This section presents the simulation results and elaborates on the power-based analysis. The power imbalance error is analyzed, and suggestions for performing the power-based analysis are provided accordingly. The power conversion processes for the two cases of the wing body configuration and the BLI configuration are presented and discussed.

3.1. The Analysis of Power Imbalance Error

Power imbalance error indicates how well mechanical energy conservation is satisfied in a computational domain. This section discusses the error in the 3D flow field of the DLR-F6 wing body configuration. Efforts were made to reduce this error in simulations.

3.1.1. Mesh Size Study and Subdomain Error Study

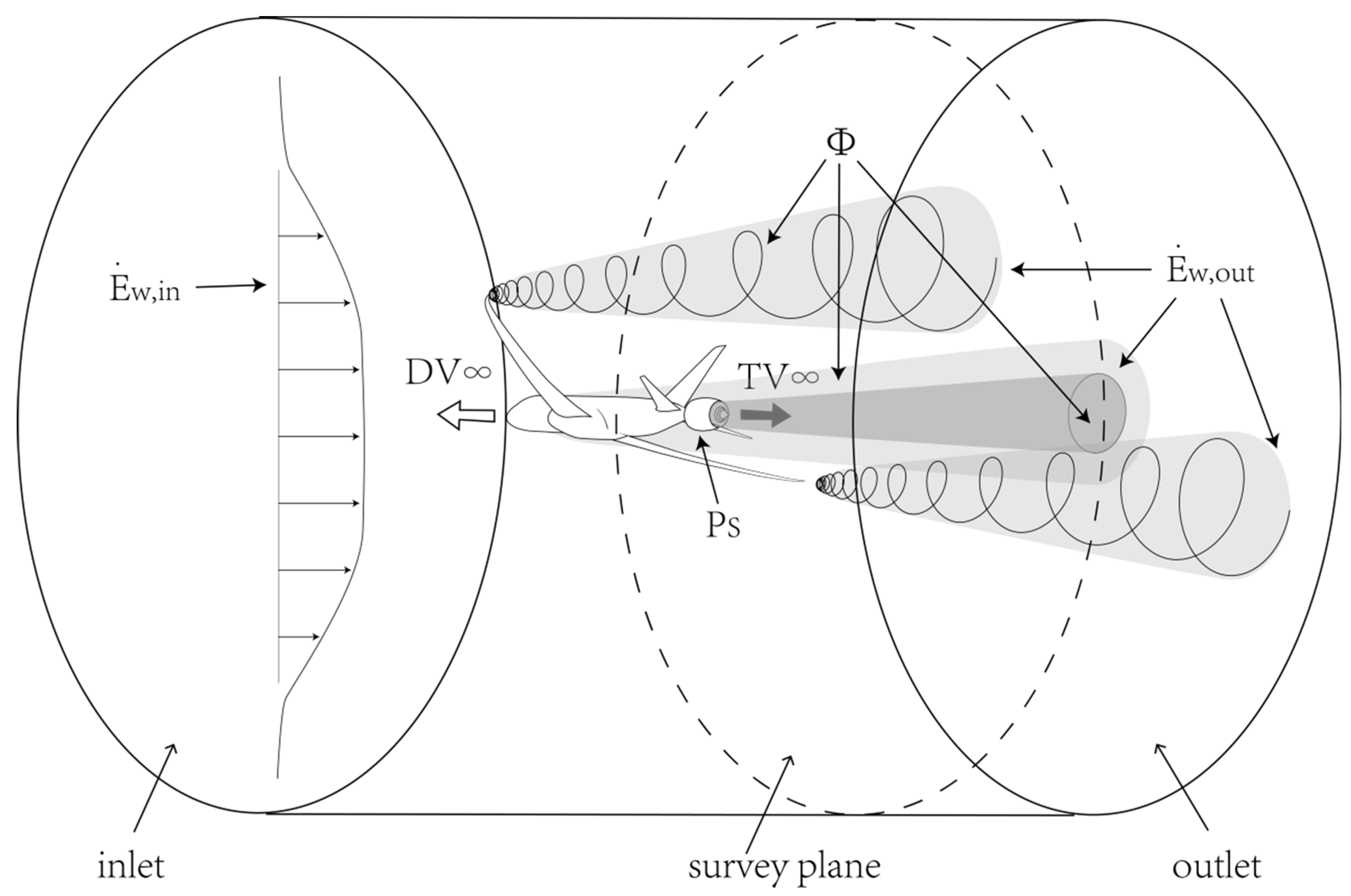

This section presents the power imbalance error of the entire computational domain. In the first place, all the power input and output terms listed in

Table 1 were evaluated. For the wing body configuration, the only power input term is the drag power, DV

∞, while the output terms are the wake power at the outlet plane,

w,out, and the viscous dissipation, Φ. Once the 3D flow field was obtained through numerical simulations, these power terms were evaluated according to their expressions, as given in

Section 2.1. The power imbalance error of the entire computational domain,

edomain, was assessed according to Equation (13). The input power, DV

∞, is used as the reference power to calculate the relative error of

edomain.

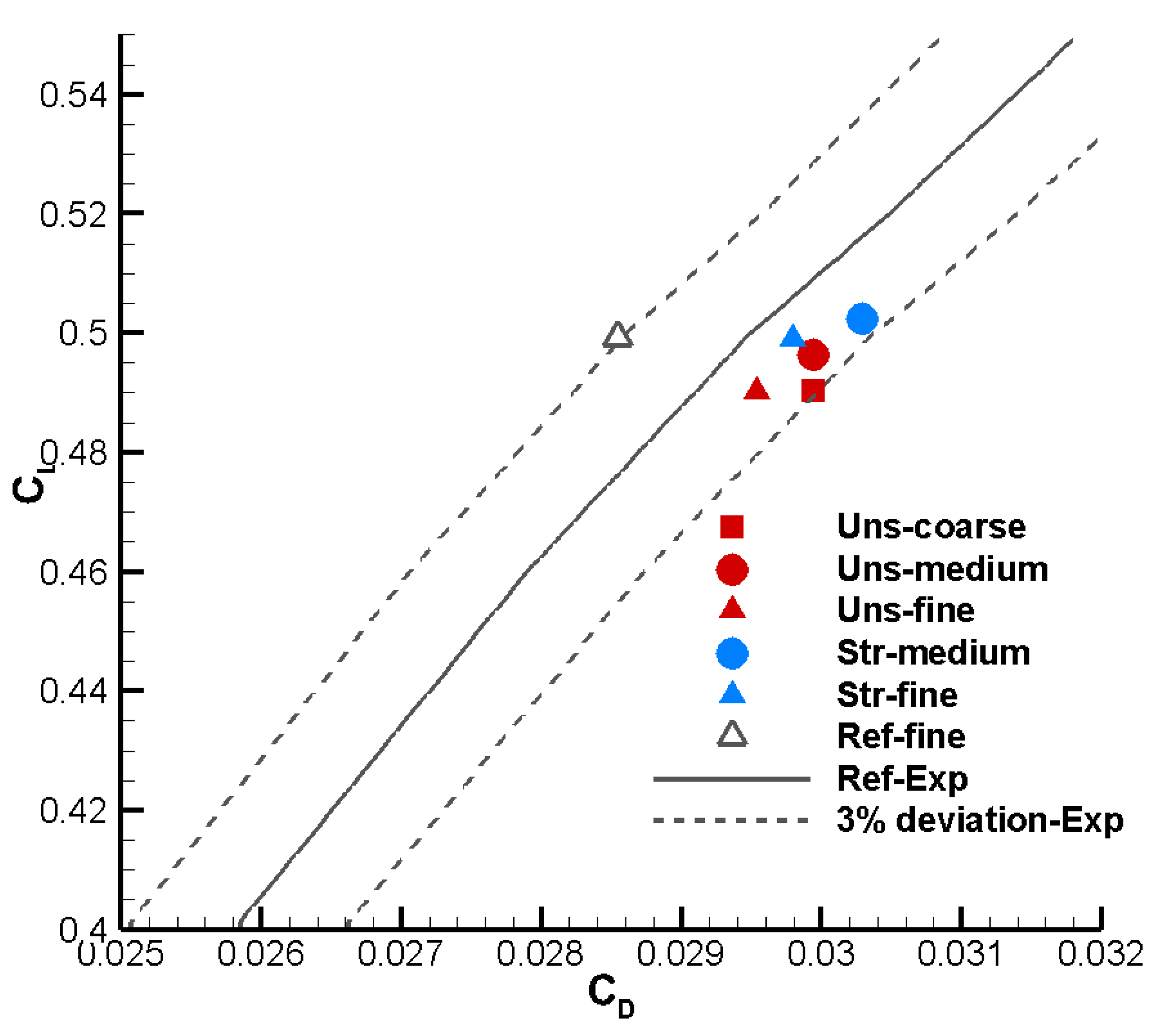

A mesh size study is presented in

Table 5. It shows that the relative differences in drag coefficient (with respect to the experiment result) were less than 3%. The aircraft drag was independent of the mesh size and its value agreed well with the experimental results. On the other hand, the value of

edomain ranged from 36.4% to 66.3%. Even though

edomain tended to decrease as mesh size increased, the errors obtained in the presented 3D simulation were much higher than the 4% value obtained in the previous incompressible 2D simulations [

23]. In general, the error in 3D flow simulation was far from a satisfactory level. It is critical to identify the main courses of the high value of

edomain.

