Geometric Accuracy Evaluation Method for Subway Stations Based on 3D Laser Scanning

Abstract

1. Introduction

2. Related Work

2.1. Registration Issues

2.1.1. Registration between Point Clouds

2.1.2. Registration between Point Clouds and BIM

2.2. Geometric Accuracy Evaluation

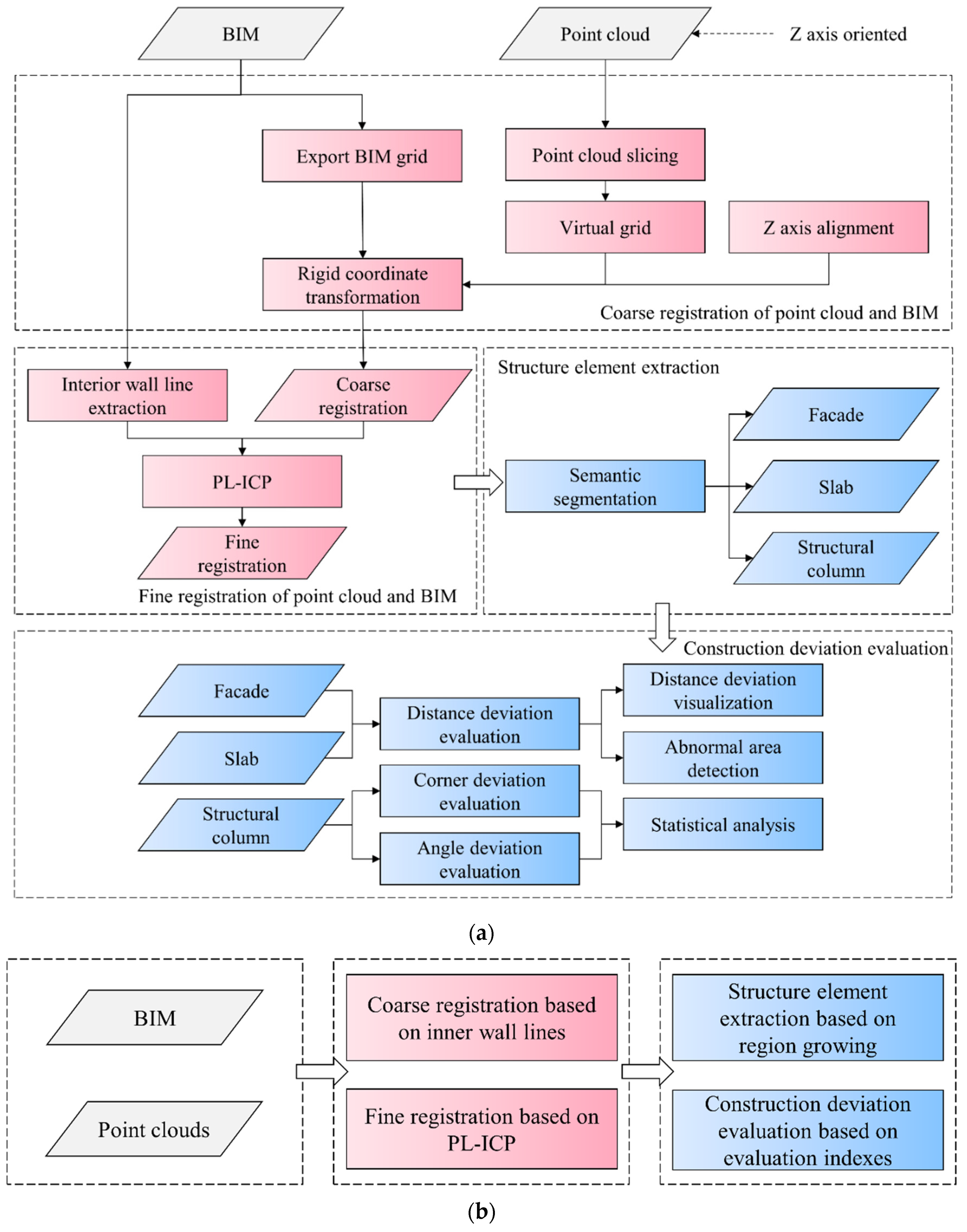

3. Research Method

3.1. Overview

- A coarse registration based on a grid is used to convert the point cloud to the survey coordinate system predefined in BIM;

- The point-to-line iterative closest point (PL-ICP) algorithm based on the inner wall lines is used to achieve fine registration;

- The structural elements of the subway station are extracted from the point cloud;

- The evaluation indexes are proposed and statistically analyzed for geometric accuracy evaluation.

