BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges

Abstract

1. Introduction

2. Literature Review

2.1. BIM for FM

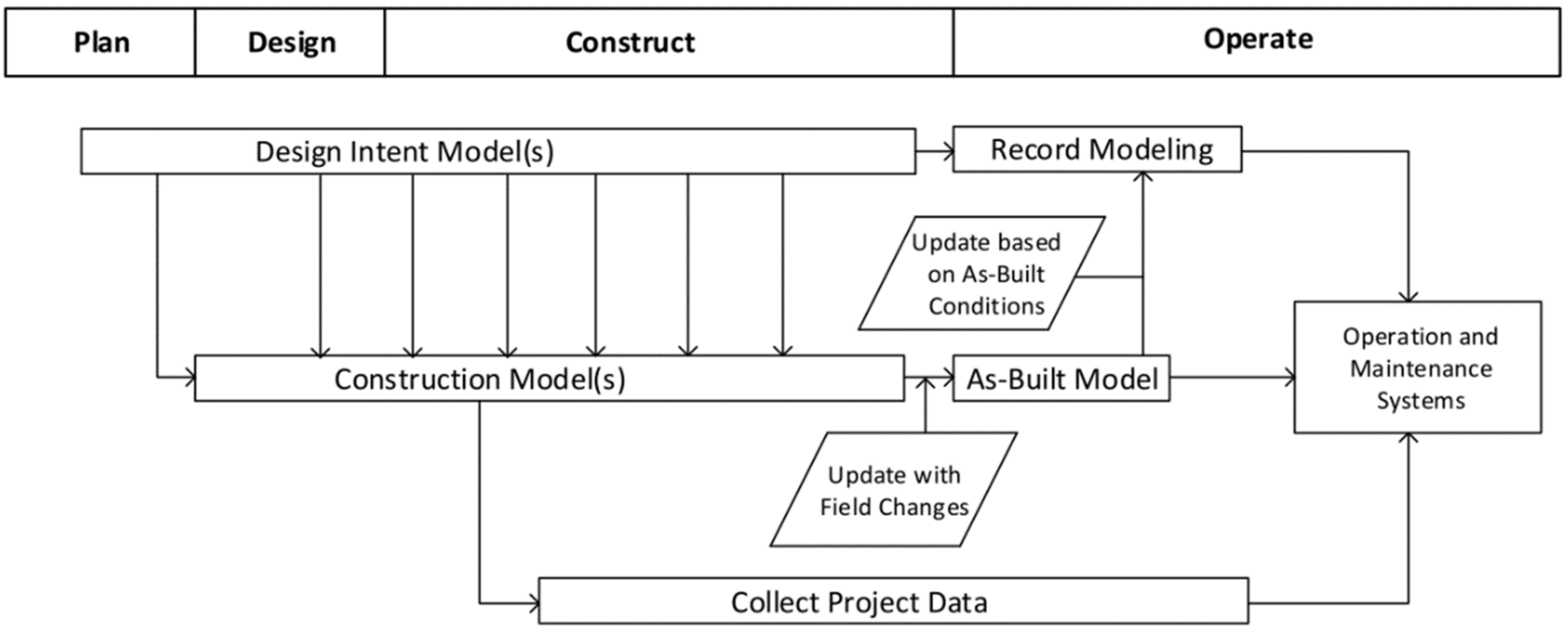

2.2. BIM-Enabled Asset Information Delivery Process

2.3. Standards for the BIM-Enabled Asset Information Delivery Process

2.4. Synthesis of Relevant Challenges in BIM-Enabled Asset Information Delivery

2.5. Summary of Literature Review

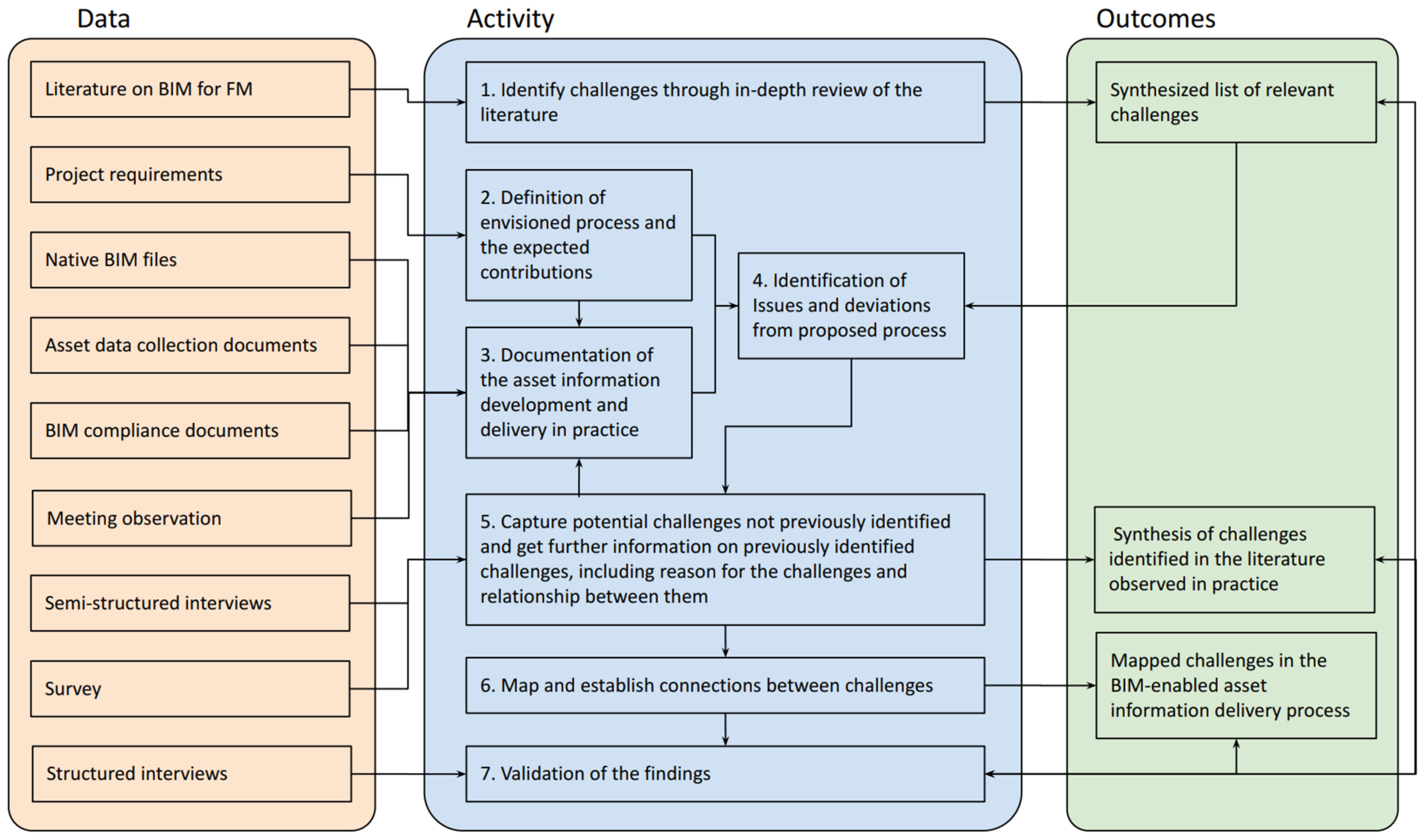

3. Materials and Methods

3.1. Case Study Approach

3.2. Data Collection

3.3. Use of the Data

3.4. Validation

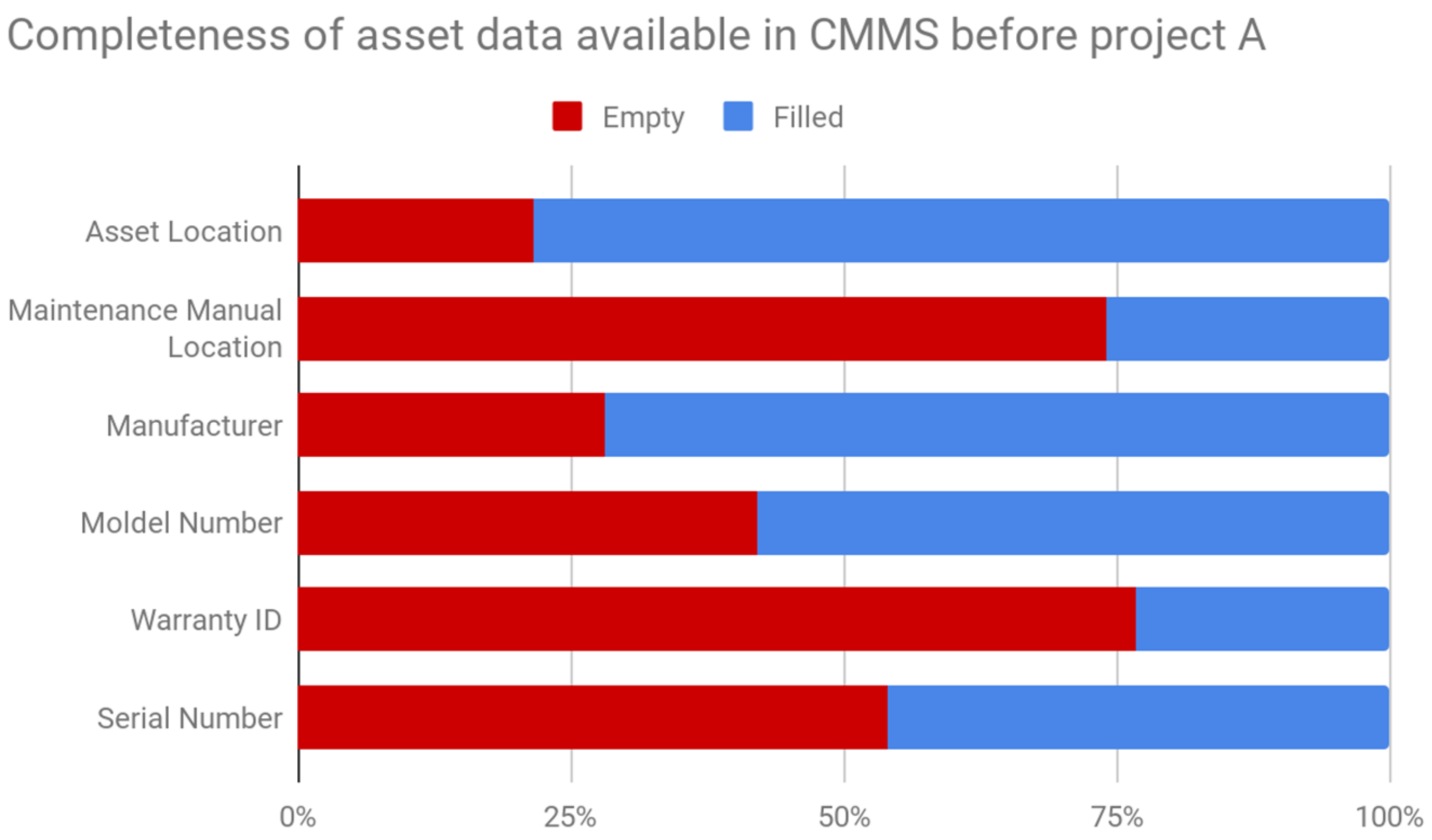

4. Case Study Projects

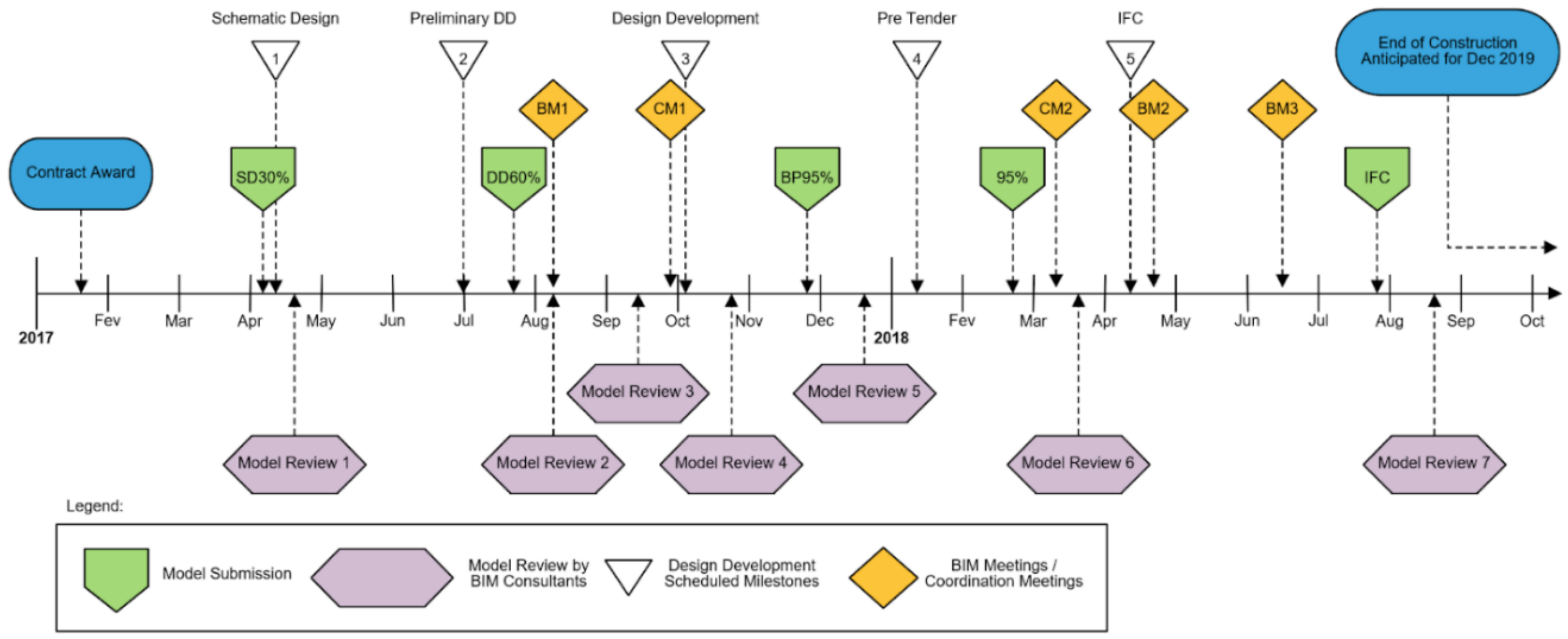