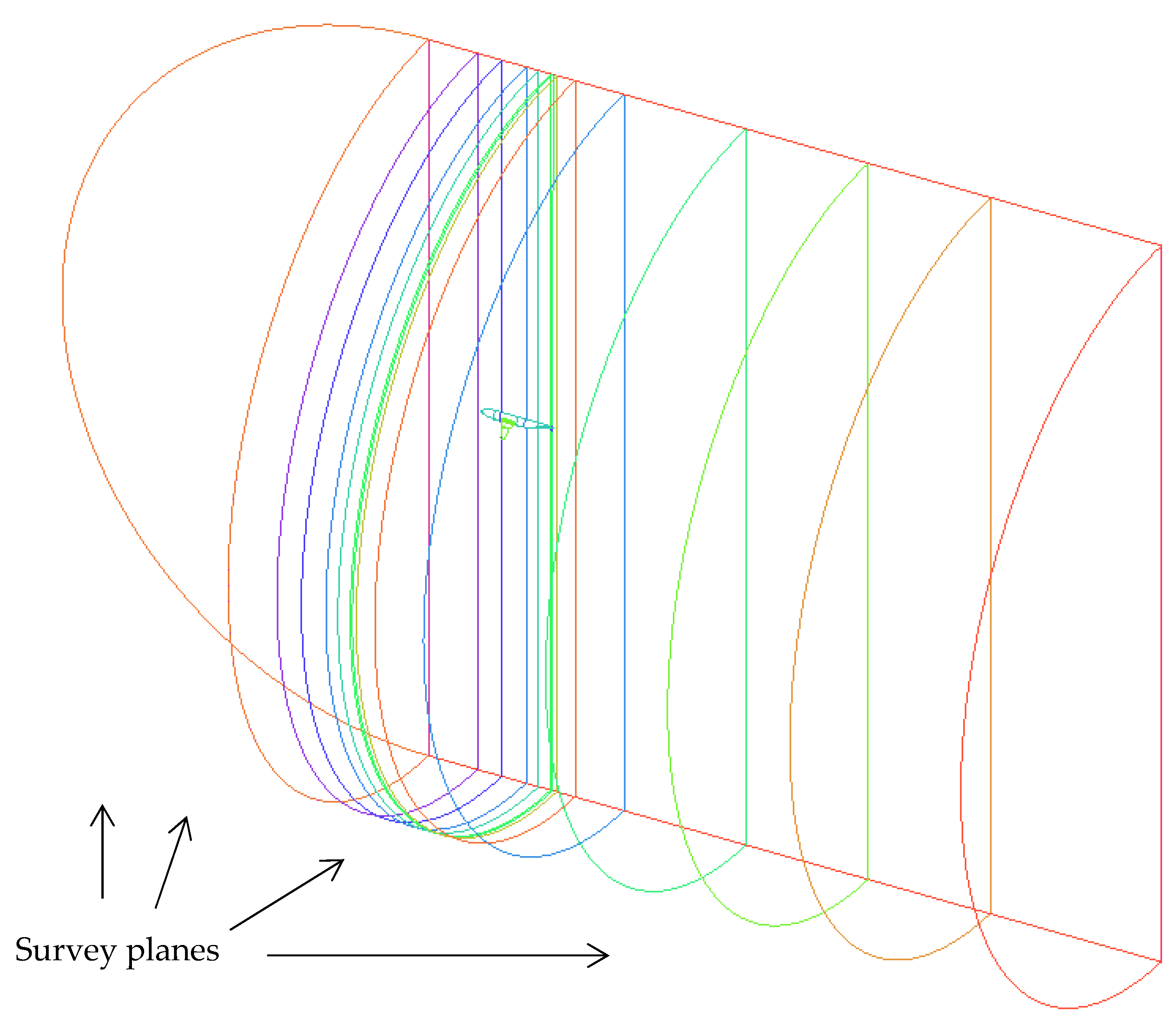

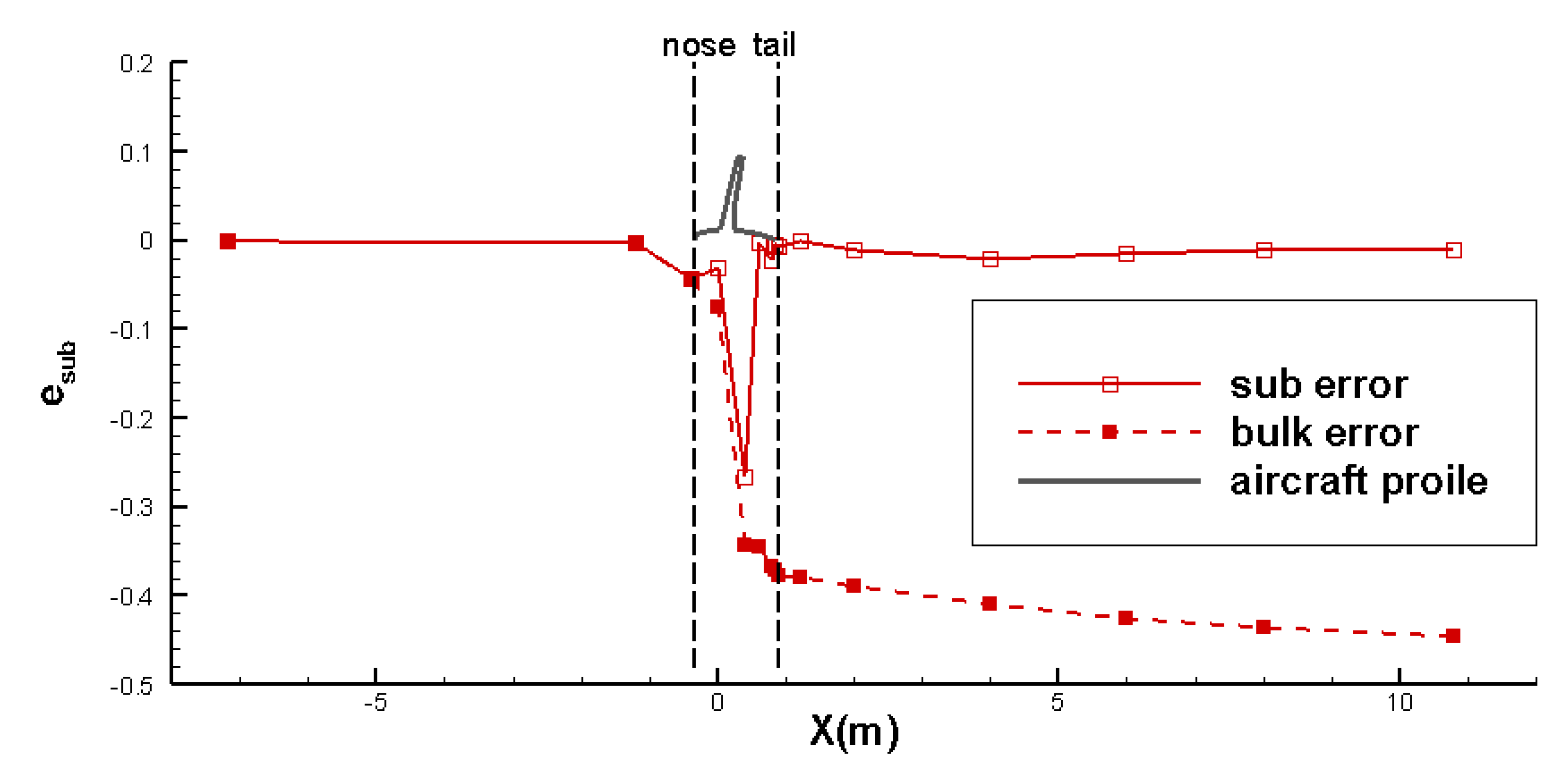

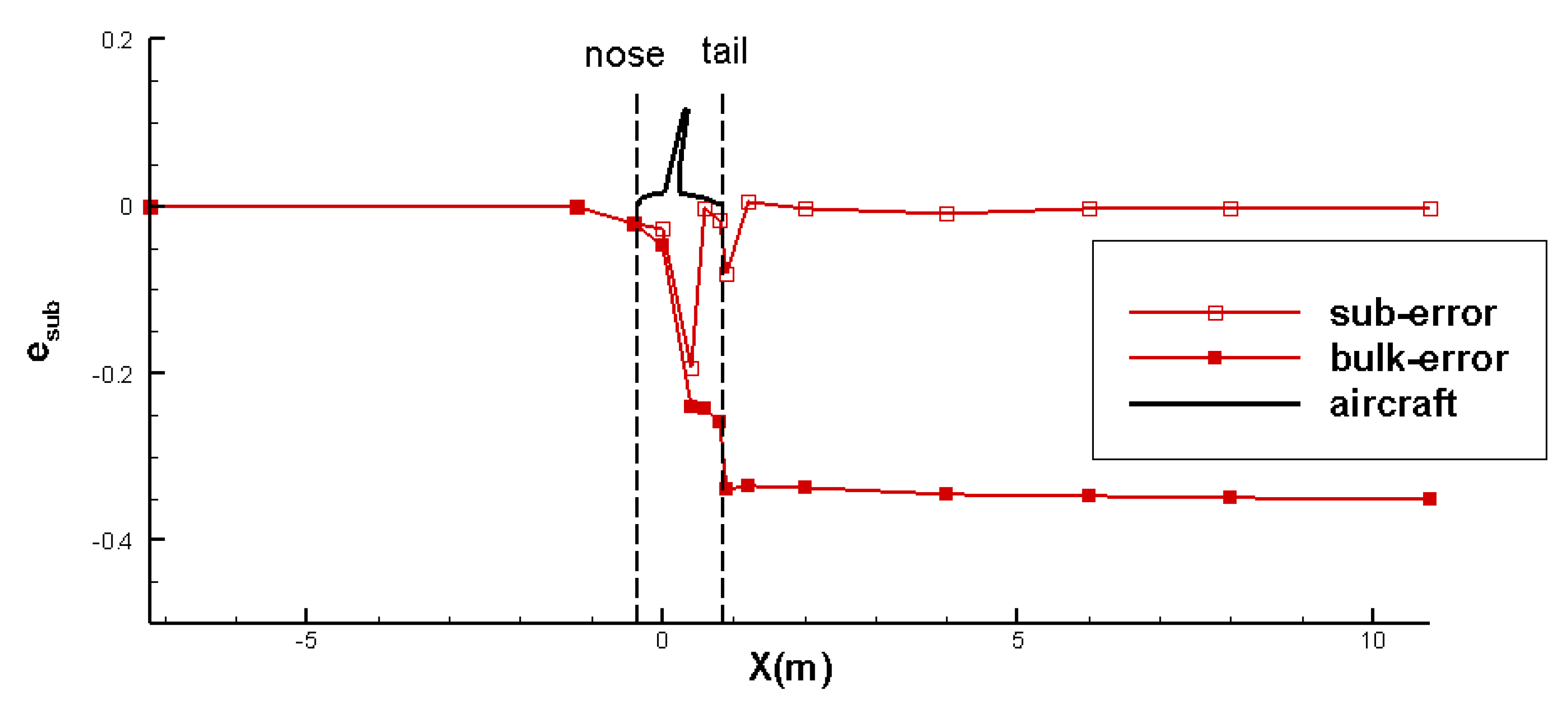

To find the major sources of power imbalance error,

edomain, this section introduces a so-called subdomain error study. As introduced in

Section 2.4, it is possible to inspect the power imbalance for an individual subdomain. In this study, all the power terms listed in

Table 1 were assessed for the individual subdomains. With these inputs, the errors of the power imbalance for the individual subdomains,

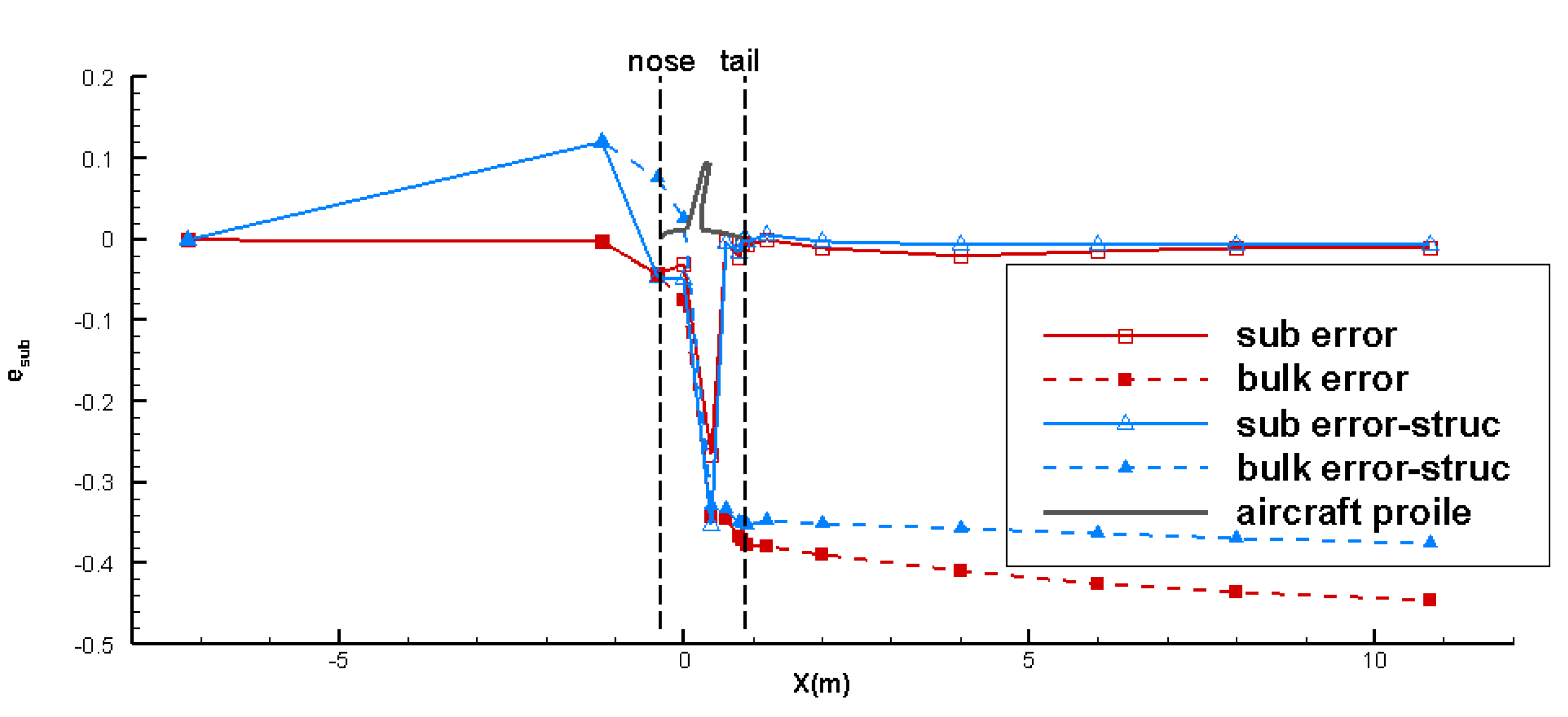

esub, were computed according to Equation (14). For demonstration purposes, the results of the unstructured medium mesh are presented. The errors were plotted at the corresponding X location of the survey planes, as shown in

Figure 10. The suberror denotes the error of an individual subdomain, while the bulk-error is defined as the accumulation of the suberrors from the first subdomain to the subdomain at the X location. This bulk error depicts how the error increases along the X axis. It is noted that the bulk error at the outlet plane simply equals

edomain.

This subdomain error study clearly showed that the error in the subdomain of the wing (denoted by ewing) made the major contribution to edomian. The ewing value was 26.8%, while edomain was 43.0%. The contributions of the other subdomains were significantly low: The suberror for the frontal body was less than 5%. The suberror in the downstream region was less than 0.5%. The error associated with the wing, ewing, was mainly responsible for the high errors of edomain. This study suggests that efforts should be made to reduce the suberror associated with the wing, ewing.

3.1.2. Impact Factors of Power Imbalance Error

This section presents possible impact factors to reduce edomain. The influences of the mesh type, discretization scheme, and turbulence model are examined. Considering that the error associated with the wing, ewing, makes the major contribution to edomain, the subdomain of the wing is highlighted.

