Thermomechanical Analysis of Steel-to-Timber Connections under Fire and the Material Density Effect

Abstract

:1. Introduction

2. Materials and Methods

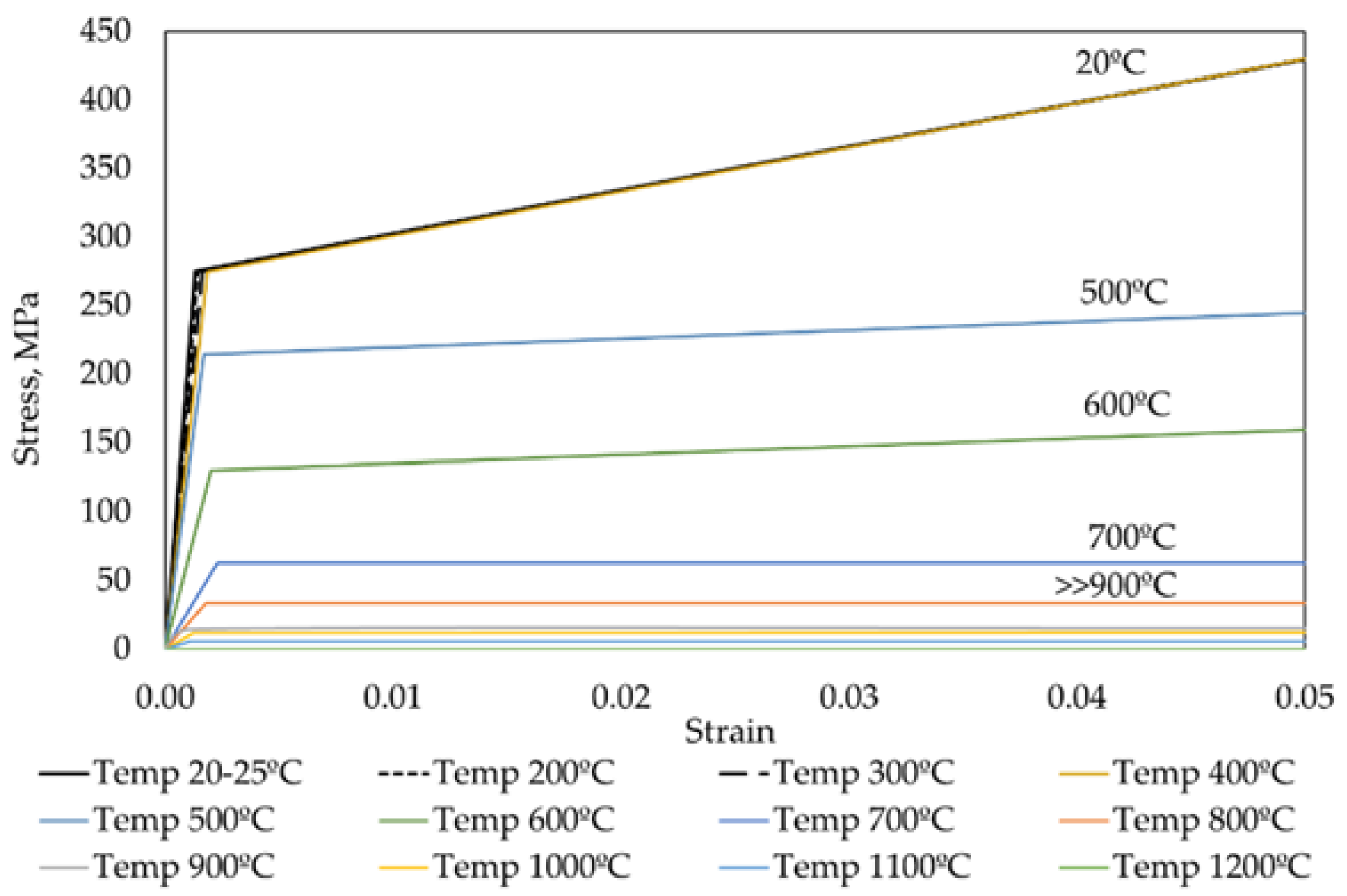

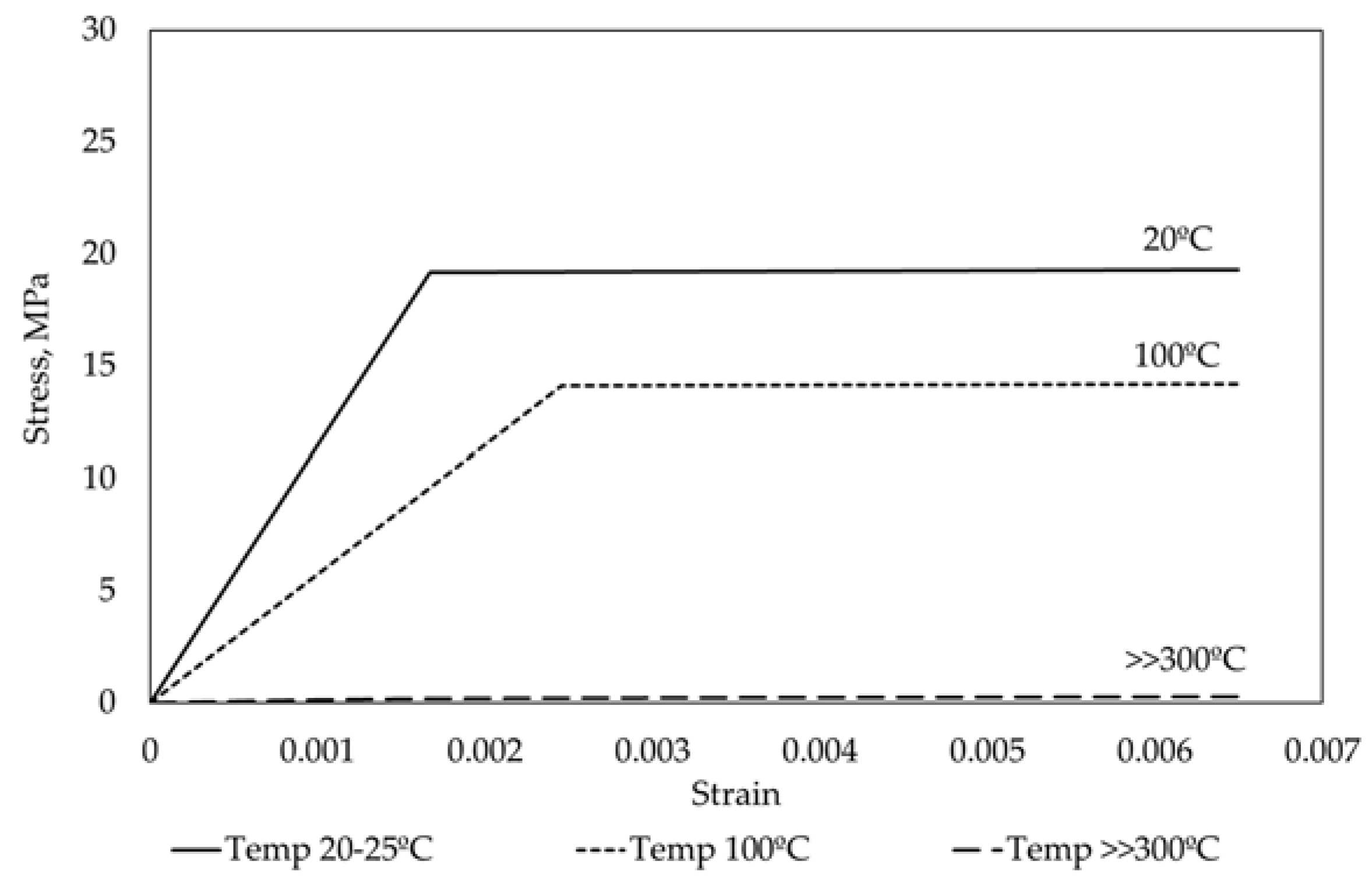

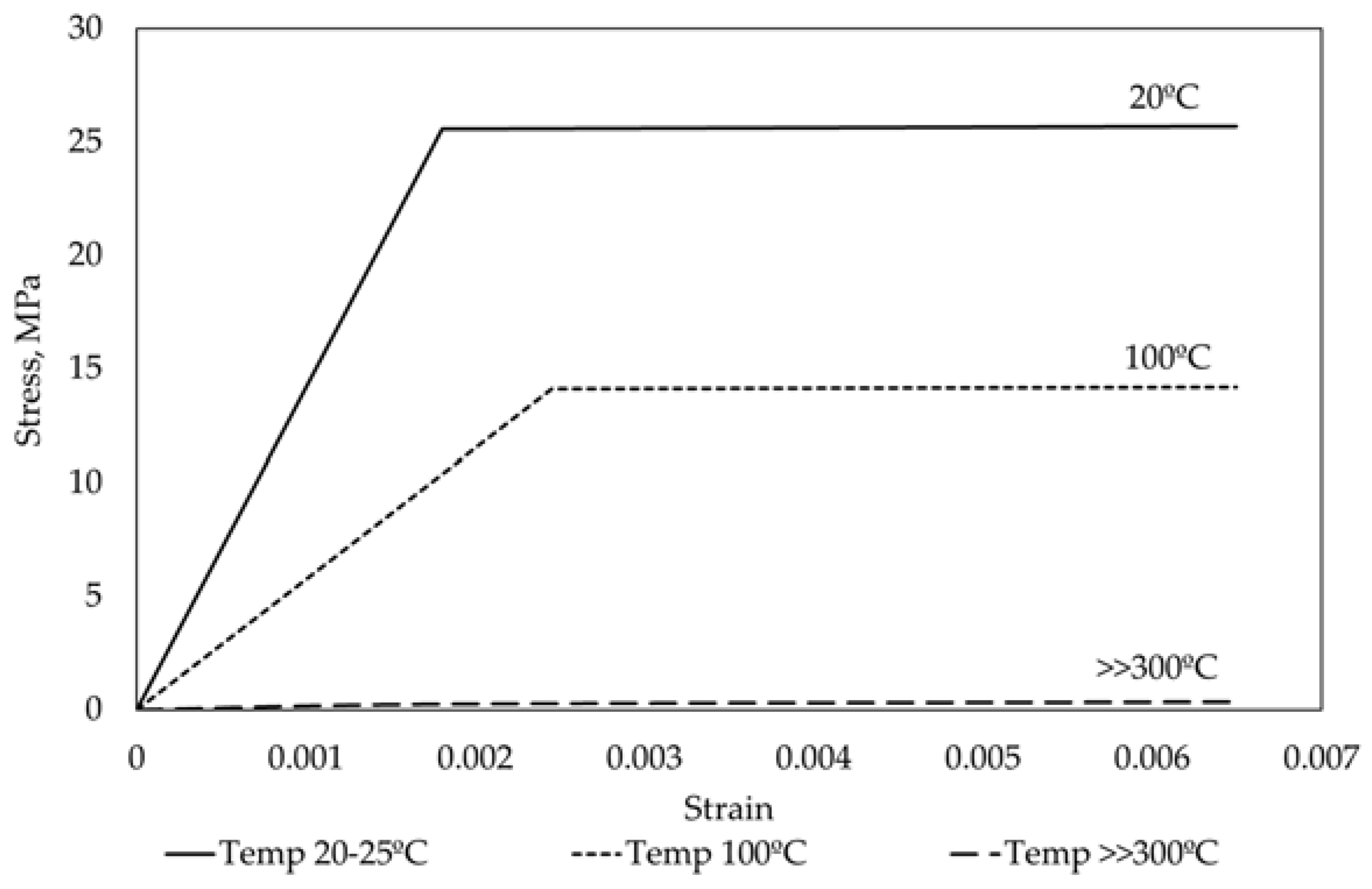

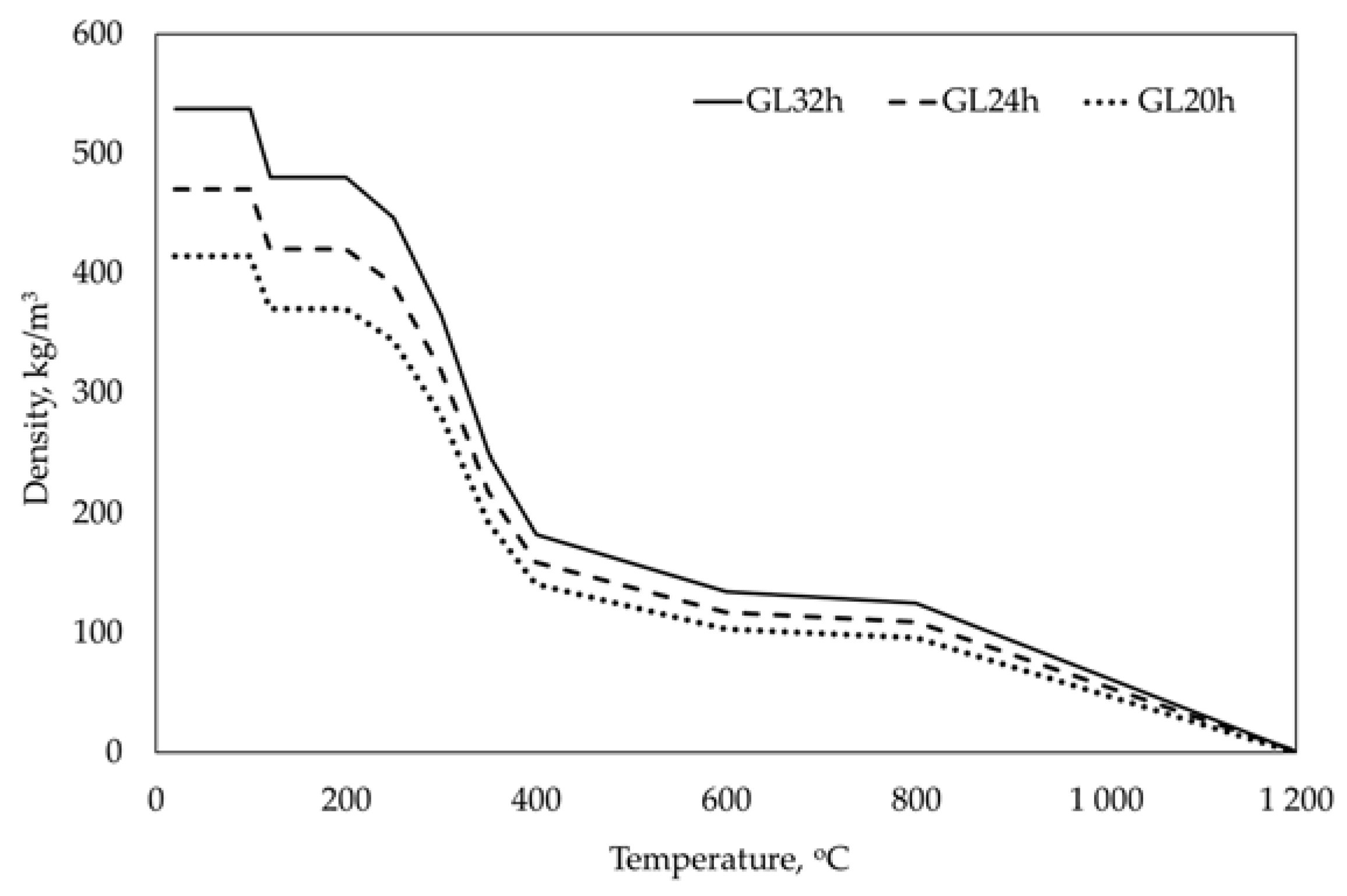

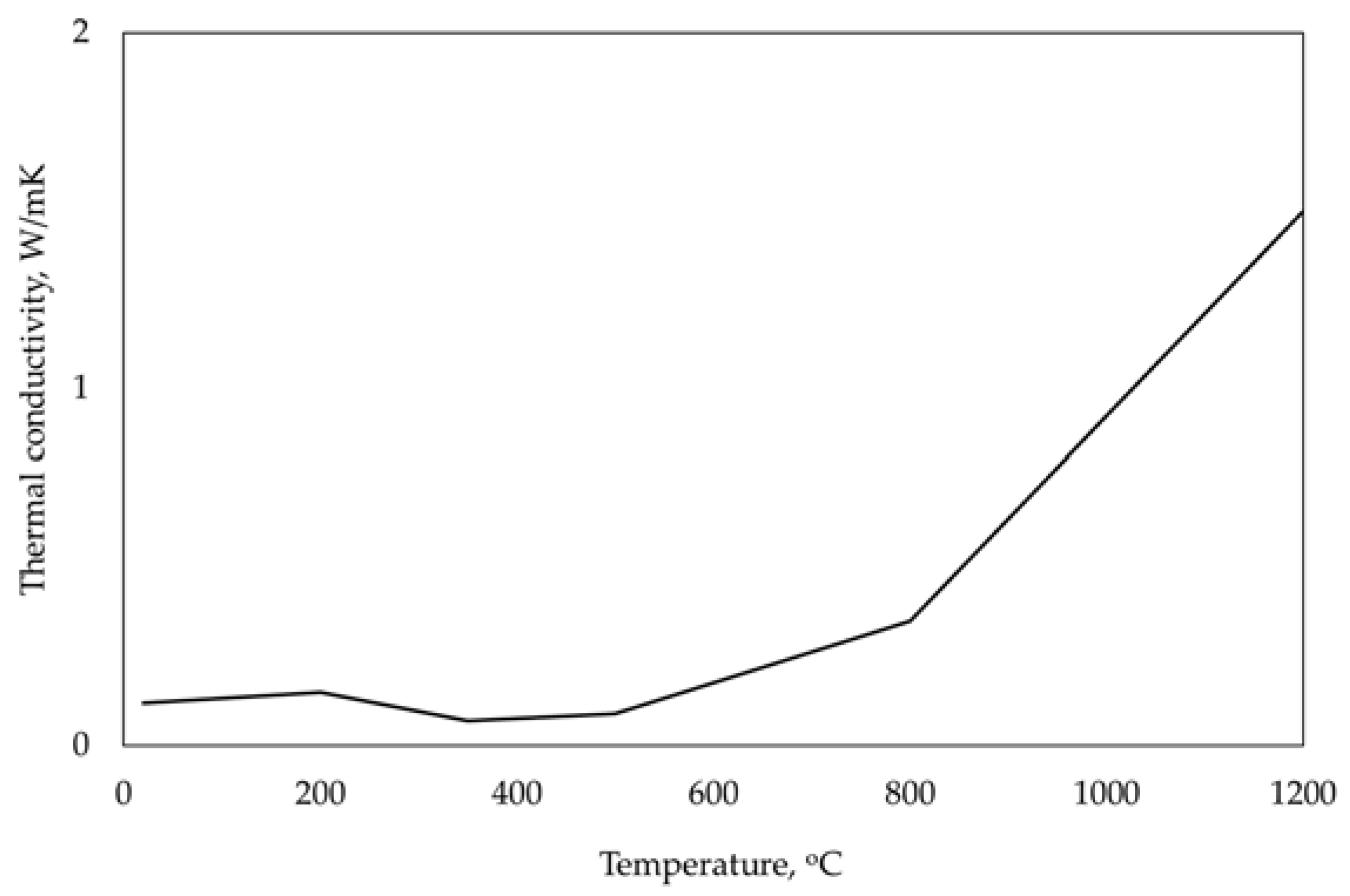

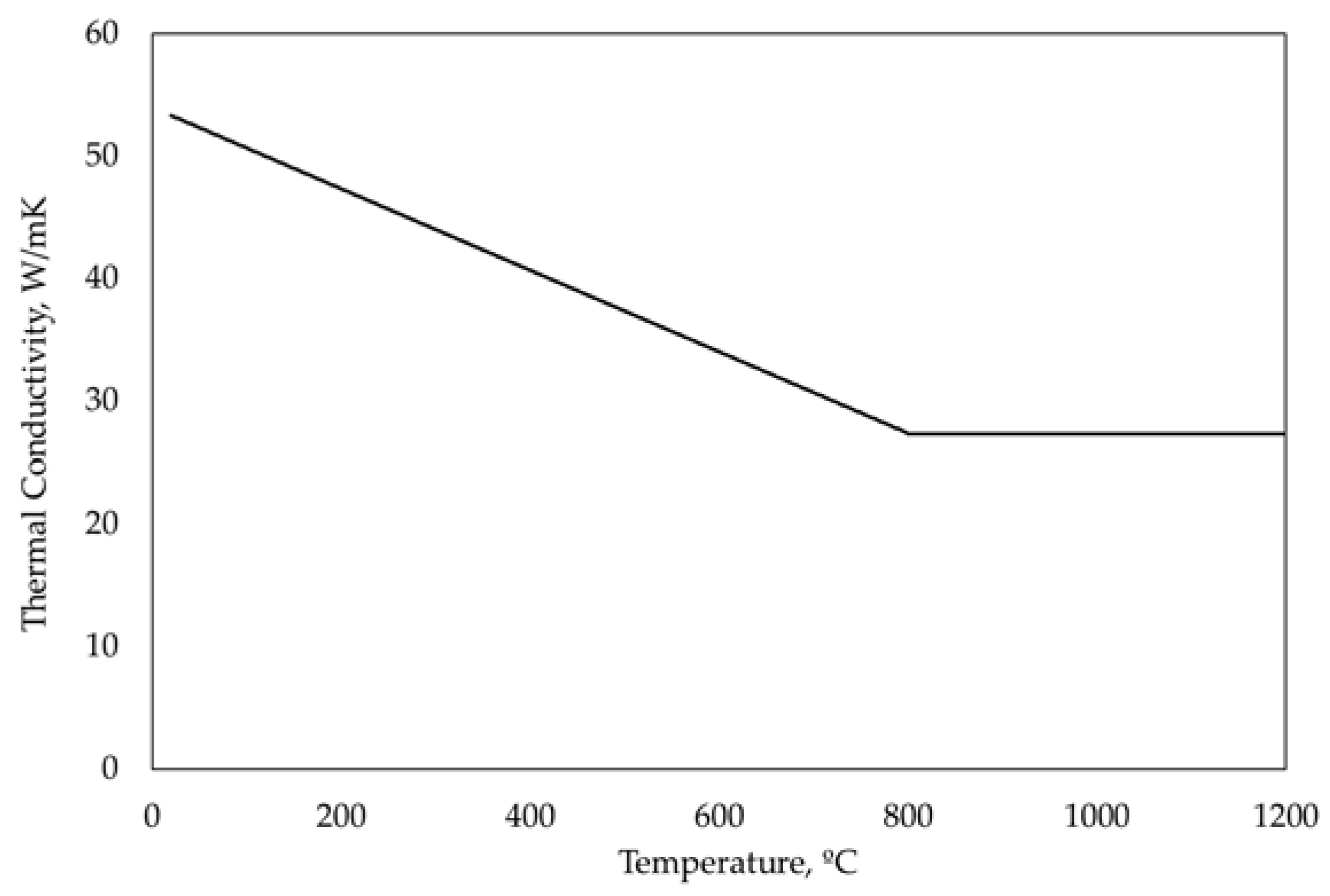

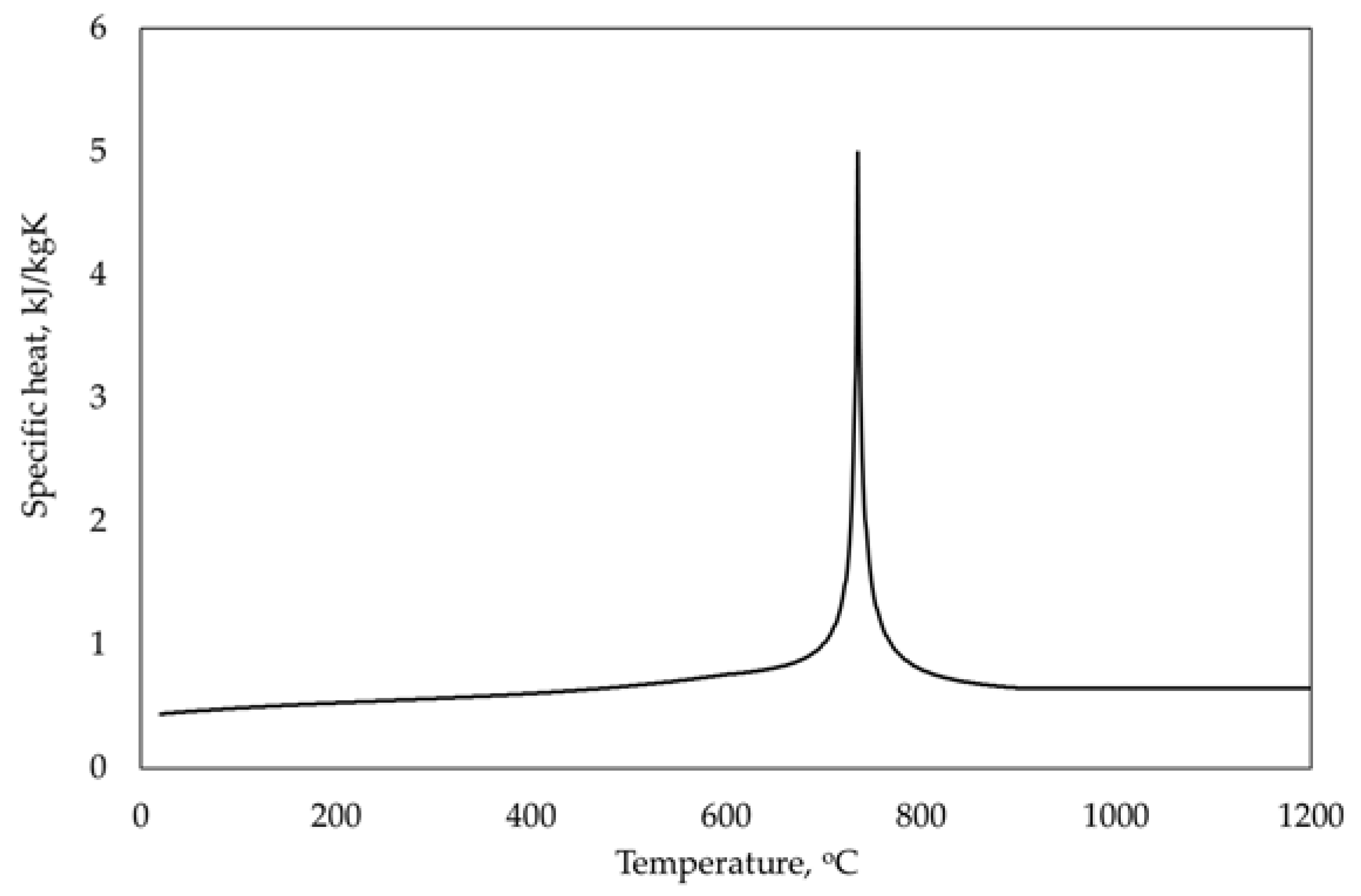

2.1. Material Properties and Fire Curve

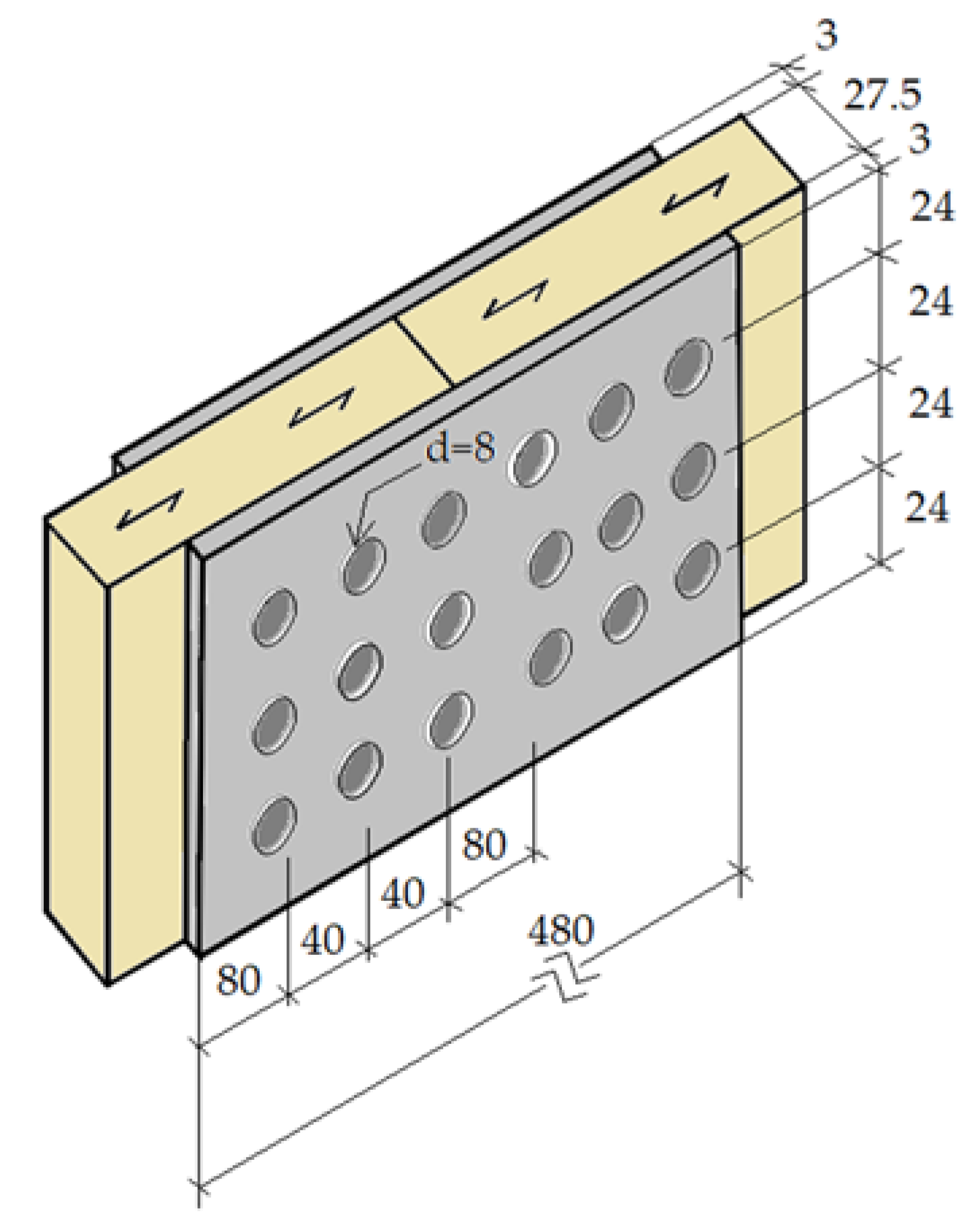

2.2. Geometric Model in the Study

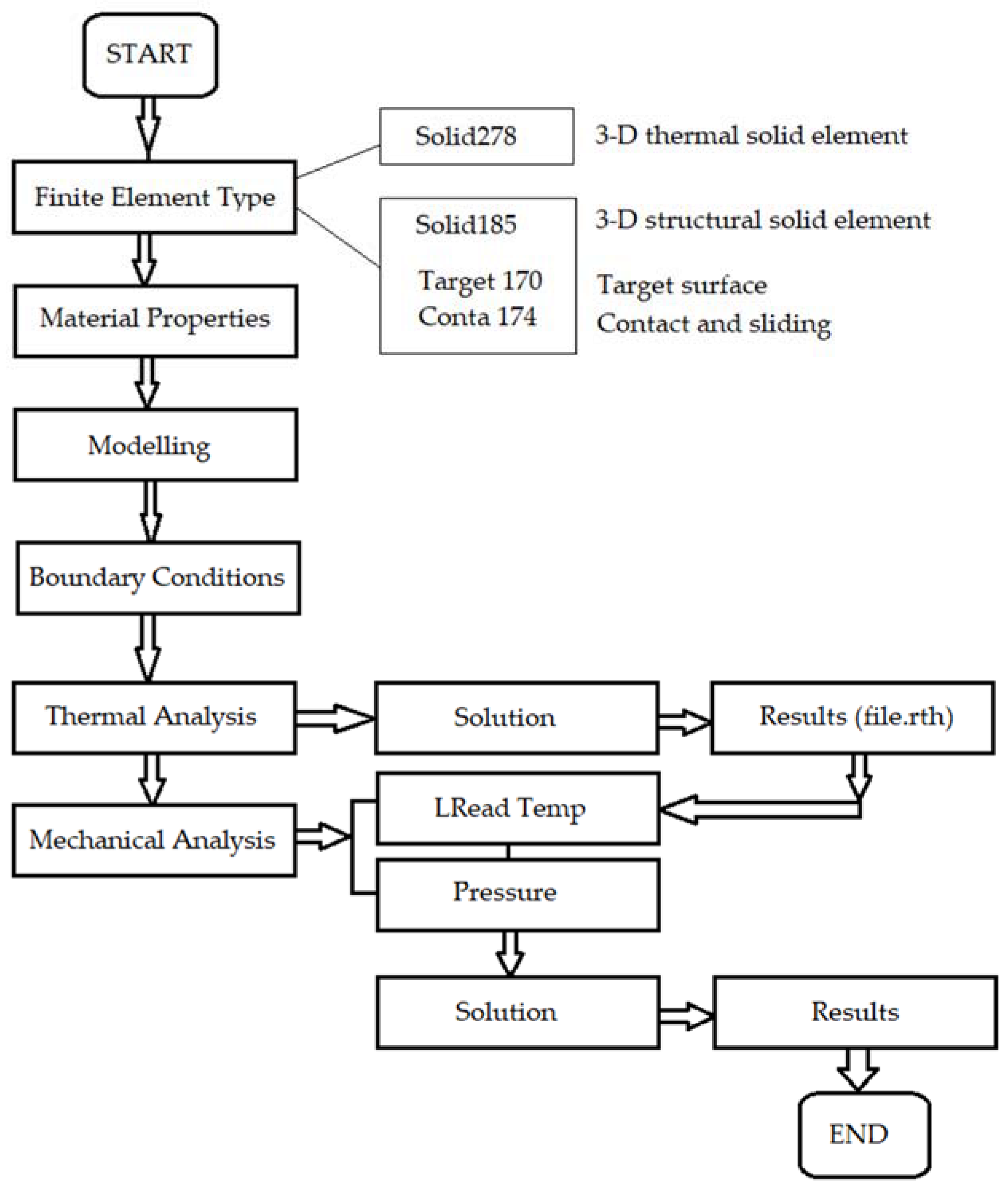

2.3. Thermomechanical Analysis

2.3.1. Thermal Analysis

2.3.2. Structural Analysis

2.4. Finite Elements

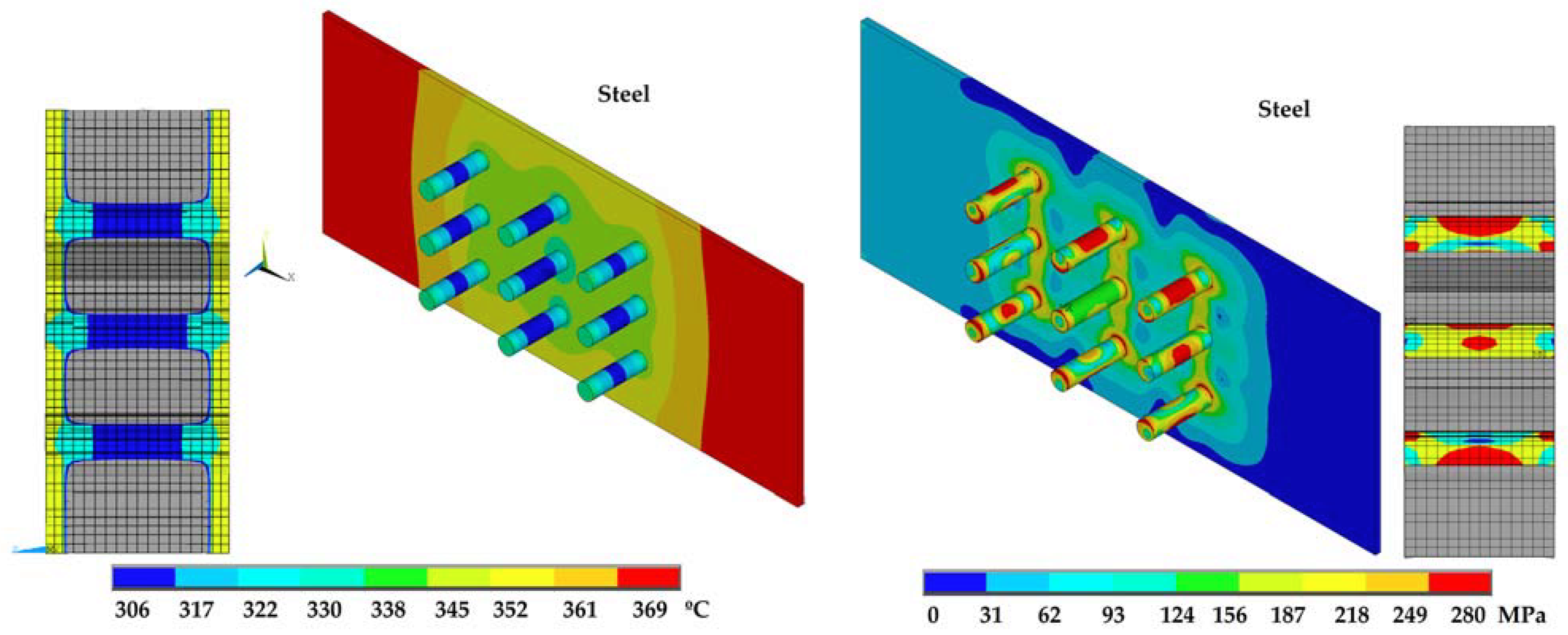

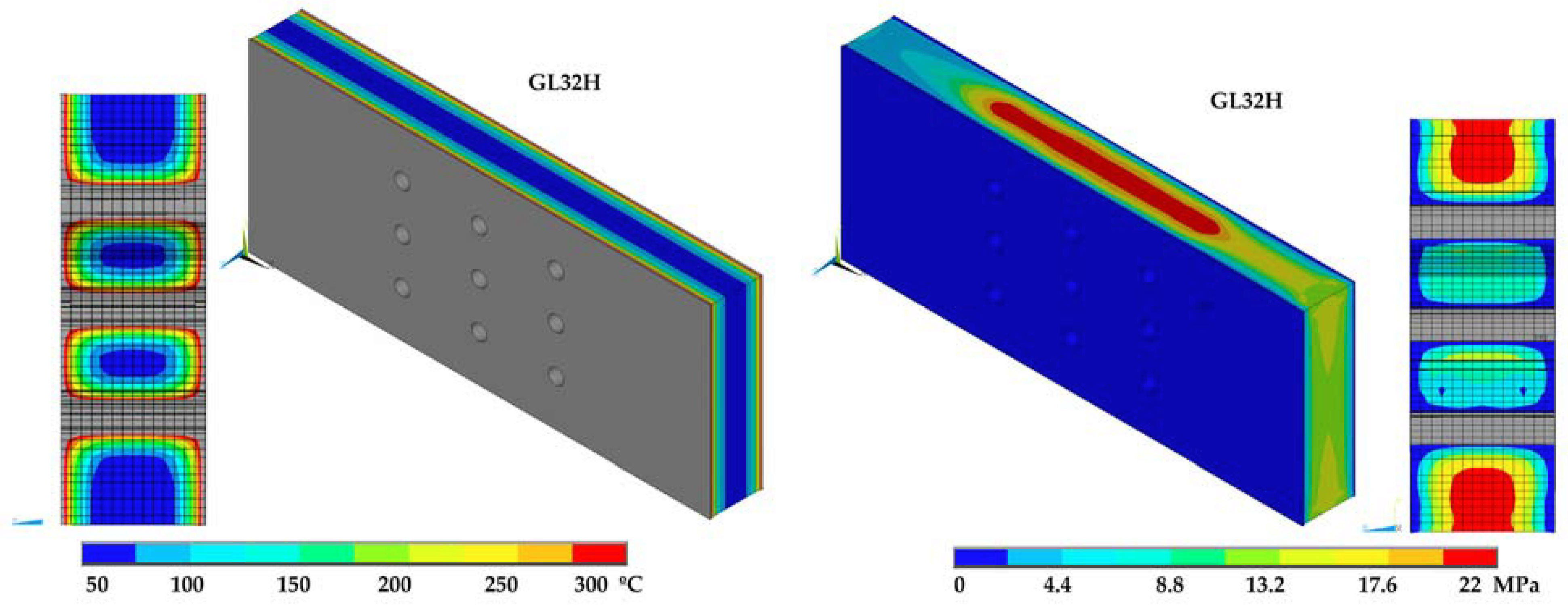

3. Results and Discussion