4.1. General Project Information—Project A

4.2. General Project Information—Project B

4.3. General Project Information—Project C

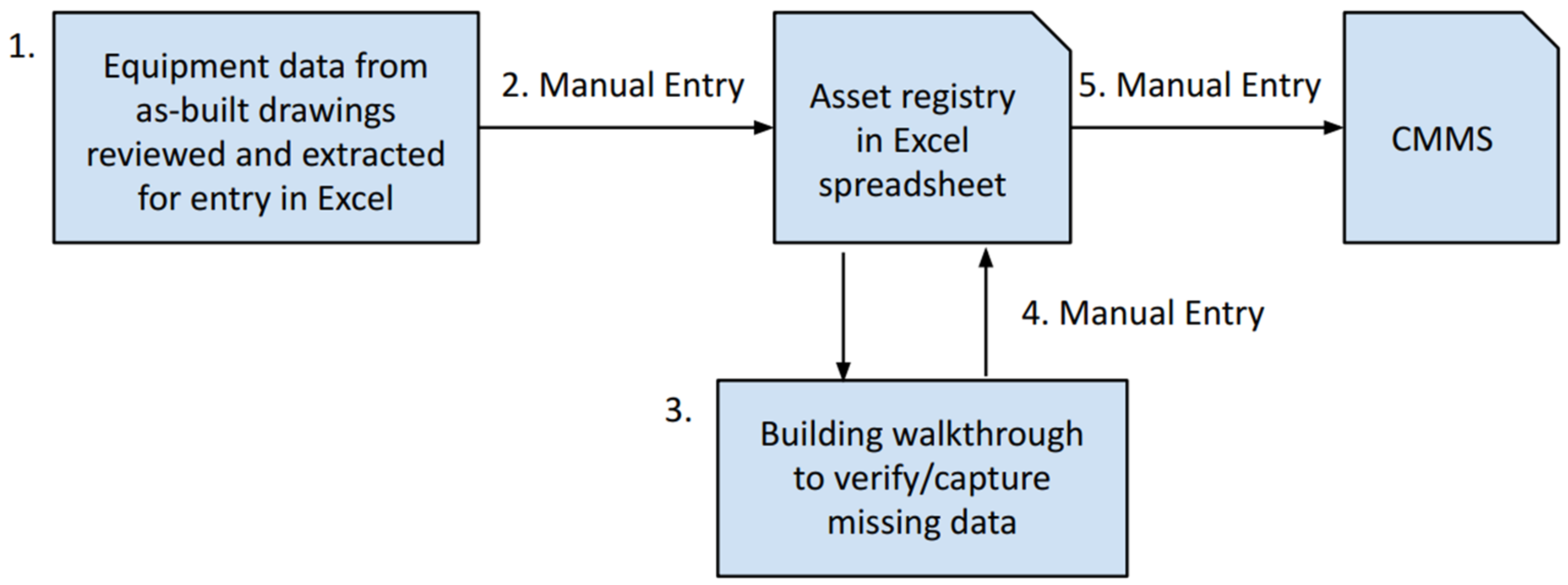

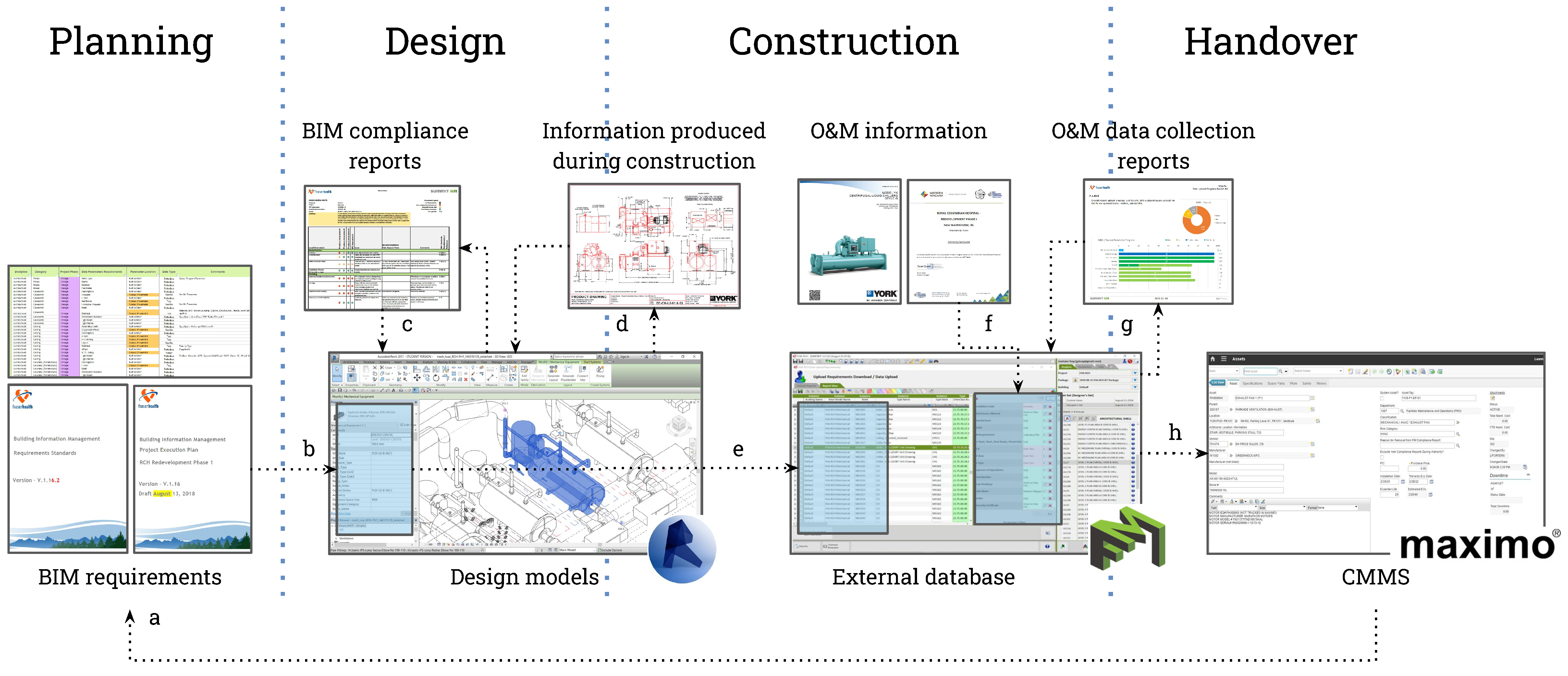

5. BIM-Enabled Asset Information Delivery Process

- a.

- Definition of the Information Requirements

- Owner Standard Requirements (OSR).—A standardized document used by the health authority (owner), to describe their goals and processes and establish the minimum BIM requirements in their projects. The OSR covered legal aspects, specific modeling requirements for the different disciplines, an accuracy table, virtual coordination workflows, etc.

