Evaluation of Viscoelastic Adhesion Strength and Stability of Composite Waterproofing Sheet Using Non-Hardening Viscoelastic Synthetic Polymer-Based Rubber Gel

Abstract

1. Introduction

2. Necessity of Viscoelastic Adhesive Performance Evaluation Method for NHV-SPRG Composite Waterproofing Sheet

2.1. Characteristics of NHV-SPRG Composite Waterproofing Sheet

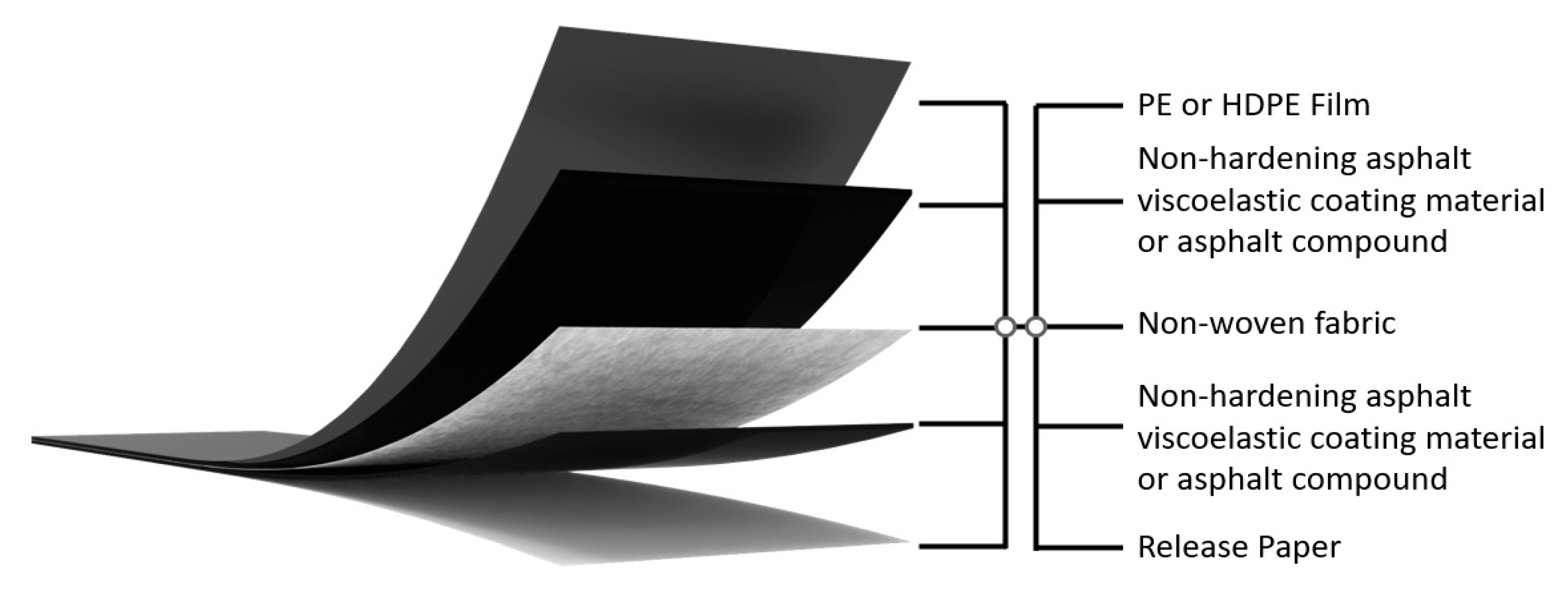

2.1.1. Composition of NHV-SPRG Composite Waterproofing Sheet

2.1.2. Types of Viscoelastic Adhesion (Limited to Composite Waterproofing Sheet Properties)

2.2. Viscoelastic Adhesive Performance Index and Test Method of NHV-SPRG Composite Waterproofing Sheet

2.2.1. Adhesive Performance Evaluation Method for NHV-SPRG Composite Waterproofing Sheet

2.2.2. Peel-Off Adhesion Strength Test (KS F 4934)

- : Peel off resistance (N/mm)

- : Maximum Load (N)

- W: Width of specimen (50 mm)

2.2.3. Peel-Off Adhesion Strength Test (KS F 2400)

2.3. Evaluation Index, Method, and Criteria for Adhesion Performance of NHV-SPRG Composite Waterproofing Sheet

2.3.1. Evaluation Method

2.3.2. Evaluation Criteria and Index

3. Viscoelastic Adhesive Strength and Stability Testing Method

3.1. Test Materials

3.1.1. Types of NHV-SPRG

3.1.2. Mortar-Based Substrate and Test Specimen

- (1)

- Substrate preparation (mortar base)

