Factorial Design to Stimulate Biomass Development with Chemically Modified Starch

Abstract

1. Introduction

2. Materials and Methods

3. Results

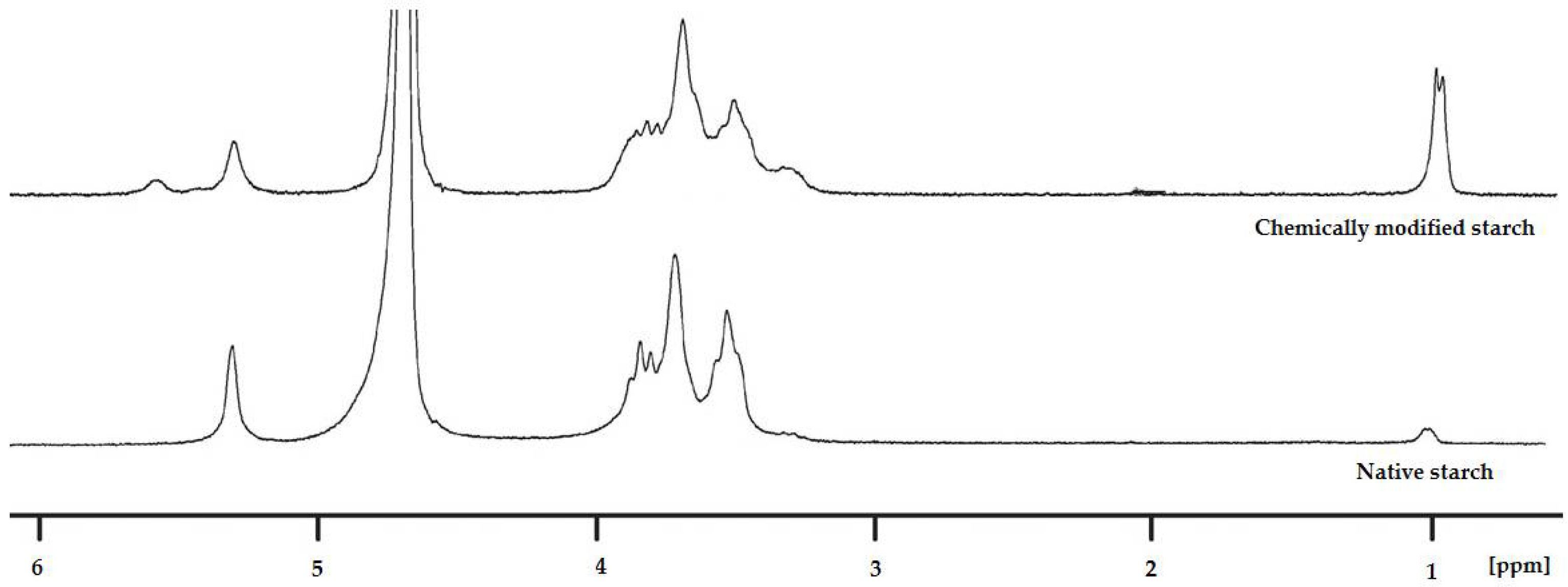

3.1. Chemical Modification of Potato Starch

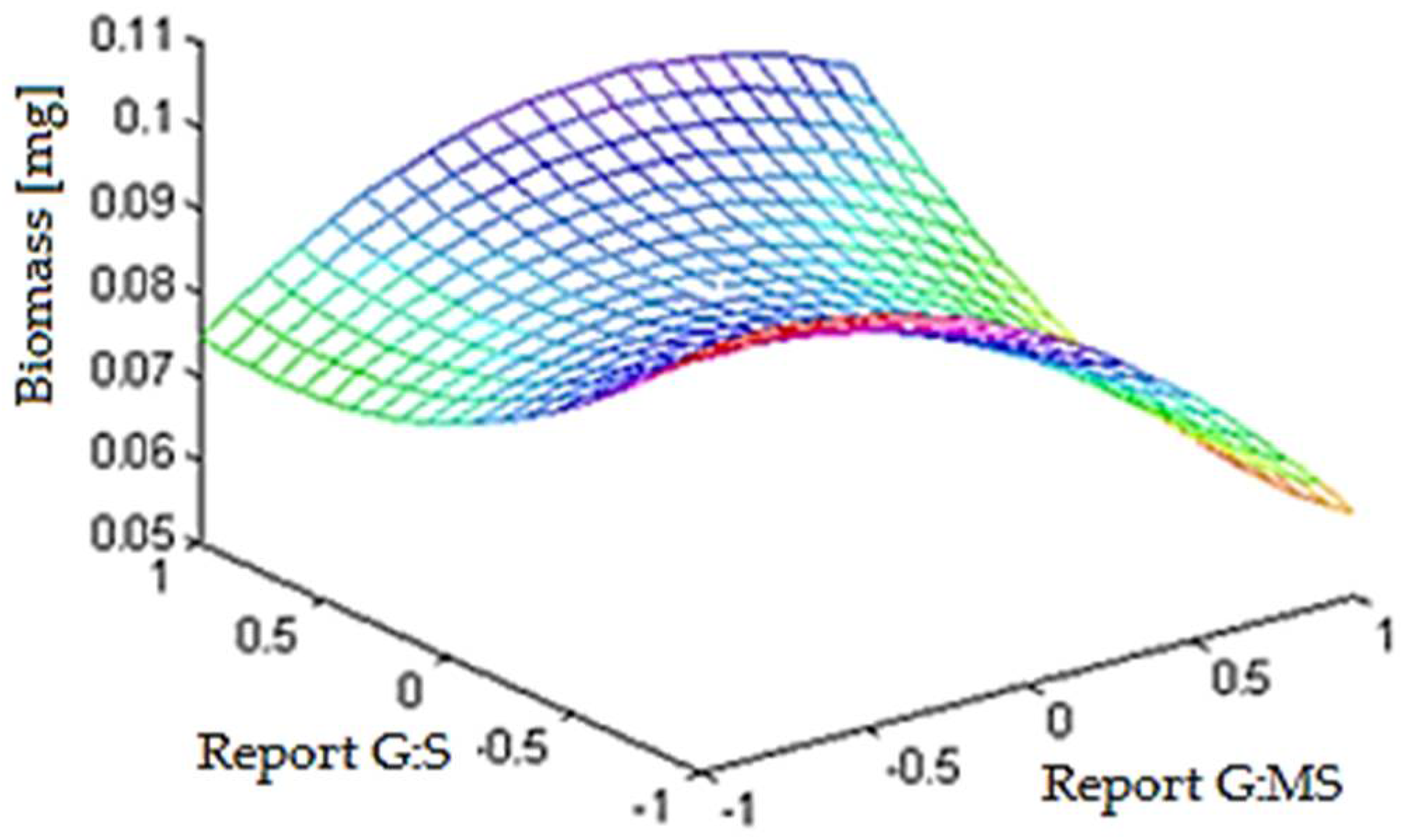

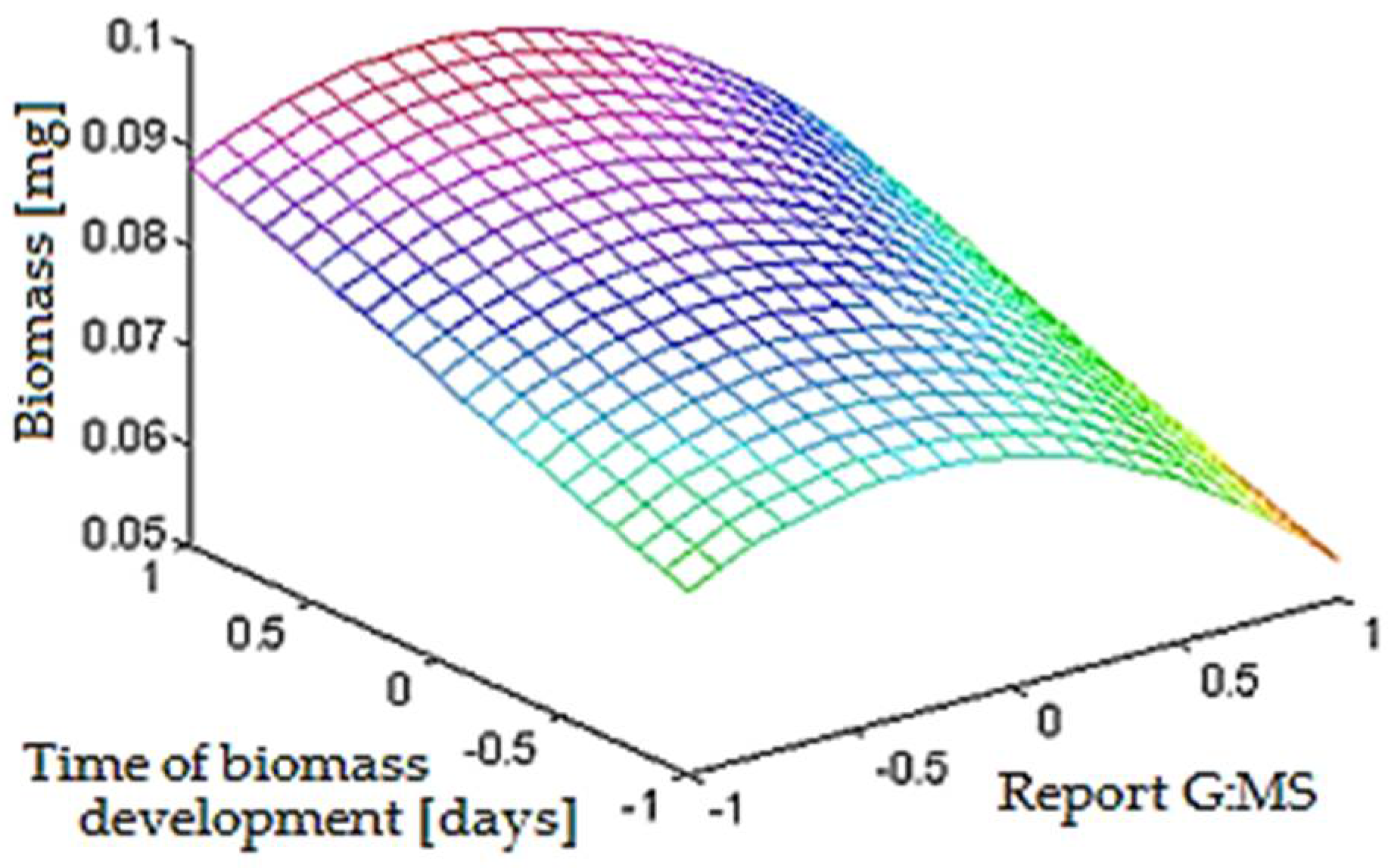

3.2. Elaboration of the Mathematical Model

- X1, X2, X3—the actual optimal values;

- x1, x2, x3—adimensional optimal values;

- ΔX1, ΔX2, ΔX3—the step of each field of variation;

- X1med, X2med, X3med—the average value reality of the parameters.

- the optimal time of development of biomass is 5.67 days ≈ 136 h;

- the optimal report between glucose and starch is 1:1.35;