- BIM Project Execution Plan (BEP).—A guideline for the coordination of the BIM development process in this specific project. The BEP was meant to be a roadmap to facilitate the reuse of the models in the future. It was prepared in collaboration between the BIM consultants and the design build teams. The content included modeling strategies, quality control protocols, and collaboration tools. It was required to be updated over time to reflect the reality of the process during the design.

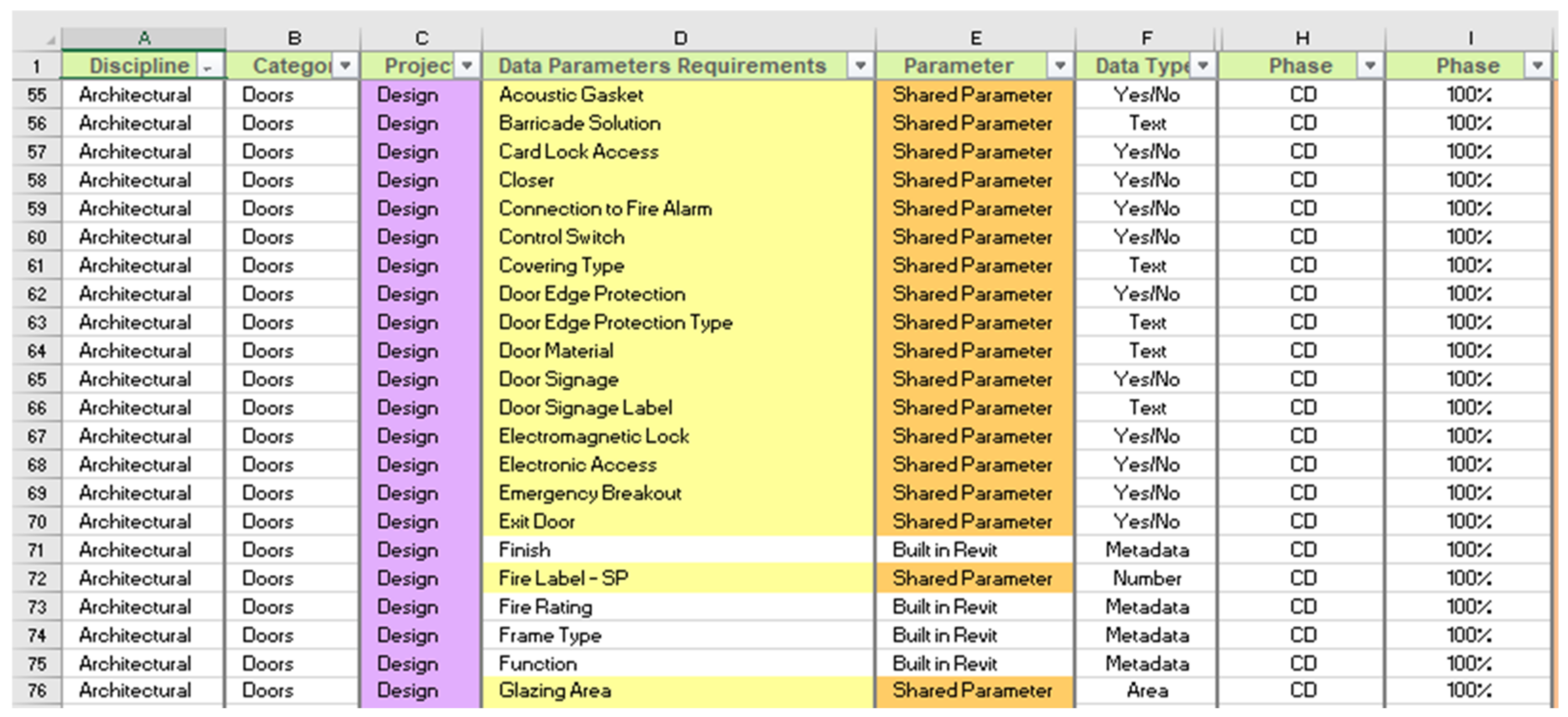

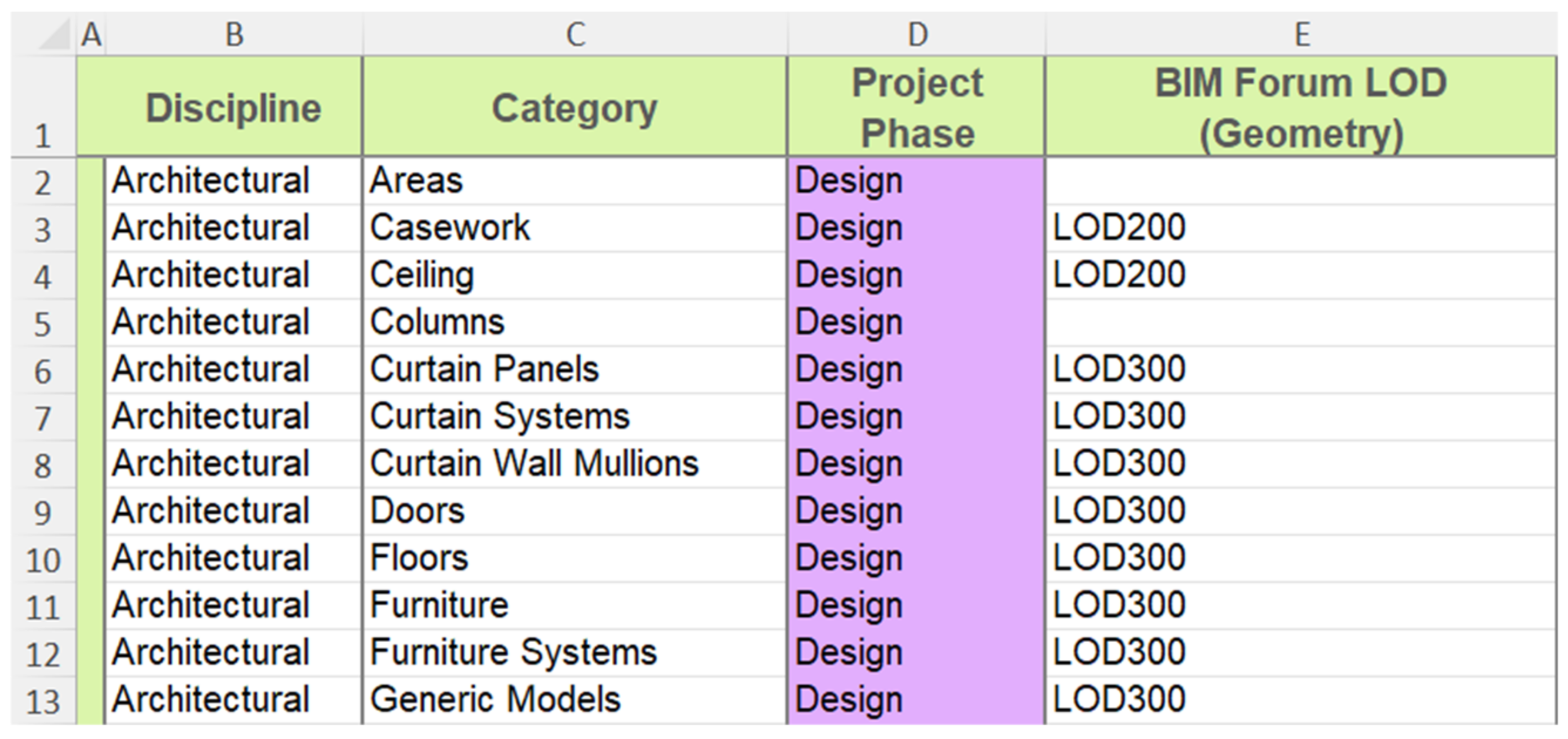

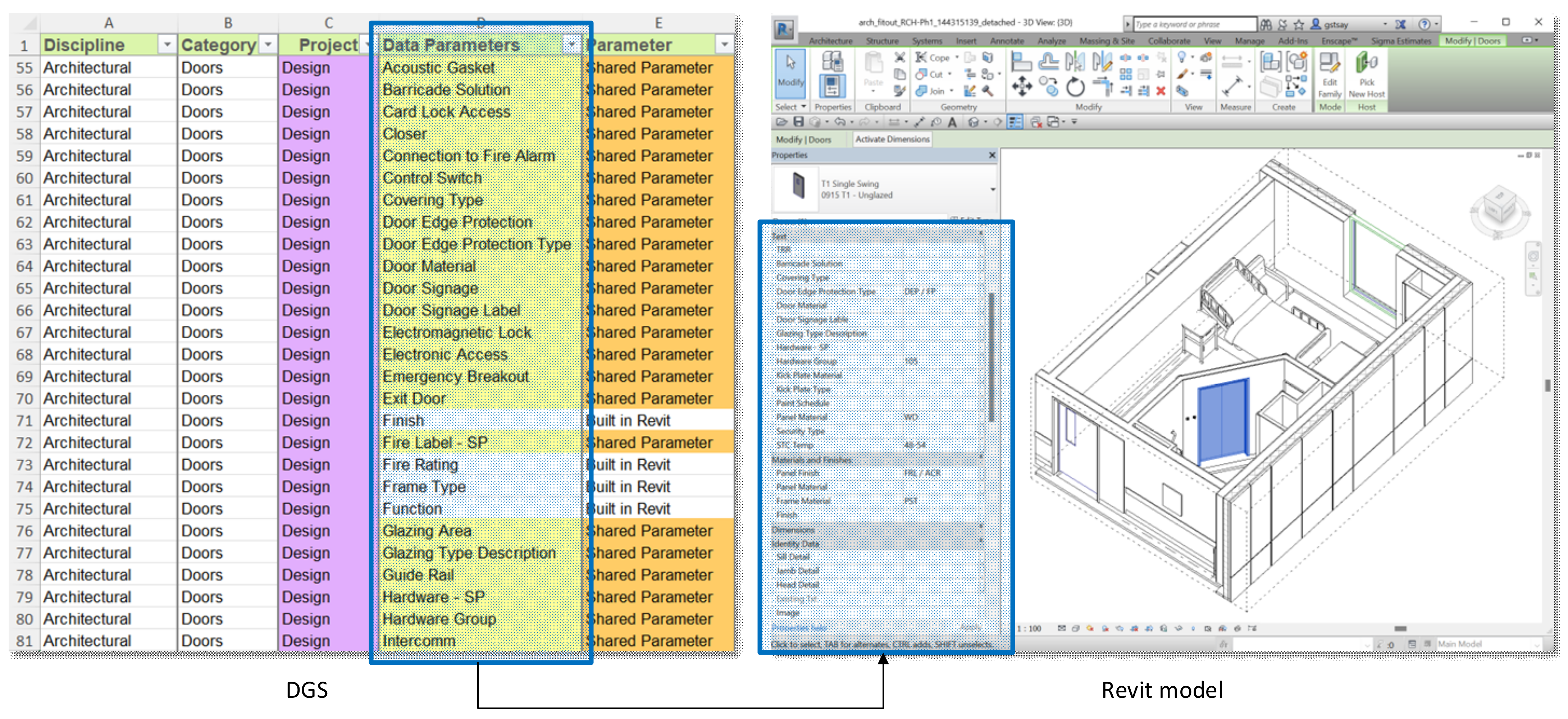

- BIM Data and Geometry Specification (DGS).—This document established the information requirements for each category of objects through the specification of parameters to be added and populated in the model. A total of 130 different data parameters were specified. It also provided the Level of Development (LoD) for each category of objects. This document also included an Object List spreadsheet containing 217 different types of assets required in the model along with their importance for FM, category specification, discipline, and naming convention.