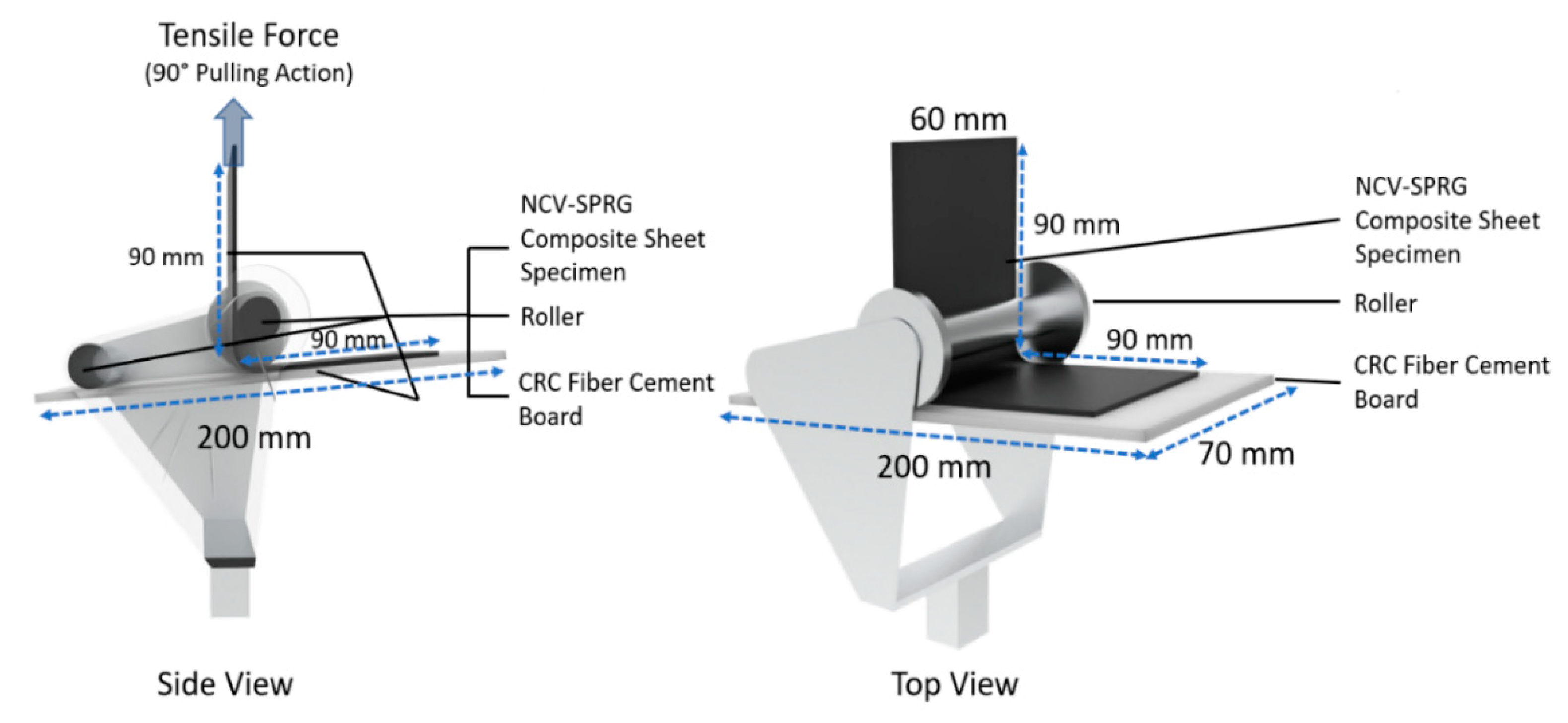

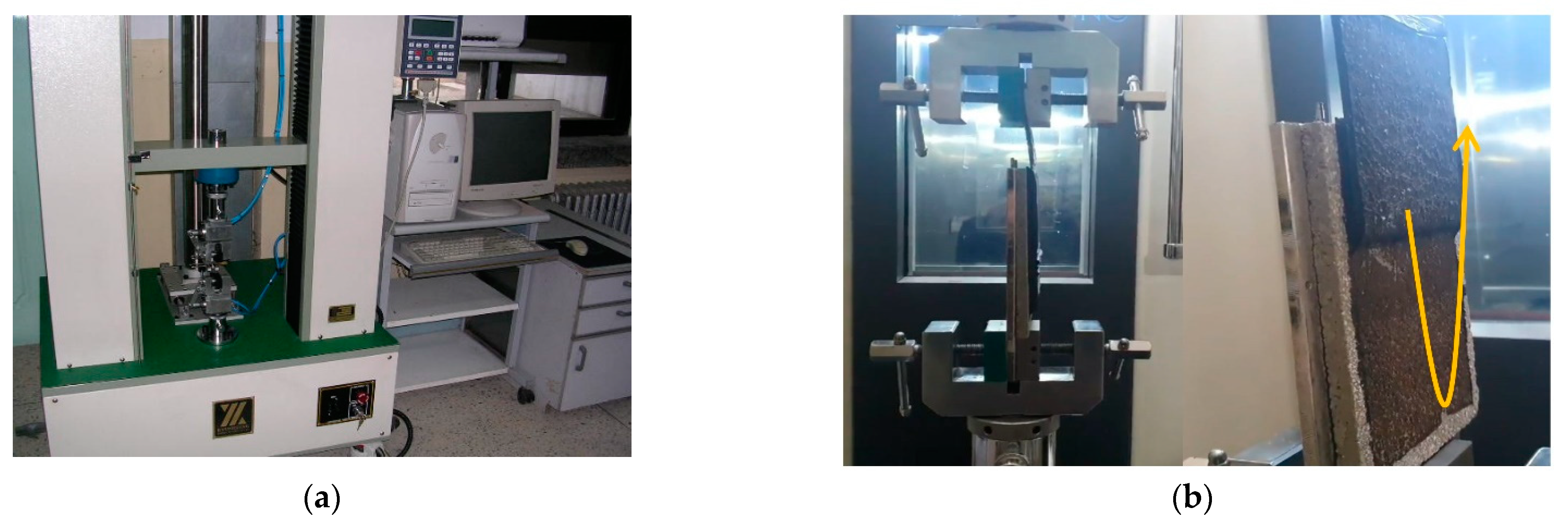

3.1.3. Test Specimens and Apparatus

3.2. Test Method for Evaluation of Viscoelastic Adhesive Strength

3.3. Evaluation Method of Viscoelastic Adhesive Performance

3.3.1. Viscoelastic Adhesive Strength

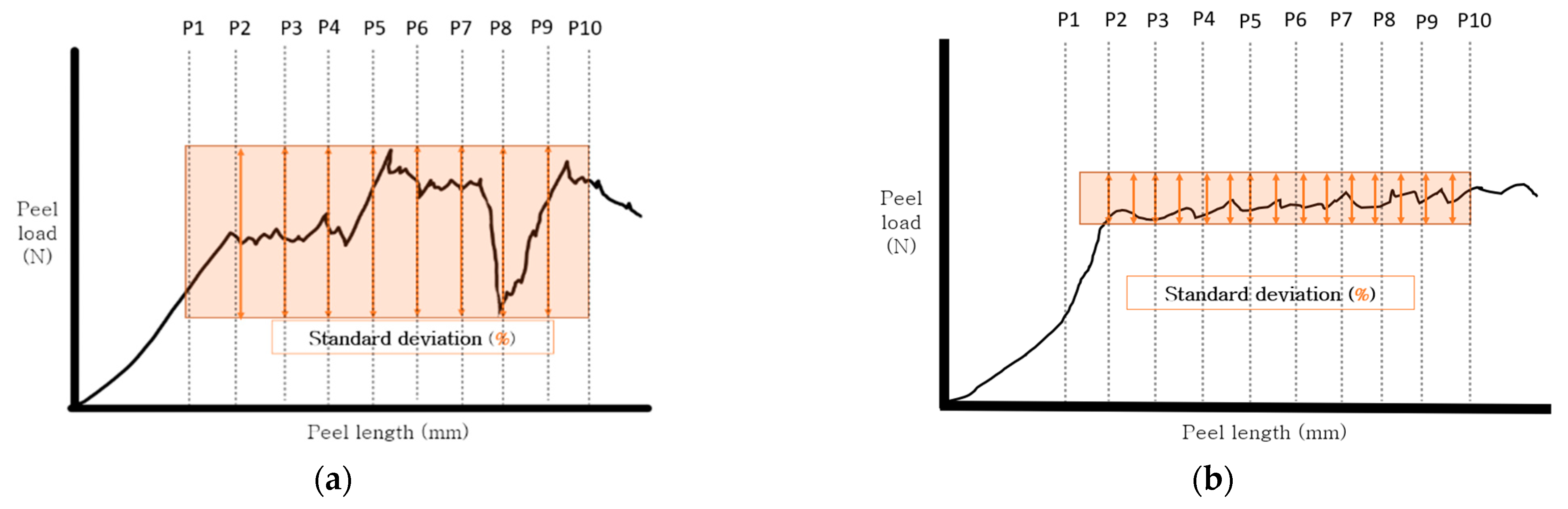

3.3.2. Adhesion Stability

