Abstract

The leaching of metal ions from orthodontic appliances into the oral cavity is problematic for metal-allergic patients. Non-metal orthodontic appliances, such as plastic and ceramic brackets and elastomeric materials, have been clinically used and are effective for treatment of metal-allergic patients. However, only a few types of orthodontic wire are available for use in patients with metal allergies, thus restricting the establishment of orthodontic force systems in these patients. Wire surfaces can be coated with various substances to prevent leaching of metal ions. However, detachment of the coating may occur during orthodontic procedures, resulting in metal ion leaching from the substrate material. This study was performed to examine the resilience of various types of coated stainless steel wire to low pH, bending, and brushing. Wire surface characteristics were examined by stereomicroscopy and scanning electron microscopy. The degree of coating detachment due to bending of the wire was quantified by determining the change in the amount of metal ions eluted from the site of the bend immersed in hydrochloric acid. Exposure of the substrate metal by brushing was investigated by energy dispersive spectrometry. The results indicated that polyethylene naphthalate (PEN)-coated wire is resilient to bending, while gold (Au)-coated and titanium nitride (TiN)-coated wires are resilient to brushing.

1. Introduction

The incidence of metal allergies has been increasing in recent years [1]. Although non-metal orthodontic appliances, such as plastic and ceramic brackets and elastomeric materials, have been used clinically and shown to be effective for the treatment of patients with metal allergies, only metal orthodontic wire is available, greatly limiting the types of orthodontic treatments that can be applied in such patients. Four types of alloy wire, i.e., stainless steel (SS), cobalt-chromium (Co-Cr), nickel-titanium (Ni-Ti), and β-titanium (β-Ti) wire, are used clinically as orthodontic arch wires for multi-bracket treatment [2].

Selective application of these alloy wires can provide a broad range of orthodontic forces at various stages of treatment. Most orthodontic wires contain metals that cause metal allergies, including nickel (Ni), cobalt (Co), and chromium (Cr), and therefore the potential for release of metal ions into the oral cavity represents a problem precluding their use in patients with metal allergies [3,4]. Fors et al. [5] showed that elution of metal ions can occur from orthodontic appliances containing metal materials and reported significantly higher Ni ion concentrations in the dental plaque of patients with orthodontic appliances compared to non-orthodontic patients. Therefore, only biocompatible β-Ti wire can be applied in patients with metal allergies, but their poor rigidity restricts their application and the establishment of proper orthodontic force systems [3]. To solve these problems and enable the use of appropriate types of wire for patients with metal allergies, it is necessary to modify the surface of orthodontic wires to prevent the leaching of metal ions into the oral cavity. Wire can be plated to increase corrosion and wear resistance, increase surface hardness, reduce friction, and improve aesthetic appearance [6,7,8]. Orthodontic wires plated with gold (Au) and rhodium (Rh) or coated with resin are already commercially available. Our previous studies [9,10] showed that plating of SS orthodontic arch-wire with titanium nitride (TiN) improved corrosion resistance and reduced friction without compromising the original mechanical properties of the substrate metal. However, coated wires may be susceptible to coating loss due to delamination or wear in the oral cavity [6]. The resulting exposure of the substrate metals in the oral cavity is associated with increased risk of developing metal allergy [11] due to metal ion leaching [12,13,14,15]. However, the details of coating loss from coated wires have yet to be elucidated.

The present study focused on the effects of low pH, mechanical deformation, and brushing as possible causes of metal exposure in the oral cavity. Low pH conditions can lead to degradation of coated orthodontic wires [12,15,16]. Mechanical deformation of the coated wire surface has been reported to result in coating loss, suggesting that coating loss may occur with bending of the wire [14,17,18]. Previous studies examined only the effects of bending at right angles [19], while orthodontic treatment often involves the bending of wires at various other angles, and it is therefore necessary to examine the effects of such bending to simulate clinical use. Brushing has also been reported to cause coating loss in epoxy resin-coated and chromium nitride (CrN)-coated wires [15,20], and the mechanical effects of brushing may also cause coating loss in other types of coated wire.

To our knowledge, there have been no previous investigations of corrosion resistance of orthodontic wires with multiple coating materials. The null hypothesis to be researched in this study was that exposure to low pH conditions (H01), bending (H02), and brushing (H03) of several types of coated orthodontic SS wire would not cause coating loss.

2. Materials and Methods

2.1. Specimens

Four types of coated wire were used in this study, i.e., gold-coated SS wire (0.016 × 0.022 inch SS wire, Peach Gold; JM Ortho, Tokyo, Japan), polyethylene naphthalate (PEN)-coated wire (0.016 × 0.022 inch SS wire, Nano White; JM Ortho, Tokyo, Japan), and Rh-coated wire (0.016 × 0.022 inch, White Wire Stainless Steel; Tomy International, Tokyo, Japan). In addition, 0.016 × 0.022 inch TiN-coated SS wire prepared by our group was also used [10]. The brackets used in this study were titanium brackets (Ortho-Dentaurum, Tokyo, Japan).