- b.

- Model development observing BIM requirements (Creation of a digital asset in BIM)

- c.

- Validation of the Asset information in BIM (compliance with BIM Requirements)

- d.

- Model updates based on design changes during construction

- e.

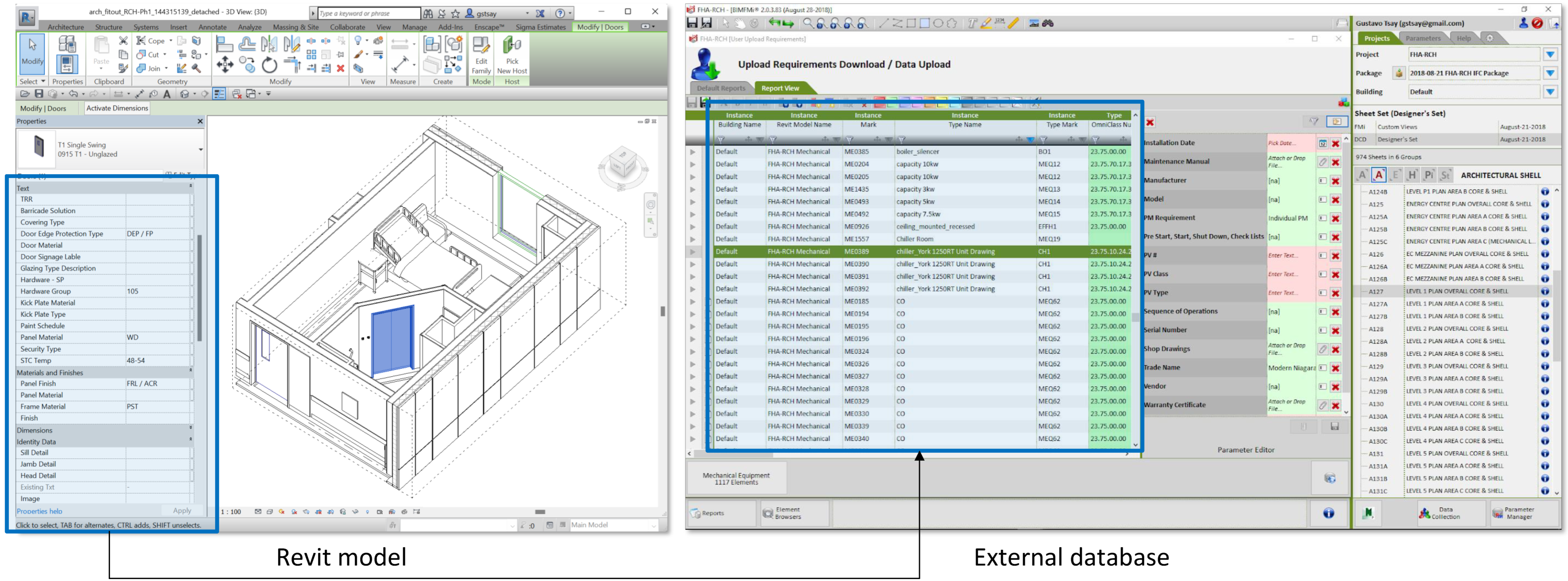

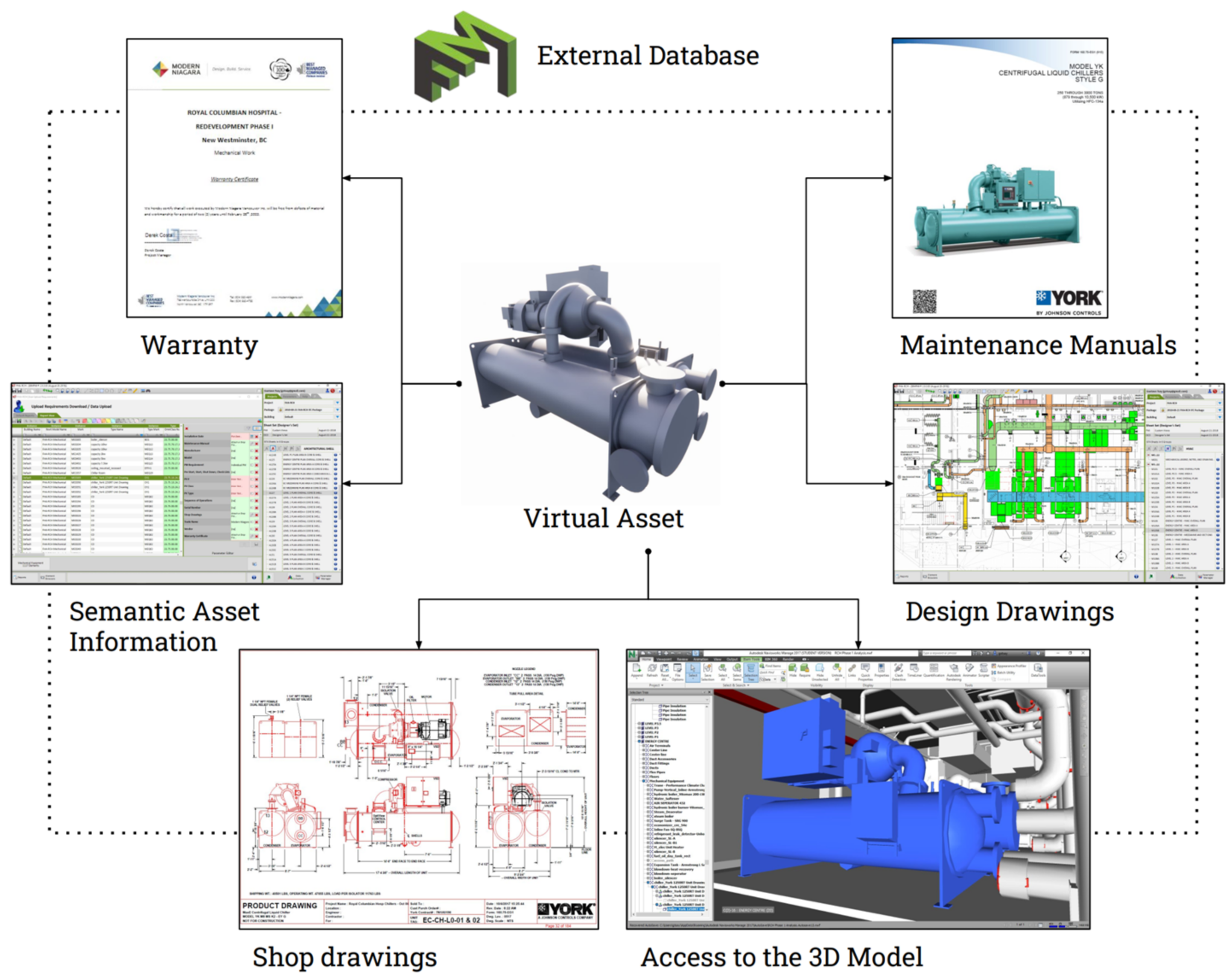

- Data extraction from design models into an external database (Creation of an asset registry)

- f.

- Association of asset information from the construction phase with respective digital assets in the external database

- g.

- Validation of the Asset Information in the External Database

- h.