- (1)

- Coefficient of Variation

- (2)

- Grade of the Linear regression Line

- PRG: Grade of the linear regression line formed from the peel load over peel length data (%)

- y: Peel load data (N)

- x: Peel length data (mm)

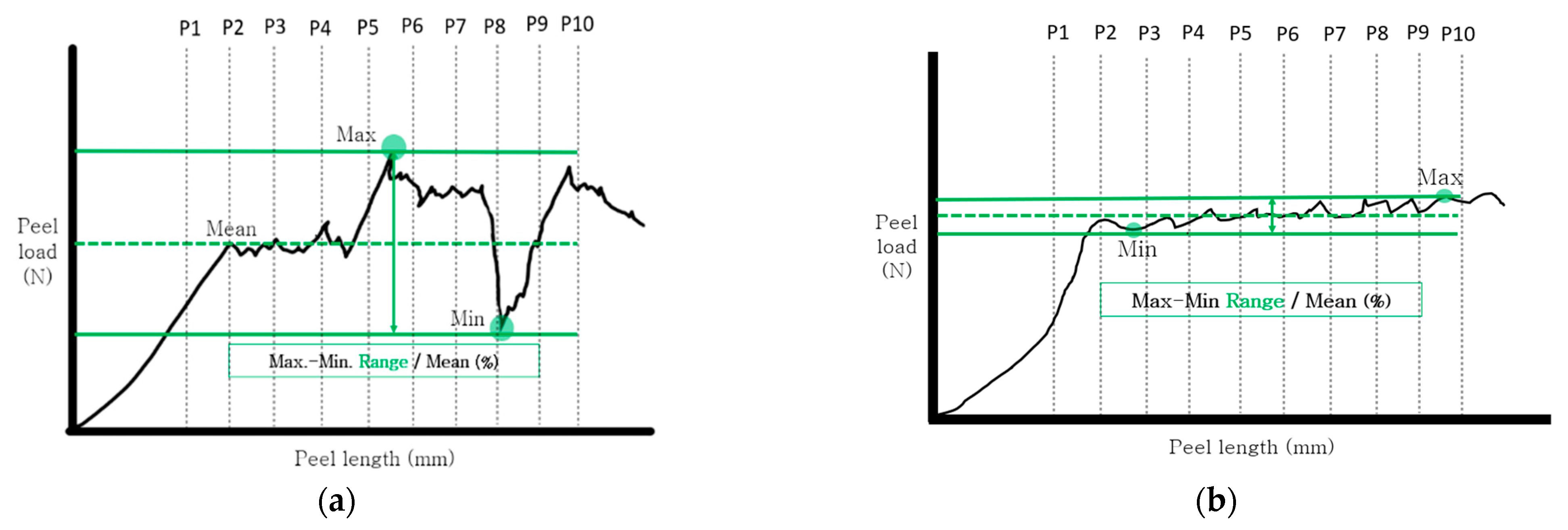

- (3)

- Percent relative range

- : Maximum peel load (N)

- : Minimum peel load (N)