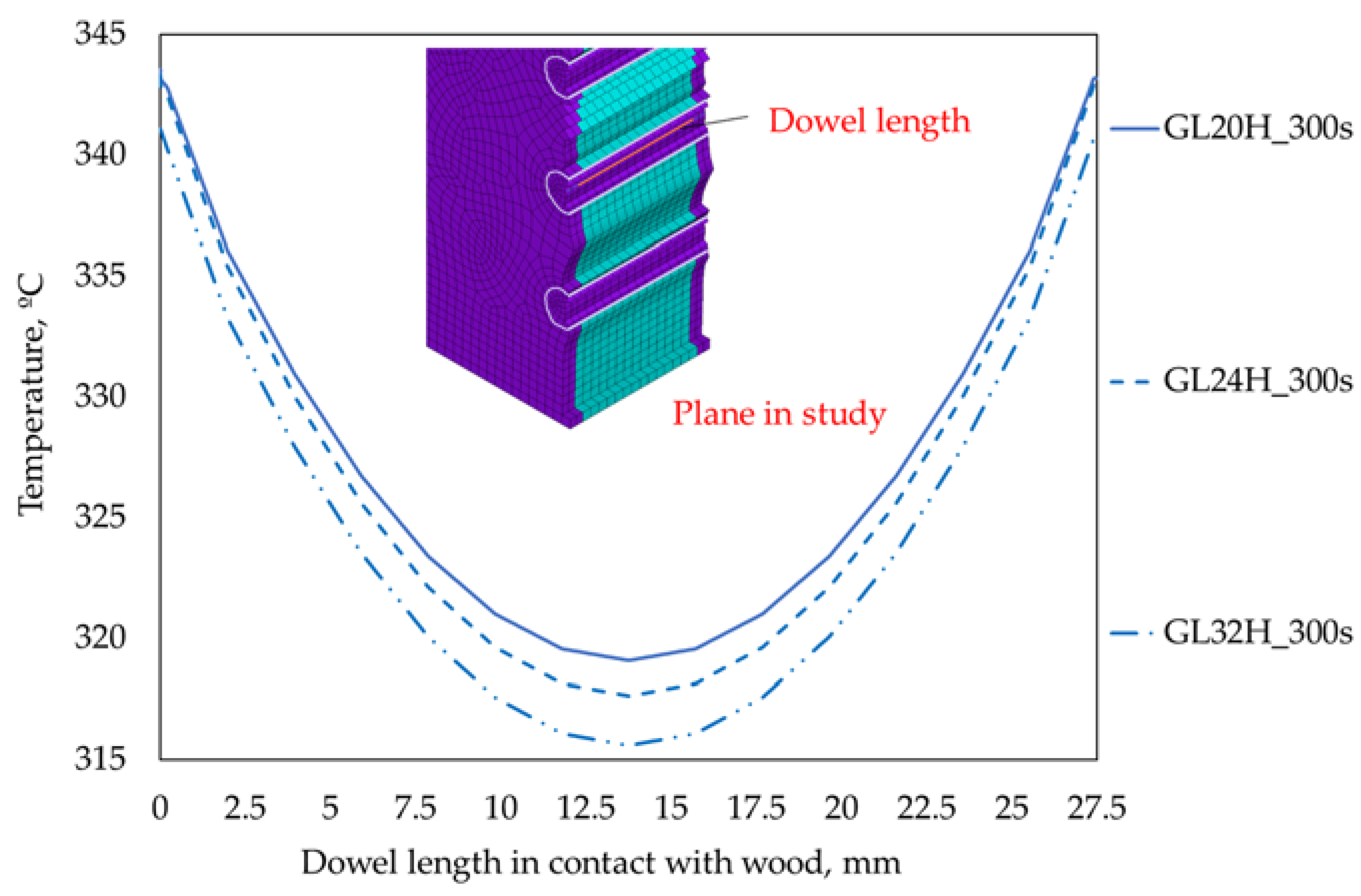

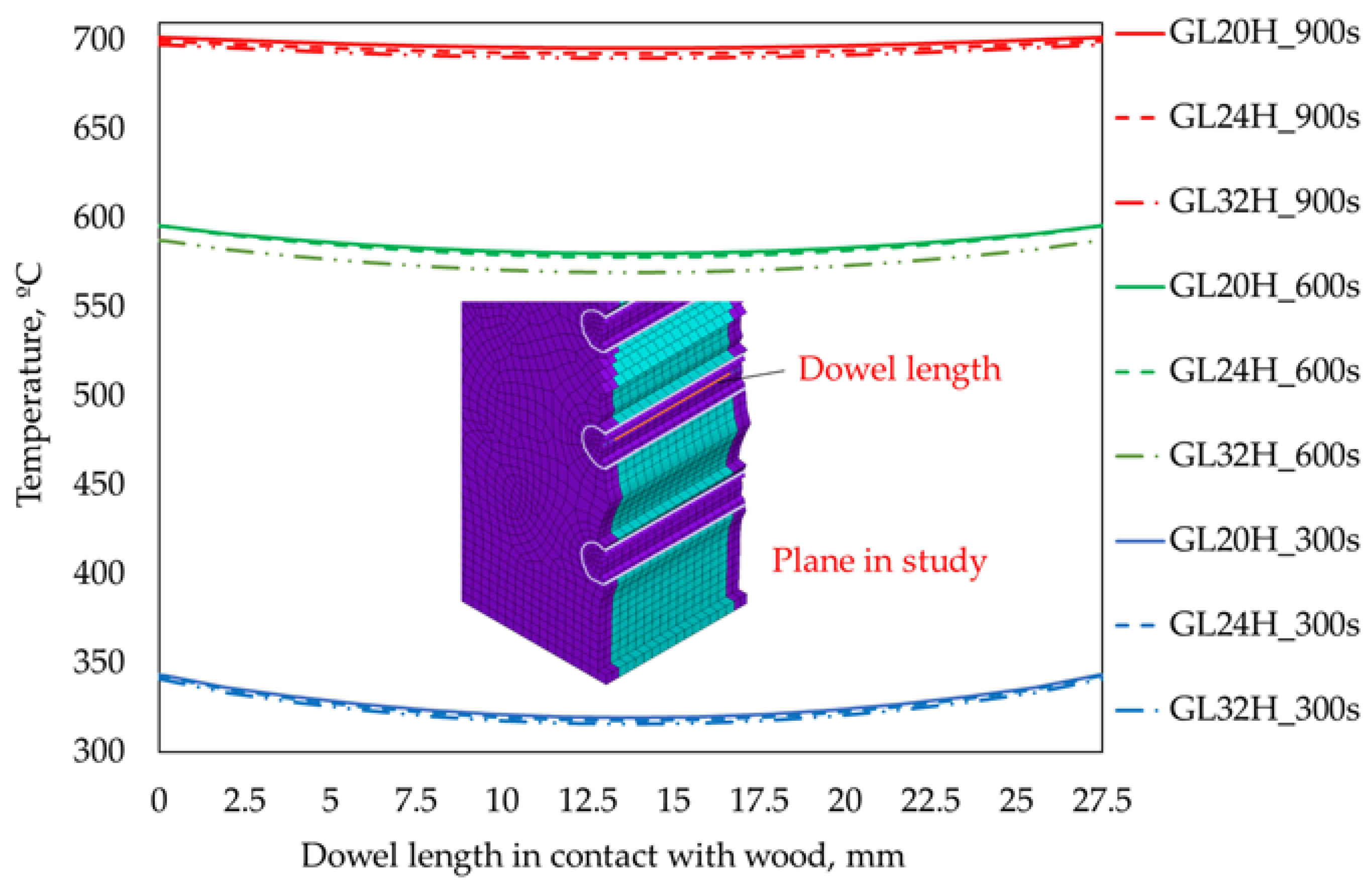

3.1. Temperature Evolution through Dowel Length in Contact with Different Wood Densities

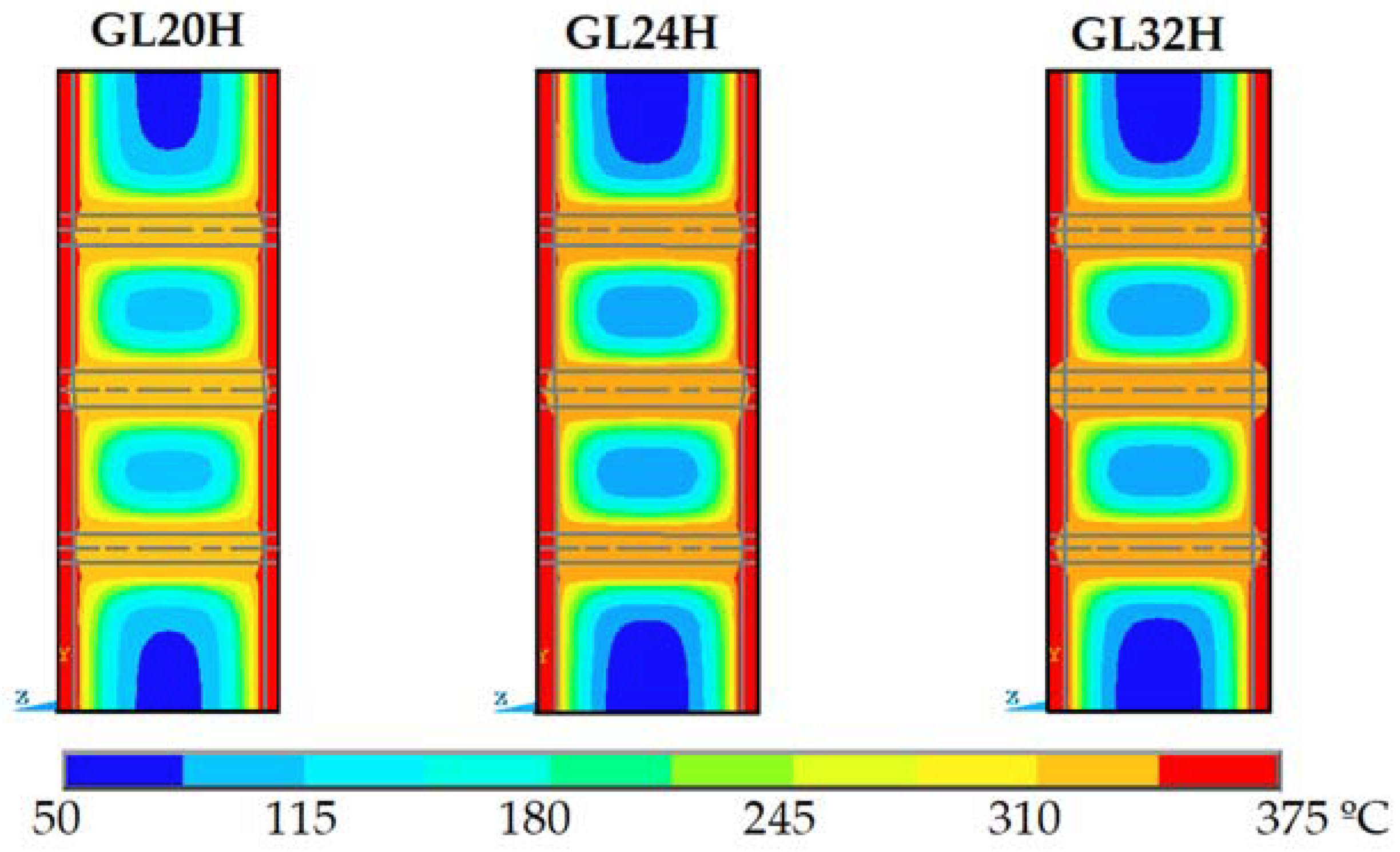

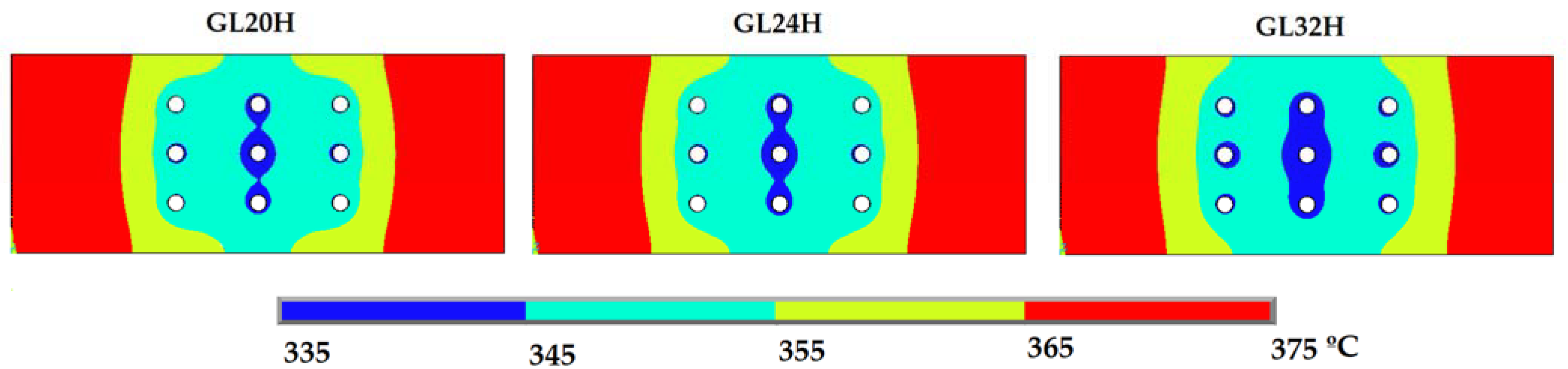

3.2. Temperature Evolution in the Connection with Different Wood Densities

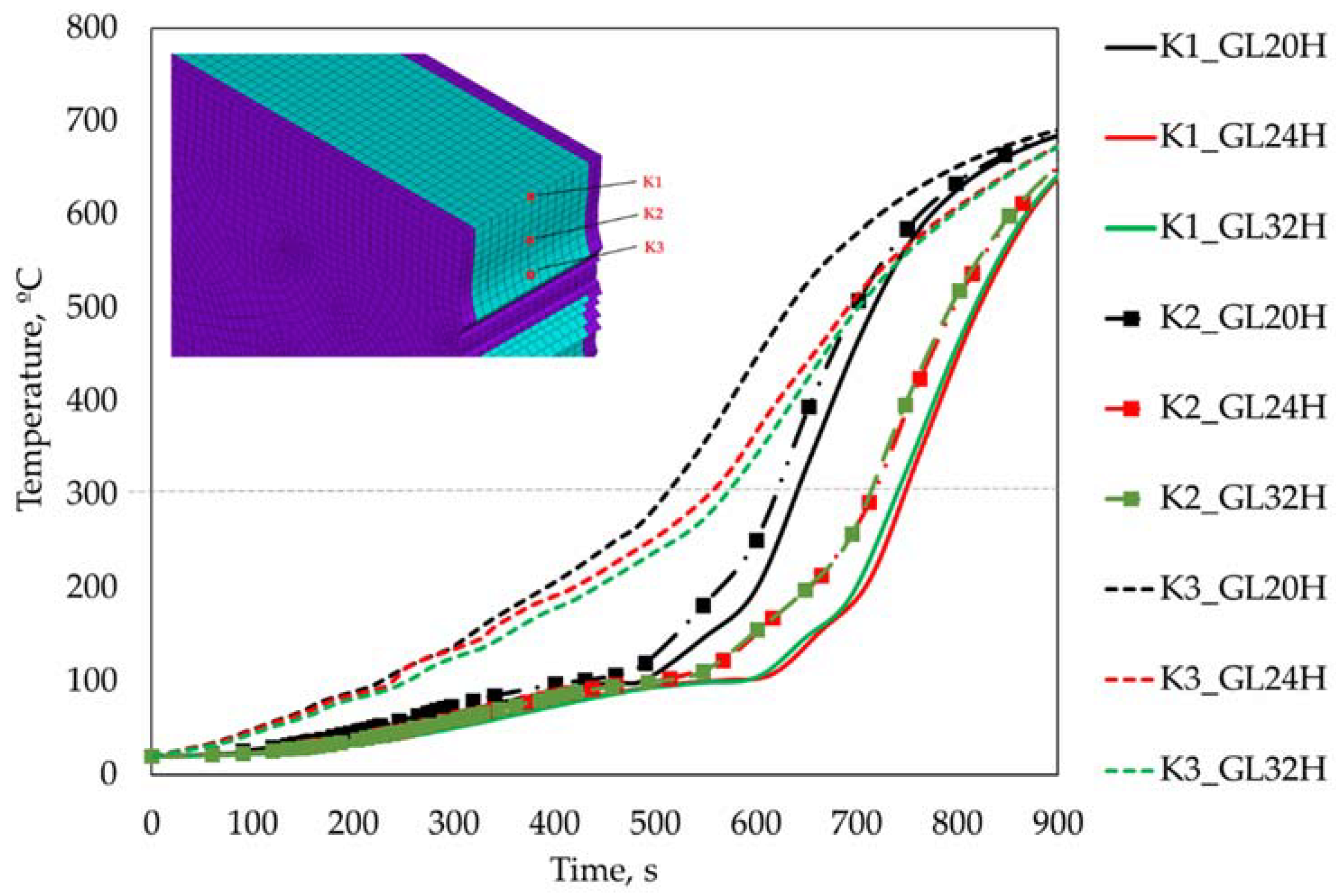

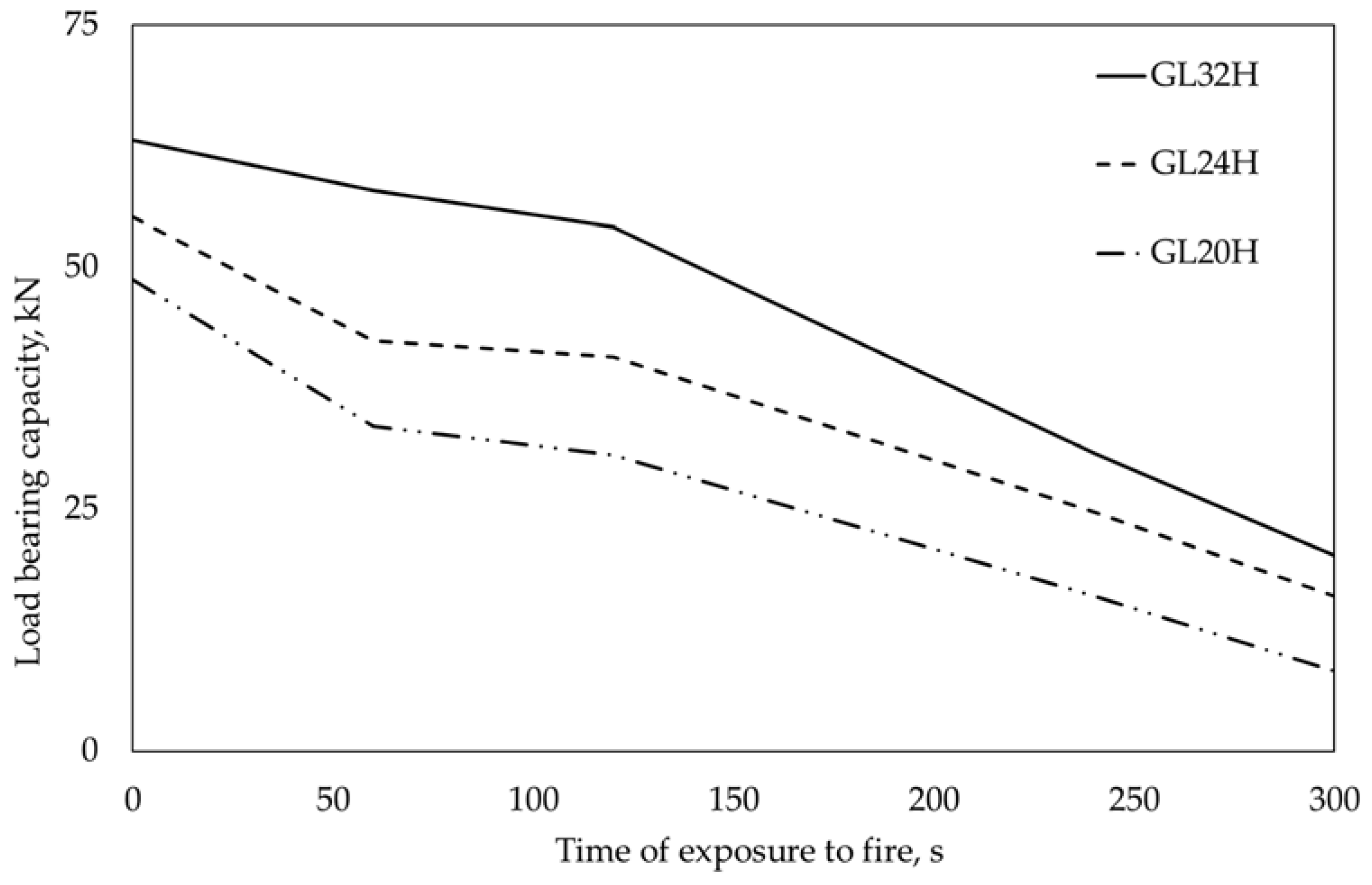

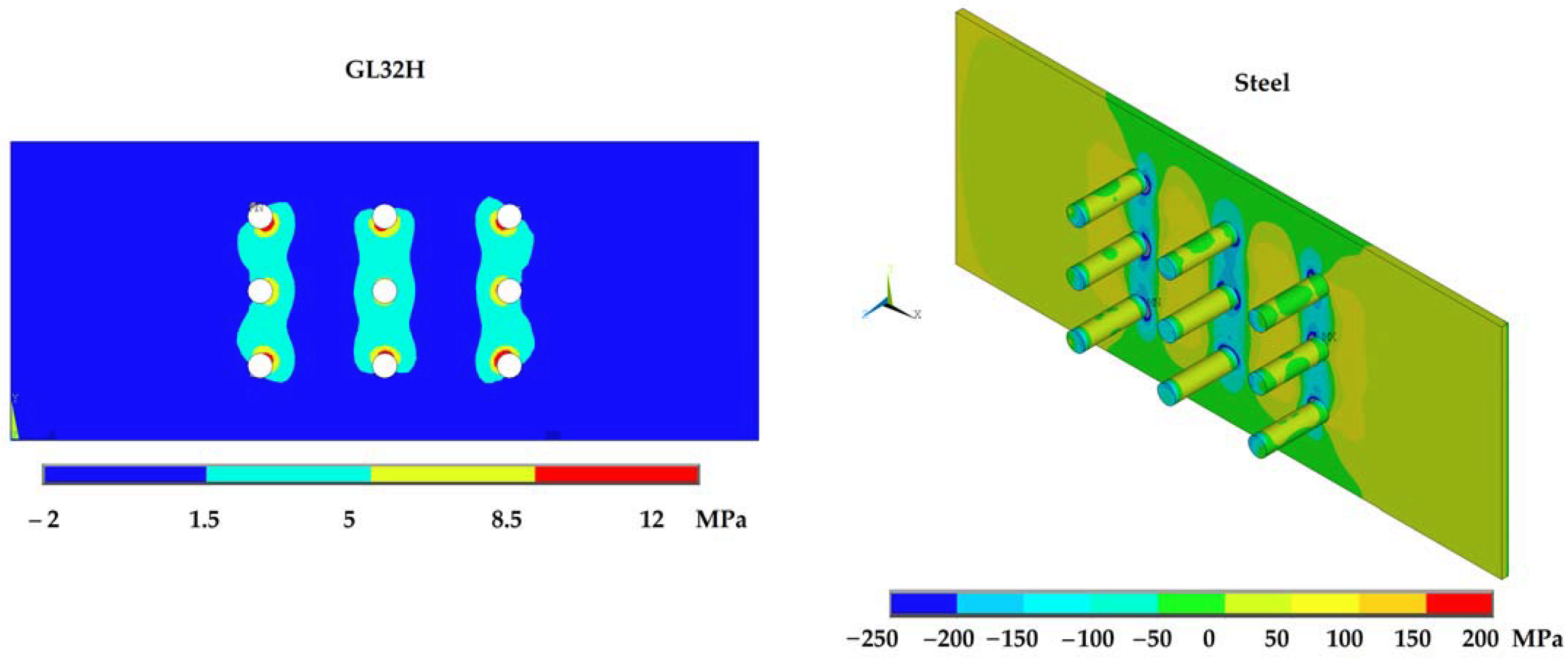

3.3. Temperature, Load-Bearing Capacity, and Stress Level in Connections with Different Wood Densities

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Belhocine, A.; Bouchetaria, M. Simulation of fully coupled thermomechanical analysis of disc brake rotor. WSEAS Trans. Appl. Theor. Mech. 2012, 3, 169–181. [Google Scholar]

