Featured Application

Potential application of the work concerns AI-supported eco-design of a novel family of products.

Abstract

Creative thinking is an inherent process in the creation of innovations. Imagination is employed to seek creative solutions. This article presents research results on the use of inventive methods to develop an eco-friendly product. A household appliance was selected as the object of research. The article deals with issues relating to eco-design, eco-innovation, and inventory. The process of selecting inventive methods was presented. Selected inventive methods used to develop the product concept were briefly characterized. Creativity sessions were conducted using the methods of brainstorming, stimulating, reverse brainstorming, word games, and superpositions. The effect of these activities is the concept for an eco-innovative product. A product design was developed that is highly recyclable and environmentally friendly. An ecological analysis of the designed product, including AI-based (artificial neural networks), was carried out, which showed the legitimacy of the actions taken to develop an environmentally friendly product. The novelty of the proposed approach consists of combining the use of research data, with new methods for their analysis using both traditional and artificial intelligent tools, to create a transparent and scalable product design. To date, this approach is unique and has no equivalent in the literature. Despite higher manufacturing costs, the more environmentally friendly refrigerator is cheaper in operation (consumes less energy) due to the ecological solutions incorporated into its design.

1. Introduction

This paper looks at the process of the development of a concept for an eco-friendly product. An approach has been taken incorporating inventive methods at the design stage to create an innovative ecological product. The authors draw on the widely promoted aspects of environmental protection, namely reducing post-consumer waste through enhanced processing and reuse and the promotion of a circular economy [1].

The main motivation behind the application of the proposed methodology is the challenges faced by engineering and the technical sciences in the face of the current problems of energy, materials and excess production waste and rubbish. Consequently, it has become necessary to re-evaluate some of the production principles within the Industry 4.0 paradigm, towards not only sustainability or the EU Green Deal, but also socially and environmentally beneficial pro-environmental behaviours that are not necessarily enforced by economic calculations, but also by other values such as recycling, water and air purity.

To comply with environmental assumptions, businesses can introduce, among other things, aspects of the Environmental Life Cycle Design (ELCD) at the product design stage [2,3]. The process of eco-design is aimed at minimizing the consumption of raw materials and energy, as well as the costs of use and the environmental footprint of the product. Eco-design combines the technological capabilities with a compliance with environmental requirements [4,5]. An alternative analytical approach is the use of artificial intelligence to simplify and accelerate the process of a semi-automatic process estimation and adjustment.

The research was conducted on a household appliance—a refrigerator. The manufacturing of household appliances, which are categorized as electrical and electronic equipment, is one of the pillars of the European economy [6] and is undergoing continuous development [7]. Enterprises operating in the household appliance sector are characterized by a high level of product innovation, which entails certain environmental protection-related issues. Household and office appliances consume high levels of energy. Household appliances are inherent in the development of modern civilization [8,9]. Indispensable in our everyday life, they quickly become obsolete, and many of them are withdrawn from use (thrown away) even when still fit for use. Most of them end up at landfill sites. Although end-of-life or scrapped electronic equipment constitutes only part of the total volume of waste, it imposes a high environmental cost as it contains heavy metals, halogenated hydrocarbons, and plastics. Highly advanced technologically and made of compound materials, this type of waste is difficult to recycle. Therefore, it is of the utmost importance to design electronic equipment with easy recycling in mind, as well as taking into consideration the directives of the European Parliament [10] (European Union, 2009) applying to, among others, manufacturers of household appliances. The research discussed here was conducted on a household appliance operating based on heat exchange—a small refrigerator for storing cosmetics and medicines.

The authors discuss notions in the fields of eco-design, eco-innovation, and the science of inventive creation. A brief description of the selected inventive methods, applied in the development of the product concept, is included. The output of the study is the concept of an eco-innovative product—a small refrigerator for storing cosmetics and medicines. The designed product is highly recyclable and environmentally friendly. Results of an environmental analysis of the product justify the actions taken to design an environmentally friendly product. An estimation of the manufacturing costs of the product was attempted.

It is a common approach to adopt inventive methods when designing a product. The TRIZ (Theory of Inventive Problem Solving) method is of special importance in the design of eco-innovative products. Livotov et al. identified more than 60 papers describing the application of TRIZ in the development of eco-innovative concepts [11]. However, the authors of the present paper chose to apply other inventive methods, such as brainstorming, stimulating, reverse brainstorming, word games, and superpositions. They all render good results, though they require the engagement of many people in the process of defining the concept of an eco-friendly product, and thus they are used less frequently.

Therefore, the authors decided to use an automated approach using inventive methods to design a new product that takes into account ecological design. In addition, the process of collecting survey data for green product design is a very time-consuming process. Analysing this data manually can also sometimes lead to erroneous results. The automation of the process of analysis and processing of the collected data allows a much more in-depth analysis (business analysis), which is increasingly important for companies that take into account environmental requirements in the production of products. The developed automatic models of pro-environmental analysis of the product construction can be then used to develop an intelligent expert system, which will support less experienced designers during the design of new products.

The requirements and approaches to the design and manufacture of new products are changing towards greater environmental friendliness without losing the most essential performance properties. The research problem lies in the need to replace existing products and their design methodologies with new solutions, of similar quality and cost, but eco-friendly, leaving a smaller carbon footprint, falling within the paradigms of sustainability, Industry 4.0, and green governance. The research gap identified relates precisely to this group of products and the methodologies for their mass yet individualized eco-friendly manufacture. The research gap is the lack of a model that accurately and flexibly reflects the eco-design process, and indirectly, the lack of guidelines for further research into more sophisticated models that are technically feasible and industrially useful. The scientific and industrial approaches to date have not been fully responsive to societal and economic demand, as they have not provided a comprehensive approach, including to the requirements and key technologies in the third decade of the 21st century. The adaptability of the proposed methodology to different materials allows it to adapt to the material difficulties we are currently witnessing. The novelty of the approach shown in this paper lies in the comprehensive demonstration of the entire design process, as a basis for the creation of procedures that can be used in industry to produce entire families of products with similar properties. The novelty of the proposed approach consists of combining the use of research data, new methods for their analysis using both traditional and artificial intelligent tools, to a transparent and scalable product design. To date, this approach is unique and has no equivalent in the literature. Applications of invention methods to the design of new products are known in the literature [12,13,14]. However, they do not take into account the ecological approaches as well as the artificial intelligence methods. In addition, this research covers everyday household appliances (including fridges). Previous studies have not covered them, thus leaving out both an important industry and an area crucial to the normal functioning of society (food preparation, storage, etc.), which cannot be dispensed with, and therefore, every pro-ecological study and solution is important here. The breakthrough also lies in the inclusion of artificial intelligence-based analysis, which will save time and better optimise the development process itself and the final product. The proposed methodology, presented in the following sections of this article, consists of several steps: the selection of inventive methods by a survey of students, description of the selected method, creativity sessions with the use of the selected methods, design (including material selection), and environmental analysis (two ways: traditional vs. AI-based). The proposed methodology (discussed further in detail) is relatively easy to replicate or adapt and can also serve as a base mode for further development. The contribution and robustness of the proposed methodology also lies in its comprehensiveness, detail, and the comparison of different approaches to explore which one is better, which will provide significant advantages to our study over other approaches and allow subsequent researchers to make an informed choice of a path forward. Design of this type will become increasingly common, and the benefits it brings to the environment will be felt by all of us.

The goal of this study was to find new, faster, and simpler methods for environmentally friendly design, including more effective AI-based models. The contributions of this work will enhance the capabilities of computer-aided design, including within the “Industry 4.0” paradigm, to make analyses and predictions beyond current scientific knowledge and engineering experience.

2. Review of the Literature

Eco-design redefines the way in which new products are developed, giving the same status to environmental sustainability as to functionality, durability, costs, time to market, aesthetic qualities, ergonomics, and quality [15,16,17,18]. Luiz et al. [19] noted a boom in research into eco-design in the 1990s, triggered by the introduction of the life cycle assessment and environmental impact analyses [20,21]. In the 1990s, the development of environmentally sustainable products was, for the first time, considered an important research topic in the domain of environmental protection [19,22]. Since the year 2000, eco-design has been defined as a research area and an organizational practice [23,24,25].

