Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill

Abstract

1. Introduction

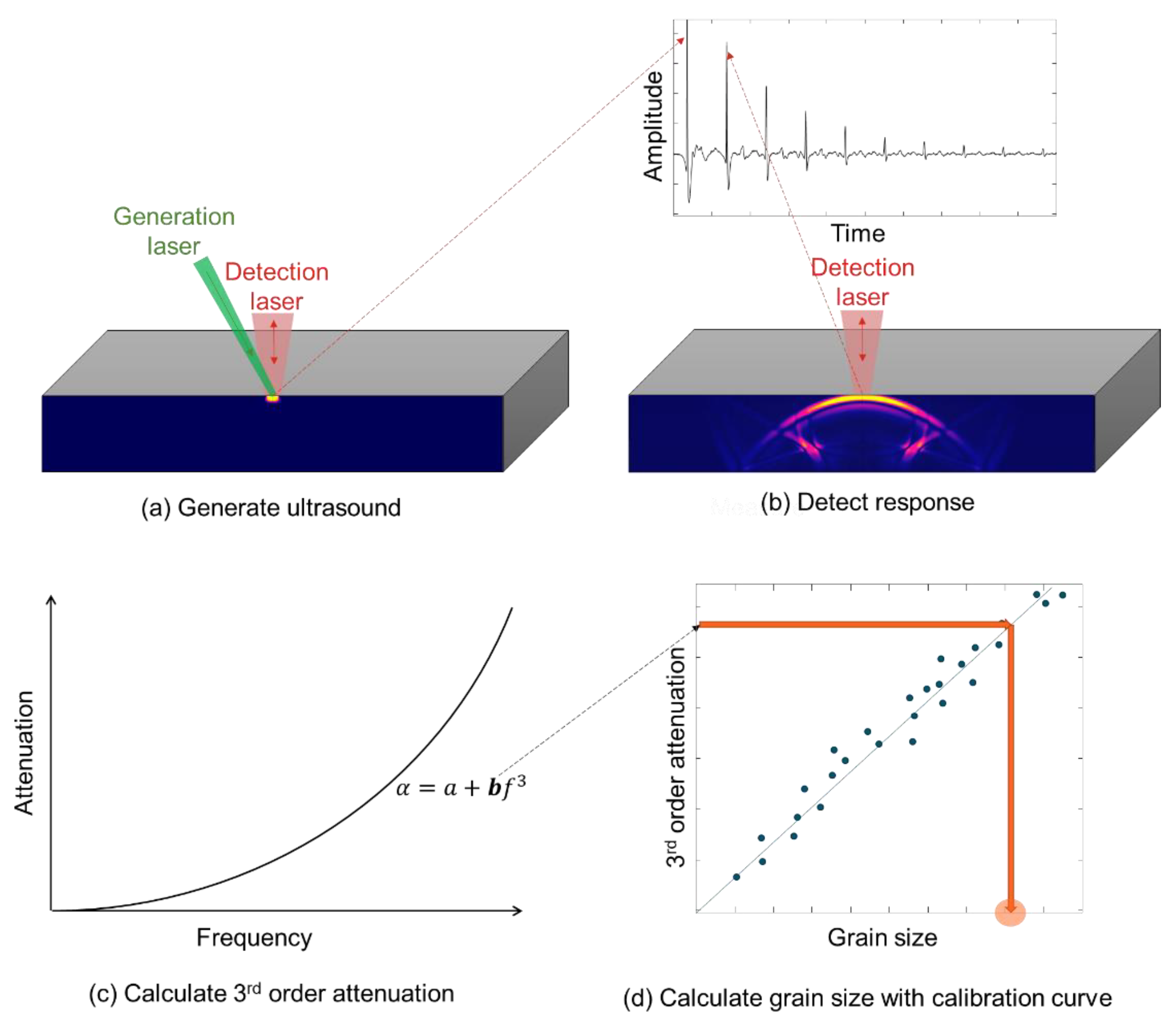

Grain-Size Measurement with Laser Ultrasonics

2. Materials and Methods

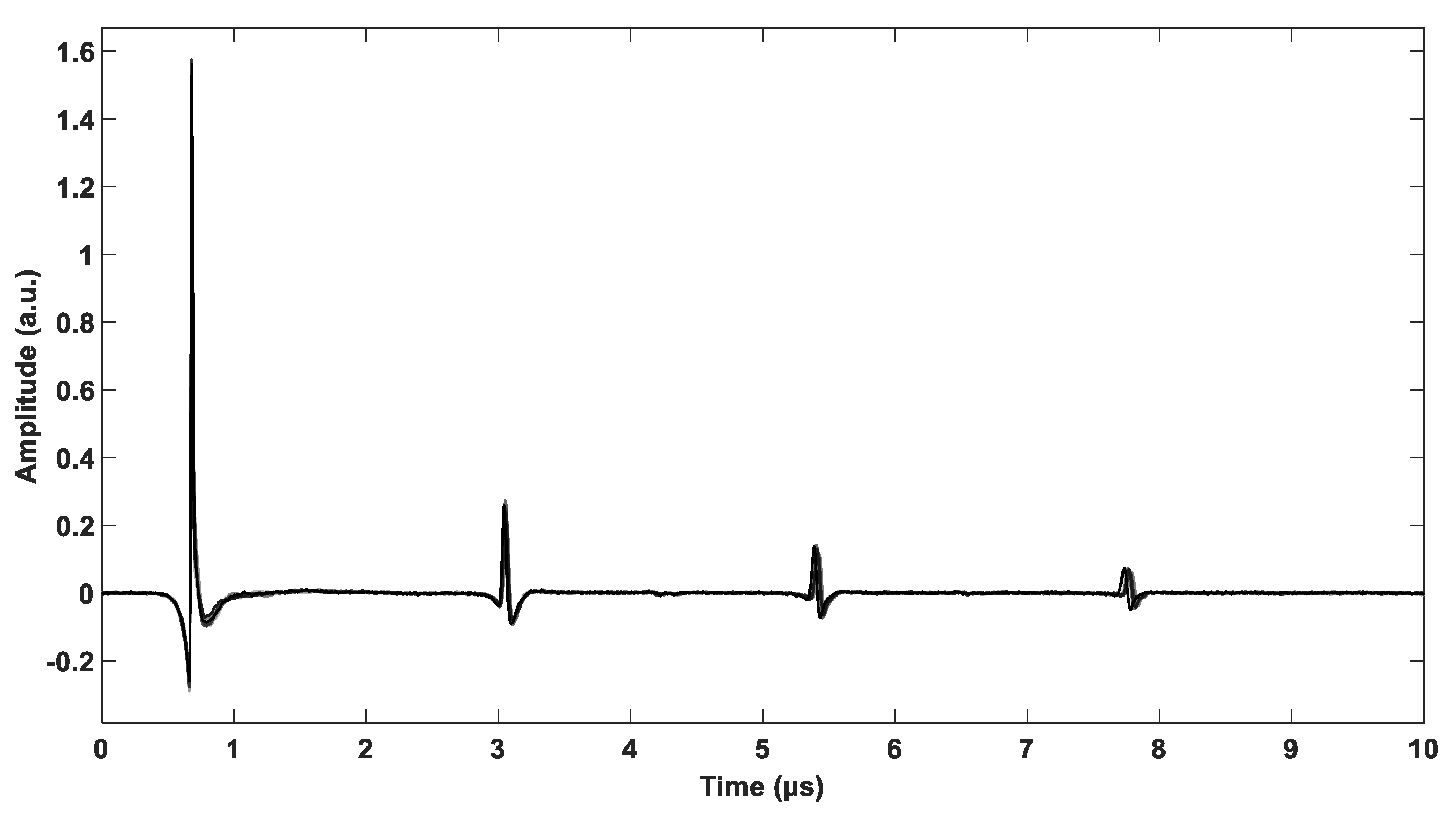

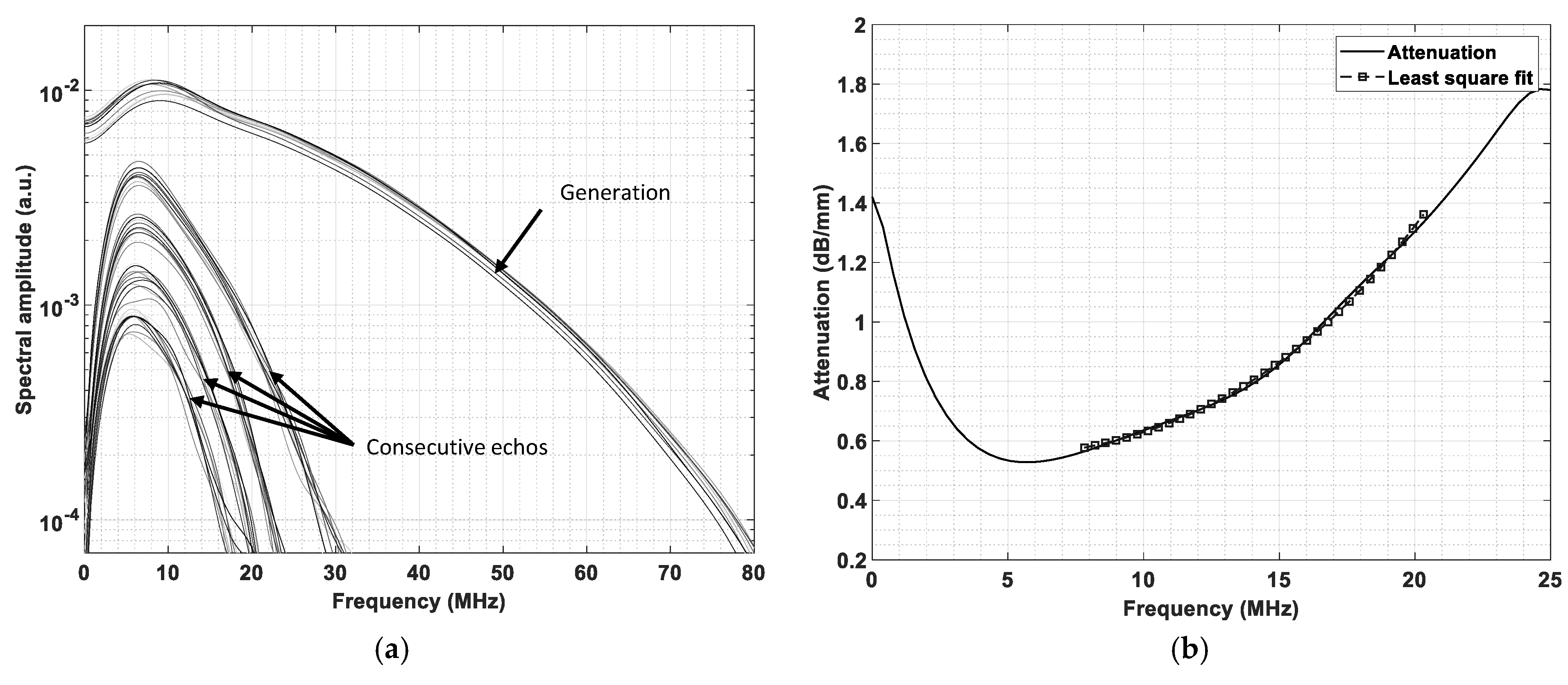

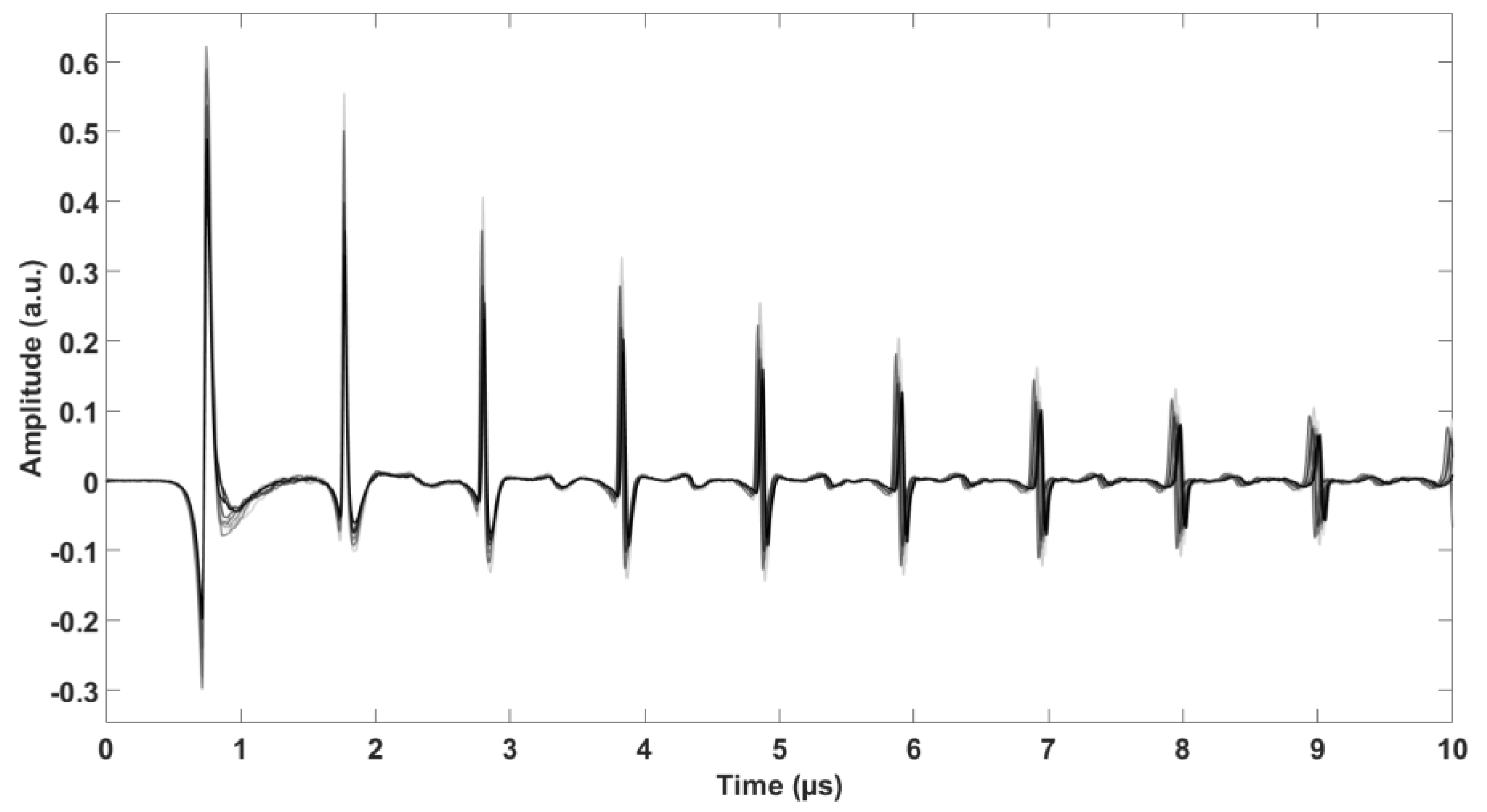

2.1. The Generation Event Method

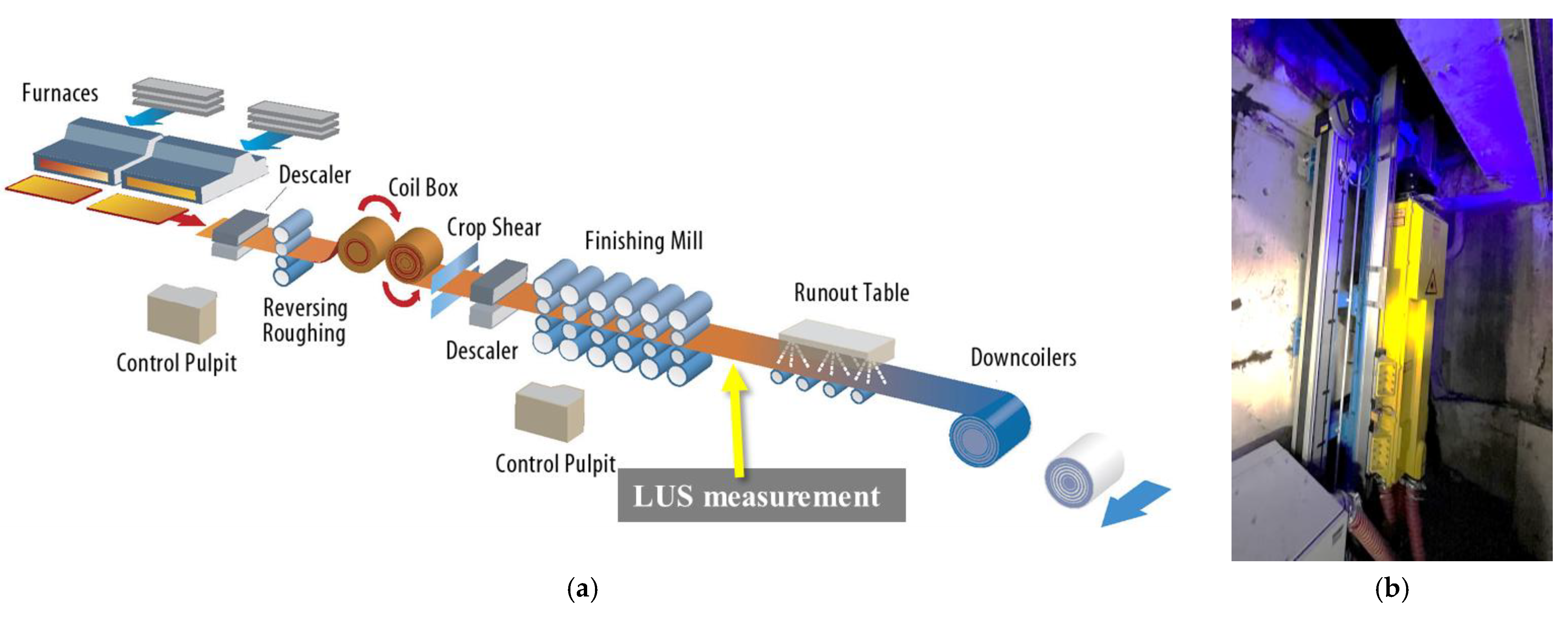

2.2. The Online Grain Size Gauge

3. Results and Discussion