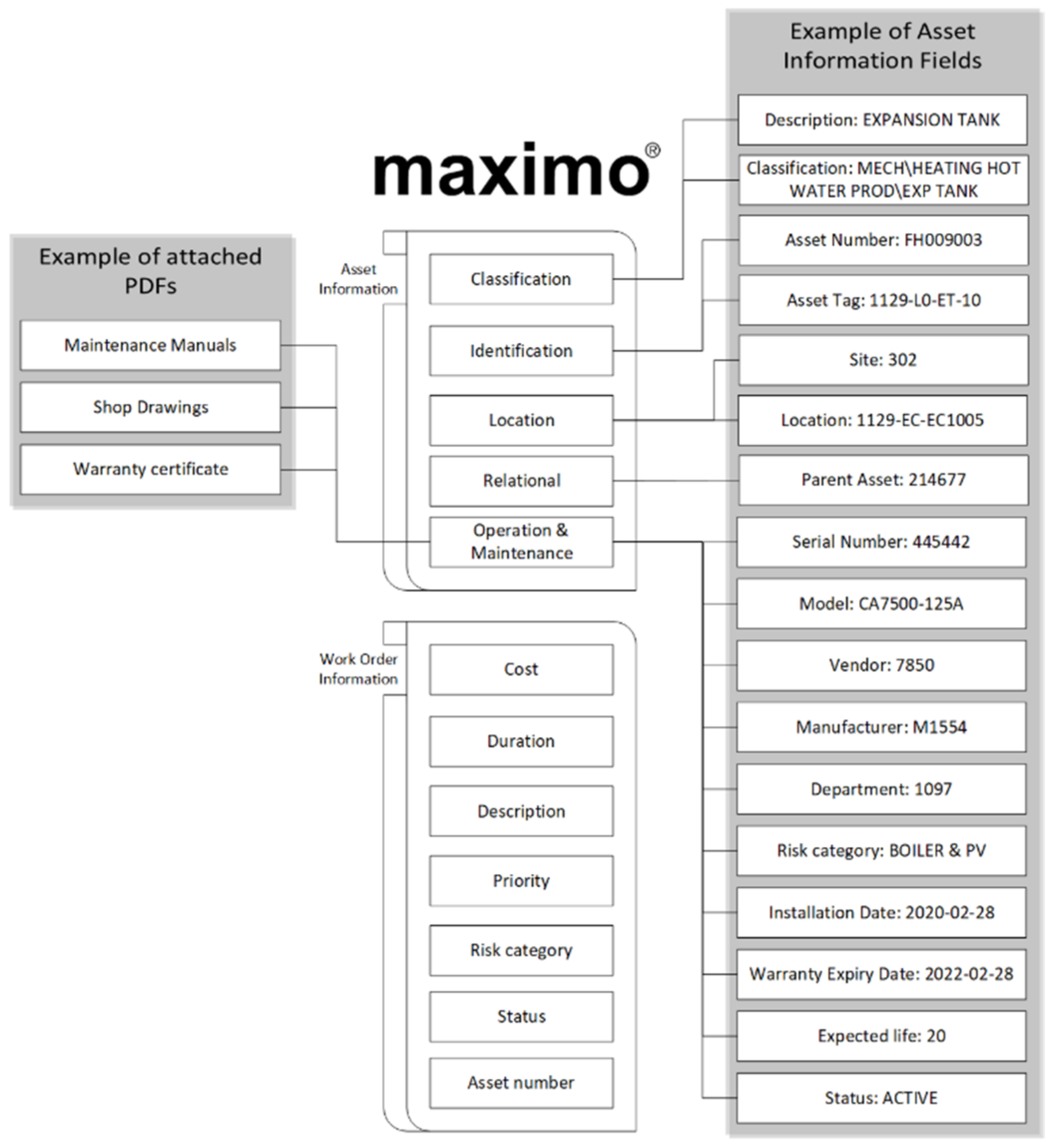

- Asset information upload into FM systems

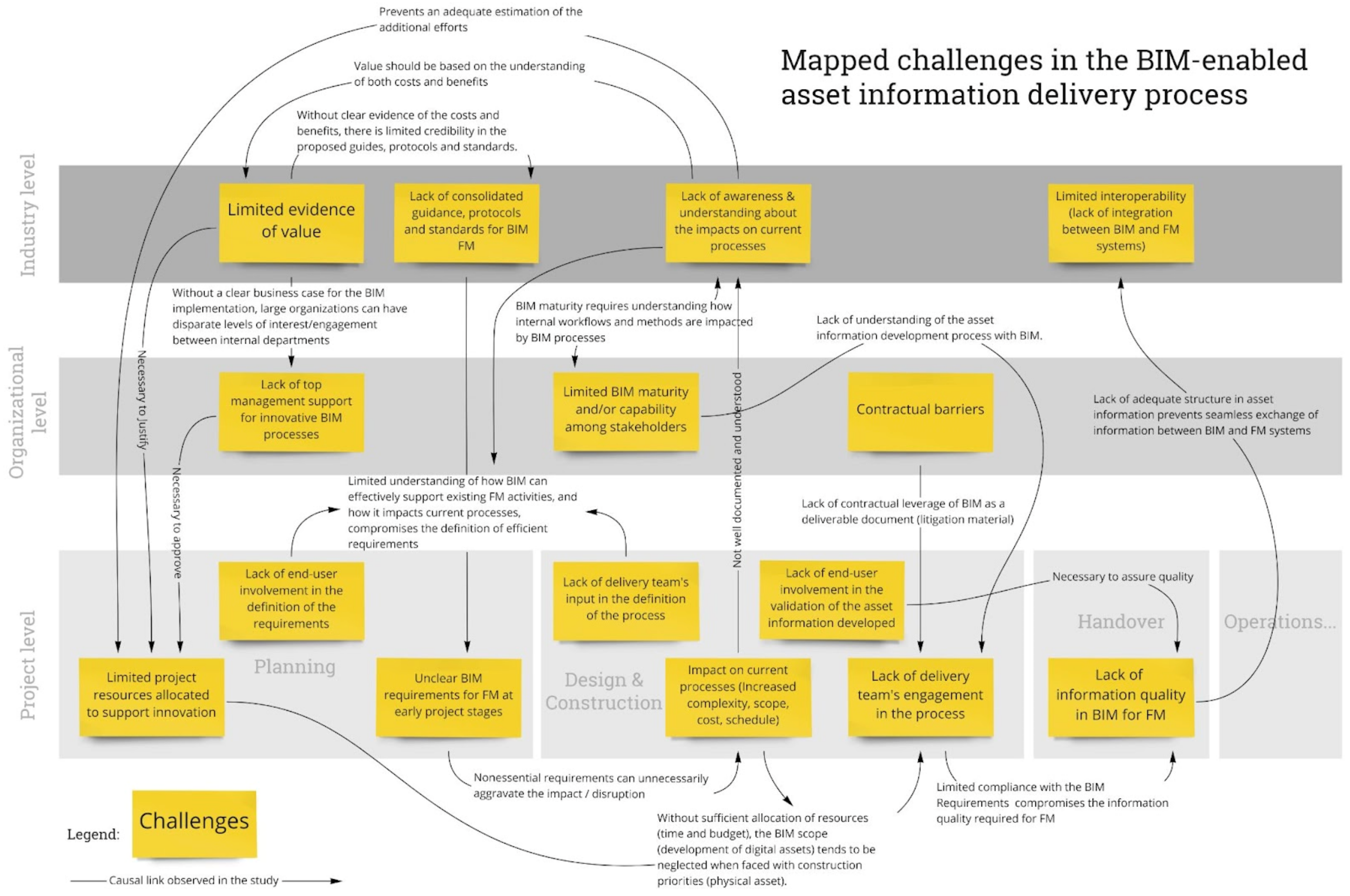

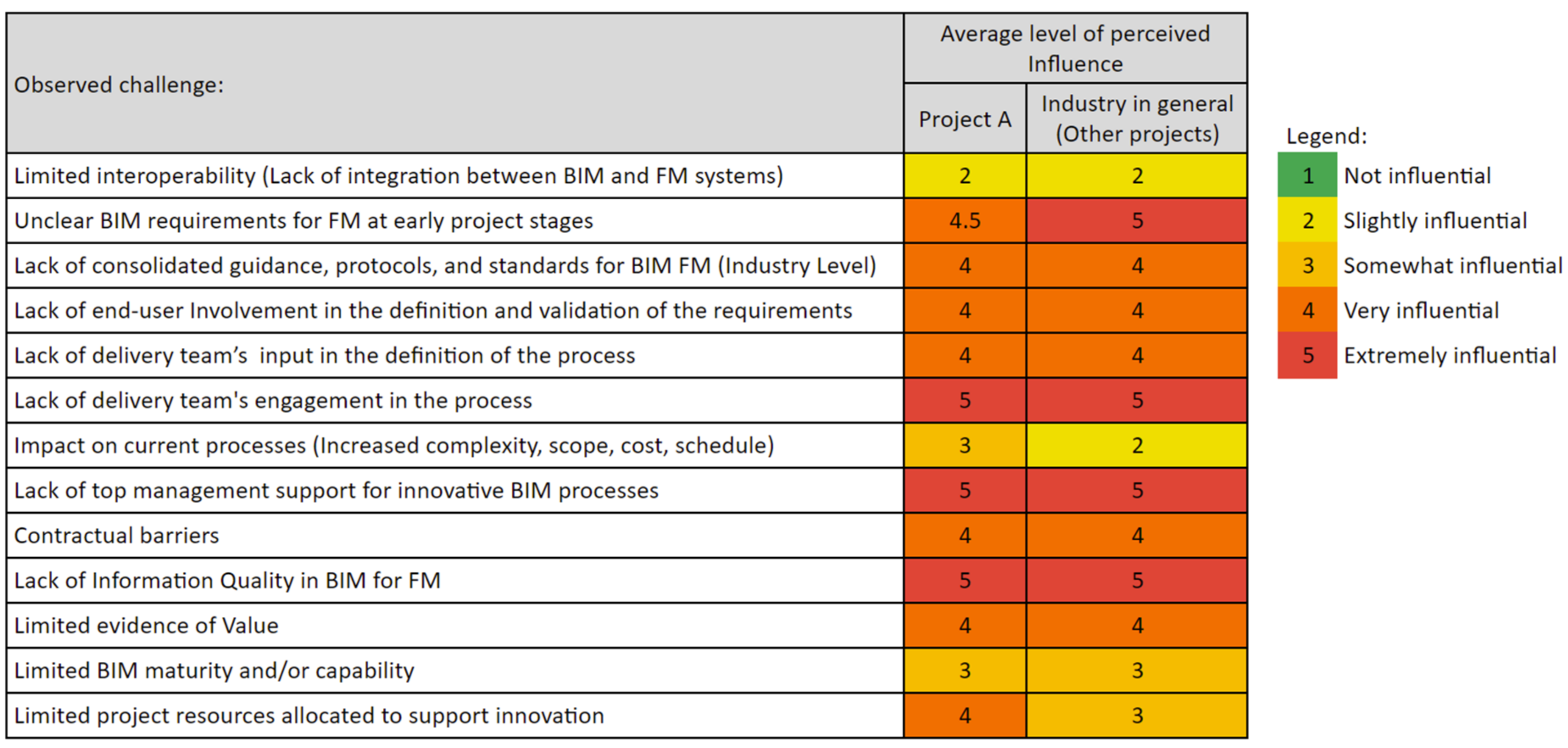

6. Synthesizing, Verifying, Mapping, and Establishing Connections between the Challenges in BIM-Enabled Asset Information Delivery

6.1. Synthesis and Verification of Challenges

6.2. Mapping and Establishing Connections between Challenges

6.3. Verification of Challenges

7. Discussion

- Highlights the importance of validating the asset information produced in BIM during design given a misalignment between the conventional way designers use BIM for their own purposes and how they are expected to use BIM to deliver asset information.

- Provides a glimpse into the existence of an additional scope that this process implies for the delivery team compared with conventional project delivery.

- Demonstrates that the idea of having BIM as a central repository of all asset information is not necessarily relevant for FM. A large portion of the information relevant to FM is not actually incorporated in BIM.

- There is a significant emphasis on the lack of interoperability as one of the main challenges in BIM for FM in the literature [6,8,19,44,60,62,63]. There have been several attempts to address this issue through the development of technological tools to automate the exchange of building information between different software. However, in this project, it was observed that the challenge of exchanging information between BIM and other FM systems stemmed from the lack of an adequate structure in the asset information that is created in BIM, in other words, a lack of information quality in BIM for FM, as discussed by [89].

- Another highly emphasized challenge in the literature is the lack of clear BIM requirements for FM at early project stages [8,19,60,62,63,64,65,66]. Although increased owner involvement has been often given as a solution for this challenge [28,66], this study demonstrates that it can be very difficult for owners to identify adequate information requirements. Having adequate input from FM teams early on in a project is still a challenge. Furthermore, there is still a limited understanding of how BIM can effectively support existing FM activities and how it impacts current design and construction processes, which compromises the definition of clear and efficient information requirements. In that sense, the support provided by standards and guidelines remains limited.