2.2. Wire Bending

To simulate clinical conditions and examine the stability of the coating after bending, coated SS wires were bent at angles of 30°, 60°, 90°, and 120° using Tweed Arch Bending Pliers (Biodent, Tokyo, Japan) in accordance with the method described previously by Krishnan et al. [19].

2.3. Brushing Tests

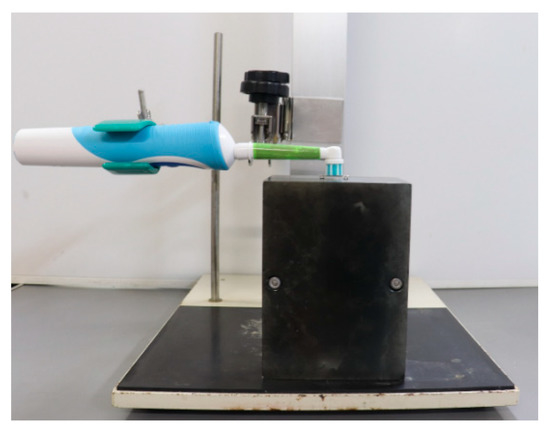

The brushing test was performed according to the method described previously by Abdul et al. [15]. Briefly, coated SS wires ligated to brackets fixed on a metal block using an elastic module (TP Orthodontics, La Porte, IN, USA) were brushed 20,000 times with an Oral-B electric toothbrush (Braun, Kronberg, Germany) fixed to the experimental stand, as shown in Figure 1.

Figure 1.

Toothbrush setup. Brackets were fixed to a metal block with adhesive. The coated wire was ligated to the brackets using an elastic module. The electric toothbrush was fixed to the experimental stand.

2.4. Observation of the Wire Surface

The wire surface at the point of bending was photographed under a stereomicroscope (M165FC; Leica, Wetzlar, Germany) and examined by scanning electron microscopy (SEM) (VE-7800; Keyence, Osaka, Japan) at magnifications of ×200, ×500, and ×1000. In addition, the wire surface before and after brushing was photographed under a stereomicroscope (M165FC; Leica, Wetzlar, Germany) and examined by SEM (JEOL JSM 7100F; JEOL, Tokyo, Japan) at magnifications of ×150, ×500, and ×1000. PEN-coated wire was coated with a thin layer of Au using a SEM sputter coating unit (JEOL JFC-1600; JEOL) and then examined by SEM.

2.5. Metal Ion Release Tests

As described previously [10], orthodontic wire samples were separately immersed in 35 mm plastic dishes (Iwaki, Osaka, Japan) containing 3 mL of 35% hydrochloric acid (HCl) (pH-1.1) (Wako Pure Chemical Industries, Ltd., Osaka, Japan), placed at 25 °C for 30 min. A section of 4 mm of each wire sample was immersed in HCl. The concentrations of Cr, manganese (Mn), iron (Fe), and Ni ions released from the wire samples into the HCl solution were measured by triple quadrupole inductively coupled plasma mass spectrometry (ICP–MS) (ICP-QQQ-Agilent 8800; Agilent Technologies, Santa Clara, CA, USA). The concentrations of Cr, Mn, Fe, and Ni ions released into the solution are shown as the mean ± SD of four replicates for each sample.

2.6. EDS Analysis

The elemental compositions of the coated wire surfaces before and after brushing were analyzed by energy dispersive spectrometry (EDS) to determine the effects of brushing on coating loss. Backscattered electron (BSE) observations operated at 15 kV and qualitative analysis of coated SS wires were performed by EDS using the JSM-7100F SEM (JEOL).

2.7. Measurement of Surface Roughness

The Surface roughness (Ra) was evaluated using a surface roughness tester (Surftest SJ-210; Mitutoyo Corp., Tokyo, Japan) according to ISO 1997, with a diamond tip radius of 5 μm, measurement force of 4.0 mN, scan speed of 0.5 mm/s, cutoff length of 0.8 mm, and a Gaussian filter. The coated samples were fixed beneath the stylus of the tester, and the mean ± SD Ra (in µm) of three replicates was determined for each sample.

2.8. Statistics

JMP® Pro software (version 16.0.0; SAS Institute Inc., Cary, NC, USA) was used for statistical analyses. Descriptive analyses of the ICP–MS and Ra data were carried out and all data are presented as the mean ± standard deviation. In the first step, the Anderson-Darling test was applied to each data set to determine its normality. The O’Brien test was then used to check significance of difference between the variances of the data sets. One-way analysis of variance (ANOVA) was also used to evaluate statistical differences between the data sets. For post hoc analysis, the Tukey–Kramer honestly significant difference (HSD) test was used to determine which groups had statistically significant differences. In all analyses, p < 0.05 was taken to indicate statistical significance.

