRD analysis for the PC mortar and those of LC3 (BFN, MFN, EXW) are shown in Table 8 (see Figure 7 for the XRD patterns). The two main peaks at 24.2° 2θ and 31° 2θ represent quartz (SiO2), and they mainly originate from the sand content of the specimens. From the mixture design, the estimate of the sand content is about 60%, which is obtained for the OPC mortar from the XRD results. A higher percentage of quartz in the clay samples (63–72%) implies that some sand impurities were in the samples. Ettringite is formed in LC3 mortars as part of the pozzolanic reactions due to the limestone reacting with additional alumina. It can be observed from Table 8 that the ettringite content seems to not be influenced by the kaolinite content of the clay; this has also been confirmed by another study [6]. It is noted that the ettringite content in the control is zero, which can be due to the low amount of aluminate in the Portland cement, detected as 1.26% in Table 5, unlike 10% common content in OPC. This could have led to small amounts of ettringite formed being converted to monosulphate.

Table 8.

Relative phase contents (%) from the XRD results by the Rietveld method.

Figure 7.

XRD patterns of the PC mortar (control in red), BFN (blue), MFN (green), and EXW (grey) at 28 days.

The amorphous phases in Table 8 include metakaolin and calcium silicate hydrates. As noted earlier, the combined formation of extra CASH, ettringite, and carbo-aluminates in the pozzolanic reaction refines the microstructure densification and strength. In addition, the consumption of portlandite signifies the pozzolanicity of the clay samples, which can be directly proportional to the kaolinite content. These results are confirmed later in this study from the strength results where EXW LC3 mortar has better relative strength.

Assuming that the content of the calcite in the OPC mortar emanates from the extender in Suretech CEM II/A-L 52.5N, then BFN, MFN, and EXW mortars can be said to contain 2.45%, 1.95%, and 2.55% calcite, which is less than about 4% of limestone originally in the mixture. This suggests that the limestone is being consumed for hydration, a physico-chemical activity from the extra nucleation sites provided by the fine particles of the limestone and the formation of mono-carboaluminates [13,30]. This result supports the better 3D void microstructure later obtained for the MFN sample with the least calcite content. The consumption of portlandite for the calcined clays is proportional to the kaolinite content. MFN, BFN, and EXW with 29.5%, 32.8%, and 41.6% contents had 0.8%, 0.6%, and 0.5% of portlandite, respectively, signifying that higher kaolinite content guarantees better pozzolanic activity.

3.2. Mortar Properties

3.2.1. Fresh State

The consistency of mortar was maintained at 180–200 mm mini-slump by using varied content of polycarboxylate-based superplasticiser shown in Table 9. The table shows the required superplasticiser content relative to that of the control (PC), and it is found that the kaolinite content correlates with the obtained consistency. Higher kaolinite content improves consistency and reduces the demand for water reducers. This is in contrast to the fact that almost 70% of the EXW clay particles are finer than the other two clay samples (Figure 3). Finer particles in a cementitious mixture generally reduce consistency [26], and higher kaolinitic content typically requires more superplasticiser dosing [3,31].

Table 9.

Relative percent of superplasticiser and mini-slump of the mortar mixtures.