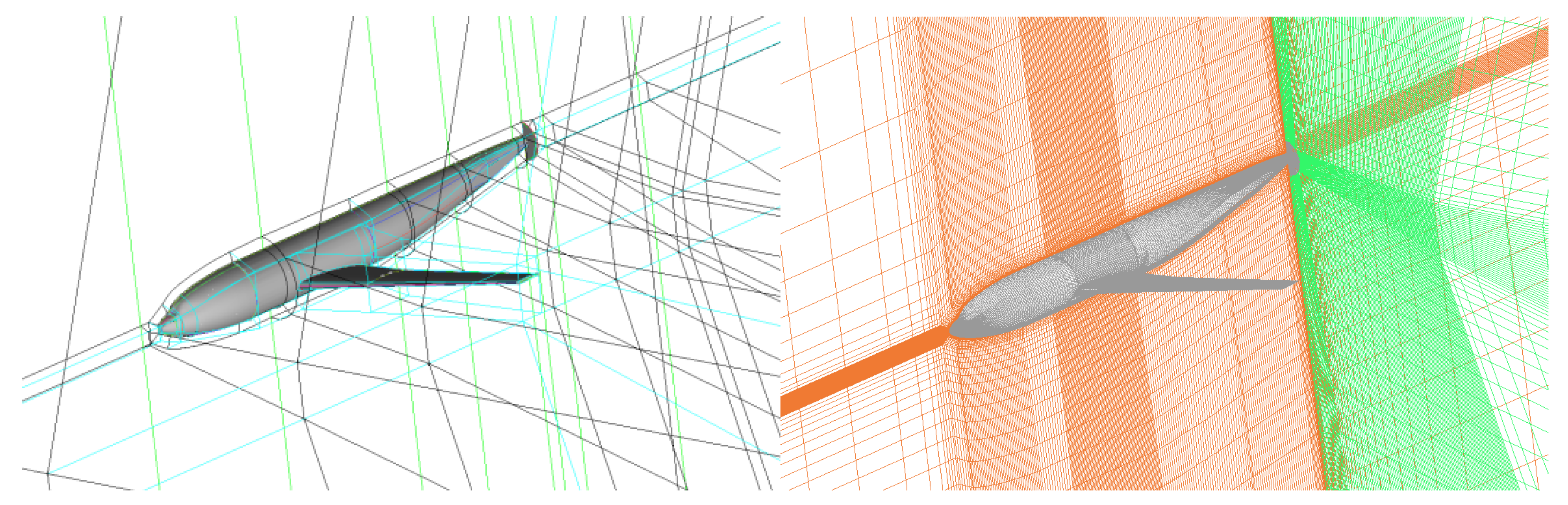

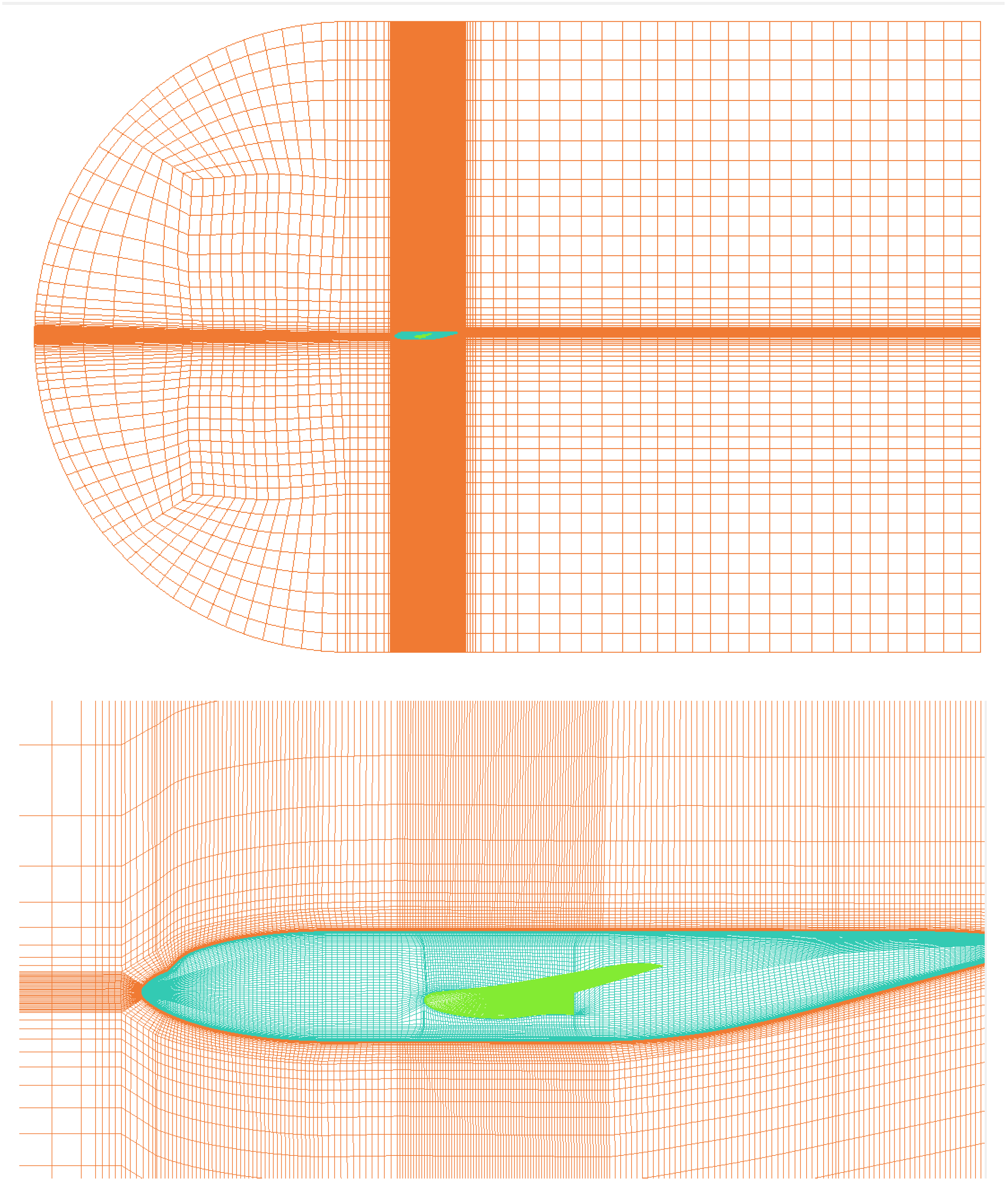

As introduced in

Section 2.3, both structured mesh and unstructured mesh were generated. The mesh sizes of the two were close: 4.1 million for the unstructured medium mesh and 5.1 million for the structured medium mesh. It was straightforward to perform the subdomain error study with their simulation results, as presented in

Figure 11. It showed the same error contributions for the two types of mesh: high-value error existed in the subdomain of the wing, which was mainly responsible for the high values of

edomain. The structured mesh indeed reduced the error in the wake region (less than 1%). Nevertheless, the error associated with the wing,

ewing (35.4%), was higher than that of the unstructured mesh (26.8%). The errors of

edomain and

ewing are summarized in

Table 6. Even if the structured mesh obtained relatively low values of

edomain, it did not offer a better result in terms of

ewing, the major error source. This study adopts the unstructured medium mesh as the reference mesh in the following discussions.

In CFD simulations, discretization methods interpolate conservative independent variables. On the other hand, interpolation causes discretization error as an important source of numerical errors. This study tested two methods for comparison: the second-order upwind and the third-order MUSCL methods. The former method is widely used, and the latter method provides higher-order precision. A first-order discretization method is not discussed due to the low order precision. A subdomain error study was performed to check the impact of the discretization methods on the reference mesh. The results are listed in

Table 7. The results showed that the reduction in

ewing due to the third-order MUSCL method was about 4.5%. Furthermore, the high-order discretization method reduced

ewing without increasing the error of other subdomains. Therefore, the high-order discretization method is suggested for power-based analysis.

A turbulent model introduces complexity to simulations, and the impact of turbulent models was examined. This study examined three typical models: the S-A model, the standard k-ε model, and the k-ω SST model. The simulations employed the same reference mesh (unstructured medium mesh) and third-order MUSCL method discretization to eliminate the effects of the other impact factors. The results of the subdomain error study are listed in

Table 8. It showed that the absolute value of

edomain ranged from 38.5% to 40.9%. The two-equation k-ω SST model led to the minimum level of power imbalance error.

As discussed in

Section 3.1.1, the mesh size study showed that an increase in mesh size tended to decrease

edomain. It might be beneficial to increase the mesh density in the subdomain of the wing. Based on the reference mesh (Unstructured medium mesh), the mesh density was increased universally over the wing surface. The total mesh size was increased accordingly from 4.1 million to about 8.0 million. This refinement of the mesh led to the reduction in

edomain from 38.5% to 36.6%, while

ewing was reduced from 22.3% to 22.0%. The increase in the mesh density of the wing reduced the power imbalance error by 2% at the cost of the doubled mesh size. Compared with the results of the unstructured fine mesh (8.2 million), the universal increase in mesh density over the wing surface did not provide an extra benefit.

A more efficient way to increase the mesh density was examined through the mesh adaptation technique. Based on the reference mesh, the mesh density was increased in the regions with the high gradient of wake power, w, After mesh adaptation, the total cell number increased from 4 million to about 8 million. The results showed that the edomain was reduced from 38.5% to 34.1% and ewing was reduced from 22.3% to 17.6%. The mesh density was mainly increased in the outer region of the boundary layer of the wing surface and in the vicinity of the trailing edge. This effort led to a notable improvement compared with the results of the unstructured fine mesh. The mesh adaptation obtained the best result for edomain (34.1%) in this study.