3. Results

3.1. Analysis of Acid Corrosion

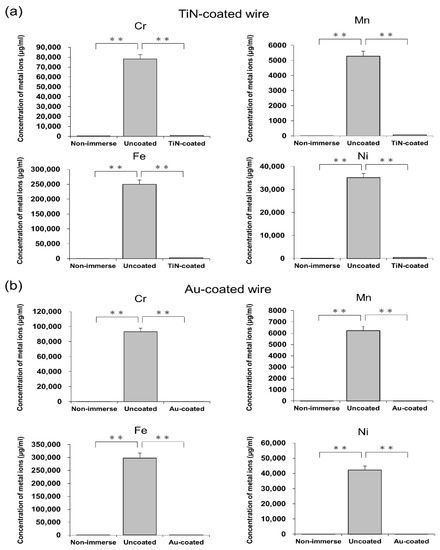

The results of analyses of metal ions release from coated wires immersed in HCl are shown in Figure 2. Statistical analysis showed that all data followed parametric behavior. Non-immerse in the figure refers to HCl solution without immersion of metal wire, while the Uncoated group refers to SS wire without any coating. All of the coatings examined showed suppression of metal ion release from the substrate metal in comparison to uncoated SS wire. However, the Rh-coated wires showed significantly increased elution of all metal ions compared to the non-immerse HCl solution without immersion of wire. Among all coated wires, the amount of metal ions eluted from the Rh-coated wire was greatest.

Figure 2.

Metal ions derived from substrate metal, SS, released from four types of coated wire immersed in HCl. After immersion in HCl for 30 min, the amounts of metal ions eluted from the wire were determined by ICP–MS: (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire. ** p < 0.01.