- the optimal report between glucose and modified starch is 1:1.27.

4. Discussion

- reactions that alter the molecular weight of polymer reactions of degradation and crosslinking reactions;

- reactions that change the properties (without major changes in their molecular weight): stabilization reactions and reactions functionalities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, Y.-E.; Kweon, M. Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum. Foods 2020, 9, 145. [Google Scholar] [CrossRef] [PubMed]

- Kristiawan, M.; Della Valle, G.; Berzin, F. Extrusion Simulation for the Design of Cereal and Legume Foods. Foods 2022, 11, 1780. [Google Scholar] [CrossRef]

- Tian, Z.; Hou, L.; Hu, M.; Gao, Y.; Li, D.; Fan, B.; Wang, F.; Li, S. Optimization of Sporulation Conditions for Bacillus subtilis BSNK-5. Processes 2022, 10, 1133. [Google Scholar] [CrossRef]

- Costa, D.S.d.; Takeuchi, K.P.; Silva, R.M.d.; Oliveira Filho, J.G.d.; Bertolo, M.R.V.; Belisário, C.M.; Egea, M.B.; Plácido, G.R. Cassava-Starch-Based Films Incorporated with Buriti (Mauritia flexuosa L.) Oil: A New Active and Bioactive Material for Food Packaging Applications. Polysaccharides 2022, 3, 121–135. [Google Scholar] [CrossRef]

- Franco, E.; Dussán, R.; Navia, D.P.; Amú, M. Study of the Annealing Effect of Starch/Polyvinyl Alcohol Films Crosslinked with Glutaraldehyde. Gels 2021, 7, 249. [Google Scholar] [CrossRef]