In summary, the study of impact factors showed that a multiblock structured mesh obtained less total power imbalance error than the unstructured mesh, especially in the wake region. The high-order discretization method was beneficial in reducing the error. The impact of the turbulent model was marginal. Increasing the mesh density in the outer region of the wing boundary layer could reduce the power imbalance error. In the best scenario, edomain was 34.1% and ewing was 17.6% for the wing body configuration. These results are used in the following discussions.

3.2. Power Conversion of Wing Body Configuration

This section aims to illustrate the mechanical power conversion process of the wing body configuration. All power terms listed in

Table 1 in the flow field were assessed. For the wing body configuration, the wake energy inflow (rate),

w,in, for the entire computational domain was zero due to the free stream flow inflow. Shaft power, P

s, was not involved in this case. The only mechanical power input was the drag power, DV

∞, and it was used as the reference power for the normalization of power terms in this case.

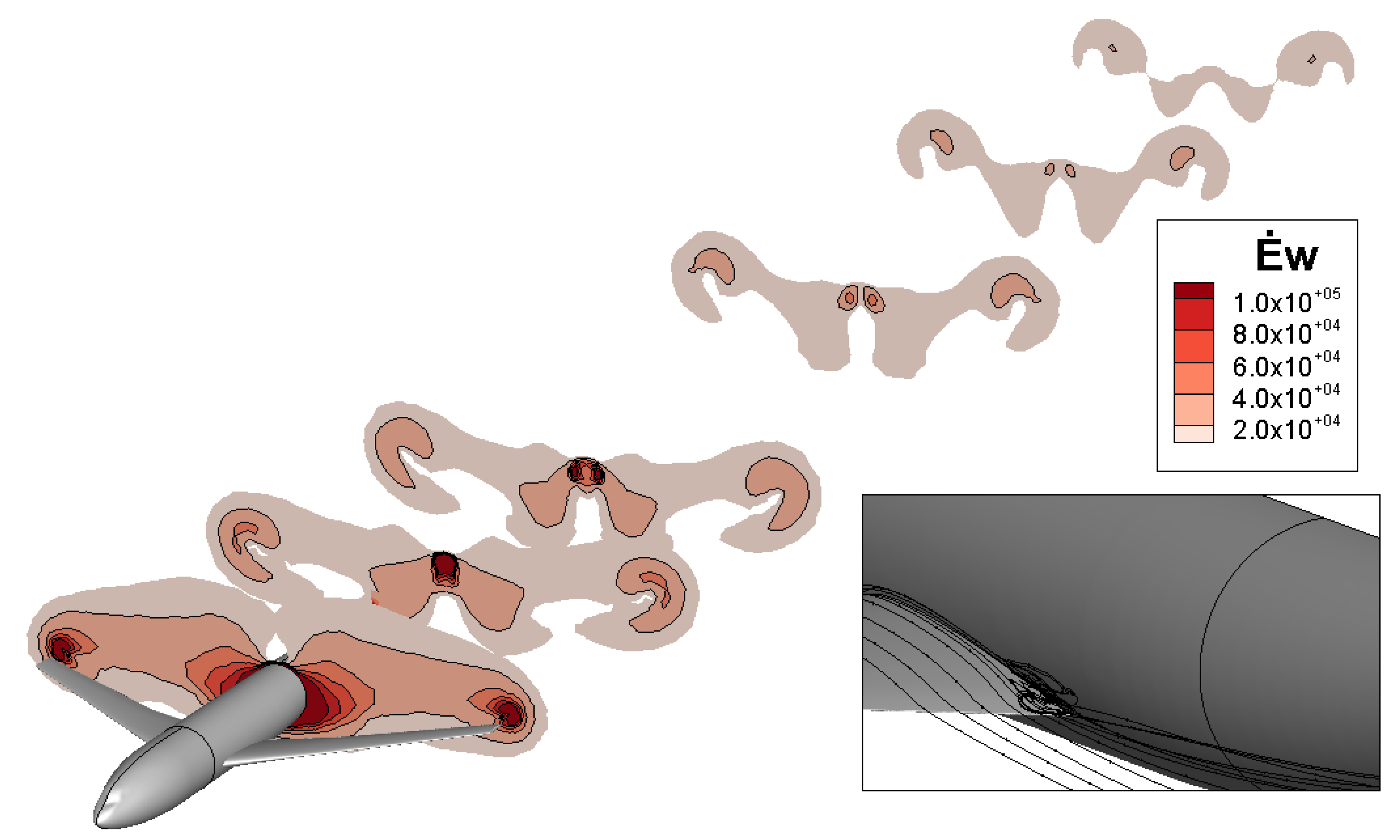

The output power terms of the wing body configuration include the wake energy flow (rate),

w, and viscous dissipation, Φ.

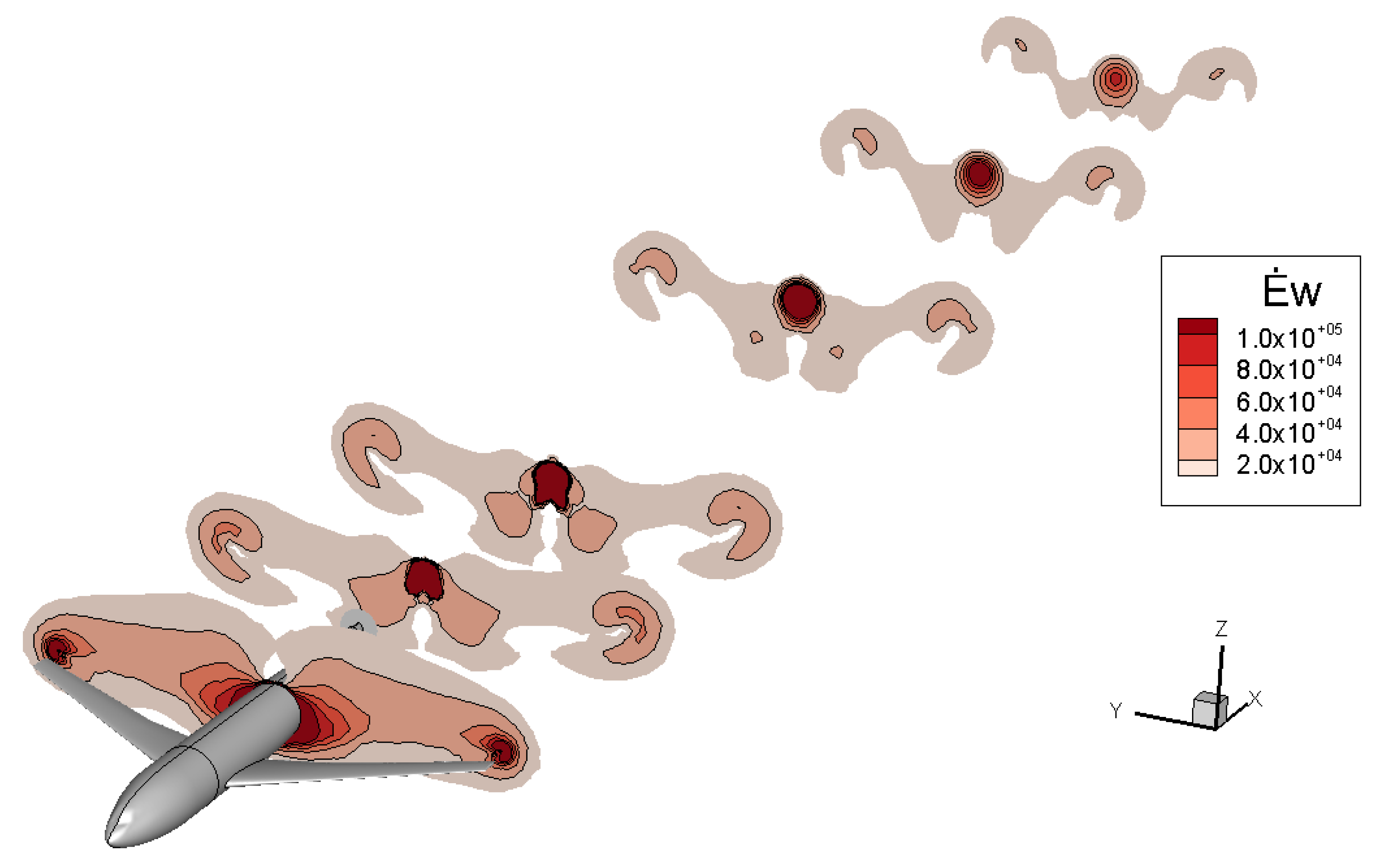

w was assessed at the survey planes and the outlet plane. The integrand of the wake power,

w, was visualized at the survey planes, as shown in

Figure 12. This figure visualizes the wake power passing through the aircraft and in the downstream flow. Crossing the aircraft, the high-intensity wake power over the body surface is highlighted. This region was thicker than the boundary layer of the body, and it was associated with the wake of the wing root. The original design of the DLR-F6 geometry suffers flow separation issues at the body–wing junction [

29], as shown on the bottom right of

Figure 12. High-intensity

w was also observed in the vicinity of the wing tip, denoting the high wake power of the wing tip vortices. In the downstream region, the intensity of the wake power gradually reduced, and the area of high wake power separated into two parts: the one corresponding to the body wake and the one for wing tip vortices.

