Abstract

The quality of rice is decreased when contaminated with fungi. Aspergillus species are the most frequently found in rice. This research proposes using a dielectric heating method for fungal inactivation in rice grains by radio frequency (RF) energy. In order to understand the interaction between the fungi contaminating rice and electrical energy, dielectric properties comparison between Aspergillus sp. BP17 and rice powder were measured using an open-ended coaxial probe with a vector network analyzer (VNA) to develop dielectric heating equipment. The effect of RF energy on the dielectric heating system (9 kW, 40.68 MHz) is investigated based on different electric field intensities (150, 190, 225, 300, and 450 kV/m) with different temperatures (70, 80, 90, 100, and 110 °C). The growth of fungi contaminating rice was determined using a direct count method and reported as a percentage of inactivation. The result showed that the fungal inactivation of 100% was obtained at the electric field intensity value ≥ 225 kV/m at the lowest temperature of 90 °C. The combination of temperature and electric field intensity significantly (p ≤ 0.05) increased the percentage of fungal inactivation in rice grains. The optimal conditions of dielectric heating are suitable for fungal inactivation in rice industries. These results indicate that the proposed dielectric heating system is useful for inactivation of Aspergillus species.

1. Introduction

Rice (Oryza sativa L.) is one of the most important grains that feed approximately 75% of the world’s population. It is a staple food of Asian countries, including China, India, Indonesia, Bangladesh, Vietnam, Philippines, Thailand, etc. [1,2]. However, the quality of rice grains can be affected by contaminated fungal contamination Aspergillus species [3,4].

Aspergillus species contamination levels in brown rice were discovered to be 103 CFU/g [5]. Rice contamination with fungal species during harvest and storage is of poor quality and low economic value. Moreover, it can harm human and animal health [6]. Some fungal species (mainly Aspergillus flavus and Aspergillus parasiticus) produce aflatoxin, which are fungal secondary metabolites that contaminate dietary staples worldwide, including maize, rice, and groundnuts [7]. Dietary exposure to aflatoxin is a public health concern due to its acute and chronic carcinogenic effects [8]. Therefore, decontamination of fungi in rice grains before storage or distribution is very important.

Techniques for fungal decontamination have been reported, including chemical, bio-logical, and physical methods [9]. Various chemicals, such as ozone (O3), have the potential to inhibit fungal growth and disrupt mycelial development through oxidation reactions. However, the use of ozone limitations in industrial applications, such as the high-cost requirement for installation and operation [10,11]. Biological methods, such as temperature, humidity, and other environmental parameters, do not kill or inhibit fungi, especially fungal spores [12]. Interestingly, there are physical mechanisms, such as radio frequency heating (RFH) and microwave heating (MWH). The methods can potentially damage fungal cells by heat generation [13,14,15], which has no toxic residues and no effect on human health. In addition, the rice industry has used RFH and MWH treatments [16,17,18].

RFH and MWH have been used for controlling various fungi in food products. For example, RF treatment used to control Aspergillus flavus in oilseed, wheat, and corn [19,20] and Penicillium crustosum in chestnuts [21]. The control of Aspergillus flavus and Aspergillus parasiticus in brown rice, barley, and corn [5,22], Penicillium spp., and Aspergillus spp. in Brazil nut seed shell and kernel has been reported using MW [23]. At the present study, dielectric heating is one of the heating techniques, including RF and MW energy. This technique can convert electrical energies into thermal energy inside the dielectric material. Depending on the electric field frequency, different heat level is generated in the dielectric material [24,25,26,27,28]. In previous studies, the application of dielectric heating is a selective heating technique for insect control in rice [29,30,31,32,33,34,35,36,37]. The method involves heating the insects to a lethal temperature (60 °C) with exposure time (30 min) and avoiding the heat generated in the rice based on the different dielectric properties [33,38]. The dielectric loss is the ability to dissipate energy in an applied electric field [31,33]. The measured dielectric loss is considered to find out the optimal frequency ranges, which leads to efficient heating system.

This is novel research that aims to optimize the best condition of dielectric heating for fungal control in rice products. The comparative effect of these dielectric heating frequency ranges on fungal growth had not yet been conducted. In addition, the effect of electric field intensity on the heating system is also examined in this study. The information about dielectric properties is an important key for developing dielectric heating industrial equipment in the future.

2. Materials and Methods

2.1. Rice Samples Preparation and Fungal Strain

Thai Hom Mali brown rice (Oryza sativa L. cv. KDML105) was purchased from the local market in Nakhon Ratchasima city, Thailand. The rice was taken out and allowed to equilibrate to room temperature (25 ± 2 °C) overnight. The moisture content of the rice sample was measured using a digital grain moisture meter (Handheld SMART SENSOR AR991, Hebei, China). Five Kg of dehulled polished rice samples was grounded to a fine powder using a grinding machine (Huangcheng HC-200, Shanghai, China), as shown in Figure 1a.

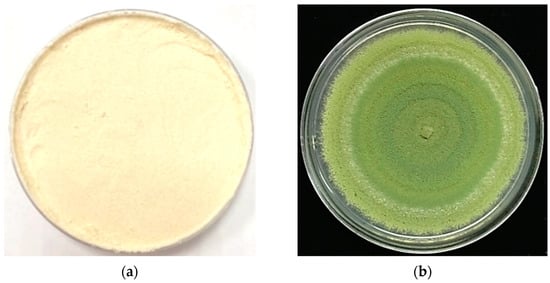

Figure 1.