- Rosu, A.M.; Veignie, E.; Surpateanu, G.; Brabie, G.; Miron, D.N.; Rafin, C. Synthesis and evaluation of hydroxypropylated potato starch as polymeric support for benzo[a]pyrene degradation by Fenton reaction. Carbohydr. Polym. 2011, 83, 1486–1491. [Google Scholar] [CrossRef]

- de Souza, A.F.; Galindo, H.M.; de Lima, M.A.B.; Ribeaux, D.R.; Rodríguez, D.M.; da Silva Andrade, R.F.; Gusmão, N.B.; de Campos-Takaki, G.M. Biotechnological Strategies for Chitosan Production by Mucoralean Strains and Dimorphism Using Renewable Substrates. Int. J. Mol. Sci. 2020, 21, 4286. [Google Scholar] [CrossRef]

- Dudeney, A.W.L.; Narayanan, A.; Tarasova, I.I. Removal Of Iron From Silica Sand: Integrated Effluent Treatment By Sulfate Reduction, Photochemical Reduction And Reverse Osmosis. In Biohydrometallurgy and the Environment toward the Mining of the 21st Century; Process Metallurgy 9A; Elsevier: Amsterdam, The Netherlands, 1999; pp. 617–625. [Google Scholar]

- Edwards, K.J.; Bond, P.L.; Gihring, T.M.; Banfield, J.F. An Archaeal Iron-Oxidising Extreme Acidophile Important In Acid Mine Drainage. Science 2000, 287, 1796–1799. Available online: https://www.science.org/doi/10.1126/science.287.5459.1796 (accessed on 9 August 2022). [CrossRef]

- Philus, C.D.; Mahanty, B. Dynamic modelling of tetrazolium-based microbial toxicity assay—A parametric proxy of traditional dose-response relationship. Environ. Sci. Pollut. Res. 2021, 28, 45390–45401. [Google Scholar] [CrossRef]

- Johnson, D.B. Importance Of Microbial Ecology In The Development Of New Mineral Technologies. Hydrometallurgy 2001, 59, 147–158. [Google Scholar] [CrossRef]

- Johnson, D.B. Biological Removal Of Sulfurous Compounds From Inorganic Wastewaters. In Environmental Technologies to Treat Sulfur Pollution: Principles and Engineering; Lens, P., Hulshoff Pol, L., Eds.; International Association on Water Quality: London, UK, 2000; pp. 175–206. [Google Scholar]

- Johnson, D.B.; Hallberg, K.B. Pitfalls of passive mine water treatment. Rev. Environ. Sci. Biotechnol. 2002, 1, 335–343. [Google Scholar] [CrossRef]

- Norris, P.R.; Burton, N.P.; Foulis, A.M. Acidophiles In Bioreactor Mineral Processing. Extremophiles 2000, 4, 71–76. [Google Scholar] [CrossRef]

- Okibe, N.; Gericke, M.; Hallberg, K.B.; Johnson, D.B. Enumeration And Characterization Of Acidophilic Microorganisms Isolated From A Pilot Plant Stirred Tank Bioleaching Operation. Appl. Environ. Microb. 2003, 69, 1936–1943. [Google Scholar] [CrossRef]

- Georgescu, A.M.; Brabie, G.; Nistor, I.D.; Nardou, F.; Penot, C. Utilization Of Experimental Design For Specific Area Optimization Of A Pillared Bentonite. J. Food Saf. 2013, XII, 284–290. [Google Scholar]

- Georgescu, A.M.; Muntianu, G.; Nistor, I.D.; Nardou, F. Modeling And Optimization of Al-Pillaring Process Using Experimental Design Procedure. J. Agroaliment. Process. Technol. 2017, 23, 212–216. [Google Scholar]

- Cerasola, V.A.; Perlotti, L.; Pennisi, G.; Orsini, F.; Gianquinto, G. Potential Use of Superabsorbent Polymer on Drought-Stressed Processing Tomato (Solanum lycopersicum L.) in a Mediterranean Climate. Horticulturae 2022, 8, 718. [Google Scholar] [CrossRef]