4. Results and Discussion

4.1. Viscoelastic Adhesion Strength

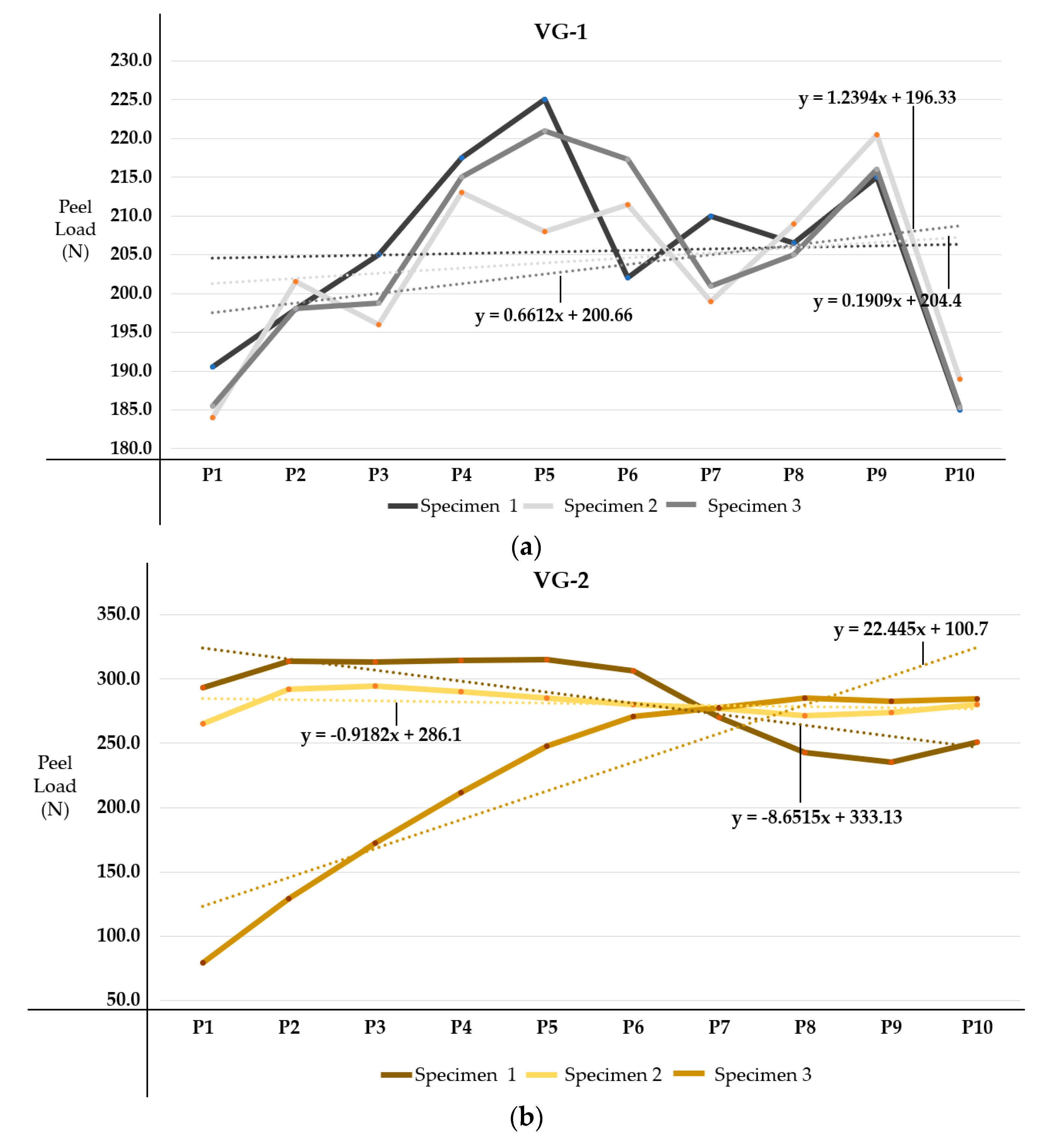

- (1)

- VG-1 Specimen

- (2)

- VG-2 Specimen

- (3)

- VG-3 Specimen

- (4)

- VG-4 Specimen

- (5)