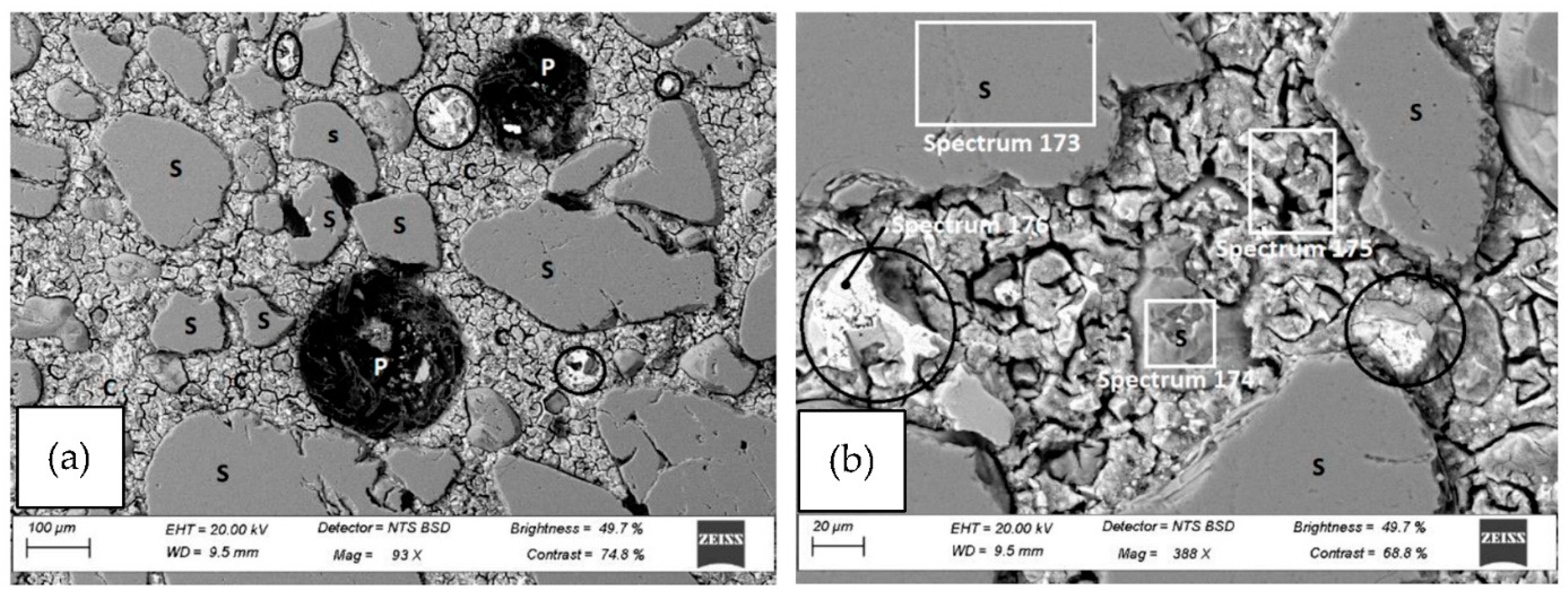

3.2.2. Microstructure and Porosity

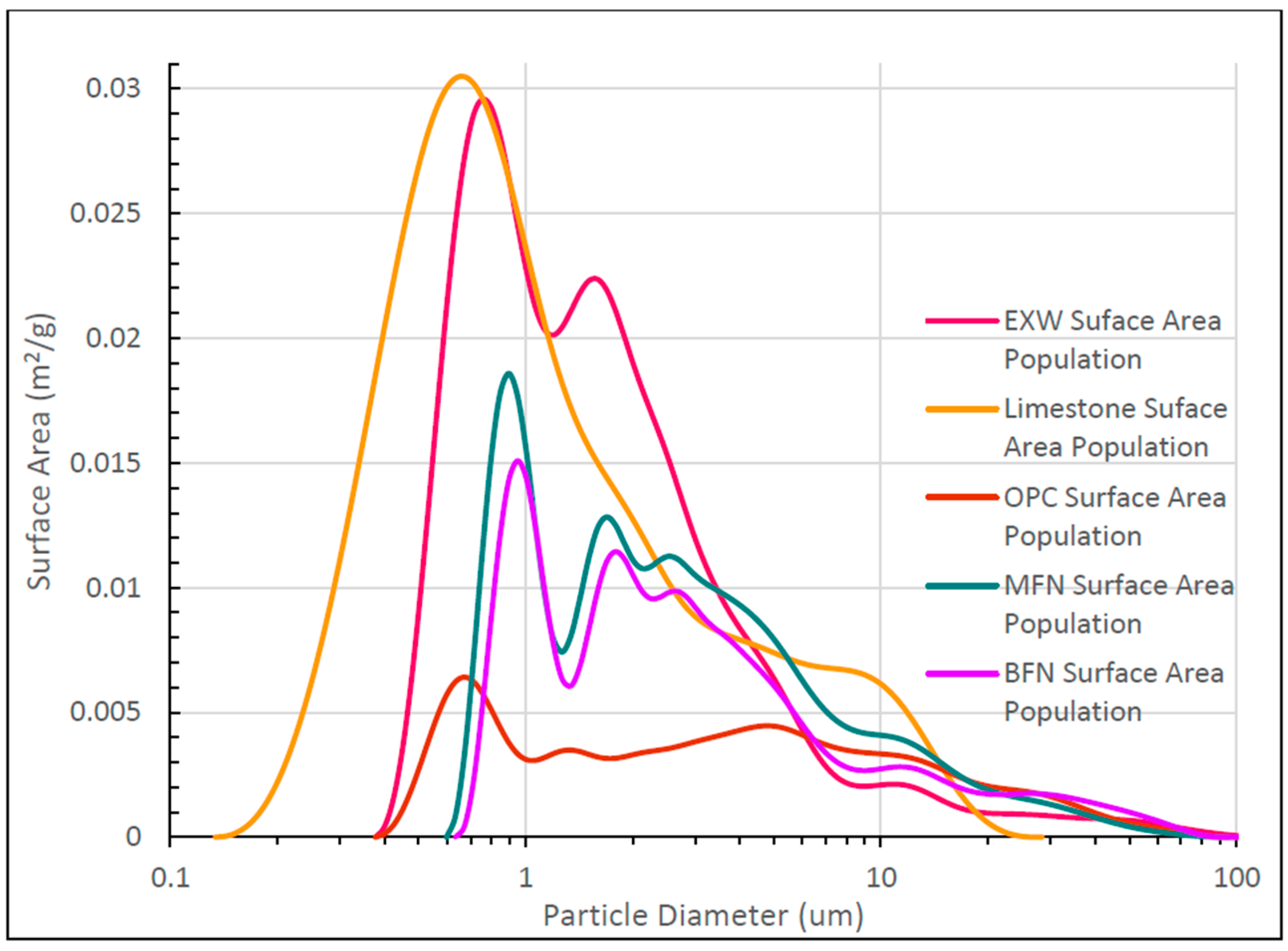

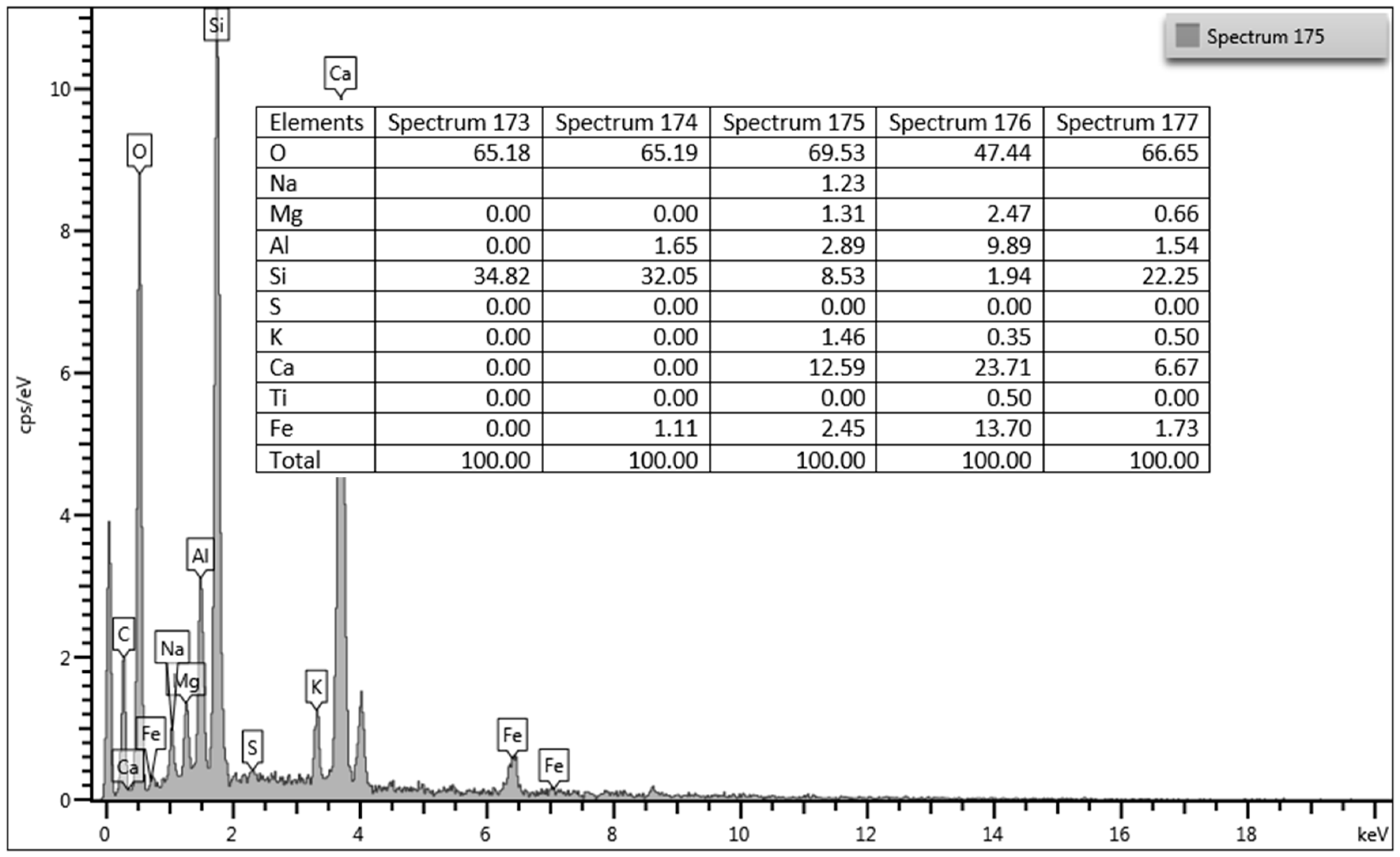

The microstructure (2D slice surface) of the mortars (OPC, EXW, BFN, MFN) was investigated under SEM + EDS. The SEM micrographs are mainly intended for qualitative analysis, and the EDS analyses of selected areas (labelled “Spectrum”) are used to adjudge the chemical composition within the spectrum. The quantitative 3D void microstructure of the mortar was investigated by XCT. These results were at 28 days of the mortar age.

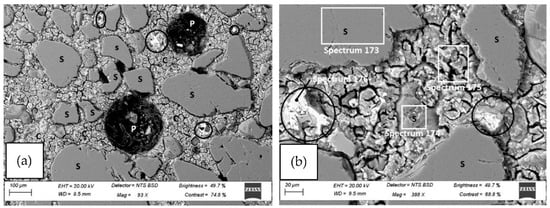

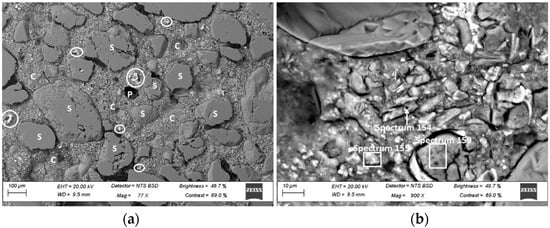

- 2D microstructural analysis

Figure 8a,b show the SEM micrographs for the PC mortar. In this micrograph and others, “S” indicates a sand particle, “P” indicates a pore, and “C” indicates cement paste. The white particles in the cement paste areas surrounded by circles are unhydrated cement grains. In Figure 8b, the "Spectrum” labels represent areas where EDS points were taken, and the elemental results are shown in the Appendix A (Figure A2). EDS analysis on Spectrum 175 showed major elements of Ca, Si, O, and Al, which implies that calcium aluminate silica hydrates (C-A-S-H) gels are formed as hydration products. Spectrum 176 identified major Ca, Al, O, and Fe elements, confirming that the white patches are tetracalcium aluminoferrite (C4AF) of unhydrated cement paste. Spectrum 173 contains only Si and O, representing silica sand particles.

Figure 8.

(a) SEM image showing the different particles in the OPC cement matrix where ‘S’ is sand, ‘P’ is a pore, ‘C’ is cement paste, and black circles showing unhydrated cement grains, (b) white blocks indicating the spectrums analysed with SEM-EDS.