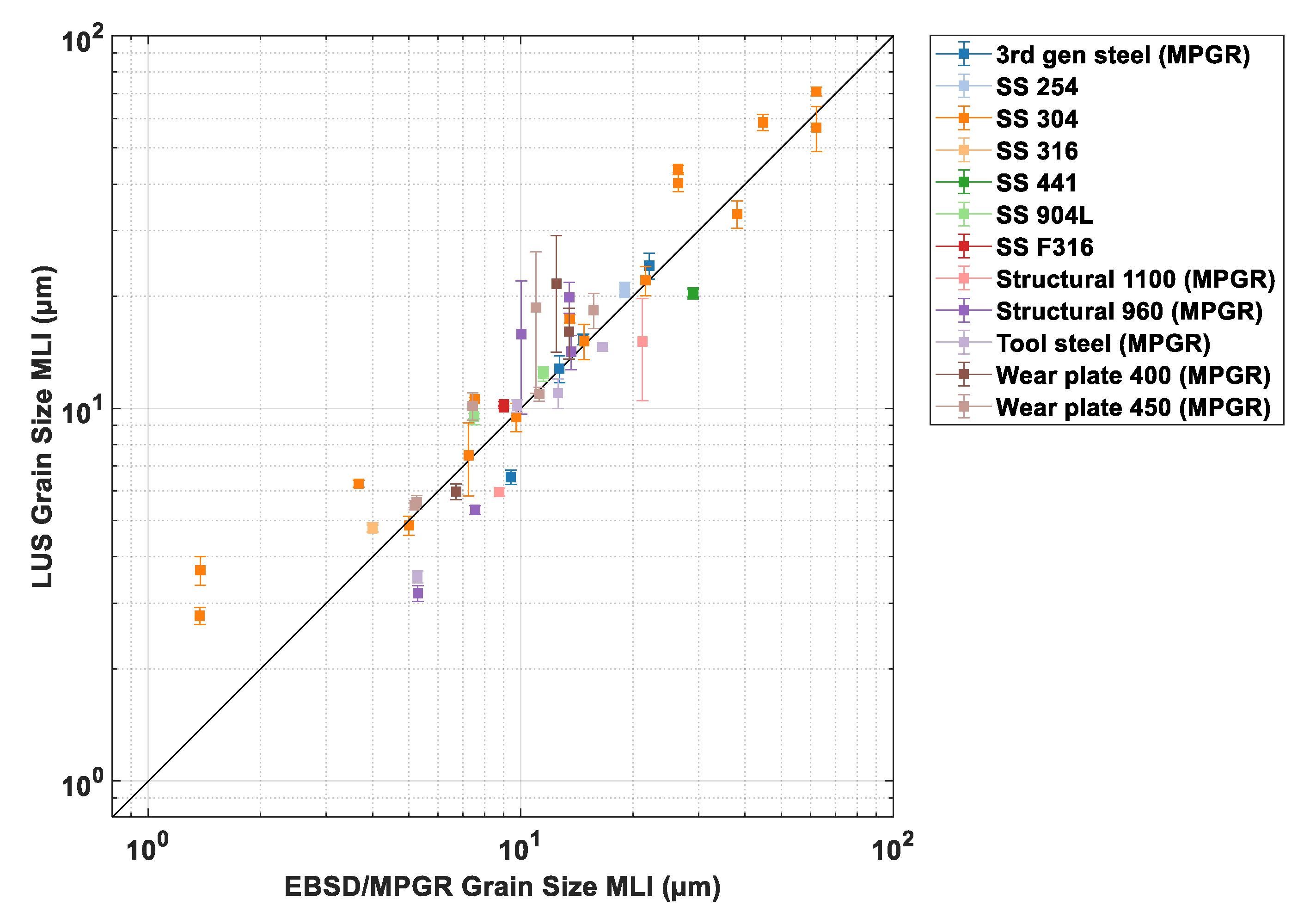

3.1. Grain-Size Calibration Curve

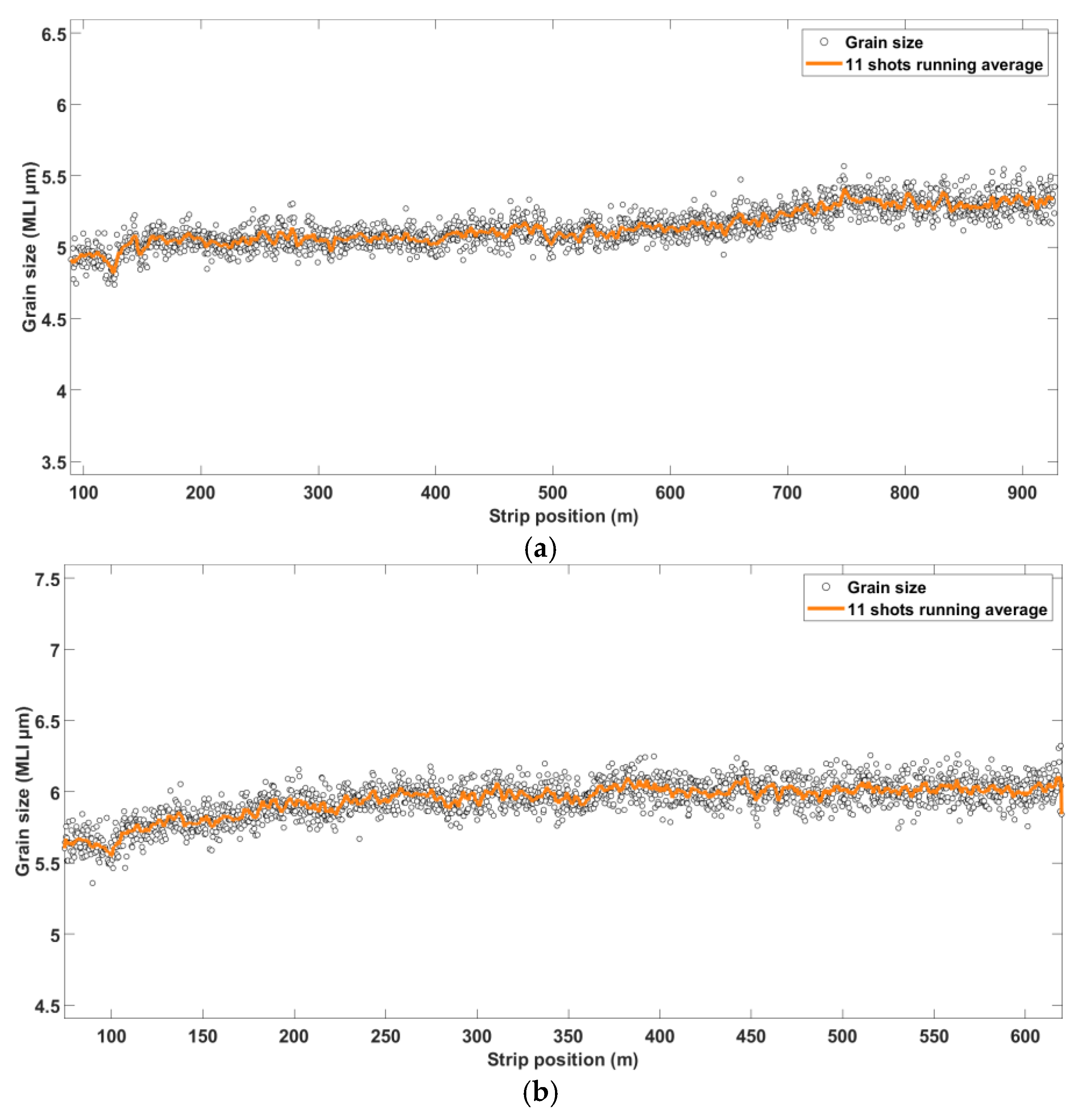

3.2. Online Measurements

- the climate control for the head and driver for the generation laser,

- the interferometer and the control computers,

- the detection laser, and

- the electronic wiring and control unit for the motors.

4. Conclusions

- Grain-size calculation performed with a new reference object-free model/algorithm utilizing the generation event as a reference spectrum.