The sample of dielectric properties measurement: (a) Rice powder sample; (b) Aspergillus sp. BP17.

The fungal strain BP17 was identified as Aspergillus sp. and procured from the culture collection of AJTR microbiology laboratory, School of Preclinical Sciences, Institute of Science, Suranaree University of Technology (Nakhon Ratchasima city, Thailand) with deposited number as BP17. The strain was cultured on Potato Dextrose Agar (PDA; Himedia, Maharashtra, India) and incubated at 30 °C for one week, as shown in Figure 1b.

2.2. Measurement of Dielectric Properties of Fine Rice Powder and Aspergillus sp. BP17

The fungal colony on PDA and 60 g of fine rice powder in a polystyrene Petri dish (diameter 100 mm and height 15 mm) were measured dielectric properties using a VNA (Agilent Technologies, Inc., Santa Clara, CA, USA) with an open-ended coaxial probe and a computer [39,40]. The probe and the network analyzer were contacted using a highly flexible coaxial. The network analyzer measurement based on software (Keysight Materials Measurement Suit; Keysight Technologies Inc., Santa Rosa, CA, USA) was set from 40 to 8500 MHz and at 1001 discrete frequencies to measure the dielectric properties. The measurement set-up is shown in Figure 2.

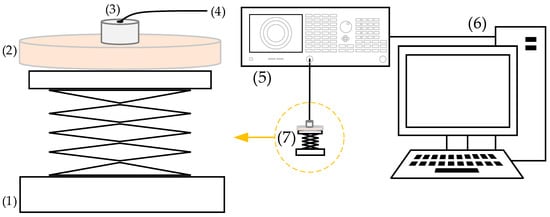

Figure 2.

Measurement equipment (1. Laboratory jack, 2. Sample, 3. Open-ended coaxial probe, 4. Coaxial cable, 5.VNA, 6. Computer with software and 7. Measurement setup).

The measurement system was turned on and kept in a standby mode at room temper-ature for approximately 60 min. Then, the network analyzer and the open-end coaxial probe were calibrated at room temperature using air, short, and deionized water as the standard [41]. After that, the calibrated probe was dried and cleaned using 70% alcohol.

For dielectric properties measurement, the samples (fungal colony on PDA and 60 g of fine rice powder) were placed on the laboratory jack and the sample surface was touched with the probe (Figure S1 in Supplementary Material). Then, the dielectric property values of each sample were measured with three replications, and the values were recorded and analyzed for optimal frequency ranges in dielectric heating experiments.

2.3. Experimental Desing for Dielectric Heating System

2.3.1. Dielectric Heating System Setting

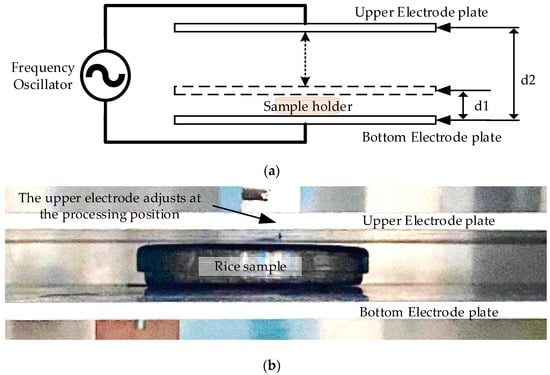

The dielectric heating system (9 kW, 40.68 MHz) was used in this study. This system mainly consisted of two parallel electrode plates and a frequency oscillator as shown in Figure 3a. The upper and bottom electrode plate size is 52 cm × 52 cm. The position of the upper electrode can be adjusted to achieve a different electric field intensity while the bottom electrode plate is fixed for placing the samples, the central position of the bottom electrode provides a better heating rate with a more uniform temperature distribution [42]. The sterile Petri dish containing the rice sample was placed at the center of the bottom electrode, as shown in Figure 3b.

Figure 3.

Schematic diagram of dielectric heating system: (a) Dielectric heating system; (b) Samples in dielectric heating system.

For dielectric heating, the power conversion in a material depends on the operating frequency, dielectric loss factor and the electric field density inside the material. The power dissipated per unit volume in the dielectric material can be expressed [43] as Equation (1):

where P is the power dissipated per unit volume (W/m3), is the frequency (Hz), is the rms electric field intensity (V/m) and ε″ is dielectric loss factor of the material being exposed to the alternating electric fields.

2.3.2. Determining the Optimal ISM Frequency Bands

Specific frequency range of RF and MW were studied at 40 to 8500 MHz based on the industrial, scientific, and medical (ISM) frequency [44]. Then, the dielectric constant (ε′) and loss (ε″) at 40.68 MHz of RF, and 915 and 2450 MHz of MW were measured and analyzed. The optimal frequency was calculated using the ratio between dielectric properties of Aspergillus sp. BP17 and rice samples, and the highest of the ratio was chosen as optimal ISM frequency (MHz).

2.3.3. The Study of Relative Electric Field Intensity and Temperature

The dielectric heating system was set the optimized ISM frequency band as 40.68 MHz. The electric field intensity was studied and calculated according to Equation (2):

where E is the electric field intensity (V/m), V is the voltage during the heating process (V), is the distance between electrodes (m).

In total, 75 dehulled polished rice samples (60 g with 8.33% moisture content) were prepared in sterile glass Petri dish and then placed at the central position of the bottom electrode under the dielectric heating system at 40.68 MHz frequency. The temperature was monitored and recorded using the infrared thermography camera (U5857A, Keysight Technologies Inc., Santa Rosa, CA, USA). At different five electric field intensities (150, 190, 225, 300, and 450 kV/m), heating time (t) was recorded three replicates at each five temperatures (T) including 70, 80, 90, 100, and 110 °C and calculated for heating rate (°C/min) according to Equation (3):

where T is the temperature in sample (°C) and t is the heating time (min).

