Classification of Road Surfaces Based on CNN Architecture and Tire Acoustical Signals

Abstract

:1. Introduction

2. Background Theory

2.1. Continuous Wavelet Transform (CWT)

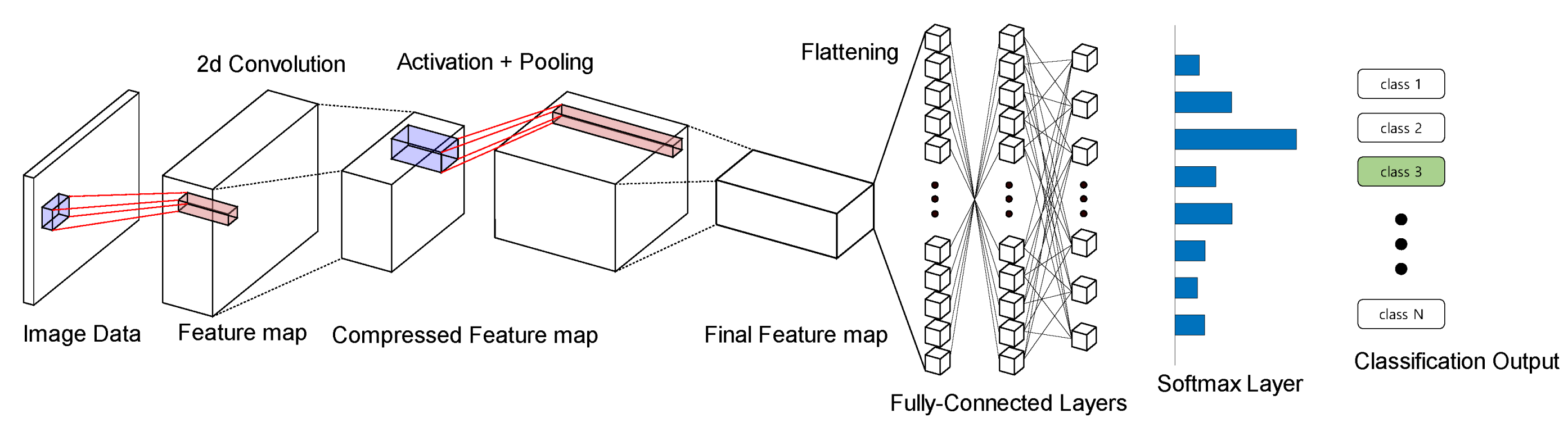

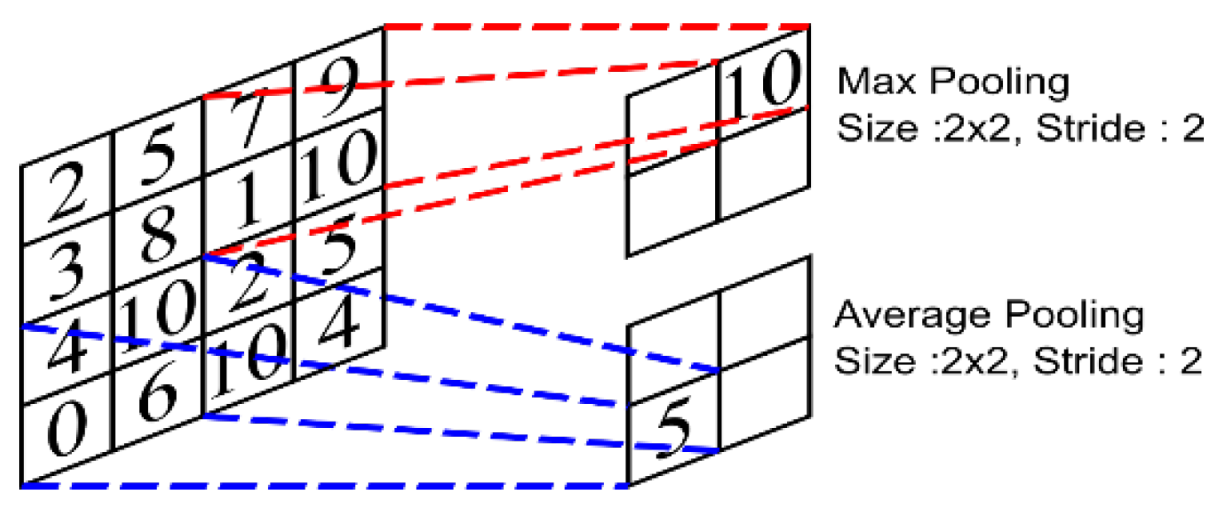

2.2. Convolutional Neural Network (CNN)

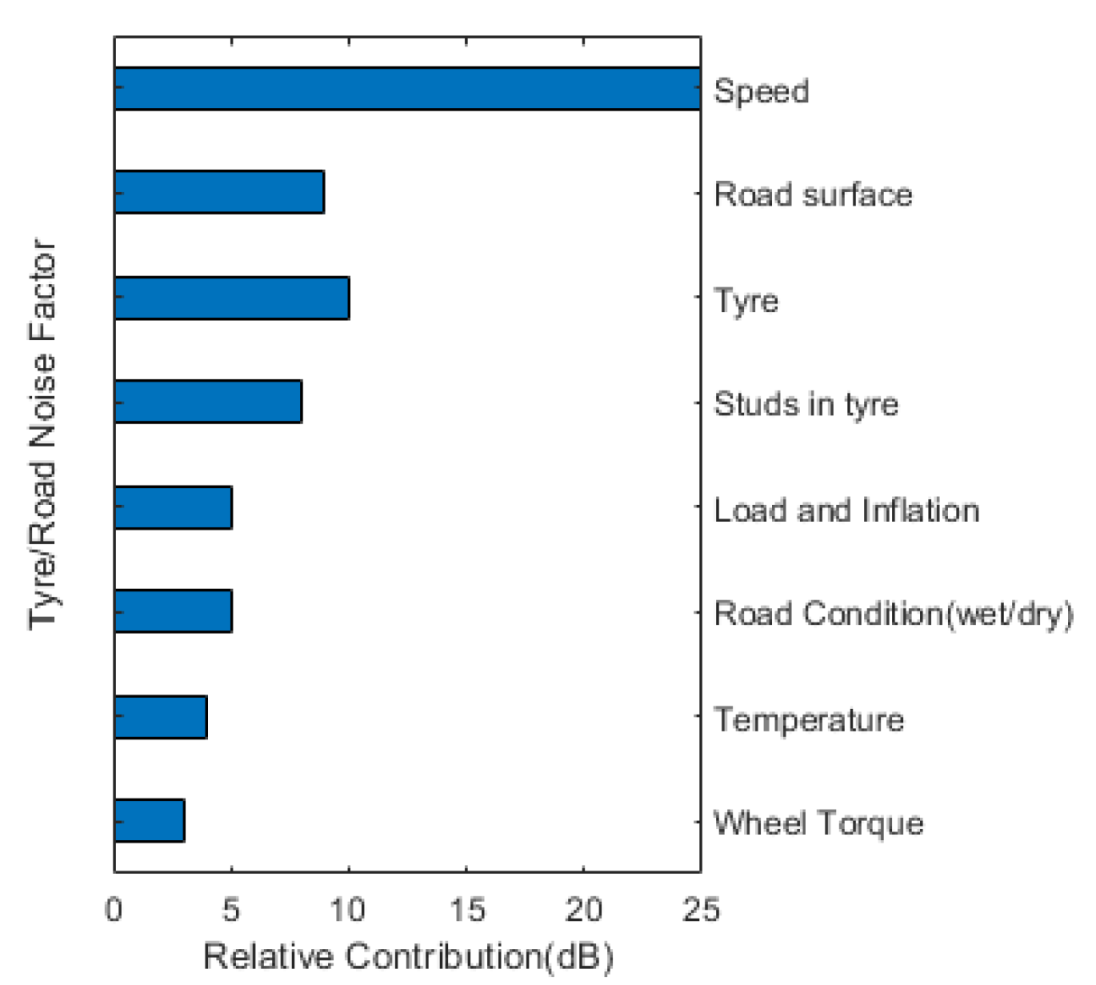

2.3. Tire-Pavement Interaction Noise

3. Experiment

3.1. Experimental Setup and Devices

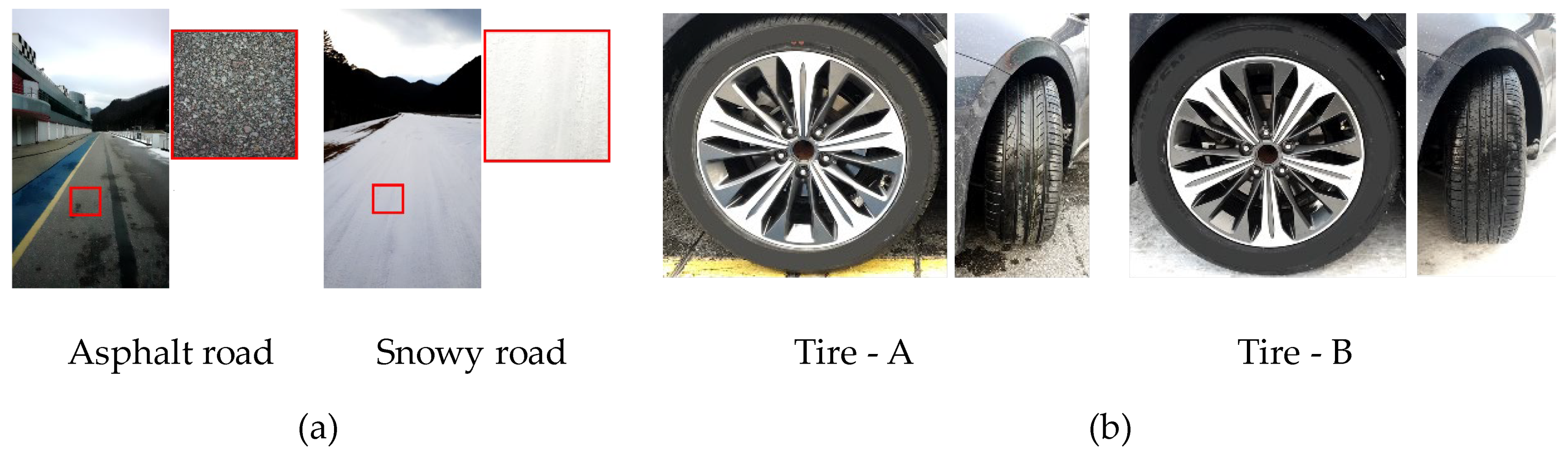