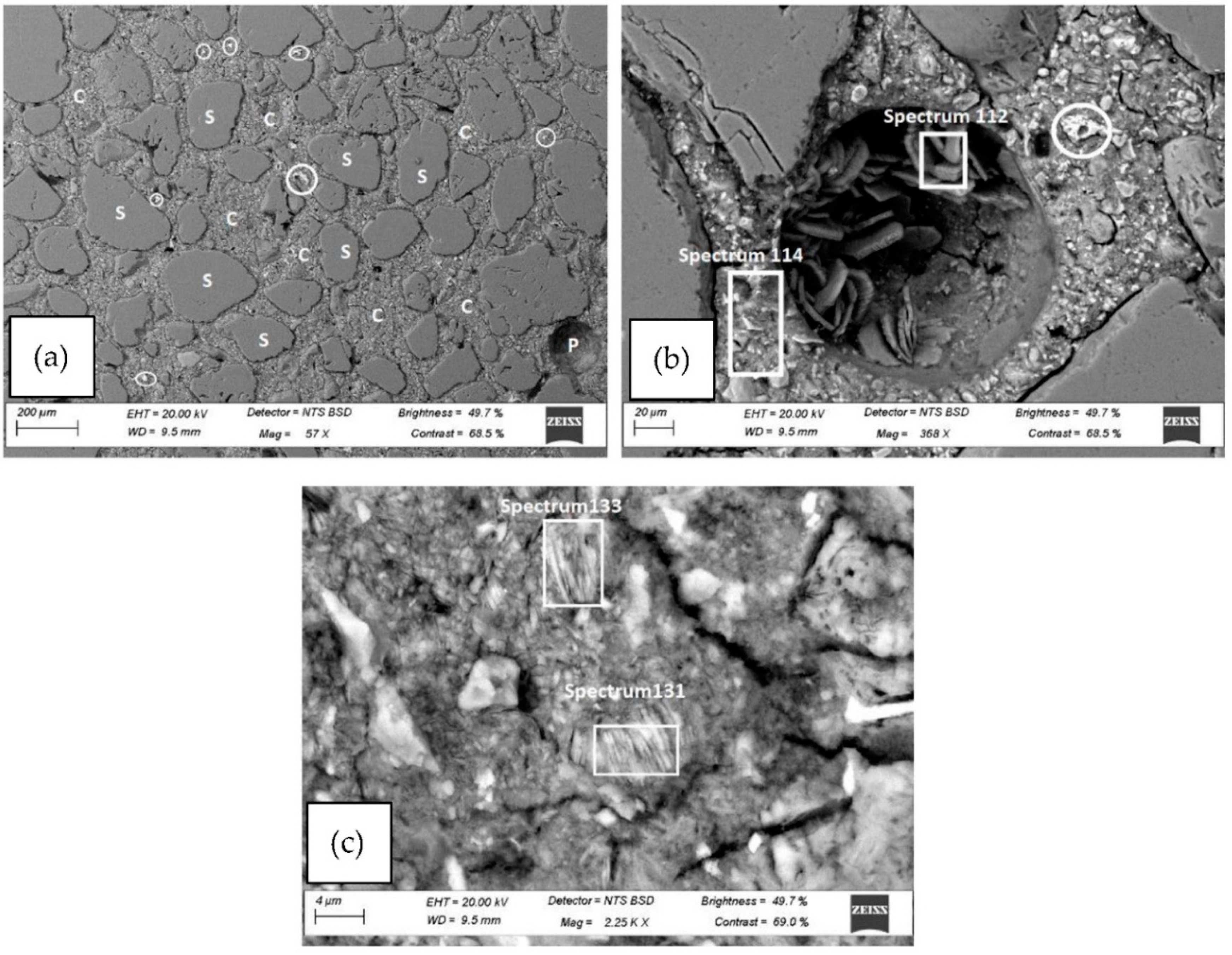

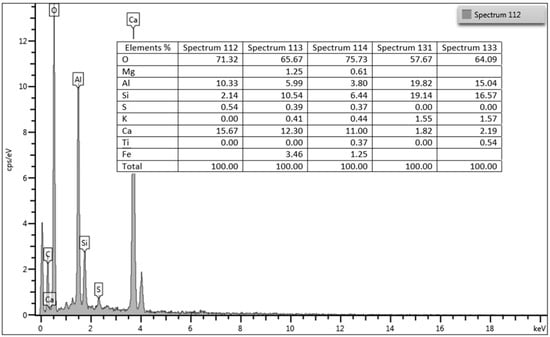

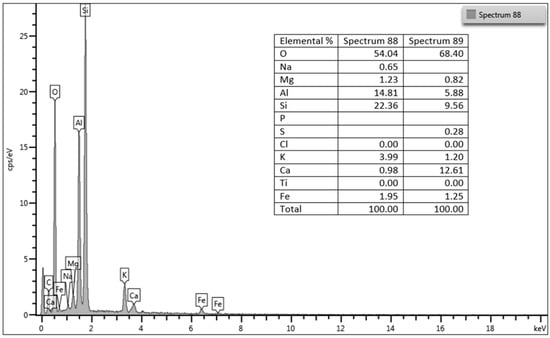

Figure 9a–c shows the SEM results of the EXW mortar. From the magnified image (Figure 9b), it can be observed that the cement paste between the sand particles (S) is significantly denser with less porosity than that of the control (PC) in Figure 8. In addition, major elements in Spectrum 112 (within the pore, see Appendix A Figure A3) are Ca, O, and Al, indicating that the plate structures formed inside the pore are hemi/mono carbo-aluminates (C4AC—0.5H12, Hc or C4AC—H11, Mc) produced from the reaction of limestone with aluminate (Al2O3) phases and Portlandite (CH). This shows that the limestone and metakaolin, forming carbo-aluminates, do fill up the microstructure. EDS Spectrum 114 has major elements Ca, Si, and O, which suggest the hydration of alite (C3S) and belite (C2S) to produce calcium silicate hydrate (C-S-H). A higher magnification micrograph (×5) (Figure 9c) shows cracked fibril structures (Spectrum 131 and 133) that look similar to those of the clay morphology in Section 3.1.4. The EDS analysis confirms the major elements as Si, O, and Al, suggesting metakaolin (Al2O32Si2); that is, after 28 days, not all the calcined clay particles are fully hydrated. It should be noted that these metakaolin particles and EDS spectrum analysis results were observed for the other LC3 mortars, as shown later.

Figure 9.

(a) SEM image showing the different particles in the EXW mortar matrix, (b) SEM image showing a large pore with hydration products forming in the pore and the area analysed by EDS for spectrum 112 and 114, (c) SEM image of metakaolin particle in the inter transitional zone (ITZ) of the mortar paste between the aggregates.