- The model used for grain-size calculation is based on 52 samples that are evaluated with EBSD/MPGR and is correlated with more than 23,000 LUS measurements. The correlation coefficient R2 of this model is 0.8.

- Calculated grain sizes from online LUS measurements provide the ability to detect small variations in austenite grain size along the strip in situ.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scruby, C.B.; Drain, L.E. Laser Ultrasonics Techniques and Applications; CRC Press: Boca Raton, FL, USA, 1990; ISBN 978-0-7503-0050-6. [Google Scholar]

- Lévesque, D.; Kruger, S.E.; Lamouche, G.; Kolarik, R.; Jeskey, G.; Choquet, M.; Monchalin, J.-P. Thickness and Grain Size Monitoring in Seamless Tube-Making Process Using Laser Ultrasonics. NDT E Int. 2006, 39, 622–626. [Google Scholar] [CrossRef]

- European Union. On Line Structure Monitoring by Laser Ultrasonics for Process Control in Rolling and Heat Treatment (CUSTOM); Dorota Artymowicz; Stefan Sundin; Bevis Hutchinson; Andy Astill; Michel Nogues; Grant agreement ID: BRPR960359; European Union: Brussels, Belgium, 2000. [Google Scholar]

- European Union. New Approaches to Non-Destructive Characterisation of Microstructure and Applications to Online Control of Steel Quality (NANDACS); Office for Official Publications of the European Communities: Luxembourg, 2006; ISBN 92-79-01089-1. [Google Scholar]

- European Union. Investigation, Modelling and Control of the Influence of the Process Route on Steel Strip Technological Parameters and Coating Appearance after Hot Dip Galvanising (IMGALVA); Link, N., Langer, M., Torre, V., Meré, J.O., Lindh-Ulmgren, E., Stolzenberg, M., Eds.; EUR Research Fund for Coal and Steel Series; Publication Office of the European Union: Luxembourg, 2009; ISBN 978-92-79-12481-5. [Google Scholar]