Taking a strategic approach to eco-design, rather than a laserfocus on the functional qualities of the product, designers are concerned with its entire life cycle, from concept to disposal. Energy efficiency, the avoidance of harmful substances, and the minimization of the consumption of materials are obvious points to consider. It is also important to extend the product’s life cycle by ensuring that it is repairable, made of recyclable materials, given a structure (selection of appropriate bonding methods) allowing for quick and easy disassembly, and the materials it is made of are compatible for recycling purposes [26]. The implementation of environmental aspects into the process of product design is time-consuming and requires relevant expertise [27]. Due to all these circumstances, designers find it increasingly difficult to resolve the environmental issues by themselves [5].

A combination of ecological aspects incorporated into the process of designing a product with new, enhanced functionalities is referred to as eco-innovation. According to the Eco-Innovation Observatory, an EU organization working with research into eco-innovative activity, eco-innovation is defined as the process of introducing a new or significantly improved product, process, organizational change, or marketing solution, which contributes to limited consumption of natural resources and reduced emissions of harmful substances throughout the life cycle, regardless of whether the environmental benefits are intentional or not [28].

According to [29], eco-innovation is the development of products and processes which contribute to sustainable development, and employment of the same to achieve direct or indirect environmental benefits in the enterprise and its business environment. It follows from the definitions above that the design of a new, improved product with a reduced environmental impact is termed eco-innovation. The concept of a new, environmentally friendly product is developed using a number of support tools [3,23]. Chou [30] defines these as techniques used for the assessment of the environmental impact of products, which streamline the Product Process Design (PPD), and divides them into the following categories:

- -

- guidelines, standards, and norms;

- -

- checklists;

- -

- comparative tools (e.g., LiDS, eko-kompas);

- -

- analytical methods (e.g., eco-indicators, environmental effect analyses, environmental impact assessments, LCA, material, energy, and toxicity (MET) matrix).

All the tools mentioned above are applied at the stage of designing a new, innovative, pro-ecological (eco-innovative) product. However, methods supporting designers in the creation of innovative solutions are also necessary, such as:

- -

- multi-criteria decision-making methods;

- -

- modelling and simulation methods;

- -

- methods supporting the creative process (or stimulating innovative solutions), such as, e.g., brainstorming, Osborn’s checklist, reverse brainstorming, biased questions.

The decision on what type of method to use depends on the stage of the eco-design process. Schischke et al. [31] defined six stages of the eco-design process (Table 1).

Table 1.

The process of eco-design—product development and related actions (own work based on [31]).

Planning and concept development are assisted by analytical methods and methods supporting creative thinking. At further stages, support of databases, guidelines, standards, norms, checklists, comparative tools, and an analytical method are sought. At the beginning of the process, it is of utmost importance to apply methods that stimulate the creativity of designers and other individuals engaged in the development of the product concept.

3. Description of the Research Problem

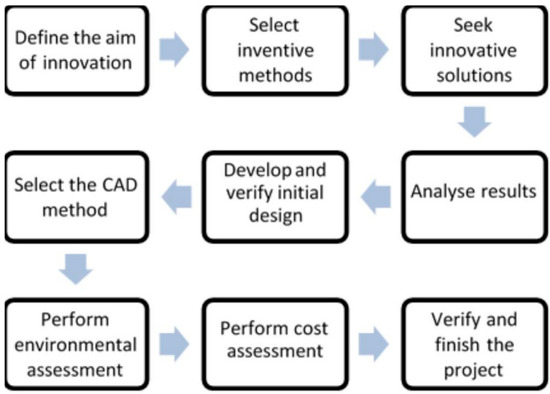

The research aimed at the development of an eco-innovative product. The research subject was a refrigerator (i.e., a large-size product) for storing medicines and/or cosmetics, for living room or bedroom use—a fact which would have an impact on its physical appearance. It was supposed to be of small dimensions and made of environmentally friendly, fully or at least partly, recyclable materials. The authors took an eco-innovative approach and changed the commonly known functionality of a refrigerator as well as incorporating some environmental aspects. Innovative solutions were explored using inventive methods. External respondents were engaged in the research. The process of eco-innovation was divided into a sequence of stages (Figure 1).

Figure 1.

Stages of eco-innovation.

4. Development of Product Concept

4.1. Selection of Methods

The inventive methods were selected through an analysis, which covered mostly methods that support creative problem solving at the stages of collection and the analysis of information, as well as seeking, analysis and evaluation of ideas.

The survey was completed by students. Characteristics of the respondents:

- first group (n = 60) from the field of Management and Production Engineering studying full-time undergraduate studies in the field of Mechanical Engineering;

- second group (n = 50) studying on a full-time bachelor’s course in the field of Mechanics.

In the study, the product was not manufactured, but only designed and the technological processes planned.

In the process, a breakdown of inventive methods by problem-solving phases, developed by Antoszkiewicz [32], was found useful. The selected methods are indicated in bold type in Table 2. These are methods which scored the highest on a scale from 1 to 5 (where 1 = low usability, and 5 = very high usability). The methods were selected taking into consideration their level of difficulty, i.e., the time necessary to learn the method, and whether experts were necessary to teach their use.

Table 2.

Usability of selected inventive methods broken down by problem-solving stages (own work based on [29]).

4.2. Description of Selected Methods

The selected methods are applied in the improvement or modernization of existing objects; therefore, their implementation in the process of designing an eco-innovative refrigerator seemed promising. A brief description of the methods is provided below:

- Brainstorming

- The most widely recognizable and commonly used inventive method for seeking ideas [33,34,35]. Developed by A.F. Osborn in the 20th century, it is implemented in four general stages [36,37]: the presentation of the method, the brainstorming session (generation of ideas), Osborn’s checklist—modifying questions, and the grouping of ideas.

- Stimulatingand reverse brainstorming

- Stimulating is an auxiliary technique used in a brainstorming session, based on Osborn’s checklist. Once it becomes clear that the research group is struggling to come up with new ideas, the stimulating technique may be useful. Reverse brainstorming is thinking ‘out of the box’, departing from schematic thinking, breaking (‘crushing’) the external world, i.e., getting rid of the established perceptions of objects. It is implemented using biased questions [38].

- Wordgame

- This method is used when seeking problem solutions. It is based on the assumption that in order to modernize an object, it is necessary to break the existing description into smaller chunks and create new ways of describing it [32]. The method has several methodological variants [38]: word analysis, play on words, and word associations.

- Superpositions

- This method is used primarily to improve existing objects (including products). It consists in uniting two or more objects to modify them into a new object. It is applied through four processes: the determination of the initial object, the creation of associated objects, superpositioning, and the development of solution variants [32].

4.3. Creativity Sessions with the Use of Selected Methods

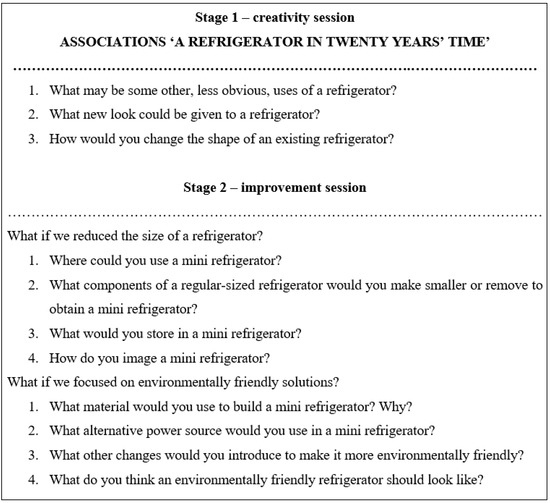

The implementation of inventive methods in the development of an eco-innovation was divided into two stages. Each stage was carried out using different methods, while the brainstorming method was applied to bring the two stages together. The respondents were divided into groups of three or four. Questionnaires had been developed to collect the ideas. At stage one, the word game (associations) and superpositions were applied. The respondents were made familiar with the general topic of the research only—they were told that the eco-innovative product to be created was a small-sized environmentally friendly refrigerator. Using the methods mentioned above, the respondents were to associate the term ‘refrigerator’ with other objects. The expected outcome of this stage was the indication of which environmental solutions should be given a closer look at the next stage, rather than the working out of a particular solution. The stage was named the creativity session. At stage two, referred to as the improvement session, the stimulating and reverse brainstorming methods were used. An initial concept of the eco-innovation was presented and a list of biased (Osborn’s) questions was developed. The outcome of this stage was a set of particular solutions proposed to be applied in the product design.