- Consideration of viscoelastic adhesive strength of NHV-SPRG

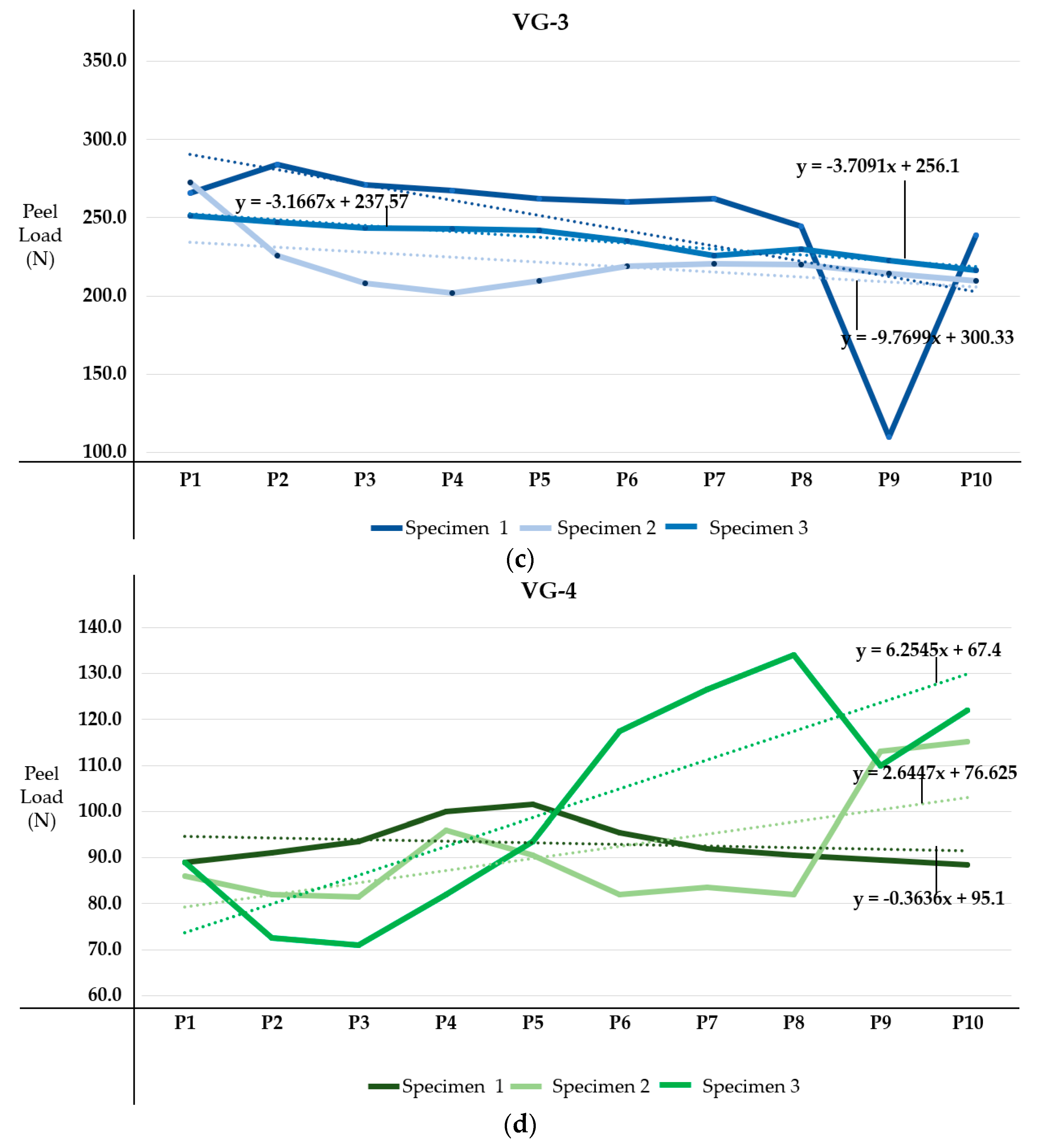

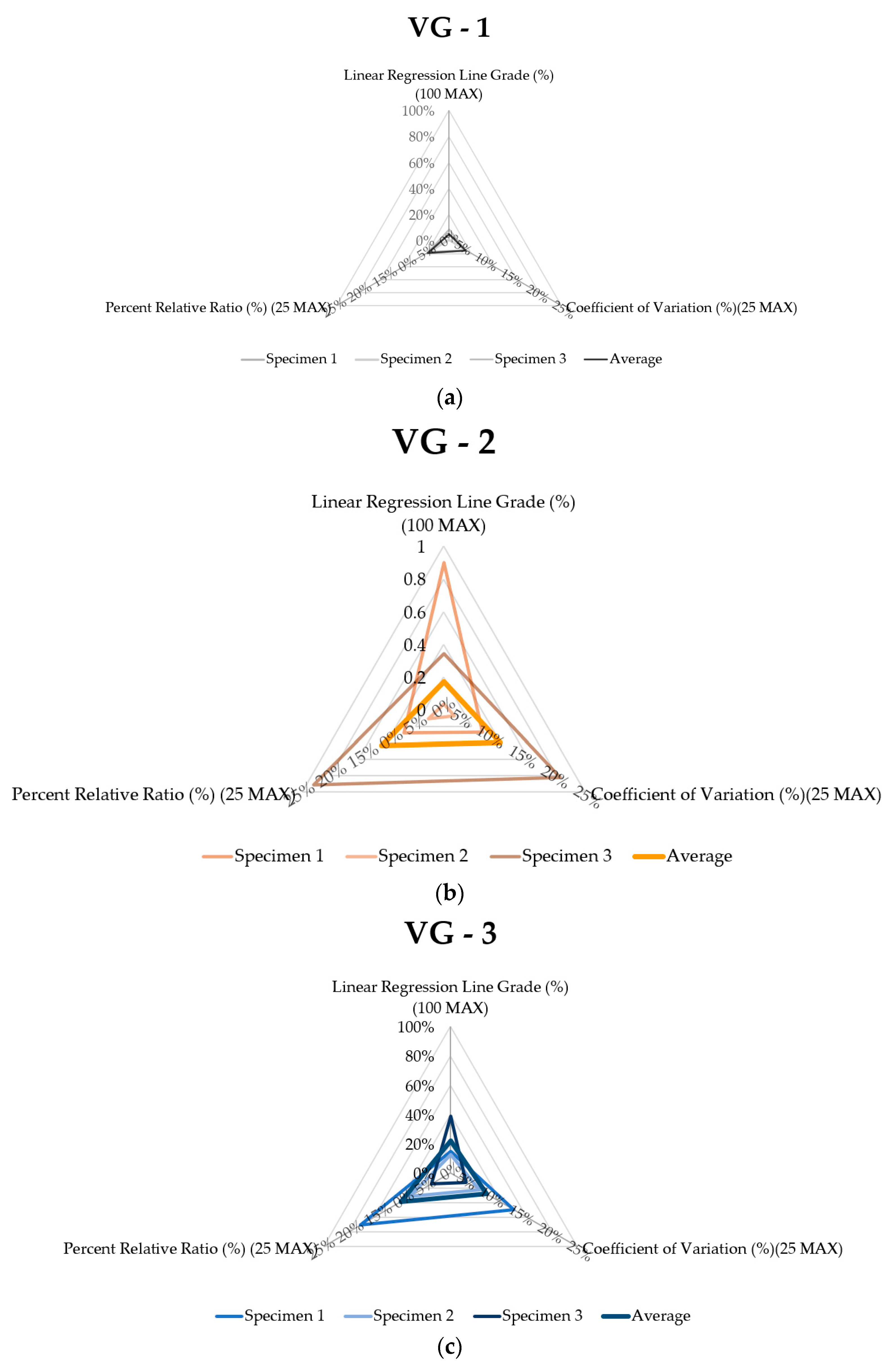

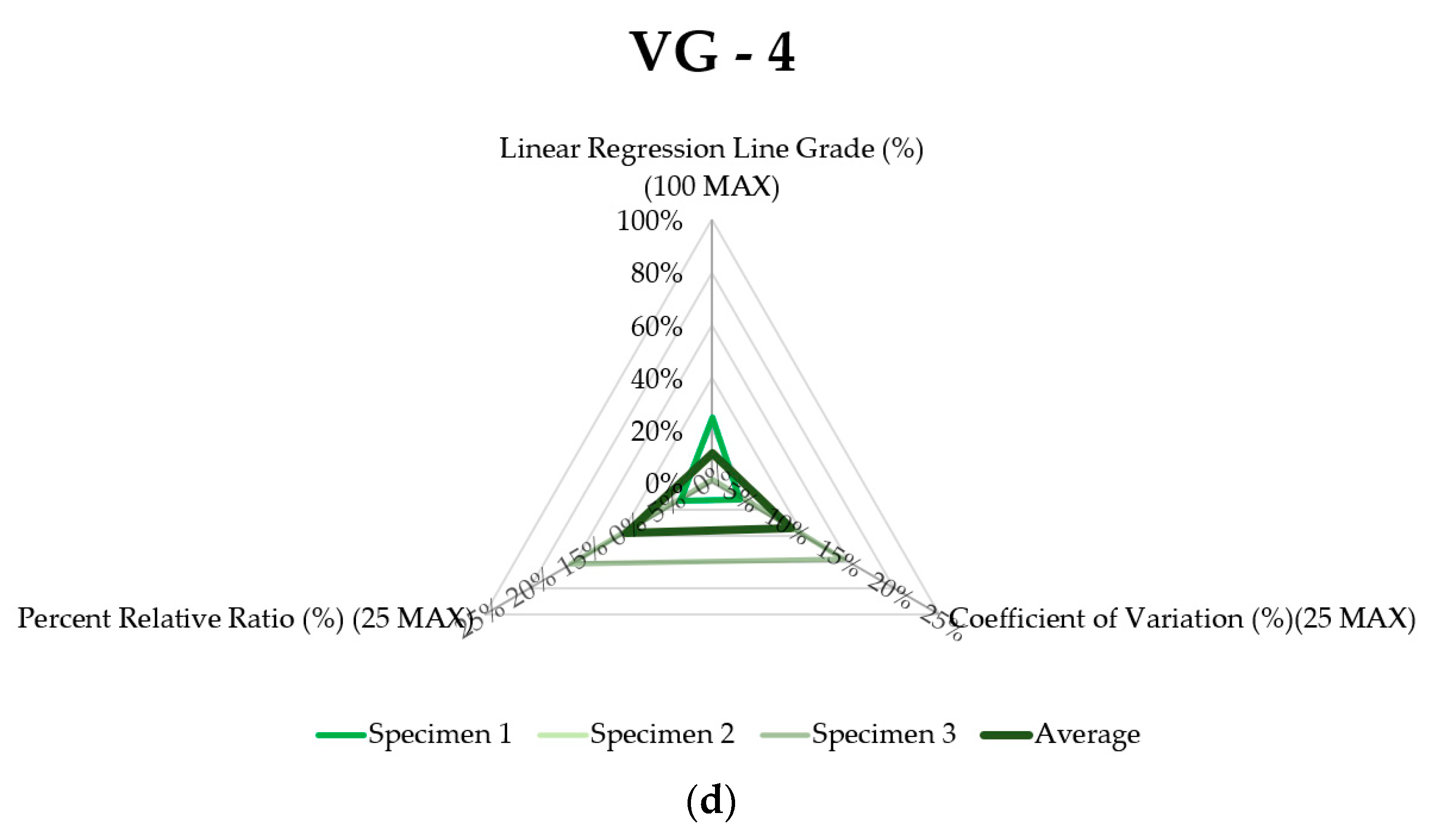

4.2. Adhesion Stability Evaluation

4.2.1. Coefficient of Variation

4.2.2. Linear Regression Line Grade

4.2.3. Percent Relative Range

4.2.4. Considerations

5. Conclusions

- (1)

- In order to reflect the material mechanism of non-hardening viscoelastic properties, as a new test method, 180° vertical tension and peel-off test were determined. Based on this, the viscoelastic adhesive strength and stability of the NHV-SPRG composite waterproofing sheets of 4 types were evaluated with respect to the peeling load (N) values for each section. As a result, the viscoelastic adhesive strength was measured as VG-1 2.04 N/mm, VG-2 2.64 N/mm, VG-3 2.34 N/mm, and VG-4 0.95 N/mm. It appeared in the order of VG-2 > VG-3 > VG-1 > VG-4.

- (2)

- Through this study, the viscoelastic adhesive strength of the four materials showed that the value of VG-4 was lower than that of the other three materials, but the average value was 1.99 N/mm. Therefore, this average value can be proposed as a quality standard value. Also, it was confirmed that the test method proposed in this study can measure the viscoelastic adhesion strength of the NHV-SPRG composite sheet in the field.

- (3)

- In the evaluation of the adhesion stability between the NHV-SPRG composite waterproofing sheet and mortar substrate, although the 4 types show different aspects of the viscoelastic adhesion performance, the change in the peel load value for each peeling section shows a change in increase or decrease, the coefficient of variation using the peel load value (limited to 10 points), the grade of linear regression line, and percent relative range to the maximum/minimum value were compared. It was confirmed that VG-1 was the most stable adhesion state, VG-4, VG-2, and VG-3 were confirmed to have similar adhesive stability.

- (4)

- Summarizing these results, the quantified viscoelastic adhesive strength of the VG-2 type was the highest, but in the adhesive stability evaluation analyzed by the peel load (N) value for each section, it was confirmed that the VG-1 type waterproofing material was high. Through these results, it was found that NHV-SPRG composite waterproofing sheets with good adhesive strength