The energy consumption (W) was calculated according to Equation (4):

where W is the energy consumption (kWh g−1), V is the voltage during the heating process (V), I is the current during the heating process (A), t is the heating time (hour), and m is the sample mass (gram).

2.3.4. Effect of Dielectric Heating on Fungal Growth

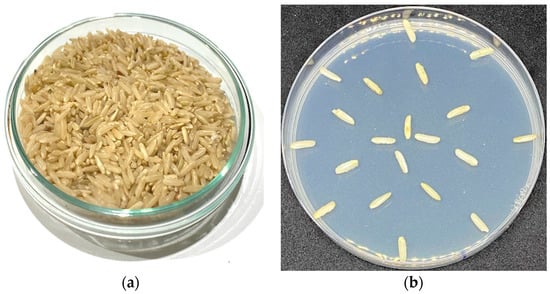

The treated seventy-five rice samples in a sterile glass Petri dish (Figure 4a) were treated at different electric field intensities (150, 190, 225, 300, and 450 kV/m) and temperatures (70, 80, 90, 100, and 110 °C) using dielectric heating system. The non-treated rice sample was used as control with three replications. The rice samples were kept in a sterile glass Petri dish during the heating process using aseptic techniques [45]. After that 20 grains of treated and non-treated (control) rice samples were randomly selected and placed on a sterile PDA using aseptic techniques under a laminar airflow cabinet (ScanLaf/Mars 1500, Labogene Aps, Lynge, Denmark) (Figure 4b). Then, the plates were incubated at room temperature for five days. The fungal mycelium was observed using a stereo microscope (Stemi 305, Carl Zeiss, Oberkochen, Germany) and compared with control groups that were not exposed to the electric field. Fungal colonies on rice seeds were counted and fungal inactivation was calculated according to Equation (5):

where NP is the number of positive rice grain, and NT is the number of total rice grain.

Figure 4.

Samples for investigating fungal inactivation: (a) rice sample; (b) rice grains on PDA before incubation.

2.4. Statistical Analysis

Each experiment was carried out in triplicate and data were statistically analyzed using SPSS Statistics version 20.0 (SPSS Inc., Chicago, IL, USA). One-way analysis of variance (ANOVA) was performed to determine the statical differences between the sample means, with the level of significance set at 5% probability. Multiple comparisons of the means were conducted using a factorial experiment test. All data were expressed as mean ± SD.

3. Results and Discussion

3.1. Optimization of Frequency Band under Dielectric Heating System

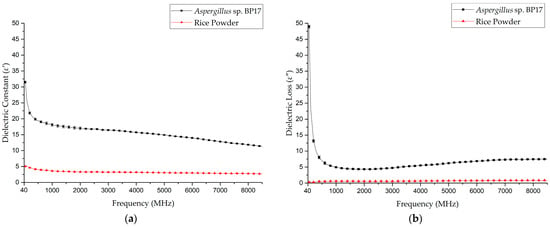

The dielectric properties [dielectric constant (ε′) and loss (ε″)] of Aspergillus sp. BP17 and rice powder samples were investigated at frequency ranges as 40 to 8500 MHz as shown in Figure 5. The result showed that dielectric constants of both Aspergillus sp. BP17 and rice powder were decreased when frequency increased. In accordance with Cheng et al. (2017) reported that the electric constant is generally decreases when frequency increases for all types of rice due to the presence of polar molecules such as glucose and fructose [40]. At low frequencies (<200 MHz), the dielectric constants of Aspergillus sp. BP17 rapidly decreased from 31.5 to 21.8 at frequencies between 40 to 200 MHz (Figure 5a, upper line). A previous study reported that the dielectric constants of fungi were higher than 4.0 at frequencies lower than 200 MHz including Botrytis cinerea, Alternaria solani, Ceratocystis radicicola, Rhizoctonia solani, Lasiodiplodia theobromae, Fusarium oxysporum and F. solani [39]. However, the dielectric constants of rice powder slowly reduced from 5.06 to 4.63 at frequencies between 40 to 200 MHz (Figure 5a, bottom line). In comparison between fungi and rice samples, Aspergillus sp. BP17 showed higher dielectric constant than the rice sample due to it being associated with cell membrane polarization [46].

Figure 5.

Dielectric properties of Aspergillus sp. BP17 and rice powder: (a) Dielectric constant (ε′) and (b) Dielectric loss (ε″).

The dielectric loss of Aspergillus sp. BP17 rapidly decreased from 48.92 to 13.13 at frequencies between 40 to 200 MHz (Figure 5b, upper line). After that, the values were slowly increased when frequencies were increased between 2000 and 8500 MHz. In contrast, the dielectric loss of rice was 0.26 and 0.86 at frequency of 40–200 and 8500 MHz, respectively (Figure 5b, bottom line). Aspergillus sp. BP17 and rice powder showed a different dielectric loss because the change of dielectric loss was caused by the relative effects of ionic conductivity and free water relaxation [40,41,47]. Moreover, the dielectric loss behavior of Aspergillus sp. BP17 was similar to the results reported in edible fungi [47] and the dielectric loss behavior of rice in this study was also similar to Jasmine rice 105, Hompathum rice, Phitsanulok rice, Chinart rice, and Gorkor 43 rice [48].