3.2. The Coordinate Registration of the Point Cloud and BIM

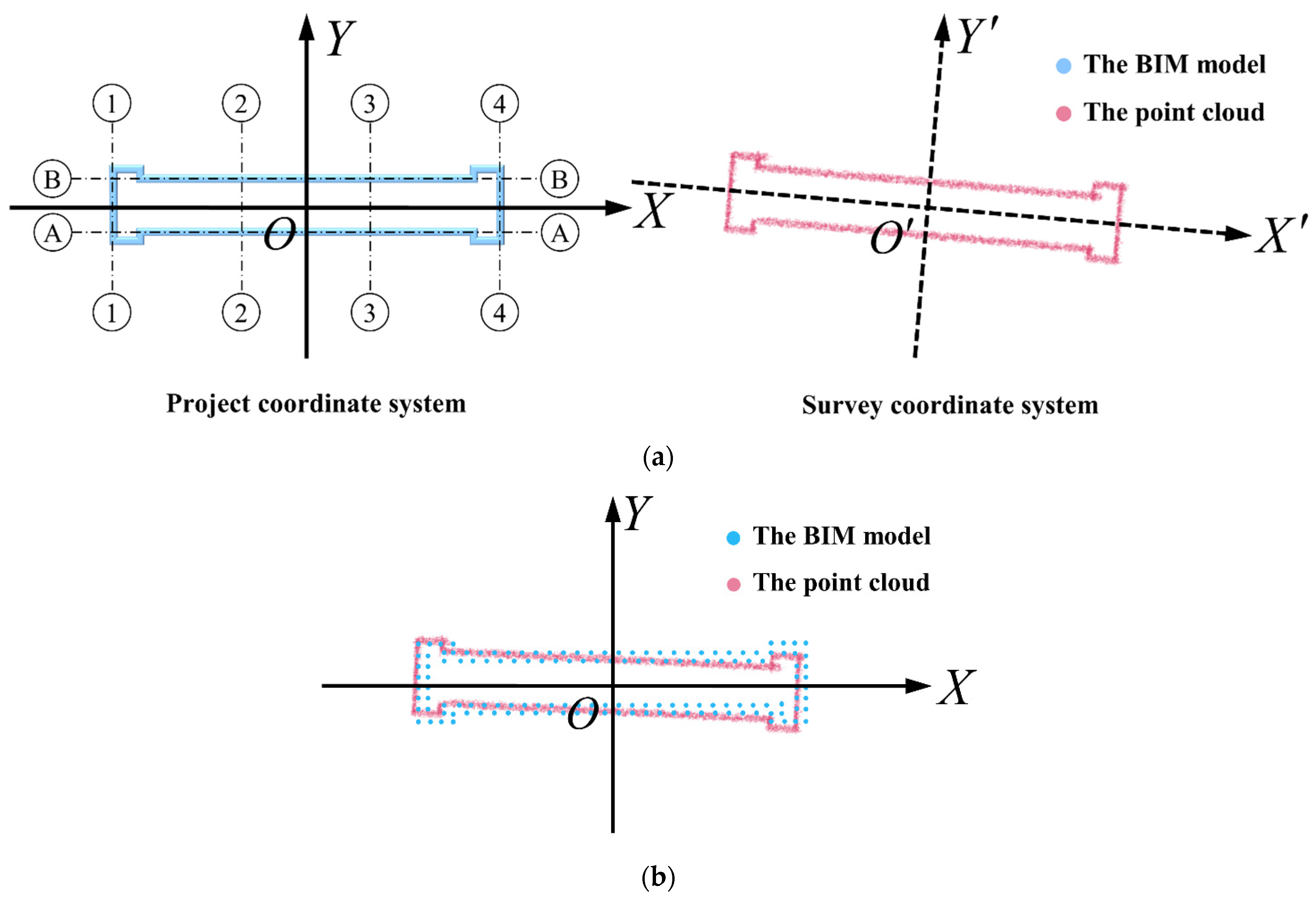

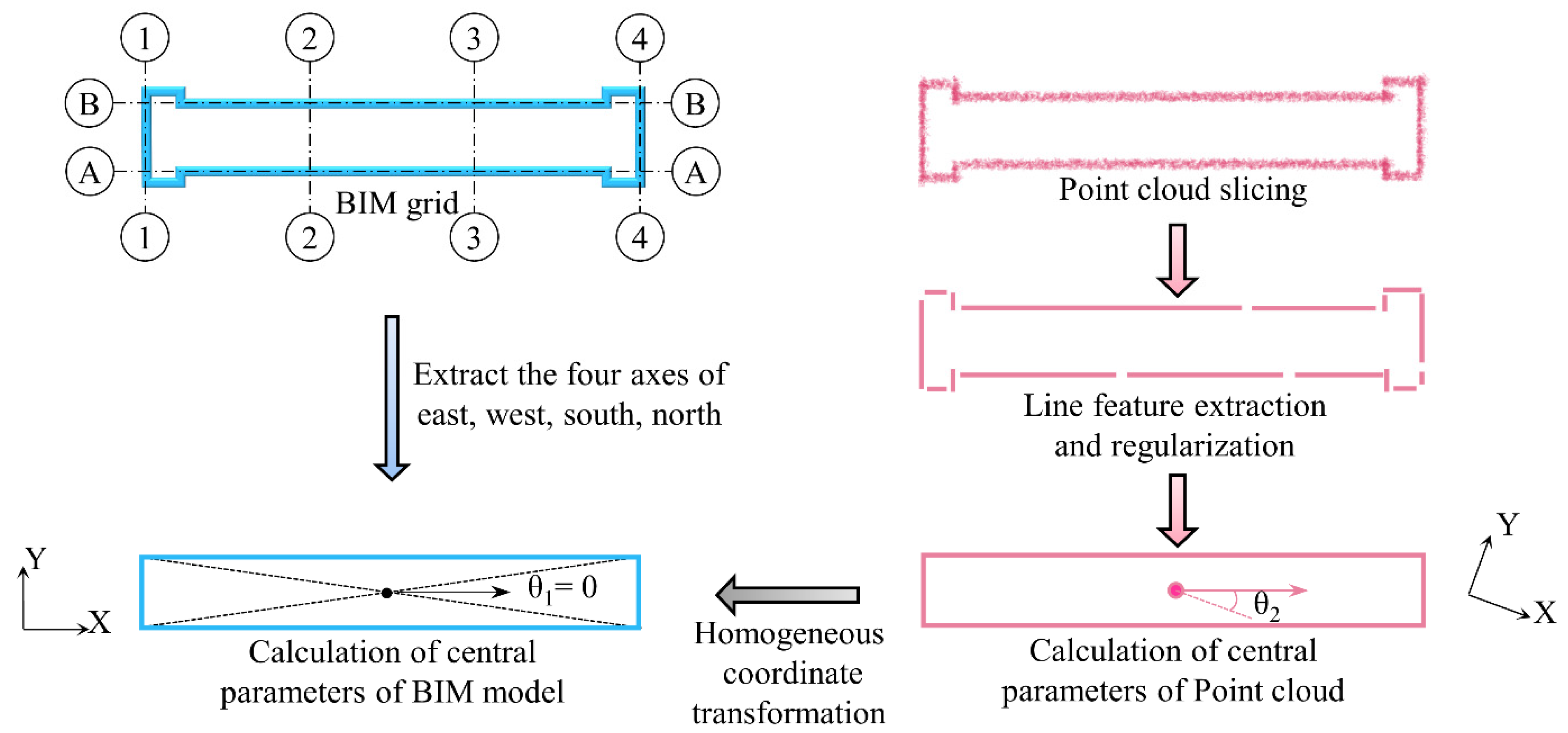

3.2.1. Coarse Registration Based on Grid

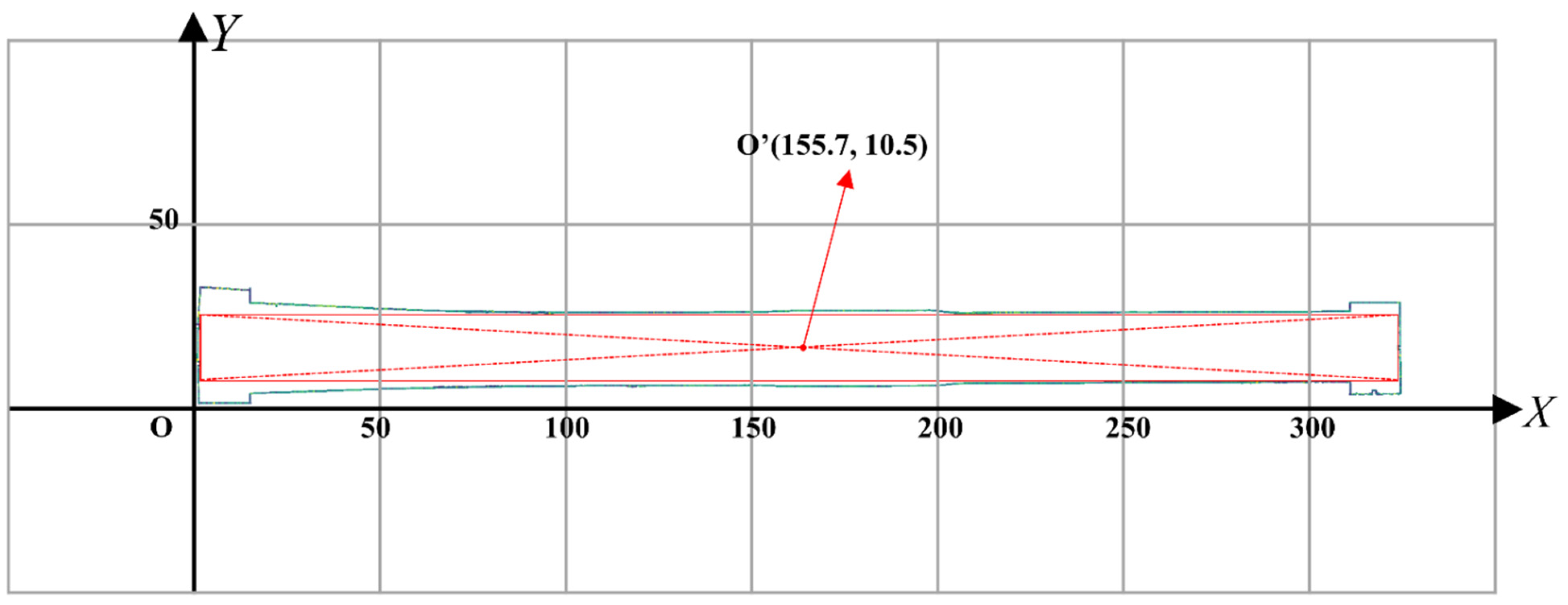

3.2.2. Fine Registration between Point Cloud and BIM

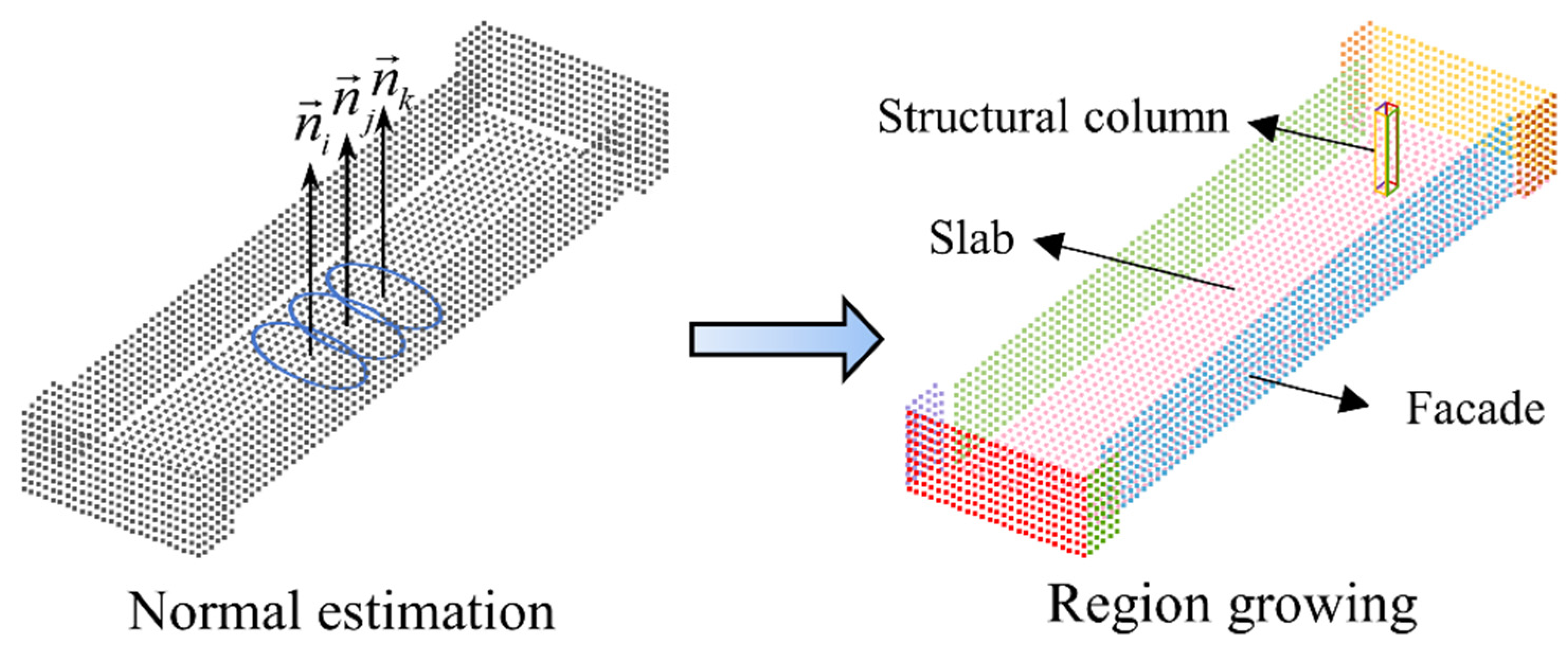

3.3. Subway Station Structure Element Extraction

3.4. Geometric Accuracy Evaluation Index

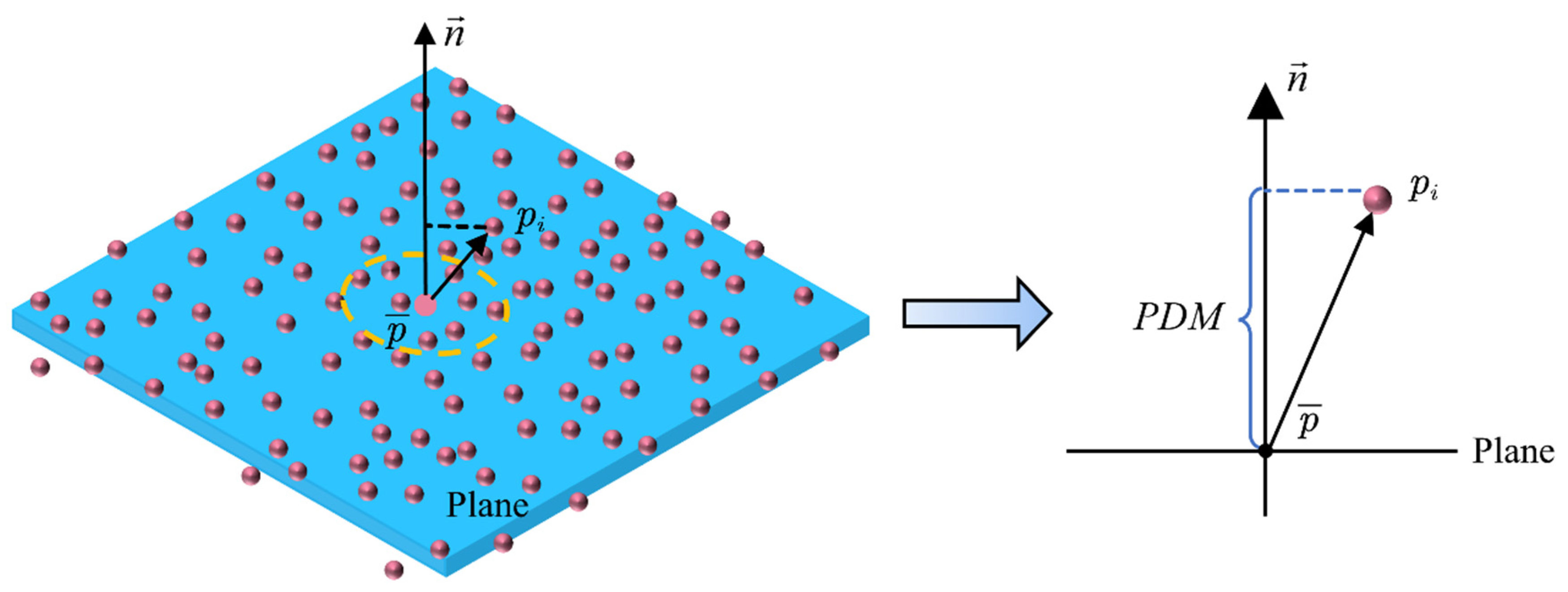

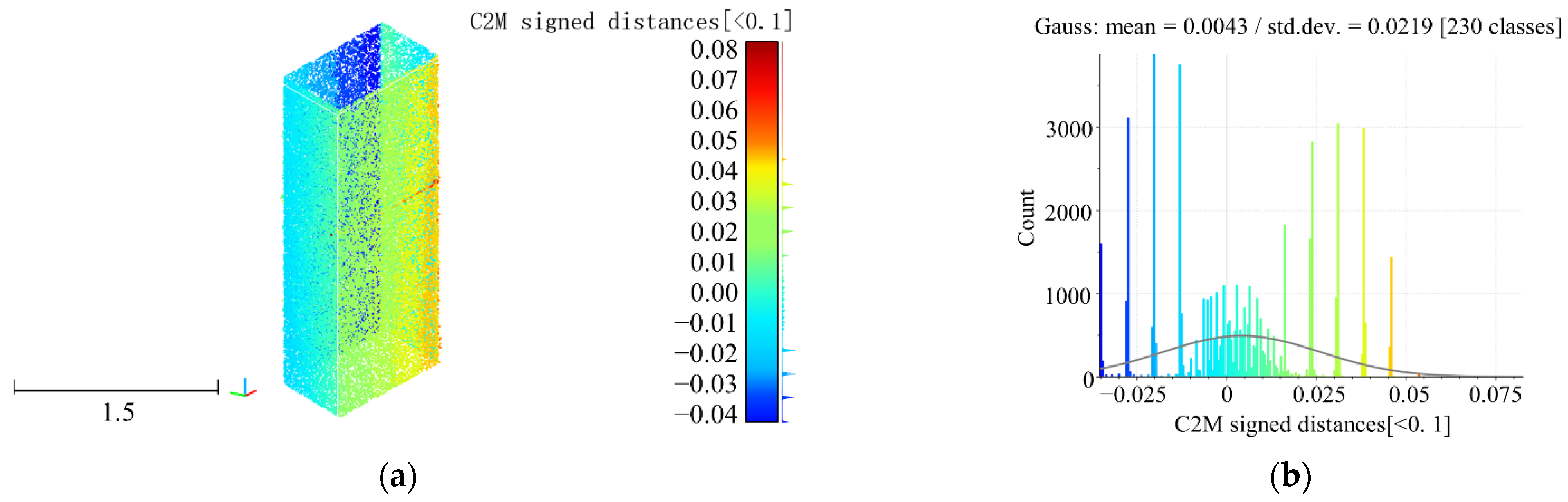

3.4.1. Surface Accuracy Evaluation

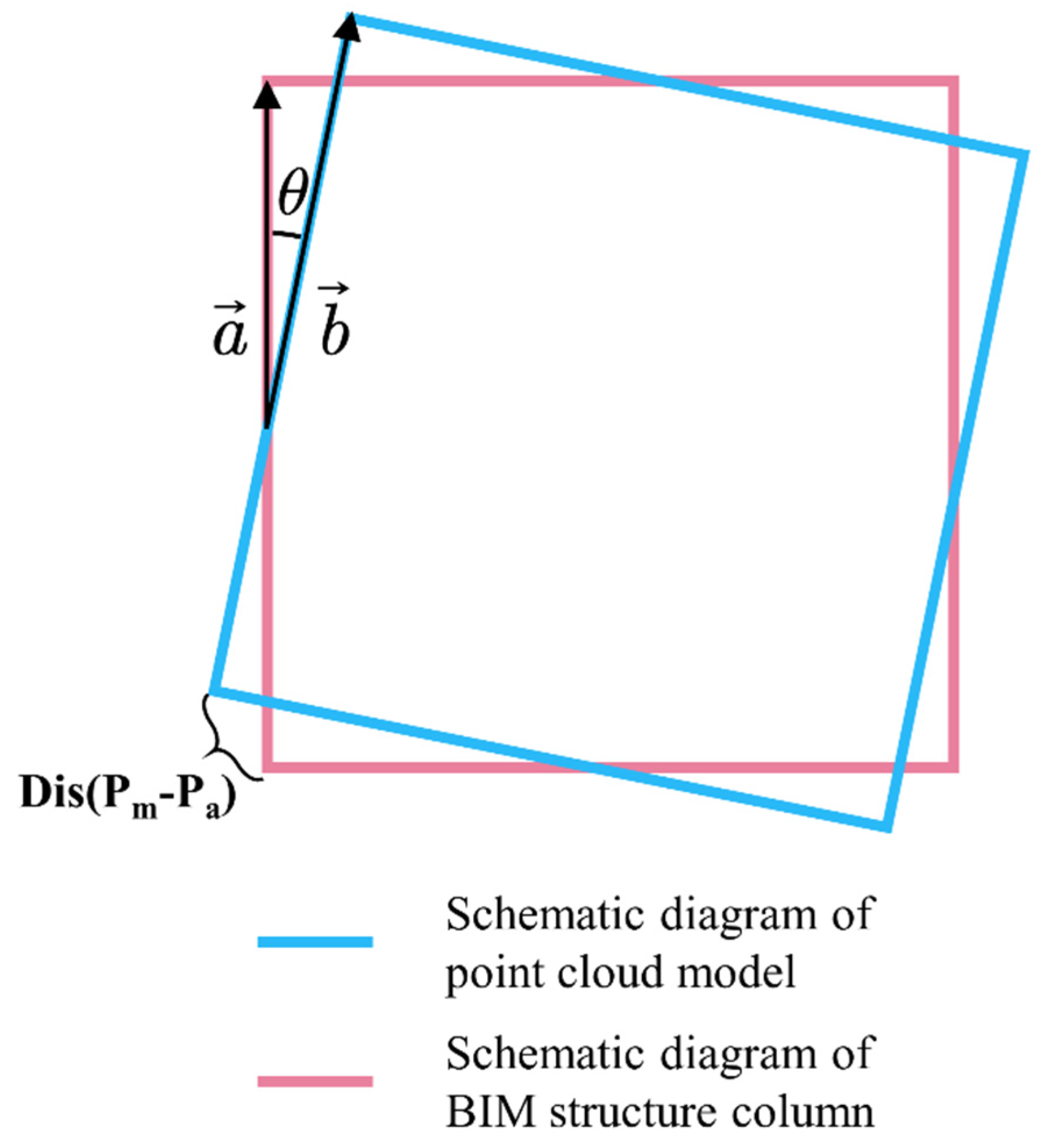

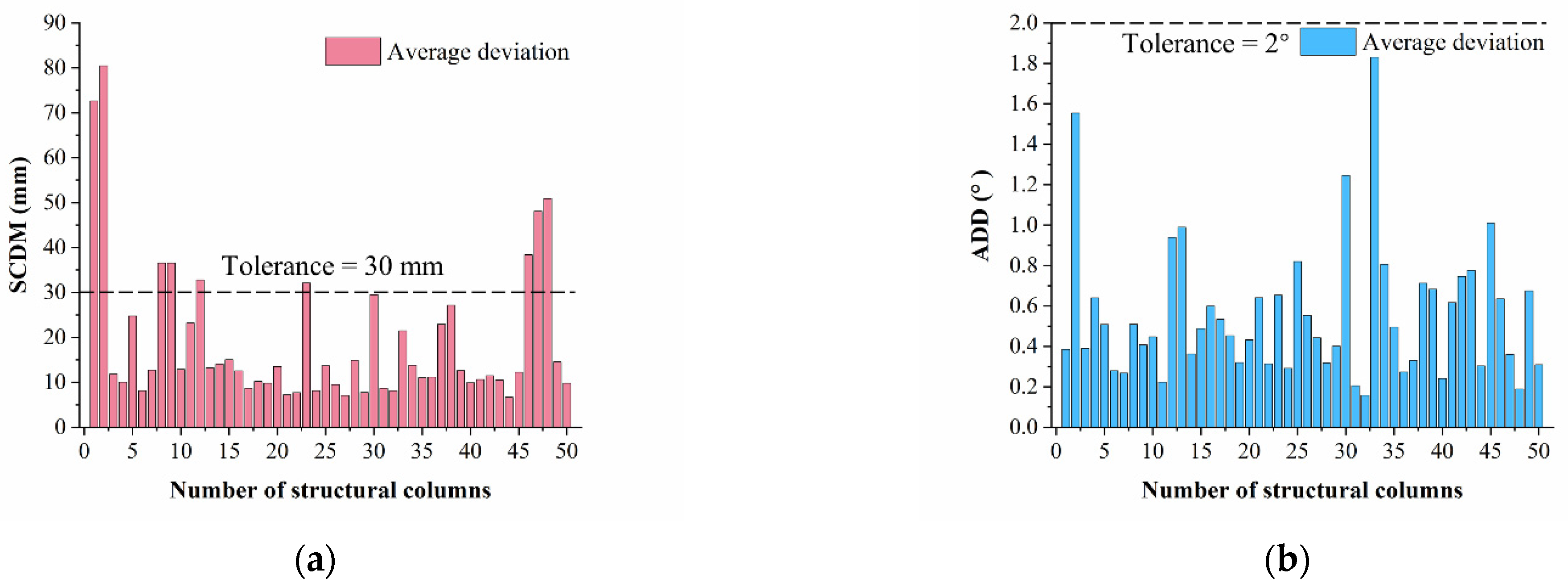

3.4.2. Structural Column Accuracy Evaluation

3.4.3. Statistical Analysis and Visualization of Deviation Results

4. Case Study

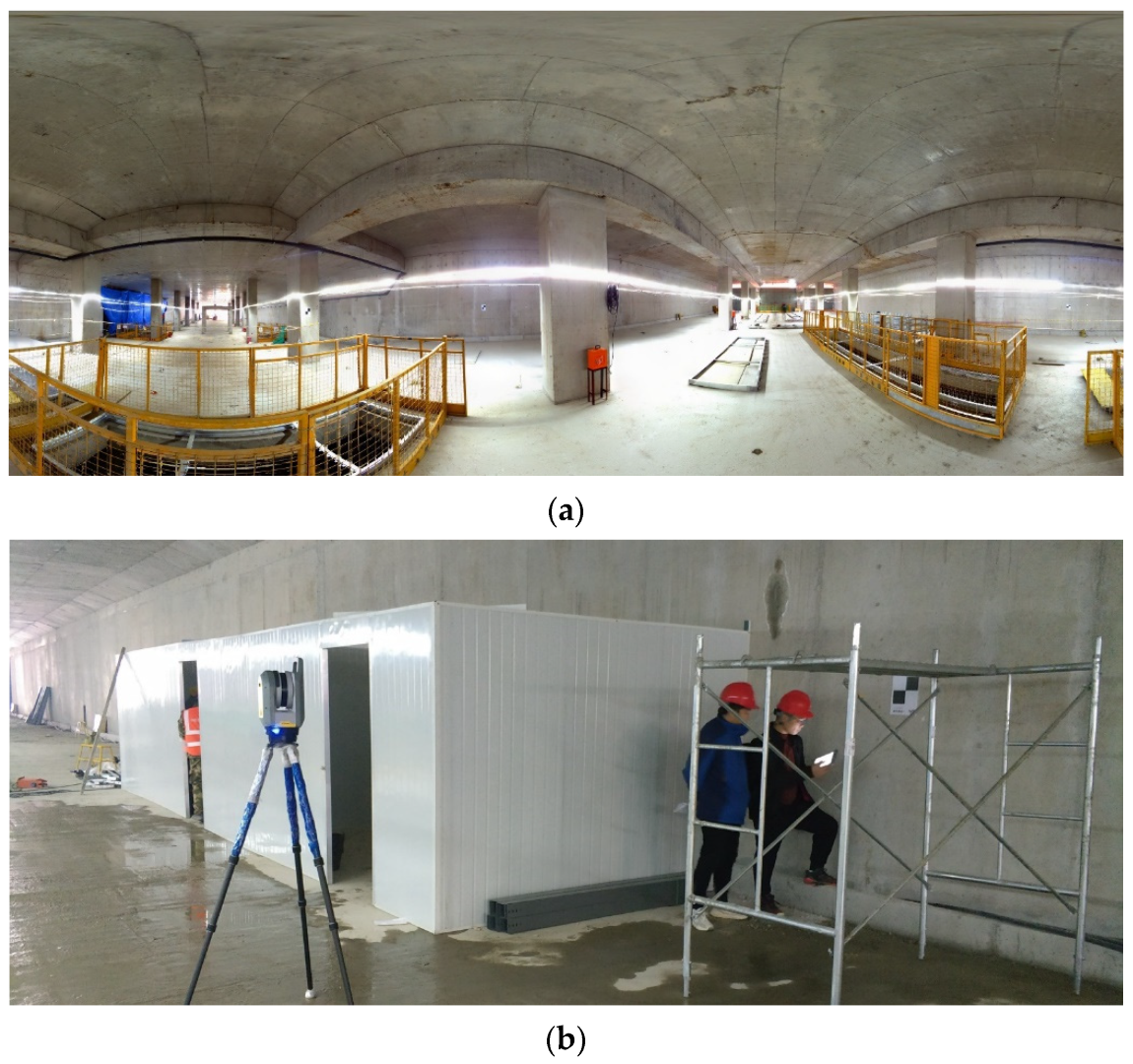

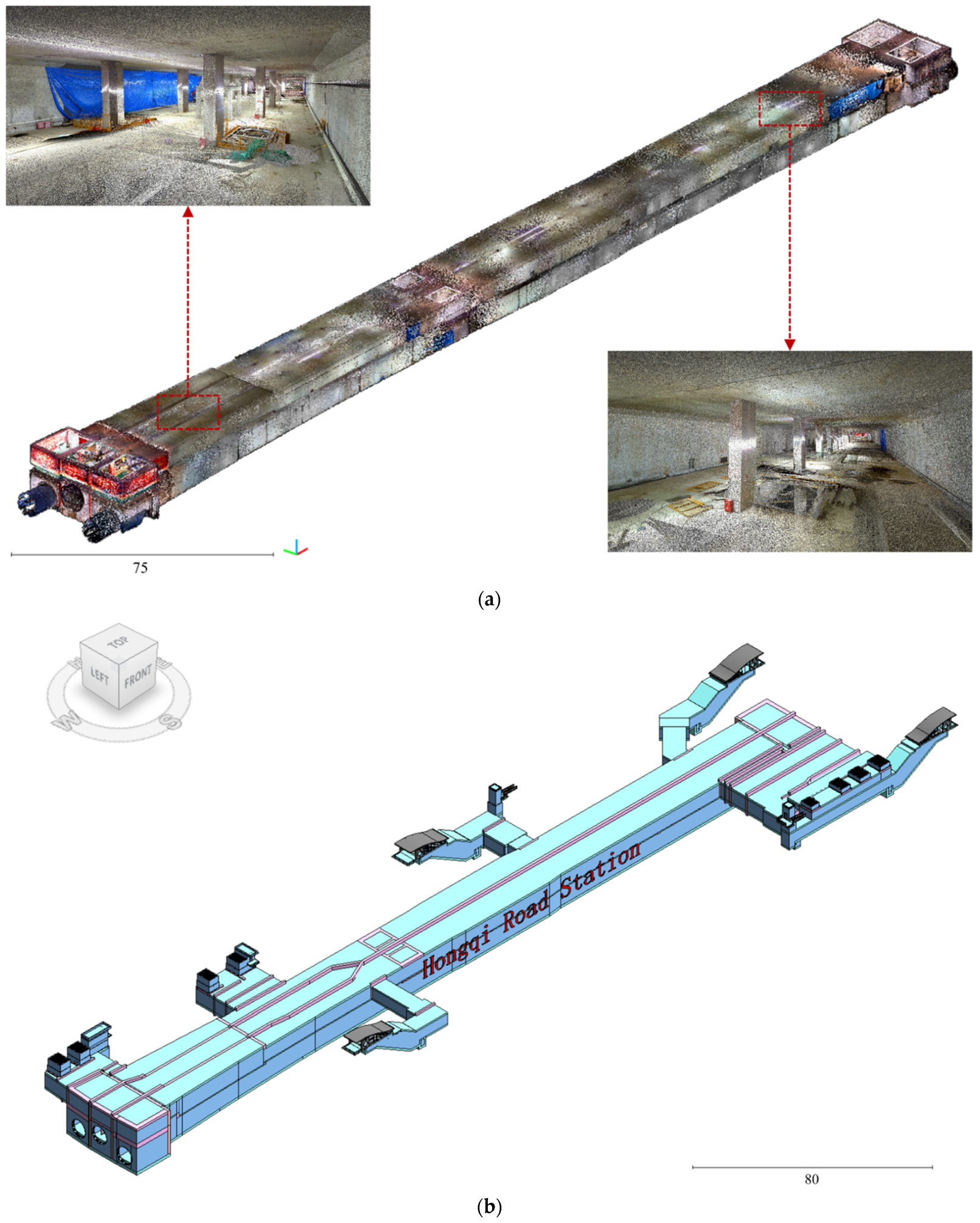

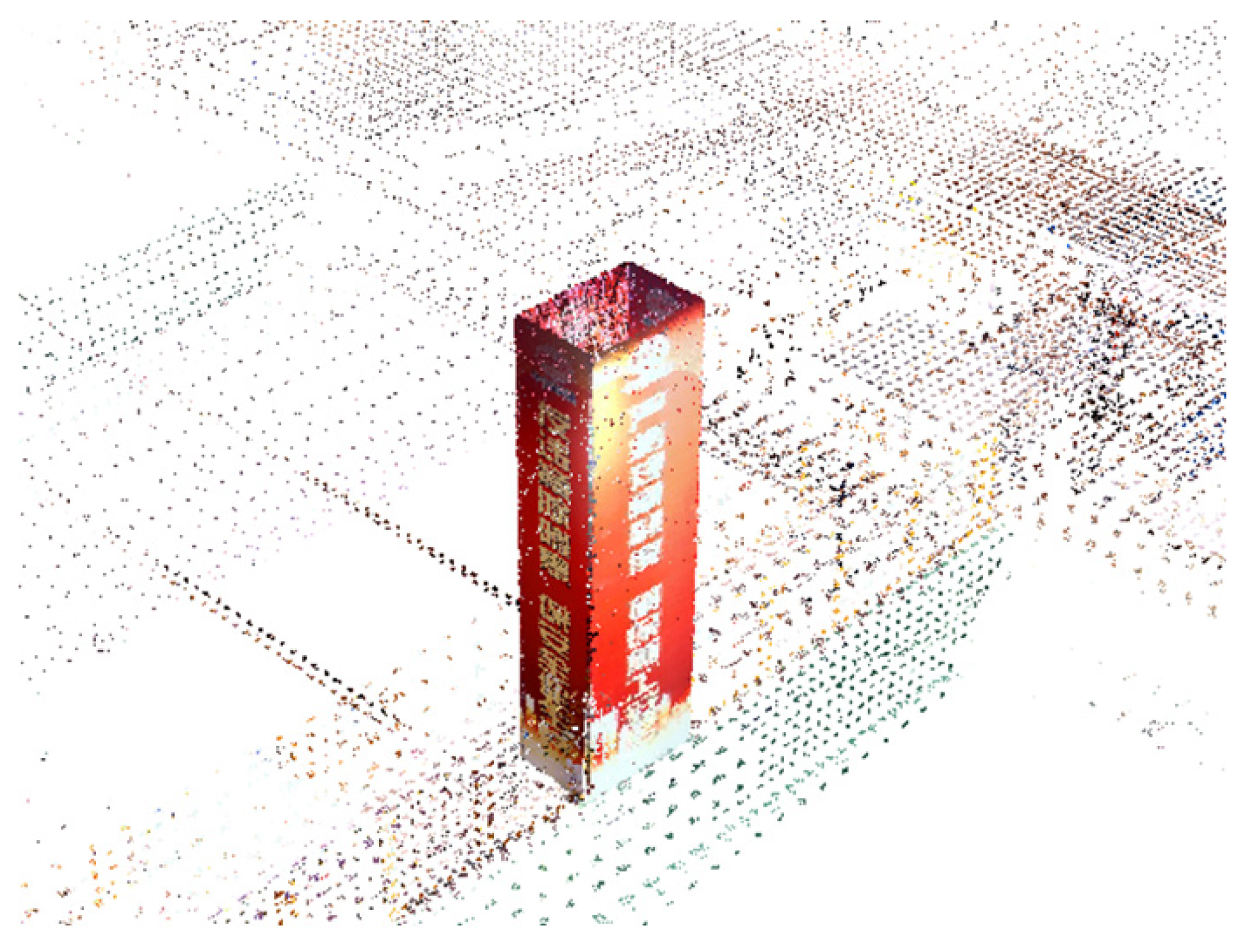

4.1. Construction Site Data Collection and Preprocessing

4.2. Point Cloud and BIM Registration

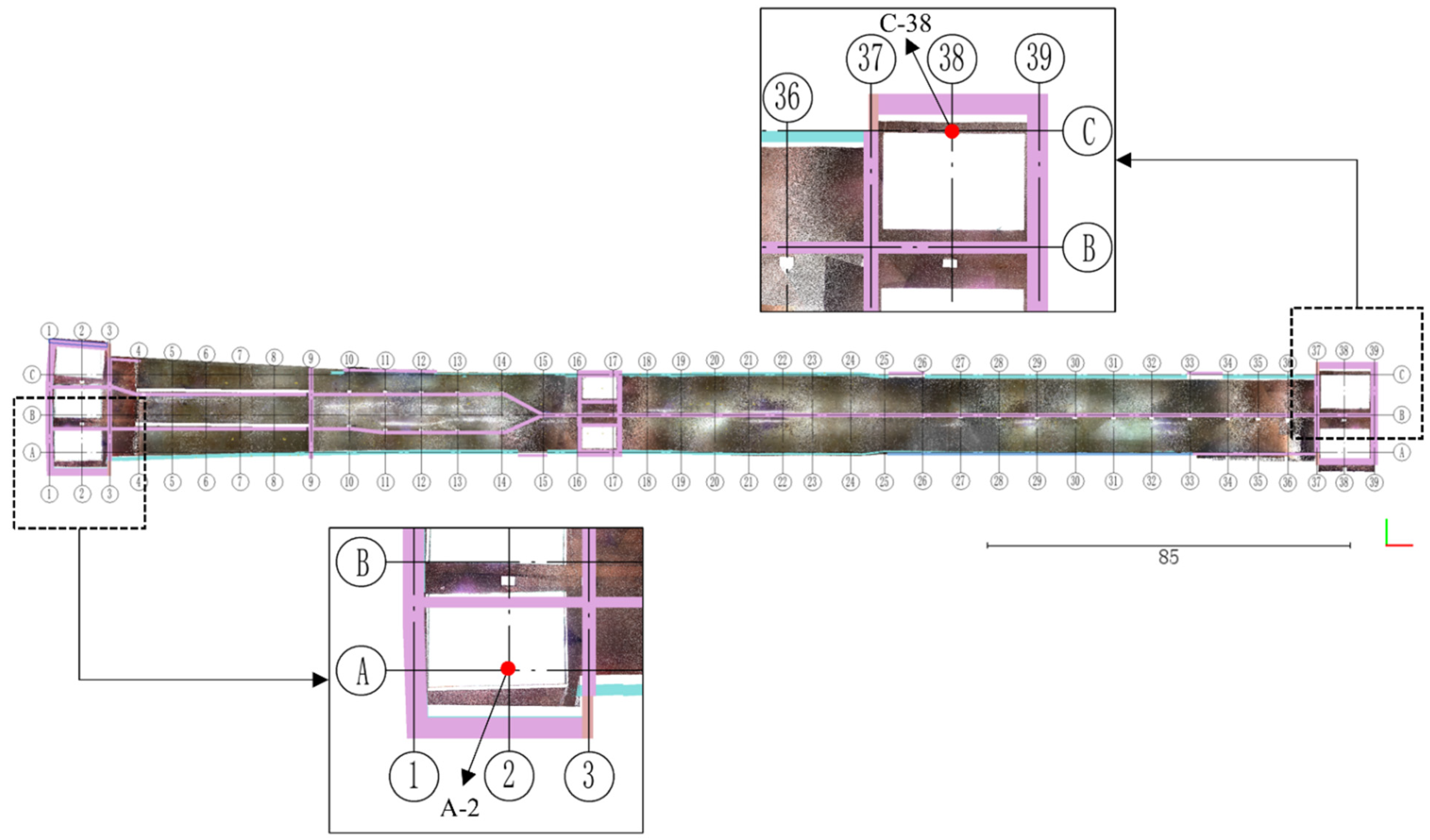

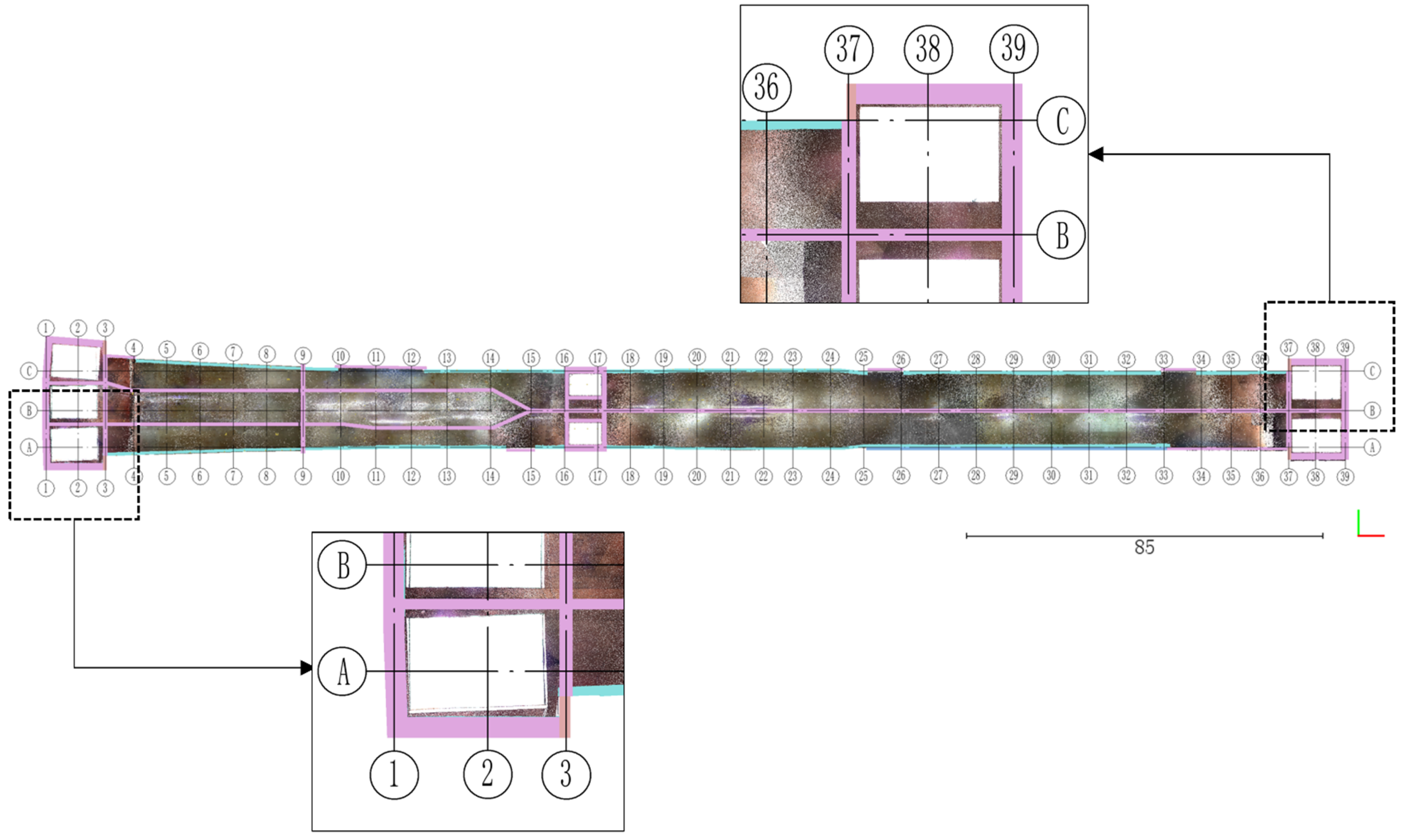

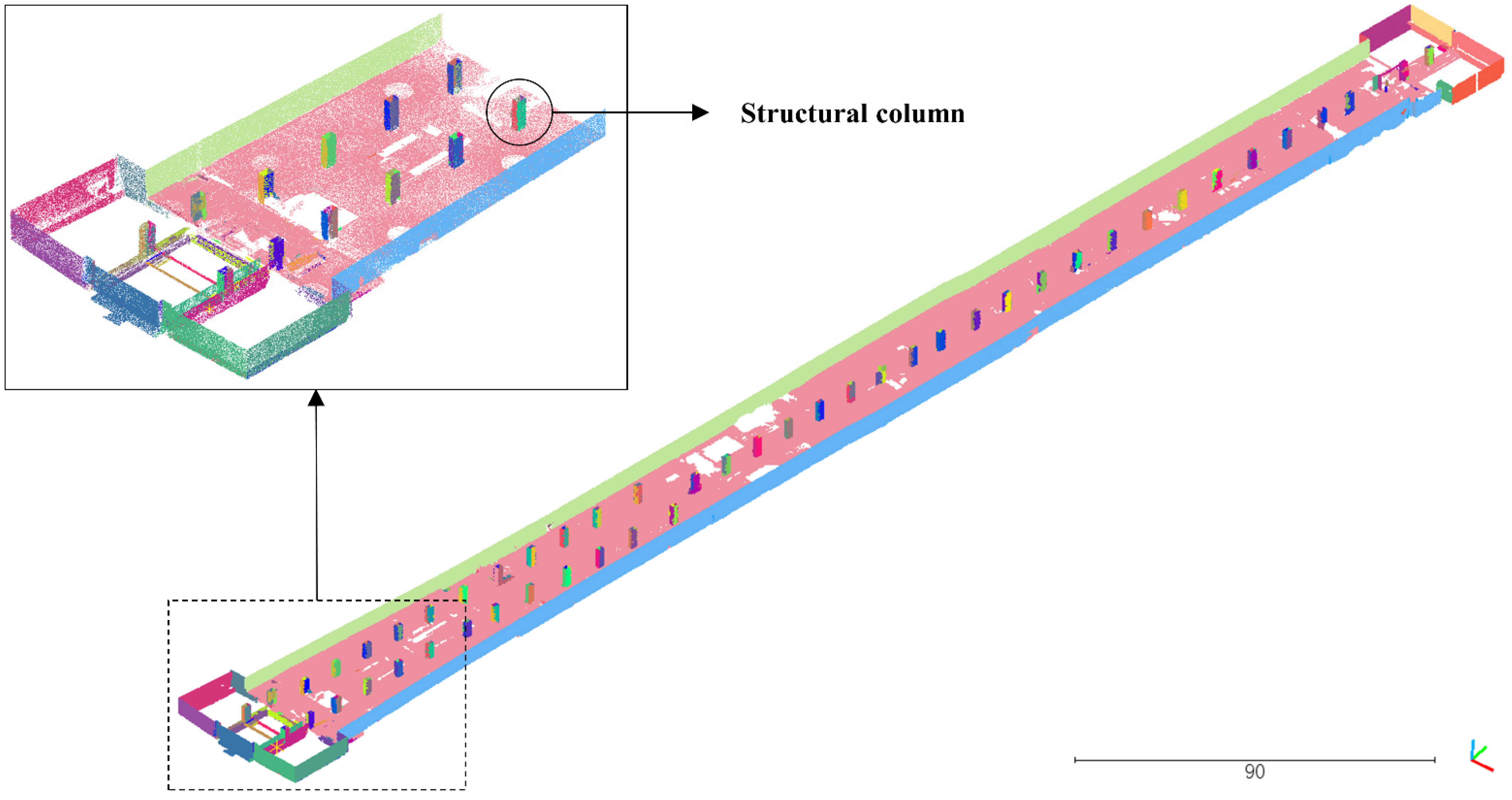

4.3. Point Cloud Structure Element Extraction

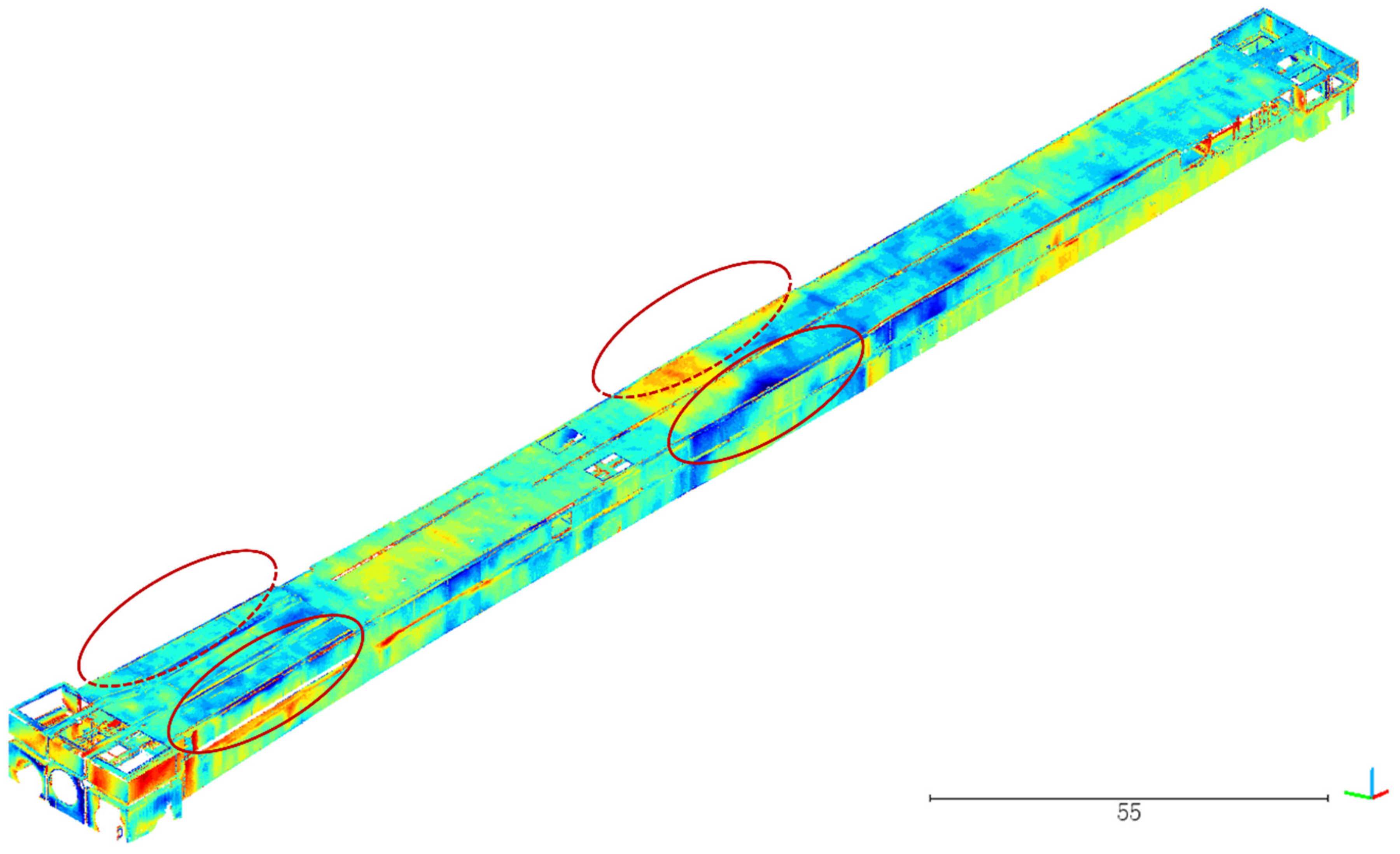

4.4. Surface Accuracy Evaluation

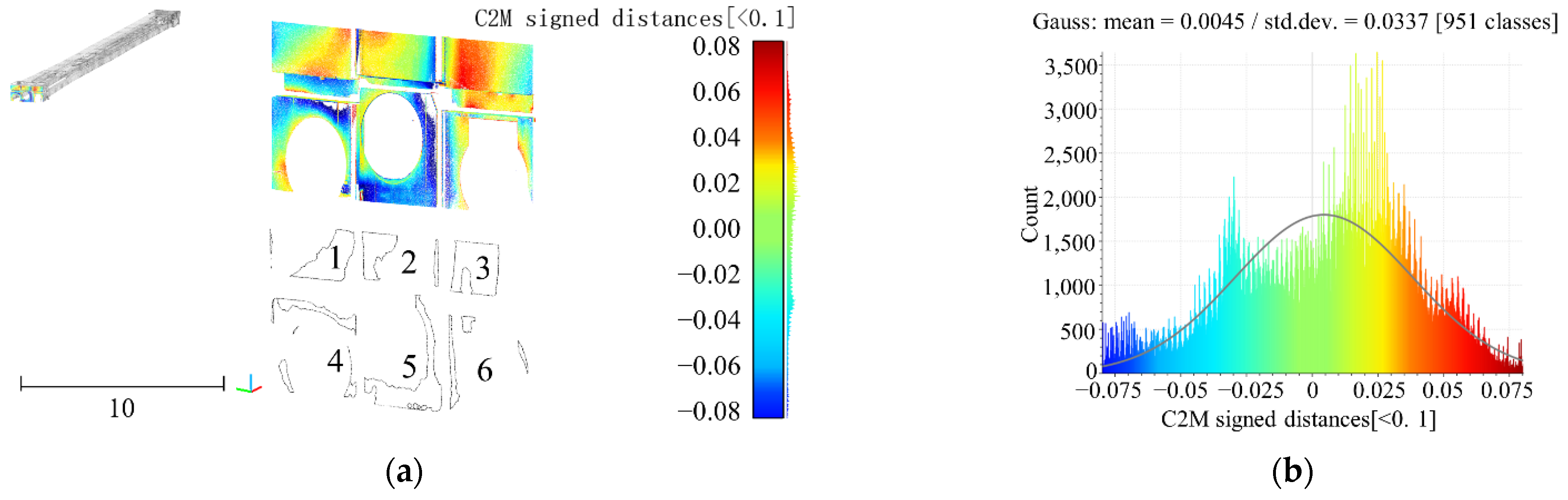

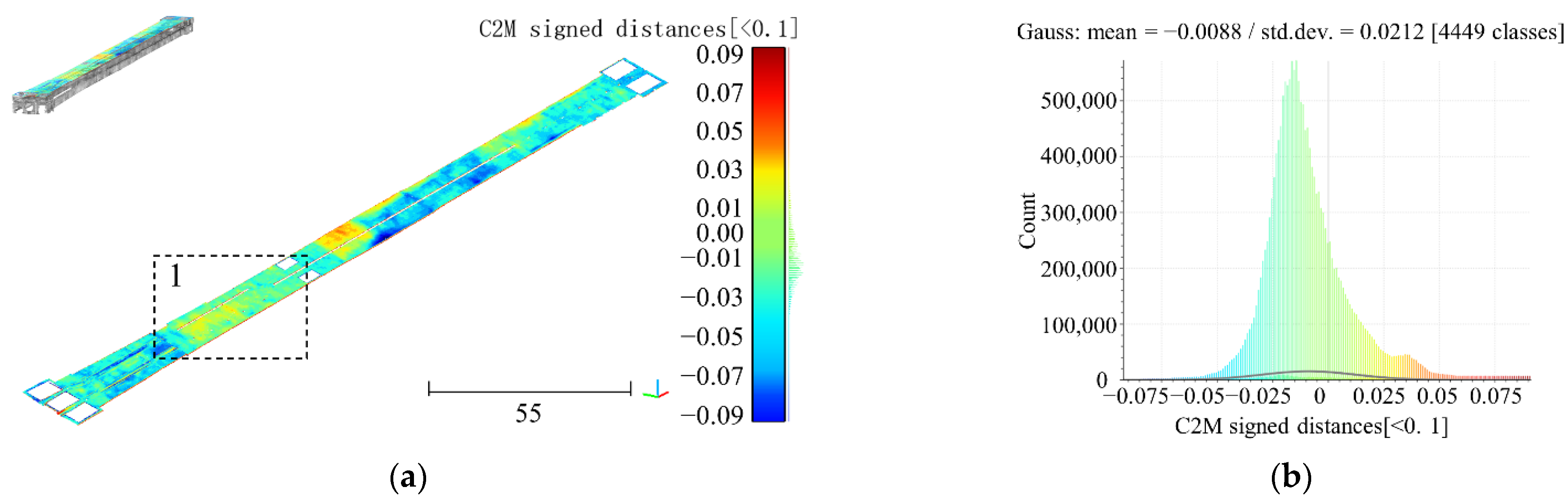