Before stage one commenced, a questionnaire had been drawn up and given to the participants of the creativity session. The participants were made familiar with the rules of the session and divided into groups. Discussion was allowed within the groups to generate the greatest possible number of ideas. Each group developed their own ideas. Stage one lasted ca. 15 min. At stage two, participants in the improvement session gave answers to the biased questions based on the reverse brainstorming and stimulating methods. The keynote of stage one was ‘association—a refrigerator in 20 years’ time’. Auxiliary questions were prepared (Figure 2). At stage two, questions were related to the eco-innovation. All the questions asked at stage one and two are listed in Figure 2.

Figure 2.

Questions asked to participants of the eco-innovation session.

The two stages delivered a number of ideas for solutions which can be applied in the design of an environmentally friendly refrigerator. Selected ideas are shown in Table 3.

Table 3.

Selected ideas gathered from the participants of the creativity session.

The creativity session focused on the specification and appearance of the fridge, while participants in the improvement session concentrated more on the environmental aspects and the types of materials which could be used in the fridge. After an analysis, the most technically feasible solutions were chosen with a particular regard for the environmental aspects. The project team analysed all of the proposals and selected the following solutions to be applied in the design:

- Storage drawers—with transparent fronts;

- For living room/bathroom use;

- A Smart Glass door;

- Rounded edges;

- Matching the furniture;

- For the storage of medicines and cosmetics;

- Thin walls;

- Modular structure—various modules to choose from—the possibility to assemble the product;

- Removable partitions;

- Lightweight.

The materials selected included wood, glass, and plastics, most of them recyclable. The decision was made to apply an antibacterial coating with silver compounds, and LED lighting.

5. Design

The mini refrigerator has the shape of a cuboid with the dimensions of 60 × 40 × 35 cm. It is worth noting here that although the designed product is a mini refrigerator, it is a large size product for recycling purposes. Pursuant to the Act [39], all cooling appliances with one dimension larger than 50 cm are regarded as large size equipment. In compliance with the initial assumptions, all the materials used in the design are recyclable. The refrigerator has a modular structure, e.g., the cooling mechanism can be easily reused. For quick and easy disassembly into components made of homogenous materials, many of the connections are of the push-in type.

The interior is made of plastic panels—polystyrene tinged with silver ions to form an antibacterial coating. The cooling mechanism is placed in the back wall of the casing. The cooling agent applied, namely IZOBUTAN R600a, is characterized by excellent thermodynamic qualities and little environmental impact. This is a non-toxic gas having zero ODP (Ozone Depletion Potential) and very low GWP (Global Warming Potential) [40].

The design incorporates one generator and two thermostats for multiple temperature zones. The temperature ranges from 1 to 70 C. Polyurethane foam insulates the interior—owing to its excellent thermal insulating qualities, a large cooling generator is not necessary.

The body, made of stainless-steel sheet, is connected to the moulded inner casing, thus hiding the cooling mechanism inside. Hinges supporting the door are mounted in the body.

Taking into consideration one of the environmental aspects—the application of renewable and biodegradable materials—the casing is made of particle board, a wood-based material. It is a building material made from specially prepared wood particles. On the outside, the particle board will be covered in natural wood veneer of the customer’s choice.

The refrigerator has a glass door. The intelligent glass used can change from transparent to translucent, depending on the user’s needs. Smart Glass is laminated glass with a foil containing liquid crystals. When voltage is applied, the crystals align and the glass turns transparent, letting light pass. When no voltage is applied, the glass becomes matt [41].

The LED lighting in the interior minimizes energy consumption. The edges of the body are rounded for safe use.

The interior can be complemented with modules to suit the customer’s choice. Modules designed for the storage of cosmetics and/or medicines are made of transparent polystyrene so that the contents are visible without the need to remove the module.

Table 4 shows a list of all the materials required to manufacture the refrigerator. Figure 3 shows the design.

Table 4.

List of materials.

Figure 3.

Refrigerator in wooden casing, right side view.

6. Environmental Analysis—Traditional Method

The environmental assessment of the refrigerator’s life cycle was carried out by the environmental quality assessment method [42]. Environmental criteria were specified and on the basis of them, a series of questions were formulated to determine the fulfilment of particular criteria. Answers to the questions were assigned a score; the total score was summed up and the arithmetic mean was calculated. Depending on the score, the product was assigned one of the grades (Table 5) calculated according to Equation (1).

where: N—number of questions, m—number of answers to the ith question, wij—score assigned to one jth answer to the ith question.

Table 5.

Environmental quality assessment grades.

The environmental quality assessment (EQA) is the arithmetic mean of answers to the questions shown in Table 6 (always one answer only).

Table 6.

Environmental quality assessment.

The following questions and answers were distinguished for the pre-manufacturing stage:

- 1.

- Product design: Future-oriented (3), Contemporary (2), The design is a passing fad (1), No information (0)

- 2.

- Description of the enterprise: Innovative (3), Offensive (2), Defensive, passive (1), Noinformation (0)

- 3.

- Description of the consumer: Bright green, green (3), Greyish green (2), Grey, black (1), No information (0)

- 4.

- Description of suppliers: Local (3), Domestic (2), Global (1), No information (0)

- 5.

- Number of materials to be used in the manufacturing: one material (3), two to four materials (2), More than five materials (1), No information (0)

- 6.

- Use of the minimum number of materials vs. durability—taken into consideration?: Priority (3), Taken into consideration (2), Not taken into consideration (1), No information (0)

- 7.

- Room for improvement: Designed for continual improvement (3), There is room for improvement (2), Improvement technically impossible (1), No information (0)

- 8.

- Possible use of replacement components: Easily available (3), Available, but expensive (2), Unavailable (1), No information (0)

- 9.

- Type of product structure: Modular (3), Partly modular (2), Integrated (1), Noinformation (0)

- 10.

- Planned recyclability: Mostly recyclable (3), Partly recyclable (2), Non-recyclable (1), No information (0)

- 11.

- Planned corrosiveness: Corrosion-resistant (3), Protected against corrosion (2), Not resistant, lack of protection (1), No information (0)

The following questions and answers were distinguished for the manufacturing stage:

- 12.

- Use of renewable raw materials: Manufacturing based on renewable raw materials (3), Renewable raw materials rarely used (2), No renewable raw materials used (1), No information (0)

- 13.

- Use of non-renewable raw materials: Not used (3), Rarely used (2), Used a lot (1), No information (0)

- 14.

- Water consumption: Low (water-saving) (3), Medium (2), High (1), No information (0)

- 15.

- Energy consumption: Low (energy-saving) (3), Medium (2), High (1), No information (0)

- 16.

- Use of toxic substances (e.g., lead, mercury): Not used (3), Used in permitted quantity (2), Used (1), No information (0)

- 17.

- Volume of reused materials [%]: 75–100% (3), 35–75% (2), 0–35% (1), No information (0)

- 18.

- Waste generation in the manufacturing process: No waste (3), Little waste (2), A lot of waste (1), No information (0)

- 19.

- Waste segregation: Full segregation (3), Partial segregation (2), No segregation (1), No information (0)

- 20.

- Mode of transport: Environmentally friendly (sea, rail) (3), Low emission of toxic substances (multimodal) (2), Substantial emission of toxic substances (road) (1), No information (0)

- 21.

- Damage in transport: No damage (3), Minor damage (to the packaging) (2), Major damage (to the product) (1), No information (0)

- 22.

- Number of defective products manufactured: No defective products (3), Up to 30% of products defective (2), More than 30% of products defective (1), No information (0)

The following questions and answers were distinguished for the post-manufacturing stage:

- 23.

- Who can use the product: All user groups (3), Specialized user groups (2), Certain individuals (1), No information (0)

- 24.

- Difficulty of use: Easy to use—intuitive (3), Need to read the instruction manual before use (2), Difficult to use (1), No information (0)

- 25.