do not have good adhesive stability. Therefore, as a future study, it is necessary to consider the mixing ratio and quality of raw materials, precision of equipment use, and temperature conditions during construction in order to maintain continuous adhesive stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NHV-SPRG | Non-hardening Viscoelastic Synthetic Polymer Rubberized Gel |

| KS | Korean Standard |

| ASTM | American Society of Testing Methods |

| JIS | Japanese Industrial Standard |

| VG | Viscoelastic Gel |

References

- Yoo, J.Y.; Kim, S.Y.; Oh, S.K. Waterproofing Performance Grade Proposal through Standard Test Result Comparison of Self Adhesive Rubberized Asphalt Sheet. Appl. Sci. 2020, 10, 7857. [Google Scholar] [CrossRef]

- Sun, J.; Shi, C.; Li, P.; Li, A. Influence of Nanomodified Waterproofing Agent on the Performance of Rigid Waterproof Concrete in Underground Engineering. J. Nanomater. 2022, 2022, 2966551. [Google Scholar] [CrossRef]

- Hamada, M.; Kishitani, K.; Koike, M.; Kariya, H. Study on Prevention of Breakage in Asphalt Waterproofing; National Research Council Canada: Otawa, ON, Canada, 2022. [Google Scholar]

- Klomranok, T.; Su, Q. Assessment of the Selection of Asphalt Binder for Full Cross-Section Asphalt Waterproof Layer in High-Speed Railway Ballastless Track. J. Mater. Civ. Eng. 2021, 33, 05021001. [Google Scholar] [CrossRef]

- Kim, D.B.; Lee, H.R.; Seo, H.J.; Park, J.S.; Oh, S.K. A Study on Guidelines and Selection Methods of Adequate Materials for Repair of Water-Leakage Cracks in Concrete Structures. J. Korea Concr. Inst. 2011, 5, 611–612. [Google Scholar]

- Lee, J.H.; Song, J.Y.; Oh, S.K. Leakage Situation and Main Leakage Areas of Domestic Residential Building Underground Parking Lots. J. Korean Recycl. Constr. Resour. Inst. 2016, 4, 496–503. [Google Scholar]

- Sarnowski, M.; Radziszewski, P.; Kowalski, K.J.; Król, J.B. Impact of high process temperature on viscoelastic properties of polymer modified bitumen in waterproofing and bridge pavements. In Proceedings of the International Conference on Road and Rail Infrastructure CETRA, Split, Croatia, 28–30 April 2014. [Google Scholar]

- Goikoetxeaundia, G.; Fernandez, M.; Munoz, M.E.; Santamaria, A. Rheology Applied to Investigate Roofing Membranes: The Case of an Ecological Alternative. Appl. Rheol. 2009, 19, 62305-1–62305-8. [Google Scholar]