3.2. Analysis of Coating Loss by Wire Bending

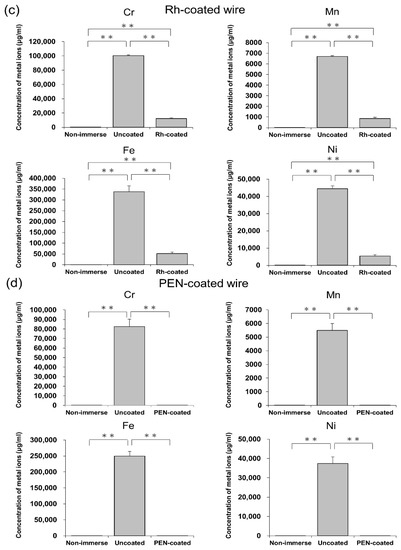

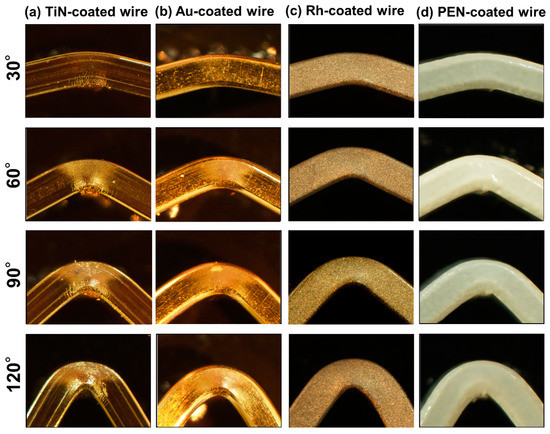

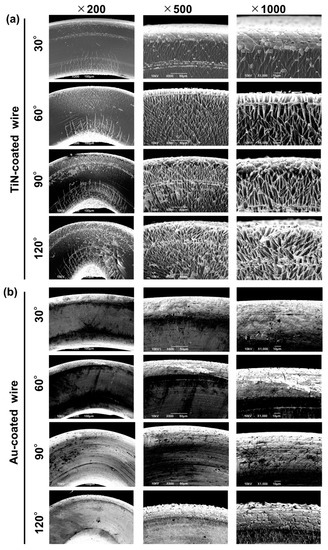

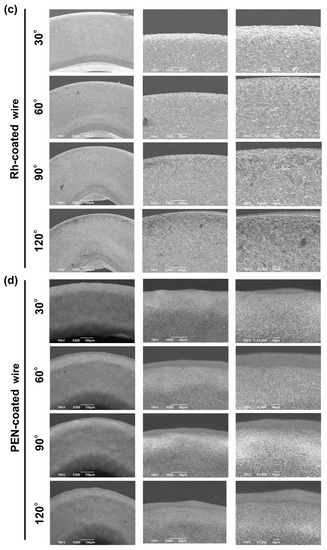

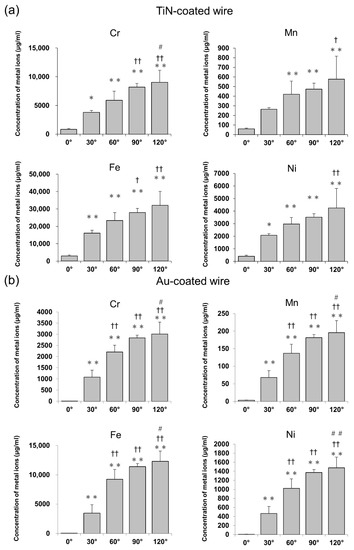

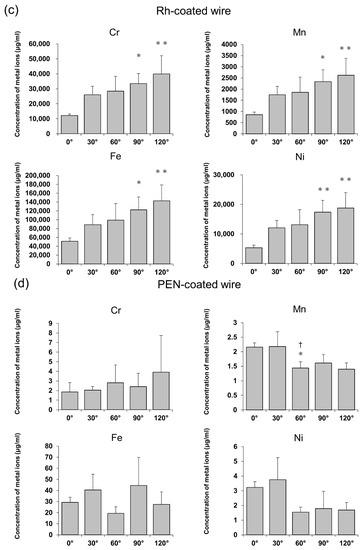

Figure 3 shows stereomicrographs of four types of coated wire with various bend angles from 30° to 120°. The TiN-coated wire showed cracks and detachment of the coating from the surface after bending. No surface deterioration was seen for the other wires. Figure 4 shows scanning electron micrographs of four types of coated wire with various bend angles from 30° to 120° (×200, ×500, ×1000). The Au-coated, TiN-coated, and Rh-coated wires showed cracks and detachment of the coating on SEM analysis (Figure 4). At a bend angle of 30°, the Au-coated wire showed only minor cracking, while clear cracks were observed in multiple locations on the TiN-coated and Rh-coated wires, and both cracking and peeling of the coating increased with increasing bend angle. On the other hand, the PEN-coated wire showed no surface deterioration on bending. Figure 5 shows metal ions derived from the substrate metal, SS, released from four types of coated wire with various bend angles from 30° to 120° immersed in HCl. Statistical analysis showed that all data followed parametric behavior. Examination of metal ion release showed that the amount of metal ion release increased with increasing wire bend angle, exception for PEN-coated wire (Figure 5). No change in elution of metal ions with increasing wire bending angle was observed for PEN-coated wire.

Figure 3.

Stereomicrographs of four types of coated wire with various bend angles from 30° to 120°: (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire.

Figure 4.

Scanning electron micrographs of four types of coated wire with various bend angles from 30° to 120° (×200 ×500 ×1000): (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire.

Figure 5.

Metal ions derived from substrate metal, SS, released from four types of coated wire with various bend angles from 30° to 120° immersed in HCl. After immersion in HCl for 30 min, the amount of metal ions eluted from the wire was determined by ICP–MS. Concentrations of metal ions eluted from coated wire: (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire. * p < 0.05 and ** p < 0.001 vs. 0°; † p < 0.05 and †† p < 0.001 vs. 30°; # p < 0.05 and ## p < 0.001 vs. 60°.

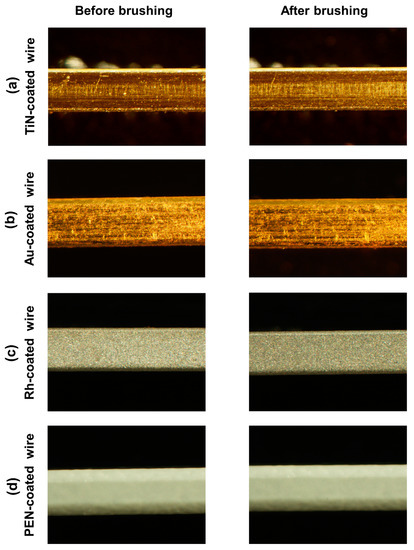

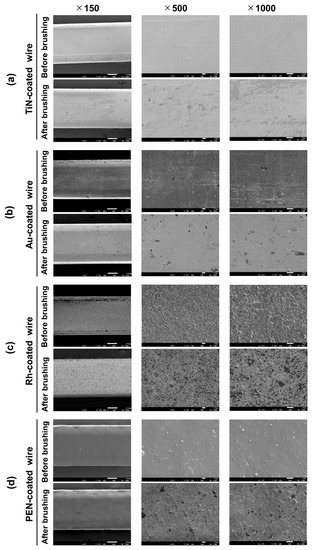

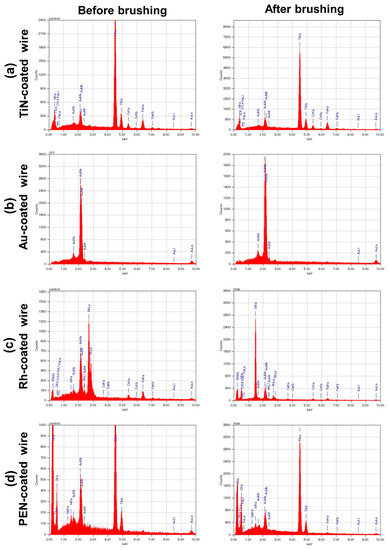

3.3. Analysis of Coating Loss by Brushing

Figure 6, Figure 7 and Figure 8 show stereomicrographs, scanning electron micrographs, and energy dispersive spectrometry data of four types of coated wire before and after brushing, respectively. No coating loss was observed on any of the four types of coated wire by stereomicroscopy after brushing (Figure 6), while SEM and EDS analysis showed coating loss associated with brushing on both Rh-coated and PEN-coated wire (Figure 7 and Figure 8).