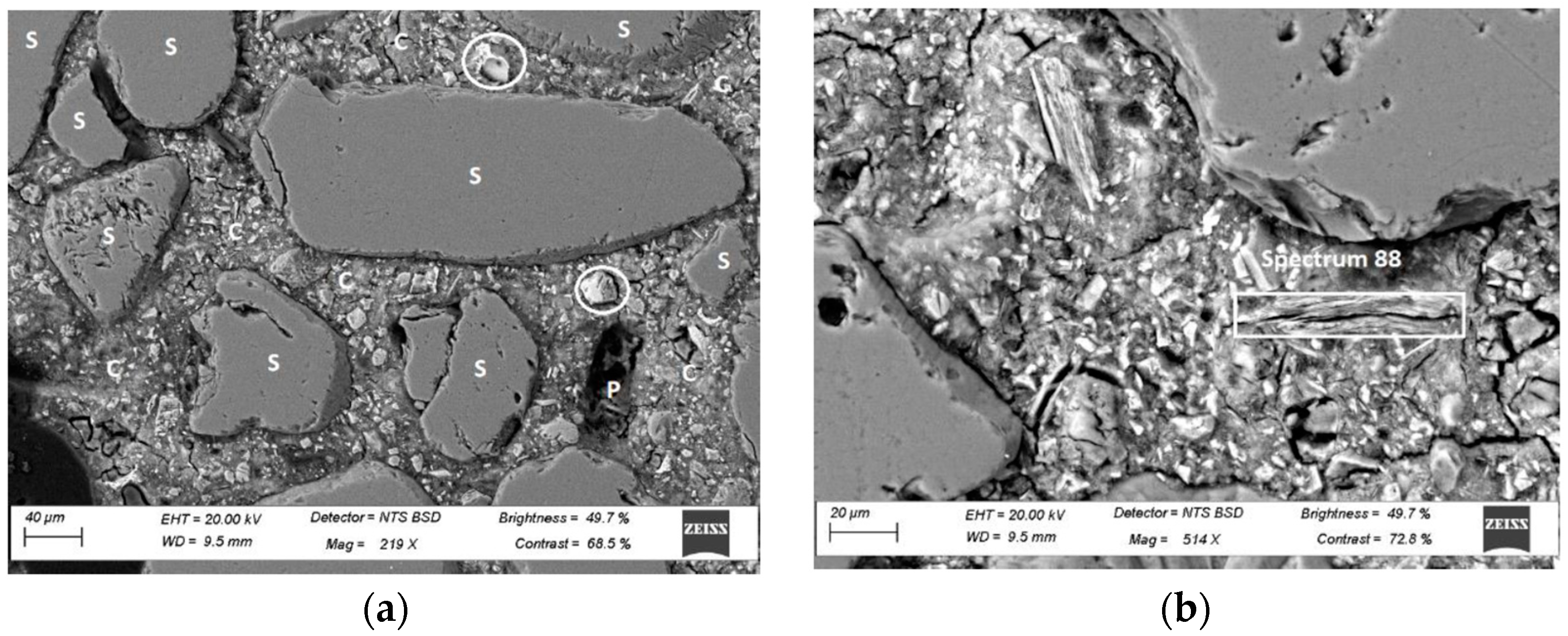

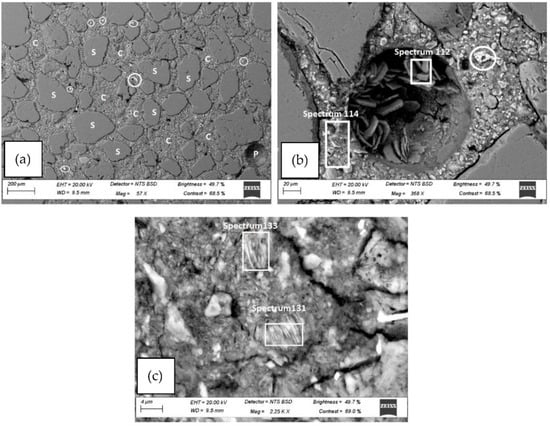

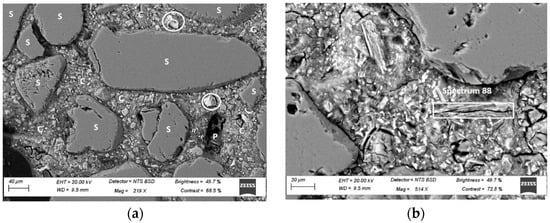

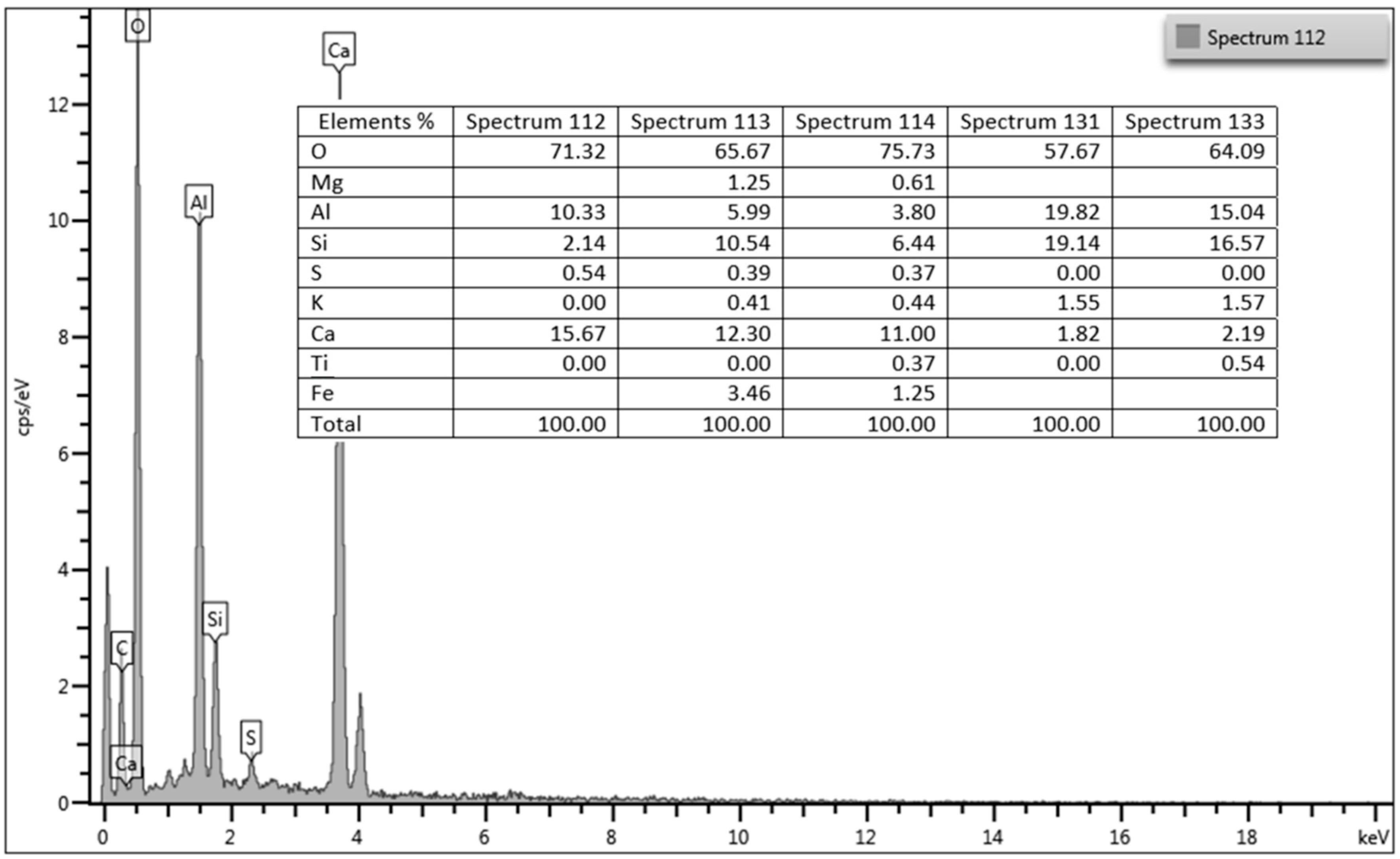

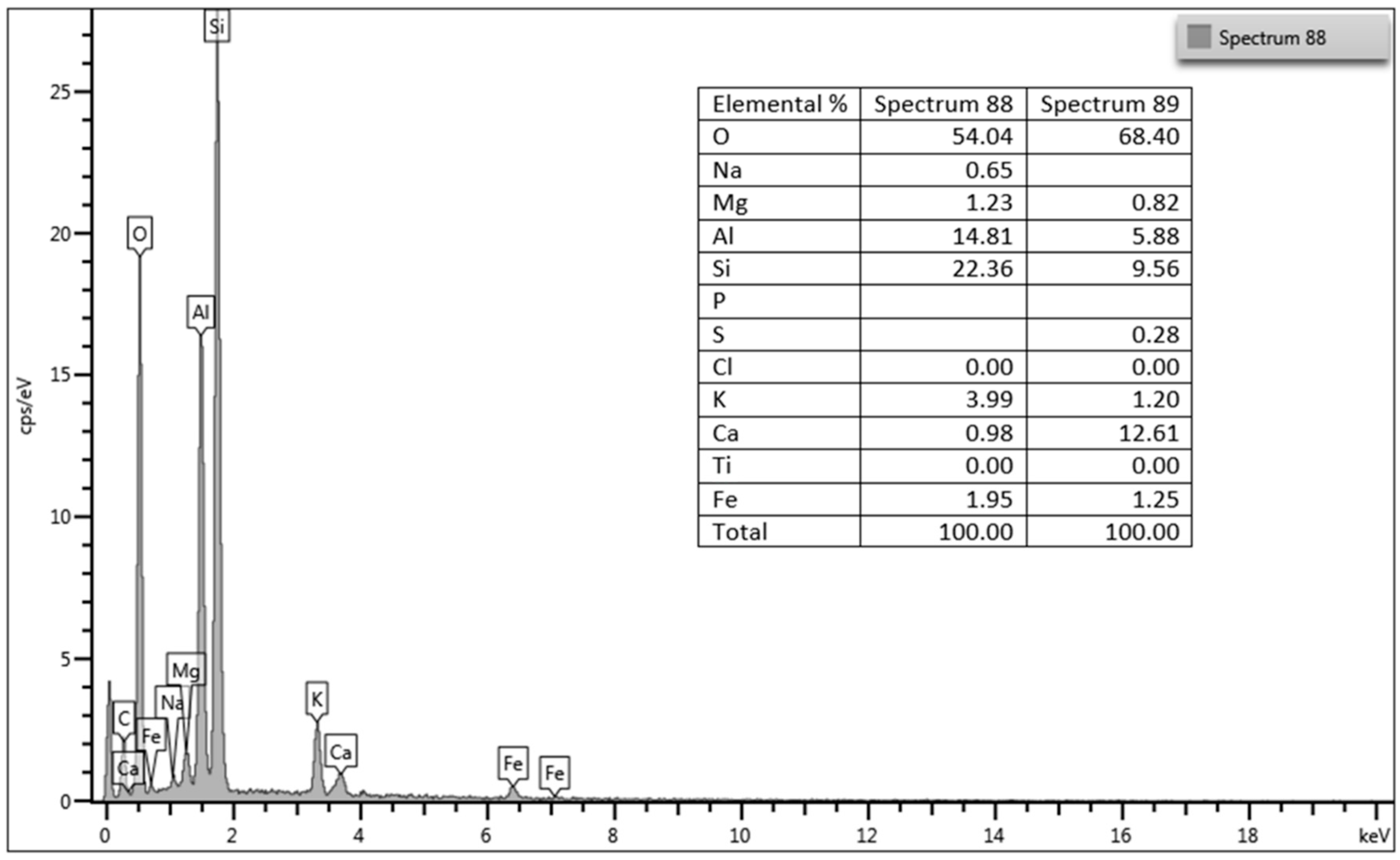

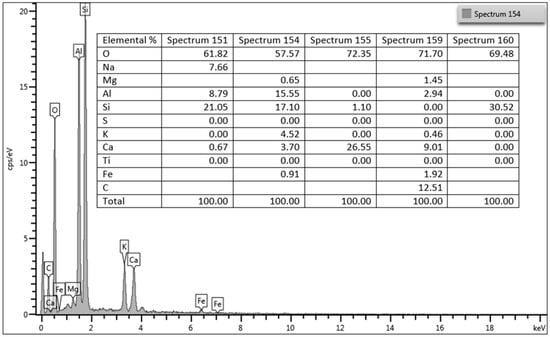

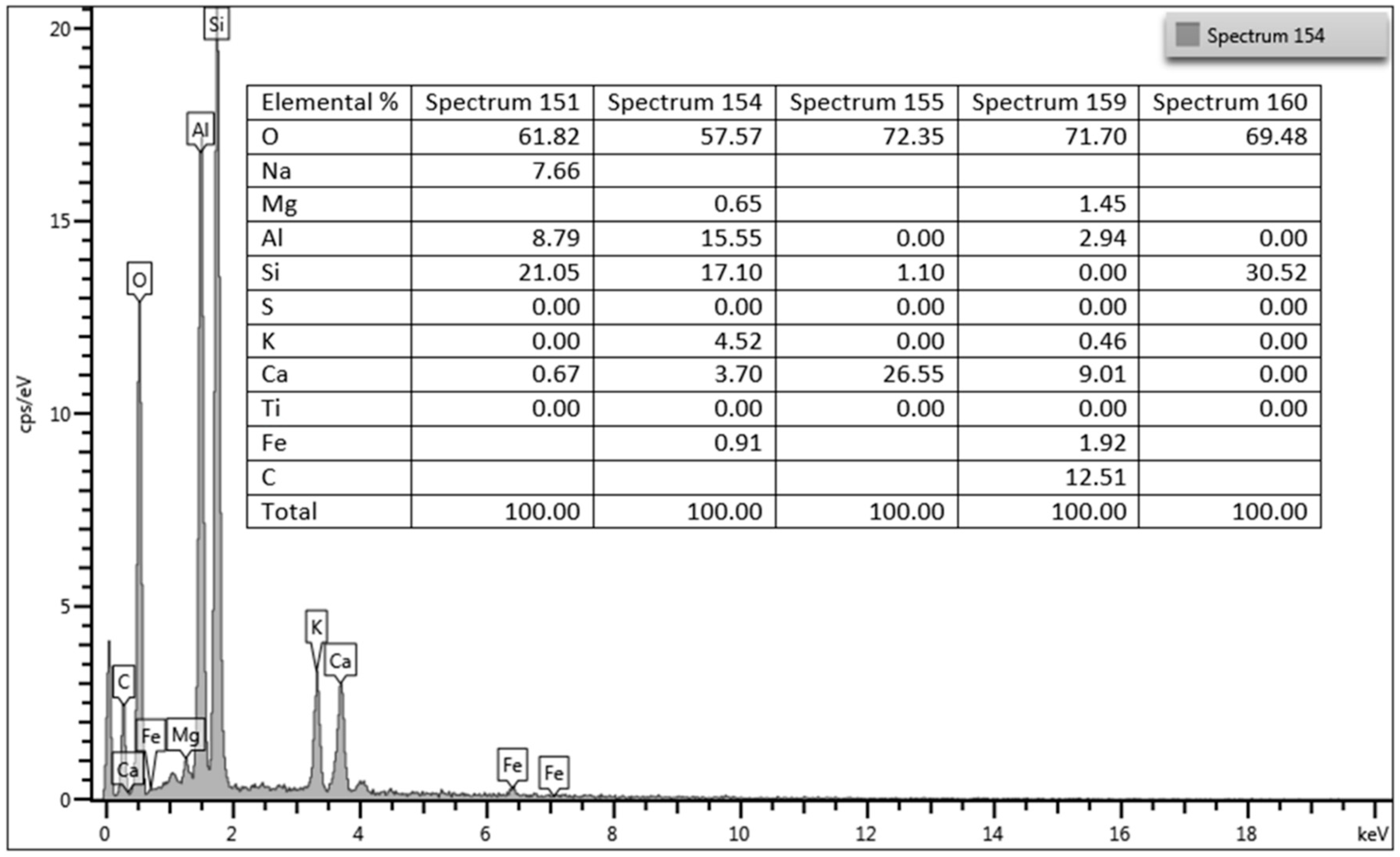

Figure 10 and Figure 11 show the 2D microstructure of the BFN and MFN LC3 mortars, respectively. Similar to EXW, a denser microstructure (compared to OPC) can be observed. Spectrum 88 and 154 in the ITZ of the BFN and paste of MFN mortars, respectively, show the metakaolin morphology observed earlier for EXW; the EDS analysis also shows major elements of Si, O, and Al, indicating metakaolin (Appendix A Figure A4). Spectrum 159 EDS analysis of MFN mortar (Appendix A Figure A5) shows major elements Ca, C, and O, suggesting limestone (CaCO3). This highlights the pure filler effect of the limestone.

Figure 10.

(a) SEM image showing the different particles in the BFN mortar matrix and white circles showing unhydrated cement grains, (b) SEM image of metakaolin particle in the inter transitional zone (ITZ) of the mortar paste between the aggregates.

Figure 11.

(a) SEM image showing the different particles in the MFN mortar, (b) Electron image showing analysed EDS spectrums 154, 155, and 159.