- Szász, A.; Hlavicka, V.; Lublóy, E.; Biró, A. Numerical modelling of the fire resistance of double sheared steel-to-timber connections. J. Build. Eng. 2021, 37, 102150. [Google Scholar] [CrossRef]

- Oliveira, P.N.; Fonseca, E.M.M.; Campilho, R.D.S.G.; Paulo, P.A.G. Analytical Equations Applied to the Study of Steel Profiles under Fire According to Different Nominal Temperature-Time Curves. Math. Comput. Appl. 2021, 26, 48. [Google Scholar] [CrossRef]

- Oliveira, P.N.; Fonseca, E.M.M.; Campilho, R.D.S.G. Easy trends to analyse structural profiles: Lumped capacitance vs simplified equation. Int. J. Saf. Sec. Eng. 2020, 10, 625–629. [Google Scholar] [CrossRef]

- Silva, V.; Fonseca, E.M.M. Design of steel-wood-steel connections at the ambient and elevated temperatures. J. Comput. Appl. Mech. 2021, 52, 85–101. [Google Scholar]

- Fonseca, E.M.M.; Silva, L.; Leite, P.A.S. Numerical model to predict the effect of wood density in wood-steel-wood connections with and without passive protection under fire. J. Fire Sci. 2020, 38, 122–135. [Google Scholar] [CrossRef]

- Fonseca, E.M.M.; Leite, P.A.S.; Silva, L. Wood Connections Under Fire Conditions Protected with Gypsum Plasterboard Types A and F. In Advances in Fire Safety Engineering; Piloto, P.A.G., Valdir, P.R., Silva, P., Eds.; Springer Nature: Cham, Switzerland, 2020; Volume 1, pp. 93–106. [Google Scholar]

- Ferreira, M.W.; Filho, L.C.P.S.; Real, M.V. Thermomechanical analysis of reinforced concrete columns exposed to fire. Rev. IBRACON Estrut. Mater. 2020, 13, e13404. [Google Scholar] [CrossRef]

- Piloto, P.A.G.; Fonseca, E.M.M. Load Bearing Capacity of Fire Rated Light Timber Frama Walls. In Proceedings of the 5th International Conference on Numerical and Symbolic Computation Developments and Applications, Porto, Portugal, 25–26 March 2021. [Google Scholar]