- Ajbar, A.; Alqahtani, R.T.; Musa, S.S. Static and Dynamic Analysis of a Continuous Bioreactor Model for the Production of Biofuel from Refinery Wastewater Using Rhodococcus opacus. Mathematics 2022, 10, 2842. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepieciński, T.; Kluz, R.; Ochałek, K.; Slota, J. Multi-Criteria Optimisation of Friction Stir Welding Parameters for EN AW-2024-T3 Aluminium Alloy Joints. Materials 2022, 15, 5428. [Google Scholar] [CrossRef]

- Meengam, C.; Sillapasa, K. Evaluation of Optimization Parameters of Semi-Solid Metal 6063 Aluminum Alloy from Friction Stir Welding Process Using Factorial Design Analysis. J. Manuf. Mater. Process. 2020, 4, 123. [Google Scholar] [CrossRef]

- Nejrotti, S.; Mannu, A.; Blangetti, M.; Baldino, S.; Fin, A.; Prandi, C. Optimization of Nazarov Cyclization of 2,4-Dimethyl-1,5-diphenylpenta-1,4-dien-3-one in Deep Eutectic Solvents by a Design of Experiments Approach. Molecules 2020, 25, 5726. [Google Scholar] [CrossRef]

- Fotovvati, B.; Balasubramanian, M.; Asadi, E. Modeling and Optimization Approaches of Laser-Based Powder-Bed Fusion Process for Ti-6Al-4V Alloy. Coatings 2020, 10, 1104. [Google Scholar] [CrossRef]

- Kiss, E.L.; Berkó, S.; Gácsi, A.; Kovács, A.; Katona, G.; Soós, J.; Csányi, E.; Gróf, I.; Harazin, A.; Deli, M.A.; et al. Design and Optimization of Nanostructured Lipid Carrier Containing Dexamethasone for Ophthalmic Use. Pharmaceutics 2019, 11, 679. [Google Scholar] [CrossRef] [PubMed]

- Ramalho, M.J.; Loureiro, J.A.; Coelho, M.A.N.; Pereira, M.C. Factorial Design as a Tool for the Optimization of PLGA Nanoparticles for the Co-Delivery of Temozolomide and O6-Benzylguanine. Pharmaceutics 2019, 11, 401. [Google Scholar] [CrossRef]

- Ali, I.; Ahmad, M.; Ganat, T. Experimental Study of Bentonite-Free Water Based Mud Reinforced with Carboxymethylated Tapioca Starch: Rheological Modeling and Optimization Using Response Surface Methodology (RSM). Polymers 2021, 13, 3320. [Google Scholar] [CrossRef]

- Schmidt, O.; Magel, E.; Frühwald, A.; Glukhykh, L.; Erdt, K.; Kaschuro, S. Influence of sugar and starch content of palm wood on fungal development and prevention of fungal colonization by acid treatment. Holzforschung 2016, 70, 783–791. [Google Scholar] [CrossRef]

- Fannin, T.E.; Marcus, M.D.; Anderson, D.A.; Bergman, H.L. Use of a fractional factorial design to evaluate interactions of environmental factors affecting biodegradation rates. Appl. Environ. Microbiol. 1981, 42, 936–943. [Google Scholar] [CrossRef] [PubMed]

- Hanrahan, G.; Zhu, J.; Gibani, S.; Patil, D.G. Chemometrics And Statistics | Experimental Design. In Encyclopedia of Analytical Science, 2nd ed.; Worsfold, P., Townshend, A., Poole, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 8–13. ISBN 9780123693976. [Google Scholar] [CrossRef]

- Lin, C.J.; Zhang, R.; Waisner, S.A. Effects of process factors on the performance of electrochemical disinfection for wastewater in a continuous-flow cell reactor. Environ. Sci. Pollut. Res. 2021, 28, 36573–36584. [Google Scholar] [CrossRef]

- Kushwaha, O.; Uthayakumar, H.; Kumaresan, K. Modeling of carbon dioxide fixation by microalgae using hybrid artificial intelligence (AI) and fuzzy logic (FL) methods and optimization by genetic algorithm (GA). Environ. Sci. Pollut. Res. 2022; Online ahead of print. [Google Scholar] [CrossRef]

| Parameter | Reduced Variable | Minimum Value (−1) | Average Value (0) | Maximum Value (+1) |