3.2. Test Roads and Tire Types

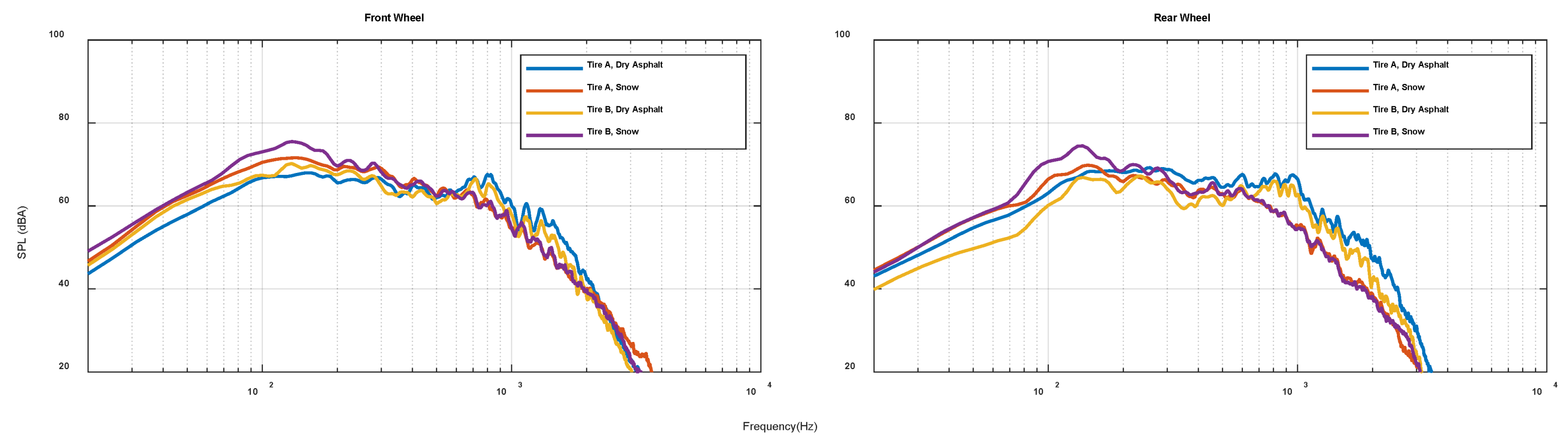

3.3. Data Acquisition and Analysis

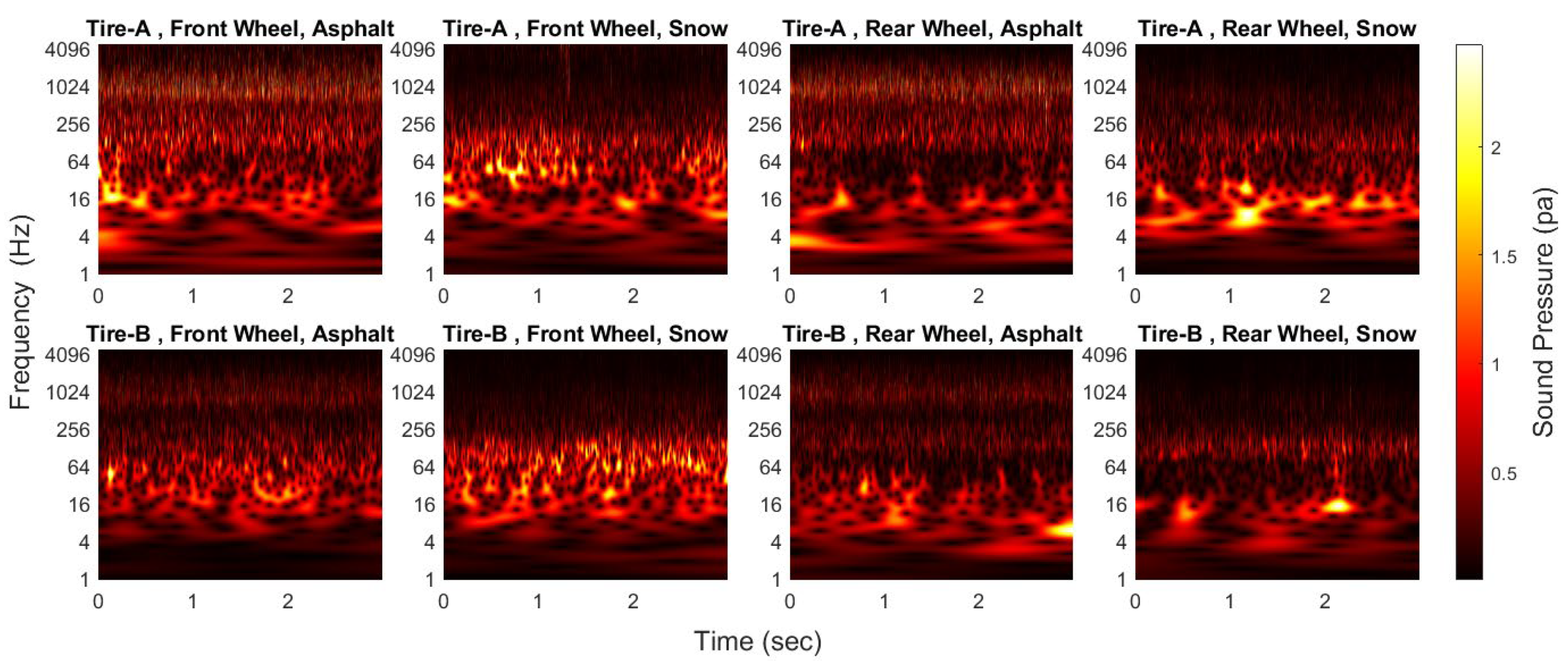

4. Data Processing

5. Training of Neural Network

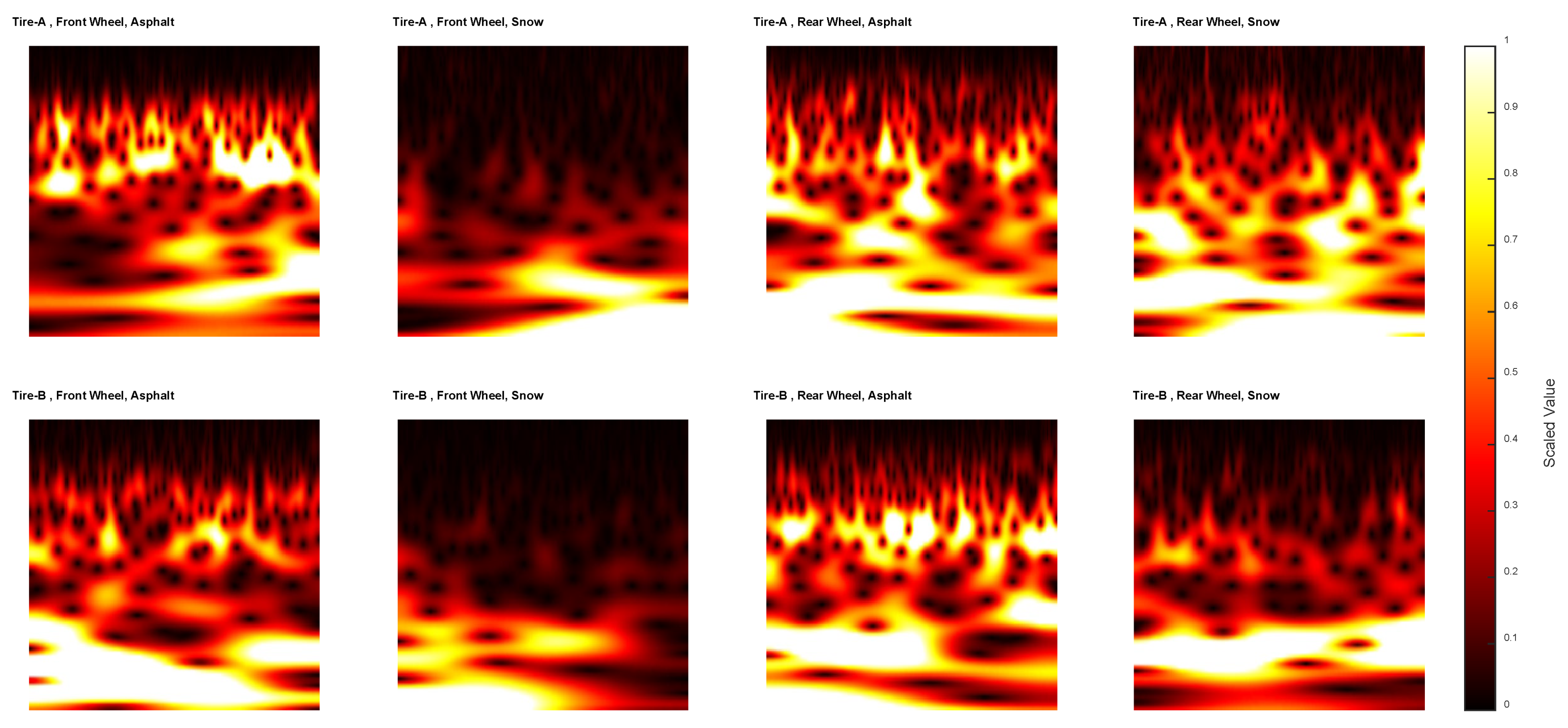

5.1. Dataset Preparation

5.2. Architecture of Network and Parameter Setup

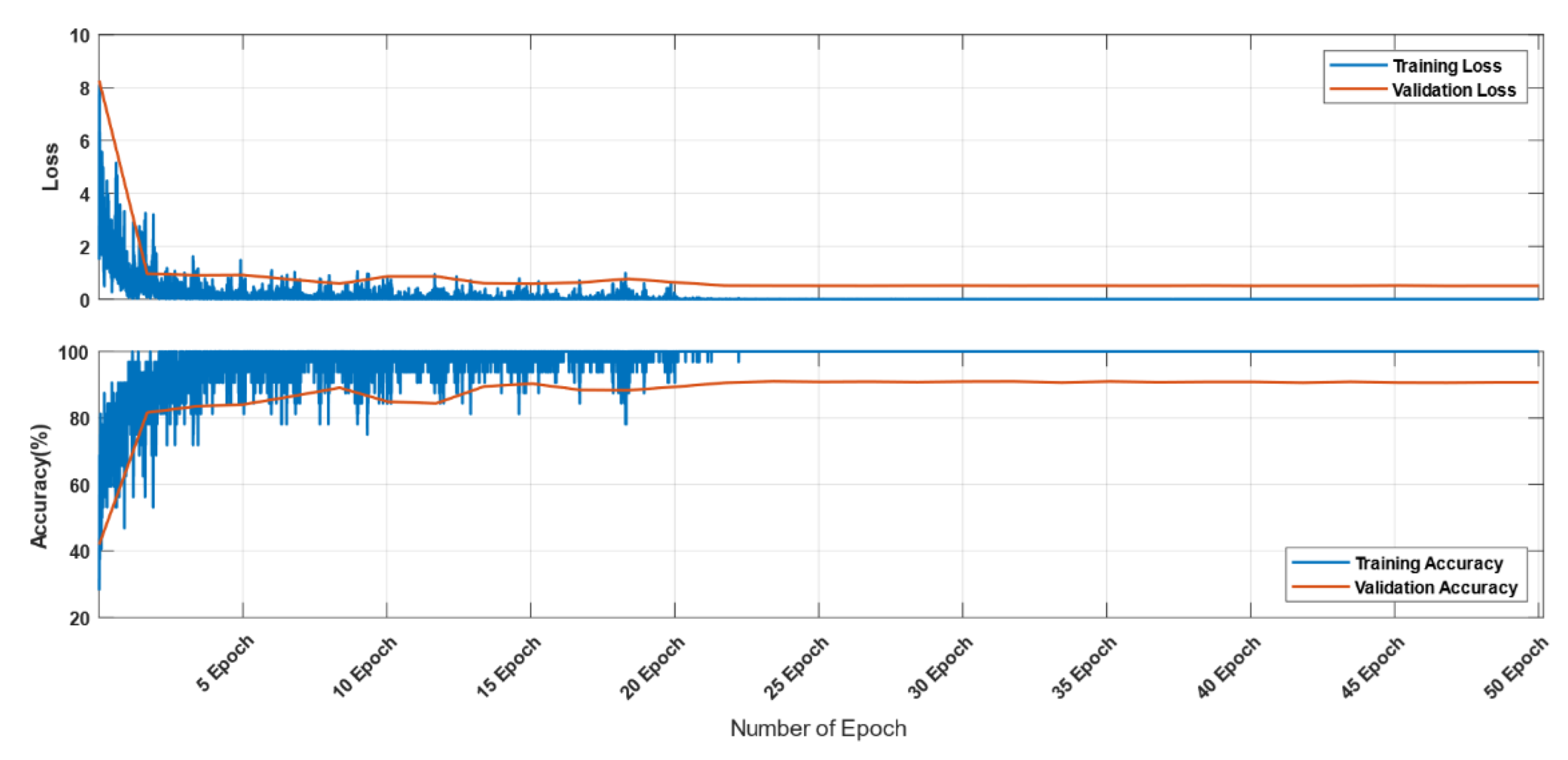

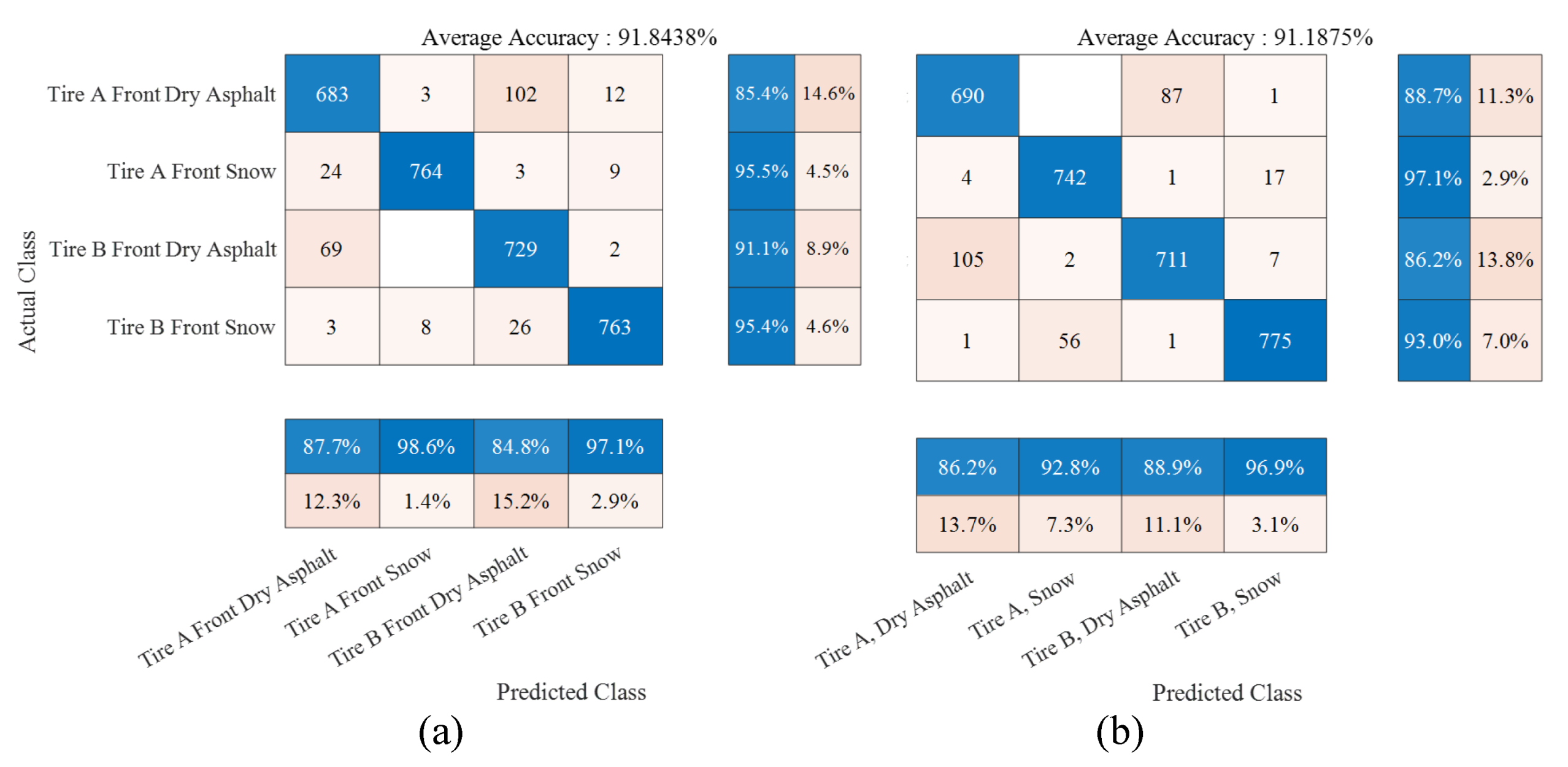

5.3. Train and Results

