Mechanical Properties and Torque/Force Generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1

Abstract

1. Introduction

2. Materials and Methods

2.1. Mechanical Tests

2.2. Simulated Canal Shaping

2.3. Differential Scanning Calorimetry (DSC)

3. Results

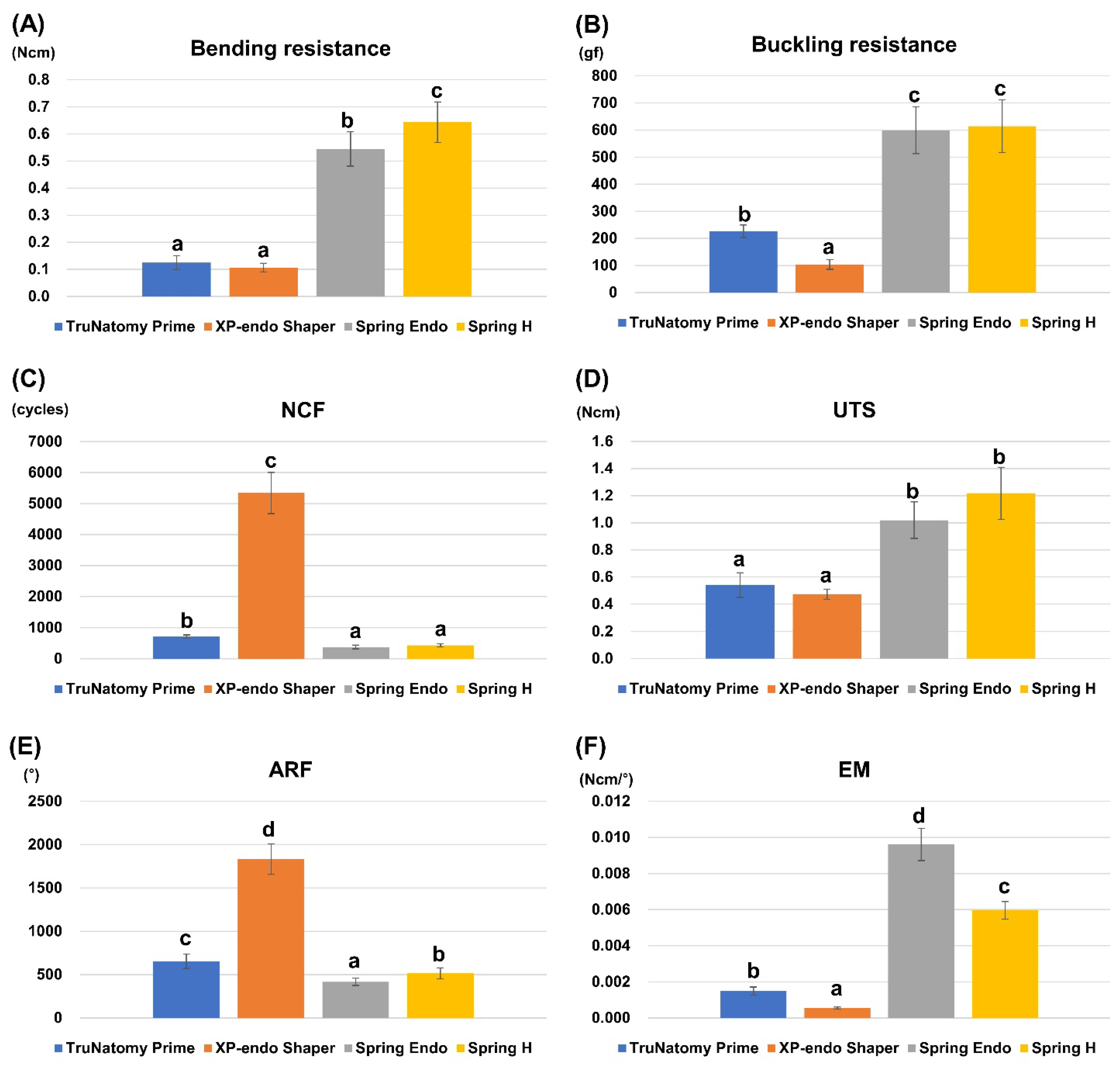

3.1. Mechanical Test Results

Pearson Correlation Analysis

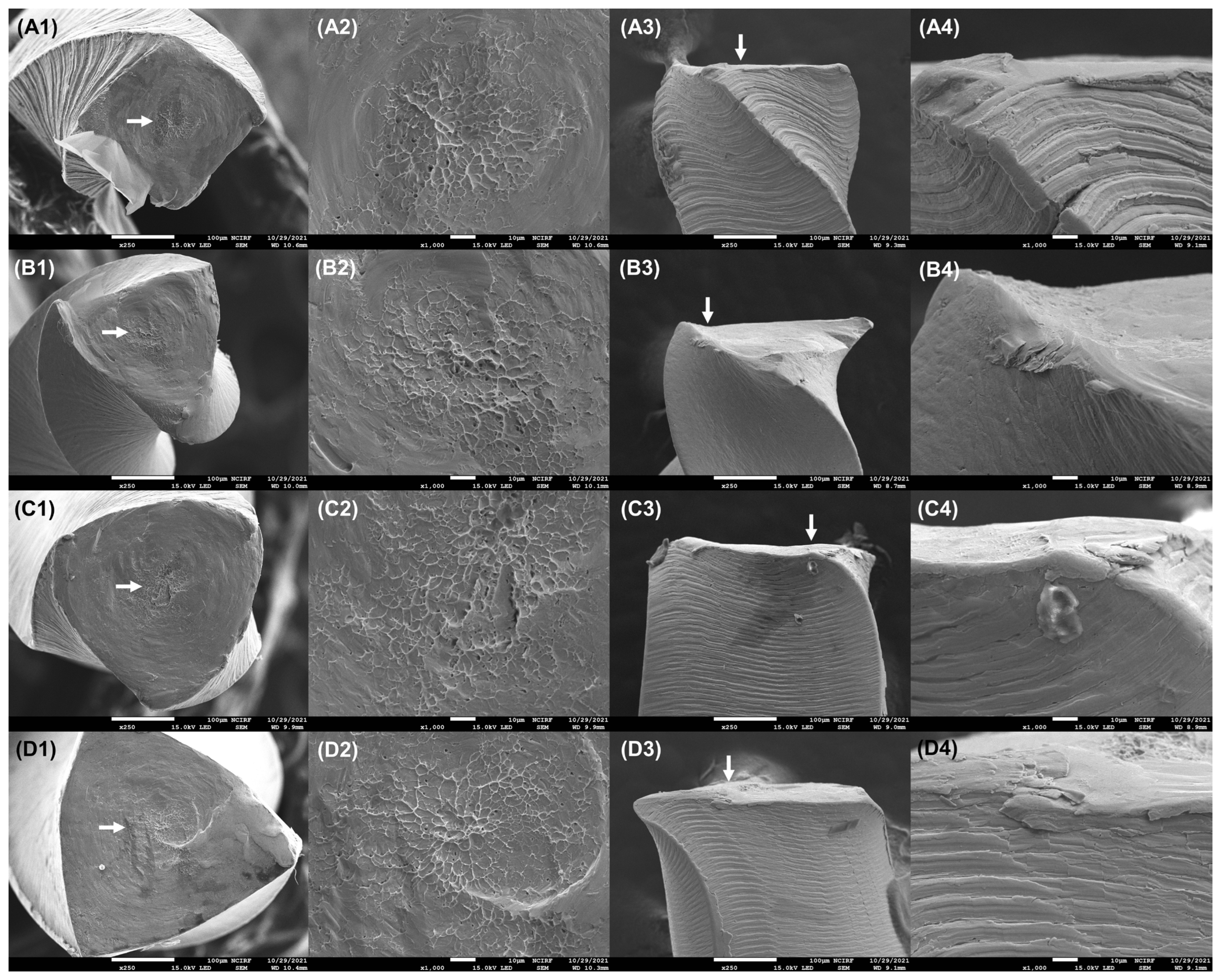

3.2. Simulated Canal Shaping Results

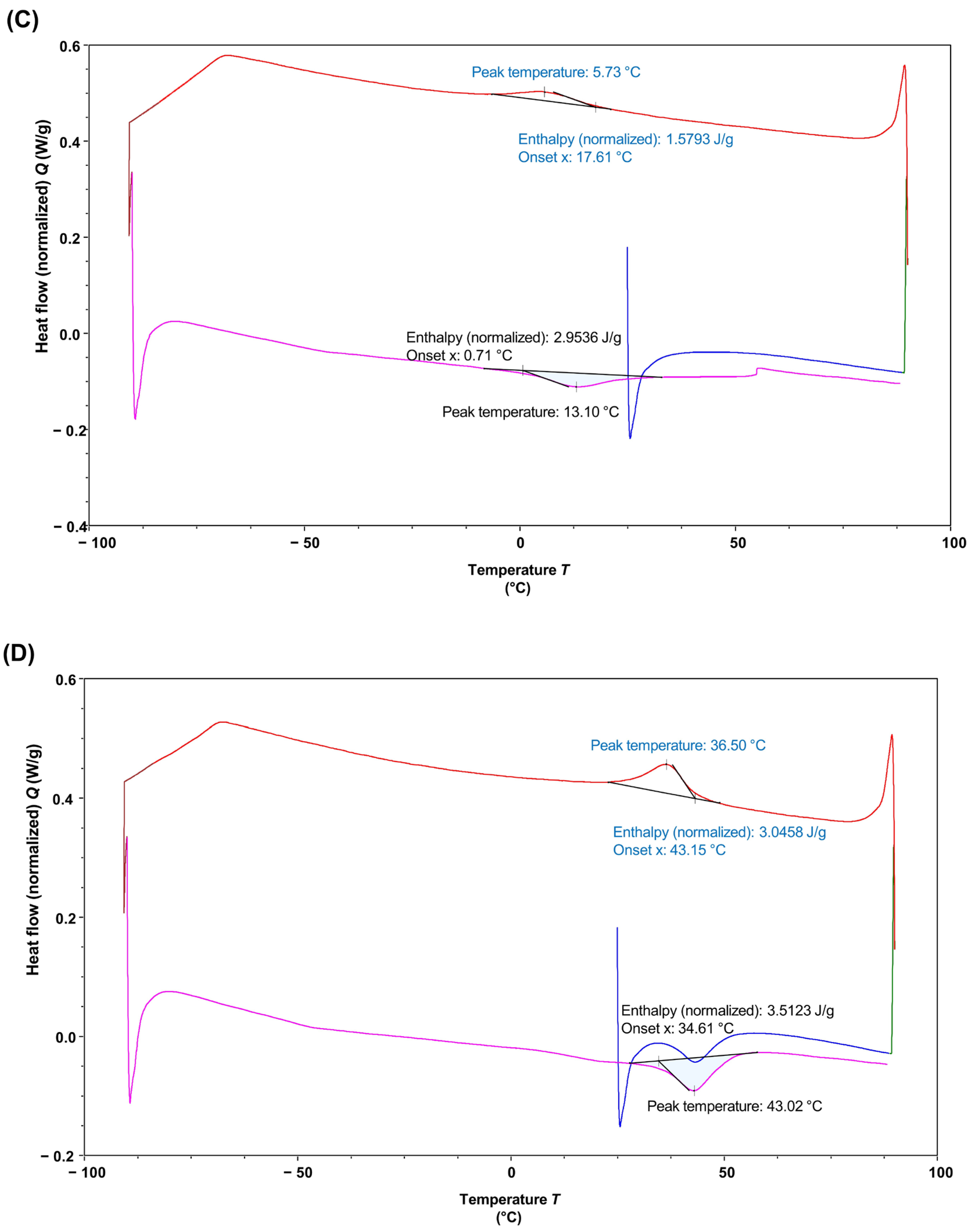

3.3. DSC

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taşdemir, T.; Aydemir, H.; Inan, U.; Unal, O. Canal preparation with Hero 642 rotary Ni-Ti instruments compared with stainless steel hand K-file assessed using computed tomography. Int. Endod. J. 2005, 38, 402–408. [Google Scholar] [CrossRef] [PubMed]

- Bürklein, S.; Zupanc, L.; Donnermeyer, D.; Tegtmeyer, K.; Schäfer, E. Effect of core mass and alloy on cyclic fatigue resistance of different nickel-titanium endodontic instruments in matching artificial canals. Materials 2021, 14, 5734. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.; Ha, J.H.; Kwak, S.W.; Kim, H.C. Advancement of mechanical properties of nickel-titanium rotary endodontic instruments by spring machining on the file shaft. Materials 2020, 13, 5246. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.M.; Shen, Y.; Zheng, W.; Li, L.; Zheng, Y.F.; Haapasalo, M. Mechanical properties of controlled memory and superelastic nickel-titanium wires used in the manufacture of rotary endodontic instruments. J. Endod. 2012, 38, 1535–1540. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Campbell, L.; Peng, B.; Haapasalo, M. Metallurgical characterization of controlled memory wire nickel-titanium rotary instruments. J. Endod. 2011, 37, 1566–1571. [Google Scholar] [CrossRef]