- Stolzenberg, M.; Schmidt, R.; Casajus, A.; Kebe, T.; Falkenstrom, M.; Martinez-de-Guerenu, A.; Link, N.; Ploegaert, H.; van den Berg, F.; Peyton, A. Online Material Characterisation at Strip Production (OMC); Office for Official Publications of the European Communities: Luxembourg, 2013; ISBN 978-92-79-28961-3. [Google Scholar]

- Van den Berg, F.; Lombard, P.; Labbé, S.; Peyton, A.; Martinez-de-Guerenu, A.; Colla, V.; Gutierrez, I.; Mocci, C.; Reboud, C.; Stolzenberg, M.; et al. Product Uniformity Control (PUC): Final Report; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-17320-5. [Google Scholar]

- Falkenström, M.; Engman, M.; Lindh-Ulmgren, E.; Hutchinson, B. Laser Ultrasonics for Process Control in the Metal Industry. Nondestruct. Test. Eval. 2011, 26, 237–252. [Google Scholar] [CrossRef]

- Legrand, N.; Satyanarayan, L.; Sarkar, S.; Engmann, M.; Falkenstrom, M.; Lundin, P.; Lindh-Ulmgren, E.; Babu, B.; Johnsson, A.; Lefaudeux, N.; et al. Combined Online Microstructure Sensor and Model for a Better Control of Hot Strip Rolling Conditions and Final Products Properties (MICROCONTROL): Final Report; Publications Office of the European Union: Luxembourg, 2015; ISBN 978-92-79-50412-9. [Google Scholar]

- Malmström, M.; Lindh-Ulmgren, E.; Hutchinson, B.; Martin, D.; Sollander, H.; Moosavi, E. In-Situ Övervakning Av Mikrostrukturer För Effektiv Utveckling Och Tillverkning Av Högpresterande Stål (REMOMIC PLUS); Jernkontorets Forskning: Stockholm, Sweden, 2018; ISSN 0280-249X. [Google Scholar]

- Satyanarayan, L.; Legrand, N.; Meilland, P.; Naumann, N.; Ayeb, A.; Lindh-Ulmgren, E.; Malmström, M.; Schwartz, T.I.; Babu, B.; Levesque, D. Combined Online Microstructure Sensor and Model for a Better Control of Hot Rolling Conditions and Final Products Properties (Phase 2) (MicroControl-PLUS); Publications Officeof the European Union: Luxembourg, 2019. [Google Scholar]

- Malmström, M. A Method and Arrangement for Estimating a Material Property of an Object by Means of a Laser Ultrasonic (LUS) Measurement Equipment. U.S. Patent 20220205954A1, 30 June 2020. [Google Scholar]

- Scruby, C.B.; Smith, R.L.; Moss, B.C. Microstructural Monitoring by Laser-Ultrasonic Attenuation and Forward Scattering. NDT Int. 1986, 19, 307–313. [Google Scholar] [CrossRef]

- Faßbender, S.; Kulakov, M.; Hoffmann, B.; Paul, M.; Peukert, H.; Arnold, W. Non-Contact and Nondestructive Evaluation of Grain-Size in Thin Metal Sheets. In Nondestructive Characterization of Materials; Höller, P., Hauk, V., Dobmann, G., Ruud, C.O., Green, R.E., Eds.; Springer: Berlin/Heidelberg, Germany, 1989; pp. 337–344. [Google Scholar]

- Dubois, M.; Militzer, M.; Moreau, A.; Bussière, J.F. A New Technique for the Quantitative Real-Time Monitoring of Austenite Grain Growth in Steel. Scr. Mater. 2000, 42, 867–874. [Google Scholar] [CrossRef]

- Kruger, S.; Lamouche, G.; Levesque, D.; Monchalin, J.-P. Method and System for Determining Material Properties Using Ultrasonic Attenuation. U.S. Patent 7353709B2, 8 April 2008. [Google Scholar]

- Kruger, S.E.; Moreau, A.; Lévesque, D.; Lord, M. Laser Ultrasonic Measurements of Scattered Waves in Steel. AIP Conf. Proc. 2001, 557, 1298–1305. [Google Scholar] [CrossRef]

- Wang, H.; Bai, X.; Ma, J.; Wu, H.; Zhang, Z. Application of Deep Learning in Nondestructive Evaluation of Metal Microstructural Grain Size. In Proceedings of the 2022 International Conference on Computer Engineering and Artificial Intelligence (ICCEAI), Shijiazhuang, China, 22–24 July 2022; pp. 581–585. [Google Scholar]