4.4.1. Facade Evaluation

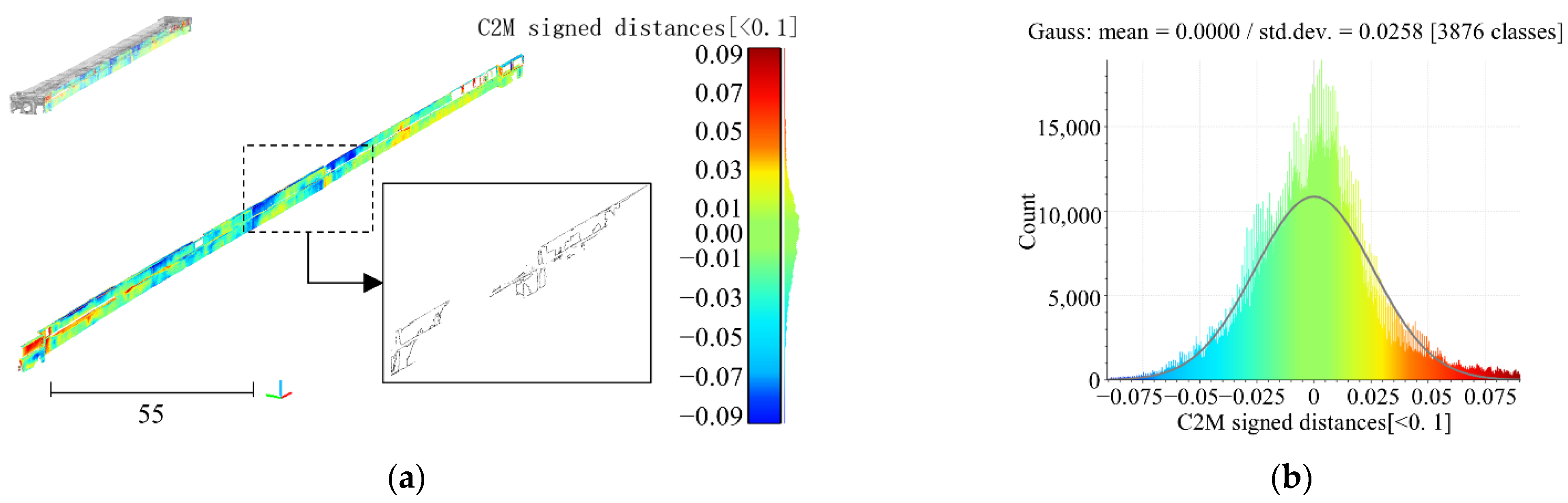

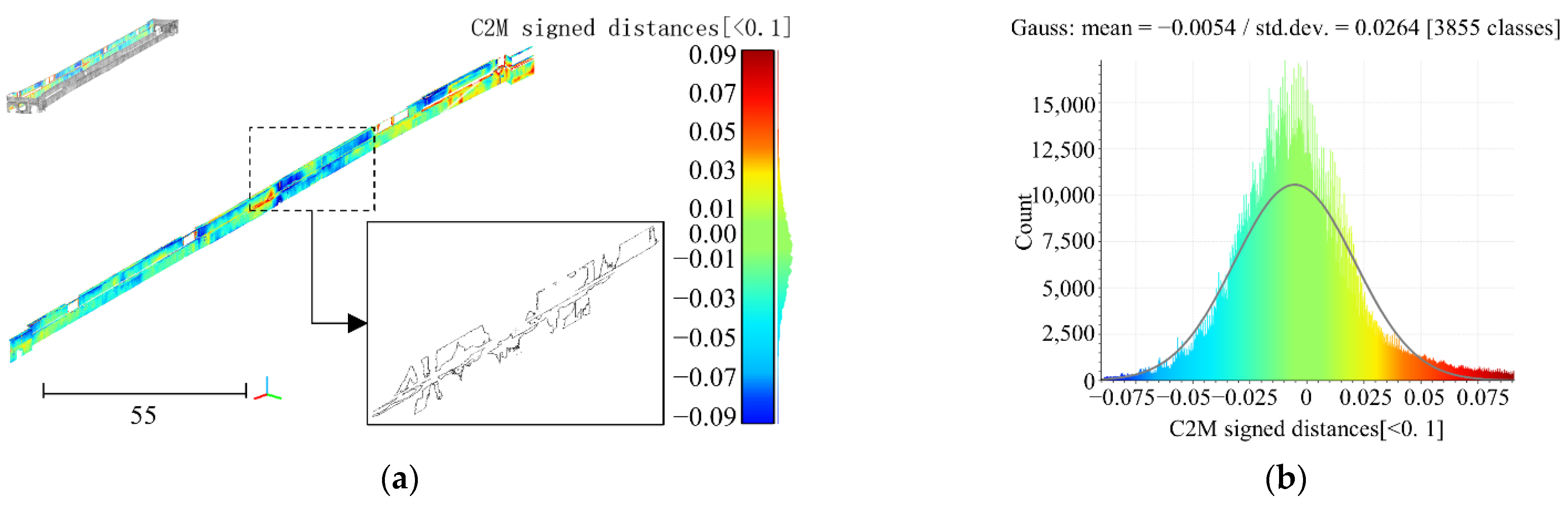

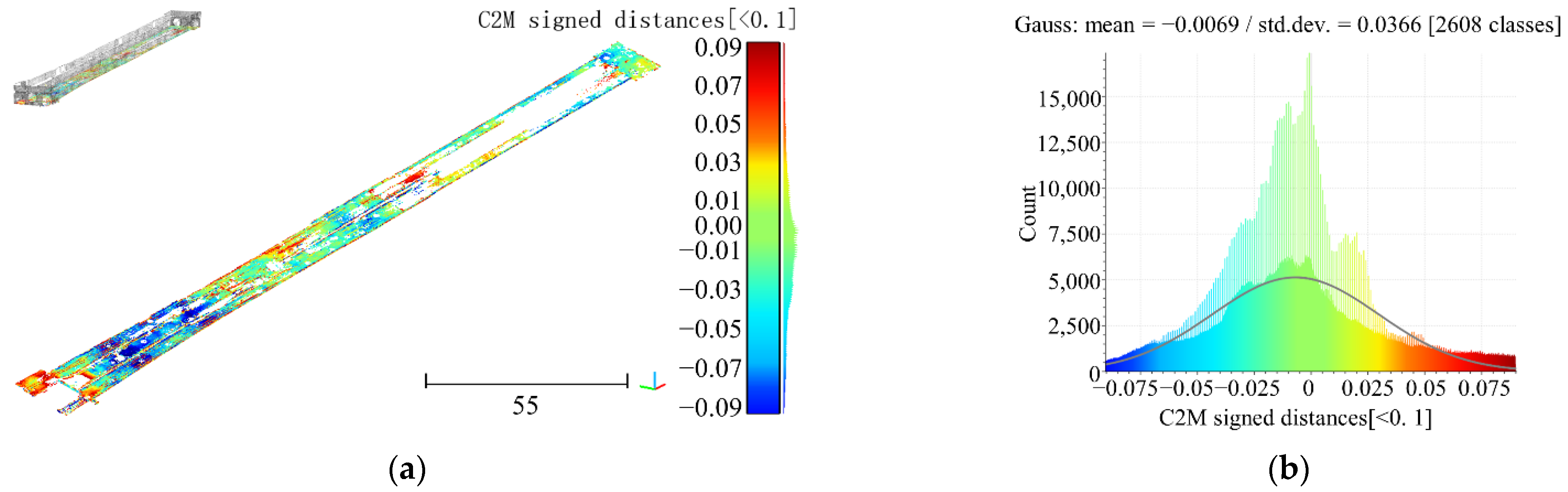

4.4.2. Evaluation of the Top and Bottom Slabs

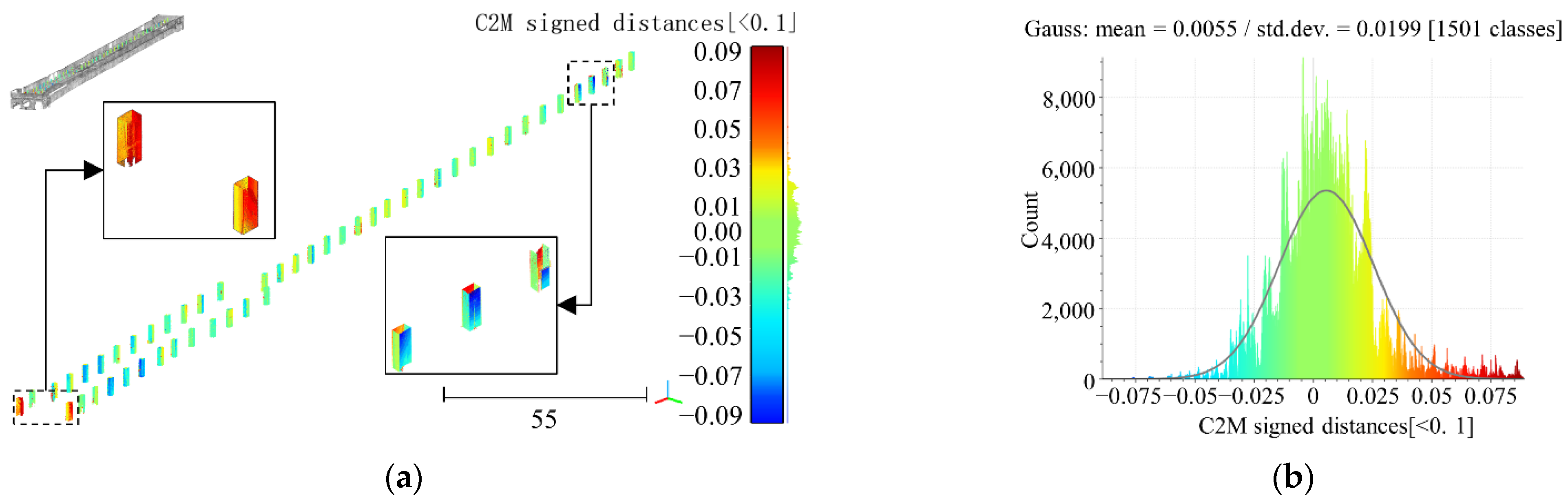

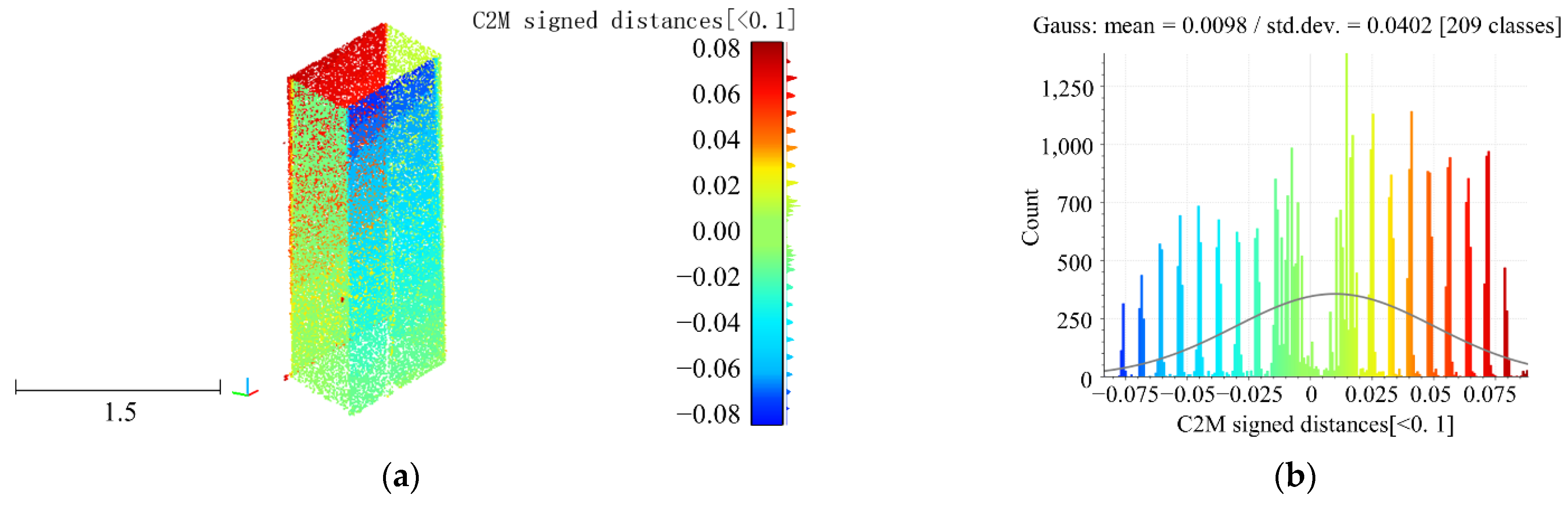

4.5. Structural Column Accuracy Evaluation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Nomenclature |

| 3D | Three-dimensional |

| BIM | Building Information Modeling |

| AEC | Architecture, Engineering, and Construction |

| 2D | Two-dimensional |

| GNSS | Global Navigation Satellite System |

| ICP | Iterative Closest Point |

| RANSAC | Random Sample Consistency |

| PCA | Principal Component Analysis |

| E | Genetic Algorithm |

| ANN | Artificial Neural Network |

| CWT | Continuous Wavelet Transform |

| PL-ICP | Point-to-line Iterative Closest Point |

| KD tree | K-Dimensional tree |

| PDM | Plane Discrepancy Metric |

| SCDM | Structural Column Discrepancy Metric |

| ADD | Angular Distance Deviation |

References

- Wang, L.; Zhang, S.; Tang, L.; Lu, Y.; Liu, Y.; Liu, Y. Optimizing Distribution of Urban Land on the Basis of Urban Land Use Intensity at Prefectural City Scale in Mainland China. Land Use Policy 2022, 115, 106037. [Google Scholar] [CrossRef]

