Experimental Investigation of Interface Characteristics between Geogrid and Coarse-Grained Soil in a Seasonally Frozen Area

Abstract

1. Introduction

2. Design of Experiment

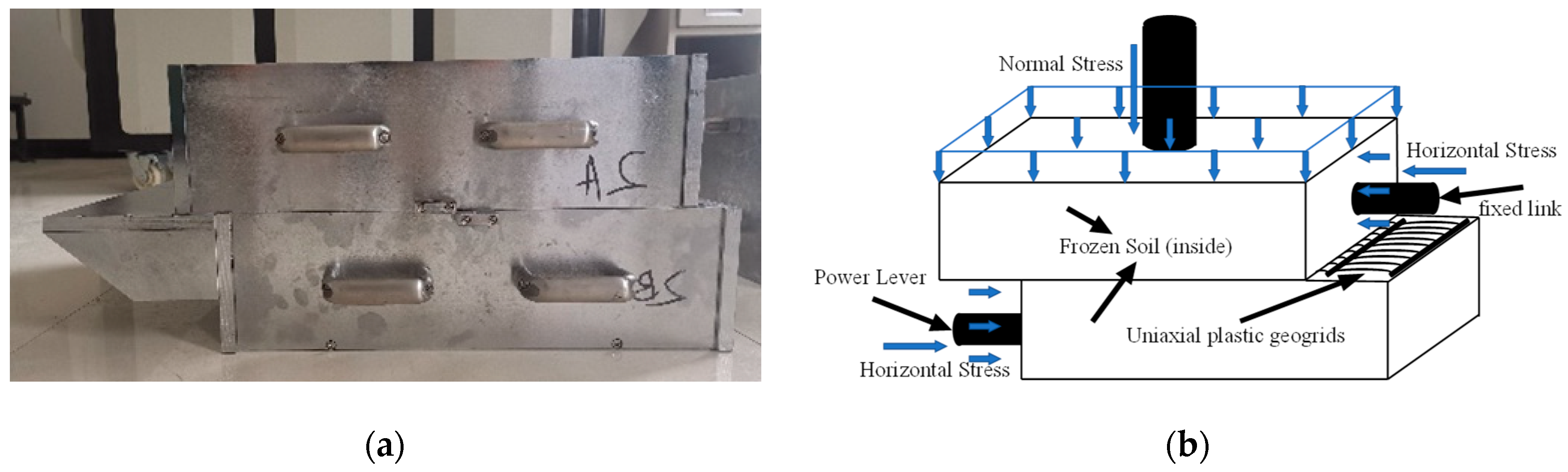

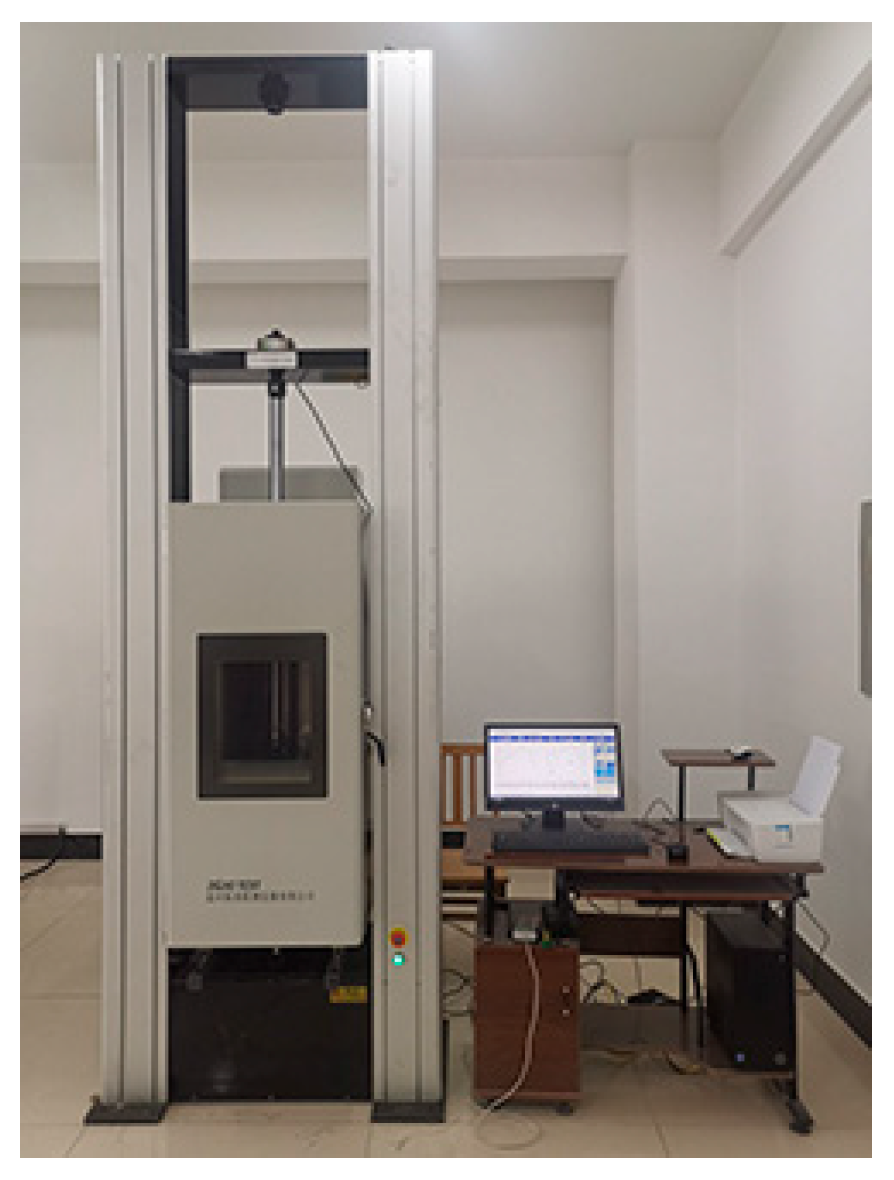

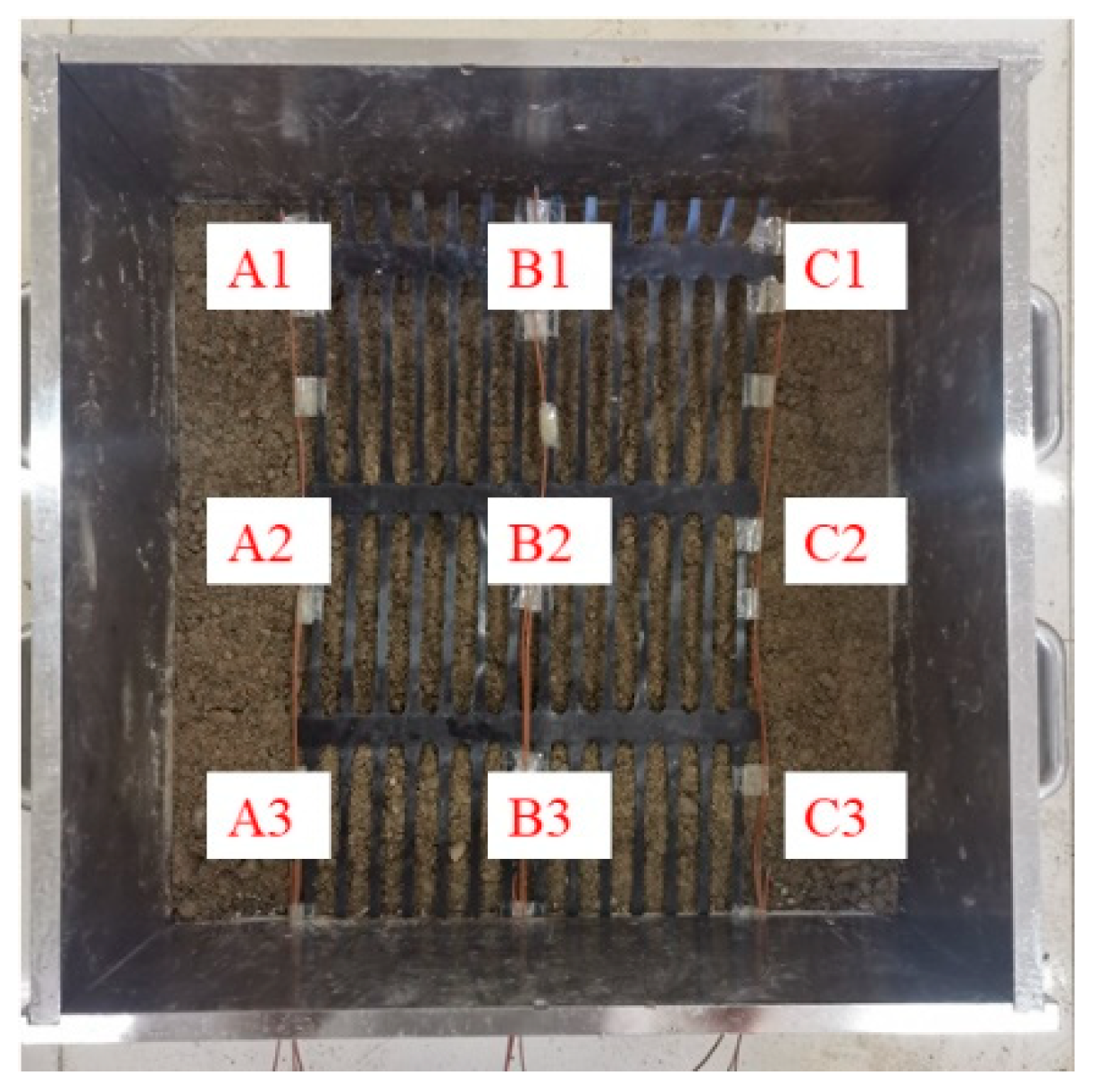

2.1. Test Equipment

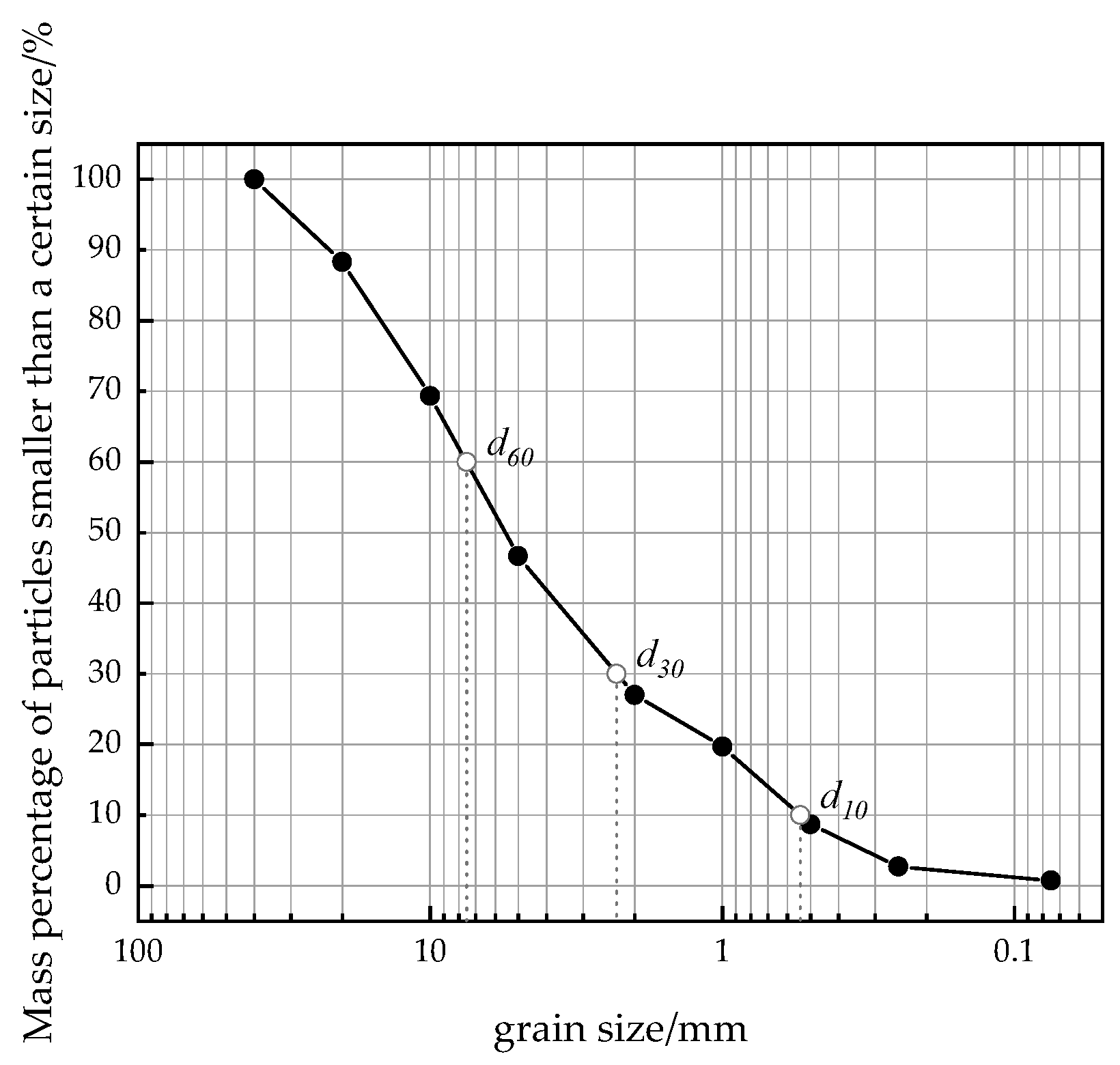

2.2. Backfill

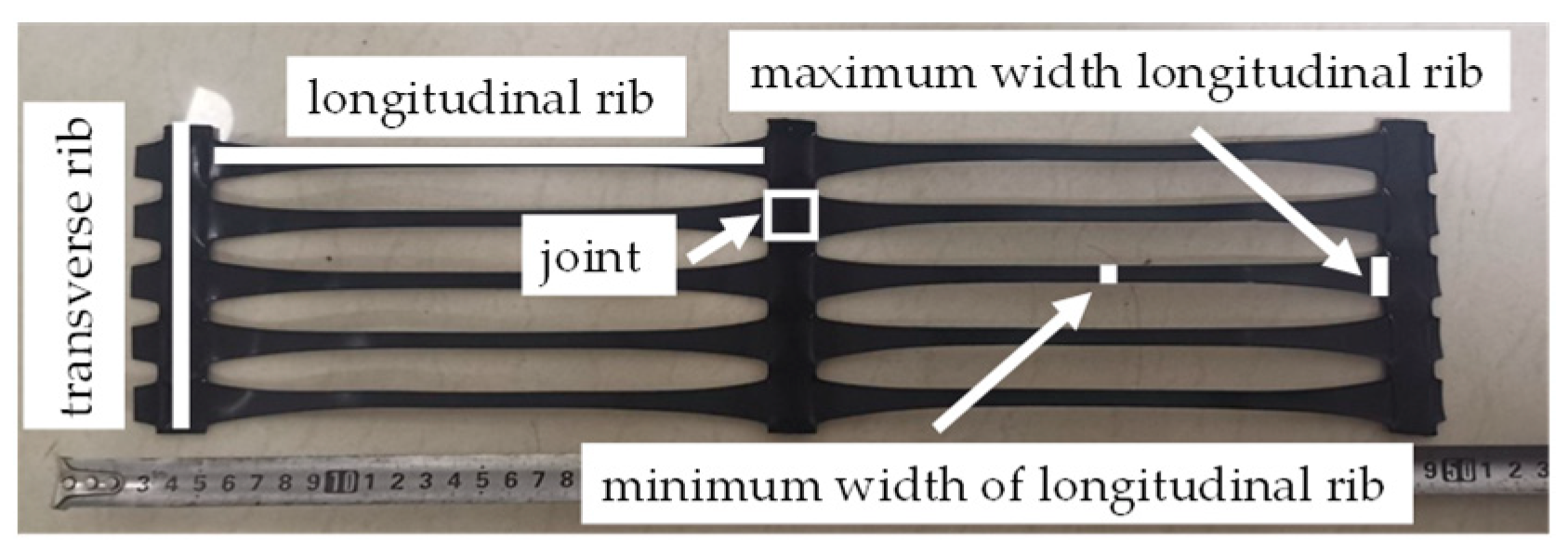

2.3. Geogrid

2.4. Test Method

3. Results and Analysis