- Description of the instruction manual: Easy to understand (3), Difficult to understand (2), Impossible to understand (1), No information (0)

- 26.

- Type of packaging: Does not require packaging (3), Reusable packaging (2), Disposable packaging (1), No information (0)

- 27.

- Recyclable packaging: 100% recyclable (3), Partly recyclable (2), Non-recyclable (1), No information (0)

- 28.

- Volume of toxic substances in the packaging: None (3), Small quantity (2), Large quantity (1), No information (0)

- 29.

- Cleaning: Easy to clean (3), Expensive to clean (2), Cleaning impossible (1), No information (0)

- 30.

- Resistance to dirt: High (3), Medium (2), Low (1), No information (0)

- 31.

- Maintenance: Maintenance free (3), Low maintenance (inexpensive) (2), High maintenance (expensive) (1), No information (0)

- 32.

- Use of additional substances, e.g., lubricating greases: No need (3), Inexpensive (2), Frequent and expensive (1), No information (0)

- 33.

- Repairs: Easy (3), Expensive (2), Impossible (1), No information (0)

- 34.

- Frequency of failures: No failures (3), Once or twice per year (2), Often, more than twice per year (1), No information (0)

- 35.

- Warranty period: More than 4 years (3), 1 to 4 years (2), Less than 1 year (1), No information (0)

- 36.

- Disassembly: Easy—intuitive (3), Only with the instruction manual (2), Difficult (1), No information (0)

- 37.

- Connecting elements: Easily visible (3), Hidden, but marked (2), Invisible (1), No information (0)

- 38.

- Separation of connecting elements: Without damage (3), Damage to connecting elements (2), Damage to the entire part (1), No information (0)

- 39.

- Number of parts connected in the product: 1 part (3), 2 to 12 parts (2), More than 12 parts (1), No information (0)

- 40.

- Types of parts connected: Of the same material—homogenous product (3), Of the same material—homogenous part (2), Of various materials (1), No information (0)

- 41.

- Use of tools during disassembly: No tools needed (3), Basic tools needed (2), Expensive, specialist tools needed (1), No information (0)

- 42.

- Water consumption during use: None (3), Medium (2), High (1), No information (0)

- 43.

- Energy consumption during use: None (3), Medium (2), High (1), No information (0)

- 44.

- Noise during use: None (3), Slight (2), Intrusive(1), No information (0)

- 45.

- Compliance with the rules of ergonomics: Totally compliant (3), Partially compliant (2), Incompliant (1), No information (0)

- 46.

- Life cycle: Longer than estimated: Universal (2), Shorter than estimated (1), No information (0)

- 47.

- Product surface: Does not change in time (3), Partly changes in time (2), Significantly changes in time (1), No information (0)

- 48.

- Wear and tear: Visible, does not cause any problems (3), Partly visible (2), Invisible (1), No information (0)

- 49.

- Additional surface area necessary for use?: No additional surface area necessary (3), Small additional surface area necessary (2), Significant additional surface area necessary (1), No information (0)

- 50.

- Information about disposal: Provided with the product (3), Not provided with the product, but easily available from other sources (2), Not provided with the product, not easily available from other sources (1), No information (0)

- 51.

- Markings of toxic substances: Fully marked (3), Partly marked (2), Not marked (1), No information (0)

- 52.

- Ecolabel: Product marked with the ecolabel (3), Product pending ecolabel (2), No ecolabel B (1), No information (0)

- 53.

- Compliance with customer requirements: Meets all customer requirements (3), Partly meets customer requirements (2), Does not meet customer requirements (1), No information (0)

- 54.

- Compliance with EU Directives (WEEE, RoHS, EuP): Meets all requirements (3), Partly meets requirements (2), Does not meet requirements (1), No information (0)

Arithmetic mean of the analysis conducted according to the environmental quality assessment wasvery high. A score of 2.67 points out of 3.0 classified the refrigerator among products of high environmental quality. Not all the questions in the questionnaire could be answered, as the refrigerator has not been manufactured. Therefore, the assessment is not conclusive.

The lowest scores were assigned to the number of materials to be used—in the pre-manufacturing stage, and the criteria concerning the number and types of connected elements, relevant to the disassembly and recycling of the refrigerator—in the post-manufacturing stage.

7. Environmental Analysis—Automatic Method Based on Artificial Neural Network

Artificial neural networks (ANNs), as a data-driven approach, are increasingly used in research on various aspects of sustainability, including closed-loop sanitation [43], accurate estimation of evapotranspiration [44,45], drinking water management [46], and water quality prediction [47] reaching to energy generation prediction [48,49].We have used ANNs and other AI-based tools (fuzzy logic, etc.) in previous studies to analyse and optimize the various types of processes: from material issues in 3D-printed exoskeletons [50,51] to patient health diagnostics [52,53]. Prior experience suggests that the use of AI-based methods can improve the efficiency, accuracy, and speed of performing many optimization processes. This applies to both big data-based research and research based on small data sets. In some applications, large homogeneous data sets are rarely available, and they are subject to more complexity than in other areas of science, clinical practice and industry. For these reasons, for several years, tools have been developed in the form of neural networks capable of

- Handling small sets of experimental or observational data;

- Helping to identify the main causal factors leading to changes in a particular variable;

- Summarizing the behaviour of a complex system: e.g., the appearance of a disease or production error [54,55].

To solve the overall problem, we used a single artificial neural network in which the input to the network was questions and answers (56, 57, stages: PRE-MANUFACTURING, MANUFACTURING, POST-MANUFACTURING) and the output was the class in Table 5 (EQA).

We made the following assumptions and initial conditions for ANN:

- The type of network was dictated by the way the computational problem was posed: feed-forward neural network with back-propagation algorithm worked well for this type of problem;

- The size of the input layer and the output layer dictated by the values of the parameters;

- Naive initialization techniques;

- Simple generalization and classification stating that the input pattern should result in specific output activations.

A feed-forward neural network with a back-propagation algorithm was used for ANN training and optimization. The machine learning-based tool, using traditional ANN, was Matlab R2021b with Neural Networks Toolbox (MathWorks, Natick, USA). This group of solutions is often used to solve problems in which the complete set of rules is not known and the mathematical model is also missing. It is then possible to construct, test and versify multiple ANN models with different architectures, including different input/output data configurations and the way they are described. In addition, it is possible and useful to optimize (not necessarily: simplify) the above description in order to improve the efficiency of the above process, including by reducing the number of input and output variables, adjusting the number of neurons in the hidden layer(s), reducing the time required to build and train the network, improving estimation accuracy, etc.

Among many ANN topologies, many experimental ANNs have been built based on the authors’ previous studies, ‘hit or miss’ trials, and the application of the genetic algorithm (GA), and only the most promising ones are presented in this paper. Genetic algorithm (GA) finds the best solution in a given search space (solves an optimization problem) in a targeted manner. In this case, it allowed the automatic optimization of the ANN structure based on the original fitness function. The fitness evaluation function was defined as:

where:

F = MSE + (1 −α) ∗ (w/wn) ∗ 10−5 + α ∗ (n/nn) ∗ 10−5

- MSE—mean square error of the ANN;

- α—weight constant, which was set to 0.8;

- w—number of weighted interconnections between the input and the hidden layer;

- wn—maximum number of all interconnections;

- n—number of neurons in the network;

- nn—maximum number of neurons in network;

- 10−5—synaptic weight constant.

According to the aforementioned fitness function, ANNs were evaluated after 1000 epochs. The components of the evaluation were the error obtained after this number of epochs and the “penalty” for network complexity.