- Gu, Y.; Kum, K.Y.; Perinpanayagam, H.; Kim, C.; Kum, D.J.; Lim, S.M.; Chang, S.W.; Baek, S.H.; Zhu, Q.; Yoo, Y.J. Various heat-treated nickel-titanium rotary instruments evaluated in S-shaped simulated resin canals. J. Dent. Sci. 2017, 12, 14–20. [Google Scholar] [CrossRef]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef]

- Silva, E.; Vieira, V.T.L.; Belladonna, F.G.; Zuolo, A.S.; Antunes, H.D.S.; Cavalcante, D.M.; Elias, C.N.; De-Deus, G. Cyclic and torsional fatigue resistance of XP-endo Shaper and TRUShape instruments. J. Endod. 2018, 44, 168–172. [Google Scholar] [CrossRef]

- Mustafa, R.; Al Omari, T.; Al-Nasrawi, S.; Al Fodeh, R.; Dkmak, A.; Haider, J. Evaluating in vitro performance of novel nickel-titanium rotary system (TruNatomy) based on debris extrusion and preparation time from severely curved canals. J. Endod. 2021, 47, 976–981. [Google Scholar] [CrossRef]

- Jose, J.; Khandelwal, A.; Siddique, R. Qualitative assessment of the surface topographic changes of XP-endo Shaper and TruNatomy files after exposure to sodium hypochlorite and ethylenediaminetetraacetic acid. Eur. Endod. J. 2021, 6, 197–204. [Google Scholar] [CrossRef]

- Falakaloğlu, S.; Silva, E.; Yeniçeri Özata, M.; Gündoğar, M. Shaping ability of different NiTi rotary systems during the preparation of printed mandibular molars. Aust. Endod. J. 2022, in press. [Google Scholar] [CrossRef]

- Lima, C.O.; Barbosa, A.F.A.; Ferreira, C.M.; Augusto, C.M.; Sassone, L.M.; Lopes, R.T.; Fidel, S.R.; Silva, E. The impact of minimally invasive root canal preparation strategies on the ability to shape root canals of mandibular molars. Int. Endod. J. 2020, 53, 1680–1688. [Google Scholar] [CrossRef]

- Aksoy, Ç.; Keriş, E.Y.; Yaman, S.D.; Ocak, M.; Geneci, F.; Çelik, H.H. Evaluation of XP-endo Shaper, Reciproc Blue, and ProTaper Universal NiTi systems on dentinal microcrack formation using micro-computed tomography. J. Endod. 2019, 45, 338–342. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E.; Mandorah, A.O. In vitro comparison of cyclic fatigue resistance of TruNatomy in single and double curvature canals compared with different nickel-titanium rotary instruments. BMC Oral Health 2020, 20, 38. [Google Scholar] [CrossRef]

- Kim, N.Y.; Kwak, S.W.; Yoon, T.H.; Ha, J.H.; Versluis, A.; Kim, H.C. Numeric evaluation of innovate spring machined nickel-titanium rotary instruments: A 3-dimensional finite element study. J. Endod. 2021, 47, 303–308. [Google Scholar] [CrossRef]

- Spring Endo File. Available online: https://denflex.kr/eng/bbs/content.php?co_id=b_1en (accessed on 1 September 2021).

- International Standard ISO 3630-1: 2019(E); Root-Canal Instruments—Part 1: General Requirements and Test Methods. International Organization for Standardization: Geneva, Switzerland, 2019.

- Ninan, E.; Berzins, D.W. Torsion and bending properties of shape memory and superelastic nickel-titanium rotary instruments. J. Endod. 2013, 39, 101–104. [Google Scholar] [CrossRef]

- Pruett, J.P.; Clement, D.J.; Carnes, D.L., Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85. [Google Scholar] [CrossRef]

- Ha, J.H.; Lee, C.J.; Kwak, S.W.; El Abed, R.; Ha, D.; Kim, H.C. Geometric optimization for development of glide path preparation nickel-titanium rotary instrument. J. Endod. 2015, 41, 916–919. [Google Scholar] [CrossRef]

- Alqedairi, A.; Alfawaz, H.; Abualjadayel, B.; Alanazi, M.; Alkhalifah, A.; Jamleh, A. Torsional resistance of three ProTaper rotary systems. BMC Oral Health 2019, 19, 124. [Google Scholar] [CrossRef]