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Müller, S.; Uchanski, M.; Hedrick, K. Estimation of the maximum tire-road friction coefficient. J. Dyn. Syst. Meas. Control 2003, 125, 607–617. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Moutinho, A.; Fioravanti, A.R.; de Paiva, E.C. Estimation of tire–road friction for road vehicles: A time delay neural network approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 4. [Google Scholar] [CrossRef]

- Rajamani, R.; Piyabongkarn, N.; Lew, J.; Yi, K.; Phanomchoeng, G. Tire-road friction-coefficient estimation. IEEE Control Syst. Mag. 2010, 30, 54–69. [Google Scholar]

- Alonso, J.; López, J.; Pavón, I.; Recuero, M.; Asensio, C.; Arcas, G.; Bravo, A. On-board wet road surface identification using tyre/road noise and support vector machines. Appl. Acoust. 2014, 76, 407–415. [Google Scholar] [CrossRef]

- Masino, J.; Pinay, J.; Reischl, M.; Gauterin, F. Road surface prediction from acoustical measurements in the tire cavity using support vector machine. Appl. Acoust. 2017, 125, 41–48. [Google Scholar] [CrossRef]

- Nolte, M.; Kister, N.; Maurer, M. Assessment of deep convolutional neural networks for road surface classification. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 381–386. [Google Scholar]

- Mohammadi, M. Road classification and condition determination using hyperspectral imagery. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 39, B7. [Google Scholar] [CrossRef]

- Lee, S.K. Improvement of impact noise in a passenger car utilizing sound metric based on wavelet transform. J. Sound Vib. 2010, 329, 3606–3619. [Google Scholar] [CrossRef]

- Aguiar-Conraria, L.; Azevedo, N.; Soares, M.J. Using wavelets to decompose the time–frequency effects of monetary policy. Phys. A Stat. Mech. Appl. 2008, 387, 2863–2878. [Google Scholar] [CrossRef]

- Addison, P.S. The Illustrated Wavelet Transform Handbook: Introductory Theory and Applications in Science, Engineering, Medicine and Finance; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Lee, S.-Y.; Lee, S.-K. Deep convolutional neural network with new training method and transfer learning for structural fault classification of vehicle instrument panel structure. J. Mech. Sci. Technol. 2020, 34, 4489–4498. [Google Scholar] [CrossRef]