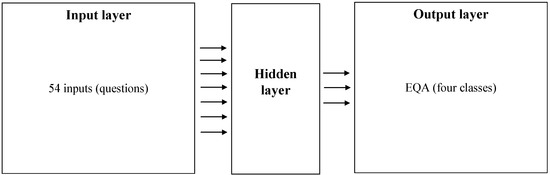

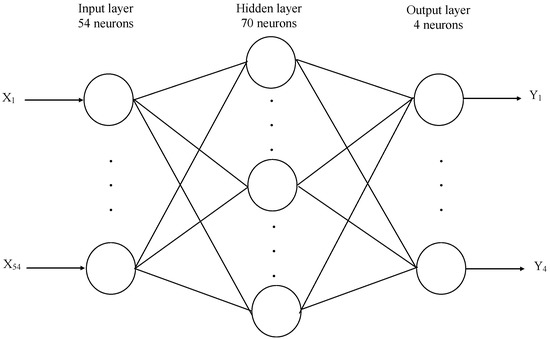

The study used a three-layer forward neural network (Figure 4), a back propagation (BP) algorithm as a popular gradient-based local search optimization technique, a Perceptron Linkage Optimization set for minimal multi-layer diagnostics focused on setting the mean squared error (MSE), and naive initialization techniques. MSE was here defined as an error between the target and the actual outputs averaged over all training examples. An MLP-type network (multi-layer perceptron) performs a mapping of an n-dimensional input vector to an m-dimensional output signal, typically using a single hidden layer with up to 3n neurons.

Figure 4.

Artificial neural network (ANN) structure: inputs and outputs.

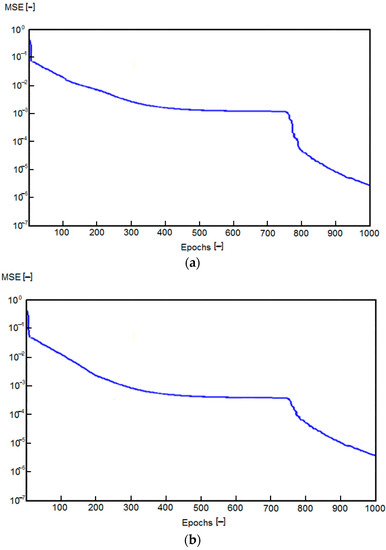

Based on the authors’ knowledge, previous research, and experience, an MLP network with a three-layer structure was chosen: the input layer, hidden layer, and output layer (Figure 4). Fifty-four neurons were placed in the input layer, each of which was responsible for answering one question (one numerical parameter) from Table 6. Four neurons were placed in the output layer, each of which was responsible for one of the four classes (value ranges) of EQA shown in Table 5. The number of neurons in the hidden layer was first estimated based on the authors’ previous knowledge and experience, as far as GA-based optimization, followed by an experimental analysis of the most likely MLP network structures. The transition functions, MSE values, and results for the aforementioned most probable MLP networks are presented in Figure 5, Table 7, Table 8 and Table 9, respectively. They show, as discussed later in the paper, MLP 54-70-4, which means an MLP network with 54 neurons in the input layer, 70 neurons in the hidden layer, and four neurons in the output layer.

Figure 5.

Values of the mean square error (MSE) during learning: (a) optimal MLP 54-70-4, (b) non-optimal MLP 54-90-4.

Table 7.

The best MLP network models for diagnostic measures.

Table 8.

Selected ANNs quality assessment.

Table 9.

(R)MSE values for three MLP neural network.

The selection of input parameters was based on the homogeneity of their numerical values, the ability to obtain the above parameters relatively quickly, and the ability to calculate the required ANN output variables from them. The input parameters had uniform values and were subject to normalization. Scaling of the input variable values was provided to maintain uniformity in the interpretation of all signals in the network and their associated weights. We used an 70%/20%/10% split of the data into three datasets: training, testing, and validation.

The weights of the neural network were preset to avoid too slow convergence of errors and falling into the trap of local minima.

Each network layer contained neurons with the same activation function (Table 7): a sigmoidal type activation function (hyperbolic tangent) was used because of its high flexibility (a nonlinear, continuous, and differentiable function).

The ANN learning process involved repeatedly presenting the patterns and modifying the weights until the network reached its target MSE after an average of 500–1000 epochs (Figure 5).

The proposed optimization method (Table 7, bold shows the best, more results are also shown in Table 8 and Table 9) is a step towards standardizing the parameter selection problem in Industry 4.0 by applying artificial intelligence methods (Figure 6).

Figure 6.

Structure of the optimal ANN.

The best results were obtained for n = 54, m = 4, and 70 neurons in the hidden layer (i.e., MLP 54-70-4), but we observed that other ANN structures were also effective, such as MLP 54-60-4 and MLP 54-80-4. ANN was able to minimize the MSE for the training set data to very small values (0.001–0.01) (Table 8 and Table 9, best choice in bold).

It is important to remember that AI-based optimization not onlyaims to simply find the optimum of the objective function, but to use it in a much more complex process to determine the best set of parameters for each case under analysis. This allows a relatively simple and fast solution of the optimization problem without defining the rules (algorithm, functions), based only on the input and output variables (data-driven approach). Based on the current study, the key issue is the proper selection of data, i.e., proposing such a set of parameters that will constitute a model set based on the knowledge gained from previous research and engineering practice. The focus should be on reflecting the real-world relationships within the problem under study, and ANN will provide a way to process them in such a way that appropriate correlations are obtained between input and output variables, extracting even non-obvious/unknown rules along the way.

The proposed ANN was able to quickly estimate and identify a solution to the problem of selecting/optimising the product parameters as a basic or competitive solution to a traditional IT program. For easily programmable tasks with complete and unchecked databases, the first of the above-mentioned solutions can be an advantage. The ANN, however, will work in almost any conditions, providing a better or worse result. Thus, the difference between using a traditional program and an ANN lies in two areas:

- Database completeness;

- Required accuracy.

8. Discussion

The conclusions related to the application of the proposed methodology are encouraging: it is practically feasible, relatively simple using modern computational methods, and at the same time, fits to societal expectations. Incorporating awareness of environmental friendliness into industrial products is not easy, but it is possible with the right attitude from both producers and consumers, i.e., building an environmentally conscious market. In time, the use of methodologies such as the one proposed will become normal. Just as now is the slow transition, with the right incentives, to hybrid and electric cars, which only ten years ago was difficult to imagine on a mass scale. Additionally, in a short while, perhaps, there will be no bottles other than returnable bottles with a deposit in every shop.

The shortcomings identified in the current methodologies and what we are proposing as an alternative include, first and foremost, the comprehensiveness and possible automation of the entire process within the Industry 4.0 paradigm. The solutions in this area to date have not covered the entire process and the areas of automation have often been dealt with piecemeal, with no emphasis on the planning process and product design or the entire product life cycle. This resulted in not all costs, including social costs, being properly valued in the product evaluation process.

8.1. Achieved Results

The designed refrigerator falls into the category of environmentally friendly products. The entirety of its interior (together with the drawers) is recyclable, as is the outer casing, once we remove the veneer. The veneer itself is also recyclable. As a result of the analysis, the product has been classified as timeless. Market analyses show that the average life cycle of a refrigerator is 13 years. The solution under analysis has an estimated life cycle of 15 years. The cosmetics market has seen a relative growth in natural cosmetics which must be stored in a refrigerator; therefore, it can be assumed that the demand for this type of product will be on the rise. The mini refrigerator can be easily redesigned once, e.g., when new, more environmentally friendly materials become available. The fridge is easily repairable. If used properly, parts of the fridge, such as the interior body or the casing, are not subject to much wear and tear, as they are not exposed to any pressure or friction force. The components of the cooling system are easily replaceable. The materials used do not change their properties in time. The refrigerator can be made of reused materials; recycled steel sheets or polystyrene boards can be used.

The manufacturing process uses environmental solutions. Although waste cannot be reduced to zero, it can be minimized, and the waste generated can be recycled.

The use of a refrigerator is inseparably connected with energy consumption, which cannot be brought down to zero. In the design under analysis, the level of energy consumption is acceptable, albeit affected by the use of Smart Glass door. However, the suppliers of Smart Glass emphasize the environmental friendliness of the product, which does not consume energy when inactive, and needs very little energy to maintain the active state [56,57].

We carefully compared the study presented here with others to show the novelty of this study, including to show that we obtained better theoretical and/or methodological results. Similar research on the development of methods related to product eco-design was conducted by Wang et al. [58]. They developed a method for product design with the possibility of an ecological assessment of electrical appliances. Their proposed solution required knowledge of design systems (CAD). The results they obtained indicated that the use of the proposed tool improved the eco-efficiency of the designed devices by about 46%. In the solutions that are described in this article, the improvement in eco-efficiency is also estimated at a similar level, especially in the last phase of the life cycle (recycling). However, the research carried out according to the proposed methods covers a broader aspect, not only the structure of the product (materials used, connections, components), but also takes into account other specific features of the product (e.g., easy to clean, easy to use—intuitive). Not only designers, but also future users are involved in the development of the product, which enables the design of an environmentally friendly product as well as the future user. We are therefore firmly convinced that the objectives of our research have been fully achieved.