|---|---|---|---|---|

| Time of development (days) | x1 | 3 | 5 | 7 |

| Report glucose:starch | x2 | 1:1 | 1:1.5 | 1:2 |

| Report glucose:modified starch | x3 | 1:1 | 1:1.5 | 1:2 |

| yk0 | y10 | y20 | y30 |

|---|---|---|---|

| Quantity of biomass [mg] | 0.142 | 0.158 | 0.079 |

| Nb. | Time of Development [days] | Report Glucose: Starch | Report Glucose: Modified Starch | Biomass [mg] |

|---|---|---|---|---|

| x1 | x2 | x3 | Y1 | |

| 1 | −1 (3) | −1 (1:1) | −1 (1:1) | 0.142 |

| 2 | 0 (1:1.5) | 0.144 | ||

| 3 | +1 (1:2) | 0.124 | ||

| 4 | 0 (1:1.5) | −1 (1:1) | 0.014 | |

| 5 | 0 (1:1.5) | 0.016 | ||

| 6 | +1 (1:2) | 0.095 | ||

| 7 | +1 (1:2) | −1 (1:1) | 0.113 | |

| 8 | 0 (1:1.5) | 0.012 | ||

| 9 | +1 (1:2) | 0.011 | ||

| 10 | 0 (5) | −1 (1:1) | −1 (1:1) | 0.143 |

| 11 | 0 (1:1.5) | 0.145 | ||

| 12 | +1 (1:2) | 0.013 | ||

| 13 | 0 (1:1.5) | −1 (1:1) | 0.096 | |

| 14 | 0 (1:1.5) | 0.014 | ||

| 15 | +1 (1:2) | 0.013 | ||

| 16 | +1 (1:2) | −1 (1:1) | 0.012 | |

| 17 | 0 (1:1.5) | 0.144 | ||

| 18 | +1 (1:2) | 0.146 | ||

| 19 | +1 (7) | −1 (1:1) | −1 (1:1) | 0.014 |

| 20 | 0 (1:1.5) | 0.099 | ||

| 21 | +1 (1:2) | 0.021 | ||

| 22 | 0 (1:1.5) | −1 (1:1) | 0.148 | |

| 23 | 0 (1:1.5) | 0.150 | ||

| 24 | +1 (1:2) | 0.146 | ||

| 25 | +1 (1:2) | −1 (1:1) | 0.095 | |

| 26 | 0 (1:1.5) | 0.098 | ||

| 27 | +1 (1:2) | 0.078 |

| Coefficients | Function of Response Y1 (Quantity of Biomass [mg]) |

|---|---|

| a0 | 0.083 |

| a1 | 9.889·10−3 |

| a2 | −7.556·10−3 |

| a3 | −7.222·10−3 |

| a11 | 3.778·10−3 |

| a22 | 9.444·10−3 |

| a33 | −0.012 |

| a12 | 0.034 |

| a13 | 2.25·10−3 |

| a23 | 0.013 |

| a123 | 7.5·10−3 |

| tj | t0 | t1 | t2 | t3 | t12 | t13 | t23 | t11 | t22 | t33 | t123 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Calculated value | 10.266 | 1.23 | 0.94 | 0.899 | 4.261 | 0.28 | 1.617 | 0.47 | 1.175 | 1.521 | 0.933 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popa, O.; Rosu, A.-M.; Nicuta, D.; Voicu, R.E.; Zichil, V.; Nistor, I.D. Factorial Design to Stimulate Biomass Development with Chemically Modified Starch. Appl. Sci. 2022, 12, 10069. https://doi.org/10.3390/app121910069

Popa O, Rosu A-M, Nicuta D, Voicu RE, Zichil V, Nistor ID. Factorial Design to Stimulate Biomass Development with Chemically Modified Starch. Applied Sciences. 2022; 12(19):10069. https://doi.org/10.3390/app121910069

Chicago/Turabian StylePopa, Olga, Ana-Maria Rosu, Daniela Nicuta, Roxana Elena Voicu, Valentin Zichil, and Ileana Denisa Nistor. 2022. "Factorial Design to Stimulate Biomass Development with Chemically Modified Starch" Applied Sciences 12, no. 19: 10069. https://doi.org/10.3390/app121910069

APA StylePopa, O., Rosu, A.-M., Nicuta, D., Voicu, R. E., Zichil, V., & Nistor, I. D. (2022). Factorial Design to Stimulate Biomass Development with Chemically Modified Starch. Applied Sciences, 12(19), 10069. https://doi.org/10.3390/app121910069