- Kim, S.; An, K.; Back, J.; Lee, S.-K.; Lee, C.; Kim, P. Health Monitoring of Power Driving System Using Sound Signal based on Deep Learning. Korean Soc. Noise Vib. Eng. 2021, 31, 47–56. [Google Scholar] [CrossRef]

- Lee, S.-K.; Lee, H.; Back, J.; An, K.; Yoon, Y.; Yum, K.; Hwang, S.-U. Prediction of tire pattern noise in early design stage based on convolutional neural network. Appl. Acoust. 2021, 172, 107617. [Google Scholar] [CrossRef]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Agarap, A.F. Deep learning using rectified linear units (relu). arXiv 2018, arXiv:1803.08375. [Google Scholar]

- Géron, A. Hands-On Machine Learning with Scikit-Learn, Keras, and TensorFlow: Concepts, Tools, and Techniques to Build Intelligent Systems; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2019. [Google Scholar]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a convolutional neural network. In Proceedings of the 2017 international conference on engineering and technology (ICET), Antalya, Turkey, 21–23 August 2017; pp. 1–6. [Google Scholar]

- Sandberg, U.; Ejsmont, J. Tyre/Road Noise. Reference Book; INFORMEX Ejsmont & Sandberg: Kisa, Japan, 2002. [Google Scholar]

- Leasure Jr, W.A.; Bender, E.K. Tire–road interaction noise. J. Acoust. Soc. Am. 1975, 58, 39–50. [Google Scholar] [CrossRef]

- Syamkumar, A.; Aditya, K.; Chowdary, V. Development of mode-wise noise prediction models for the noise generated due to tyre-pavement surface interaction. Adv. Mater. Res. 2013, 723, 50–57. [Google Scholar] [CrossRef]

- Iwao, K.; Yamazaki, I. A study on the mechanism of tire/road noise. JSAE Rev. 1996, 17, 139–144. [Google Scholar] [CrossRef]

- Ioffe, S.; Szegedy, C. Batch Normalization: Accelerating Deep Network Training by Reducing Internal Covariate Shift. In Proceedings of the 32nd International Conference on Machine Learning, Lille, France, 6–11 July 2015; Volume 37, pp. 448–456. [Google Scholar]

| Front Wheel | Tire-A | Tire-B | Rear Wheel | Tire-A | Tire-B |

|---|---|---|---|---|---|

| Asphalt | 4718 | 6322 | Asphalt | 4718 | 6322 |

| Snow | 11,157 | 7785 | Snow | 11,157 | 7785 |

| Name | Value/Method |

|---|---|

| Mini Batch Size | 32 |

| Maximum Epochs | 50 |

| Initial Learning Rate | 0.001 |

| Learning Rate Schedule | Step decay |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.; Lee, C.-H.; Jea, H.-M.; Lee, S.-K.; Yoon, Y.; Lee, J.; Yum, K.; Hwang, S.-U. Classification of Road Surfaces Based on CNN Architecture and Tire Acoustical Signals. Appl. Sci. 2022, 12, 9521. https://doi.org/10.3390/app12199521

Yoo J, Lee C-H, Jea H-M, Lee S-K, Yoon Y, Lee J, Yum K, Hwang S-U. Classification of Road Surfaces Based on CNN Architecture and Tire Acoustical Signals. Applied Sciences. 2022; 12(19):9521. https://doi.org/10.3390/app12199521

Chicago/Turabian StyleYoo, Jinhwan, Chang-Hun Lee, Hae-Min Jea, Sang-Kwon Lee, Youngsam Yoon, Jaehun Lee, Kiho Yum, and Seoung-Uk Hwang. 2022. "Classification of Road Surfaces Based on CNN Architecture and Tire Acoustical Signals" Applied Sciences 12, no. 19: 9521. https://doi.org/10.3390/app12199521

APA StyleYoo, J., Lee, C.-H., Jea, H.-M., Lee, S.-K., Yoon, Y., Lee, J., Yum, K., & Hwang, S.-U. (2022). Classification of Road Surfaces Based on CNN Architecture and Tire Acoustical Signals. Applied Sciences, 12(19), 9521. https://doi.org/10.3390/app12199521