Figure 6.

Stereomicrographs of four types of coated wire before and after brushing: (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire.

Figure 7.

Scanning electron micrographs of four types of coated wire before and after brushing (×200, ×500, ×1000 ): (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire.

Figure 8.

Energy dispersive spectrometry of four types of coated wire before and after brushing: (a) TiN-coated wire; (b) Au-coated wire; (c) Rh-coated wire; (d) PEN-coated wire.

3.4. Analysis of Surface Roughness

Table 1 shows the surface roughness of four types of coated wire. Statistical analysis showed that all data followed parametric behavior. The roughness of the wire surface was different for each type of coated wire. There were significant differences in the Ra of each type of coated wire (p < 0.01) except between TiN-coated and Rh-coated wire, with a maximum Ra of 0.532 ± 0.014 μm for PEN-coated wire and a minimum Ra of 0.028 ± 0.004 μm for Au-coated wire (Table 1).

Table 1.

Surface roughness of coated wire.

4. Discussion

The rigidity of orthodontic wires is important in orthodontic treatment [3]. Although SS wire has high rigidity, it cannot be used in patients with metal allergies because it contains Ni, and only the less rigid β-Ti wire is available in such patients [3]. The surfaces of orthodontic wires have been modified in various ways to prevent the release of metal ions into the oral environment in efforts to overcome this issue. Corrosion resistance can be improved by coating the wire with various substances, which is expected to provide a wider selection of wires for use in patients with metal allergies [8]. We reported previously that plating of orthodontic wire with TiN improved corrosion resistance and reduced friction without compromising its original mechanical properties [9,10]. The present study was performed to examine the resilience of such coatings to conditions of low pH and both bending and brushing of the wire.

ICP–MS showed that all forms of wire coating significantly suppressed metal ion elution on immersion in HCl for 30 min in comparison to uncoated controls, suggesting that all of the coatings used in this study inhibit acid corrosion. However, the degree of inhibition differed for each type of coating, with Au plating and PEN coating showing the greatest inhibitory effects on metal ion elution. On the other hand, the amount of metal ions eluted from the Rh-coated wire was the greatest, and the amount of metal ions was significantly larger than that of HCl solution without wire immersion. Therefore, the use of Rh-coated wire should be avoided in patients with metal allergies. Plating with Au markedly suppressed acid corrosion, as its standard electrode potential is higher than that of hydrogen [21]. Conversely, as the standard electrode potential of Ti is lower than that of hydrogen, TiN-coated wire showed more corrosion than Au-coated wire. PEN has been shown to have marked resistance to chemical corrosion [22,23], and therefore PEN-coated wire was resistant to immersion in HCl. On the other hand, Rh-coated wire showed more corrosion than Au-coated wire, even though Rh has a higher standard electrode potential than hydrogen. This increased corrosion may have been due to the greater Ra of Rh-coated wire compared to the Au-coated wire, as shown in Table 1 [24]. The null hypothesis (H01) was rejected, as exposure of TiN-coated and Rh-coated wires to low pH conditions caused coating loss.

It is often necessary to bend orthodontic SS arch wires up to an angle of about 120° to make loops for use in orthodontic treatment. This study analyzed the effects of bending of wires at angles in the range from 30° to 120°, as commonly used in clinical practice, on the coating material and consequently on the release of metal ions from the substrate. Cracks in the bend area were seen on stereomicroscopy only in the TiN coating, and no such cracks or detachment of the coating were seen for the other types of coated wire. SEM analysis showed no coating loss in the PEN-coated wires after bending, while cracks and detachment were observed in the Au-coated, TiN-coated, and Rh-coated wires. At a bend angle of 30°, the Au-coated wire showed only minor cracking, while the TiN-coated and Rh-coated wires showed clear cracks in multiple locations. This lack of crack formation may have been due to the high ductility of Au [25]. The degree of cracking and detachment became more pronounced with increasing angle in the Au-coated, TiN-coated, and Rh-coated wires, with the TiN coating showing particularly notable disruption. The application of external stress was reported to result in multiple crack formation and localized delamination of TiN coating on SS [26], and therefore TiN-coated wire may also have poor resilience to external stresses, such as bending of the wire. In addition, the decrease in fracture strength with increasing thickness of TiN coating was shown to result in a reduction in fatigue strength [27]. It would be difficult to make the TiN coating any thinner than that used in the present study, which had a thickness of 0.3 μm. The relations between bend angle and the amount of metal ion elution from bend sites of coated wires immersed in HCl were analyzed by ICP–MS, and the results confirmed the SEM data and showed increased elution of metal ions derived from the substrate metal, SS, with increasing bend angle. These results suggest that with increasing bend angle, the coating cracked and detachment increased, exposing more of the substrate metal in the wire. On the other hand, the PEN coating suppressed metal ion elution even with bending at an angle of 120°, suggesting no coating loss under these conditions. However, the amount of Mn ion elution from PEN-coated wire was significantly lower at a bend angle of 60° than at bend angles of 0° and 30°. Only a trace amount of Mn ion elution was detected at all bend angles, suggesting that Mn elution did not occur at any bend angle examined. PEN has been shown to have good tensile strength and elastic modulus, and to undergo elongation at break [28]. Furthermore, the results of the present study suggest that PEN has sufficient durability for the range of bends used in orthodontic treatment. The null hypothesis (H02) was rejected, because bending of TiN-coated, Au-coated, and Rh-coated wires caused coating loss.