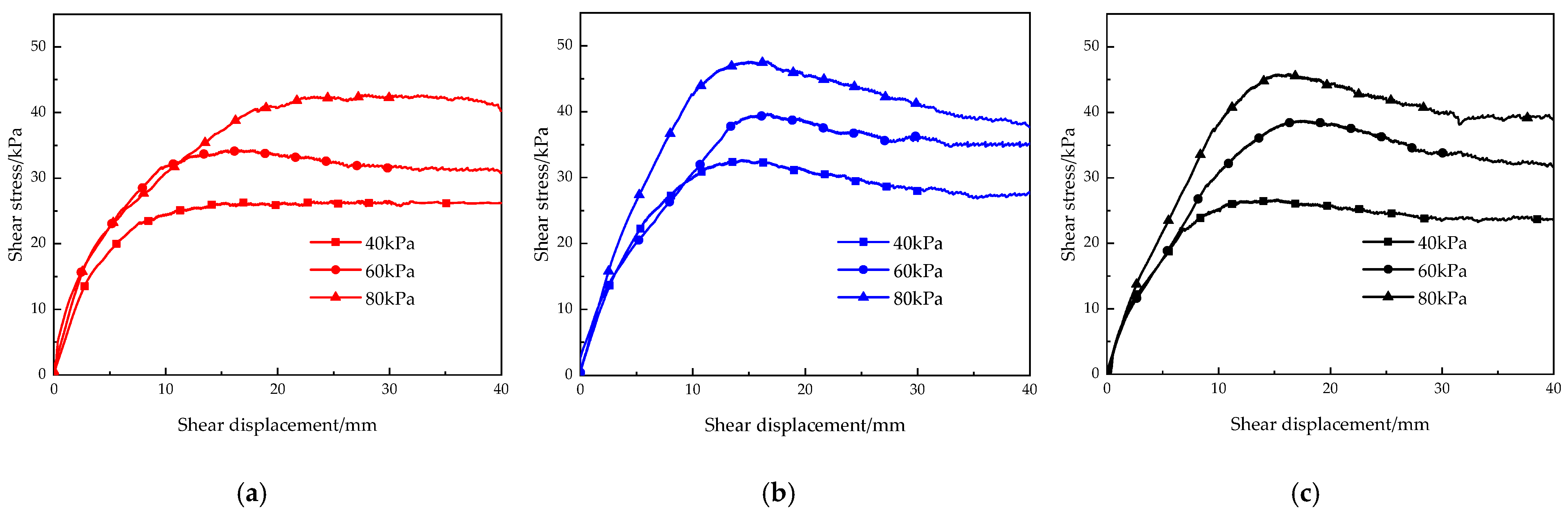

3.1. Nonfreezing State (0 °C)-Reinforced Soil Interface Characteristics

3.2. Freezing State (−5 °C) Reinforced Soil Interface Characteristics

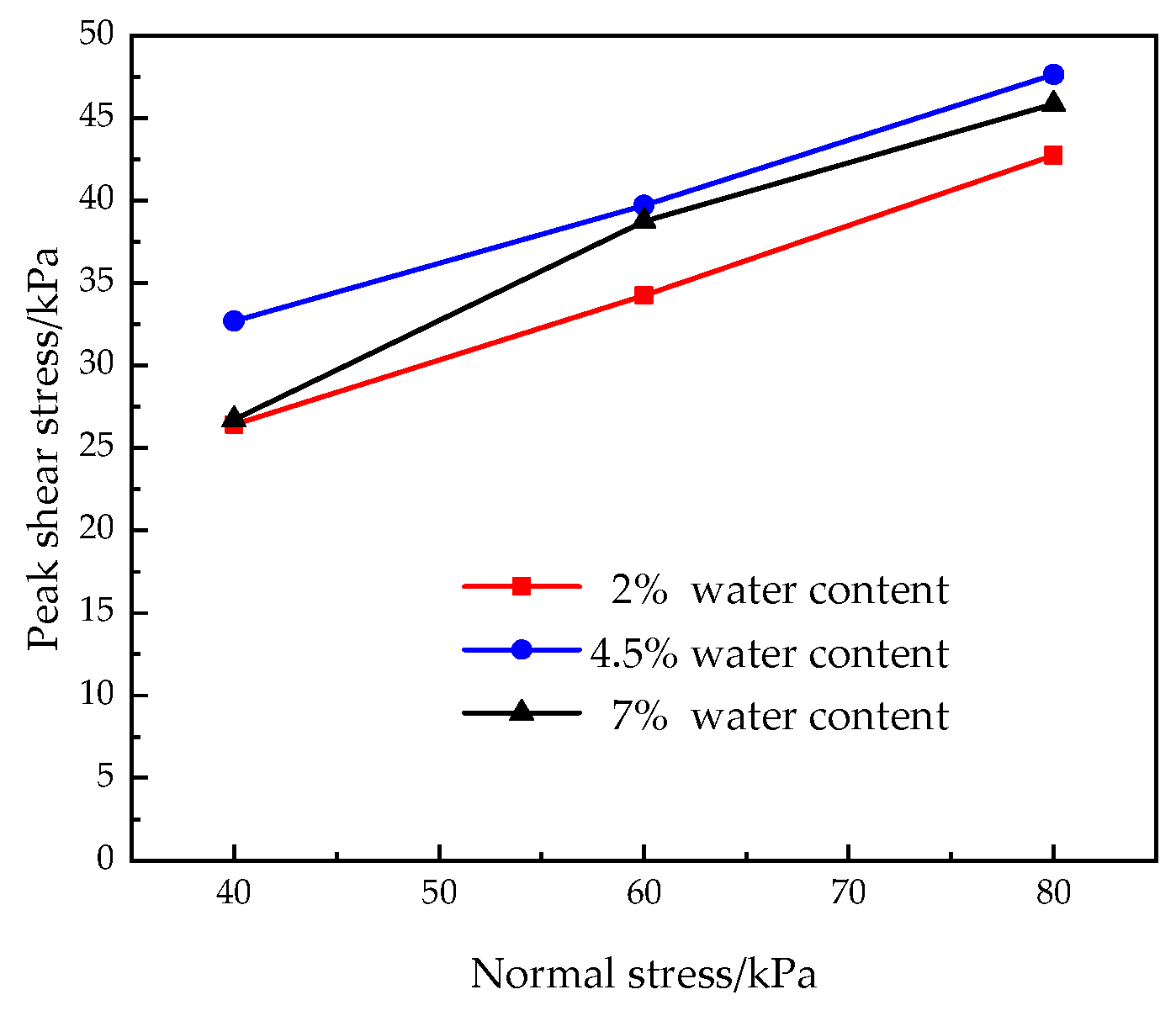

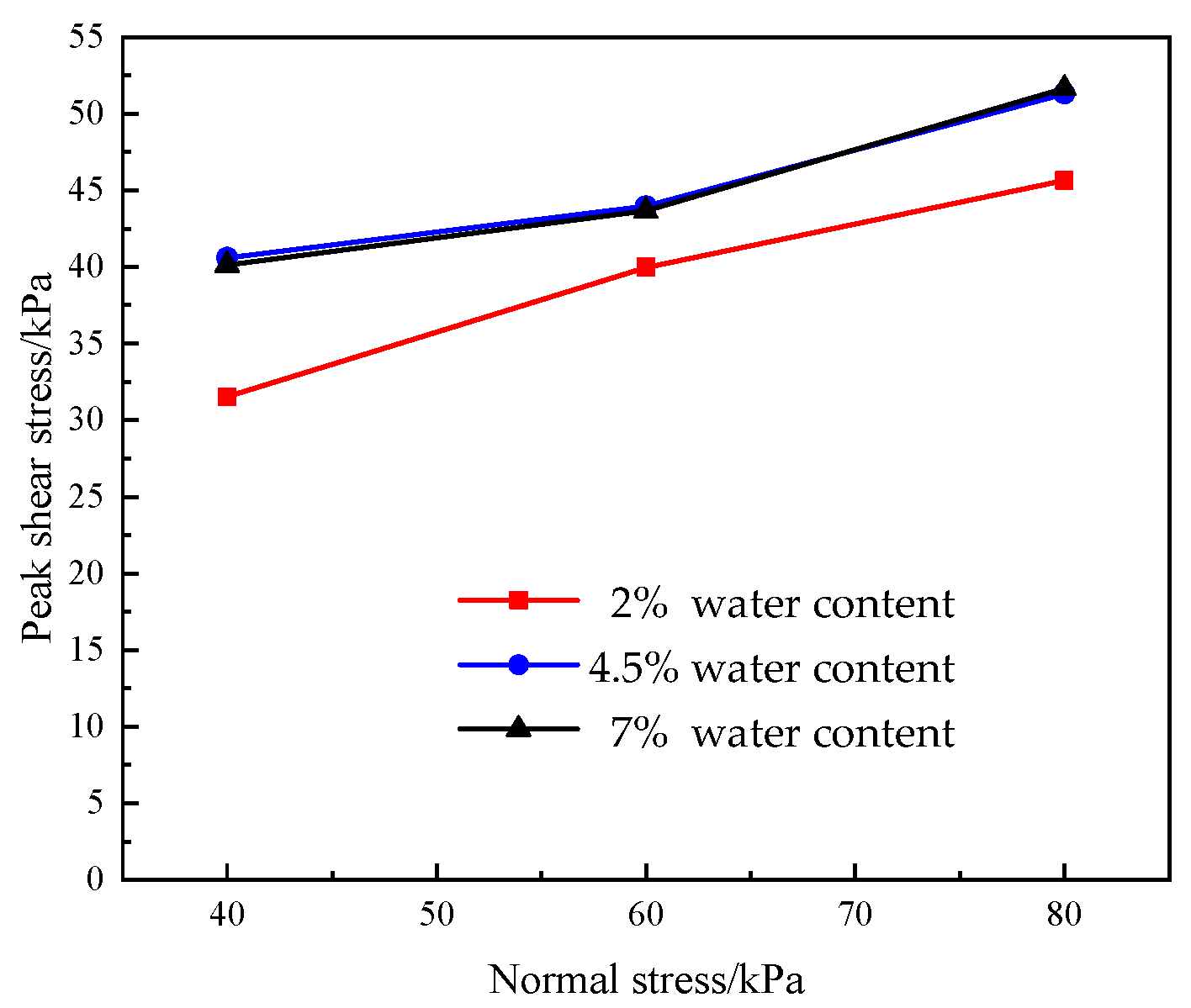

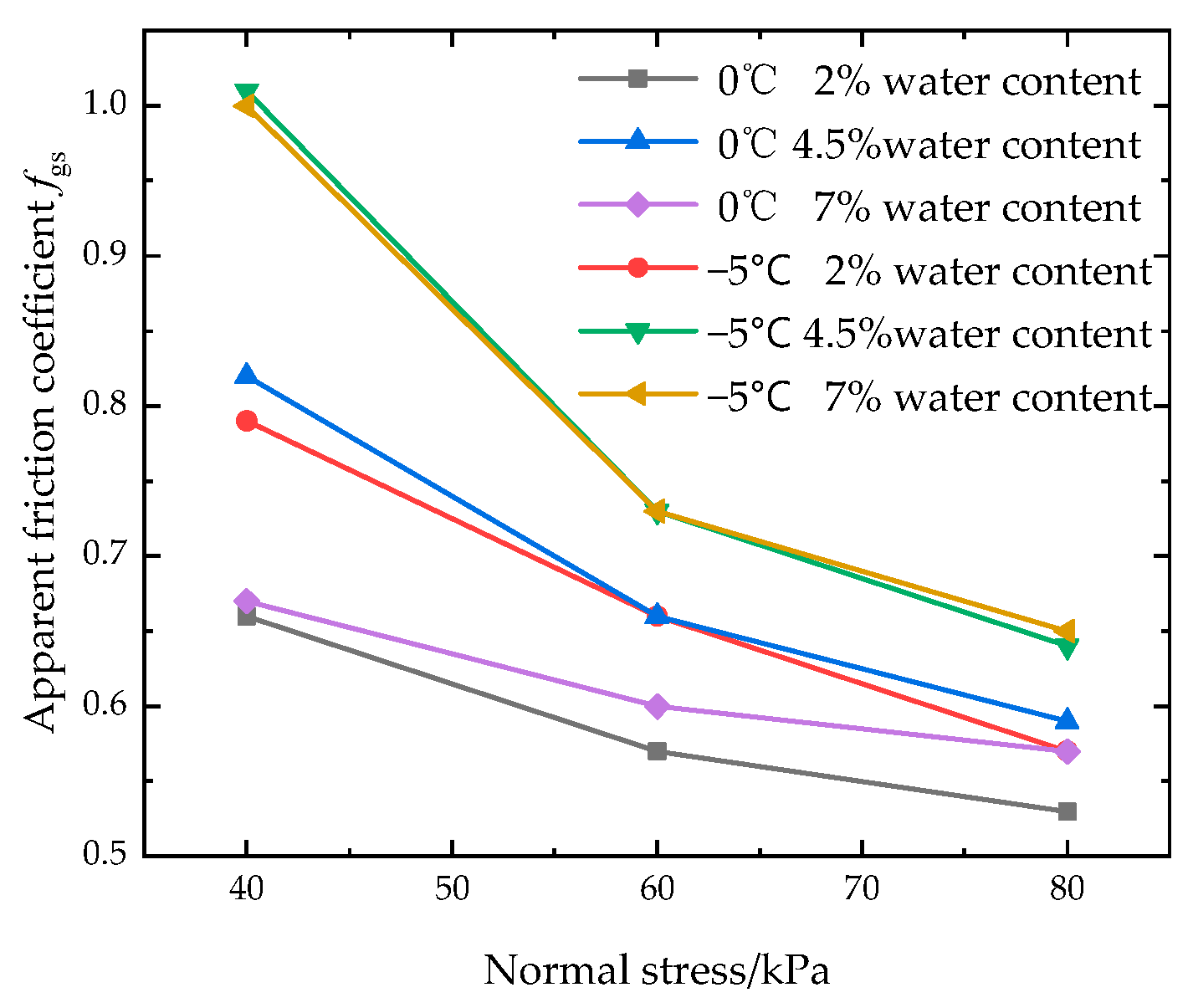

3.3. Influence of Water Content and Temperature on the Shear Strength Index of the Reinforced Soil Interface

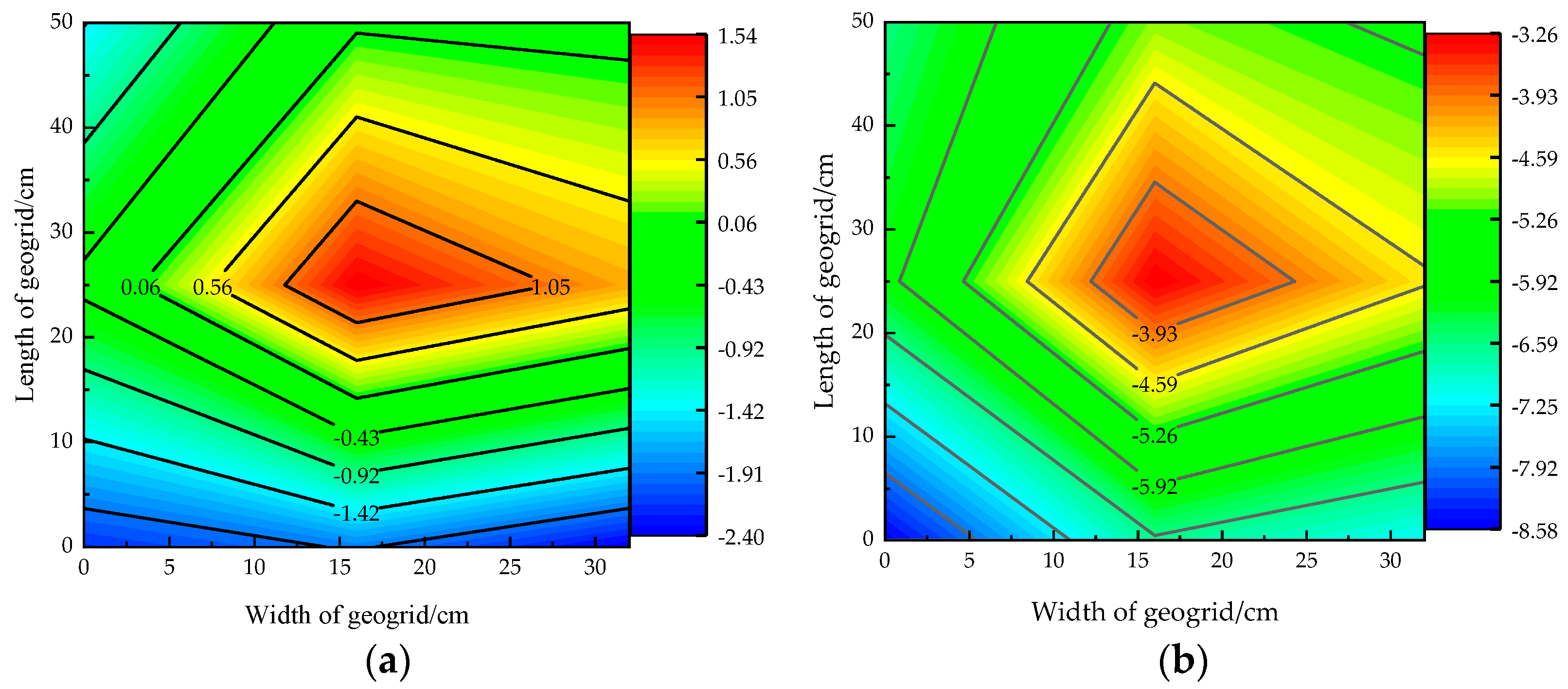

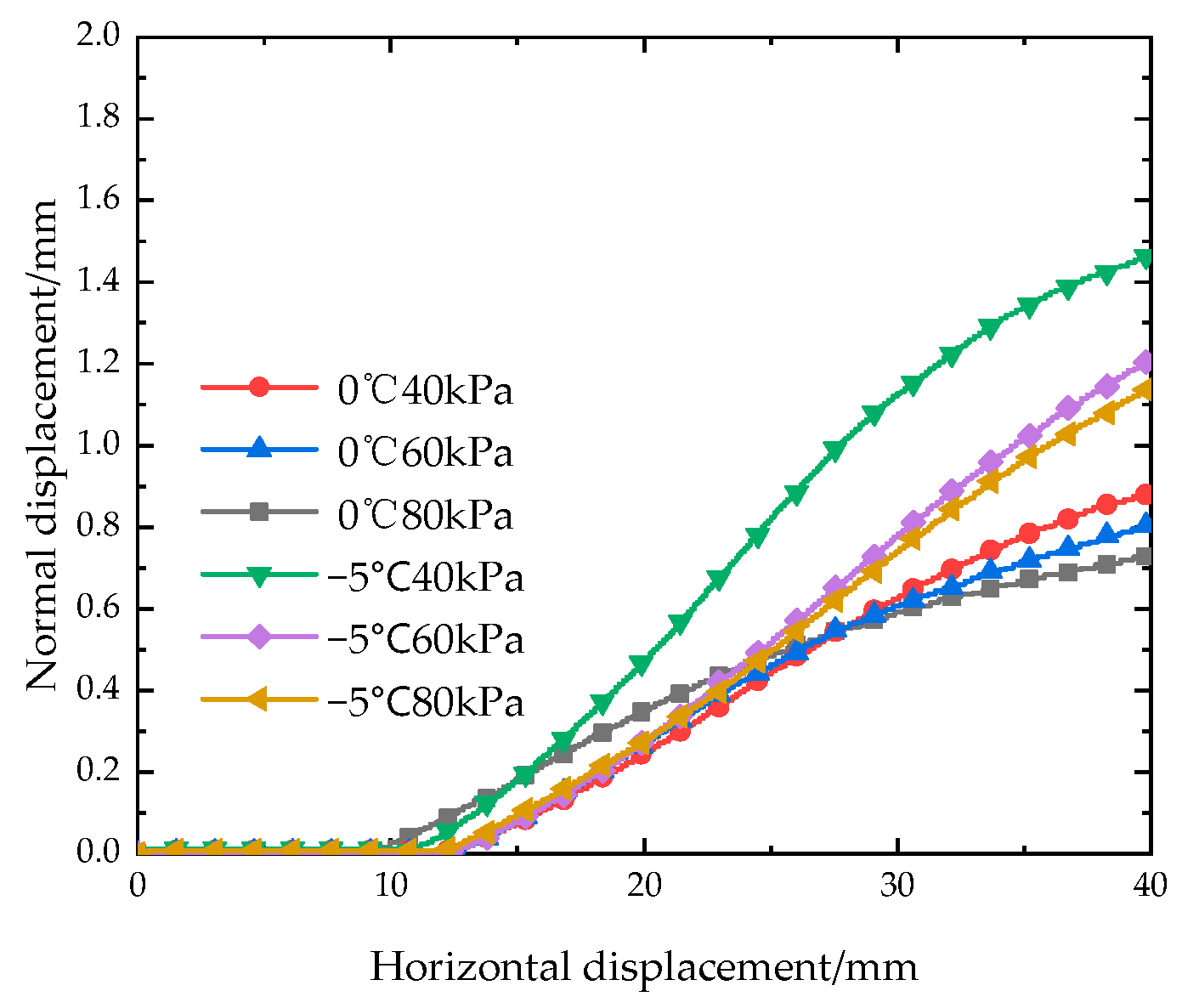