- Audebert, M.; Dhima, D.; Taazount, M.; Bouchaïr, A. Numerical investigations on the thermo-mechanical behavior of steel-to-timber joints exposed to fire. Eng. Struct. 2011, 33, 3257–3268. [Google Scholar] [CrossRef]

- Ansys, Inc. ANSYS Mechanical APD 2020 R2, Release 2; Ansys Drive: Canonsburg, PA, USA, 2020. [Google Scholar]

- ISO 834-1: Fire Resistance Tests-Elements of Building Construction-Part 1: General Requirement. Available online: https://www.iso.org/standard/2576.html (accessed on 2 March 2022).

- CEN. Action on Structures. EN1991-1-2: Eurocode 1. Part 1–2: General Actions-Actions on Structures Exposed to Fire; The European Union: Brussels, Belgium, 2002. [Google Scholar]

- European Committee for Standardization. Eurocode 5: Design of Timber Structures. Part 1-2: General Structural Fire Design; BSI: Brussels, Belgium, 2004. [Google Scholar]

- European Committee for Standardization. Eurocode 3: Design of Steel Structures. Part 1-2: General Rules—Structural fire design; BSI: London, UK, 2010. [Google Scholar]

- European Committee for Standardization. Eurocode 5: Design of Timber Structures. Part 1-1: General Common Rules and Rules for Buildings; BSI: Brussels, Belgium, 2004. [Google Scholar]

- Fonseca, E.M.M.; Leite, P.A.S.; Silva, L.D.S.; Silva, V.S.B.; Lopes, H.M. Parametric Study of Three Types of Timber Connections with Metal Fasteners Using Eurocode 5. Appl. Sci. 2022, 12, 1701. [Google Scholar] [CrossRef]

- Miao, C.; Fernando, D.; Heitzmann, M.T.; Bailleres, H. GFRP-to-timber bonded joints: Adhesive selection. Int. J. Adhes. 2019, 94, 29–39. [Google Scholar] [CrossRef]