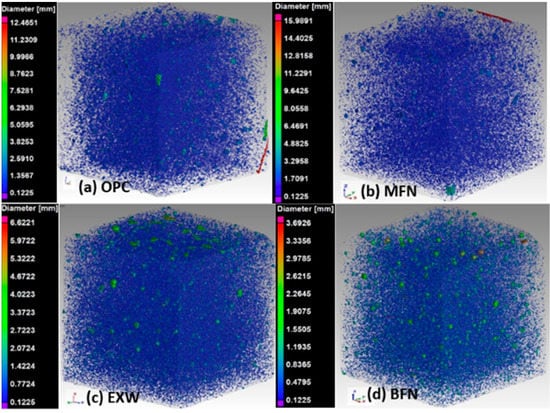

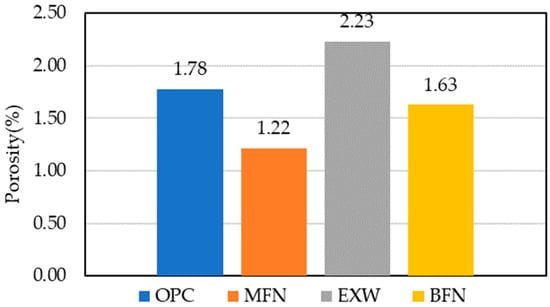

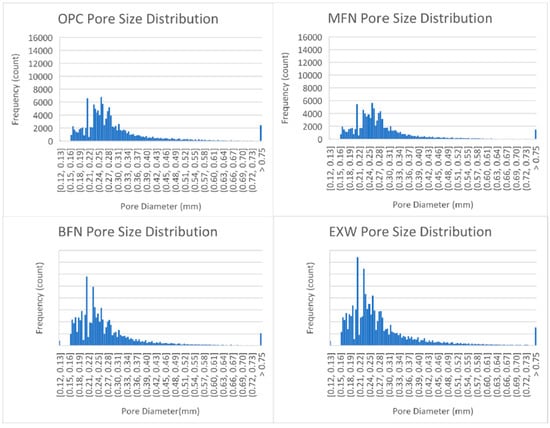

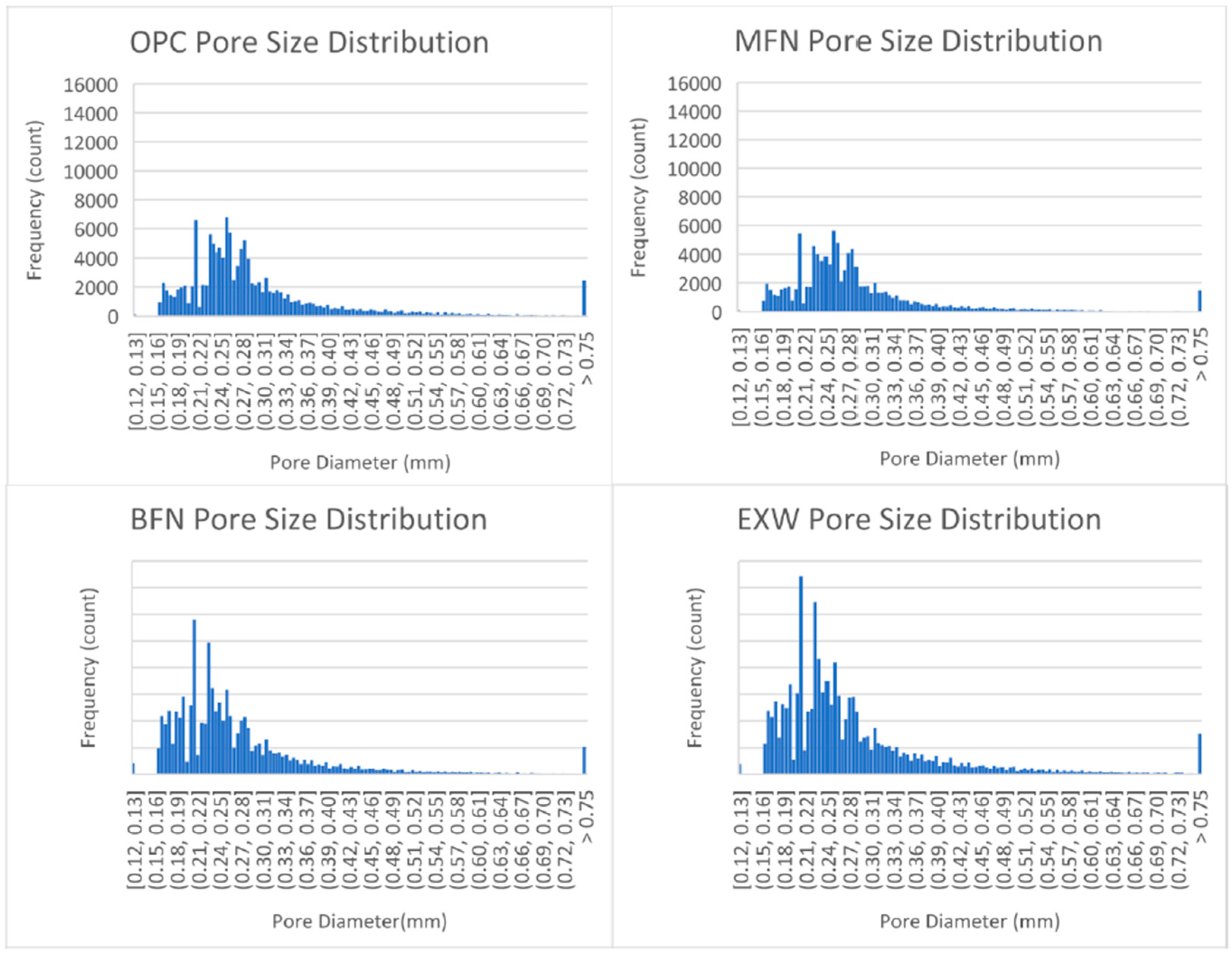

- 3D void microstructure

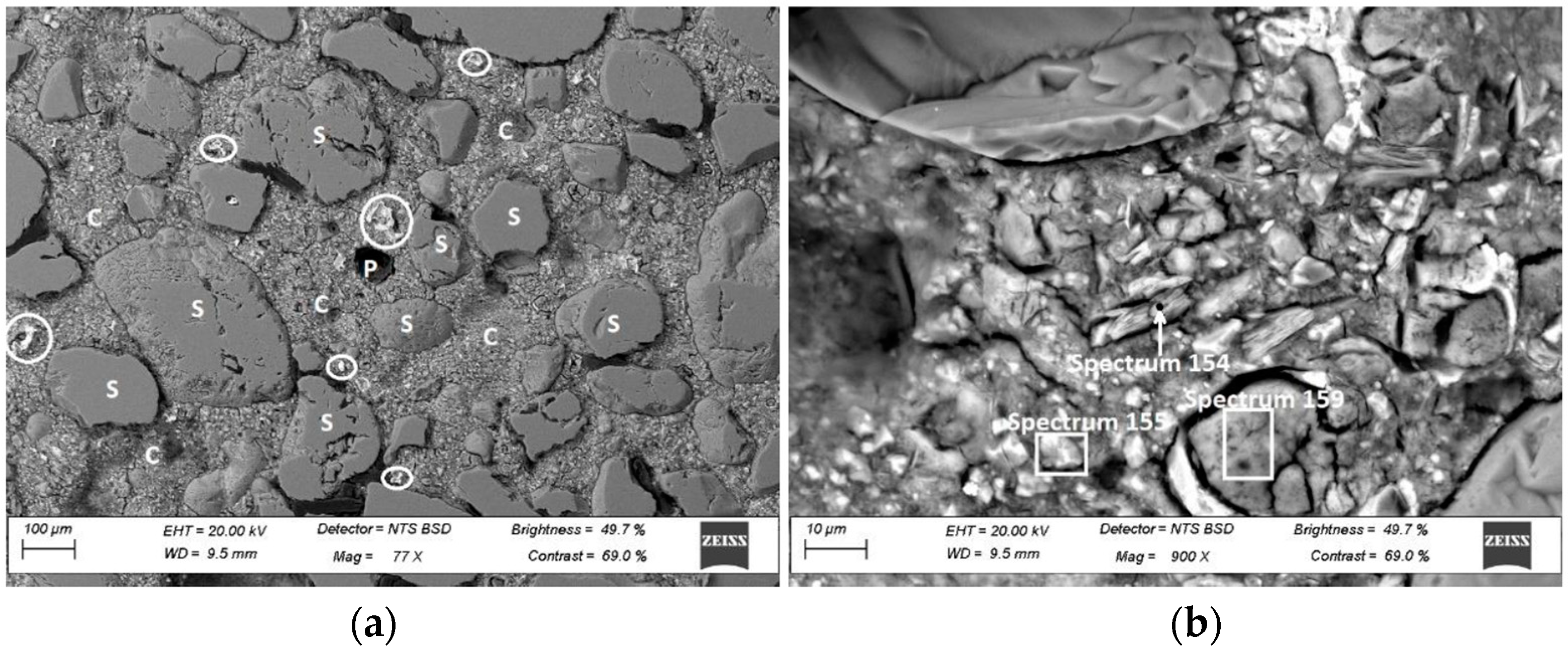

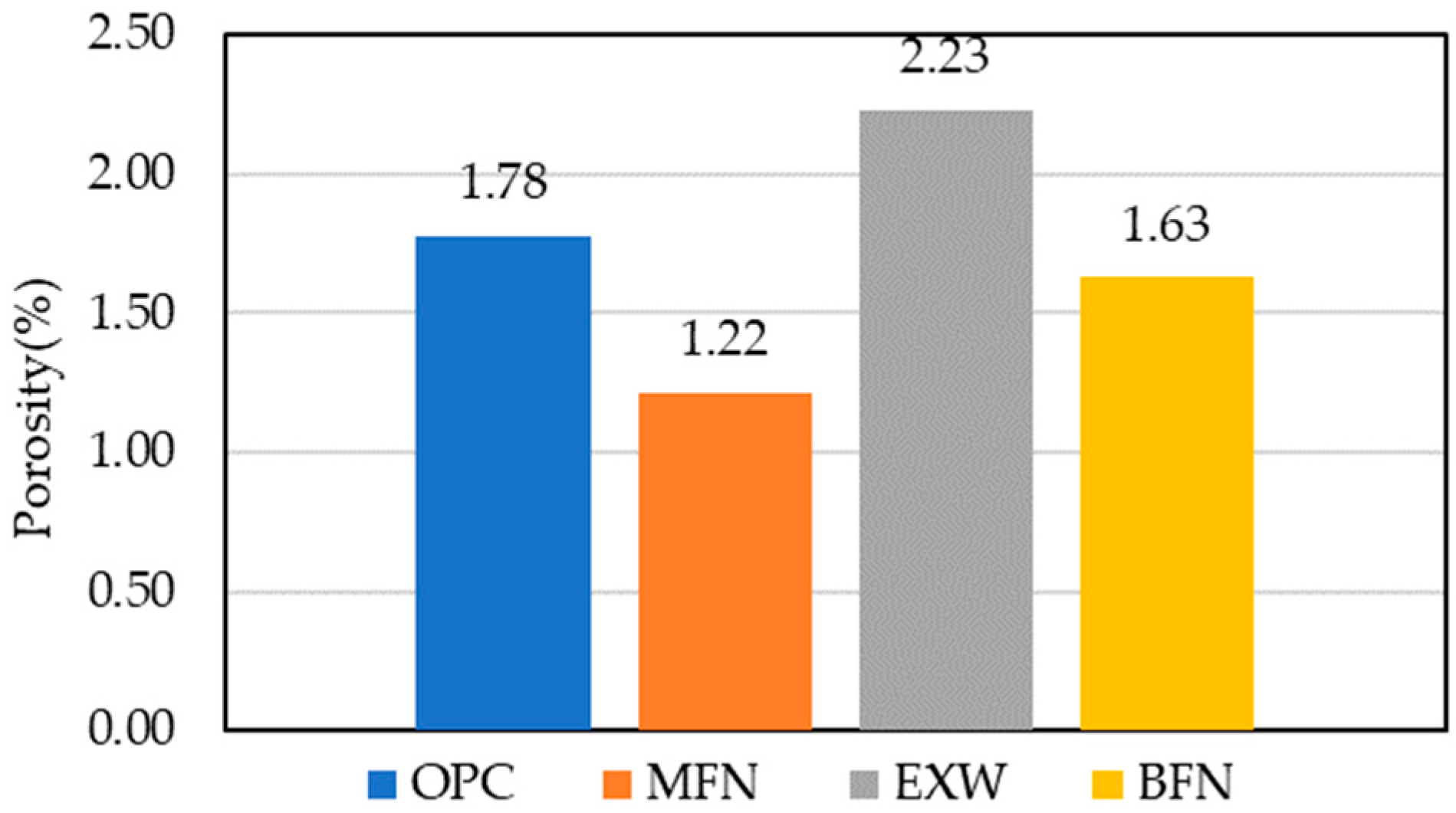

A visual overview of the void microstructure of the mortar samples investigated by XCT is shown in Figure 12a–d. It shows the micro-CT porosity images of specimens in 3D XYZ-plane and the pore sizes are colour coded according to size. The pores with sphericity larger than 0.6 and size larger than 80 μm were identified. The percentage of the void in each mortar is shown in Figure 13. The distribution of the pore sizes and the summary of the statistical analyses of the pore diameters are given in the Appendix A (Figure A6 and Table A1). Generally, the higher the percentage of voids in the mortar specimen, the greater the durability issues. Porosity affects the mass transport properties of the mortar [24,32]. Therefore, the void of the mortar can help to evaluate the durability of the LC3 system compared to that of the PC as a control (Figure 12a).

Figure 12.

Micro-CT porosity analysis of specimens in 3D XYZ-plane. (a) OPC, (b) MFN, (c) EXW, (d) BFN.

Figure 13.

Percentage porosity of the mortar at 28 days.

OPC, the control specimen, has a porosity percentage of 1.78 % as seen in Figure 13, and has the largest range and mean values of pore diameters as seen in the Appendix A Table A1. MFN LC3 mortar has the lowest porosity, 31% less than the control (PC), followed by BFN (8%), while EXW has a porosity 25% higher than the PC. This implies that the SEM 2D microstructure evaluation may not be adequate to indicate the mortars’ overall porous nature, as it visually suggests that EXW seems to have less porosity than the PC. From the void size distribution and statistical analysis in the Appendix A (Figure A6 and Table A1), a larger percentage of the void sizes is around 0.21 mm for PC and LC3 systems. However, the PC generally has a higher pore diameter (average and maximum) than the LC3 systems. This indicates the better pore refinement generally associated with LC3 systems [4,7,10].

Earlier studies suggest that higher kaolinite content leads to better pore refinement [4,6]. This is not the case in the current study, where EXW LC3 mortar with the highest kaolinite content has the highest percentage of porosity and vice versa. It should be noted that the former studies refer to binder paste gel pores (<10 nm) and capillary pores less than 1000 nm (that is, nanoscale), while the current study examines mortar air voids at macroscale ≥60,000 nm (60 µm). This is a size range similar to the maximum grain size of the binders (Figure 3). This suggests that the inclusion of sand complicates the influence of kaolinite content on the mortar microstructure and accentuates the importance of using fine limestone. From Section 3.1.5, clay mortars with the least calcite (CaCO3) content signify the highest limestone consumption, which is found to translate into lower porosity. This suggests that the degree of consumption (hydration) of limestone becomes more important than the kaolinite content for the microscale void refinement of LC3 mortar.