3.4. Shear Dilation Characteristics of Reinforced Soil Composite

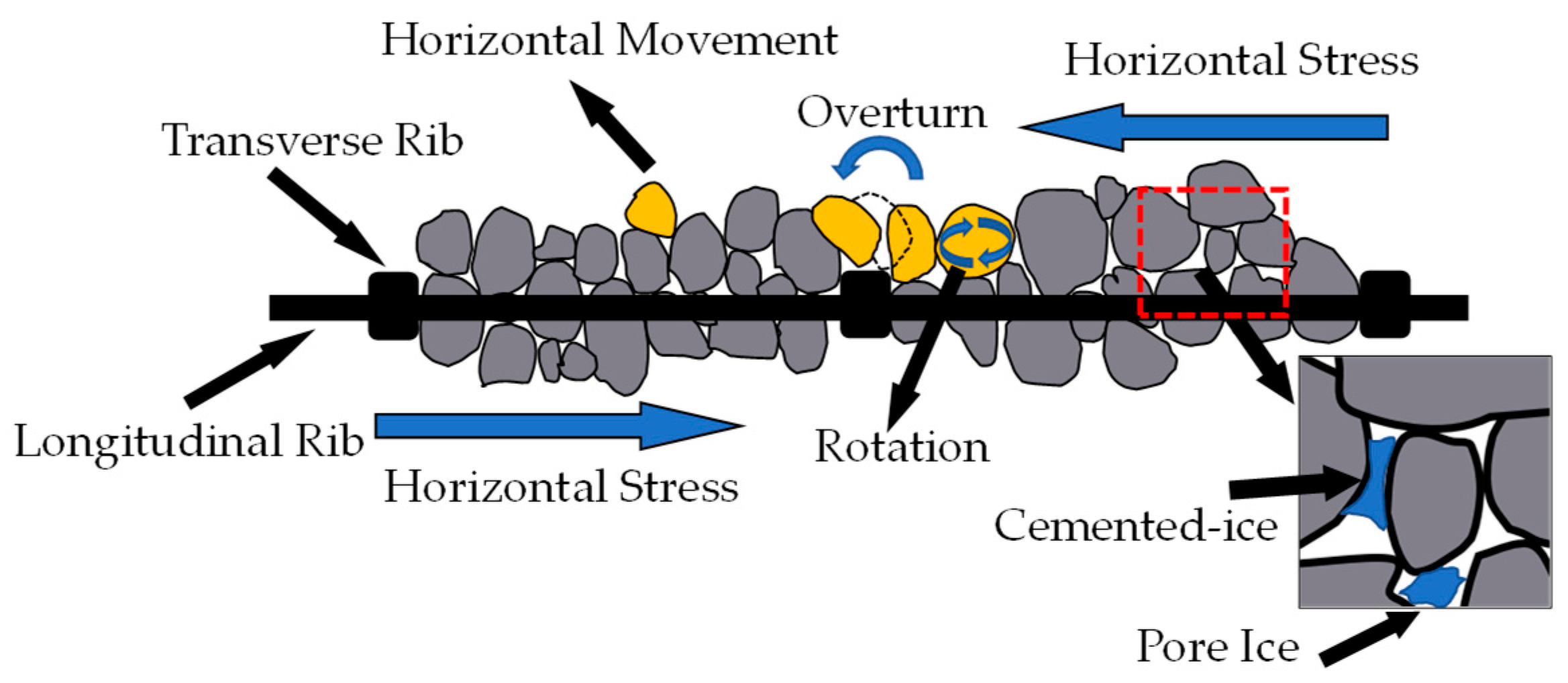

4. Discussion

5. Conclusion

- The trends of the shear displacement-shear stress curve of the geogrid–coarse-grained soil interface under the nonfreezing state (0 °C) and freezing state (−5 °C) are basically the same. Under the condition of low normal stress, the curve has no obvious peak value, which is closer to the ideal elastic-plastic double linear model. In the state of high normal stress, the curves have more obvious peaks, and the curve type is closer to the elastic-strain softening type.

- In the nonfreezing state (0 °C), there is a strong correlation between the shear strength and water content. When the water content is 4.5%, the peak shear stress under each normal stress is the largest. However, the larger water content will reduce the interface shear strength of the reinforced soil composite. The shear strength of the interface between the frozen state (−5 °C) and the nonfrozen state (0 °C) is different. When the water content is 4.5% and 7%, the peak shear stresses under different normal stresses are very close. The main sources of the difference are the cementation of pore ice in the soil skeleton under the freezing state (−5 °C), the improvement in the strength of the soil particles and the further interlocking effect of the geogrid on the soil.

- Compared with coarse-grained soil reinforced by geogrids in the nonfreezing state (0 °C), the shear strength of the frozen state (−5 °C) is significantly improved. Under normal stresses of 40 kPa, 60 kPa and 80 kPa, when the water content is 2%, the corresponding peak shear stress increases by 19.39%, 21.71% and 11.34%, respectively. When the water content is 4.5%, the corresponding peak shear stress decreases by 29.98%, 16.17%, and 13.83%. When the water content is 7%, the corresponding peak shear stress decreases by 50.85%, 18.64%, and 21.96%.