- Ahn, D.S.; Oh, K.H.; Park, J.S.; Oh, S.K. Viscosity and Waterproofing Performance Evaluation of Synthetic Polymerized Rubber Gel (SPRG) after Screw Mixing. Appl. Sci. 2018, 8, 1989. [Google Scholar] [CrossRef]

- Saulnier, F.; Ondarc¸uhu, T.; Aradian, A.; Raphael, E. Adhesion between a Viscoelastic Material and a Solid Surface. Macromolecules 2004, 37, 1067–1075. [Google Scholar] [CrossRef]

- Kumhar, R.; Kundu, S.; Gupta, S. Modelling of Love Waves in Fluid Saturated Porous Viscoelastic Medium resting over an Exponentially Graded Inhomogeneous Half-space Influenced by Gravity. J. Appl. Comput. Mech. 2020, 6, 517–530. [Google Scholar]

- Oh, S.K. A Study on Guidelines for the Repair of Water-Leakage Cracks in Concrete Structures. J. Korea Inst. Build. Constr. 2010, 10, 97–108. [Google Scholar] [CrossRef][Green Version]

- Oh, S.K. Cause Analysis and Leakage Repair Material and Method Selection for Leakage Crack Repair. Construction Management News, 4 March 2012; pp. 74–81. Available online: http://www.ekacem.or.kr/pds/gamribull/2012/201202/%EA%B9%80%EB%A6%AC3-4%EC%9B%94-%EB%B0%A9%EC%88%98%EA%B8%B0%EC%88%A0%EC%9E%90%EB%A3%8C.pdf (accessed on 18 May 2022).

- An, K.W.; Kim, S.R.; Oh, S.K. Development and Study on the Future Employment of Waterproofing Design Guideline for Leakage Prevention of Residential Underground Structure. J. Archit. Inst. Korea 2017, 37, 1073–1074. [Google Scholar]

- JC/T 2428-2017; Non-Curable Rubber Modified Asphalt Coating for Waterproofing. 91.120.30. CN-JC: Beijing, China, 2017.

- International Organization for Standardization Technical Committee 71 Subcommittee 7, ISO TS 16774:2011 Parts 1–6; Guidelines for the Repair of Water-leakage Cracks in Concrete Structures; ISO: Geneva, Switzerland, 2016–2017.

- Dennis, L. Bean, Epoxy-Resin Grouting of Cracks in Concrete; Department of the Army—Final Report; 1985. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a164306.pdf (accessed on 18 July 2022).

- Korea Land & Housing Corporation. Establishment of Measures to Improve Quality of House Waterproofing Methods for Zero Defects in Quality Management; Public Housing Project Office: Seoul, Korea, 2017; pp. 1–3. [Google Scholar]

- Pro, O. Water Control using polyurethane resins. In Proceedings of the 9th International Mine Water Association Congress Proceedings, Oviedo, Spain, 5–7 September 2005; pp. 289–293. [Google Scholar]

| Type | Composition | Property |

|---|---|---|

| VG-1 | Acrylamide, persulfate (one or two of sodium, ammonium, potassium), asphalt, other additives, etc. |

|

| VG-2 | Asphalt, inorganic filler for viscosity control, processor oil, strength modifier, heat-resistance modifier, adhesion modifier, flow prevention additive, waste tire, etc. |

|

| VG-3 | Asphalt, bentonite, oil, rubber, water-soluble polymer resin, other additives etc. |

|

| VG-4 | Asphalt, inorganic filler for viscosity control, processor oil, asphalt modifier, strength modifier, ammonium, potassium, asphalt, other additives, etc. |

|

| Parts | Viscoelastic Material Test Method Part |

|---|---|

| Substrate base size | 320 × 120 mm |

| Waterproofing sheet specimen size | 480 × 100 mm |

| Specimen adhesion surface area | 150 × 100 mm |

| State | Specimen Types | |||

|---|---|---|---|---|

| VG-1 | VG-2 | VG-3 | VG-4 | |

| Specimen Image |  |  |  |  |

| State | Specimen Types | |||

|---|---|---|---|---|

| VG-1 | VG-2 | VG-3 | VG-4 | |

| (a) Sheet Specimens |  |  |  |  |

| (b) Setting for Testing |  |  |  |  |

| (c) After Testing |  |  |  |  |

| Peel Length P Interval (mm) | Average Peel off Load and Adhesion Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P(t) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | Average Peel off Load (N), Ps | Visco-Elastic Adhesion Strength (N/mm) | |

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 | ||||

| ① | 190.5 | 198.0 | 205.0 | 217.5 | 225.0 | 202.0 | 210.0 | 206.5 | 215.0 | 185.0 | 205.5 | 204.3 | 2.04 |

| ② | 184.0 | 201.5 | 196.0 | 213.0 | 208.0 | 211.5 | 199.0 | 209.0 | 220.5 | 189.0 | 203.2 | ||

| ③ | 185.5 | 198.0 | 198.8 | 215.0 | 221.0 | 217.3 | 201.0 | 205.0 | 216.0 | 185.3 | 204.3 | ||

| # | Peel Length P Interval (mm) | Average Peel off Load and Adhesion Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P(t) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | Average Peel off Load (N), Ps | Visco-Elastic Adhesion Strength (N/mm) | |

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 | ||||

| ① | 293.5 | 314.0 | 313.0 | 314.5 | 315.0 | 306.5 | 270.0 | 243.0 | 235.0 | 251.0 | 285.6 | 263.6 | 2.64 |

| ② | 265.0 | 292.0 | 294.5 | 290.5 | 285.5 | 280.5 | 277.0 | 271.5 | 274.0 | 280.0 | 281.1 | ||

| ③ | 79.5 | 129.5 | 172.5 | 211.5 | 247.5 | 271.0 | 277.5 | 285.0 | 283.0 | 284.5 | 224.2 | ||

| # | Peel Length P Interval (mm) | Average Peel off Load and Adhesion Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P(t) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | Average Peel off Load (N), Ps | Visco-Elastic Adhesion Strength (N/mm) | |