According to the US Federal Communication Commission (FCC), it has been reported that the optimal specific frequencies for ISM uses 13.56, 27.12, and 40.68 MHz of RF and 915 and 2,450 MHz of MW [44]. So, three ISM frequency bands, including 40.68, 915, and 2450 MHz, were selected and calculated the ratio of dielectric constant and loss in fungal and rice powder samples (Table 1). The result showed that optimal frequency was 40.68 MHz based on the highest of ratio (194.9 folds) between dielectric loss of Aspergillus sp. BP17 and rice powder, which is the same result with Figure 5b. Therefore, at a frequency with the high difference of dielectric loss between fungi and rice can be applied for fungal inactivation using dielectric heating applications based on the “thermal runaway” phenomenon as described [33]. Therefore, the frequency of 40.68 MHz was selected for fungal control using dielectric heating system in the next experiment.

Table 1.

Dielectric properties of Aspergillus sp. BP17 and rice powder.

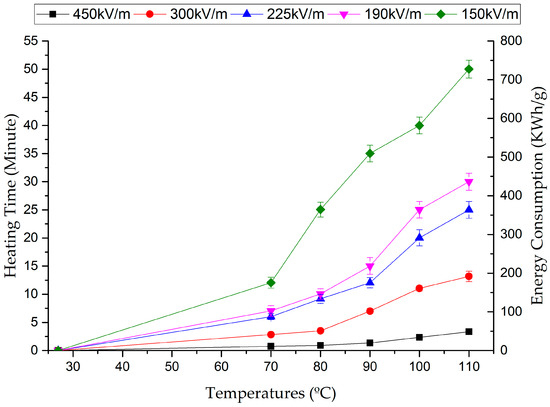

3.2. Study of Relative Electric Field Intensity and Temperature on Heating System

The effect of relative electric field intensities and temperatures (heating time-temperature histories and energy consumption-temperature histories) was investigated at the selected frequency of 40.68 MHz (Figure 6). The result showed that the heating time-temperature histories and energy consumption-temperature histories were nonlinear. The graph also indicates that the heating time and energy consumption decreased when electric field intensities increased. The optimal electric field intensity was 450 kV/mbased on the highest ratio (26.26 folds at 90 °C) between the heating time comparison of 450 kV/m and 150 kV/m for each temperature (35 min, and 47.25 °C/min). The differences in the heating time are because of various heating mechanisms [49]. It has been reported that dielectric materials convert electric energy to heat when placed into an electromagnetic field in the range of radio and microwave frequencies [43,50]. Similar to the earlier work, heating rate and heating time changed with electrode gaps [51,52,53]. Moreover, the optimal electric field intensity was 450 kV/m based on the highest of ratio (26.26 folds at 90 °C) between the energy consumption comparison of 450 kV/m and 150 kV/m for each temperature (0.33 kWh/g). This result showed that the increased electric field intensity allowed less energy in the dielectric heating system. Similar to the earlier work, energy comparison changed with electrode gaps (1.98 folds at 80 °C) [49].

Figure 6.

The relative electric field intensity and temperature in the heating system.

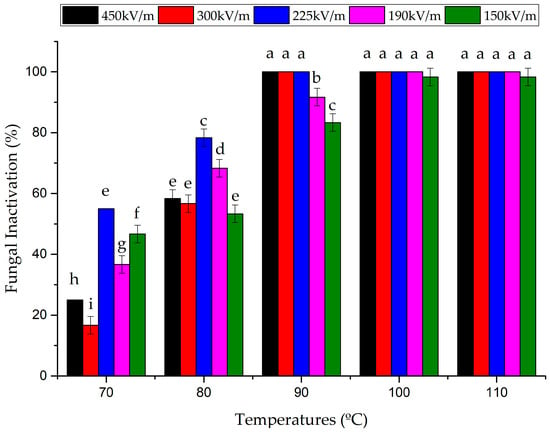

3.3. Effect of Dielectric Heating Condition on Fungal Growth

The rice samples were treated by the heating system at a selected frequency and electric field intensity of 40.68 MHz with 150, 190, 225, 300, and 450 kV/m, respectively. The fungal inactivation on the rice sample was obtained by using temperature with electric field intensity (Figure 7). As seen in Figure 7, the synergies of temperatures and electric field intensities can be divided into nine groups (a–i, which are from the highest to lowest group of the fungal inactivation). The result showed that the fungal inactivation of 100% was obtained at the electric field intensity value ≥ 225 kV/m at the lowest temperature of 90 °C. Based on statistical analysis, the fungal inactivation in rice grains was significant (p ≤ 0.05) by the effects of the combination of temperature and electric field intensity. A previous study reported that the effect of both the thermal and non-thermal was caused by the pasteurization mechanism on micro-organisms at the cellular level [54]. Here, the fungal inactivation of 100% was obtained using 190 kV/m at 100 and 110 °C, 225 kV/m at 90, 100 and 110 °C, 300 k V/m at 90, 100 and 110 °C, 450 kV/m at 90, 100 and 110 °C (Figure 7). The effect of different temperatures on fungal inhibition has been reported including Aspergillus sp. in canned strawberries (94 °C) [55] and grape juice (85 °C) [56], Aspergillus niger (90 °C) and Aspergillus flavus in oil seed (90 °C) [19], Aspergillus flavus in Khao Dawk Mali 105 (90 °C) [57], and the other Aspergillus species with a neosartorya-morph (80–90 °C) [58].

Figure 7.