8.2. Limitations of the Work

No functional limitations were observed in the proposed solution compared to traditional counterparts. Also, no limitations were observed that may affect the robustness of the results now and/or in the future. Due to its green features, the purchase of the fridge could be subsidised, similar to the purchase of electric cars in some countries. Nevertheless, the proposed solution is only the first of a family of products dedicated to the green revolution. For the reasons mentioned above, it is a limitation of the work to narrow the spectrum to one type of product. The development of a whole family of similar products is very likely, both due to green changes in global production and due to constraints in the supply of materials (raw materials of semi-finished products, electronic parts, and other rare earth elements) and energy. This will, perhaps, create new challenges related to green mass production and simultaneous life-cycle monitoring for many products with assured recycling, including the use of the Internet of Things, cloud computing, and artificial intelligence. This situation is the subject of our further research and will be reflected in future publications.

8.3. Expected Impact

Ecological design has a significant impact on local and global changes, including the development of Industry 4.0 towards sustainability, in particular towards sustainable intelligent use of biofuels with optimal use of green energy sources under conditions of flexible production and economically independent closed-loop, customer-centred logistics for different types of materials, products and services. In particular, the results of our research may have:

- 1.

- social impact through:

- Educating new generations in the so-called ‘green deal’, instilling respect for the environment and its resources in harmonious development with human civilization;

- Building public awareness of environmentally friendly household appliances,

- Long-term research on, e.g., market preferences and promotion of pro-health and pro-environmental behaviour;

- Building environmentally conscious customer groups as co-participants in the processes rather than mere consumers of their effects;

- Shaping general global trends: the results presented in this work can actually impact people, cities, the environment, etc. making the notion of ‘human smart cities’ an aspiration for the planned, thoughtful sustainability of whole communities, not just infrastructure;

- 2.

- expected impact on research:

- Scholars can use this work as inspiration for further research into innovative pro-environmental organisational processes, production, and new products and services;

- Sustainability can play role of a key aspect in research in science and technology, medical, or humanities and social sciences;

- 3.

- expected impact on industry and trade:

- Short-term impact: industrial practitioners can benefit from reading this work by rethinking and adapting existing industrial processes towards sustainability;

- Development of a family of products with different properties, made of different materials (including decorative) and in different sizes, including built-in;

- The emergence of additional functionalities supported by new modules, including those based on the Internet of Things (IoT) and Artificial Intelligence (AI) (a strategy of growing products, in line with user needs, through simple improvements rather than product replacement);

- In the future: 3D printing from environmentally friendly materials, with print parameters and materials selected by AI, and optimization of a template purchased in a virtual shop to the needs of a specific customer within a zero-waste paradigm.

8.4. Directions for Further Research

Further research should focus on the aforementioned social, scientific, and industrial impacts. There is no doubt that ecological, healthy, tailor-made household appliances, which meet customers’ needs, will have a longer life cycle, thus contributing to the reduced consumption of resources and their environmental impact. This seems to be a natural course of development of household appliances. It is clear that future research should also focus on multi-material technologies or materials in which parameters or functions change or combine with different structural, physical, and chemical parameters, including screening different combinations of technologies and materials based on their digital twins.

The process parameters were also estimated efficiently using ANN. This article indicates the effectiveness of ANN in research on new, pro-ecological products: prediction of eco-efficiency, green marketing, predictors of pro-environmental behaviours, links between education and pro-environmental behaviour, the use of ANN in the inventory model in conditions of uncertainty and inflation, and benefits from maintenance technology with promotion and time-dependent degradation under fuzzy learning conditions (based on linguistically described parameters). The solutions presented in this paper are a promising tool in the field of computational analysis and design of environment-friendly products. Our results confirm that such processes may be AI-based and optimized toward the successful and sustainable production of usable/functional products. Automation of the process of selecting process parameters, technology, and materials used requires an appropriate tool (ANN). This not only improves environmental friendliness but also the product quality, and reduces the time required to prepare such an automatically created set of parameters. The selection process itself can be easily adapted to different technology/material combinations, as well as developed to create a more advanced tool, useful for mass production and continuous technical control within the Industry 4.0 paradigm. Easier modification through the use of modifiable templates and faster production, as well as client satisfaction, are also of high importance and quickly assessed.

On the other hand, within the reverse process before construction/production, the choice of a particular solution (technologies, materials) can significantly influence the mitigation of the design, production costs, sustainability, data accuracy, process efficiency, and multifunctionality of the project. The technology and procedure described in this paper not only make it possible to ensure verified sustainability, but also to integrate it in the form of physical and logical processes. Describing them in a way that is understandable to existing users will allow you to implement similar software and processes in large-scale, automated, and robotic production. The potential use of digital twins will translate into increased process and product reliability, cost reduction, and increased efficiency.

In the area of related assessment approaches, no single leading metric for assessing the novelty in engineering design has been identified to date [59]. Despite this, it is well known that innovation (understood as both the development of unique new solutions and the continuous process of improving on previous solutions) is a key element necessary for competitive advantage and industrial development. While a user-centred approach is particularly valuable, innovation is often already apparent at the laboratory research stage, where the customer is not always yet well-defined and new application areas are not fully identified [60,61]. It is also important to assess the efficiency and systematicity of idea generation in engineering design, so that the viability of maintaining particular lines of research in an industrial setting can be assessed [62]. In the current world, it is important to merge creativity research with sustainability research [63,64]. Research by Li et al. has shown that green transformational leadership influences the green intrinsic motivation and creativity of employees, motivating them to produce clean and green products and services [63]. Creative problem solving of holistically framed problems/barriers provides a way for the emergence of more radical and breakthrough solutions to sustainability problems [64]. In order to optimize and reduce the number of ANN variables, a genetic algorithm was used. The most important discovery in the direction of research is finding newer, faster and simpler methods of environmentally friendly design, including through more effective models based on artificial intelligence. The contribution of this work will increase the possibilities of computer-aided design, including in the “Industry 4.0” paradigm, for analysis and forecasting beyond current scientific knowledge and engineering experience. Until now, the unused potential is the direct reading and analysis of parameters from the production line software and the fuzzy logic in the analysis of linguistic features. It is worth noting that different ANNs can meet the different requirements of scientists and engineers optimizing production processes. However, they may require more complex structures, more computing power, or data processing time than the MLP network presented in this paper. Thus, the key cost-effect ratio for the profitability of industrial production may be less favourable or production may even be unprofitable.

9. Conclusions

Creative thinking is an inherent process in the creation of innovations. Imagination is employed to seek creative solutions. The problem under analysis can be viewed from another perspective and a solution can be found. The employment of inventive methods in the creative process helps sort what we know about the problem. With the environmental aspects included, the methods not only help create a new, improved product, but also make it eco-innovative. In order to properly conduct research into the use of inventive methods, several methods had to be used. It was observed during the creativity session that inexperienced respondents (i.e., those, who had never used inventive methods before or, in general, did not use any methods of creative problem solving), rather than come up with specific solutions, provided general ideas of solutions. The group of the most creative respondents proposed particular solutions, some of which were infeasible.

Unfortunately, the environmentally friendly materials used in the design have raised the estimated costs of the product, compared to less environmentally friendly similar products available on the Polish market [65]. However, an increased public awareness of environmental protection opens the door to designing innovative products, such as the refrigerator, whose prices are slightly higher than those of less ecological equivalents. In spite of the higher manufacturing costs, the more environmentally friendly refrigerator is cheaper in operation (consumes less energy), owing to the ecological solutions incorporated into its design.AI-based design can significantly support environmentally friendly production [66].The optimization and automation of process and material factors improves the ability to provide environmentally friendly products and services necessary for normal everyday life.