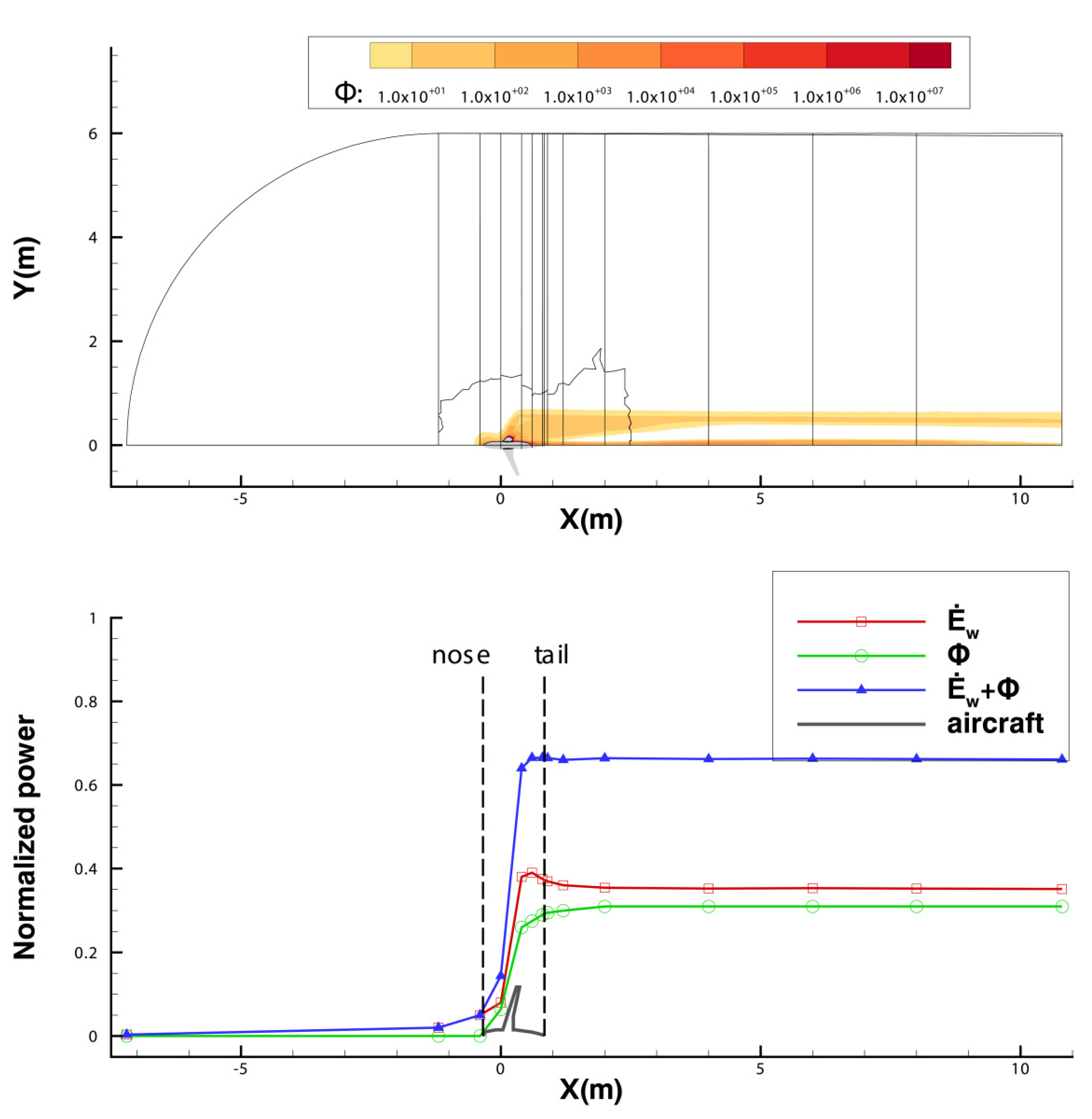

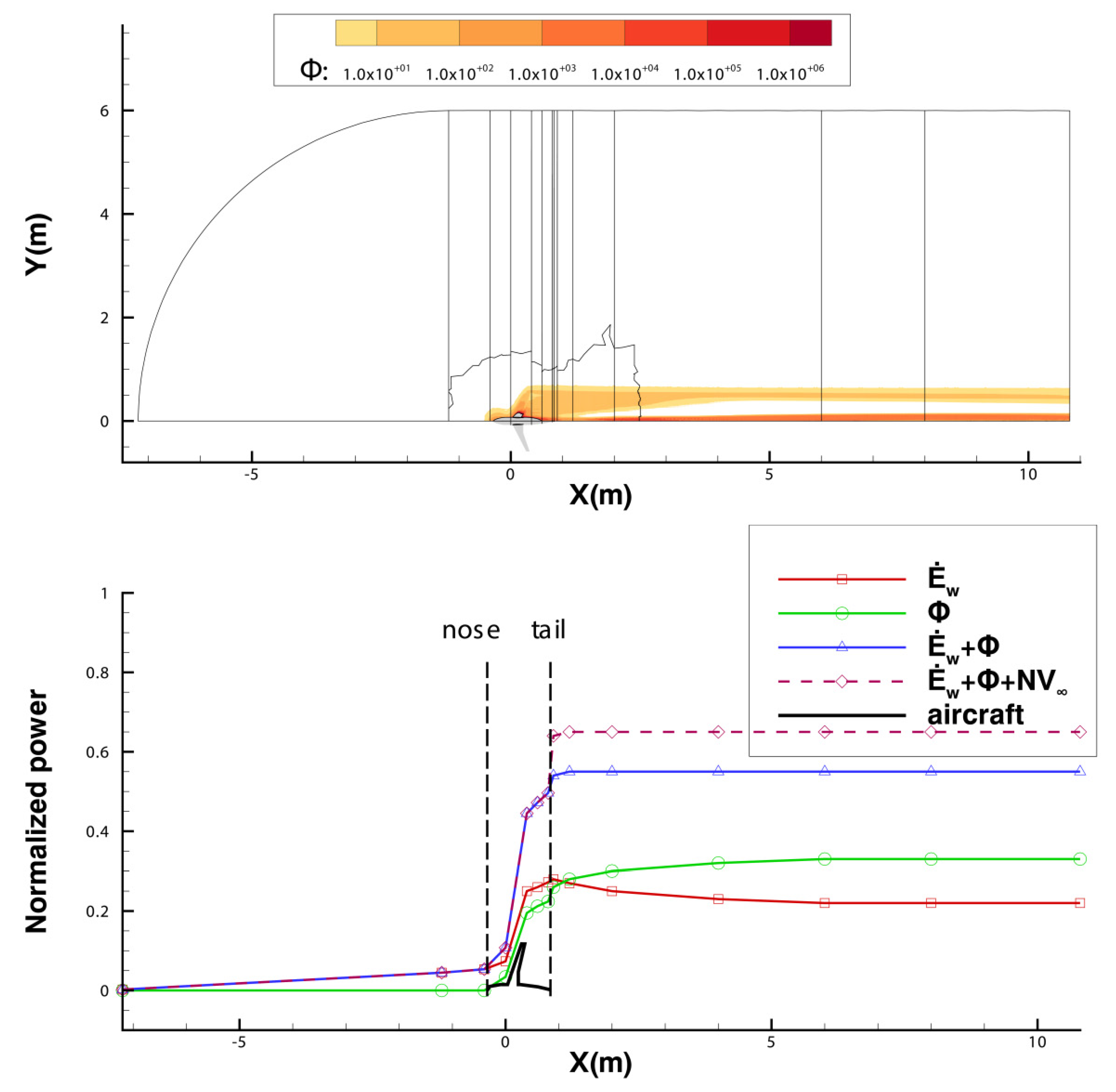

Viscous dissipation, Φ, is the sink term of power. As elaborated in

Section 2.1, it exists in the viscous region (boundary layer and wake) where the velocity gradient exists. The top plot in

Figure 13 illustrates the integrand of the viscous dissipation in the flow field. A high intensity of Φ was observed in the region over the airframe surface and in the downstream wake. In the downstream wake, the intensity of Φ in the body wake was higher than that of the wing wake. Compared with the wing wake, the body wake might be less stable, and its mechanical energy dissipated at a faster pace.