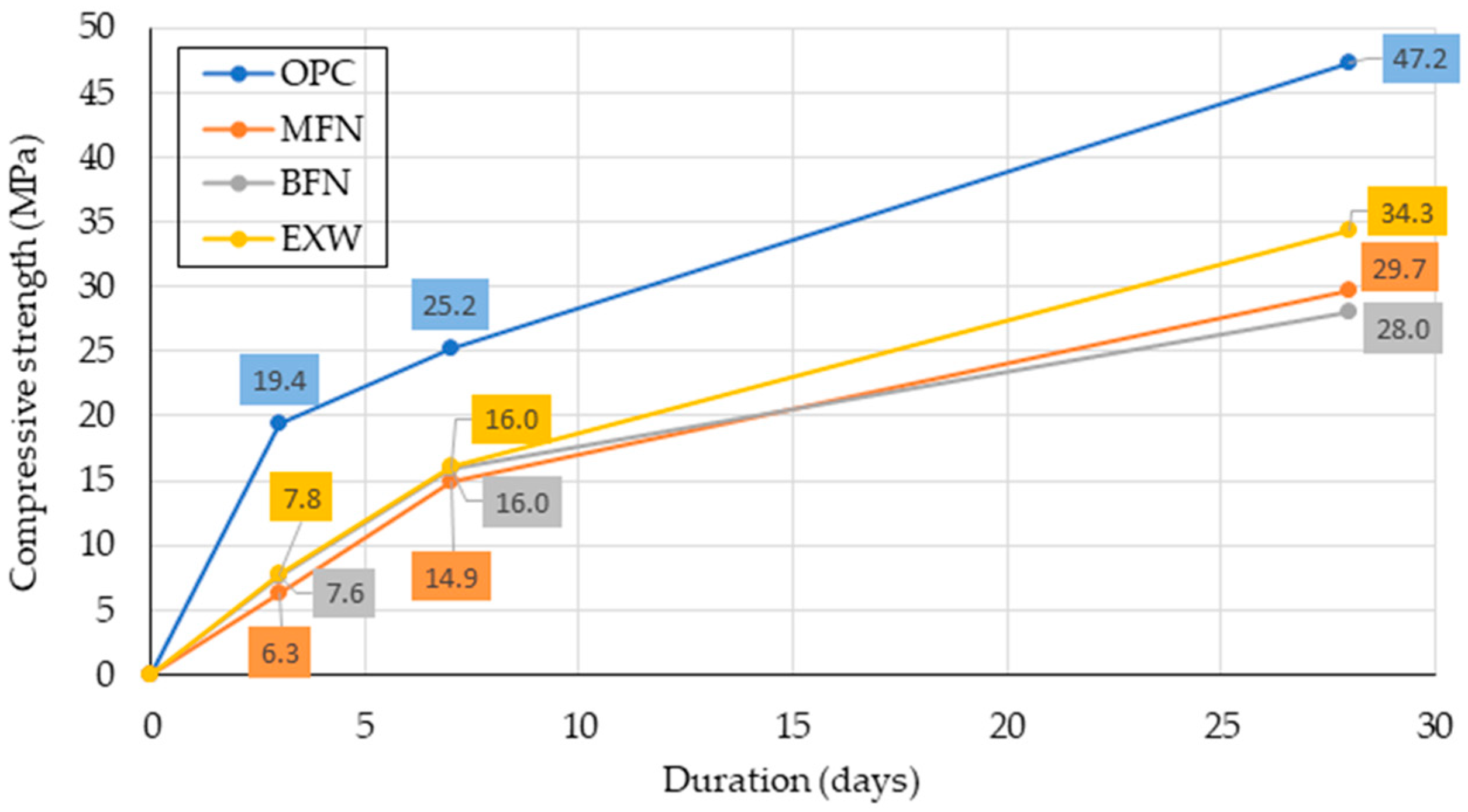

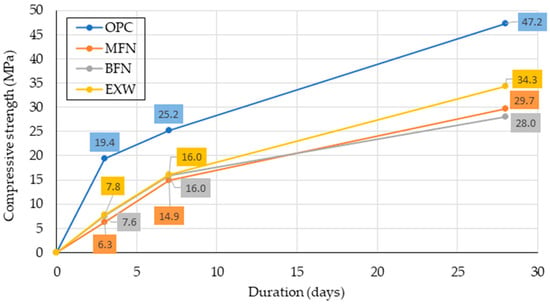

3.3. Compressive Strength

Figure 14 shows the strength development of the mortar specimens, PC and LC3 (MFN, BFN, and EXW). The PC mortar has higher compressive strength than the LC3 mortar. The LC3 mortar only achieved 63%, 59%, and 73% of the strength of the PC mortar at 28 days. Previous studies [6,7,9,10] showed that calcined clay with at least 40% kaolinite content could achieve similar strength as OPC. This is not the case in the current study, as the cement type already contained limestone (Suretech CEM II/A-L 52.5 N in Table 6). Therefore, the equivalent contents in the LC3 are estimated as 40% clinker, 30% calcined clay, 22.5% limestone, and 5% gypsum instead of 50% clinker, 30% calcined clay, 15% limestone, and 5% gypsum stated in previous studies [6,7,9,10]. The compressive strength of the LC3 mortars normalised by the clinker fraction yields 37, 35, and 43 MPa for MFN, BFN, and EXW, respectively, at 28 days. The normalised strength results show that South African clay with kaolinite content above 40% can achieve similar strength to PC and, therefore, is viable for the industrial production of LC3 binder intended for structural concrete (40 MPa designed strength in the case of this study). This shows that efforts must be taken to use pure clinker rather than commercially available Portland cement in South Africa. For on-site implementation, it is recommended that the intrinsic content of limestone and gypsum in commercially available PC should be considered to achieve equivalent 30% limestone and 5% gypsum that guarantee similar strength to the OPC.

Figure 14.

Compressive strength development of the mortar specimens.

Efforts were taken in the current study to maximise the physico-chemical interaction of the limestone and calcined clay with PC by ensuring higher or similar fineness to that of the PC. The hydration and microstructure mineralogy and porosity results of the clay mortars justify this approach, but the obtained strength of the LC3 mortar is less than that of the PC due to the reduced effective clinker content and increased effective limestone and gypsum contents. Further research is required to optimise the binder to ensure satisfactory early strength. The long-term strength of the mortars (PC and LC3) is expected to be similar, as already shown by other studies. The LC3 mortar specimens tend to have similar strength at 3 and 7 curing ages, while the influence of the kaolinite content becomes evident at 28 days of age. It is envisaged that the increased effective content of the gypsum caused the similarly reduced early strength of the LC3 mortar. EXW mortar, with the highest kaolinite content, has the highest strength of the three clay samples at 28 days. Likewise, higher Portlandite consumption (obtained from the mineralogy results) allowed higher strength to be obtained.

4. Conclusions

This study investigates the potential of South African kaolinitic clay for limestone calcined clay cement (LC3). Three samples of kaolinitic clay were selected at different locations within the Grahamstown region of South Africa. The study characterised the locally obtained limestone and calcined clay samples and examined the mortar made from these calcined clays compared to OPC mortar as a control. Effort was taken to maximise the physico-chemical interaction of the limestone and calcined clay with OPC by ensuring higher or similar fineness to that of the OPC. Emphases were placed on the hydration phase mineralogy/content and the mortars’ microstructure, strength, and 3D void structure. The following conclusions can be made from the study.

- Varied kaolinite content of raw clay can yield similar pozzolanic oxide (SiO2 + Al2O3) content of the calcined clay, the main component of the target metakaolin (Al2O7Si2) from the raw clay calcination. The calcined clay particles tend to be flat, irregular, and elongated, with fibril surface cracks. Pozzolanic activity of the LC3 is directly proportional to the kaolinite content and can be associated with the consumed portlandite.

- Increased kaolinite content of LC3 tends to increase the consistency of the mortar mixture, thereby reducing the demand for water reducer. Limestone and metakaolin densify the microstructural pores of LC3 systems by forming carbo-aluminates coupled with filler effects and pozzolanic reaction. It is noted that at 28 days, not all the calcined clay particles are fully hydrated. The limestone can also contribute to pure filler effects.

- The results suggest that SEM 2D microstructure evaluation may not be adequate to indicate the overall porous nature of LC3 mortars. The degree of limestone hydration tends to be more important than kaolinite content for microscale void refinement of LC3 mortar.

- The observed hydration and microstructure mineralogy of the South African clay samples (LC3) seem to correlate well with the existing literature on LC3 from other regions. Therefore, achieving the designed strength for the control OPC with the LC3 with a minimum kaolinite content of 40% is possible, and consideration must be given to the intrinsic content of limestone in commercially available Portland cement.

It can be concluded from this study that the performance of South African clay for use as LC3 cement is satisfactory and has the potential to be embraced by the cement industry from an engineering point of view. For on-site LC3 formulation, it is recommended that the intrinsic content of limestone and gypsum in commercially available Portland cement be considered to achieve equivalent 30% limestone (and 5% gypsum) that guarantees similar strength to the OPC. Further research is required to optimise the binder for early strength (≤3 days), investigate the long-term durability, and examine the financial considerations for large-scale production and benefits for carbon footprint reduction.

Author Contributions

Conceptualization, A.J.B. and H.K.; methodology, H.K.; software, H.K.; validation, A.J.B. and H.K.; formal analysis, H.K.; investigation, H.K.; resources, O.M.O. and N.N.B.; data curation, H.K.; writing—original draft preparation, A.J.B. and J.T.K.; writing—review and editing, A.J.B., J.T.K., S.C.P., M.J.M., O.M.O. and N.N.B.; visualization, H.K. and J.T.K.; supervision, A.J.B.; project administration, A.J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data shall be made available upon request.