As it was not possible to determine whether brushing affected coating loss on coated wires by stereomicroscopy, the surface properties of the wires were next examined by SEM. On SEM analysis, each type of wire showed black areas after brushing. EDS analysis was performed to determine whether there was coating loss and exposure of the substrate metal at these areas. TiN-coated, Au-coated, and PEN-coated wires did not appear to show significant changes before and after brushing. On the other hand, a change was observed in Rh-coated wires after brushing. In the Rh-coated wire, a peak of Rh was observed before brushing, which decreased after brushing and a new peak of Al was observed. It is possible that Al used in the pretreatment was exposed due to detachment of the Rh coating. However, although the manufacturer of the wire stated that they pretreat the Rh-coated wire to improve its coloration, precise data on the materials used were not available due to their policy of keeping this information confidential. In addition, Ti peaks were detected in the PEN coating both before and after brushing, which were due to the use of Ti oxide directly beneath the coating. As the PEN coating was as thin as 50 μm, the Ti peak may have been detected even before brushing. Due to the thinness of the PEN coating and the detection of substrate metal both before and after brushing, it may be difficult to discuss coating loss of PEN-coated wire based on EDS analysis. However, new trace peaks of Fe were detected after brushing, suggesting that coating loss may have occurred in the PEN-coated wire. Taken together, these results suggest that brushing does not result in coating loss from TiN-coated and Au-coated wires, but that it may cause loss of the coating from Rh-coated and PEN-coated wires. In addition, coating loss may have occurred on the PEN-coated wire, but further analysis is needed. Therefore, the null hypothesis (H03) was rejected.

The results showed that both PEN coating and Au plating resulted in high degrees of acid corrosion resistance, that PEN coating improved durability against bending of the wire, and that the TiN coating and Au plating are resilient to damage by brushing. The acid corrosion resistance and durability were different for each type of coating material. Exposure of the substrate metal due to coating loss can cause the onset of metal-allergic reactions in patients with metal allergies [12]. Rh has excellent aesthetic properties as a coating material [14,16,29], but the results of the present study suggested that it is unsuitable for use in patients with metal allergies. As TiN-coated and Au-coated wires are resilient to damage by brushing but not bending, it may be possible to first bend the wire to the necessary shape and then coat the wire to avoid the risk of metal exposure in the oral environment. In this study, brushing using an electric toothbrush corresponding in hardness to that likely to be encountered in clinical situations may have caused detachment of the PEN coating from the wire. Therefore, it would be advisable to select a toothbrush with softer filaments in patients treated with PEN-coated wire. To examine this issue in more depth, it is necessary to compare the degree of coating loss between different brushing conditions, e.g., with changes in the filament hardness and number of brushings. Statistical analysis is needed to compare the amount of metal exposure between conditions. Although costly, it may also be possible to avoid metal exposure by simply replacing the coated wire every month.

This study was performed to analyze the durability of various coating materials on orthodontic wire in vitro. Further studies are required to examine the amounts of metal ions eluted from bent test samples immersed in artificial saliva over longer time courses to determine how long Au, TiN, and PEN coatings can remain in good condition in the oral cavity during orthodontic treatment. Gold-coated, Ti, ceramic, and plastic brackets have been applied in orthodontic treatment of patients with metal allergies [3], but galvanic corrosion may occur with some combinations of wires and brackets as for metal brackets [14,30,31]. Therefore, investigations should be performed with various combinations of wires and brackets to ensure that they will not induce galvanic currents, and the biocompatibility of each coating material should also be examined.

5. Conclusions

Coating of orthodontic wires showed suppression of the elution of metal ions from the substrate metal when immersed in HCl, but the resilience to damage by mechanical stimuli differed between the different coating materials examined in this study. The use of PEN-coated wire is recommended for orthodontic treatment requiring wire bending in patients with metal allergy, and patients should be advised to use a toothbrush with softer filaments to avoid damage to the coating material and thus prevent metal exposure. Bending of Au-coated and TiN-coated wires should be avoided as much as possible, and if necessary, plating should be performed after bending of these wires.