- British Standards Institution. Timber Structures. Glued Laminated Timber. Strength Classes and Determination of Characteristic Values; BSI: London, UK, 1999. [Google Scholar]

- Green, D.W.; Winandy, J.E.; Kretschmann, D.E. Mechanical Properties of Wood. In Wood Handbook; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; 463p. [Google Scholar]

- European Committee for Standardization. Eurocode 3: Design of Steel Structures. Part 1-1: General Rules and Rules for Buildings; BSI: London, UK, 2005. [Google Scholar]

- Dorn, M.; Habrová, K.; Koubek, R.; Serrano, E. Determinations of coefficients of friction for laminated veneer lumber on steel under high pressure loads. Friction 2021, 9, 367–379. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomes, C.; Fonseca, E.M.M.; Lopes, H.M. Thermomechanical Analysis of Steel-to-Timber Connections under Fire and the Material Density Effect. Appl. Sci. 2022, 12, 10516. https://doi.org/10.3390/app122010516

Gomes C, Fonseca EMM, Lopes HM. Thermomechanical Analysis of Steel-to-Timber Connections under Fire and the Material Density Effect. Applied Sciences. 2022; 12(20):10516. https://doi.org/10.3390/app122010516

Chicago/Turabian StyleGomes, Carlos, Elza M. M. Fonseca, and Hernâni M. Lopes. 2022. "Thermomechanical Analysis of Steel-to-Timber Connections under Fire and the Material Density Effect" Applied Sciences 12, no. 20: 10516. https://doi.org/10.3390/app122010516

APA StyleGomes, C., Fonseca, E. M. M., & Lopes, H. M. (2022). Thermomechanical Analysis of Steel-to-Timber Connections under Fire and the Material Density Effect. Applied Sciences, 12(20), 10516. https://doi.org/10.3390/app122010516

_Yang.png)