This study visualized the change in power terms by placing their values at the corresponding X coordinates, as shown at the bottom of

Figure 13. This plot illustrates how the power conversion process occurred in the flow field: drag power, DV

∞, was transferred into wake power,

w, as well as viscous dissipation, Φ.

The wake power,

w, increased quickly after the nose, reaching the peak value (37% of the total power input) after the wing. After that, it dropped quickly after the tail and decreased slowly downstream. The abrupt increase in

w was the result of mechanical power accumulation due to the boundary layer, the separated flow in the body–wing junction, and the wing tip vortices. The mild decrease in

w downstream of the fuselage corresponded to the dissipation of the aircraft wake. At the outlet plane,

w remained 35% of the total power input, indicating a substantial amount of mechanical power in the aircraft wake, as shown in

Figure 12.

Viscous dissipation, Φ, remained almost zero before the aircraft nose, mildly increased along the frontal fuselage, and quickly increased through the wing region. In general, it kept increasing from the nose to the tail. At the X locus of the tail, Φ took about 31% of the total power input, mainly corresponding to the mechanical power loss associated with the boundary layer of the aircraft surface, while in the downstream region, the increase in Φ was less than 2%, indicating a relatively slow process of dissipation in the downstream wake. It was noted that the power input was about 34.1% higher than the summation of the output power at the outlet plane. The difference was the error of the mechanical power imbalance, as discussed in

Section 3.1. The error in this 3D simulation was significantly higher than the 4% value in the previous study of 2D turbulent flow simulation [

23].

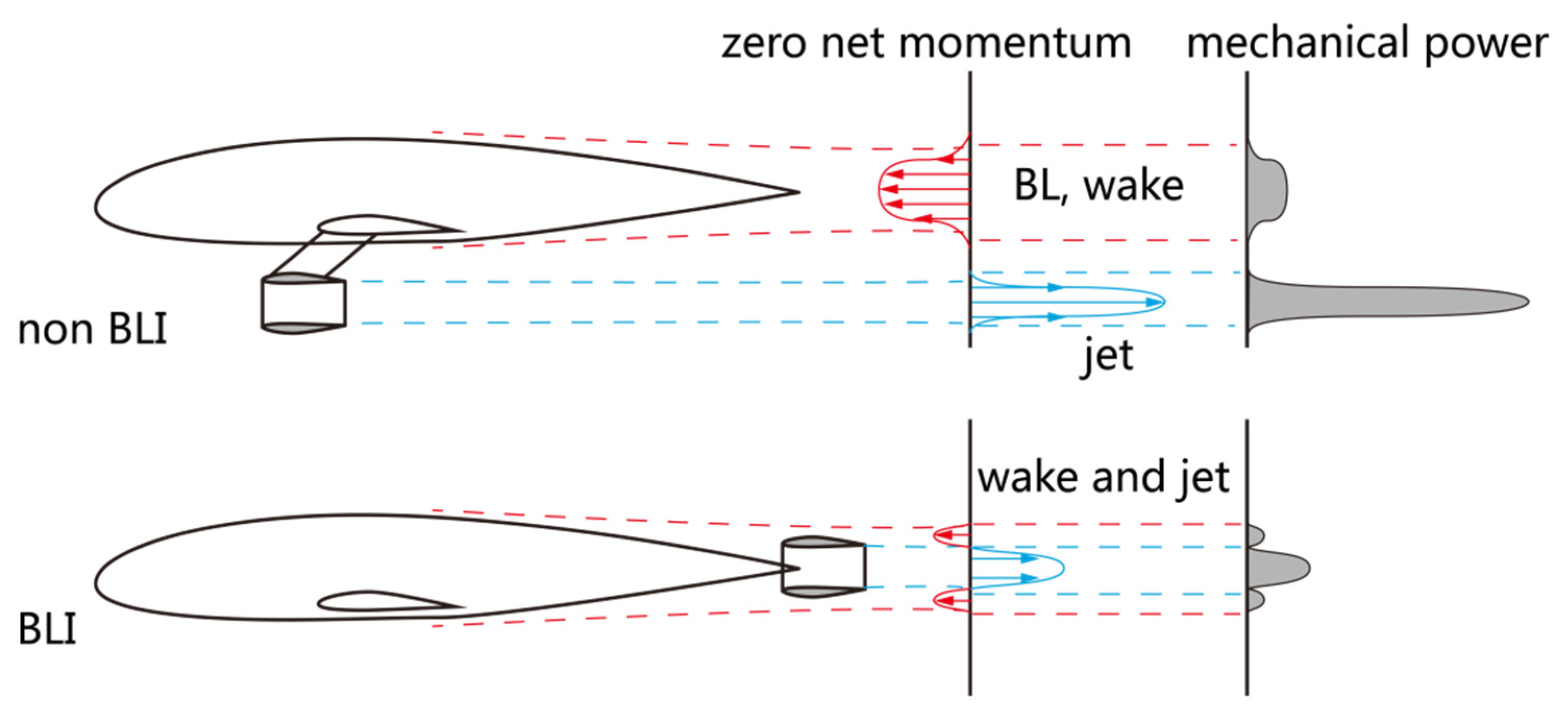

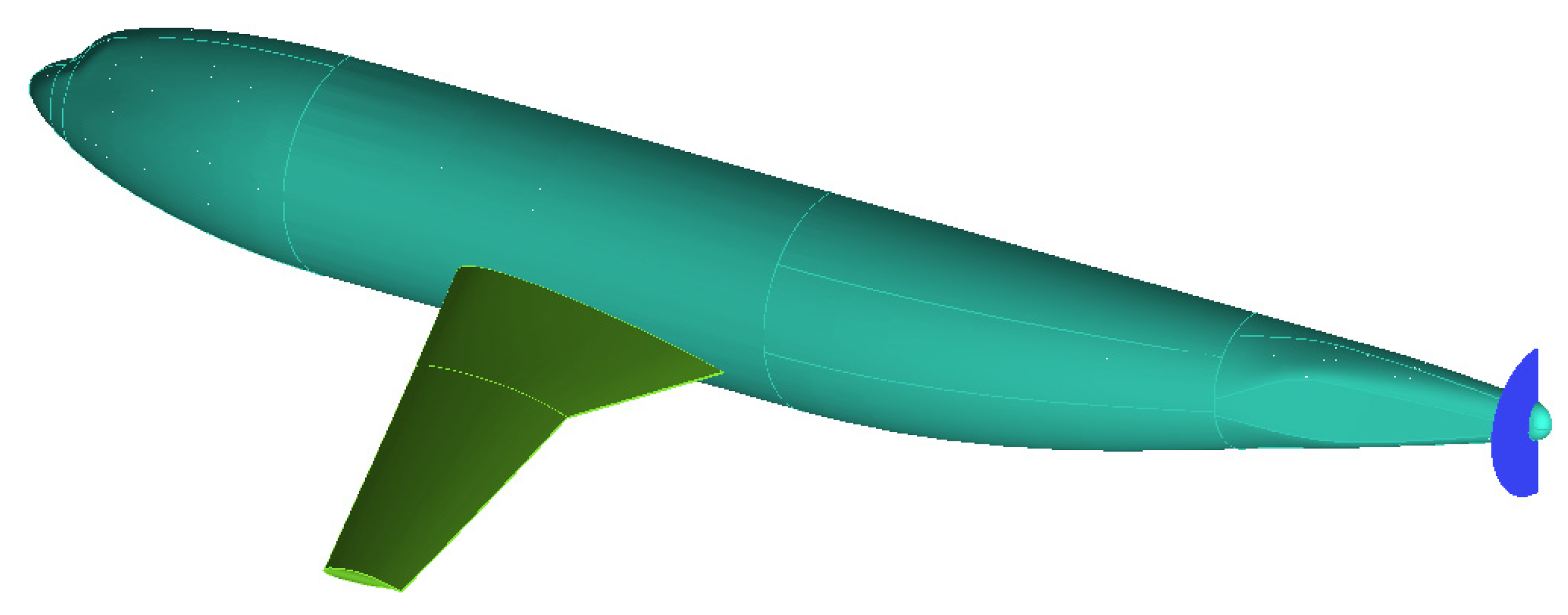

3.3. Power Conversion of Boundary Layer Ingestion Configuration

Various sources in the previous study on BLI showed that the value of power saving due to BLI is in the range of 3~10%. On the other hand, the error of mechanical power imbalance is about 30%. The precision of power-based analysis in 3D simulation is not adequate to study the power saving of BLI. This section limits the discussion to the aspect of the power conversion process of the aircraft using BLI.