- The apparent friction coefficient between the geogrid and coarse-grained soil interface in the nonfreezing state (0 °C) and freezing state (−5 °C) decreases with increasing normal stress, and the downward trend is steep to slow. This is mainly because the soil particles are more likely to move under the action of the transverse ribs of the geogrid under the condition of low normal stress. With the decrease in temperature, the dilatancy phenomenon of the reinforced soil composite is more obvious.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, B.Y.; Pan, B.T.; Cheng, W.M.; Han, J.F.; Qi, D.L.; Zhu, C. Research on geomorphological regionalization of China. Acta Geogr. Sin. 2013, 68, 291–306. [Google Scholar] [CrossRef]

- Zhu, B.Q.; Yu, J.J.; Qin, X.G.; Liu, Z.T.; Xiong, H.G. Formation and evolution of sandy deserts in Xinjiang: The palaeo-environmental evidences. Acta Geogr. Sin. 2013, 68, 661–679. [Google Scholar] [CrossRef]

- Li, J.T.; Wang, K.Z.; Li, Y.P.; Sun, G.H.; Chu, C.H.; Li, L.Q.; Zhu, Z.X. geomorphological features, crustal composition and geological evolution of the Tianshan Mountains. Geol. Bull. China 2006, 8, 895–909. [Google Scholar] [CrossRef]

- Shen, L.S.; Yang, G.Q.; Cheng, H.T.; Zheng, R.J.; Chen, J.C. Optimization Technology for Geogrid-Reinforced Subgrade Widening Projects of Highways. Chin. J. Geotech. Eng. 2013, 35, 789–793. [Google Scholar] [CrossRef]

- Qian, Y.; Han, J.; Pokharel, S.K.; Parsons, R.L. Performance of Triangular Aperture Geogrid-Reinforced Base Courses over Weak Subgrade under Cyclic Loading. J. Mater. Civ. Eng. 2013, 25, 1013–1021. [Google Scholar] [CrossRef]

- Singh, M.; Trivedi, A.; Shukla, S.K. Evaluation of geosynthetic reinforcement in unpaved road using moving wheel load test. Geotext. Geomembr. 2022, 50, 581–589. [Google Scholar] [CrossRef]

- Zadehmohamad, M.; Luo, N.; Abu-Farsakh, M.; Voyiadjis, G. Evaluating long-term benefits of geosynthetics in flexible pavements built over weak subgrades by finite element and Mechanistic-Empirical analyses. Geotext. Geomembr. 2022, 50, 455–469. [Google Scholar] [CrossRef]

- Su, Q.; Cai, Y. Geogrid- and Geocell-Reinforced Sand Blanket: Model Test and the Ability to Reduce Deformation. J. Southwest Jiaotong Univ. 2001, 36, 176–180. [Google Scholar] [CrossRef]

- Yang, G.Q.; Li, G.X.; Zheng, B.J. Experimental Studies on Interface Friction Characteristics of Geogrids. Chin. J. Geotech. Eng. 2006, 8, 948–952. [Google Scholar]

- Wang, M.Y.; Gong, X.N.; Bao, C.G.; Shi, G.L. Pull-Out Behavior of The Interface Between Geogrid and Compacted Expansive Soil. Eng. Mech. 2009, 26, 145–151. [Google Scholar]

- Chen, R.; Luan, M.T.; Zhao, W.; Xu, X.Y.; Hao, D.X. Research on pull-out test and frictional resistance characteristic of geogrids. Rock Soil Mech. 2009, 30, 960–964. [Google Scholar] [CrossRef]

- Liu, J. Study on Mechanical Properties and Reinforcing Mechanism of Geogrid Reinforced Gravelly Soil; Hefei University of Technology: Hefei, China, 2018. [Google Scholar]

- Mirzaalimohammadi, A.; Ghazavi, M.; Lajevardi, S.H.; Roustaei, M. Experimental Investigation on Pullout Behavior of Geosynthetics with Varying Dimension. Int. J. Géoméch. 2021, 21, 04021089. [Google Scholar] [CrossRef]

- Chen, J.-N.; Ren, X.; Xu, H.; Zhang, C.; Xia, L. Effects of Grain Size and Moisture Content on the Strength of Geogrid-Reinforced Sand in Direct Shear Mode. Int. J. Géoméch. 2022, 22, 04022006. [Google Scholar] [CrossRef]

- Zhao, L.; Cheng, G.D.; Ding, Y.J. Studies on Frozen Ground of China. J. Geogr. Sci. 2004, 14, 411–416. [Google Scholar] [CrossRef]

- Song, Y.Y. Study on Reinforced Performance of Geogrids in Seasonal Frozen Soil; Northeast Electric Power University: Jilin, China, 2017. [Google Scholar]

- Chen, R.; Wang, X.Q.; Hao, D.X.; Song, Y.Y.; Xue, N. Experimental Investigation on Reinforced Characteristics of Geogrids in Seasonal Frozen Soil. Chin. J. Geotech. Eng. 2019, 41, 1101–1107. [Google Scholar] [CrossRef]

- Wei, J.; Xu, Z.Y.; Bao, L.M.; Ge, J.J. Experimental Study on Embankment Slope Protection with Geocell in Permafrost Regions of Qinghai-Tibet Railway. Chin. J. Rock Mech. Eng. 2006, 3168–3173. [Google Scholar] [CrossRef]

- Bai, Q.; He, G.; Wang, Y.; Liu, J. Experimental Investigation on Mechanical Properties of Geocell Strips at Low Temperature. Materials 2022, 15, 5456. [Google Scholar] [CrossRef]

- Xu, J.; Niu, F.J.; Niu, Y.H.; Hou, Z.J. Analysis on The Moisture Migration of Subgrade Soil Under Effect of Temperature Gradient. J. Chongqing Univ. 2013, 36, 150–158. [Google Scholar] [CrossRef]

- Wang, Y.H. Macroscopic and Mesoscopic Experimental Study on The Mechanism of Water Migration of Coarse Grained Soil under Freezing-Thawing Cycle And Load; Shijiazhuang Tiedao University: Shijiazhuang, China, 2020. [Google Scholar]

- Wang, E.L.; Xu, X.Y. Experimental Study on Tensile Characteristics of Plastic Geogrid under Low Temperature. Rock Soil Mech. 2008, 29, 1507–1511. [Google Scholar] [CrossRef]

- JTG E50-2006; Test Methods of Geosynthetics for Highway Engineering. PRC Ministry of Transportation: Beijing, China. (In Chinese)

- SL 235-2012; Specification for Test and Measurement of Geosynthetics. China Water Resources and Hydropower Press: Beijing, China, 2012. (In Chinese)

- ASTM D6706-01; Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil. ASTM: West Conshohocken, PA, USA, 2013.