Acknowledgments

The authors acknowledge the Department of Civil Engineering, Stellenbosch University, for access to facilities to conduct the tests and the provision of materials.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Specific surface area distribution of the three calcined clays, limestone and OPC.

Figure A1.

Specific surface area distribution of the three calcined clays, limestone and OPC.

Figure A2.

EDS analysis from the spectrum 175 of OPC mortar (the insert table is the % elemental composition of other spectrums).

Figure A2.

EDS analysis from the spectrum 175 of OPC mortar (the insert table is the % elemental composition of other spectrums).

Figure A3.

EDS analysis from the spectrum 112 of EXW mortar (the insert table is the % elemental composition of other spectrums).

Figure A3.

EDS analysis from the spectrum 112 of EXW mortar (the insert table is the % elemental composition of other spectrums).

Figure A4.

EDS analysis from the spectrum 88 of BFN mortar (the insert table is the % elemental composition of other spectrums).

Figure A4.

EDS analysis from the spectrum 88 of BFN mortar (the insert table is the % elemental composition of other spectrums).

Figure A5.

EDS analysis from the spectrum 154 of MFN mortar (the insert table is the % elemental composition of other spectrums).

Figure A5.

EDS analysis from the spectrum 154 of MFN mortar (the insert table is the % elemental composition of other spectrums).

Figure A6.

Frequency of the pore diameters in the mortar samples at 28 days age.

Figure A6.

Frequency of the pore diameters in the mortar samples at 28 days age.

Table A1.

Statistical summary of pore diameters.

Table A1.

Statistical summary of pore diameters.

| OPC Statistical Summary of Pore Diameter | Mfn Statistical Summary of Pore Diameter | ||

| Mean | 0.30426 | Mean | 0.294894 |

| Standard Error | 0.00042 | Standard Error | 0.000412 |

| Median | 0.2657 | Median | 0.2621 |

| Mode | 0.2121 | Mode | 0.2121 |

| Standard Deviation | 0.152626 | Standard Deviation | 0.133591 |

| Sample Variance | 0.023293 | Sample Variance | 0.017847 |

| Kurtosis | 86.38983 | Kurtosis | 52.39284 |

| Skewness | 5.805636 | Skewness | 4.925806 |

| Range | 7.0354 | Range | 4.3761 |

| Minimum | 0.1225 | Minimum | 0.1225 |

| Maximum | 7.1579 | Maximum | 4.4986 |

| Sum | 40207.3 | Sum | 30,980.39 |

| Count | 132,148 | Count | 105,056 |

| OPC Statistical Summary Of Pore Diameter | MFN Statistical Summary of Pore Diameter | ||

| Mean | r | Mean | 0.287649713 |

| Standard Error | 0.00032 | Standard Error | 0.00030636 |

| Median | 0.2449 | Median | 0.2488 |

| Mode | 0.2121 | Mode | 0.2121 |

| Standard Deviation | 0.130085 | Standard Deviation | 0.142124828 |

| Sample Variance | 0.016922 | Sample Variance | 0.020199467 |

| Kurtosis | 39.17251 | Kurtosis | 79.71507142 |

| Skewness | 4.337844 | Skewness | 5.50304214 |

| Range | 3.5701 | Range | 6.4996 |

| Minimum | 0.1225 | Minimum | 0.1225 |

| Maximum | 3.6926 | Maximum | 6.6221 |

| Sum | 46,136.06 | Sum | 61,906.8206 |

| Count | 165,527 | Count | 21,5216 |

References

- Krishnan, S.; Emmanuel, A.C.; Shah, V.; Parashar, A.; Mishra, G.; Maity, S.; Bishnoi, S. Industrial production of limestone calcined clay cement: Experience and insights. Green Mater. 2018, 7, 15–27. [Google Scholar] [CrossRef]

- Bahman-Zadeh, F.; Ramezanianpour, A.A.; Zolfagharnasab, A. Effect of carbonation on chloride binding capacity of limestone calcined clay cement (LC3) and binary pastes. J. Build. Eng. 2022, 52, 104447. [Google Scholar] [CrossRef]

- Briki, Y.; Avet, F.; Zajac, M.; Bowen, P.; Ben Haha, M.; Scrivener, K. Understanding of the factors slowing down metakaolin reaction in limestone calcined clay cement (LC3) at late ages. Cem. Concr. Res. 2021, 146, 106477. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Zhang, Z.; Ma, Y.; Wang, H. Recent progress of utilisation of activated kaolinitic clay in cementitious construction materials. Comp. Part B Eng. 2021, 211, 108636. [Google Scholar] [CrossRef]

- Leo, E.S.; Alexander, M.G. Potential of Selected South African Kaolinite Clays for Clinker Replacement in Concrete; RILEM Bookseries: Singapore, 2020. [Google Scholar]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Jaskulski, R.; Jóźwiak-Niedźwiedzka, D.; Yakymechko, Y. Calcined clay as supplementary cementitious material. Materials 2020, 13, 4734. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.; Wong, H.; Kamyab, H.; Scrivener, K. Performance of limestone calcined clay cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Berriel, S.S.; Favier, A.; Domínguez, E.R.; Machado, I.S.; Heierli, U.; Scrivener, K.; Hernández, F.M.; Habert, G. Assessing the environmental and economic potential of limestone calcined clay cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Yu, J.; Wu, H.L.; Mishra, D.K.; Li, G.; Leung, C.K. Compressive strength and environmental impact of sustainable blended cement with high-dosage limestone and calcined clay (LC2). J. Clean. Prod. 2021, 278, 123616. [Google Scholar] [CrossRef]

- Musbau, K.D.; Kolawole, J.T.; Babafemi, A.J.; Olalusi, O.B. Comparative performance of limestone calcined clay and limestone calcined laterite blended cement concrete. Clean. Eng. Tech. 2021, 4, 100264. [Google Scholar] [CrossRef]

- Zunino, F.; Boehm-Courjault, E.; Scrivener, K. The impact of calcite impurities in clays containing kaolinite on their reactivity in cement after calcination. Mater. Struct. 2020, 53, 1–15. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Diaz, A.A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Hou, P.; Chen, H.; Wang, Y.; Cheng, X. The microstructure and mechanical properties of cementitious materials comprised of limestone, calcined clay and clinker. Ceram.-Silik. 2019, 63, 356–364. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M. Calcined Clays for Sustainable Concrete: Influence of Calcined Clay-Limestone Ratio on Properties of Concrete with Limestone Calcined Clay Cement (LC3); Springer: Singapore, 2020. [Google Scholar]

- Webb, P.A. A Primer on Particle Sizing by Static Laser Light Scattering. Micromeritics Technical Workshop Series: Introduction to the Latest ANSI/ISO Standard for Laser Particle Size Analysis. 2000. Available online: https://docplayer.net/23912060-A-primer-on-particle-sizing-by-static-laser-light-scattering.html (accessed on 15 March 2022).

- Gao, Z.; Wang, L.; Yang, H. Investigation of the residual mechanical and porosity properties of cement mortar under axial stress during heating. Materials 2021, 14, 1944. [Google Scholar] [CrossRef]

- Paiva, H.; Silva, A.S.; Velosa, A.; Cachim, P.; Ferreira, V. Microstructure and hardened state properties on pozzolan-containing concrete. Constr. Build. Mater. 2017, 140, 374–384. [Google Scholar] [CrossRef]

- Verryn, S. Services-XRD. 2021. Available online: https://xrd.co.za/services/ (accessed on 24 May 2021).

- Standard No. SANS 5863:2006; Concrete Tests—Compressive Strength of Hardened Concrete. The South African Bureau of Standards (SANS): Pretoria, South Africa, 2006.

- du Plessis, A.; Le Roux, S.G.; Guelpa, A. The CT Scanner Facility at Stellenbosch University: An open access X-ray computed tomography laboratory. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2016, 384, 42–49. [Google Scholar] [CrossRef]

- du Plessis, A.; Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Afroz, S.; Castel, A. Influence of calcined clay reactivity on the mechanical properties and chloride diffusion resistance of limestone calcined clay cement (LC3) concrete. J. Mar. Sci. Eng. 2020, 8, 301. [Google Scholar] [CrossRef]

- Kolawole, J.T.; Babafemi, A.J.; Fanijo, E.; Paul, S.C.; Combrinck, R. State-of-the-art review on the use of sugarcane bagasse ash in cementitious materials. Cem. Concr. Comp. 2021, 118, 103975. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. The reaction between metakaolin and limestone and its effect in porosity refinement and mechanical properties. Cem. Concr. Res. 2021, 140, 106307. [Google Scholar] [CrossRef]

- Standard No. ASTM C618:2018; Standard Specification of Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- Kolawole, J.T.; Olusola, K.O.; Babafemi, A.J.; Olalusi, O.B.; Fanijo, E. Blended cement binders containing bamboo leaf ash and ground clay brick waste for sustainable concrete. Materials 2021, 15, 101045. [Google Scholar] [CrossRef]

- Ipavec, A.; Gabrovšek, R.; Vuk, T.; Kaučič, V.; Maček, J.; Meden, A. Carboaluminate phases formation during the hydration of calcite-containing Portland cement. J. Am. Ceram. Soc. 2011, 94, 1238–1242. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Dyer, T.D. Pozzolanas and pozzolanic materials. Lea’s Chem. Cem. Concr. 2019, 5, 363–467. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).