- Although the impacts on current processes (increased complexity, scope, cost, schedule) have been mentioned in previous studies [51,60,62,65,66], there is still little information on exactly how the activities of design teams, general contractors, and trades will be impacted by this process. A lack of awareness about these impacts can prevent these stakeholders from making well-informed decisions during the Request for Proposal, and for the allocation of resources required for the project, which ultimately compromises the quality of the asset information achieved at the end of the process.

- Finally, it was observed that the limited evidence of value in the literature is a central challenge that directly affects important aspects of the asset information delivery process at the project, organization, and industry levels. Although some studies [6,64,90] provide estimates of value based on surveys and interviews, the evidence of value is not sufficiently robust to provide adequate support for decision making.

8. Conclusions

- A detailed analysis of the relevant literature on owner-driven BIM requirements, implementation for FM purposes, and the associated challenges;

- A detailed ethnographic longitudinal analysis of the asset information delivery process on a complex project with stringent BIM requirements for FM; and

- Synthesis and confirmation of relevant challenges in the literature, augmented by a detailed mapping of these challenges overlaid against the observed asset information delivery process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AECO | Architecture, Engineering, Construction, and Operations |

| AIR | Asset Information Requirements |

| ARQTS | Asset Risk and Quality Technical Services (Department of owner organization in projects A and B) |

| BEP | BIM Execution Plan |

| BIM | Building Information Model or Modeling |

| COBie | Construction Operations Building information exchange |

| CMMS | Computerized Maintenance Management System |

| DGS | Data and Geometry Specification (Part of BIM requirements on projects A, B, and C) |

| EIR | Exchange Information Requirements |

| FM | Facilities Management |

| FMO | Facilities Management and Operations (Department of owner organization in projects A and B) |

| IFC | Industry Foundation Class |

| GC | General Contractor |

| LOD | Level of Development |

| MVD | Model View Definition |

| O&M | Operations and Maintenance |

| OIR | Organizational Information Requirements |

| OSR | Owner Standard Requirements (Part of BIM requirements in projects A and B) |

References

- Liu, R.; Issa, R.R.A. Survey: Common Knowledge in BIM for Facility Maintenance. J. Perform. Constr. Facil. 2016, 30, 04015033. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-Enabled Facilities Operation and Maintenance: A Review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Kim, S.; Poirier, E.A.; Staub-French, S. Information Commissioning: Bridging the Gap between Digital and Physical Built Assets. J. Facil. Manag. 2020, 18, 231–245. [Google Scholar] [CrossRef]

- Cavka, H.B.; Staub-French, S.; Poirier, E.A. Levels of BIM Compliance for Model Handover. J. Inf. Technol. Constr. (ITcon) 2018, 23, 243–258. [Google Scholar]

- Durdyev, S.; Ashour, M.; Connelly, S.; Mahdiyar, A. Barriers to the Implementation of Building Information Modelling (BIM) for Facility Management. J. Build. Eng. 2022, 46, 103736. [Google Scholar] [CrossRef]

- Teicholz, P. BIM for Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 1-118-41762-3. [Google Scholar]

- Liu, R.; Issa, R.R.A. Issues in BIM for Facility Management from Industry Practitioners’ Perspectives. Comput. Civ. Eng. 2013, 2013, 411–418. [Google Scholar] [CrossRef]

- Kassem, M.; Kelly, G.; Dawood, N.; Serginson, M.; Lockley, S. BIM in Facilities Management Applications: A Case Study of a Large University Complex. Built Environ. Proj. Asset Manag. 2015, 5, 261. [Google Scholar] [CrossRef]

- Matarneh, S.T.; Danso-Amoako, M.; Al-Bizri, S.; Gaterell, M.; Matarneh, R. Building Information Modeling for Facilities Management: A Literature Review and Future Research Directions. J. Build. Eng. 2019, 24, 100755. [Google Scholar] [CrossRef]

- Dixit, M.K.; Venkatraj, V.; Ostadalimakhmalbaf, M.; Pariafsai, F.; Lavy, S. Integration of Facility Management and Building Information Modeling (BIM): A Review of Key Issues and Challenges. Facilities 2019, 37, 455–483. [Google Scholar] [CrossRef]

- Kula, B.; Ergen, E. Implementation of a BIM-FM Platform at an International Airport Project: Case Study. J. Constr. Eng. Manag. 2021, 147, 05021002. [Google Scholar] [CrossRef]

- Becerik-Gerber, B.; Jazizadeh, F.; Li, N.; Calis, G. Calis Gulben Application Areas and Data Requirements for BIM-Enabled Facilities Management. J. Constr. Eng. Manag. 2012, 138, 431–442. [Google Scholar] [CrossRef]

- Siebelink, S.; Voordijk, H.; Endedijk, M.; Adriaanse, A. Understanding Barriers to BIM Implementation: Their Impact across Organizational Levels in Relation to BIM Maturity. Front. Eng. Manag. 2021, 8, 236–257. [Google Scholar] [CrossRef]

- Korpela, J.; Miettinen, R.; Salmikivi, T.; Ihalainen, J. The Challenges and Potentials of Utilizing Building Information Modelling in Facility Management: The Case of the Center for Properties and Facilities of the University of Helsinki. Constr. Manag. Econ. 2015, 33, 3–17. [Google Scholar] [CrossRef]

- Naing, T.M.; Sadeghifam, A.N.; Joo, M.S. Identifying the Critical Barriers Factors to the Implementation of Building Information Modelling (BIM) in the Sarawak’s Construction Industry. Civ. Sustain. Urban Eng. 2022, 2, 21–32. [Google Scholar] [CrossRef]

- Liu, H.; Abudayyeh, O.; Liou, W. BIM-Based Smart Facility Management: A Review of Present Research Status, Challenges, and Future Needs. In Proceedings of the Construction Research Congress, Tempe, AZ, USA, 8–10 March 2020; pp. 1087–1095. [Google Scholar] [CrossRef]

- Naghshbandi, S.N. BIM for Facility Management: Challenges and Research Gaps. Civ. Eng. J. 2016, 2, 679–684. [Google Scholar] [CrossRef]

- Messner, J.; Kreider, R. BIM Planning Guide for Facility Owners; Pennsylvania State University: University Park, PA, USA, 2013. [Google Scholar]

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The Building Information Modelling Trajectory in Facilities Management: A Review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Edirisinghe, R.; London, K.A.; Kalutara, P.; Aranda-Mena, G. Building Information Modelling for Facility Management: Are We There Yet? Eng. Constr. Archit. Manag. 2017, 24, 1119–1154. [Google Scholar] [CrossRef]

- Arayici, Y.; Onyenobi, T.; Egbu, C. Building Information Modelling (BIM) for Facilities Management (FM): The Mediacity Case Study Approach. Int. J. 3D Inf. Modeling IJ3DIM 2012, 1, 55–73. [Google Scholar] [CrossRef]

- Atkin, B.; Brooks, A. Total Facilities Management; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 1405127902. [Google Scholar]

- Porwal, A.; Hewage, K.N. Building Information Modeling (BIM) Partnering Framework for Public Construction Projects. Autom. Constr. 2013, 31, 204–214. [Google Scholar] [CrossRef]

- Koch, C.; Hansen, G.K.; Jacobsen, K. Missed Opportunities: Two Case Studies of Digitalization of FM in Hospitals. Facilities 2018, 37, 381–394. [Google Scholar] [CrossRef]

- Mayo, G.; Giel, B.; ISSA, R. BIM use and requirements among building owners. In Proceedings of the Computing in Civil Engineering: Proceedings of the 2012 ASCE International Conference on Computing in Civil Engineering, Clearwater Beach, FL, USA, 17–20 June 2012. [Google Scholar]

- Munir, M.; Kiviniemi, A.; Jones, S.; Finnegan, S. BIM-Based Operational Information Requirements for Asset Owners. Archit. Eng. Des. Manag. 2020, 16, 100–114. [Google Scholar] [CrossRef]

- Akcamete, A.; Akinci, B.; Garrett, J.H. Potential utilization of building information models for planning maintenance activities. In Proceedings of the International Conference on Computing in Civil and Building Engineering, Nottingham, UK, 30 June 2010; Volume 2010, pp. 151–157. [Google Scholar]

- Liu, R.; Issa, R.R.A. 3D Visualization of Sub-Surface Pipelines in Connection with the Building Utilities: Integrating GIS and BIM for Facility Management; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 341–348. [Google Scholar] [CrossRef]

- Motawa, I.; Almarshad, A. A Knowledge-Based BIM System for Building Maintenance. Autom. Constr. 2013, 29, 173–182. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelaty, A. Monitoring Thermal Comfort in Subways Using Building Information Modeling. Energy Build. 2014, 84, 252–257. [Google Scholar] [CrossRef]

- Lee, C.-H.; Tsai, M.-H.; Kang, S.-C. A Visual Tool for Accessibility Study of Pipeline Maintenance during Design. Vis. Eng. 2014, 2, 6. [Google Scholar] [CrossRef]

- Koch, C.; Neges, M.; König, M.; Abramovici, M. Natural Markers for Augmented Reality Based Indoor Navigation and Facility Maintenance. Autom. Constr. 2014, 48, 18–30. [Google Scholar] [CrossRef]

- Motamedi, A.; Hammad, A.; Asen, Y. Knowledge-Assisted BIM-Based Visual Analytics for Failure Root Cause Detection in Facilities Management. Autom. Constr. 2014, 43, 73–83. [Google Scholar] [CrossRef]

- Yang, X.; Ergan, S. Leveraging BIM to Provide Automated Support for Efficient Troubleshooting of HVAC-Related Problems. J. Comput. Civ. Eng. 2016, 30, 04015023. [Google Scholar] [CrossRef]

- Golabchi, A.; Akula, M.; Kamat, V. Automated Building Information Modeling for Fault Detection and Diagnostics in Commercial HVAC Systems. Facilities 2016, 34, 233–246. [Google Scholar] [CrossRef]

- Shalabi, F.; Turkan, Y. IFC BIM-Based Facility Management Approach to Optimize Data Collection for Corrective Maintenance. J. Perform. Constr. Facil. 2017, 31, 04016081. [Google Scholar] [CrossRef]

- Cox, B.; Terry, F. Creating a BIM for Emergency Management. J. Build. Inf. Model. 2008, 24–25. [Google Scholar]