The relative electric field intensity and temperature on fungal growth. Average ± standard deviation from three replicate experiments. Different letters in the same column are considered significantly different according to Duncan’s multiple comparison test (p ≤ 0.05).

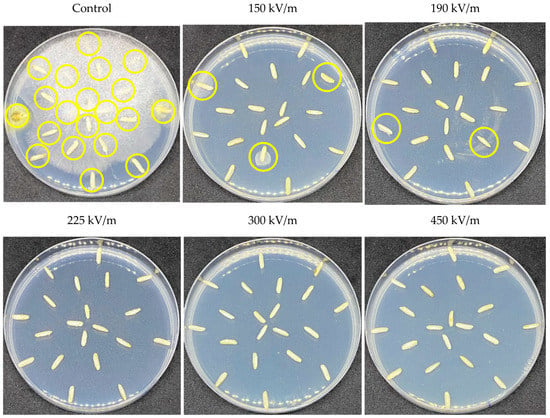

To visualize the effect of dielectric heating on fungal growth based on different electric intensities, six samples including one non-treated sample (control) and five treated samples (150, 190, 225, 300, and 450 kV/m ) were selected to show fungal inactivation. Figure 8 shows the fungal growth on PDA after rice samples were treated with different electric intensities at 90 °C. Fungal mycelium was grown from rice grains in the control agar plate. On the contrary, fungal growth from rice grains was deceased based on 150 k V/m and 190 kV/m, and the hyphae were not germinated from rice grains that were treated with electric field intensity value ≥ 225 kV/m at 90 °C. This indicates that the optimal conditions of dielectric heating (combination of 225 kV/m and 90 °C) are powerful for fungal inactivation in rice grains by dielectric heating. Cain reported that the electric field (194 kV/m) has a non-thermal effect on the cellular membrane (in the air of electrode gaps) [59]. Use of both thermal and non-thermal mechanisms was reported in Aspergillus fumigatus and Neosartorya fischeri in apple juice (83 and 92 °C with 20 V/cm, 83 °C with 27 V/cm, and 90 °C with 9 V/cm) [60,61] and Aspergillus niger in tomato (89 °C with 36 V/cm) [62].

Figure 8.

The fungal growth on Petri dish after treated with different electric intensity at 90 °C.

The results indicate that the contaminated fungi in rice grain products can be eliminated using the dielectric heating machine. The system can generate heat on fungal cells faster than the surrounding media/environments. As a result, the rapid oscillation of the fungal cell leads to elastic limit, rupture, and cell death [63].

This study suggested that dielectric heating is an effective method for fungal inactivation in rice grains. Additionally, the optimal conditions of dielectric heating are suitable for inactivation of contaminated fungi in rice industries.

4. Conclusions

In the present study, the dielectric properties between Aspergillus sp. BP17 and rice were studied, and the optimal frequency of 40.68 MHz was selected for fungal inactivation using the dielectric heating system. The optimization of dielectric heating for fungal inactivation was evaluated by the relationship between electric field intensity and temperature. The results showed that dielectric heating treatment killed or inhibited fungi on rice grains. The best condition (energy consumption of 0.33 kWh/g and fungal inactivation of 100%) was obtained at 450 kV/m and 90 °C. This study provides knowledge of dielectric heating for developing the heating system and equipment for rice products.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app122010478/s1, Figure S1: Measuring dielectric properties of sample: (a) Rice powder sample; (b) Aspergillus sp. BP17.

Author Contributions

Conceptualization, C.S., S.S., C.T., T.T. and W.P.; methodology, C.S. and. S.S.; validation, C.S., S.S., C.T., T.T. and W.P.; formal analysis, C.S., S.S. and W.P.; investigation, C.S., S.S. and C.T.; data curation, C.S. and S.S; writing—original draft preparation, C.S. and S.S.; writing—review and editing, C.S., S.S., C.T. and W.P.; visualization, C.S.; supervision, S.S. and C.T.; project administration, S.S. and C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Suranaree University of Technology (SUT), Thailand Science Research and Innovation (TSRI), and National Science Research and Innovation Fund (NSRF) (NRIIS no. 179289).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by Suranaree University of Technology, Thailand Science Research and Innovation, and National Science Research and Innovation Fund.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Savi, G.D.; Piacentini, K.C.; Rocha, L.O.; Carnielli-Queiroz, L.; Furtado, B.G.; Scussel, R.; Zanoni, E.T.; Machado-de-Ávila, R.A.; Corrêa, B.; Angioletto, E. Incidence of toxigenic fungi and zearalenone in rice grains from Brazil. Int. J. Food Microbiol. 2018, 270, 5–13. [Google Scholar] [CrossRef] [PubMed]

- Rice Consumption Per Capita. Available online: https://www.helgilibrary.com/indicators/rice-consumption-per-capita (accessed on 5 October 2022).