Author Contributions

Conceptualization, A.I. and H.K.; methodology, A.I. and H.K.; validation, A.I. and H.K.; formal analysis, A.I.; investigation, A.I.; resources, A.I. and H.K.; data curation, A.I.; writing—original draft preparation, A.I.; writing—review and editing, H.K.; visualization, A.I., T.N. and F.O.; supervision, H.K. and I.M.; project administration, H.K.; funding acquisition, A.I. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by JSPS KAKENHI grants from the Japan Society for the Promotion of Science (No. K20K187740).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on reasonable request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Au | gold |

| Co | cobalt |

| Co-Cr | cobalt-chromium |

| Cr | chromium |

| CrN | chromium nitride |

| EDS | energy dispersive spectrometry |

| Fe | iron |

| ICP–MS | inductively coupled plasma mass spectrometry |

| Mn | manganese |

| Ni | nickel |

| Ni-Ti | nickel titanium |

| PEN | polyethylene naphthalate |

| Rh | rhodium |

| SEM | scanning electron microscopy |

| SS | stainless steel |

| TiN | titanium nitride |

| β-Ti | β-titanium |

References

- Mortz, C.; Bindslev-Jensen, C.; Andersen, K. Prevalence, incidence rates and persistence of contact allergy and allergic contact dermatitis in The Odense Adolescence Cohort Study: A 15-year follow-up. Br. J. Dermatol. 2012, 168, 318–325. [Google Scholar] [CrossRef]

- Kusy, R.P. A review of contemporary archwires: Their properties and characteristics. Angle Orthod. 1997, 67, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Hida, M.; Miyazawa, K.; Tsuruta, S.; Kurosawa, M.; Hata, Y.; Kawai, T.; Goto, S. Effect of heat treatment conditions on the mechanical properties of Ti-6Mo-4Sn alloy for orthodontic wires. Dent. Mater. J. 2013, 32, 462–467. [Google Scholar] [CrossRef]

- Hwang, C.-J.; Shin, J.-S.; Cha, J.Y. Metal release from simulated fixed orthodontic appliances. Am. J. Orthod. Dentofac. Orthop. 2001, 120, 383–391. [Google Scholar] [CrossRef]

- Fors, R.; Persson, M. Nickel in dental plaque and saliva in patients with and without orthodontic appliances. Eur. J. Orthod. 2006, 28, 292–297. [Google Scholar] [CrossRef]

- Arango, S.; Peláez-Vargas, A.; García, C. Coating and Surface Treatments on Orthodontic Metallic Materials. Coatings 2012, 3, 1–15. [Google Scholar] [CrossRef]

- Kishore, S.; Felicita, A.S.; Siva, S. Evaluation of Nickel Release in Blood and Periodontal Tissue with the Use of NiTi Wires, Bands and Brackets in Orthodontics—A Systematic Review. J. Evol. Med. Dent. Sci. 2021, 10, 1539–1546. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Fehrman, J.; Barnes, A.C.; Zapf, A.M.; Zinelis, S.; Berzins, D.W. Titanium Nitride and Nitrogen Ion Implanted Coated Dental Materials. Coatings 2012, 2, 160–178. [Google Scholar] [CrossRef]

- Ito, A.; Kitaura, H.; Sugisawa, H.; Noguchi, T.; Ohori, F.; Mizoguchi, I. Titanium Nitride Plating Reduces Nickel Ion Release from Orthodontic Wire. Appl. Sci. 2021, 11, 9745. [Google Scholar] [CrossRef]

- Sugisawa, H.; Kitaura, H.; Ueda, K.; Kimura, K.; Ishida, M.; Ochi, Y.; Kishikawa, A.; Ogawa, S.; Takano-Yamamoto, T. Corrosion resistance and mechanical properties of titanium nitride plating on orthodontic wires. Dent. Mater. J. 2018, 37, 286–292. [Google Scholar] [CrossRef]

- Katic, V.; Curkovic, L.; Bosnjak, M.U.; Peros, K.; Mandic, D.; Spalj, S. Effect of pH, fluoride and hydrofluoric acid concentration on ion release from NiTi wires with various coatings. Dent. Mater. J. 2017, 36, 149–156. [Google Scholar] [CrossRef][Green Version]

- de Amorim, M.C.; Gomes, S.d.R.; da Silva, B.P.; Aoki, I.V.; Basting, R.T. Surface Micromorphology, Ion Release and Resistance to Corrosion of Orthodontic Wires Aesthetic Coating Subject to Degradation. J. Bio-Tribo-Corrosion 2021, 8, 22. [Google Scholar] [CrossRef]

- Da Silva, D.L.; Mattos, C.T.; Simão, R.A.; Ruellas, A.C.D.O. Coating stability and surface characteristics of esthetic orthodontic coated archwires. Angle Orthod. 2013, 83, 994–1001. [Google Scholar] [CrossRef]

- Wu, H.; Yang, J.; Yan, Y.; Zheng, B.; Algahefi, A.L.; Ma, S.; Liu, Y. Study of Al–SiO2 aesthetic composite coating on orthodontic metal archwire. Coatings 2022, 12, 746. [Google Scholar] [CrossRef]