- Hu, Z.-Z.; Tian, P.-L.; Li, S.-W.; Zhang, J.-P. BIM-Based Integrated Delivery Technologies for Intelligent MEP Management in the Operation and Maintenance Phase. Adv. Eng. Softw. 2018, 115, 1–16. [Google Scholar] [CrossRef]

- Chen, W.; Chen, K.; Cheng, J.C.P.; Wang, Q.; Gan, V.J.L. BIM-Based Framework for Automatic Scheduling of Facility Maintenance Work Orders. Autom. Constr. 2018, 91, 15–30. [Google Scholar] [CrossRef]

- Yoon, J.H.; Cha, H.S.; Kim, J. Three-Dimensional Location-Based O&M Data Management System for Large Commercial Office Buildings. J. Perform. Constr. Facil. 2019, 33, 04019010. [Google Scholar]

- Beatty, R.; Eastman, C.; Kim, K.; Fang, Y. Case Study 2: Texas A&M Health Science Center-a Case Study of BIM and COBie for Facility Management. In BIM for Facility Managers; Wiley-Academy: Hoboken, NJ, USA, 2013; pp. 164–184. [Google Scholar]

- Winfield, M. Construction 4.0 and ISO 19650: A Panacea for the Digital Revolution? Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 173, 175–181. [Google Scholar] [CrossRef]

- Smith, D.K.; Tardif, M. Building Information Modeling: A Strategic Implementation Guide for Architects, Engineers, Constructors, and Real Estate Asset Managers; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 0-470-25003-8. [Google Scholar]

- Pishdad-Bozorgi, P.; Gao, X.; Eastman, C.; Self, A.P. Planning and Developing Facility Management-Enabled Building Information Model (FM-Enabled BIM). Autom. Constr. 2018, 87, 22–38. [Google Scholar] [CrossRef]

- Thabet, W.; Lucas, J.; Johnston, S. A Case Study for Improving BIM-FM Handover for a Large Educational Institution. In Proceedings of the Construction Research Congress 2016, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 2177–2186. [Google Scholar] [CrossRef]

- National Institute of Building Science (NIBS). National BIM Guide for Owners. Washington DC, USA. 2017. Available online: https://www.nibs.org/reports/national-bim-guide-owners (accessed on 3 August 2022).

- Borhani, A.; Lee, H.W.; Dossick, C.S.; Osburn, L.; Kinsman, M. BIM to Facilities Management: Presenting a Proven Workflow for Information Exchange. In Proceedings of the Computing in Civil Engineering 2017, Seattle, WA, USA, 25–27 June 2017; pp. 51–58. [Google Scholar] [CrossRef]

- Motamedi, A.; Iordanova, I.; Forgues, D. FM-BIM preparation method and quality assessment measures. In Proceedings of the 17th International Conference on Computing in Civil and Building Engineering (ICCCBE), Tampere, Finland, 5 June 2018. [Google Scholar]

- Orr, K.; Shen, Z.; Juneja, P.K.; Snodgrass, N.; Kim, H. Intelligent Facilities: Applicability and Flexibility of Open BIM Standards for Operations and Maintenance. In Proceedings of the Construction Research Congress 2014, Atlanta, GA, USA, 13 May 2014; American Society of Civil Engineers: Atlanta, GA, USA, 2014; pp. 1951–1960. [Google Scholar]

- Pavón, R.M.; Alberti, M.G.; Álvarez, A.A.A.; Del Rosario Chiyón Carrasco, I. Use of BIM-FM to Transform Large Conventional Public Buildings into Efficient and Smart Sustainable Buildings. Energies 2021, 14, 3127. [Google Scholar] [CrossRef]

- Abdirad, H.; Dossick, C.S. Normative and Descriptive Models for COBie Implementation: Discrepancies and Limitations. Eng. Constr. Archit. Manag. 2019, 26, 1820. [Google Scholar] [CrossRef]

- Heaton, J.; Parlikad, A.K.; Schooling, J. Design and Development of BIM Models to Support Operations and Maintenance. Comput. Ind. 2019, 111, 172–186. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, Y.; Li, Y.; Le, Y.; Xiao, J. Quantifying and Visualizing Value Exchanges in Building Information Modeling (BIM) Projects. Autom. Constr. 2019, 99, 91–108. [Google Scholar] [CrossRef]

- Sattenini, A.; Azhar, S.; Thuston, J. Preparing a building information model for facility maintenance and management. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Korea , 29 June 2011; pp. 144–149. [Google Scholar]

- Mayo, G.; Issa, R.R.A. Nongeometric Building Information Needs Assessment for Facilities Management. J. Manag. Eng. 2016, 32, 04015054. [Google Scholar] [CrossRef]

- East, B.; Carrasquillo-Mangual, M. The COBie Guide; National Institute of Building Sciences: Champaign, IL, USA, 2013; Available online: https://www.wbdg.org/bim/cobie/cobie-guide (accessed on 3 August 2022).

- Sabol, L. Building Information Modeling & Facility Management. IFMA World Workplace Nov 2008, 1–13. Available online: https://www.scribd.com/document/115333784/2-Sabol-Bim-Facility (accessed on 3 August 2022).

- Lee, Y.-C.; Eastman, C.M.; Solihin, W. Logic for Ensuring the Data Exchange Integrity of Building Information Models. Autom. Constr. 2018, 85, 249–262. [Google Scholar] [CrossRef]

- Eastman, C.M.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 0-470-54137-7. [Google Scholar]

- Jang, R.; Collinge, W. Improving BIM Asset and Facilities Management Processes: A Mechanical and Electrical (M&E) Contractor Perspective. J. Build. Eng. 2020, 32, 101540. [Google Scholar] [CrossRef]

- Bosch, A.; Volker, L.; Koutamanis, A. BIM in the Operations Stage: Bottlenecks and Implications for Owners. Built Environ. Proj. Asset Manag. 2015, 5, 331–343. [Google Scholar] [CrossRef]

- Patacas, J.; Dawood, N.; Kassem, M. BIM for Facilities Management: A Framework and a Common Data Environment Using Open Standards. Autom. Constr. 2020, 120, 103366. [Google Scholar] [CrossRef]

- Parsanezhad, P.; Dimyadi, J. Effective facility management and operations via a BIM-based integrated information system. In Proceedings of the Joint CIB W070, W111 & W118 Conference, Technical University of Denmark, Denmark, Copenhagen, 21–23 May 2014; pp. 442–453. [Google Scholar]

- Lavy, S.; Jawadekar, S. A Case Study of Using BIM and COBie for Facility Management. Int. J. Facil. Manag. 2014, 5, 1–16. [Google Scholar]

- Codinhoto, R.; Kiviniemi, A. BIM for FM: A Case Support for Business Life Cycle. In Product Lifecycle Management for a Global Market; IFIP Advances in Information and Communication Technology; Fukuda, S., Bernard, A., Gurumoorthy, B., Bouras, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 442, pp. 63–74. ISBN 978-3-662-45936-2. [Google Scholar]

- Love, P.E.D.; Matthews, J.; Simpson, I.; Hill, A.; Olatunji, O.A. A Benefits Realization Management Building Information Modeling Framework for Asset Owners. Autom. Constr. 2014, 37, 1. [Google Scholar] [CrossRef]

- Song, J.; Migliaccio, G.C.; Wang, G.; Lu, H. Exploring the Influence of System Quality, Information Quality, and External Service on BIM User Satisfaction. J. Manag. Eng. 2017, 33, 04017036. [Google Scholar] [CrossRef]

- Lavy, S.; Saxena, N.; Dixit, M. Effects of BIM and COBie Database Facility Management on Work Order Processing Times: Case Study. J. Perform. Constr. Facil. 2019, 33, 04019069. [Google Scholar] [CrossRef]

- Sarel, L.; Nishaant, S. Quantifying the Effect of Using BIM and COBie for Facility Management on Work Order Processing Times: A Case Study; IFMA: Houston, TX, USA, 2015; Available online: https://community.ifma.org/cfs-file/__key/telligent-evolution-components-attachments/13-465-00-00-01-05-75-22/2015_5F00_Quantifying-the-Effect-of-BIM-and-COBie-for-FM_5F00_Article.pdf (accessed on 3 August 2022).

- Fallon, K.; Palmer, M.E. General Buildings Information Handover Guide: Principles, Methodology and Case Studies—An Industry Sector Guide of the Information Handover Guide Series; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007; p. NIST IR 7417. [Google Scholar]

- Kasprzak, C.; Ramesh, A.; Dubler, C. Developing standards to assess the quality of BIM criteria for facilities management. In Proceedings of the Architectural Engineering Conference 2013, State College, PE, USA, 3–5 April 2013. [Google Scholar] [CrossRef]

- Fellows, R.; Liu, A. Research Methods for Construction; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; Sage: London, UK, 2009; Volume 5, ISBN 1-4129-6099-1. [Google Scholar]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Bakis, N.; Kagioglou, M.; Aouad, G. Evaluating the business benefits of information systems. In Proceedings of the 3rd International SCRI Symposium, Salford Centre for Research and Innovation, University of Salford, Salford, UK, 3–4 April 2006. [Google Scholar]

- Richards, L.; Morse, J.M. README FIRST for a User’s Guide to Qualitative Methods; Sage: London, UK, 2012; ISBN 978-1-4129-9806-2. [Google Scholar]

- Miles, M.B.; Huberman, A.M.; Saldana, J. Qualitative Data Analysis: A Methods Sourcebook. Third Edition; SAGE Publications: London, UK, 2014; ISBN 978-1-4522-5787-7. [Google Scholar]

- Phelps, A.F.; Horman, M.J. Ethnographic Theory-Building Research in Construction. J. Constr. Eng. Manag. 2010, 136, 58–65. [Google Scholar] [CrossRef]

- Kvale, S. Planning an Interview Study: Doing Interviews; Sage Publications, Ltd.: London, UK, 2007; ISBN 978-0-7619-4977-0. [Google Scholar]

- Abowitz, D.; Toole, T. Mixed Method Research: Fundamental Issues of Design, Validity, and Reliability in Construction Research. J. Constr. Eng. Manag.-ASCE 2010, 136, 108–116. [Google Scholar] [CrossRef]

- Glaser, B.G. Theoretical Sensitivity; University of California: San Diego, CA, USA, 1978; ISBN 978-0-686-24892-7. [Google Scholar]

- Glaser, B.G.; Strauss, A.L.; Strutzel, E. The Discovery of Grounded Theory; Strategies for Qualitative Research. Nurs. Res. 1968, 17, 364. [Google Scholar] [CrossRef]

- Breckenridge, J.; Jones, D. Demystifying Theoretical Sampling in Grounded Theory Research. Grounded Theory Rev. 2009, 8, 113–126. [Google Scholar]

- Creswell, J.W. Mixed-Method Research: Introduction and Application. In Handbook of Educational Policy; Elsevier: Amsterdam, The Netherlands, 1999; pp. 455–472. [Google Scholar]

- Love, P.; Holt, G.; Li, H. Triangulation in Construction Management Research. Eng. Constr. Arch. Manag. 2002, 9, 294–303. [Google Scholar] [CrossRef]

- ENR 2019 Top 225 International Design Firms 1–100|Engineering News-Record. Available online: https://www.enr.com/toplists/2019-Top-225-International-Design-Firms-1 (accessed on 2 September 2022).