- Gonçalves, A.; Gkrillas, A.; Dorne, J.L.; Dall’Asta, C.; Palumbo, R.; Lima, N.; Battilani, P.; Venâncio, A.; Giorni, P. Pre- and postharvest strategies to minimize mycotoxin contamination in the rice food chain. Compr. Rev. Food Sci. Food Saf. 2019, 18, 441–454. [Google Scholar] [CrossRef]

- Kittipong, S.; Kunya, C.; Kanjana, P.; Sa-ang, C.; Grissana, S.; Yotsaporn, T.; Rujira, P.; Witchuda, R.; Rasamee, D. Investigation on the Contamination of Aflatoxin B1 in Thai Rice. Thai Rice Res. J. 2018, 1, 30–36. [Google Scholar]

- Lee, S.H.; Park, S.Y.; Byun, K.H.; Chun, H.S.; Ha, S.D. Effects of microwaves on the reduction of Aspergillus flavus and Aspergillus parasiticus on brown rice (Oryza sativa L.) and barley (Hordeum vulgare L.). Food Addit. Contam. 2017, 34, 1193–1200. [Google Scholar] [CrossRef]

- Mannaa, M.; Kim, K.D. Influence of temperature and water activity on deleterious fungi and mycotoxin production during grain storage. Mycobiology 2017, 45, 240–254. [Google Scholar] [CrossRef]

- Trung, T.S.; Bailly, J.; Querin, A.; Le Bars, P.; Guerre, P. Fungal contamination of rice from south Vietnam, mycotoxinogenesis of selected strains and residues in rice. Rev. Médecine Vétérinaire 2001, 152, 555–560. [Google Scholar]

- Ali, N. Aflatoxins in rice: Worldwide occurrence and public health perspectives. Toxicol. Rep. 2019, 6, 1188–1197. [Google Scholar] [CrossRef]

- Akhila, P.P.; Sunooj, K.V.; Aaliya, B.; Navaf, M.; Sudheesh, C.; Sabu, S.; Khaneghah, A.M. Application of electromagnetic radiations for decontamination of fungi and mycotoxins in food products: A comprehensive review. Trends Food Sci. Technol. 2021, 114, 399–409. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Hajeb, P.; Ehsani, R.J. Application of ozone for degradation of mycotoxins in food: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1777–1808. [Google Scholar] [CrossRef]

- Yang, K.; Li, K.; Pan, L.; Luo, X.; Xing, J.; Wang, J.; Wang, L.; Wang, R.; Zhai, Y.; Chen, Z. Effect of Ozone and Electron Beam Irradiation on Degradation of Zearalenone and Ochratoxin, A. Toxins 2020, 12, 138. [Google Scholar] [CrossRef]

- Srivastava, S.; Mishra, H.N. Ecofriendly nonchemical/nonthermal methods for disinfestation and control of pest/fungal infestation during storage of major important cereal grains: A review. Front. Nutr. 2021, 2, 93–105. [Google Scholar] [CrossRef]

- Wason, S.; Verma, T.; Subbiah, J. Validation of process technologies for enhancing the safety of low-moisture foods: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4950–4992. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Hu, J.; Xiong, S.; Zhao, S. Effect of low-dose microwave radiation on Aspergillus parasiticus. Food Control 2011, 22, 1078–1084. [Google Scholar] [CrossRef]

- Schmidt, M.; Zannini, E.; Arendt, E.K. Recent Advances in Physical Post-Harvest Treatments for Shelf-Life Extension of Cereal Crops. Foods 2018, 7, 45. [Google Scholar] [CrossRef] [PubMed]

- Mir, S.A.; Dar, B.; Shah, M.A.; Sofi, S.A.; Hamdani, A.M.; Oliveira, C.A.; Moosavi, M.H.; Khaneghah, A.M.; Sant’Ana, A.S. Application of New Technologies in Decontamination of Mycotoxins in Cereal Grains: Challenges, and Perspectives. Food Chem. Toxicol. 2021, 148, 111976. [Google Scholar] [CrossRef]

- Chandravarnan, P.; Agyei, D.; Ali, A. Green and sustainable technologies for the decontamination of fungi and mycotoxins in rice: A review. Trends Food Sci. Technol. 2022, 124, 278–295. [Google Scholar] [CrossRef]

- Zhang, Y.; Pandiselvam, R.; Zhu, H.; Su, D.; Wang, H.; Ai, Z.; Kothakota, A.; Khaneghah, A.M.; Liu, Y. Impact of Radio Frequency Treatment on Textural Properties of Food Products: An Updated Review. Trends Food Sci. Technol. 2022, 124, 154–166. [Google Scholar] [CrossRef]

- Vearasilp, S.; Thobunluepop, P.; Thanapornpoonpong, S.N.; Pawelzik, E.; von Hörsten, D. Radio frequency heating on lipid peroxidation, decreasing oxidative stress and aflatoxin B1 reduction in Perilla frutescens L. highland oil seed. Agric. Agric. Sci. Procedia 2015, 5, 177–183. [Google Scholar] [CrossRef]

- Jiao, S.; Zhong, Y.; Deng, Y. Hot air-assisted radio frequency heating effects on wheat and corn seeds: Quality change and fungi inhibition. J. Stored Prod. Res. 2016, 69, 265–271. [Google Scholar] [CrossRef]

- Hou, L.X.; Kou, X.X.; Li, R.; Wang, S.J. Thermal inactivation of fungi in chestnuts by hot air assisted radio frequency treatments. Food Control 2018, 93, 297–304. [Google Scholar] [CrossRef]

- da Silva, A.C.; Sarturi, H.J.; Dall’Oglio, E.L.; Soares, M.A.; de Sousa, P.T.; Gomes de Vasconcelos, L.; Kuhnen, C.A. Microwave drying and disinfestation of Brazil nut seeds. Food Control 2016, 70, 119–129. [Google Scholar] [CrossRef]

- Zheng, A.J.; Zhang, L.H.; Wang, S.J. Verification of radio frequency pasteurization treatment for controlling Aspergillus parasiticus on corn grains. Int. J. Food Microbiol. 2017, 249, 27–34. [Google Scholar] [CrossRef] [PubMed]