- Stanke, F.E.; Kino, G.S. A Unified Theory for Elastic Wave Propagation in Polycrystalline Materials. J. Acoust. Soc. Am. 1984, 75, 665–681. [Google Scholar] [CrossRef]

- Sarkar, S.; Moreau, A.; Militzer, M.; Poole, W.J. Evolution of Austenite Recrystallization and Grain Growth Using Laser Ultrasonics. Metall. Mater. Trans. A 2008, 39, 897–907. [Google Scholar] [CrossRef]

- Militzer, M.; Garcin, T.; Poole, W.J. In Situ Measurements of Grain Growth and Recrystallization by Laser Ultrasonics. Mater. Sci. Forum 2013, 753, 25–30. [Google Scholar] [CrossRef]

- Moreau, A.; Lévesque, D.; Sarkar, S. Laser-Ultrasonics for Metallurgy: Overview and Latest Developments; NRC: Ottawa, ON, Canada, 2013. [Google Scholar] [CrossRef]

- Garcin, T.; Schmitt, J.H.; Militzer, M. In-Situ Laser Ultrasonic Grain Size Measurement in Superalloy INCONEL 718. J. Alloys Compd. 2016, 670, 329–336. [Google Scholar] [CrossRef]

- Keyvani, M.; Garcin, T.; Fabrègue, D.; Militzer, M.; Yamanaka, K.; Chiba, A. Continuous Measurements of Recrystallization and Grain Growth in Cobalt Super Alloys. Metall. Mater. Trans. A 2017, 48, 2363–2374. [Google Scholar] [CrossRef]

- Nyyssönen, T.; Malmström, M.; Lindell, D.; Jansson, A.; Lönnqvist, J.; Hutchinson, B. Laser Ultrasonic Measurements as a Complementary Technique for Parent Austenite Reconstruction in Advanced High-Strength Steels. Appl. Sci. 2022; submitted. [Google Scholar]

- Klein, M.B. Beam Coupling in Undoped GaAs at 1.06 Μm Using the Photorefractive Effect. Opt. Lett. 1984, 9, 350–352. [Google Scholar] [CrossRef] [PubMed]

- Blouin, A.; Monchalin, J. Detection of Ultrasonic Motion of a Scattering Surface by Two-wave Mixing in a Photorefractive GaAs Crystal. Appl. Phys. Lett. 1994, 65, 932–934. [Google Scholar] [CrossRef]

- Hutchinson, B.; Malmström, M.; Lönnqvist, J.; Bate, P.; Ehteshami, H.; Korzhavyi, P.A. Elasticity and Wave Velocity in Fcc Iron (Austenite) at Elevated Temperatures—Experimental Verification of Ab-Initio Calculations. Ultrasonics 2018, 87, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Garcin, T. Laser Ultrasonic Sensitivity to Abnormal Grain Growth and Twinning during Metal Processing. In Proceedings of the 3rd International Workshop on Laser-Ultrasound for Metals, Stockholm, Sweden, 21–22 September 2017. [Google Scholar]

- Dever, D.J. Temperature Dependence of the Elastic Constants in A-iron Single Crystals: Relationship to Spin Order and Diffusion Anomalies. J. Appl. Phys. 1972, 43, 3293–3301. [Google Scholar] [CrossRef]

- Malmström, M. Optical Material Detector for Safer Laser Ultrasonic Measurements. In Proceedings of the NDE 2021—Virtual Conference & Exhibition, Virtual, Chennai, India, 9–11 December 2021; p. CP103. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malmström, M.; Jansson, A.; Hutchinson, B.; Lönnqvist, J.; Gillgren, L.; Bäcke, L.; Sollander, H.; Bärwald, M.; Hochhard, S.; Lundin, P. Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill. Appl. Sci. 2022, 12, 10048. https://doi.org/10.3390/app121910048

Malmström M, Jansson A, Hutchinson B, Lönnqvist J, Gillgren L, Bäcke L, Sollander H, Bärwald M, Hochhard S, Lundin P. Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill. Applied Sciences. 2022; 12(19):10048. https://doi.org/10.3390/app121910048

Chicago/Turabian StyleMalmström, Mikael, Anton Jansson, Bevis Hutchinson, Johan Lönnqvist, Lars Gillgren, Linda Bäcke, Hans Sollander, Matthias Bärwald, Sascha Hochhard, and Peter Lundin. 2022. "Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill" Applied Sciences 12, no. 19: 10048. https://doi.org/10.3390/app121910048

APA StyleMalmström, M., Jansson, A., Hutchinson, B., Lönnqvist, J., Gillgren, L., Bäcke, L., Sollander, H., Bärwald, M., Hochhard, S., & Lundin, P. (2022). Laser-Ultrasound-Based Grain Size Gauge for the Hot Strip Mill. Applied Sciences, 12(19), 10048. https://doi.org/10.3390/app121910048