The simple hybrid ANN/GA solution provides a fast and reliable second opinion system for processing and optimization. Despite the complexity of the modelled process, the number of parameters taken into account in the optimization process may be reduced, and the selection of the number of neurons in the hidden AR layer affects the speed and accuracy of predicting the initial set of parameters. For more advanced solutions, deep neural networks may be used. The developed automatic models of pro-environmental analysis of product design can then be used to develop an intelligent expert system that will assist less experienced designers when designing subsequent new products.

Author Contributions

Conceptualization, E.D., I.R. and D.M.; methodology, E.D., I.R. and D.M.; software, E.D., I.R., D.M. and J.D.; validation, E.D., I.R. and D.M.; formal analysis, E.D., I.R. and D.M.; investigation, E.D., I.R., D.M. and J.D.; resources, E.D. and I.R.; data curation, E.D., I.R., D.M. and J.D.; writing—original draft preparation, E.D., I.R., D.M. and J.D.; writing—review and editing, E.D., I.R., D.M. and J.D.; visualization, I.R. and D.M.; supervision, E.D., I.R., D.M. and J.D.; project administration, E.D. and I.R.; funding acquisition, E.D., I.R., and D.M. All authors have read and agreed to the published version of the manuscript.

Funding

The work presented in the paper has been co-financed under grant for Poznan University of Technology (grant no. 0613/SBAD/4710) and grant to maintain the research potential of Kazimierz Wielki University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank for their help, Paulina Szczap and Marta Tomczuk in participation in the research. Especially in conducting a session of excellence (of the creativity session) and collecting data from session participants.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Monteiroa, J.; Silva, F.J.G.; Ramosa, S.F.; Campilhoa, R.D.S.G.; Fonseca, A.M. Eco-Design and Sustainability in Packaging: A Survey. Procedia Manuf. 2019, 38, 1741–1749. [Google Scholar] [CrossRef]

- Kong, L.; Wang, l.; Li, F.; Tian, G.; Li, J.; Cai, Z.; Zhou, J.; Fu, Y. A life-cycle integrated model for product eco-design in the conceptual design phase. J. Clean. Prod. 2022, 363, 132516. [Google Scholar] [CrossRef]

- Rousseaux, P.; Gremy-Gros, C.; Bonnin, M.; Henriel-Ricordel, C.; Bernard, P.; Floury, L.; Staigre, G.; Vincent, P. Eco-tool-seeker: A new and unique business guide for choosing ecodesigntools. J. Clean. Prod. 2017, 151, 546–577. [Google Scholar] [CrossRef]

- Sakao, T.; Brambila-Macias, S.A. Do we share an understanding of transdisciplinarity in environmental sustainability research? J. Clean. Prod. 2018, 170, 1399–1403. [Google Scholar] [CrossRef]

- Brambila-Macias, S.A.; Sakao, T. Effective ecodesign implementation with the support of a lifecycle engineer. J. Clean. Prod. 2021, 279, 123520. [Google Scholar] [CrossRef]

- Hischier, R.; Reale, F.; Castellani, V.; Sala, S. Environmental impacts of household appliances in Europe and scenarios for their impact reduction. J. Clean. Prod. 2020, 267, 121952. [Google Scholar] [CrossRef]

- Global consumption value of household appliances from 2013 to 2020. Available online: https://www.statista.com/statistics/270868/forecast-of-global-market-demand-of-electrical-appliances-and-houseware/ (accessed on 24 January 2022).

- Castellani, V.; Hidalgo, C.; Gelabert, L.; Riera, M.R.; Escamilla, M.; SanyeMengual, E.; Sala, S. Consumer Footprint: Basket of Products Indicator on Household Goods; Technical Report EUR 29710 EN; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Reale, F.; Castellani, V.; Hischier, R.; Sala, S. Consumer Footprint: Basket of Products Indicator on Household Appliances; Technical Report EUR 29758 EN; European Commission, Joint Research Center: Luxembourg, 2019; ISBN 9789276050032. [Google Scholar] [CrossRef]

- Directive 2009/125/EC of the European Parliament and of the Council Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. 2009. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:285:0010:0035:en:PDF (accessed on 24 January 2022).

- Livotov, P.; Sekaran, A.P.C.; Mas’Udah; Law, R.; Reay, D.; Sarsenova, A.; Sayyareh, S. Eco-innovation in process engineering: Contradictions, inventive principles and methods. Therm. Sci. Eng. Prog. 2019, 9, 52–65. [Google Scholar] [CrossRef]

- Lin, L.; Rasovska, I.; De Guio, R.; Dubois, S. Optimization Methods for Inventive Design. In TRIZ—The Theory of Inventive Problem Solving; Cavallucci, D., Ed.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Hanifi, M.; Chibane, H.; Houssin, R.; Cavallucci, D. A Method to Formulate Problem in Initial Analysis of Inventive Design. In Proceedings of the IFIP International Conference on Product Lifecycle Management, Rapperswil, Switzerland, 5–8 July 2020; Nyffenegger, F., Ríos, J., Rivest, L., Bouras, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 594. [Google Scholar] [CrossRef]

- Yehya, M.I.; Houssin, R.; Coulibaly, A.; Chibane, H. State of the Art for Evaluation of Inventive Design Solution Concepts. In Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing, Aix en Provence, France, 2–4 June 2020; Roucoules, L., Paredes, M., Eynard, B., Morer Camo, P., Rizzi, C., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; Zanette, E.T.; Filho, A.G.; Ometto, A.R.; Rozenfeld, H. Ecodesign methods focused on remanufacturing. J. Clean. Prod. 2010, 18, 21–31. [Google Scholar] [CrossRef]

- Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Karwasz, A. Multi-agent System to Support Decision-Making Process in Ecodesign. In Proceedings of the 10th International Conference on Soft Computing Models in Industrial and Environmental Applications, Burgos, Spain, 15–17 June 2015; Springer: Berlin/Heidelberg, Germany, 2015; Volume 368, pp. 463–474. [Google Scholar]

- Karwasz, A.; Dostatni, E.; Diakun, J.; Grajewski, D.; Wichniarek, R.; Stachura, M. Estimating the cost of product recycling with the use of ecodesign support system. Manag. Prod. Eng. Rev. 2016, 7, 33–39. [Google Scholar] [CrossRef]

- Dostatni, E.; Rojek, I.; Hamrol, A. The Use of Machine Learning Method in Concurrent Ecodesign of Products and Technological Processes. In Advances in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 321–330. [Google Scholar]

- Luiz, J.V.R.; Jugend, D.; Jabbour, C.J.C.; Luiz, O.R.; de Souza, F.B. Ecodesign field of research throughout the world: Mapping the territory by using an evolutionary lens. Scientometrics 2016, 109, 241–259. [Google Scholar] [CrossRef]

- Hendrickson, C.; Horvath, A.; Joshi, S.; Lave, L. Economic input-output models for environmental lifecycle assessment. Environ. Sci. Technol. 1998, 32, 184–191. [Google Scholar] [CrossRef]

- Joshi, S. Product environmental life-cycle assessment using input-output techniques. J. Ind. Ecol. 1999, 3, 95–120. [Google Scholar] [CrossRef]

- Boks, C.; McAloone, T.C. Transitions in sustainable product design research. Int. J. Prod. Dev. 2009, 9, 429–449. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Diwekar, U.; Shastri, Y. Design for environment: A state-of-the-art review. Clean Technol. Environ. Policy 2011, 13, 227–240. [Google Scholar] [CrossRef]

- Karlsson, R.; Luttropp, C. EcoDesign: What’s happening? An overview of the subject area of EcoDesign and of the papers in this special issue. J. Clean. Prod. 2006, 14, 1291–1298. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Hamrol, A. Ecodesign of Technological Processes with the Use of Decision Trees Method. In Proceedings of the International Joint Conference SOCO’17-CISIS’17-ICEUTE’17, León, Spain, 6–8 September 2018; Springer: Berlin/Heidelberg, Germany, 2018; Volume 649, pp. 318–327. [Google Scholar]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development capabilities for smart products. CIRP Ann. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- O’Brien, M.; Bleischwitz, R.; Steger, S.; Fischer, S. Europe in Transition: Paving the Way to a Green Economy through Eco-Innovation; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- Lee, C.-H.; Wu, K.-J.; Tseng, M.-L. Resource management practice through eco-innovation toward sustainable development using qualitative information and quantitative data. J. Clean. Prod. 2018, 202, 120–129. [Google Scholar] [CrossRef]

- Chou, J.-R. An ARIZ-based life cycle engineering model for eco-design. J. Clean. Prod. 2014, 66, 210–223. [Google Scholar] [CrossRef]

- Schischke, K.; Hagelüken, M.; Steffenhagen, G. An Introduction to the Eco-Design Strategy. Why, What and How? Available online: https://docplayer.pl/2284947-Wprowadzenie-do-strategii-ekoprojektowania-dlaczego-co-i-jak.html (accessed on 6 November 2020).