- Wu, S.K.; Lin, H.C.; Chou, T.S. A study of electrical-resistivity, internal-friction and shear modulus on an aged TI49NI51 alloy. Acta Metall. Mater. 1990, 38, 95–102. [Google Scholar] [CrossRef]

- Adiguzel, M.; Capar, I.D. Comparison of cyclic fatigue resistance of WaveOne and WaveOne Gold Small, Primary, and Large instruments. J. Endod. 2017, 43, 623–627. [Google Scholar] [CrossRef] [PubMed]

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int. Endod. J. 2006, 39, 755–763. [Google Scholar] [CrossRef] [PubMed]

- Sivas Yilmaz, Ö.; Keskin, C.; Aydemir, H. Comparison of the torsional resistance of 4 different glide path instruments. J. Endod. 2021, 47, 970–975. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.; Giraldes, J.F.N.; de Lima, C.O.; Vieira, V.T.L.; Elias, C.N.; Antunes, H.S. Influence of heat treatment on torsional resistance and surface roughness of nickel-titanium instruments. Int. Endod. J. 2019, 52, 1645–1651. [Google Scholar] [CrossRef] [PubMed]

- Lopes, H.P.; Elias, C.N.; Siqueira, J.F., Jr.; Soares, R.G.; Souza, L.C.; Oliveira, J.C.; Lopes, W.S.; Mangelli, M. Mechanical behavior of pathfinding endodontic instruments. J. Endod. 2012, 38, 1417–1421. [Google Scholar] [CrossRef] [PubMed]

- Jafarzadeh, H.; Abbott, P.V. Ledge formation: Review of a great challenge in endodontics. J. Endod. 2007, 33, 1155–1162. [Google Scholar] [CrossRef]

- Martins, J.N.R.; Silva, E.; Marques, D.; Pereira, M.R.; Arantes-Oliveira, S.; Martins, R.F.; Braz Fernandes, F.M.; Versiani, M.A. Evaluation of design, metallurgy, microhardness, and mechanical properties of glide path instruments: A multimethod approach. J. Endod. 2021, 47, 1917–1923. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E. Torsional resistance of XP-endo Shaper at body teperature compared with several nickel-titanium rotary instruments. Int. Endod. J. 2018, 51, 572–576. [Google Scholar] [CrossRef]

- De-Deus, G.; Belladonna, F.G.; Zuolo, A.S.; Cavalcante, D.M.; Simões Carvalho, M.; Marinho, A.; Souza, E.M.; Lopes, R.T.; Silva, E. 3-dimensional ability assessment in removing root filling material from pair-matched oval-shaped canals using thermal-treated Instruments. J. Endod. 2019, 45, 1135–1141. [Google Scholar] [CrossRef]

- Fukumori, Y.; Nishijyo, M.; Tokita, D.; Miyara, K.; Ebihara, A.; Okiji, T. Comparative analysis of mechanical properties of differently tapered nickeltitanium endodontic rotary instruments. Dent. Mater. J. 2018, 37, 667–674. [Google Scholar] [CrossRef]

- Kyaw, M.S.; Ebihara, A.; Kasuga, Y.; Maki, K.; Kimura, S.; Htun, P.H.; Nakatsukasa, T.; Okiji, T. Influence of rotational speed on torque/force generation and shaping ability during root canal instrumentation of extracted teeth with continuous rotation and optimum torque reverse motion. Int. Endod. J. 2021, 54, 1614–1622. [Google Scholar] [CrossRef]

- Merima, B.; Ivona, B.; Dubravka, M.; Gianluca, P.; Ivica, A. Surface roughness and cyclic fatigue resistance of reciprocating and novel rotary instruments after use in curved root canals. Aust. Endod. J. 2022, in press. [Google Scholar] [CrossRef]

| Product | Size | Taper | Length | Alloy Type | Manufacturer |

|---|---|---|---|---|---|

| TruNatomy Prime | #26 | 4%, variable | 21 mm | Unknown heat treatment | Denstply Sirona, Ballaigues, Switzerland |

| XP-endo Shaper | #30 | 1% | 21 mm | Max-Wire | FKG Dentaire, La Chaux-de-Fonds, Switzerland |

| Spring Endo file unheated finish (Spring Endo) | #25 | Variable | 23 mm | Conventional | Denflex, Seoul, Republic of Korea |

| Spring Endo file heated finish (Spring H) | #25 | Variable | 23 mm | Gold wire | Denflex, Seoul, Republic of Korea |