- Abdulkader, Y.C.; Kamaruddin, A.F.; Mydin, R.B.S. Effects of salivary pH on coating durability of two different aesthetic archwire coatings under a simulated intraoral environment. Saudi Dent. J. 2019, 32, 306–313. [Google Scholar] [CrossRef]

- Osmani, Z.J.; Poljšak, B.; Zelenika, S.; Kamenar, E.; Marković, K.; Perčić, M.; Katić, V. Ion release and surface changes of nickel–titanium archwires induced by changes in the pH value of the saliva—Significance for human health risk assessment. Materials 2022, 15, 1994. [Google Scholar] [CrossRef]

- Muguruma, T.; Iijima, M.; Kawaguchi, M.; Mizoguchi, I. Effects of Sp2/Sp3 ratio and hydrogen content on in vitro bending and frictional performance of DLC-coated orthodontic stainless steels. Coatings 2018, 8, 199. [Google Scholar] [CrossRef]

- Shirakawa, N.; Iwata, T.; Miyake, S.; Otuka, T.; Koizumi, S.; Kawata, T. Mechanical properties of orthodontic wires covered with a polyether ether ketone tube. Angle Orthod. 2018, 88, 442–449. [Google Scholar] [CrossRef]

- Krishnan, V.; Krishnan, A.; Remya, R.; Ravikumar, K.; Nair, S.A.; Shibli, S.; Varma, H.; Sukumaran, K.; Kumar, K.J. Development and evaluation of two PVD-coated β-titanium orthodontic archwires for fluoride-induced corrosion protection. Acta Biomater. 2011, 7, 1913–1927. [Google Scholar] [CrossRef]

- Arici, N.; Akdeniz, B.S.; Oz, A.A.; Gencer, Y.; Tarakci, M.; Arici, S. Effectiveness of medical coating materials in decreasing friction between orthodontic brackets and archwires. Korean J. Orthod. 2021, 51, 270–281. [Google Scholar] [CrossRef]

- Bard, A.J.; Parsons, R.; Jordan, J. Standard Potentials in Aqueous Solution, 1st ed.; Routledge: London, UK, 2017; ISBN 978-0-203-73876-4. [Google Scholar]

- Leonard, L. Advances in engineering plastics. Adv. Mater. Process 1997, 152, 29–32. [Google Scholar]

- Lillwitz, L. Production of dimethyl-2,6-naphthalenedicarboxylate: Precursor to polyethylene naphthalate. Appl. Catal. A Gen. 2001, 221, 337–358. [Google Scholar] [CrossRef]

- Hilbert, L.R.; Bagge-Ravn, D.; Kold, J.; Gram, L. Influence of surface roughness of stainless steel on microbial adhesion and corrosion resistance. Int. Biodeterior. Biodegrad. 2003, 52, 175–185. [Google Scholar] [CrossRef]

- Gornostyrev, Y.N.; Katsnelson, M.I.; Medvedeva, N.I.; Mryasov, O.N.; Freeman, A.J.; Trefilov, A.V. Peculiarities of defect structure and mechanical properties of iridium: Results of ab initio electronic structure calculations. Phys. Rev. B 2000, 62, 7802–7808. [Google Scholar] [CrossRef]

- Latella, B.; Gan, B.; Davies, K.; McKenzie, D.; McCulloch, D. Titanium nitride/vanadium nitride alloy coatings: Mechanical properties and adhesion characteristics. Surf. Coat. Technol. 2006, 200, 3605–3611. [Google Scholar] [CrossRef]

- Morita, T.; Takahashi, H.; Shimizu, M.; Kawasaki, K. Factors controlling the fatigue strength of nitrided titanium. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 85–92. [Google Scholar] [CrossRef]

- Karayannidis, G.P.; Papachristos, N.; Bikiaris, D.N.; Papageorgiou, G.Z. Synthesis, crystallization and tensile properties of poly(ethylene terephthalate-co-2,6-naphthalate)s with low naphthalate units content. Polymer 2003, 44, 7801–7808. [Google Scholar] [CrossRef]

- Collier, S.; Pandis, N.; Johal, A.; Qureshi, U.; Sharma, P.K.; Fleming, P.S. A prospective cohort study assessing the appearance of retrieved aesthetic orthodontic archwires. Orthod. Craniofacial Res. 2017, 21, 27–32. [Google Scholar] [CrossRef] [PubMed]

- Ozkomur, A.; Erbil, M.; Akova, T. Diamondlike Carbon Coating as a Galvanic Corrosion Barrier Between Dental Implant Abutments and Nickel-Chromium Superstructures. Int. J. Oral Maxillofac. Implant. 2013, 28, 1037–1047. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Li, M.; Luo, S.; Zeng, C.; Shen, J.; Lin, H.; Cao, C. Corrosion behavior of TiN coated type 316 stainless steel in simulated PEMFC environments. Corros. Sci. 2004, 46, 1369–1380. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).