- Lin, Y.-C.; Chen, Y.-P.; Huang, W.-T.; Hong, C.-C. Development of BIM Execution Plan for BIM Model Management during the Pre-Operation Phase: A Case Study. Buildings 2016, 6, 8. [Google Scholar] [CrossRef]

- Katipamula, S.; Gowri, K.; Hernandez, G. An Open-Source Automated Continuous Condition-Based Maintenance Platform for Commercial Buildings. Sci. Technol. Built Environ. 2017, 23, 546–556. [Google Scholar] [CrossRef]

- Zadeh, P.A.; Wang, G.; Cavka, H.B.; Staub-French, S.; Pottinger, R. Information Quality Assessment for Facility Management. Adv. Eng. Inform. 2017, 33, 181–205. [Google Scholar] [CrossRef]

- Manning, R.; Messner, J.I. Case Studies in BIM Implementation for Programming of Healthcare Facilities. Electron. J. Inf. Technol. Constr. 2008, 13, 446–457. [Google Scholar]

| Authors | Purpose of BIM Implementation for FM |

|---|---|

| [27] | Perform routine maintenance of the Mechanical, Electrical and Plumbing (MEP) system and its subsystems by sorting out the priority of maintenance tasks |

| [28] | Use GIS and BIM to obtain facility O&M information |

| [29] | Develop a decision support tool for preventive/corrective maintenance |

| [30] | Employ 2D barcodes to identify and locate specific equipment and utilize a wireless sensor network to monitor thermal conditions |

| [31] | Evaluate pipeline maintenance accessibility with visualization and provide a suitable traffic flow for engineers |

| [32] | Use augmented reality to display natural markers for indoor navigation and facility maintenance (such as exit signs and position marks of fire extinguishers) |

| [33] | Failure root cause detection |

| [34] | Increase the efficiency of the HVAC-related troubleshooting process by identifying applicable causes and retrieving information for HVAC-related problems |

| [35] | Use a fault detection and diagnostics algorithm to automate the process of detecting malfunctioning HVAC equipment |

| [36] | Integrate corrective maintenance data in BIM and link alarm reports of equipment failures and the related maintenance information from the Computerized Maintenance Management Information System (CMMS) |

| [37] | Emergency management |

| [38] | Run routine O&M tasks and effectively respond to MEP-related emergencies |

| [39] | Generate and schedule facility maintenance work orders |

| [40] | Develope a data management system based on location-based data analysis in the FM field |

| Challenge/Issue | Mentioned by | Short Description or Example |

|---|---|---|

| Limited interoperability (Lack of integration between BIM and FM systems) | [2,6,8,11,12,16,19,44,60,62,63] | “There are still many limitations with BIM integration into existing CAFM systems; this integration is necessary as not all FM related information is suitable for hosting in a BIM Environment.” [19] |

| Unclear BIM requirements for FM at early project stages | [6,8,16,19,60,62,63,64,65,66] | “BIM requirements for data interoperability with enterprise systems is a complex topic, since facilities information systems are widely divergent, and will be a key issue with deploying BIM within FM.” [6] |

| Lack of consolidated guidance, protocols, and standards for BIM FM (Industry level) | [10,17,19,63,65] | “Lack of standardized tools and processes … remains a key challenge for both the design team members and the building owner.” [19] |

| Lack of end-user Involvement in the definition and validation of the requirements (Internal buy-in) | [10,17,52,60,65,66] | “Generally, asset owners do not engage in the design and engineering of a new project and therefore the operations and management of the facility are not considered in the formative stages.” [66]; “FM team direct relationship with business core activities or FM was limited or nonexistent.” [65] |

| Lack of delivery team’s engagement in the process (External buy-in) | [18,44,65] | “It is also important that there is buy-in from all the team members so that all parts can have as much success as possible. Without buy-in from all members, it will decrease the quality of the BIM product, lead to added work by other project members and could result, at worst, in unsuccessful implementation of BIM on that project.” [18] |

| Impact on current processes (Increased complexity, scope, cost, schedule) | [10,51,60,62,65,66] | “The challenge around producing specific asset registers with related COBie requirements can result in increased project costs and time, generating repetitive activities during the project lifecycle.” [60] |

| Lack of top management support for innovative BIM processes | [13,67] | “If the BIM guidance from the top level is insufficient, then people will continue working on their project islands and will focus on their own uncoordinated developments. In other words, the top management must facilitate internal boundary spanning to make sure that people within the organization will share BIM developments not only within their respective departments or projects but throughout the entire organization.” [13] |

| Contractual barriers | [10,12,17,60,64] | “Communication is inhibited by the contractual boundaries” [60]; “Lack of sufficient legal framework for integrating owners’ view in design and construction” [12] |

| Lack of information quality in BIM for FM | [14,19,44,52,62,63,64] | “The asset management team notes that the BIM model is “simply not fifit for purpose” and does not meet their requirements, with often bulk COBie excel sheets handed over with little structure in place.” [52] |

| Limited evidence of value | [2,8,66,68,69,70] | “Many asset owners are still skeptical about the value of adopting and integrating BIM technologies and processes into their existing organizational infrastructure and operations. Such a view deserves exploring as it is the asset owner who is ultimately best positioned to realize the benefits that can be derived by implementing a BIM strategy.” [66] |

| Limited BIM maturity and/or capability | [60,62] | “Shortage of BIM skills in the FM industry” [8] |

| Limited project resources allocated to support innovation | [12,44] | “The time constraint imposed on this highly demanding and complex project makes this first-time implementation of the new FM-enabled BIM process challenging.” [44]; “Undefined fee structures for additional scope” [12]. |

| Project | A | B | C |

|---|---|---|---|

| Building type | Hospital | Hospital | Residential |

| Location | BC, Canada | BC, Canada | BC, Canada |

| Owner type | Public sector | Public sector | Public sector |

| Budget | $258.9 million | $807.0 million | $30.0 million |

| Estimated completion | Summer 2020 | Early 2025 | Late 2023 |

| Delivery method | Design-Build | Design-Build | Construction Manager |

| Area | Approximately 36,500 square meters | (Information currently unavailable) | Approximately 7735 square meters in gross floor area |

| BIM requirements | BIM required for FM | BIM required for FM | BIM required for FM |

| Data collection | Interviews, survey, document analysis (including models), meeting observation | Interviews, document analysis (including models) | Interviews, survey, document analysis (including models), meeting observation |

| Project phases covered in data collection | Planning, design, construction, and handover | Planning, design, and beginning of construction | Planning and design |

| Picture |  |  |  |

| Data Collection | Type of Data Collected | Data Collected from Project A |

|---|---|---|

| Document analysis | Native BIM files | 20 models: 4 disciplines, 5 design stages |

| BIM compliance documents | 7 model audit review reports, 2 compliance meeting minutes | |

| Project requirements | Request for Proposal, Statement of Requirements, BIM Requirements (included the Owner Standard Requirements, the Data and Geometry Specifications, and the BIM Execution Plan) | |

| Asset data collection documents | Asset data collection reports, several spreadsheets used for the asset data collection and management, access to the BIMFMi external database, and spreadsheets with data exported from Maximo | |

| Semi-structured Interviews | Owners | 11 interviews with different participants including the director involved in the BIM implementation process, asset information specialist, senior design leader, facilities systems and support project leader, and maintenance planner |

| Design team | 1 interview with the BIM manager | |

| General contractors | 2 interviews, one with the virtual design and construction coordinator and another with the design manager | |

| Trades | 1 interview with the project manager of the electric trade | |

| Consultants | 5 interviews with the BIM consultants, 2 interviews with the asset data consultants, and 1 interview with the CMMS consultant | |

| Meeting observation | BIM and asset data collection meetings | 22 meetings during the end of construction and handover, including owners, BIM consultants, asset data consultants and the CMMS consultant |

| Survey | In-depth survey with design team | 19 responses to a survey containing 12 multiple-choice and open-ended questions that was internally distributed in the design firm |

| Observed Challenge/Issue Identified in the Literature | Example of Challenges/Issues Observed in Project A |

|---|---|

| Limited interoperability (lack of integration between BIM and FM systems) |

|

| Unclear BIM requirements for FM at early project stages |

|

| Lack of consolidated guidance, protocols and standards for BIM FM (industry level) |

|

| Lack of end-user involvement in the definition and validation of the requirements (internal buy-in) |

|

| Lack of delivery team’s input in the definition of the process | Limited use of the BEP:

|

| Lack of delivery team’s engagement in the process | Regarding the collection of asset information from the GC and trades, it was observed that a large part of the required information (PDFs and semantic information) was not provided as expected. This missing information had to be collected separately by the CMMS consultant and during the labeling process. According to the interviews, the main reasons for not providing the information were:

|

| Impact on current processes (increased complexity, scope, cost, schedule) and lack of awareness about this impact | Impacts of BIM requirements for FM:

|

| Lack of top management support for innovative BIM processes |

|

| Contractual barriers | Lack of contractual leverage to enforce the BIM requirements:

|

| Lack of information quality in BIM for FM | Quality control of the information in the models:

|

| Limited evidence of value | Understanding the value of the BIM implementation process for FMO:

|

| Limited BIM maturity and/or capability | Limited BIM maturity among stakeholders:

|

| Limited project resources allocated to support innovation |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsay, G.S.; Staub-French, S.; Poirier, É. BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges. Appl. Sci. 2022, 12, 9542. https://doi.org/10.3390/app12199542

Tsay GS, Staub-French S, Poirier É. BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges. Applied Sciences. 2022; 12(19):9542. https://doi.org/10.3390/app12199542

Chicago/Turabian StyleTsay, Gustavo Salles, Sheryl Staub-French, and Érik Poirier. 2022. "BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges" Applied Sciences 12, no. 19: 9542. https://doi.org/10.3390/app12199542

APA StyleTsay, G. S., Staub-French, S., & Poirier, É. (2022). BIM for Facilities Management: An Investigation into the Asset Information Delivery Process and the Associated Challenges. Applied Sciences, 12(19), 9542. https://doi.org/10.3390/app12199542