- Zhou, Z.; Irizarry, J.; Zhou, J. Development of a Database Exclusively for Subway Construction Accidents and Corresponding Analyses. Tunn. Undergr. Space Technol. 2021, 111, 103852. [Google Scholar] [CrossRef]

- Guo, Q.; Amin, S.; Hao, Q.; Haas, O. Resilience Assessment of Safety System at Subway Construction Sites Applying Analytic Network Process and Extension Cloud Models. Reliab. Eng. Syst. Saf. 2020, 201, 106956. [Google Scholar] [CrossRef]

- Zhang, C.; Arditi, D. Automated Progress Control Using Laser Scanning Technology. Autom. Constr. 2013, 36, 108–116. [Google Scholar] [CrossRef]

- Navon, R. Research in Automated Measurement of Project Performance Indicators. Autom. Constr. 2007, 16, 176–188. [Google Scholar] [CrossRef]

- Mirzaei, K.; Arashpour, M.; Asadi, E.; Masoumi, H.; Bai, Y.; Behnood, A. 3D Point Cloud Data Processing with Machine Learning for Construction and Infrastructure Applications: A Comprehensive Review. Adv. Eng. Inform. 2022, 51, 101501. [Google Scholar] [CrossRef]

- Yan, Y.; Hajjar, J.F. Automated Extraction of Structural Elements in Steel Girder Bridges from Laser Point Clouds. Autom. Constr. 2021, 125, 103582. [Google Scholar] [CrossRef]