- Antoszkiewicz, J. Heuristic Methods. Creative Problem Solving; PWE: Warsaw, Poland, 1990. [Google Scholar]

- Kuzma, E.; SantinPadilha, L.; Sehnem, S.; Julkovski, D.J.; Roman, D.J. The relationship between innovation and sustainability: A meta-analytic study. J. Clean. Prod. 2020, 259, 120745. [Google Scholar] [CrossRef]

- Zhu, Y.; Ritter, S.M.; Dijksterhuis, A. Creativity: Intrapersonal and Interpersonal Selection of Creative Ideas. J.Create.Behav. 2020, 54, 626–635. [Google Scholar] [CrossRef]

- Brainstorm—8 Rules. Available online: https://public-media.interaction-design.org/pdf/Brainstorm.pdf (accessed on 16 December 2021).

- Jagoda-Sobalak, D.; Knosala, R. Implementation of inventive methods in designing an innovative product. In Innovations in Management and Production Engineering; Publishing House of the Polish Society of Production Management: Opole, Poland, 2013; pp. 78–86. Available online: http://www.ptzp.org.pl/files/konferencje/kzz/artyk_pdf_2013/p007.pdf (accessed on 16 December 2021).

- Lapunka, I.; Jagoda-Sobalak, D.; Marek-Kolodziej, K. Innovation Project Machine in a Systems Approach to Engineering Management. In CBU International Conference Proceedings; ISE Research Institute: Freiburg, Germany, 2017; pp. 261–268. [Google Scholar]

- Montag-Smit, T.; Maertz, C.P. Searching outside the box in creative problem solving: The role of creative thinking skills and domain knowledge. J. Bus. Res. 2017, 81, 1–10. [Google Scholar] [CrossRef]

- FAO; FAOLEX. Act on Waste Electrical and Electronic Equipment. 2015. Available online: https://www.ecolex.org/details/legislation/act-on-waste-electrical-and-electronic-equipment-lex-faoc113636/ (accessed on 4 August 2022).

- Industrial Gases. Available online: http://www.linde-gaz.pl (accessed on 27 December 2021).

- Smart Glass. Available online: http://smartglasspolska.pl (accessed on 20 December 2021).

- Kruszyńska, A. The Method of Ecological Quality Assessment of Products. Master’s Thesis, Poznan University of Technology, Poznań, Poland, 2014. [Google Scholar]

- Ganesapillai, M.; Sinha, A.; Mehta, R.; Tiwari, A.; Chellappa, V.; Drewnowski, J. Design and Analysis of Artificial Neural Network (ANN) Models for Achieving Self-Sustainability in Sanitation. Appl. Sci. 2022, 12, 3384. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; Zhang, J.; Tang, L.; Bai, Y. Using Artificial Neural Network Algorithm and Remote Sensing Vegetation Index Improves the Accuracy of the Penman-Monteith Equation to Estimate Cropland Evapotranspiration. Appl. Sci. 2021, 11, 8649. [Google Scholar] [CrossRef]

- Fernández-López, A.; Marín-Sánchez, D.; García-Mateos, G.; Ruiz-Canales, A.; Ferrández-Villena-García, M.; Molina-Martínez, J.M. A Machine Learning Method to Estimate Reference Evapotranspiration Using Soil Moisture Sensors. Appl. Sci. 2020, 10, 1912. [Google Scholar] [CrossRef]

- Menapace, A.; Zanfei, A.; Righetti, M. Tuning ANN Hyperparameters for Forecasting Drinking Water Demand. Appl. Sci. 2021, 11, 4290. [Google Scholar] [CrossRef]

- Chen, Y.; Song, L.; Liu, Y.; Yang, L.; Li, D. A Review of the Artificial Neural Network Models for Water Quality Prediction. Appl. Sci. 2020, 10, 5776. [Google Scholar] [CrossRef]

- Ma, Y.-J.; Zhai, M.-Y. A Dual-Step Integrated Machine Learning Model for 24h-Ahead Wind Energy Generation Prediction Based on Actual Measurement Data and Environmental Factors. Appl. Sci. 2019, 9, 2125. [Google Scholar] [CrossRef]

- Faraji, J.; Abazari, A.; Babaei, M.; Muyeen, S.M.; Benbouzid, M. Day-Ahead Optimization of Prosumer Considering Battery Depreciation and Weather Prediction for Renewable Energy Sources. Appl. Sci. 2020, 10, 2774. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-optimized technological aspects of the material used in 3D printing processes for selected medical applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Macko, M.; Szczepański, Z.; Dostatni, E. Optimization of extrusion-based 3D printing process using neural networks for sustainable development. Materials 2021, 14, 2737. [Google Scholar] [CrossRef] [PubMed]

- Prokopowicz, P.; Mikołajewski, D.; Tyburek, K.; Mikołajewska, E. Computational gait analysis for post-stroke rehabilitation purposes using fuzzy numbers, fractal dimension and neural networks. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 191–198. [Google Scholar]

- Prokopowicz, P.; Mikołajewski, D. Fuzzy Approach to Computational Classification of Burnout—Preliminary Findings. Appl. Sci. 2022, 12, 3767. [Google Scholar] [CrossRef]

- Pasini, A. Artificial neural networks for small dataset analysis. J. Thorac. Dis. 2015, 7, 953–960. [Google Scholar] [PubMed]

- Feng, S.; Zhou, H.; Dong, H. Using deep neural network with small dataset to predict material defects. Mater. Des. 2019, 162, 300–310. [Google Scholar] [CrossRef]

- Michałowski, T.; Zieliński, K. Glass with Variable Translucency. Available online: https://www.swiat-szkla.pl/kontakt/7236-szklo-o-zmiennej-przeziernosci.html (accessed on 25 January 2022).

- Profiglass. Available online: http://www.profiglass.com.pl/ (accessed on 25 January 2022).

- Wang, S.; Su, D.; Ma, M.; Kuang, W. Sustainable product development and service approach for application in industrial lighting products. Sustain. Prod. Consum. 2021, 27, 1808–1821. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Rotini, F. Novelty metrics in engineering design. J. Eng. Des. 2021, 32, 590–620. [Google Scholar] [CrossRef]

- Bazzaro, F.; Meyer, Y. User-centred design approach with misidentified end-users: Case study for smart composite structures. J. Eng. Des. 2022, 33, 1–14. [Google Scholar] [CrossRef]

- Jagtap, S. Design creativity: Refined method for novelty assessment. Int. J. Des. Creat. Innov. 2019, 7, 99–115. [Google Scholar] [CrossRef]

- Nelson, B.A.; Wilson, J.O.; Rosen, D.; Yen, J. Refined metrics for measuring ideation effectiveness. Des. Stud. 2009, 30, 737–743. [Google Scholar] [CrossRef]

- Li, W.; Bhutto, T.A.; Xuhui, W.; Maitlo, Q.; Zafar, A.U.; Bhutto, N.A. Unlocking employees’ green creativity: The effects of green transformational leadership, green intrinsic, and extrinsic motivation. J. Clean. Prod. 2020, 255, 120229. [Google Scholar] [CrossRef]

- Kajzer Mitchell, I.; Walinga, J. The creative imperative: The role of creativity, creative problem solving and insight as key drivers for sustainability. J. Clean. Prod. 2017, 140, 1872–1884. [Google Scholar] [CrossRef]

- Media Expert. Available online: http://www.mediaexpert.pl/ (accessed on 25 January 2022).

- Rojek, I. Neural networks as performance improvement models in intelligent CAPP systems. Control. Cybern. 2010, 39, 55–68. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).