| TruNatomy Prime | XP-Endo Shaper | Spring Endo | Spring H | |

|---|---|---|---|---|

| Bending resistance (Ncm) | 0.125 ± 0.026 a | 0.106 ± 0.016 a | 0.544 ± 0.063 b | 0.643 ± 0.074 c |

| Buckling resistance (gf) | 226.34 ± 23.69 b | 103.99 ± 17.64 a | 599.28 ± 86.16 c | 614.35 ± 97.51 c |

| NCF | 712.81 ± 54.49 b | 5344.46 ± 665.86 c | 376.04 ± 60.11 a | 433.20 ± 52.34 a |

| UTS (Ncm) | 0.540 ± 0.090 a | 0.471 ± 0.037 a | 1.019 ± 0.135 b | 1.217 ± 0.192 b |

| ARF (degrees) | 654.71 ± 83.14 c | 1834.09 ± 176.82 d | 417.41 ± 42.94 a | 515.33 ± 62.85 b |

| EM (Ncm/degrees) | 0.00149 ± 0.00022 b | 0.00056 ± 0.00006 a | 0.00961 ± 0.00089 d | 0.00597 ± 0.00048 c |

| Pearson Correlation Analysis | |||

|---|---|---|---|

| Coefficient | p-Value | ||

| Bending resistance | Buckling resistance | 0.930 * | <0.001 |

| NCF | –0.621 * | <0.001 | |

| UTS | 0.932 | <0.001 | |

| ARF | –0.664 * | <0.001 | |

| EM | 0.848 * | <0.001 | |

| Buckling resistance | NCF | –0.723 * | <0.001 |

| UTS | 0.907 | <0.001 | |

| ARF | –0.774 * | 0.001 | |

| EM | 0.897 * | <0.001 | |

| NCF | UTS | –0.616 * | <0.001 |

| ARF | 0.961 | <0.001 | |

| EM | –0.642 * | <0.001 | |

| ARF | UTS | –0.656 * | <0.001 |

| TruNatomy Prime | XP-Endo Shaper | Spring Endo | Spring H | |

|---|---|---|---|---|

| Maximum clockwise torque (Ncm) | 0.171 ± 0.044 a | 1.543 ± 0.129 c | 0.978 ± 0.295 b | 1.773 ± 0.728 c |

| Maximum screw-in force (gf) | 66.42 ± 30.10 a | 157.30 ± 12.90 b | 499.65 ± 185.48 c | 661.32 ± 199.82 c |

| Mass of resin blocks after shaping (gm) | 3.4188 ± 0.0050 b | 3.4118 ± 0.0052 a | 3.4201 ± 0.0036 b | 3.4202 ± 0.0052 b |

| Cooling | Heating | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Rs (°C) | Rf (°C) | ΔH (J/g) | Ms (°C) | Mf (°C) | ΔH (J/g) | As (°C) | Af (°C) | ΔH (J/g) | |

| TruNatomy Prime | 25.52 | 17.86 | 3.83 | –37.84 | –59.62 | 13.64 | 16.73 | 30.77 | 17.19 |

| XP-endo Shaper | 29.51 | 21.53 | 4.28 | –38.76 | –77.70 | 10.32 | 30.02 | 38.46 | 15.98 |

| Spring Endo | 17.61 | –5.17 | 1.58 | 0.71 | 29.33 | 2.95 | |||

| Spring H | 43.15 | 28.13 | 3.05 | 34.61 | 52.13 | 3.51 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, S.; Jeon, B.-K.; Chang, S.W. Mechanical Properties and Torque/Force Generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1. Appl. Sci. 2022, 12, 10393. https://doi.org/10.3390/app122010393

Oh S, Jeon B-K, Chang SW. Mechanical Properties and Torque/Force Generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1. Applied Sciences. 2022; 12(20):10393. https://doi.org/10.3390/app122010393

Chicago/Turabian StyleOh, Soram, Bong-Ki Jeon, and Seok Woo Chang. 2022. "Mechanical Properties and Torque/Force Generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1" Applied Sciences 12, no. 20: 10393. https://doi.org/10.3390/app122010393

APA StyleOh, S., Jeon, B.-K., & Chang, S. W. (2022). Mechanical Properties and Torque/Force Generation of XP-Endo Shaper, Trunatomy, Spring Endo File, and Spring Endo Heated Finish File, Part 1. Applied Sciences, 12(20), 10393. https://doi.org/10.3390/app122010393