- Jia, S.; Liu, C.; Guan, X.; Wu, H.; Zeng, D.; Guo, J. Bidirectional Interaction between BIM and Construction Processes Using a Multisource Geospatial Data Enabled Point Cloud Model. Autom. Constr. 2022, 134, 104096. [Google Scholar] [CrossRef]

- Reja, V.K.; Varghese, K.; Ha, Q.P. Computer Vision-Based Construction Progress Monitoring. Autom. Constr. 2022, 138, 104245. [Google Scholar] [CrossRef]

- Angjeliu, G.; Cardani, G.; Coronelli, D. A Parametric Model for Ribbed Masonry Vaults. Autom. Constr. 2019, 105, 102785. [Google Scholar] [CrossRef]

- Bassier, M.; Hadjidemetriou, G.; Vergauwen, M.; Van Roy, N.; Verstrynge, E. Implementation of Scan-to-BIM and FEM for the Documentation and Analysis of Heritage Timber Roof Structures. In Proceedings of the Digital Heritage. Progress in Cultural Heritage: Documentation, Preservation, and Protection, Nicosia, Cyprus, 31 October–5 November 2016; Ioannides, M., Fink, E., Moropoulou, A., Hagedorn-Saupe, M., Fresa, A., Liestøl, G., Rajcic, V., Grussenmeyer, P., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 79–90. [Google Scholar]

- Angjeliu, G.; Coronelli, D.; Cardani, G. Development of the Simulation Model for Digital Twin Applications in Historical Masonry Buildings: The Integration between Numerical and Experimental Reality. Comput. Struct. 2020, 238, 106282. [Google Scholar] [CrossRef]