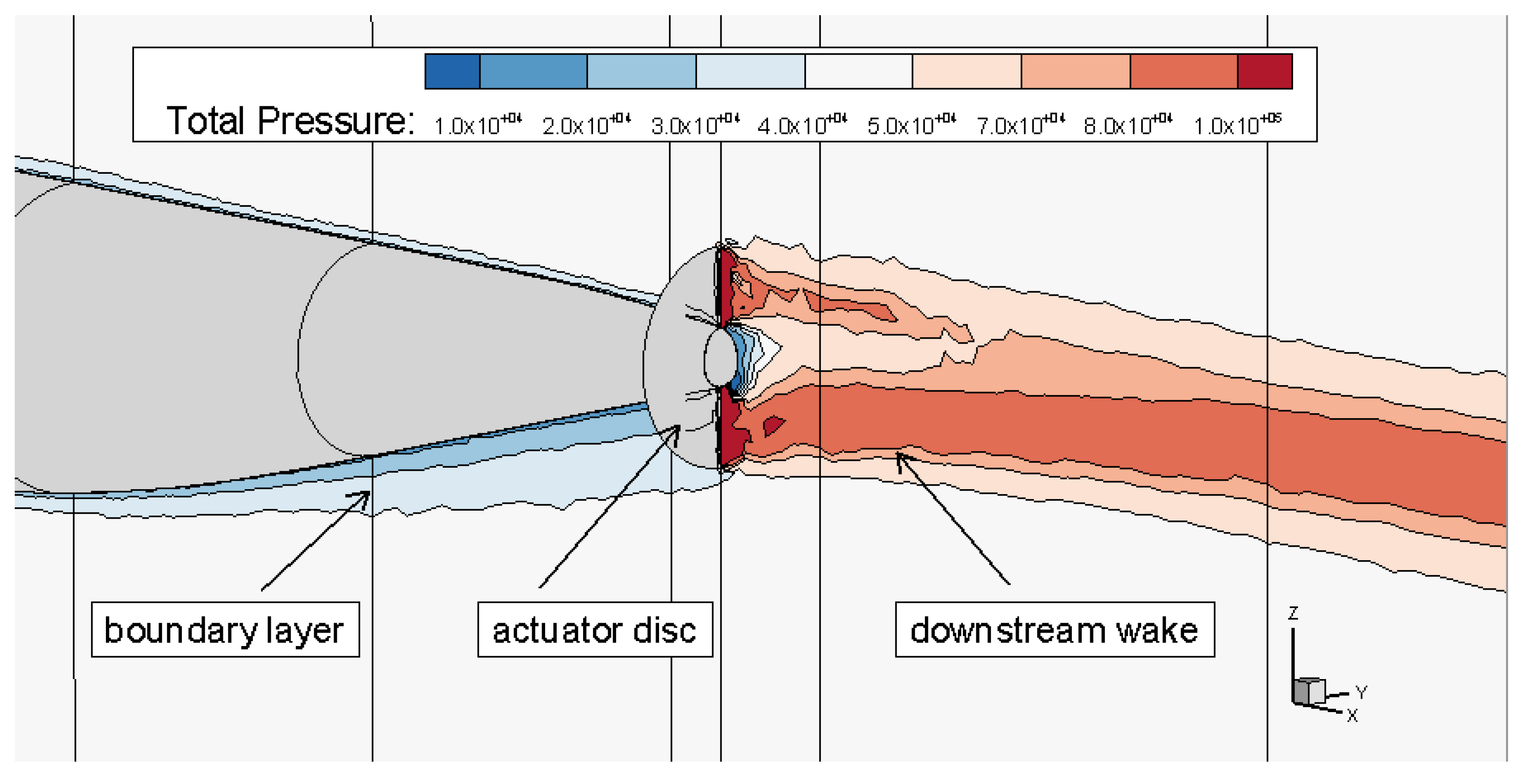

The BLI configuration combines the wing body configuration with a BLI propulsor. This study employed a wake-filling actuator disc model with a nonuniform pressure jump to mimic an ideal BLI propulsor [

13,

31]. This model re-energized the ingested boundary layer flow into the state of free stream so that the mechanical energy of the downstream wake and jet was minimized. The actuator disc model utilized a UDF function, which increased the total pressure of the ingested flow into a constant total pressure, P

t,const. In this case the P

t,const value was 46,000 Pascal, higher than the free stream total pressure. In this manner, the thrust, T, generated by the actuator disc model was higher than the airframe drag, D. The UDF function enabled a nonuniform pressure jump ΔP, which was simply equal to P

t,const-P

t,upstream. P

t,upstream refers to the total pressure of the upstream flow. The thrust of this actuator disc model, T, was obtained as the surface integral of ΔP over the disc plane, as given in Equation (16). The T value was 116 N, so the TV

∞ value of 30,232 watts was obtained. It was noted that TV

∞ was considered a power output term, while the actual power input of the propulsor was shaft power, P

s, which was evaluated using Equation (7). In this BLI case, the P

s value was 54,793 watts and was used as the reference value for normalizing the power terms.

Figure 14 shows the total pressure distribution at the symmetry plane in the vicinity of the actuator disc model. The boundary layer of the body is denoted by the contours of low-valued total pressure over the body surface. It was noted that the boundary layer over the bottom surface was thicker than that over the top surface. This was attributed to the non-axisymmetric pressure diffusion of the aft body shape. The total pressure was not uniform in the region behind the actuator disc model. Therefore, the actuator disc model was not capable of refilling the total pressure in an ideal manner. This could be attributed to the highly distorted flow ingested by the actuator disc. This study suggests that the aft body should be axisymmetric to best utilize the BLI benefit.

Aircraft drag, D, is the drag force imposed on the wing and body surface. The drag coefficient was 0.03290 in the BLI configuration. That was about 8% higher than the value in the wing body configuration. The increase in drag was due to the suction of the actuator disc model imposed on the aft body. The drag power, DV∞, is obtained by multiplying D by V∞ as a power input of the flow field.

As discussed, the wake energy flow,

w, was assessed as the surface integral over the survey planes and the outlet plane. The integrand of

w is illustrated in

Figure 15. Compared with the pattern in the case of the wing body configuration. The pattern in the BLI case is similar: the wake power accumulated as the flow passed through the aircraft and gradually reduced in the downstream region. Compared with the wing body configuration, a notable difference for the BLI configuration was the high intensity of

w in the downstream flow of the actuator disc. The downstream wake power was increased rather than decreased in this configuration. This was associated with the excessive high-momentum addition of the actuator disc: the thrust not only balanced the body drag but also overcame the wing drag.

The top picture of

Figure 16 illustrates the intensity of Φ in the flow field. The high intensity of Φ is highlighted around the airframe surface and in the aircraft’s downstream region. Once all of the power inputs and outputs terms in the flow field were calculated, they were normalized and plotted at the corresponding X coordinates, as shown in

Figure 16. This figure illustrates the power conversion process of the BLI configuration with a propulsor. It shares a similar pattern to that of the wing body configuration.

The bottom plot in

Figure 16 illustrates the power conversion process of the BLI configuration. The shaft power, P

s, as the only power input in the flow field, was implanted in the flow field by the propulsor. P

s was converted into viscous dissipation, Φ, and wake power at the outlet plane,

w,out, as well as the net force power, NV

∞.

The viscous dissipation, Φ, increased along the stream and shared a similar pattern as in the wing body configuration. It increased quickly over the aircraft surface, taking about 28% of the total power input at the body tail. Then, Φ increased by 5% in the downstream region. Besides the viscous dissipation of the aircraft wake, the increase in Φ in the downstream region was associated with the dissipation of the jet behind the actuator disc model.

The wake power, w, increases across the airframe and decreases in the downstream reflow. At the outlet, w took 22% of the total input power. This indicated a notable amount of mechanical power in the downstream flow mixed with the jet and wake. This study shows the limitations of a single wake-filling actuator disc model: It can refill the body wake, but it is not able to reduce the wing wake. On the other hand, the momentum excess of the actuator disc model was required to balance the momentum deficit of the wing. Therefore, the actuator disc model in this BLI configuration was not capable of reducing the downstream mechanical power to zero.

For the BLI configuration, the thrust power, TV∞, and drag power, DV∞, mutually cancelled each other, leaving a finite value (10% of the total input power) of the net force power, NV∞, as a power output term. NV∞ was used to accelerate the aircraft. This was different from the wing body configuration, in which NV∞ was zero to maintain the thrust/drag equilibrium. In the plot of power conversion, the total power input, Ps, was not identical to the summation of the outputs in the flow field. The difference was about 35%, denoting the power imbalance error for the BLI case.

A subdomain error study was performed to process the simulation results of the BLI configuration, as presented in

Figure 17. It was clear that the error associated with the wing was 19.3%, which was significantly higher than the errors from the other subdomains, while the error of the BLI propulsor was 8.2%. This study shows that the error associated with the wing as well as the propulsor was mainly responsible for the high values of power imbalance error. The error of the mechanical power imbalance was larger than the typical values of power saving due to BLI. So far, the precision of power-based analysis in 3D simulation is not adequate to analyze the power saving of BLI. This poses challenges for future work.