- Feng, H.; Yin, Y.; Tang, J. Microwave drying of food and agricultural materials: Basics and heat and mass transfer modeling. Food Eng. Rev. 2012, 4, 89–106. [Google Scholar] [CrossRef]

- Höhlig, B.; Schmidt, D.; Mechtcherine, V.; Hempel, S.; Schrofl, C.; Trommler, U.; Roland, U. Effects of dielectric heating of fresh concrete on its microstructure and strength in the hardened state. Constr. Build. Mater. 2015, 81, 24–34. [Google Scholar] [CrossRef]

- Ling, B.; Liu, X.; Zhang, L.; Wang, S. Effects of temperature, moisture, and metal salt content on dielectric properties of rice bran associated with radio frequency heating. Sci. Rep. 2018, 8, 4427. [Google Scholar] [CrossRef]

- Ling, B.; Cheng, T.; Wang, S. Recent developments in applications of radio frequency heating for improving safety and quality of food grains and their products: A review. Crit. Rev. Food Sci. Nutr. 2019, 60, 2622–2642. [Google Scholar] [CrossRef]

- Goñi, S.M.; d’Amore, M.; Della Valle, M.; Olivera, D.F.; Salvadori, V.O.; Marra, F. Effect of Load Spatial Configuration on the Heating of Chicken Meat Assisted by Radio Frequency at 40.68 MHz. Foods 2022, 11, 1096. [Google Scholar] [CrossRef]

- Sosa-Morales, M.E.; Valerio-Junco, L.; López-Malo, A.; García, H.S. Dielectric properties of foods: Reported data in the 21st century and their potential applications. LWT Food Sci. Technol. 2010, 43, 1169–1179. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Factors Influencing the Dielectric Properties of Agricultural and Food Products. J. Microware Power Electromagn. Energy 2012, 46, 93–107. [Google Scholar] [CrossRef]

- Nelson, S.O. Dielectric Properties of Agricultural Materials and Their Applications, 1st ed.; Academic Press: Amsterdam, The Netherlands, 2015; p. 33. [Google Scholar]

- Zhou, L.; Ling, B.; Zheng, A.; Zhang, B.; Wang, S. Developing radio frequency technology for postharvest insect control in milled rice. J. Stored Prod. Res. 2015, 62, 22–31. [Google Scholar] [CrossRef]

- Hou, L.; Johnson, J.A.; Wang, S. Radio frequency heating for postharvest control of pests in agricultural products: A review. Postharvest Biol. Technol. 2016, 113, 106–118. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, Y.; Tang, Y.; Yang, R.; Yan, W.; Zhao, W. Radio frequency heating as a disinfestation method against Corcyra cephalonica and its effect on properties of milled rice. J. Stored Prod. Res. 2018, 77, 112–121. [Google Scholar] [CrossRef]

- Hou, L.; Liu, Q.; Wang, S. Efficiency of industrial-scale radio frequency treatments to control Rhyzopertha dominica (fabricius) in rough, brown, and milled rice. Biosyst. Eng. 2019, 186, 246–258. [Google Scholar] [CrossRef]

- Cui, M.; Sun, W.; Xia, L.; Wang, Z.; Cao, Y.; Wu, Y. Effect of radio frequency heating on the mortality of Rhizopertha dominica (F.) and its impact on grain quality. J. Stored Prod. Res. 2020, 89, 101695. [Google Scholar] [CrossRef]

- Hou, L.; Wu, Y.; Kou, X.; Li, R.; Wang, S. Developing high-temperature-short-time radio frequency disinfestation treatments in coix seeds: Insect mortality, product quality and energy consumption. Biosyst. Eng. 2022, 215, 262–270. [Google Scholar] [CrossRef]

- Mohamad, S.N.H.; Muhamad, I.I.; Mohd Jusoh, Y.M.; Khairuddin, N. Dielectric properties for selected wall material in the development of microwave-encapsulation-drying. J. Food Sci. Technol. 2018, 55, 5161–5165. [Google Scholar] [CrossRef]

- Hussein, M.I.; Jithin, D.; Rajmohan, I.J.; Sham, A.; Saeed, E.E.M.; AbuQamar, S.F. Microwave characterization of hydrophilic and hydrophobic plant pathogenic fungi using open-ended coaxial probe. IEEE Access 2019, 7, 45841–45849. [Google Scholar] [CrossRef]

- Cheng, E.M.; You, K.Y.; Lee, K.Y.; Abbas, Z.; Rahim, H.A.; Khor, S.F.; Zakaria, Z.; Lee, Y.S. Dielectric spectroscopy technique for carbohydrate characterization of fragrant rice, brown rice and white rice. In Proceedings of the 2017 Progress in Electromagnetics Research Symposium-Fall (PIERS-FALL), Singapore, 19–22 November 2017; pp. 205–209. [Google Scholar] [CrossRef]

- Bansal, N.; Dhaliwal, A.S.; Mann, K.S. Dielectric characterization of rapeseed (Brassica napus L.) from 10 to 3000 MHz. Biosyst. Eng. 2016, 143, 1–8. [Google Scholar] [CrossRef]

- Ozturk, S.; Kong, F.B.; Singh, R.K.; Kuzy, J.D.; Li, C.Y.; Trabelsi, S. Dielectric properties, heating rate, and heating uniformity of various seasoning spices and their mixtures with radio frequency heating. J. Food Eng. 2018, 228, 128–141. [Google Scholar] [CrossRef]

- Nelson, S.O. Fundamentals of dielectric properties measurements and agricultural applications. J. Microw. Power Electromagn. Energy 2010, 44, 98–113. [Google Scholar] [CrossRef]