- Liu, J.; Fu, L.; Cheng, G.; Li, D.; Zhou, J.; Cui, N.; Chen, Y.F. Automated BIM Reconstruction of Full-Scale Complex Tubular Engineering Structures Using Terrestrial Laser Scanning. Remote Sens. 2022, 14, 1659. [Google Scholar] [CrossRef]

- Stepinac, M.; Lulić, L.; Ožić, K. The Role of UAV and Laser Scanners in the Post-Earthquake Assessment of Heritage Buildings after the 2020 Earthquakes in Croatia. In Advanced Nondestructive and Structural Techniques for Diagnosis, Redesign and Health Monitoring for the Preservation of Cultural Heritage; Springer: Cham, Switzerland, 2022; pp. 167–177. [Google Scholar] [CrossRef]

- Bae, J.; Lee, J.; Jang, A.; Ju, Y.K.; Park, M.J. SMART SKY EYE System for Preliminary Structural Safety Assessment of Buildings Using Unmanned Aerial Vehicles. Sensors 2022, 22, 2762. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.K. Applications of 3D Point Cloud Data in the Construction Industry: A Fifteen-Year Review from 2004 to 2018. Adv. Eng. Inform. 2019, 39, 306–319. [Google Scholar] [CrossRef]

- Chi, H.L.; Kim, M.K.; Liu, K.Z.; Thedja, J.P.P.; Seo, J.; Lee, D.E. Rebar Inspection Integrating Augmented Reality and Laser Scanning. Autom. Constr. 2022, 136, 104183. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.K.; Cheng, J.C.P.; Sohn, H. Automated Quality Assessment of Precast Concrete Elements with Geometry Irregularities Using Terrestrial Laser Scanning. Autom. Constr. 2016, 68, 170–182. [Google Scholar] [CrossRef]

- Kim, M.K.; Wang, Q.; Park, J.W.; Cheng, J.C.P.; Sohn, H.; Chang, C.C. Automated Dimensional Quality Assurance of Full-Scale Precast Concrete Elements Using Laser Scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

- Bosché, F. Automated Recognition of 3D CAD Model Objects in Laser Scans and Calculation of As-Built Dimensions for Dimensional Compliance Control in Construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Wang, Q.; Kim, M.K.; Sohn, H.; Cheng, J.C. Surface Flatness and Distortion Inspection of Precast Concrete Elements Using Laser Scanning Technology. Smart Struct. Syst. 2016, 18, 601–623. [Google Scholar] [CrossRef]

- Bosché, F.; Biotteau, B. Terrestrial Laser Scanning and Continuous Wavelet Transform for Controlling Surface Flatness in Construction—A First Investigation. Adv. Eng. Inform. 2015, 29, 591–601. [Google Scholar] [CrossRef]

- Xiuren, Y.; Meiqun, H.; Zhiyong, P.; Fang, L. Calculation of Dynamic Assembly and Tensioning Loads at Multiple Points of Prefabricated Structure. Tunn. Undergr. Space Technol. 2022, 126, 104564. [Google Scholar] [CrossRef]