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 | ||||

| ① | 266.0 | 284.0 | 271.0 | 267.5 | 262.0 | 259.9 | 262.0 | 244.5 | 110.0 | 239.0 | 246.6 | 234.1 | 2.34 |

| ② | 272.5 | 226.0 | 208.0 | 202.0 | 209.5 | 219.0 | 220.5 | 220.0 | 214.5 | 209.5 | 220.2 | ||

| ③ | 251.5 | 247.0 | 243.5 | 243.0 | 242.0 | 235.0 | 226.0 | 230.0 | 222.5 | 216.5 | 235.7 | ||

| # | Peel Length P Interval (mm) | Average Peel off Load and Adhesion Strength | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P(t) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | Average Peel off Load (N), Ps | Visco-Elastic Adhesion Strength (N/mm) | |

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 | ||||

| ① | 89.0 | 91.0 | 93.5 | 100.0 | 101.5 | 95.5 | 92.0 | 90.5 | 89.5 | 88.5 | 93.1 | 95.4 | 0.95 |

| ② | 86.0 | 82.0 | 81.5 | 96.0 | 90.5 | 82.0 | 83.5 | 82.0 | 113.0 | 115.2 | 91.2 | ||

| ③ | 89.0 | 72.5 | 71.0 | 82.0 | 93.5 | 117.5 | 126.5 | 134.0 | 110.0 | 122.0 | 101.8 | ||

| Specimen | Average Peel Load (N) | Standard Deviation (N) | Coefficient of Variation (%) | |

|---|---|---|---|---|

| VG-1 | ① | 205.5 | 12.25 | 6 |

| ② | 203.2 | 11.37 | 6 | |

| ③ | 204.3 | 13.28 | 6 | |

| Avg. | 204.3 | 12.30 | 6 | |

| VG-2 | ① | 285.6 | 32.61 | 11 |

| ② | 281.1 | 9.58 | 3 | |

| ③ | 224.2 | 73.87 | 33 | |

| Avg. | 263.6 | 38.68 | 15.9 | |

| VG-3 | ① | 246.6 | 49.64 | 20 |

| ② | 220.2 | 19.75 | 9 | |

| ③ | 235.7 | 11.55 | 5 | |

| Avg. | 234.1 | 26.98 | 11.3 | |

| VG-4 | ① | 93.1 | 4.56 | 5 |

| ② | 91.2 | 12.95 | 14 | |

| ③ | 101.8 | 23.09 | 23 | |

| Avg. | 95.4 | 13.54 | 13.9 | |

| Specimen | Slope | Regression Line Grade (%) | |

|---|---|---|---|

| VG-1 | ① | 1.24 | 1.24 |

| ② | 0.19 | 0.19 | |

| ③ | 2.15 | 2.15 | |

| Avg. | 1.19 | 1.19 | |

| VG-2 | ① | 22.4 | 22.45 |

| ② | −0.92 | 0.92 | |

| ③ | −8.65 | 8.65 | |

| Avg. | 4.29 | 4.29 | |

| VG-3 | ① | −3.71 | 3.71 |

| ② | −3.16 | 3.17 | |

| ③ | −9.76 | 9.77 | |

| Avg. | −5.55 | 5.55 | |

| VG-4 | ① | 6.25 | 6.25 |

| ② | 2.64 | 2.64 | |

| ③ | −0.36 | 0.36 | |

| Avg. | 2.85 | 2.85 | |

| Specimen | Max. Peel Load (N) | Min. Peel Load (N) | Average Peel Load (N) | Average Percent Relative Range (%) | |

|---|---|---|---|---|---|

| VG-1 | ① | 185 | 225 | 205.45 | 19.5% |

| ② | 184 | 220.5 | 203.15 | 18.0% | |

| ③ | 182 | 223 | 203.28 | 18.5% | |

| Avg. | 183.67 | 222.83 | 203.96 | 18.7% | |

| VG-2 | ① | 235 | 315 | 285.55 | 28.0% |

| ② | 265 | 294.5 | 281.05 | 10.5% | |

| ③ | 79.5 | 285 | 224.15 | 91.7% | |

| Avg. | 193.17 | 298.17 | 263.58 | 43.4% | |

| VG-3 | ① | 110.01 | 284 | 246.591 | 70.6% |

| ② | 202 | 272.5 | 220.15 | 32.0% | |

| ③ | 216.5 | 251.5 | 235.7 | 14.8% | |

| Avg. | 176.17 | 269.33 | 234.15 | 39.1% | |

| VG-4 | ① | 88.5 | 101.5 | 93.1 | 14.0% |

| ② | 81.5 | 115.2 | 91.171 | 37.0% | |

| ③ | 71 | 134 | 101.8 | 61.9% | |

| Avg. | 80.33 | 116.90 | 95.36 | 37.6% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, J.; Oh, K.; Kim, S.; Jiang, B.; He, X.; Oh, S. Evaluation of Viscoelastic Adhesion Strength and Stability of Composite Waterproofing Sheet Using Non-Hardening Viscoelastic Synthetic Polymer-Based Rubber Gel. Appl. Sci. 2022, 12, 9619. https://doi.org/10.3390/app12199619

Jeon J, Oh K, Kim S, Jiang B, He X, Oh S. Evaluation of Viscoelastic Adhesion Strength and Stability of Composite Waterproofing Sheet Using Non-Hardening Viscoelastic Synthetic Polymer-Based Rubber Gel. Applied Sciences. 2022; 12(19):9619. https://doi.org/10.3390/app12199619

Chicago/Turabian StyleJeon, Junhong, Kyuhwan Oh, Sooyeon Kim, Bo Jiang, Xingyang He, and Sangkeun Oh. 2022. "Evaluation of Viscoelastic Adhesion Strength and Stability of Composite Waterproofing Sheet Using Non-Hardening Viscoelastic Synthetic Polymer-Based Rubber Gel" Applied Sciences 12, no. 19: 9619. https://doi.org/10.3390/app12199619

APA StyleJeon, J., Oh, K., Kim, S., Jiang, B., He, X., & Oh, S. (2022). Evaluation of Viscoelastic Adhesion Strength and Stability of Composite Waterproofing Sheet Using Non-Hardening Viscoelastic Synthetic Polymer-Based Rubber Gel. Applied Sciences, 12(19), 9619. https://doi.org/10.3390/app12199619