- He, P.F.; Ma, W.; Mu, Y.H.; Dong, J.H.; Huang, Y.T. Study on Freezing Strength Characteristics and Formation Mechanism of Frozen Soil-Concrete Interface. Trans. Chin. Soc. Agric. Eng. 2018, 34, 127–133. [Google Scholar] [CrossRef]

- Xie, Y.M.; Chen, T.; Wang, J.Z.; Gu, S.B.; Zhu, F.Y. Study on Dynamic Shear Characteristics of Frozen Clay-Concrete Interface. J. Railw. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Ma, D.D.; Ma, Q.Y.; Huang, K.; Yuan, P.; Yao, Z.M. Strength of Artificially Frozen Silty Clay with Different Negative Temperatures under Dynamic and Static Combined Loading and Deformation Characteristic Analysis. J. Vib. Shock. 2022, 41, 154–160. [Google Scholar] [CrossRef]

- Esmaeili-Falak, M.; Katebi, H.; Javadi, A.A. Effect of Freezing on Stress–Strain Characteristics of Granular and Cohesive Soils. J. Cold Reg. Eng. 2020, 34. [Google Scholar] [CrossRef]

- Wang, J.; Gutierrez, M. Discrete element simulations of direct shear specimen scale effects. Géotechnique 2010, 60, 395–409. [Google Scholar] [CrossRef]

- Suits, L.D.; Sheahan, T.; Cerato, A.; Lutenegger, A. Specimen Size and Scale Effects of Direct Shear Box Tests of Sands. Geotech. Test. J. 2006, 29, 6. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, Q.H.; Ma, W.; Dong, S.S.; Wang, D.Y.; Niu, F.J.; Zhang, M.L. Experimental Investigation on The Effect of Fiberglass Reinforced Plastic Cover on Adfreeze Bond Strength. Cold Reg. Sci. Technol. 2016, 131, 108–115. [Google Scholar] [CrossRef]

- Ma, W.; Wang, D.Y. Frozen Soil Mechanics; China Science Publishing: Beijing, China, 2014. [Google Scholar]

- Chen, R.; Hao, D.X.; Luan, M.T.; Zhao, W. Reinforcement Mechanism of Transverse and Longitudinal Geogrid Ribs. J. Build. Materials. 2013, 16, 544–548. [Google Scholar] [CrossRef]

- Wang, J.Q.; Zhou, J.; Huang, L.Y.; Huang, S.B. Macroscopic and Mesoscopic Studies of Interface Interaction on Geosynthetics by Use of Large Direct Shear Tests. Chin. J. Geotech. Eng. 2013, 35, 908–915. [Google Scholar]

- Zheng, J.J.; Cao, W.Z.; Zhou, Y.J.; Jiang, J.G. Pull-Out Test Study of Interface Behavior Between Triaxial Geogrid and Soil. Rock Soil Mech. 2017, 38, 317–324. [Google Scholar] [CrossRef]

- Palmeira, E.M. Soil–geosynthetic interaction: Modelling and analysis. Geotext. Geomembr. 2009, 27, 368–390. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhu, X.X.; Liu, J.K.; Lv, P.; Liu, Z.Y. Experimental Study on Direct Shear Tests of Coarse-grained Fillings of High-speed Railway Subgrade in Cold Region. J. China Railw. Society. 2016, 38, 102–109. [Google Scholar] [CrossRef]

- Tang, L.Y.; Wang, X.; Qiu, P.Y.; Jin, L. Study on Shear Performance of Soil-Rock Mixture at the Freezing-Thawing Interface in Permafrost Regions. Rock Soil Mech. 2020, 41, 3225–3235. [Google Scholar] [CrossRef]

- Du, Y.; Tang, L.Y.; Yang, L.J.; Wang, X.; Bai, M.M. Interface Characteristics of Frozen Soil-Structure Thawing Process Based on Nuclear Magnetic Resonance. Chin. J. Geotech. Eng. 2019, 41, 2316–2322. [Google Scholar] [CrossRef]

- Liu, K.F.; Xu, J.P.; Zhou, Q.S.; Xie, X.Y.; Hu, Y. Large-Scale Direct Shear Tests on Properties of Geogrid-Soil Interfaces. Chin. J. Geotech. Eng. 2019, 41, 185–188. [Google Scholar] [CrossRef]

- Ochiai, H.; Yasufuku, N.; Yamaji, T.; Xu, G.-L.; Hirai, T. Experimental Evaluation of Reinforcement in Geogrid-Soil Structure. In Proceedings of the International Symposium on Earth Reinforcement, Kyushu, Japan, 12–14 November 1996; pp. 249–254. [Google Scholar]

- Wang, Z.; Jacobs, F.; Ziegler, M. Experimental and DEM investigation of geogrid–soil interaction under pullout loads. Geotext. Geomembr. 2016, 44, 230–246. [Google Scholar] [CrossRef]

| Characteristic Particle Size | Coefficient of Uniformity | Coefficient of Curvature | Maximum Dry Density/g·cm−3 | Optimum Water Content/% | ||

|---|---|---|---|---|---|---|

| d60 | d30 | d10 | ||||

| 7.51 | 2.3 | 0.54 | 13.9 | 1.3 | 2.39 | 4.37 |

| Table 1. | Tensile Force of Different Elongation/kN·m−1 | Fracture Tensile Force /kN·m−1 | Fracture Elongation /% | ||||

|---|---|---|---|---|---|---|---|

| F1% | F2% | F3% | F4% | F5% | |||

| 0 °C | 22.60 | 33.31 | 41.42 | 48.74 | 55.60 | 85.28 | 11.45 |

| −5 °C | 26.14 | 38.82 | 48.50 | 57.24 | 65.43 | 91.57 | 9.90 |

| Sample | Strength Fitting Curve | Goodness of Fit R2 | Cohesion c/kPa | Internal Friction Angle φ/° | |

|---|---|---|---|---|---|

| 0 °C | 2% | y = 0.41x + 9.97 | 0.99 | 9.97 | 22.29 |

| 4.5% | y = 0.37x + 17.57 | 0.99 | 17.57 | 20.30 | |

| 7% | y = 0.48x + 8.38 | 0.96 | 8.38 | 25.64 | |

| −5 °C | 2% | y = 0.35x + 17.88 | 0.97 | 17.88 | 19.29 |

| 4.5% | y = 0.27x + 29.25 | 0.91 | 29.25 | 15.11 | |

| 7% | y = 0.29x + 27.87 | 0.90 | 27.87 | 16.17 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Q.; Liu, J.; Wang, Y.; Du, H.; Wang, B. Experimental Investigation of Interface Characteristics between Geogrid and Coarse-Grained Soil in a Seasonally Frozen Area. Appl. Sci. 2022, 12, 10187. https://doi.org/10.3390/app121910187

Bai Q, Liu J, Wang Y, Du H, Wang B. Experimental Investigation of Interface Characteristics between Geogrid and Coarse-Grained Soil in a Seasonally Frozen Area. Applied Sciences. 2022; 12(19):10187. https://doi.org/10.3390/app121910187

Chicago/Turabian StyleBai, Qiyu, Jie Liu, Yong Wang, Haoyuan Du, and Bin Wang. 2022. "Experimental Investigation of Interface Characteristics between Geogrid and Coarse-Grained Soil in a Seasonally Frozen Area" Applied Sciences 12, no. 19: 10187. https://doi.org/10.3390/app121910187

APA StyleBai, Q., Liu, J., Wang, Y., Du, H., & Wang, B. (2022). Experimental Investigation of Interface Characteristics between Geogrid and Coarse-Grained Soil in a Seasonally Frozen Area. Applied Sciences, 12(19), 10187. https://doi.org/10.3390/app121910187