- Yang, X.; Lin, F. Prefabrication Technology for Underground Metro Station Structure. Tunn. Undergr. Space Technol. 2021, 108, 103717. [Google Scholar] [CrossRef]

- Li, D.; Liu, J.; Feng, L.; Zhou, Y.; Liu, P.; Chen, Y.F. Terrestrial Laser Scanning Assisted Flatness Quality Assessment for Two Different Types of Concrete Surfaces. Measurement 2020, 154, 107436. [Google Scholar] [CrossRef]

- Kim, M.K.; Wang, Q.; Yoon, S.; Sohn, H. A Mirror-Aided Laser Scanning System for Geometric Quality Inspection of Side Surfaces of Precast Concrete Elements. Measurement 2019, 141, 420–428. [Google Scholar] [CrossRef]

- Bosché, F. Plane-Based Registration of Construction Laser Scans with 3D/4D Building Models. Adv. Eng. Inform. 2012, 26, 90–102. [Google Scholar] [CrossRef]

- Guo, Y.; Sohel, F.; Bennamoun, M.; Lu, M.; Wan, J. Rotational Projection Statistics for 3D Local Surface Description and Object Recognition. Int. J. Comput. Vis. 2013, 105, 63–86. [Google Scholar] [CrossRef]

- Franaszek, M.; Cheok, G.S.; Witzgall, C. Fast Automatic Registration of Range Images from 3D Imaging Systems Using Sphere Targets. Autom. Constr. 2009, 18, 265–274. [Google Scholar] [CrossRef]

- Guarnieri, A.; Vettore, A.; Remondino, F.; Church, O.P. Photogrammetry and Ground-Based Laser Scanning: Assessment of Metric Accuracy of the 3D Model of Pozzoveggiani Church; The Pennsylvania State University: State College, PA, USA, 2004. [Google Scholar]

- Weinmann, M. Reconstruction and Analysis of 3D Scenes; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Stamos, I.; Leordeanu, M. Automated Feature-Based Range Registration of Urban Scenes of Large Scale. In Proceedings of the 2003 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Madison, WI, USA, 18–20 June 2003; Proceedings. IEEE: Piscataway, NJ, USA, 2003; Volume 2, pp. II–Ii. [Google Scholar]

- Xu, Y.; Boerner, R.; Yao, W.; Hoegner, L.; Stilla, U. Automated Coase Registation of Point Clouds in 3D Urban Scenesusing Voexl Baesd Plane Constraint. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, IV-2/W4, 185–191. [Google Scholar] [CrossRef]

- Dold, C. Extended Gaussian Images for the Registration of Terrestrial Scan Data. In Proceedings of the ISPRS Workshop Laser scanning, Enschede, The Netherlands, 12–14 September 2005; pp. 180–185. [Google Scholar]

- Dong, Z.; Liang, F.; Yang, B.; Xu, Y.; Zang, Y.; Li, J.; Wang, Y.; Dai, W.; Fan, H.; Hyyppä, J.; et al. Registration of Large-Scale Terrestrial Laser Scanner Point Clouds: A Review and Benchmark. ISPRS J. Photogramm. Remote Sens. 2020, 163, 327–342. [Google Scholar] [CrossRef]

- Vermandere, J.; Bassier, M.; Vergauwen, M. Two-Step Alignment of Mixed Reality Devices to Existing Building Data. Remote Sens. 2022, 14, 2680. [Google Scholar] [CrossRef]

- Besl, P.; McKay, N. Method for Registration of 3-D Shapes. In Sensor Fusion IV: Control Paradigms and Data Structures International Society for Optics and Photonics; SPIE: Bellingham, WA, USA, 1992; pp. 586–607. [Google Scholar]

- Censi, A. An ICP Variant Using a Point-to-Line Metric. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 19–25. [Google Scholar]

- Rusinkiewicz, S.; Levoy, M. Efficient Variants of the ICP Algorithm. In Proceedings of the Third International Conference on 3-D Digital Imaging and Modeling, Quebec City, QC, Canada, 28 May–1 June 2001; pp. 145–152. [Google Scholar]

- Segal, A.; Haehnel, D.; Thrun, S. Generalized-Icp. In Robotics: Science and Systems; University of Washington: Seattle, WA, USA, 2009; Volume 2, p. 435. [Google Scholar]

- Bueno, M.; Bosché, F.; González-Jorge, H.; Martínez-Sánchez, J.; Arias, P. 4-Plane Congruent Sets for Automatic Registration of as-Is 3D Point Clouds with 3D BIM Models. Autom. Constr. 2018, 89, 120–134. [Google Scholar] [CrossRef]

- Chen, J.; Cho, Y.K. Point-to-Point Comparison Method for Automated Scan-vs-Bim Deviation Detection. In Proceedings of the 2018 17th International Conference on Computing in Civil and Building Engineering, Tampere, Finland, 4–7 June 2018; pp. 5–7. [Google Scholar]

- Harirchian, E.; Aghakouchaki Hosseini, S.E.; Jadhav, K.; Kumari, V.; Rasulzade, S.; Işık, E.; Wasif, M.; Lahmer, T. A Review on Application of Soft Computing Techniques for the Rapid Visual Safety Evaluation and Damage Classification of Existing Buildings. J. Build. Eng. 2021, 43, 102536. [Google Scholar] [CrossRef]

- Bülbül, M.A.; Harirchian, E.; Işık, M.F.; Aghakouchaki Hosseini, S.E.; Işık, E. A Hybrid ANN-GA Model for an Automated Rapid Vulnerability Assessment of Existing RC Buildings. Appl. Sci. 2022, 12, 5138. [Google Scholar] [CrossRef]

- Harirchian, E.; Jadhav, K.; Kumari, V.; Lahmer, T. ML-EHSAPP: A Prototype for Machine Learning-Based Earthquake Hazard Safety Assessment of Structures by Using a Smartphone App. Null 2022, 26, 5279–5299. [Google Scholar] [CrossRef]

- Puri, N.; Valero, E.; Turkan, Y.; Bosché, F. Assessment of Compliance of Dimensional Tolerances in Concrete Slabs Using TLS Data and the 2D Continuous Wavelet Transform. Autom. Constr. 2018, 94, 62–72. [Google Scholar] [CrossRef]

- Kim, M.K.; Sohn, H.; Chang, C.C. Automated Dimensional Quality Assessment of Precast Concrete Panels Using Terrestrial Laser Scanning. Autom. Constr. 2014, 45, 163–177. [Google Scholar] [CrossRef]

- Akinci, B.; Boukamp, F.; Gordon, C.; Huber, D.; Lyons, C.; Park, K. A Formalism for Utilization of Sensor Systems and Integrated Project Models for Active Construction Quality Control. Autom. Constr. 2006, 15, 124–138. [Google Scholar] [CrossRef]

- Kim, M.K.; Cheng, J.C.P.; Sohn, H.; Chang, C.C. A Framework for Dimensional and Surface Quality Assessment of Precast Concrete Elements Using BIM and 3D Laser Scanning. Autom. Constr. 2015, 49, 225–238. [Google Scholar] [CrossRef]

- Valero, E.; Bosché, F.; Bueno, M. Laser Scanning for BIM. J. Inf. Technol. Constr. (ITcon) 2022, 27, 486–495. [Google Scholar] [CrossRef]

- Jiang, Q.; Shi, Y.E.; Yan, F.; Zheng, H.; Kou, Y.Y.; He, B.G. Reconstitution Method for Tunnel Spatiotemporal Deformation Based on 3D Laser Scanning Technology and Corresponding Instability Warning. Eng. Fail. Anal. 2021, 125, 105391. [Google Scholar] [CrossRef]

- Yang, F.; Zhou, G.; Su, F.; Zuo, X.; Tang, L.; Liang, Y.; Zhu, H.; Li, L. Automatic Indoor Reconstruction from Point Clouds in Multi-Room Environments with Curved Walls. Sensors 2019, 19, 3798. [Google Scholar] [CrossRef] [PubMed]

- Chetverikov, D.; Svirko, D.; Stepanov, D.; Krsek, P. The Trimmed Iterative Closest Point Algorithm. In Proceedings of the 2002 International Conference on Pattern Recognition, Quebec City, QC, Canada, 11–15 August 2002; Volume 3, pp. 545–548. [Google Scholar]

- Liu, J.; Zhang, Q.; Wu, J.; Zhao, Y. Dimensional Accuracy and Structural Performance Assessment of Spatial Structure Components Using 3D Laser Scanning. Autom. Constr. 2018, 96, 324–336. [Google Scholar] [CrossRef]

- Zhang, R.; El-Gohary, N. A Deep Neural Network-Based Method for Deep Information Extraction Using Transfer Learning Strategies to Support Automated Compliance Checking. Autom. Constr. 2021, 132, 103834. [Google Scholar] [CrossRef]

- Rabbani, T.; Van Den Heuvel, F.; Vosselmann, G. Segmentation of Point Clouds Using Smoothness Constraint. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 248–253. [Google Scholar]

- Yang, F.; Li, L.; Su, F.; Li, D.; Zhu, H.; Ying, S.; Zuo, X.; Tang, L. Semantic Decomposition and Recognition of Indoor Spaces with Structural Constraints for 3D Indoor Modelling. Autom. Constr. 2019, 106, 102913. [Google Scholar] [CrossRef]

- CH/Z 3017—2015; Technical Specifications for Terrestrial Three-Dimensional Laser Scanning. The Central Peoples Government of the People’s Republic of China: Beijing, China.

| Structural Element | Number of Points | Point Density (pts/m2) |

|---|---|---|

| East facade | 755,424 | 5502 |

| West facade | 902,986 | 4386 |

| North facade | 15,022,981 | 6351 |

| South facade | 14,858,647 | 6533 |

| Roof slab | 19,793,397 | 5182 |

| Base slab | 6,799,713 | 3742 |

| Structural column | 2,252,290 | 5513 |

| Exceed Tolerance | Not Exceed Tolerance | ||

|---|---|---|---|

|  |  |  |

| C-2 | A-2 | A-4 | C-12 |

|  |  |  |

| B-35 | B-36 | A-12 | A-13 |

|  |  |  |

| B-34 | C-6 | B-15 | B-17 |

|  |  |  |

| A-5 | A-7 | B-20 | B-32 |

| Structural Column | SCDM (mm) | ADD (°) |

|---|---|---|

| A-2 | 80.5 | 1.55 |

| C-2 | 72.6 | 0.39 |

| B-36 | 50.9 | 0.19 |

| B-35 | 48.1 | 0.36 |

| B-34 | 38.3 | 0.64 |

| C-6 | 36.6 | 0.41 |

| A-5 | 36.6 | 0.39 |

| A-7 | 32.8 | 0.94 |

| C-13 | 32.1 | 0.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Qian, P.; Liu, Y.; Li, T.; Yang, L.; Yang, F. Geometric Accuracy Evaluation Method for Subway Stations Based on 3D Laser Scanning. Appl. Sci. 2022, 12, 9535. https://doi.org/10.3390/app12199535

Wang Q, Qian P, Liu Y, Li T, Yang L, Yang F. Geometric Accuracy Evaluation Method for Subway Stations Based on 3D Laser Scanning. Applied Sciences. 2022; 12(19):9535. https://doi.org/10.3390/app12199535

Chicago/Turabian StyleWang, Quankai, Peng Qian, Yunping Liu, Tao Li, Lei Yang, and Fan Yang. 2022. "Geometric Accuracy Evaluation Method for Subway Stations Based on 3D Laser Scanning" Applied Sciences 12, no. 19: 9535. https://doi.org/10.3390/app12199535

APA StyleWang, Q., Qian, P., Liu, Y., Li, T., Yang, L., & Yang, F. (2022). Geometric Accuracy Evaluation Method for Subway Stations Based on 3D Laser Scanning. Applied Sciences, 12(19), 9535. https://doi.org/10.3390/app12199535