- Jiao, Y.; Tang, J.; Wang, Y.; Koral, T.L. Radio-frequency applications for food processing and safety. Annu. Rev. Food Sci. Technol. 2018, 9, 105–127. [Google Scholar] [CrossRef] [PubMed]

- Saran, S.; Gurjar, M.; Baronia, A.; Sivapurapu, V.; Ghosh, P.S.; Raju, G.M.; Maurya, I. Heating, ventilation and air conditioning (HVAC) in intensive care unit. Crit. Care 2020, 24, 194. [Google Scholar] [CrossRef] [PubMed]

- François, A.; Tong, C.; Thomas, C.; Jean, J.F.; Mary, P.; David, D.; Katia, G. Microwaving biological cells: Intracellular analysis with microwave dielectric spectroscopy. IEEE Microw. Mag. 2015, 16, 87–96. [Google Scholar] [CrossRef]

- Qi, S.; Han, J.; Lagnika, C.; Jiang, N.; Qian, C.; Liu, C.; Li, D.; Tao, Y.; Yu, Z.; Wang, L.; et al. Dielectric properties of edible fungi powder related to radio-frequency and microwave drying. Food Prod. Process. Nutr. 2021, 3, 15. [Google Scholar] [CrossRef]

- Wasusathien, W.; Santalunai, S.; Thosdeekoraphat, T.; Thongsopa, C. Rice Types Classification by Using Dielectric Properties Measurement with Saline Water Increasing Technique. In Proceedings of the 2020 International Symposium on Electrical Insulating Materials (ISEIM), Tokyo, Japan, 13–17 September 2020; pp. 433–438. [Google Scholar]

- Cao, X.; Zhang, M.; Chitrakar, B.; Mujumdar, A.S.; Zhong, Q.; Wang, Z.; Wang, L. Radio frequency heating for powder pasteurization of barley grass: Antioxidant substances, sensory quality, microbial load and energy consumption. J. Sci. Food Agric. 2019, 99, 4460–4467. [Google Scholar] [CrossRef]

- El Khaled, D.; Castellano, N.; Gázquez, J.; Perea-Moreno, A.-J.; Manzano-Agugliaro, F. Dielectric Spectroscopy in Biomaterials: Agrophysics. Materials 2016, 9, 310. [Google Scholar] [CrossRef]

- Birla, S.L.; Wang, S.; Tang, J.; Tiwari, G. Characterization of radio frequency heating of fresh fruits influenced by dielectric properties. J. Food Eng. 2008, 89, 390–398. [Google Scholar] [CrossRef]

- Kim, S.Y.; Sagong, H.G.; Choi, S.H.; Ryu, S.; Kang, D.H. Radio-frequency heating to inactivate Salmonella Typhimurium and Escherichia coli O157:H7 on black and red pepper spice. Int. J. Food Microbiol. 2012, 153, 171–175. [Google Scholar] [CrossRef]

- Bedane, T.F.; Chen, L.; Marra, F.; Wang, S. Experimental study of radio frequency (RF) thawing of foods with movement on conveyor belt. J. Food Eng. 2017, 201, 17–25. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Hu, Y.; Wang, L. Microwaves, a potential treatment for bacteria: A review. Front. Microbiol. 2022, 13, 1–14. [Google Scholar] [CrossRef]

- Kavanagh, J.; Larchet, N.; Stuart, M. Occurrence of a heat-resistant species of Aspergillus in canned strawberries. Nature 1963, 198, 1322. [Google Scholar] [CrossRef]

- Splittstoesser, D.F.; Splittstoesser, C.M. Ascospores of Byssochlamys fulva compared with those of a heat resistant Aspergillus. J. Food Sci. 1977, 42, 685–688. [Google Scholar] [CrossRef]

- Naka, J.; Vearasilp, S.; Thanapornpoonpong, S.N. Effects of radio frequency heat treatment to control of Aspergillus flavus aflatoxin B1 and quality in rice var. KDML 105 in different bagging densities. Warasan Kaset 2013, 29, 1–12. [Google Scholar]

- Dijksterhuis, J. Fungal spores: Highly variable and stress-resistant vehicles for distribution and spoilage. Food Microbiol. 2019, 81, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Cain, C.A. A theoretical basis for microwave and RF field effects on excitable cellular membranes. IEEE Trans. Microw. Theory Tech. 1980, 2, 142–147. [Google Scholar] [CrossRef]

- Müller, W.A.; Pasin, M.V.A.; Sarkis, J.R.; Marczak, L.D.F. Effect of pasteurization on Aspergillus fumigatus in apple juice: Analysis of the thermal and electric effects. Int. J. Food Microbiol. 2021, 338, 108993. [Google Scholar] [CrossRef] [PubMed]

- Müller, W.A.; Marczak, L.D.F.; Sarkis, J.R. Thermal and kinetic integrated models applied for Aspergillus fumigatus inactivation during ohmic and conventional juice pasteurization. J. Food Eng. 2022, 319, 110907. [Google Scholar] [CrossRef]

- Yıldız, H.; Baysal, T. Effects of alternative current heating treatment on Aspergillus niger, pectin methylesterase and pectin content in tomato. J. Food Eng. 2006, 75, 327–332. [Google Scholar] [CrossRef]

- Orsat, V.; Raghavan, G.V. Radio-Frequency Processing. In Emerging Technologies for Food Processing, 2nd ed.; Da-Wen, S., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 385–398. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).